1. Introduction

In recent years, there has been a substantial increase in the focus on data analytics among practitioners and academics alike [

1]. Many companies have recognized the potential of analytics to enhance their performance and have made efforts to incorporate it into their operations. Research reports indicate that analytics is among the highest priorities on organizations’ agendas [

2]. Supply chain management is an area where the deployment of analytics can have significant impacts [

3]. According to Notteboom et al. [

4], over one-third of the surveyed organizations have begun integrating data analytics into their supply chain management processes. Analytics plays a significant role in supply chains by using historical and real-time data to anticipate future occurrences and make proactive decisions [

5,

6]. It helps businesses to better understand demand trends, manage inventory levels, boost operational effectiveness, and increase customer happiness [

7,

8]. On the other hand, the efficient application of big data analytics for demand forecasting in the digital supply chain must be looked at [

9]. Organizations may increase their forecasting accuracy and better predict client wants by utilizing historical and current data [

10]. To improve the accuracy of demand forecasting, research might concentrate on creating complex algorithms and models that consider a variety of variables, including seasonality, market trends, and consumer behavior [

11,

12]. The digital supply chain refers to supply networks where digital technologies (IoT, AI, blockchain, and big data analytics) are integrated across organizational boundaries to enable real-time visibility, predictive capabilities, and automated decision-making throughout the value chain.

In addition, with the use of big data analytics for inventory control, organizations may optimize their inventory levels, lower stock-outs, and save holding costs by using huge volumes of data collected from several sources along the supply chain [

13]. In order to establish the ideal inventory levels in dynamic digital supply chain systems, predictive analytics models that consider variables like lead times, supplier dependability, and consumer demand patterns may be developed [

14]. According to Chehbi-Gamoura et al. [

15], data and quantitative methods are used in big data supply chain analytics to support decision-making throughout the whole supply chain. It makes two major advances: it firstly provides researchers with access to a wealth of information that is not frequently available in internal systems like supply chain management and electronic records [

16]. Additionally, it evaluates both recent and historical data using rigorous statistical approaches. It produces new data that supply chain decision-makers may utilize to improve front-line operations or make strategic decisions like choosing the most effective supply chain operating models [

17].

In supply chain management, a critical research gap persists in understanding their synergistic integration and collective impact on organizational performance. The current literature predominantly examines these technologies in isolation—evaluating blockchain implementations, Internet of Things applications, or big data analytics capabilities as discrete phenomena rather than as complementary components of a comprehensive digital ecosystem. This siloed approach fails to capture the transformative potential that emerges when these technologies operate in concert. As Zurayk [

18] observes, scholarly attention has largely focused on documenting individual technological benefits rather than exploring the multiplicative effects and strategic advantages created through their purposeful integration. This research gap is particularly significant as organizations increasingly seek holistic digital transformation strategies rather than piecemeal technological solutions.

This study aims to develop an integrated framework that maps the synergistic relationship between big data analytics and digital technologies for optimizing supply chain management operations. Through a systematic analysis of the existing literature, the research seeks to bridge the current knowledge gap in how these technologies collectively transform traditional supply chains into data-driven, agile ecosystems. The study is guided by three specific objectives: (1) To identify and categorize the critical technological enablers and organizational capabilities that facilitate a successful digital supply chain transformation across different industries; (2) to examine the interrelationships between big data analytics capabilities, digital technologies implementation, and measurable supply chain performance outcomes; and (3) to construct and validate a comprehensive framework that provides organizations with a structured approach to assess their digital maturity, identify technological gaps, and develop strategic implementation roadmaps for digital supply chain optimization. This research will contribute to both theory and practice by offering a unified framework that guides organizations in their digital transformation journey.

2. Literature Review

Organizations may use big data analytics to mine the massive volumes of structured and unstructured data produced by the supply chain for valuable insights [

19]. In addition, there are several analytics methods available today, including machine learning, exploratory data analysis, case-based reasoning, predictive analytics, and data mining [

5]. These methods have a huge potential for helping businesses gain useful insights from unstructured data, which will help them better understand the preferences and demands of their consumers [

20]. The use of these current approaches is frequently constrained despite their capabilities [

21]. It has been highlighted that existing methods for big data analytics frequently have a mechanical bent [

22]. Additionally, several academics have noted that big data analytics approaches are underutilized when it comes to assisting the development of new goods [

23,

24].

Besides this, organizations are increasingly utilizing digital technology and big data analytics to improve their supply chain operations to stay competitive in this changing environment [

25]. Digital technologies and big data analytics provide organizations with previously unheard-of opportunities to obtain insightful data, streamline operations, and come to wise conclusions [

26]. According to [

27], supply chain management has undergone a transformation thanks to the development of digital technologies like the Internet of Things (IoT), artificial intelligence (AI), and blockchain. These technologies make it possible to gather enormous volumes of data from several sources, such as sensors, gadgets, and systems [

28]. This data may be integrated with modern analytics methods to provide actionable insight, giving organizations real-time visibility, predictive power, and better decision-making.

Furthermore, digital technologies provide seamless communication, real-time information exchange, and cooperation among supply chain stakeholders in the context of the digital supply chain, which is an interconnected ecosystem [

29]. According to [

30], the way organizations plan, carry out, and monitor their supply chain operations may change because of this paradigm shift from conventional supply chain management practices to digital supply chain management. In addition, big data analytics is one of the main facilitators of the digital supply chain. In the current digital era, organizations have both possibilities and difficulties due to the abundance of data [

31]. The integration of technological advances with supply chain management offers end-to-end visibility and traceability [

32]. RFID tags and sensors, for example, may follow items along the supply chain, recording data on location, temperature, humidity, and other vital aspects [

33]. Organizations may improve customer satisfaction by proactively identifying bottlenecks, optimizing inventory levels, and ensuring a timely delivery by analyzing this data in real-time [

34].

Digital supply chain collaboration fundamentally differs from traditional supply chain coordination by leveraging advanced digital technologies to create interconnected, intelligent ecosystems that transcend organizational boundaries [

35]. While conventional supply chain management focuses on transactional efficiency and linear information flows, digital supply chain collaboration encompasses three critical dimensions: technological convergence (the seamless integration of IoT sensors, blockchain ledgers, and AI-driven analytics across partner networks), collaborative intelligence (real-time shared decision-making enabled by unified data platforms and predictive algorithms), and dynamic value co-creation (joint innovation processes that generate synergistic benefits that are impossible through individual organizational efforts) [

36,

37]. This conceptualization extends beyond the mere digitization of existing processes to represent a fundamental transformation in how supply chain partners interact, innovate, and create value collectively.

