1. Introduction

Inventory management plays a decisive role in supply chain performance, particularly when the products handled are of high value. The lack of adequate management policies to deal with such products often results in disproportionately large financial and operational impacts.

Recent studies emphasize the need for resilient inventory strategies in contexts of supply and demand disruptions. The authors of [

1] review inventory management practices, including stockpiling, multi-sourcing, capacity reservation, and flexible contracts, categorizing them as supply-side or demand-side risk. Such strategies are particularly pertinent for high-value products (HVPs), which cannot abide supply interruptions without substantial cost.

Effective inventory management strategies are crucial for mitigating risks and optimizing the supply chain. These strategies not only help with reducing costs but also enhance the overall efficiency and resilience of the supply chain. Key strategies include Just-in-Time (JIT) and lean inventory practices, advanced analytics, and collaborative partnerships, which are supported by technological advancements and robust risk management practices.

JIT and lean inventory practices focus on reducing waste and ensuring that inventory is available only when needed. This allows for minimizing the holding costs and reducing the risk of obsolescence. These practices enhance supply chain efficiency by aligning production schedules with demand forecasts, thus optimizing inventory levels [

2]. Applying advanced analytics and predictive modeling allows companies to forecast demand more accurately, thereby optimizing inventory levels and reducing the risk of stockouts or overstocking. AI-driven predictive analytics can enhance decision-making processes, enabling real-time adjustments to inventory management strategies [

3].

Building strong partnerships with suppliers and other supply chain stakeholders can improve visibility and coordination, leading to more efficient inventory management. Strategic supplier partnerships and collaborations are crucial for synchronizing the supply chain, improving quality, and managing risks associated with high-value inventory. Vendor-Managed Inventory (VMI) is an example of such collaboration, where suppliers manage inventory levels based on real-time data, reducing the burden on the company. Recent studies offer more practical applications of VMI in highly critical contexts. For instance, Ref. [

4] incorporates environmental concerns and transport/storage costs (green production and emissions) into the VMI model, something increasingly relevant for HVPs with regulatory or sustainability requirements. Also, Ref. [

5] compares different high-value replenishment policies in hospital environments, showing that models that reduce or eliminate safety stock can generate cost savings when there is visibility or reliable forecasting.

In [

6], recent developments in sustainable inventory management are examined, emphasizing key trends, benefits, challenges, and future directions of digital transformation in advancing supply chain sustainability. The authors provide evidence that Industry 4.0 is reshaping sustainable inventory practices through the integration of technologies and AI-driven analytics, which enhance efficiency, reduce costs, and support the formulation of sustainability strategies across different management domains. Furthermore, circular economy principles, Lean Six Sigma methodologies, and digitalization foster waste reduction and resource optimization, reinforcing the transition toward more adaptive and resilient supply chains.

By integrating these strategies, organizations can enhance operational resilience, reduce costs, and align inventory management with economic and environmental goals, ultimately minimizing economic losses [

7,

8].

In the electronics industry, inventory management has become especially critical due to high product value, fast product lifecycles, frequent technological obsolescence, and volatility in both demand and supply. Efficient inventory practices can mean the difference between profitability and losses from overstock, markdowns, or missed sales. Electronics see high rates of returns for warranty, repair, and refurbishment. These reverse flows require holding inventory of failed devices or spare parts, which leads to special modeling issues. The authors of [

9] examine a closed-loop supply chain where failed devices are refurbished and either used to serve warranty demands or sold via side channels. They propose models capturing dynamics of returns and depreciating value, considering the optimization of “sell-down” policies, i.e., how fast selling refurbished/warranty inventories compares with keeping them in stock. They also consider deterministic versus stochastic demand settings and analyze sensitivity to parameters like failure rates, lead time, and resale value.

The definition of appropriate batch sizing policies plays a central role in improving processes, balancing supply and demand. The implementation of inventory management policies not only contributes to risk mitigation but also improves the responsiveness of the supply chain in highly dynamic and competitive markets [

10]. The order size should be determined by minimizing the total logistics cost, which covers both ordering costs and inventory holding costs. In addition, profit maximization is also a key objective, ensuring that ordering and inventory management decisions not only optimize operating costs but also contribute to the company’s profit margin increasing. This outcome is due to the balance between logistics efficiency and profitability [

11,

12].

The effectiveness of a supply chain is often evaluated by inventory performance. A one-size-fits-all approach to inventory management is inadequate, especially when comparing products of different added values. Critical distinctions, risks, and strategic divergences between managing HVP and traditional products are very important to consider [

13]. The management of HVP is primarily an exercise in capital risk mitigation, while traditional product management focuses on operational cost optimization across high volume. HVPs often fall into the Low-Mix, Low-Volume, High-Value (LMLV-HV) category, amplifying the challenges of demand uncertainty and obsolescence. Different perspectives on inventory management of HVPs and traditional products are presented in

Table 1.

HVP inventory management may require distinct approaches from traditional inventory, prioritizing criticality, risk, and strategic value over pure cost efficiency. The field is evolving towards digital-enabled optimization, but research remains fragmented—especially in empirical validation and integration across sectors. Clear distinctions exist in strategic priorities, modeling frameworks, risk assessment, and performance measurement. The literature underscores the need for industry-specific adaptations and more rigorous cross-sector integration [

19]. Quantitative evidence supports the integration of smart technologies (IoT, ML, and blockchain) for HVP management. Innovation lies in extending multi-echelon frameworks, validating models empirically across industries, and including sustainability as a key decision metric [

20].

This study explores the need for more efficient stock management practices to optimize purchasing and inventory costs within a manufacturing environment. In addition, it develops an electronics industry case study for which the demand variability creates challenges for inventory control. The case study illustrates how adoption stock management strategies can reduce excess inventory, minimize stockouts, and improve overall supply chain responsiveness, ultimately leading to cost savings and enhanced operational efficiency.