3. Materials and Methods

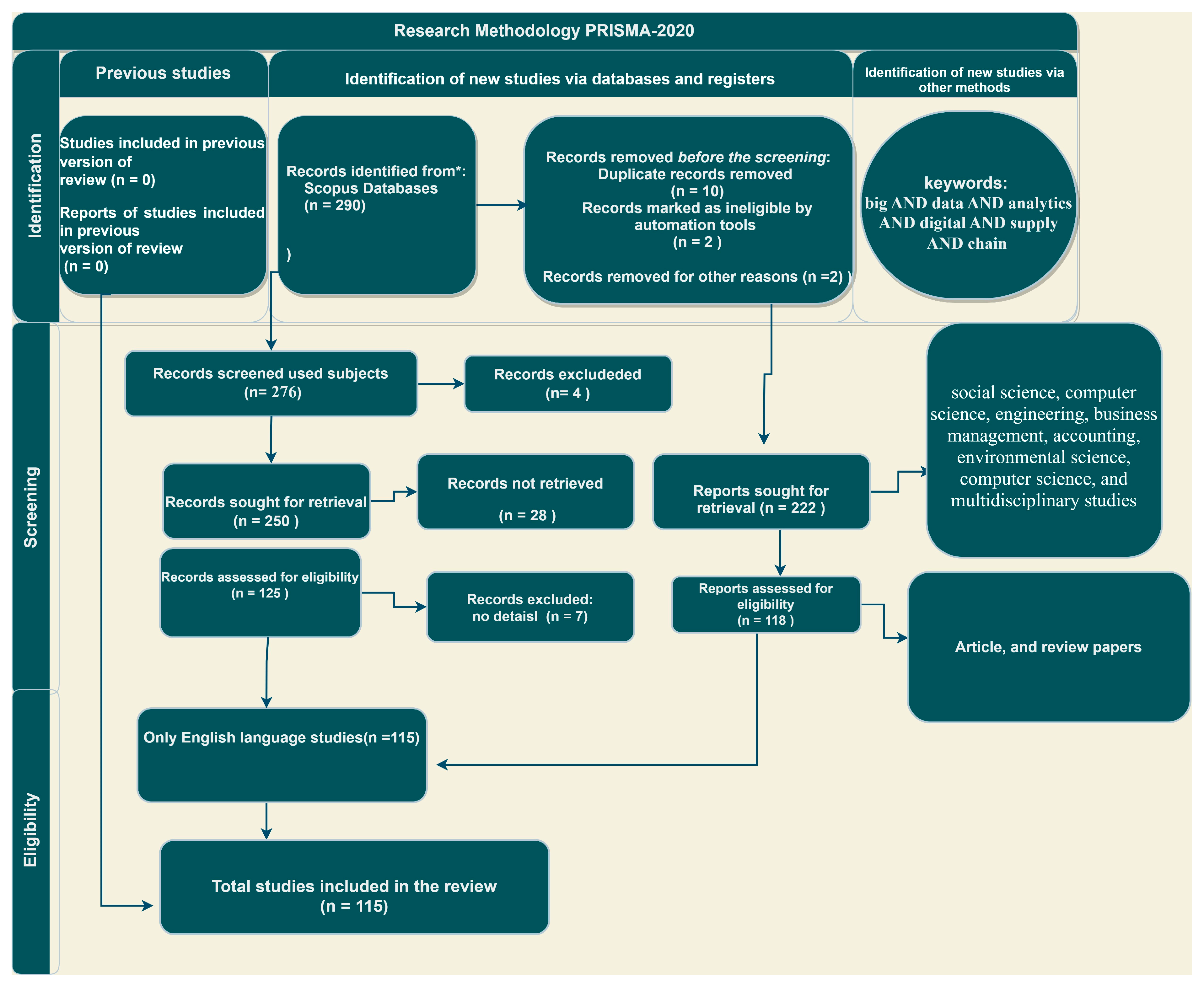

The systematic literature review methodology used in this study is based on the PRISMA declaration [

38,

39]. The systematic literature review methodology employed PRISMA guidelines to comprehensively analyze the integration of big data analytics and digital technologies in supply chain management across diverse industry contexts.

Table S1: PRISMA 2020 Checklist used for the inclusion and exclusion of the articles. An extensive search was conducted in Scopus and Web of Science databases using the precisely formulated query: “(big AND data AND analytics AND digital AND supply AND chain)”, with restrictions to final publications, articles/chapters/reviews, and journal sources only.

The sequential filtering process identified 290 initial publications, refined to 125 candidate studies through title and abstract screening, and finalized to 96 publications meeting our research criteria. Exclusion criteria included the following: publications prior to 2012, duplicates, non-article formats, and non-English publications. An industry distribution analysis of the final 96 publications revealed significant sectoral representation: manufacturing industries (59 publications, 61.5%), service sectors (20 publications, 20.8%), healthcare and pharmaceuticals (8 publications, 8.3%), agriculture and food supply chains (6 publications, 6.3%), and technology/logistics services (3 publications, 3.1%). Geographic distribution spanned 34 countries across six continents, with predominant representation from developed economies (North America and Europe: 67%) and emerging markets (Asia-Pacific: 28%, others: 5%), ensuring the broad applicability of findings across different economic contexts. This comprehensive industry and regional coverage strengthen the generalizability of our Digital Supply Chain Orchestration Framework across diverse organizational contexts and supply chain configurations, addressing potential limitations in sectoral or geographical bias that could affect the universality of our theoretical contributions.

Figure 1 below illustrates the inclusion and exclusion of the articles.

Studies were included if they (1) examined two or more digital technologies (big data analytics, IoT, AI, and blockchain) within the same supply chain context; (2) analyzed synergistic relationships, interdependencies, or integration mechanisms between technologies; (3) investigated how multiple technologies collectively impact supply chain performance rather than additive individual effects; and (4) discussed technological convergence, orchestration, or ecosystem approaches to digital transformation.

We excluded studies that (1) focused exclusively on one technology without considering complementary digital capabilities; (2) treated multiple technologies as separate, unrelated interventions; (3) measured only individual technology performance without examining integration benefits; and (4) lacked discussion of technological interdependencies or collaborative effects.

During full-text screening, we specifically searched for terms indicating integration (“synergy,” “convergence,” “orchestration,” “ecosystem,” and “integrated approach”) versus isolation (“standalone,” “individual impact,” and “specific technology”). Studies discussing “digital transformation” or “Industry 4.0” were included only if they demonstrated technological interdependence rather than parallel implementation. This rigorous distinction ensured our final 96 publications genuinely addressed integrated digital ecosystems rather than fragmented technology adoption, supporting our framework’s emphasis on orchestrated technological convergence.

4. Results

Descriptive

Table 1 provides a comprehensive overview of the literature corpus spanning 2012 to 2024, revealing significant insights into the research landscape of digital supply chain analytics. The analysis encompasses 96 documents drawn from 64 distinct sources, demonstrating a robust scholarly diversity while maintaining focused relevance. With an impressive annual growth rate of 25.35%, this field exhibits remarkable expansion, while the low document average age (2.44 years) confirms its contemporary relevance. The substantial citation impact (71.93 citations per document on average) indicates the influential nature of publications in this domain. The extensive reference base (8887 total references) demonstrates the thorough grounding of research within existing knowledge frameworks, while the rich keyword diversity (562 Keywords Plus and 375 Author’s Keywords) reflects the multifaceted nature of digital supply chain research. Collaboration patterns reveal a predominantly team-based approach, with 311 authors contributing to the literature corpus, relatively few single-authored documents [

8], and an average of 3.42 co-authors per publication. Notably, 42.71% of papers involve international co-authorships, highlighting the global collaborative nature of this research area. The document distribution by type (83 articles and 13 reviews) indicates a field primarily focused on original research while maintaining a sufficient synthesis through reviews, collectively forming a balanced foundation for our analytical framework.

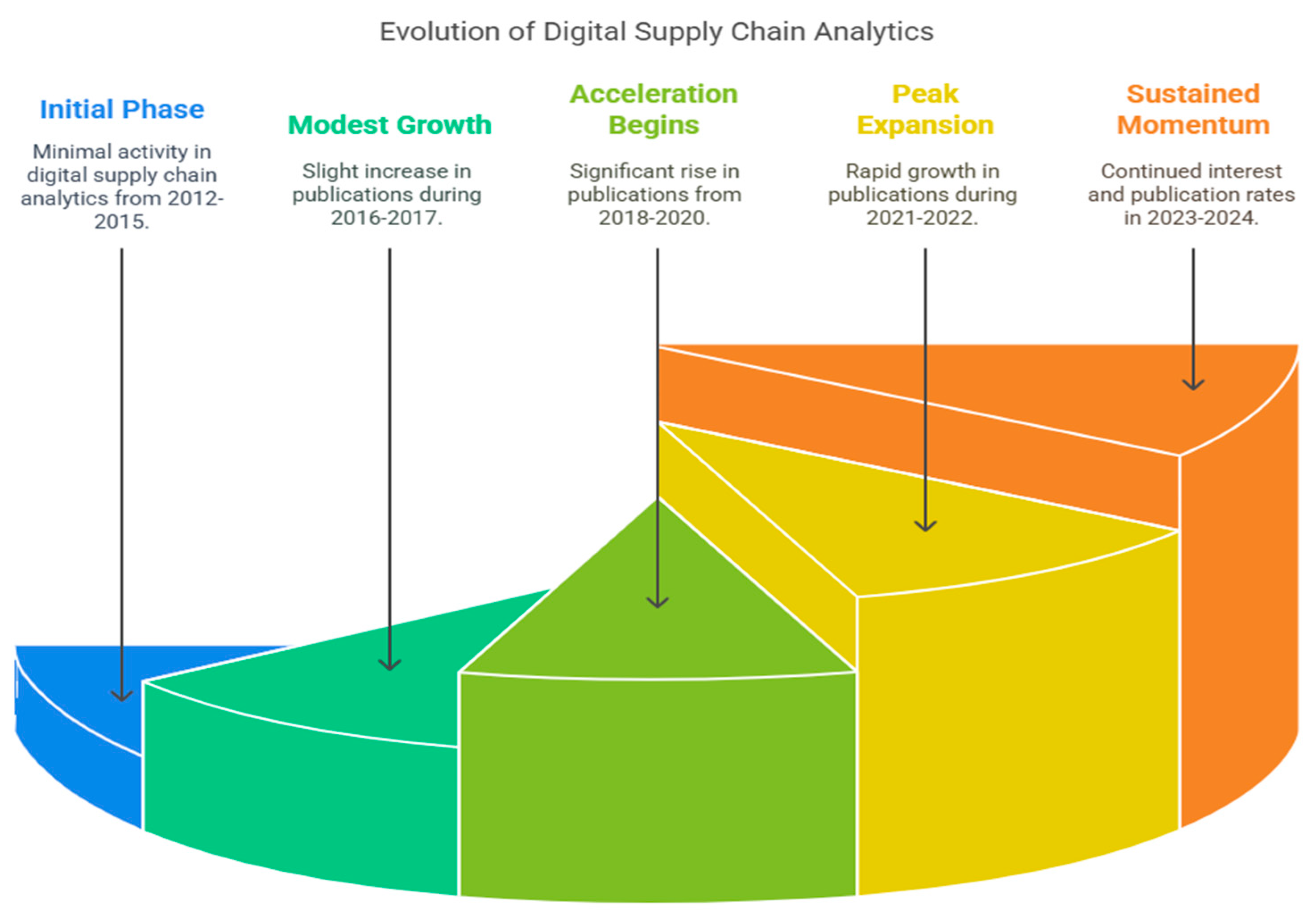

In addition,

Figure 2 illustrates the chronological distribution of publications on digital supply chain analytics from 2012 to 2024, revealing a clear pattern of an accelerating scholarly interest that reflects the field’s evolution from nascent concept to central research domain. The field’s emergence was marked by minimal activity during 2012–2015 (averaging one publication annually), followed by modest growth in 2016–2017 (two and three publications, respectively). Substantial acceleration began in 2018 (six articles) and continued through 2019–2020 (nine and ten articles, respectively), coinciding with an increased industry recognition of digital transformation imperatives. The most significant expansion occurred during 2021–2022, with publications nearly doubling from 18 to a peak of 32 articles, representing a 78% year-over-year increase that underscores the field’s theoretical maturation and practical relevance. While 2023 showed stabilization with 12 publications, 2024 data through July indicates a robust momentum with 15 publications representing a sustained high-level scholarly engagement. This temporal progression demonstrates the transformation of digital supply chain analytics from an emerging concept to an established research priority, directly correlating with the widespread industry adoption of digital technologies and reflecting the critical importance of data-driven approaches in enhancing supply chain resilience and organizational performance in an increasingly complex global business environment.

In addition, the citation analysis reveals notable patterns in the scholarly impact of the digital supply chain literature in

Table 2. While early publications (2012–2017) were few in number, they demonstrated a variable but often substantial citation impact, most notably the landmark 2014 publication that garnered an exceptional 788 citations. The period from 2018 to 2021 shows an increased publication volume coinciding with fluctuating citation rates—peaking dramatically in 2019 with an average of 271.33 citations per article across nine publications. More recent publications (2022–2024) show a predictable decline in citation metrics, reflecting their shorter time in the academic discourse rather than diminished quality or relevance. When normalized for time (Mean TC per Year), the 2014 and 2019 publications emerge as particularly influential in shaping the field. This citation pattern reflects both the maturing of digital supply chain analytics as a research domain and the presence of seminal works that have significantly influenced subsequent scholarship.