Regarding this study’s contribution to the research gap, many papers in the literature discuss different methods for inventory management, but HVPs have different characteristics that need a dedicated study. Thus, this paper contributes to supply chain management research by focusing on inventory management practices specifically within HVPs, a context often overlooked in prior studies, where risks and costs differ from conventional goods. Through a case study approach, it provides empirical evidence on how inventory policies affect cost efficiency, service reliability, and risk mitigation. By linking theory with practice, it advances the understanding of supply chain resilience in high-value environments and delivers practical insights for company managers. It provides specific case evidence, showing how material classification and replenishment policies behave in an HVP environment. The literature covers classification methods and review models separately, whereas there is limited applied work showing their simultaneous relevance in costs and service levels in a real manufacturing setting. In the current study, ABC/XYZ are applied, and both Q and P-models are analyzed. Therefore, the study contributes to both academic understanding and managerial practice for the secure and efficient management of HVPs.

To address these contributions, this paper is divided into four sections. After this section, which contextualizes the theme and presents the objectives,

Section 2 presents the materials and methods where the case study is described in detail, the chosen HVP is characterized, and the different tools used to analyze the case study are presented. The third section details the results obtained and the discussion. Finally,

Section 4 provides the main conclusions and outlines directions for future work.

2. Materials and Methods

This section presents the case study in the field of electronics under study, focusing on the inventory management requirements to produce the Bitburg M1.4/50 lens, along with the methods and metrics used to optimize the supply chain process.

2.1. Research Framework

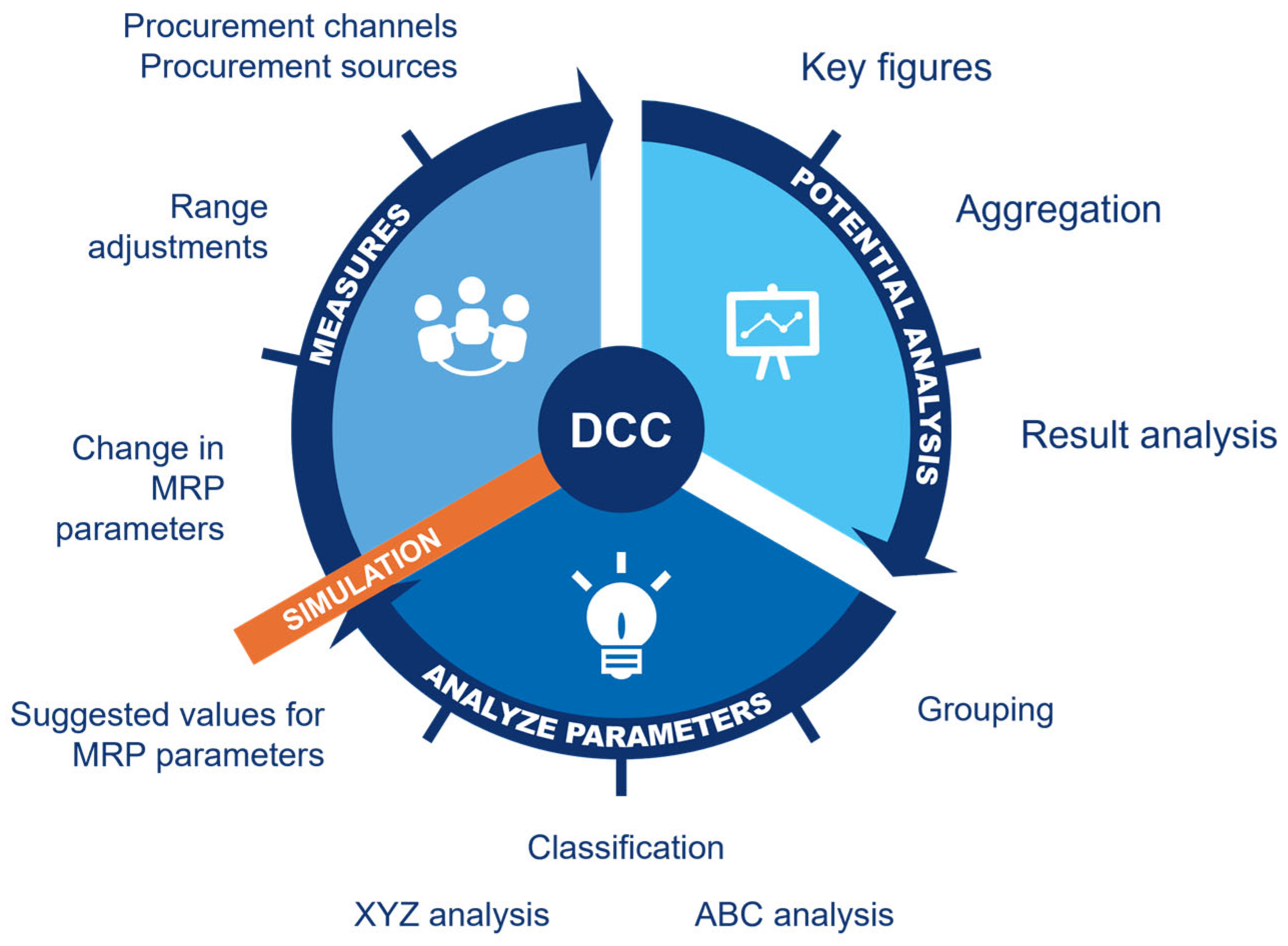

A framework (

Figure 1) was proposed for inventory management, linking demand forecasting with the purchasing strategy through four key operational phases. Production needs are forecasted using historical data to provide a reliable basis for demand planning. To provide a cost-effective process, it is necessary to optimize the inventory. This can be ensured by balancing the stock levels, the holding and ordering costs, and the stockouts. The subsequent phase translates these inventory needs into detailed schedules that specify what items are required, in what quantities, and when to order (Material Requirement Planning (MRP)). Finally, the materials’ supply can be guaranteed through a purchasing order to secure timely delivery. Thus, this framework creates a data-driven process that supports demand-aligned purchasing decisions.

2.2. Industry Case Study Description

This applied research was conducted within a multinational company specialized in the production of non-ophthalmic optical instruments and equipment, including cameras, scopes, lenses, and binoculars. The company’s production system is structured into three main sectors: mechanics, optics, and assembly.

The mechanics sector is responsible for transforming raw materials, such as aluminum, brass, magnesium, steel, and titanium, into the required components. This is divided into two processes: machining processes, mainly focused on turning, milling, and engraving processes, and surface treatment processes, including manual polishing, followed by anodizing and chroming to ensure durability, and concluding with painting.