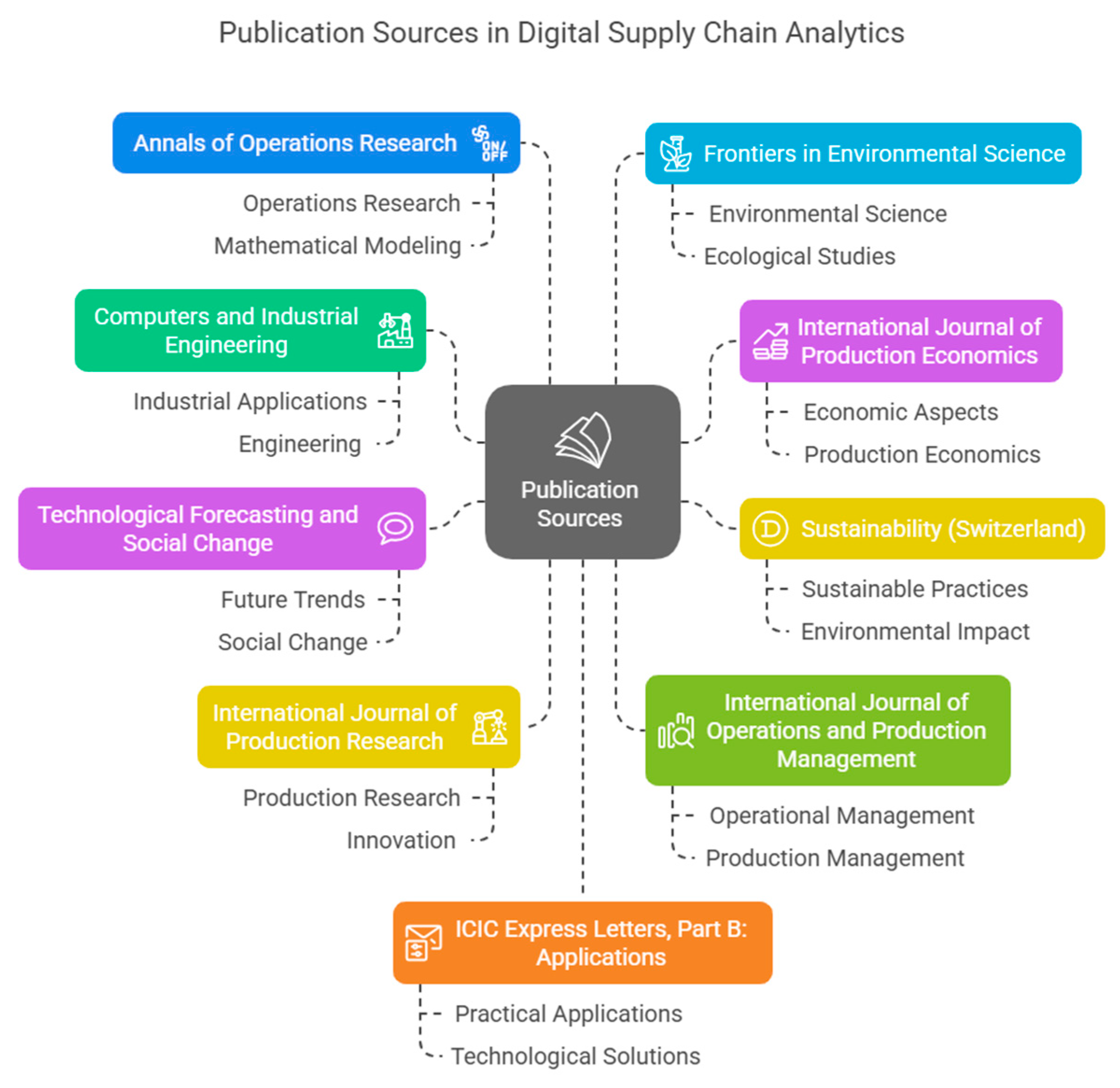

Figure 3 shows a breakdown of the distribution of the study’s papers, arranged according to the sources from which they came. The sources that have produced a sizable number of articles for the study are highlighted in the table. With seven publications, “Computers and Industrial Engineering” has the most articles out of the sources that were found. The “International Journal of Production Economics,” “Sustainability (Switzerland),” and “Technological Forecasting and Social Change,” each of which contributed five papers, came in second through fourth. Other noteworthy sources include “International Journal of Production Research” with four articles, “International Journal of Operations and Production Management” with three articles, “Annals of Operations Research,” “Frontiers in Environmental Science,” “ICIC Express Letters, Part B: Applications,” and “IEEE Access,” each with two articles. Several sites have also provided two papers apiece, including “International Journal of Logistics Management,” “Journal of Industrial Information Integration,” “Journal of Systems Science and Systems Engineering,” “Operations Management Research,” and “Processes.” This breakdown of articles by sources identifies the leading scholarly journals and publications in the area and highlights the sources that have actively added to the body of knowledge on the subject at hand.

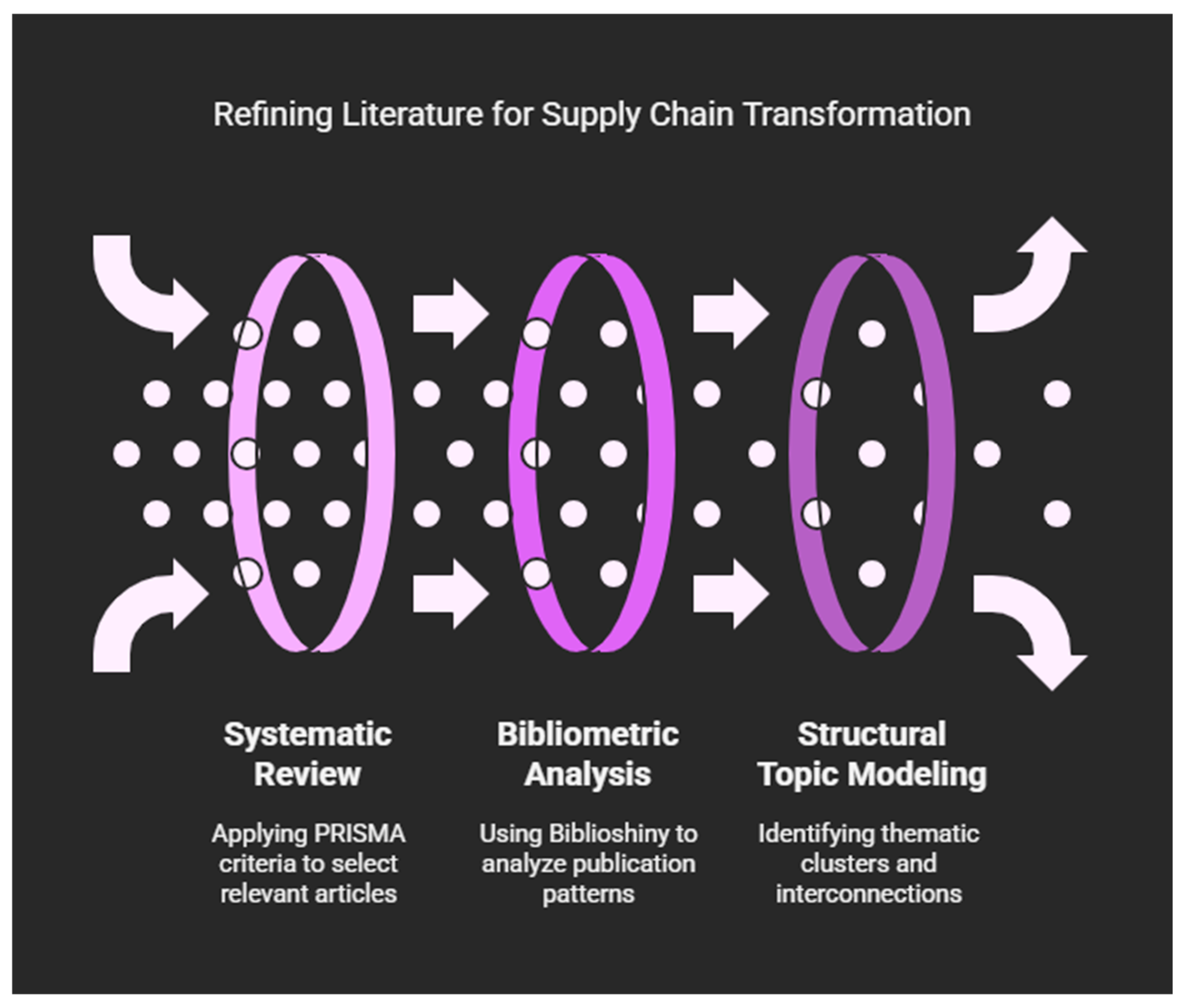

5. Multistage Data Analysis

This study employs a rigorous multistage analytical framework that aligns with the research objective of developing an integrated framework for digital supply chain transformation. The PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) methodology provides a structured approach for article selection, ensuring a systematic inclusion and exclusion criteria that minimize bias while capturing the most relevant literature spanning digital technologies and big data analytics in supply chain contexts. This systematic approach yielded 96 highly relevant publications from an initial pool of 290 candidates. Building on this foundation, the Biblioshiny package in RStudio (2025.05.0) enabled a comprehensive bibliometric analysis, generating quantitative insights into publication patterns, citation impacts, and collaboration networks that revealed the temporal evolution and intellectual structure of the field. This bibliometric foundation was then enriched through structural topic modeling (STM), which algorithmically identified latent thematic clusters and their interconnections across the literature corpus. This methodological triangulation—combining systematic review protocols, quantitative bibliometric analysis, and computational topic modeling—provided complementary perspectives that collectively strengthened the validity of our findings.

Figure 4 below illustrates the multistage data analysis process.

5.1. Bibliometric Analysis

The use of RStudio software in conjunction with the Biblioshiny technique is warranted for delivering a thorough and all-encompassing analysis of the present status of generative AI applications in the fields of hospitality and destination marketing. Biblioshiny, an R package (2025.05.0), is especially tailored for performing bibliometric and scientometric analysis), rendering it well-suited for investigating research trends and patterns in this domain. The bibliometric analysis of the top 10 journals publishing digital supply chain research reveals a landscape dominated by operations and production management outlets with varying impact profiles in

Table 3. The International Journal of Production Economics emerges as the most influential venue, achieving the highest h-index [

5] and an extraordinary 1743 citations across just five publications since 2019, demonstrating an exceptional citation density and scholarly impact. Similarly impressive is Technological Forecasting and Social Change, which, despite only entering the field in 2021, has rapidly accumulated citations with the highest m-index (1.33), indicating a substantial momentum and contemporary relevance. Production-focused journals collectively form the core knowledge base, with International Journal of Production Research showing strong citation performance (1090 citations from four articles) and Computers and Industrial Engineering demonstrating the highest publication volume (seven articles). The technological dimension is represented by IEEE Access, which, despite having only two publications, has garnered 795 citations since 2014. This journal distribution reflects the field’s interdisciplinary nature, bridging operations management and technological innovation, while also highlighting the concentrated influence of a small set of high-impact journals that are shaping theoretical and practical developments in digital supply chain management.