The optics sector is divided into prisms for manufacturing binoculars and cameras and producing lenses for binoculars, scopes, and objectives. Operations include milling, grinding, polishing, washing, centering, bonding, and lacquering.

Assembly is the final stage of production, where components from mechanics and optics are combined with direct raw materials, such as electronic components. The entire assembly process is manual and sequential, resembling an artisanal operation, ultimately yielding the finished product, which is then packaged and shipped to customers.

Production planning is initiated by demand forecasts entered at the company’s Enterprise Resource Planning (ERP) system. Production plans are derived from both purchase forecasts and confirmed orders. Each planner, responsible for a predefined product portfolio, uses the internal production management system to meet weekly requirements, establishing the production rate according to production capacity and the available stock. The proposed production plan must

Meet customer demand (fulfill confirmed orders);

Balance inventory to absorb demand fluctuations;

Minimize production complexity (reduce variability).

Production planning is defined on a weekly basis, integrating functionalities such as stock balancing and backlog monitoring (representing overdue production). The plan is discussed and adjusted considering supplier delays or internal production issues.

Confirmed orders generate, via MRP explosion, planned orders for finished products and in-house components, as well as purchase requisitions for required raw materials. These suggestions are based not only on demand but also on product Bill of Materials (BOMs), inventory levels, lead times, cycle times, and predefined order quantities.

Planned orders, once approved, become production orders in the sectors of mechanics and optics. These orders follow the complete production process, with each step confirmed in the system. Orders include lot size, part reference, production start and end dates, responsible planner, and operation routing. Purchase requests are released according to approval workflows before being sent to suppliers. Assembly operations, by contrast, adopt a backflush strategy, meaning orders are only released at the end of production based on the actual finished quantity.

At the end of production process, finished products are packaged and transferred to the shipping warehouse. From there, they are either moved to a cross-company or delivered directly to customers for third-party orders.

The company’s ERP system includes dedicated inventory management software, integrating MPR, logistics, and supply chain management (

Figure 2). It enables real-time visibility of inventory and identification of critical materials and allows for comparison between current planning and alternative scenarios. Software functionalities include

Integration of specific requirement indices;

ABC and XYZ inventory classification;

Product lifecycle integration;

MRP parameter simulation;

Material grouping.

Inventory management is guided by objectives such as maintaining a maximum stock level, minimizing dead stock (ideally limited to safety stock levels), optimizing lot sizes, and ensuring high delivery availability. Achieving these objectives requires continuous monitoring and control.

2.3. Product Characterization

A representative product was selected to conduct a detailed analysis of the procurement process and to study inventory management policies in order to reduce inventory levels and optimize purchase lot sizes. This product is the basis for evaluating the company’s supply strategy and supports the exploration of new processes or approaches.

Among the company’s broad product portfolio, lenses were identified as particularly relevant for analysis. Within this category, the lens Bitburg M1.4/50 was chosen because it had the highest projected demand for the year 2024 when compared to other lenses (2353 units). Also, this lens passes through all production sectors—mechanics, optics, and assembly—making it an ideal model for developing stock management policies. Structurally, the lens is composed of the

Schneckengang and the optical head (see

Figure 3).

Based on the production value stream mapping, the potential bottleneck corresponds to the polishing process, which shows a cycle time of 49 min and a setup time of 240 min. Such factors may negatively impact process efficiency and increase Work in Process (WIP). Additionally, long waiting times between stages, particularly in mechanics and optics, further compromise production flow.

The model is produced in two colors and consists of 137 components. Of these, 85 are purchased materials, and 52 are manufactured (mechanics, optics, assembly, or subcontracted). However, the analysis is limited to materials purchased exclusively for this lens, reducing the sample to 13 components. Analyses were performed on these 13 parts to understand inventory management practices and assess how stocks are controlled.

The costs of the 13 components under analysis are shown in

Table 2. The unit cost of each part (based on average purchase price) was multiplied by the quantity used in the final product. Thus, the material cost of producing one lens is EUR 58. Among the 13 components (C1 to C13), only two require more than one unit per lens.

2.4. Stock Classification Systems

Inventory management has several benefits, such as the control of stock, material acquisition, and reduction in lead time [

21]. In this way, before defining the stock policy to be used, it is important to classify the materials since not all items have the same importance.

2.4.1. ABC Analysis

The most common method of material classification is the ABC method, also known as the application of the Pareto principle [

22]. ABC analysis is a technique used to identify the state of warehouse inventory management. Due to its simplicity and its great usefulness, it has been widely applied in different fields [

23].

The method divides the items into three classes (A, B, and C). Class A represents the most relevant items and, according to the Pareto rule, comprises about 20% of the inventory that accounts for 80% of total revenue. Class B refers to items of medium relevance, which make up 30% of the items and correspond to 15% of revenue. Finally, Class C represents only 5% of the total revenue; however, despite its reduced importance, it includes about 50% of the items. Thus, ABC classification is applied to compute each item’s annual consumption value, and items are ranked in classes according to cumulative thresholds. As an inventory control tool, ABC classification helps prioritize resources [

24].

The average stock is characterized as the quantity or value of items kept in inventory during a given period, usually a full year. It is also possible to calculate the stock holding level, which is the inverse of the turnover ratio and represents the consumption time ensured by the average stock. As such, the lower the value, the greater the efficiency, since it means there is higher turnover. The analysis of the average stock allows for the likelihood of stock obsolescence to be reduced and contributes to minimizing the costs associated with storage and holding.

2.4.2. XYZ Analysis

The ordering process is influenced by both fluctuations in demand and product prices. To address these variations, products can be grouped and classified using a method known as XYZ analysis [

25].

The outcome of the XYZ analysis provides valuable insights for assessing how each part of the inventory should be monitored and controlled, according to its level of importance, by examining patterns of demand fluctuation [

21]:

Items classified as X are the most predictable, consisting of materials with relatively constant or rarely fluctuating usage, for which forecasting is generally more reliable.

Items classified as Y exhibit substantial demand fluctuations, often resulting from seasonality or shifts in product use.

Items classified as Z are the most irregular, making forecast reliability considerably lower.