Themes Identification Analysis

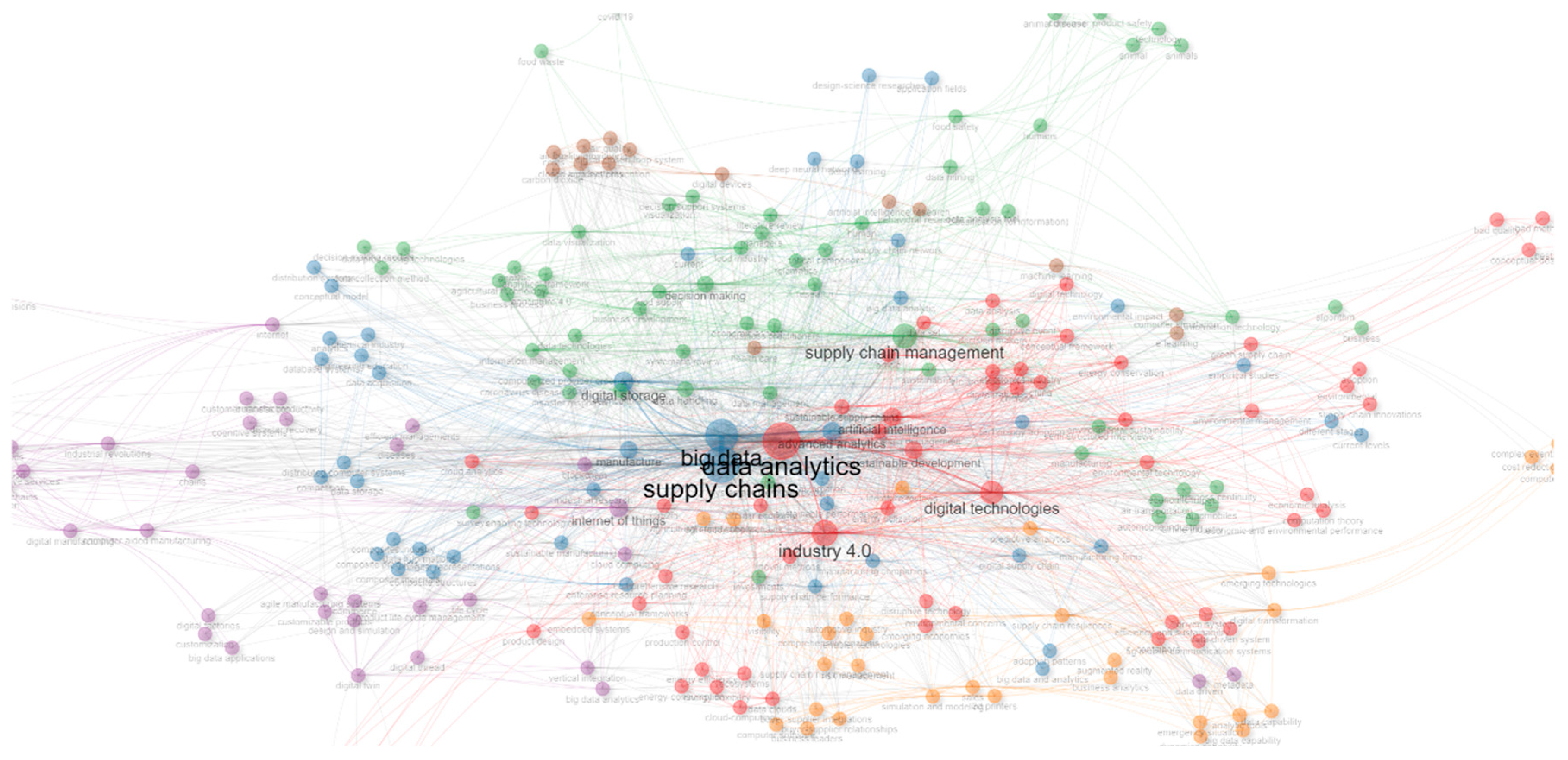

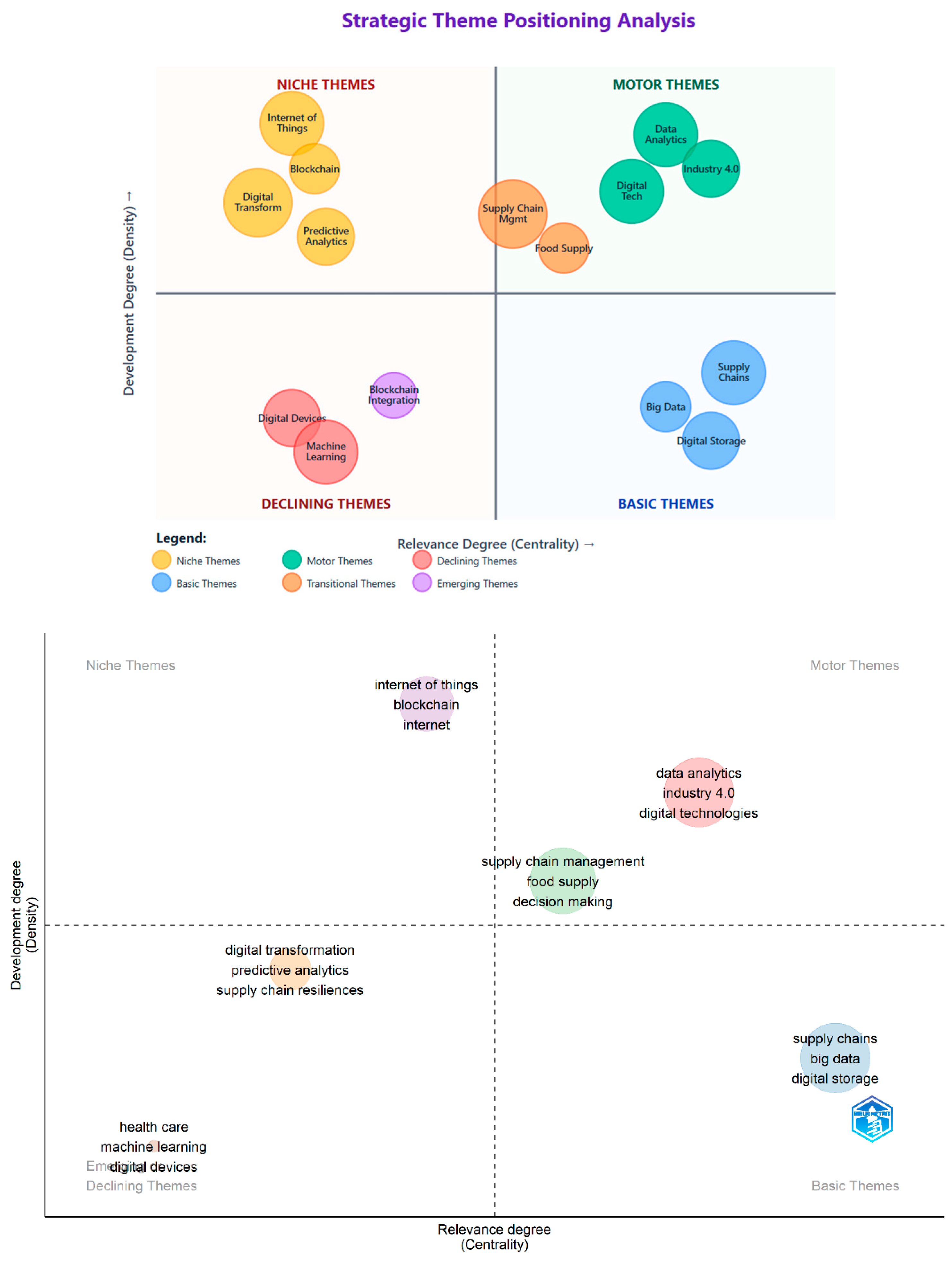

Thematic maps were made using the Author’s Keywords to analyze the progression and patterns in the literature. The thematic map derived from the Author’s Keywords is shown in

Figure 5. The Biblioshiny program’s text processing and mapping tool, which makes use of the R package, made it easier to generate themes. To guarantee the intelligibility of the maps and the delivery of insightful information, specific parameters were put into place. These parameters included a choice of 200 words, a minimum of five clusters per word, and the display of two labels per cluster, keeping all other variables at their default defaults.

A list of keywords may be thought of as a succinct summary of a particular study issue, and the metrics’ density and centrality can be applied to any research topic. While centrality quantifies the degree of connectivity with other themes, density gauges the degree of interconnectedness among all the keywords [

40]. A thematic map is split into four quadrants based on the density and prominence of the topics and is shown as a strategic diagram [

41]. According to sources [

40,

41], these quadrants each have unique properties.

Niche themes (upper-left quadrant; high density and low centrality): These are referred to as “highly developed and isolated themes” by others. Internally, the linkages between topics are strong, yet externally, they are weak. They are just tangentially related to the field.

Motor themes (upper-right quadrant; high density and centrality): This quadrant tackles well-developed themes that are critical to a study area’s structure.

Emerging or declining themes (lower-left quadrant; low density and low centrality): This quadrant displays peripheral and weakly developed motifs.

Fundamental motifs (lower-right quadrant; low density, high centrality): Despite their lack of development, the ideas in the lower-right quadrant are critical for a study subject. As a result, this quadrant focuses on “general, basic, and transversal” issues.

Six major topic clusters are present, as shown by the thematic map in

Figure 6: supply chains, data analytics, the Internet of Things, digital transformation, and supply chain management. The Internet of Things, blockchain, and Internet clusters are in the niche topics quadrant of the thematic map, indicating their sporadic significance to the larger field. There are two clusters within the motor themes quadrant which comprise well-developed and important study subjects, like supply chain management and data analytics. Three clusters, including the ones for supply chains and big data, highlight the fundamental topics. Machine learning and digital gadgets are the defining characteristics of the developing themes, whereas peer-to-peer networks seem to be on the decline. Environmental sustainability and data science can be found in the space between specialized and developing subject clusters.

Table 4 of thematic cluster analysis reveals three dominant intellectual territories in digital supply chain research, each with distinct structural characteristics. Supply chain management emerges as the foundational cluster with the highest centrality (14.95) and cluster frequency (245), indicating its role as the core knowledge domain connecting various research streams. This cluster functions as the conceptual anchor for digital supply chain research, bridging theoretical frameworks with practical applications across the literature corpus. Digital transformation occupies the intermediate position, balancing moderate centrality (9.50) with high density (101.05), suggesting a well-developed thematic area with substantial internal cohesion that connects core supply chain concepts with technological innovations. This cluster represents the transitional knowledge domain where traditional supply chain management intersects with emerging digital capabilities. Big data analytics, despite having the lowest centrality (4.97), demonstrates the highest density (113.22), characterizing it as a specialized research domain with strong internal connections but more limited bridges to other clusters.