This method, applied in materials management, classifies products according to the Coefficient of Variation (CV), which is associated with demand regularity, while considering item consumption. The CV measures the standard deviation of consumption in relation to the average of its demand. The analysis is primarily employed for material requirement planning and management.

According to the literature, the items’ classification as X, Y, or Z can vary, even within the specific business context in which they are applied. For instance, Ref. [

26] defines X items as those with a CV below 0.5, Y items as those with a CV between 0.5 and 1, and Z items as those with a CV above 1.

Conversely, the authors of [

27] classify X items as those with a CV of up to 10%, Y items with a CV between 10% and 25%, and the remaining items as Z. However, it is evident that items with more stable demand exhibit a lower CV value, whereas products with irregular or unpredictable demand exhibit a higher CV value.

Nevertheless, no fixed standard exists to determine these classifications, allowing for their adjustment to a specific organizational context.

In this study, the XYZ classification was attributed considering the CV values from

Table 3. Therefore, X items were defined as those with a CV below the value of 0.7, Y items as those with a CV value between 0.7 and 1.5, and Z items as those with a CV value above 1.5.

2.4.3. ABC/XYZ Analysis

The ABC and XYZ methods are combined to achieve a more effective classification of a company’s warehouse inventory. This combined method integrates both ABC and XYZ analyses, acknowledging that the ABC analysis alone often fails to sufficiently differentiate items as it evaluates them solely based on their value. Given that consumption regularity is also a critical factor in inventory management, the combined ABC/XYZ approach provides a more comprehensive and insightful assessment [

28].

According to [

21], the XYZ analysis is particularly valuable when both demand fluctuations and item consumption are high. A combined application of the ABC and XYZ methods, as illustrated in

Table 4, yields improved results concerning inventory management.

For instance, AX and BX items exhibit a high value share and are relatively easy to predict as they are subject to regular consumption, making them easier to manage. In contrast, AZ and BZ items are considered challenging as they account for a substantial share of business volume but, due to their irregular demand patterns, they are difficult to forecast accurately.

2.5. Stock Management Policies

Inventory management is key to supply chain and operations performance, whereas the primary goal is to satisfy the demand “at the right time, in the right place and at the right quality” while minimizing costs. Integrated inventory decisions ensure uninterrupted service. Thus, inventory policies directly affect responsiveness and competitiveness: high stock levels tie up capital in holding costs, whereas low stock levels lead to stockouts and lost sales. So, the fundamental tradeoff in inventory control policies is between service level (avoiding stockouts) and holding cost (storage, obsolescence, or capital). Therefore, reorder points and safety stock levels are set to achieve a target service probability.

2.5.1. Continuous Review Model (Q-Model)

Under a continuous review policy, inventory levels are monitored, and an order of fixed size

Q is placed when the stock equals a preset reorder quantity. Continuous review policies are widely used for high-priority items or where real-time tracking is feasible, since they can react immediately to demand fluctuations. Thus, the continuous review model calculates the Economic Order Quantity (EOQ), which can be determined using Equation (1):

where

corresponds to the annual demand,

is the ordering cost per order, and

is the annual holding cost per unit. Iterative simulations can be performed to adjust the EOQ, incorporating stockout costs (

).

In this model, the reorder point (

) is also calculated by using Equation (2), where

μ represents the average demand during lead time,

z represents the safety factor for the desired service level, and

σ is the standard deviation of demand during the lead time.

This approach allows for more accurate inventory control, but it requires continuous monitoring, which can increase supply process complexity.

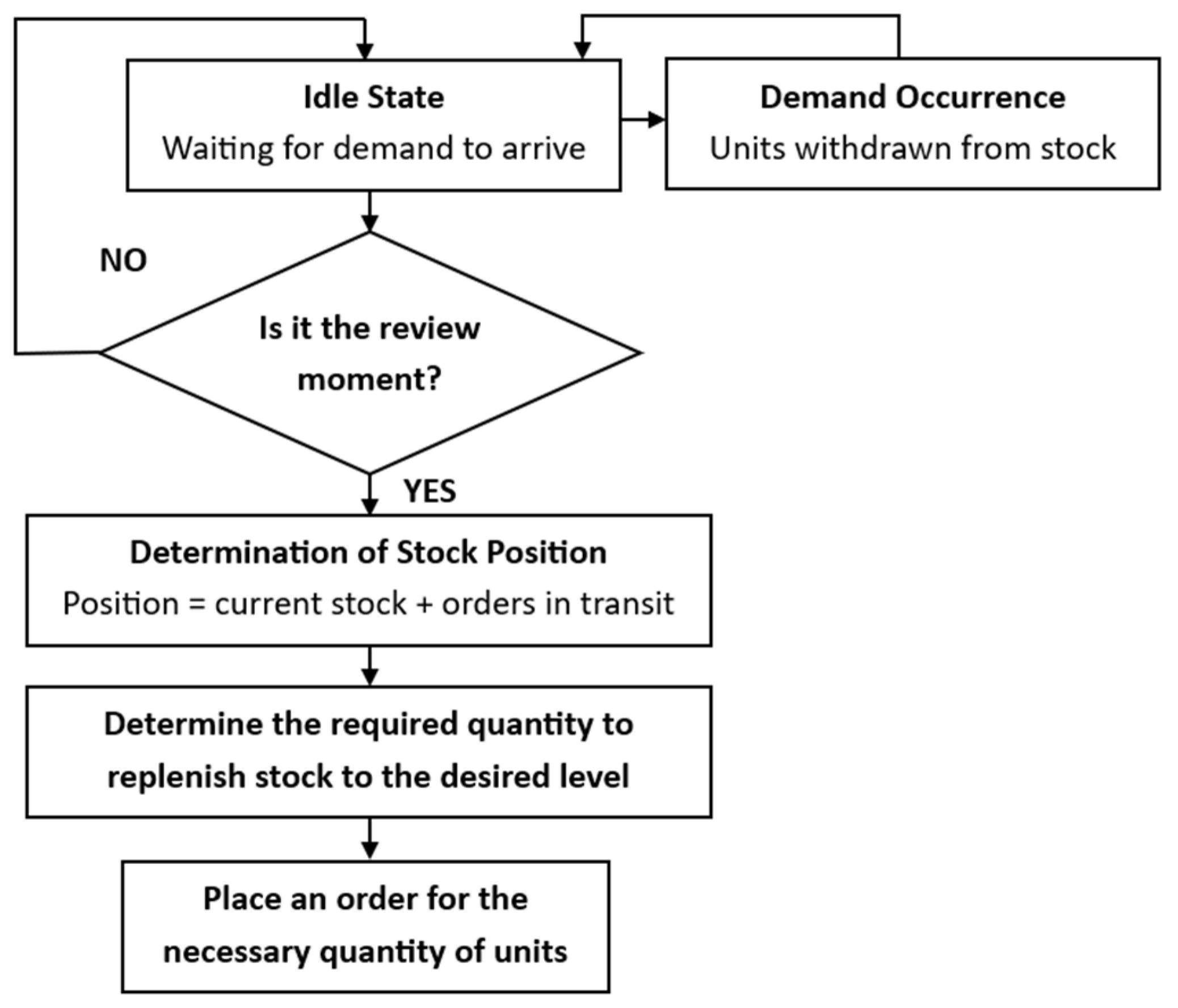

Figure 4 shows the flowchart of the continuous model, where the stock position can be estimated and compared with the reorder point, so an order can be placed. In this model, a fixed quantity is ordered each time, and the period between orders depends on demand [

29].

2.5.2. Periodic Review Model (P-Model)

Periodic policies simplify replenishment planning and allow coordination, but they require larger safety stocks to cover the entire review interval. The periodic review model analyses inventory at fixed intervals and places orders to replenish stocks to the target stock level (

). Thus, the calculation of the target stock level corresponds to Equation (3):

where

represents the review period plus the lead time. The safety stock can be calculated to ensure a certain service level.

The P-model simplifies inventory monitoring and aligns with synchronized procurement cycles, but it requires larger safety stocks to maintain service levels comparable to the Q-model. In this system, the inventory position is updated only at the end of each period, and all replenishments match those intervals.

The

P-model is applied when continuous tracking is impractical or when grouping orders into batches reduces handling costs [

29].

Figure 5 shows the flowchart of the

P-model. The order takes place only when the stock review point is reached and the quantity corresponds to the quantity required to replenish stock to the target level. The period between orders is predefined and fixed.

Both the

Q-model and

P-model are applied in inventory optimization under uncertainty, since they account for stochastic demand and lead time variability, allowing companies to balance holding costs against service targets [

30].

3. Results and Discussion

In this section, the main results are presented, considering the stock value data from a full year to assess the impact of inventory management on the supply process.

3.1. Stock Value Analysis

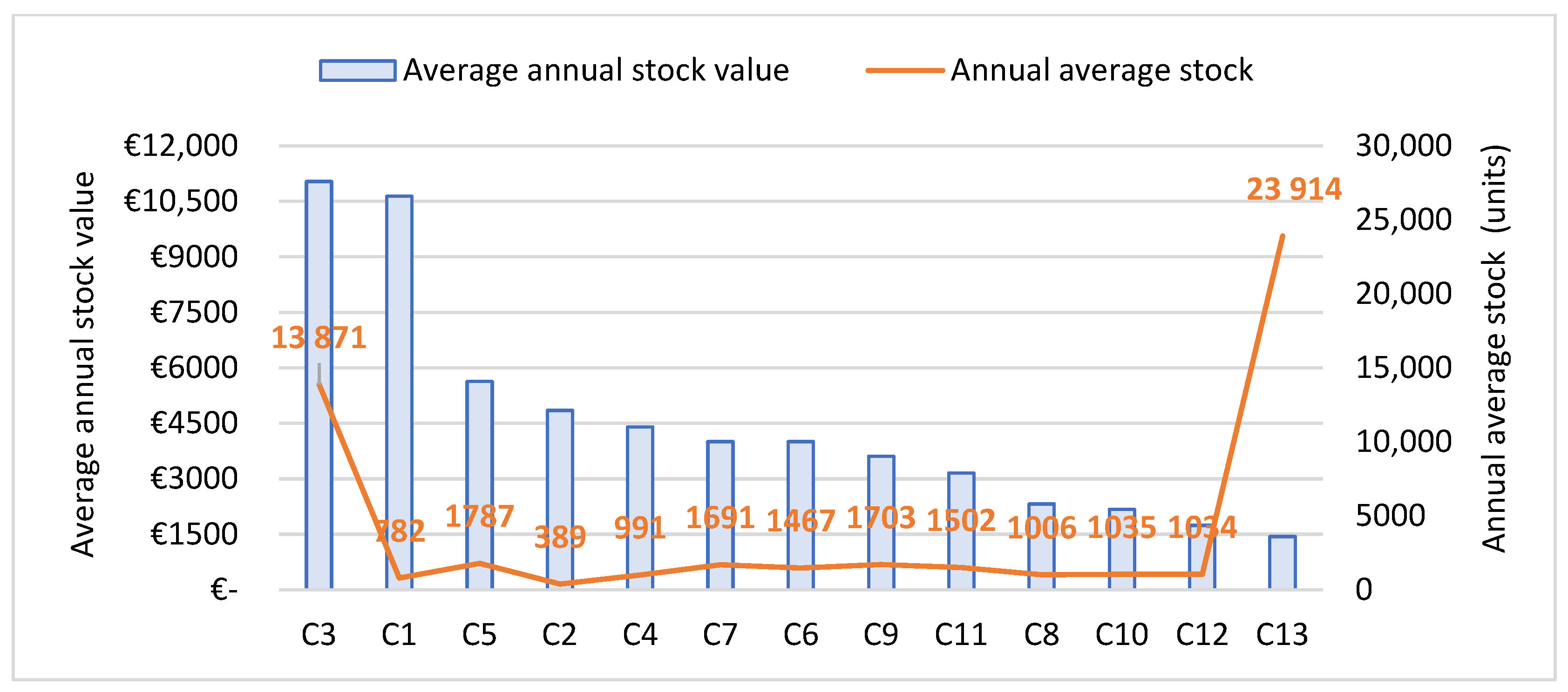

An ABC analysis was conducted for the average stock value and for the average stock quantity based on the data from 2023.