In addition,

Table 5 presents the keyword analysis for the Supply Chain Management cluster, revealing the conceptual foundation of the digital supply chain literature. The core terminology is anchored by “supply chains management”, demonstrating the fundamental integration of traditional supply chain concepts with data-driven approaches. The high betweenness centrality values of these terms (3431.14 and 3696.61) indicate their critical bridging function within the knowledge domain. Supporting operational terminology includes “digital storage” (13 occurrences), “advanced analytics” [

10], and “manufacture” [

8], while implementation-focused terms like “supply chain performance” and “digital supply chain” appear with moderate frequency. The centrality metrics collectively reveal a mature conceptual ecosystem where technological terms (e.g., “data acquisition,” “enterprise resource planning”) interconnect with operational concerns (“sustainable manufacturing,” “environmental impact”). This keyword distribution demonstrates how supply chain management has evolved from traditional operational focus to a technology-enriched domain where data analytics capabilities are now considered fundamental rather than peripheral, confirming the conceptual foundation for our integrated digital supply chain framework.

Furthermore,

Table 6 presents the keyword analysis for the digital transformation cluster, revealing the technological enablers driving supply chain evolution. This cluster demonstrates a dual focus on both transformative technologies and their operational applications. The foundational technologies are anchored by the “Internet of Things” (eight occurrences, 1142.91 betweenness centrality) and “blockchain” (five occurrences), with “digital transformation” itself (five occurrences, 493.92 betweenness centrality) serving as the conceptual bridge between technology and implementation. The cluster reveals a rich technological ecosystem incorporating “cloud computing,” “digital twin,” and “computer-aided manufacturing,” while simultaneously emphasizing outcome-oriented concepts like “supply chain resilience” (four occurrences) and “predictive analytics” (four occurrences). The high betweenness centrality of key technologies indicates their role as intellectual bridges connecting various research streams. Particularly notable is the presence of both established technologies (e.g., “Internet”) and emerging applications (e.g., “3D printers,” “embedded systems”), demonstrating the cluster’s temporal breadth. The centrality metrics collectively illustrate how digital transformation represents the operational manifestation of technological innovation, connecting abstract technological capabilities with concrete business outcomes like “risk management,” “visibility,” and “simulation and modeling” in the supply chain context.

Moreover,

Table 7 presents the keyword analysis for the big data analytics cluster, revealing the analytical foundation driving digital supply chain innovation. This cluster is anchored by “data analytics” (33 occurrences) with an exceptional betweenness centrality (4267.51) that far exceeds other terms, positioning it as the primary bridge connecting various analytical concepts. The cluster demonstrates a clear technological progression from foundational “Industry 4.0” terminology (16 occurrences) through enabling “digital technologies” (12 occurrences) to specific implementations like “artificial intelligence” (7 occurrences). Notably, the cluster reveals a strong sustainability orientation with terms like “sustainable development” (nine occurrences), “environmental technology,” and “circular economy” appearing with significant frequency. The centrality metrics illustrate how big data analytics functions as both a technological capability and a strategic enabler, with high closeness centrality values indicating dense interconnections between technical concepts and business applications. The co-occurrence of analytical terms with sustainability concepts (e.g., “green supply chain,” “environmental sustainability”) demonstrates how data analytics increasingly supports environmental objectives in supply chain operations.

5.2. Structural Topic Model (STM) Analysis

A Structural Topic Model (STM) approach was selected for this research due to its advanced capabilities in uncovering latent thematic structures while accounting for document-level metadata, which is particularly crucial for analyzing the evolution of robotics research [

42]. The STM extends traditional topic modeling by incorporating document-level covariates, enabling the examination of how research themes vary across different journals and time periods [

43].

First, the document-topic attention distribution is modeled using a logistic normal distribution:

where

$X_d

$ represents document covariates,

$\Gamma

$ captures coefficient relationships, and

$\Sigma

$ is the covariance matrix.

Second, the topic-word distributions are formed by combining multiple components:

where

$m

$ represents the baseline word distribution,

$\kappa^{(t)} _k

$ captures topic-specific deviations,

$\kappa^{(c)}_{y_d}

$ represents covariate effects, and

$\kappa^{(i)}_{y_d,k}

$ models interactions.

Third, the topic assignment for each word follows a multinomial distribution:

Finally, the observed words are generated conditionally on their topics:

This mathematical framework enables STM to effectively model relationships between document metadata and topical content while maintaining computational tractability through variational inference methods [

44]. The model’s ability to incorporate document-level covariates makes it particularly suitable for analyzing how military–economic relationships vary across different contexts in our study.