Figure 6 illustrates the annual average stock per component, considering both value (€) and unit quantity, ranked by stock value. This provides insights into the relationship between stock volume and economic impact, identifying the high-cost components with potential for inventory optimization.

Furthermore, the analysis shows that only C13 and C3 maintain significantly high unit stock levels. Despite its low unit cost, C13 is the most frequently stocked component, while C3 is relevant both in financial and physical stock management.

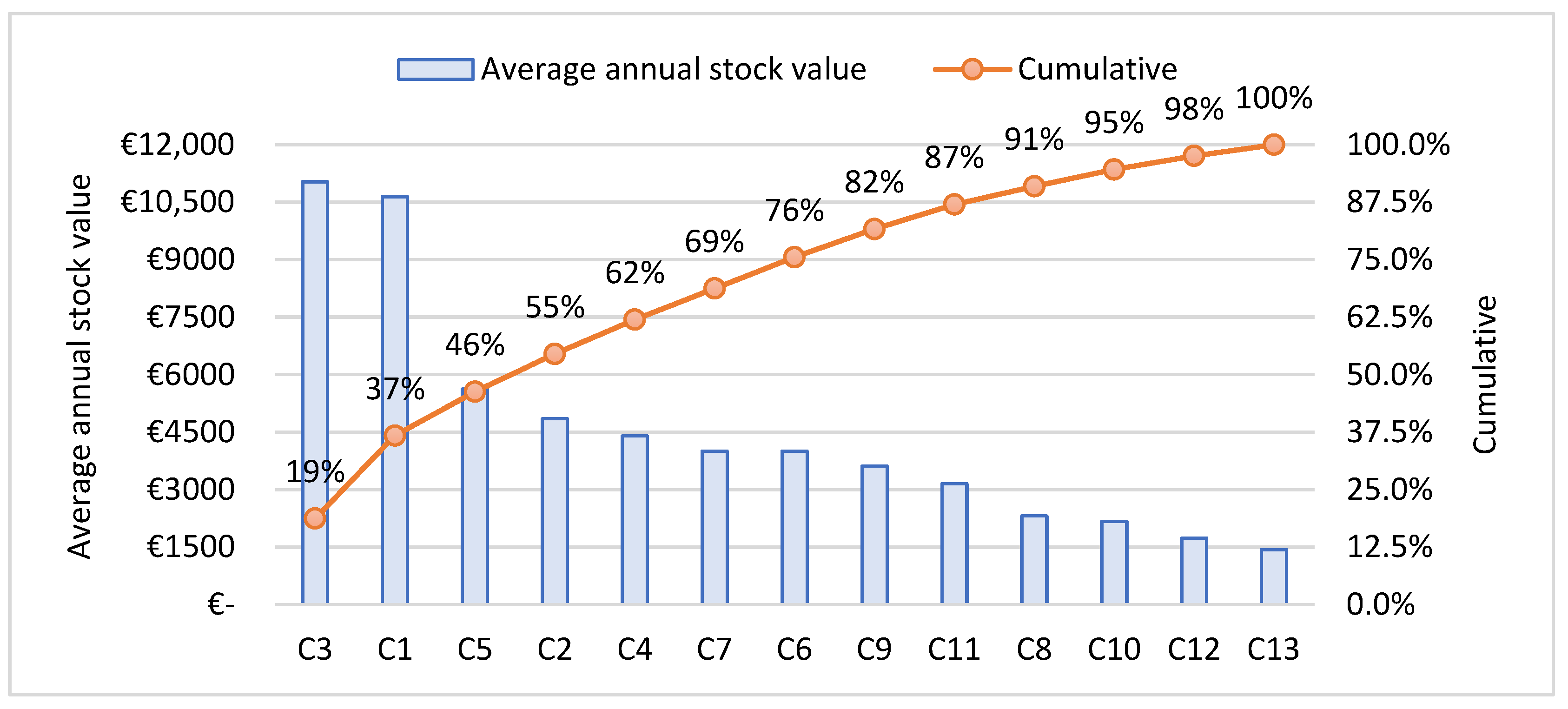

Figure 7 presents an ABC analysis based on stock value, highlighting the distribution of value across items. The analysis shows that

Class A includes components C3, C1, C5, C2, C4, C7, and C6;

Class B includes C9, C11, C8, and C10;

Class C includes C12 and C13.

Class A and Class B components show higher stock values when compared to the others. On average, they account for approximately EUR 10,800, while the next highest component represents only EUR 5628 in stock. This indicates that Classes A and B lead the financial weight of the inventory.

Also, C3 is a component with high cost, high use, and major impact on inventory value. C1 and C2 are high-value components but with relatively low stock quantities. Therefore, importance is driven by cost, not volume. Item C13, despite being classified as Class C in value analysis, represents the highest share of stock by quantity. Given its negligible unit cost, this does not pose a noteworthy financial concern.

3.2. Stock Coverage Analysis

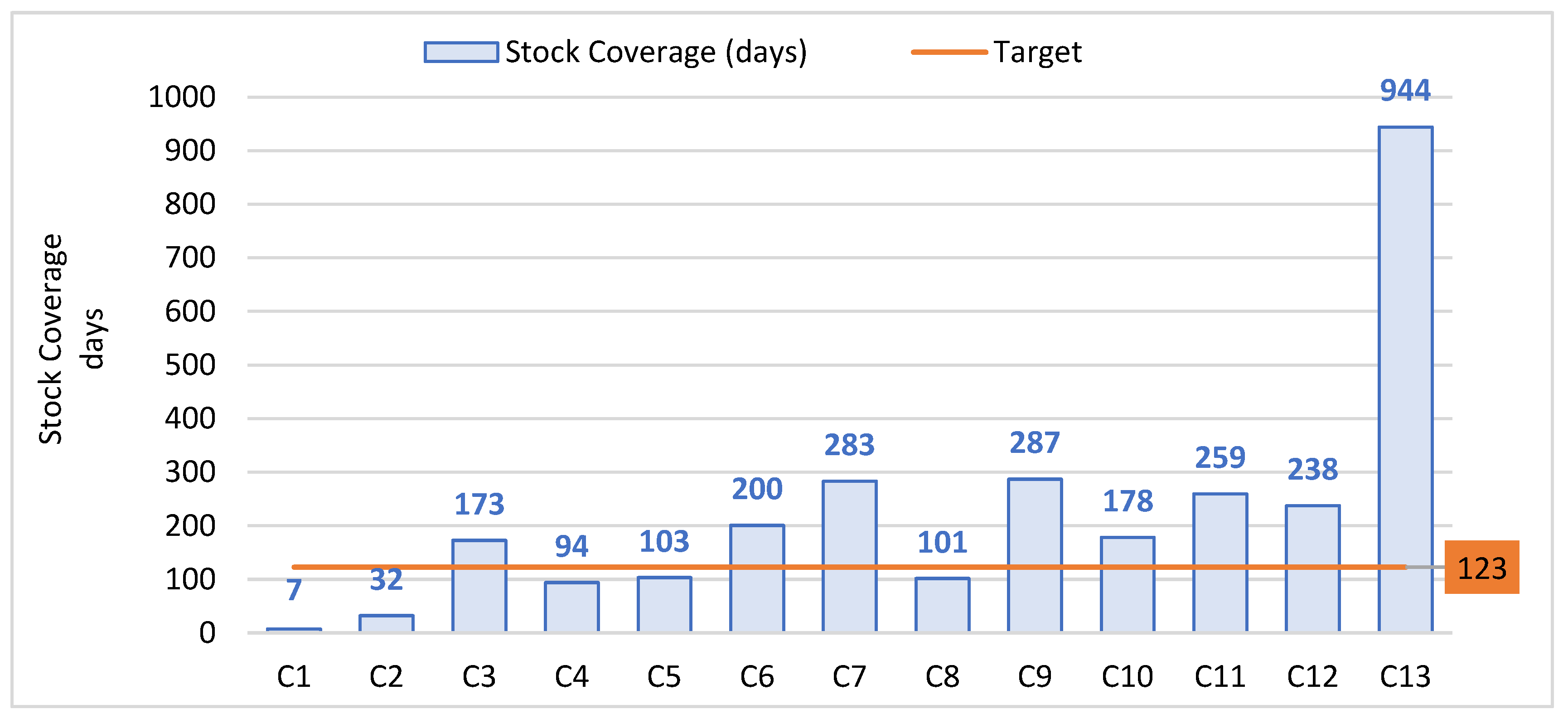

To assess how long stocks can sustain operations without replenishment, stock coverage was calculated. This metric divides the available stock by the average consumption rate, being a key performance indicator. The company set a target coverage of 123 days for all stocked components. This benchmark is adjusted annually in proportion to budget variations. Using this as a reference, stock coverage was calculated for the 13 components under study based on annual consumption data and stock levels.

Figure 8 presents the stock coverage (days) for each component and the average annual stock value (in thousands of euros). Results show that components C1, C2, C4, C5, and C8 were the ones below the company’s coverage target.

The four most representative components in turnover (C1, C2, C4, and C8) also exhibit lower stock coverage, indicating faster inventory rotation. C13 shows the highest stock coverage but the lowest turnover, meaning that large volumes of this component remain in stock with minimal consumption.

Stock level fluctuations were analyzed to identify seasonal patterns and demand variability in inventory management. Both were determined for each component, allowing the calculation of the total replenishment lead time (from order confirmation to stock availability). Additionally, the Minimum Order Quantity (MOQ) imposed by suppliers was also estimated, i.e., the minimum quantity that is required to be ordered when placing an order. The only exception in this analysis corresponds to component C2, which requires a fixed lot size of 750 units. This analysis is presented in

Table 5.

3.3. Analysis of Stock Management Policies

Several parameters were set concerning the application of continuous and periodic review models to evaluate the impact of stock management policies. Those parameters include the service levels, the safety factor, and the stockout cost that was calculated based on these same service levels. The ordering cost was provided by the company, which assigned an average value of EUR 100 per order. The annual holding cost was established considering the market in which the company operates and the reference values used in reference [

31], converging to a percentage value of 30% of the unit cost of each material.

Table 6 presents the data required to implement inventory management policies.

Once all the data necessary to parameterize the inventory management policies had been collected and estimated, those policies were simulated using Microsoft Excel, considering the data from the year 2023. The model incorporates the material inflows according to the policy under evaluation. Also, the actual consumption for each item in 2023 was considered.

In

Table 7, the weekly average inventory balances for the continuous review model (

Q-Model) and the periodic review model (

P-Model) are reported, as well as a comparison with the company’s actual performance in the same year.

To clarify the analysis, the values in the table are highlighted with different colors. Values highlighted in red denote the components in which the application of the tested model would have predicted stockouts. The values highlighted in green correspond to policies that not only avoid stockouts but also achieve an average inventory balance lower than the company’s historical average, thereby reflecting a better outcome. Finally, the values highlighted in black represent scenarios without stockouts in which the company’s actual average stock balance remains lower.

Both models show greater efficiency in achieving viable results when materials are classified as X due to their consistent and predictable consumption patterns. As consumption becomes more variable, stockouts tend to occur. Otherwise, higher average inventory balances are required to buffer against these fluctuations.

It should be noted that the results for component C13 remain unchanged since none of the inventory management policies required this component to be ordered in 2023, given its high inventory levels (classified as a C item by ABC analysis and as an X component according to XYZ analysis).

The four components (C4, C5, C8, and C10) for which none of the policies are valid due to the existence of stockouts are justifiable given that, for example, in the case of component C10, there is an unusual scrap of 3845 materials for which the stochastic models presented are unable to provide an alternative, since they are based only on the actual consumption of the components.

When testing stock management policies for a scenario in which consumption only corresponds to the production order outputs, it was verified that component C10 would no longer have stockouts, as can be seen in

Table 7.

In

Table 8, the annual cost of the inventory management polices is presented and compared with the actual costs supported by the company in 2023. Both inventory management models represent better options for the strategy currently employed by the company for all the components, except for component C2. In this case, the company’s current system delivers better performance both in terms of inventory levels and monetary cost.

To evaluate the impact of the service level on the annual costs, a sensitivity analysis was performed considering a variation of +/−10% (

Table 9). As can be seen from the analysis in

Table 9, with higher service levels, the annual cost increases and decreases for lower service levels. The strategy to be adopted for the different components remains the same, supporting the robustness of the models applied.

A closer analysis of the costs shows that, even with a higher inventory level, the costs associated with the tested policies are lower and, consequently, more advantageous.

The policies that achieved the best results for each component, specifically under the constraint of no stockouts, are summarized in

Table 10.

When comparing the simulated review models with the company’s actual data, a 33% reduction in total cost is observed, falling from EUR 15,752 in the company’s records to EUR 10,584 under the proposed policies.

Although some components show a higher inventory balance than the company’s, such as component C1, with 2310 units in the model versus 788 units in the real data from the company, their associated costs are lower.

Overall, the review models yielded reduced costs despite only a marginal difference in the total inventory balance (46,053 units in the simulated models versus 46,966 units in the company).

3.4. Discussion

This paper demonstrates how the integration of theoretical inventory models with materials classification can provide actionable insights within a real manufacturing environment. Due to the challenges associated with managing stock in HVP production, inventory policies need to be differentiated. The application of Q-model and P-model inventory systems illustrates how simulation and data analytics can guide policy selection for each type of product component. Indeed, no single inventory policy fits all items; rather, model selection should depend on demand regularity, item value, and supplier constraints. By combining ABC (value-based) and XYZ (demand variability) analyses, managers can make data-driven decisions by linking demand stability with cost significance. An example of this is the study’s empirical finding that applying optimized stock management models resulted in a 33% cost reduction for the components analyzed.

Considering an in-depth analysis of the results, AX items (C1, C3, C6, C9, and C11) performed better with the Q-model, whereas AY items (C2, C4, C5, and C7) tended to perform better with the application of the P-model.

These results are consistent with inventory theory and can be explained by the interaction between value and demand variability. Since AX items have low variability, the safety stock required by the Q-model is lower but sufficient to achieve a high service level. However, those items require continuous monitoring to provide stock replenishment when needed, avoiding both stockouts and excess inventory.

High value and moderate fluctuating demand (AY items) make fixed review cycles more efficient since the P-Model smooths variability by reviewing at fixed periods. This means that the P-model performs better under fluctuating demand since it allows a tradeoff between sightly increased inventory and a lower risk of stockouts.

BY items (C8, C10, and C12) perform similarly for both models, but the P-Model may be favored because the periodic reviews allow for balancing cost and supply. The specific case of CX item (C13) depicts a low value and stable demand component but with a high stock, meaning that neither the Q-Model nor the P-Model triggers new orders.

Although the continuous and periodic models were simulated using Microsoft Excel for analytical validation, their adoption within the enterprise environment requires integration into the company’s ERP system. This transition involves technological and organizational challenges that influence the feasibility and sustainability of the proposed solutions. Thus, those challenges are proportional to the software/integrated systems’ capabilities to receive real-time inventory data and production planning scheduling. While the Q-Model demands continuous monitoring to generate a purchasing order once the reorder point is reached, the P-Model requires fixed-interval reviews and replenishment cycles that are easier to parameterize but need to be synchronized with production planning. Therefore, reliable data integration is of utmost importance for successful inventory management.

4. Conclusions

The main objective of this work was to improve inventory management, optimizing purchasing and inventory costs within a manufacturing environment, with the aim of reducing both inventory and associated costs through a case study application in an electronic HPV company. To achieve this objective, the study began with a detailed analysis of the materials of a lens, considered representative of the company’s products, focusing specifically on the year 2023. Several ABC analyses were performed to identify the most and least important materials, evaluating turnover, stock coverage, and stock variation throughout the year, including all material entries and exits, providing a clear view of consumption patterns and replenishment needs.

After gaining a deeper understanding of how the company manages its stocks and purchases raw materials, specific studies were conducted for 13 components exclusive to the objective. Regarding the material classification systems, 5 out of the 13 components were classified as AX (C3, C6, C9, C11, and C1), corresponding to items with stable demand and high value, while 4 were classified as AY (C5, C2, C4, and C7), representing an intermediate fluctuating demand and high value stock. Components C12, C8, and C10 were classified as BY, representing components of intermediate value and a fluctuating demand. Component C13 was classified as CX, a component with stable demand but a slow mover due to high stock.

This analysis supports the decision-making of the supply process since demand forecasting plays an important role in inventory management, particularly when combined with classification methods such as the ABC and XYZ methods.

By integrating both methods, management can prioritize forecasting efforts on HPVs with stable demand, ensuring optimal stock levels and minimizing holding costs. Similarly, HPVs with erratic demand require advanced forecasting techniques to mitigate risks. This synergy between demand forecasting and inventory classification enables companies to allocate resources effectively, reduce waste, and maintain a reliable supply of HPVs.

The purpose of the stock management policy simulation was to verify whether the application of stochastic stock management models, such as the continuous review model and the periodic review model, would be beneficial to the company. After performing the calculations, it was observed that for 9 of the 13 components analyzed, the results were valuable. Thus, the best management policy was selected to each of these nine components, and the related costs were also calculated.

It was concluded that the MOQs for most materials were well defined, given that this minimum order quantity was always respected except for component C7, which had an MOQ of 6750 units, but the optimal quantity for the continuous review model was found to be 1072 units. Component C13 had an MOQ of 30,000 units, and the optimal quantity of the continuous review model was found to be 11,659. These are two situations that need to be reviewed, and a new agreement with the supplier should be proposed to improve the supply of these components. For components for which the periodic review model proved beneficial, the existence of the MOQ is a limiting factor because this type of model is characterized by constant changes in the order batch.

Nevertheless, the implementation of the policies selected for nine components resulted in a 33% reduction in costs, corresponding to a decrease of EUR 5168 per year. In addition, there was an estimated decrease of 900 units in the average inventory. Given that these results were obtained considering a sample of only nine materials, it is plausible to expect that a broader application of appropriate stock management policies could lead to even more significant cost reductions and a substantial impact on the company’s supply management.

For future work, we propose the use of advanced forecasting techniques, such as machine learning and predictive analytics, since these techniques are increasingly used to predict demand patterns for HPVs, as well as the application of models to optimize inventory across multiple stages of the supply chain.