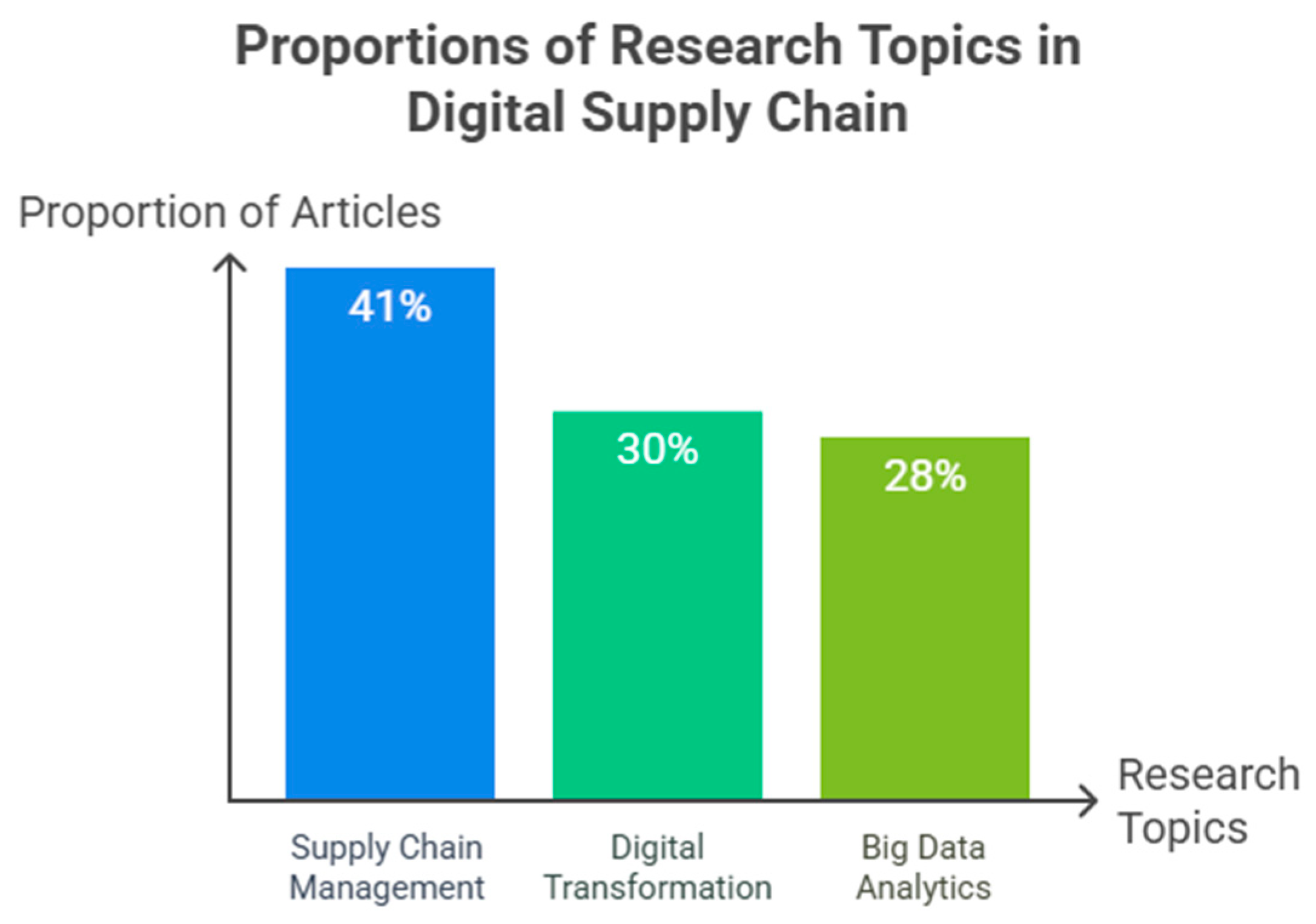

Figure 7 illustrates the proportions of research topics within the digital supply chain domain, highlighting three key areas. Supply chain management dominates the research landscape, accounting for 41% of the published articles, reflecting its central role in optimizing operations and logistics. Digital transformation follows at 30%, underscoring the growing emphasis on integrating digital technologies to enhance supply chain efficiency and agility. Big data analytics represents 28% of the research, indicating its significance in leveraging data-driven insights for decision-making and predictive analysis. Together, these topics showcase the evolving focus of the digital supply chain field, where traditional management practices intersect with cutting-edge technological advancements.

In addition to that,

Figure 8 illustrates the longitudinal evolution of three critical business topics from 2012 to 2024, aligning with our study objective to track shifting organizational priorities in response to technological and environmental changes. Supply chain management demonstrates a consistent upward trajectory (from −0.2 to 0.7), reflecting its transformation from an operational concern to a strategic imperative, with a notable acceleration following the 2020 pandemic that exposed vulnerabilities in global supply networks. Digital transformation exhibits a more cyclical pattern, peaking around 2014–2015 (0.6), declining through 2022 (0.3), then experiencing a renewal in 2023–2024 (0.38) with the emergence of generative AI technologies. Big data analytics shows the most dramatic change, beginning with a high prevalence (0.9) during the initial hype phase, then steadily declining to 0.15 by 2024 as these practices became normalized within standard business operations. These complementary trends demonstrate the maturation of business technology discourse over the twelve-year study period, with organizations evolving from a singular technological focus toward a more balanced appreciation of both digital capabilities and physical supply chain resilience—a key finding that addresses our research question regarding the integration of technological trends into holistic business strategies.

In addition,

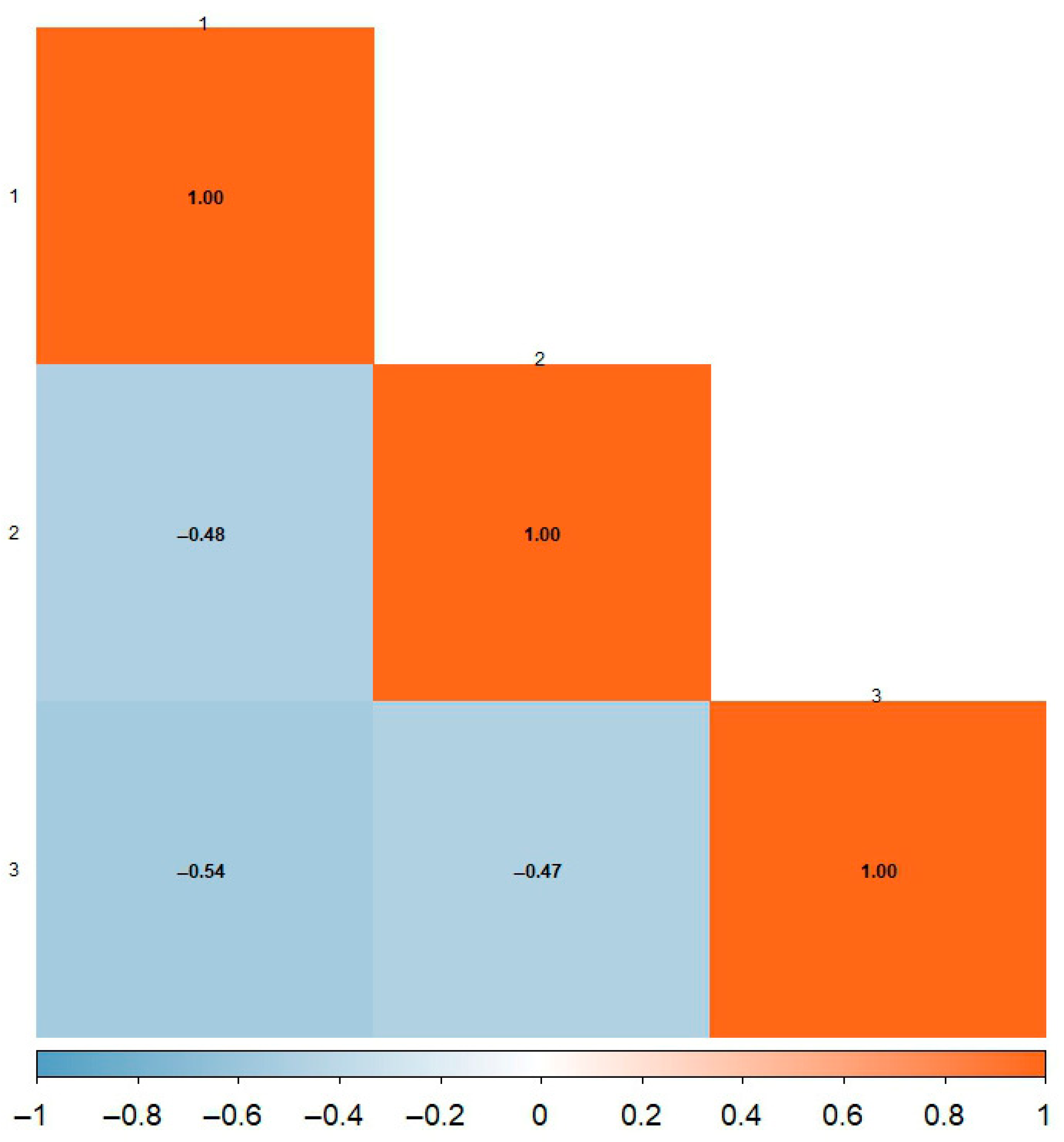

Figure 9 of the correlation matrix reveals important relationships between the three business themes under study. Each theme shows a perfect positive correlation with itself (diagonal values of 1.00), as expected in any correlation matrix. The off-diagonal elements indicate moderate to strong negative correlations between the themes. Specifically, Theme 1 and Theme 2 show a substantial negative correlation of −0.48, suggesting that as one theme gains prevalence, the other tends to decrease. Similarly, Theme 1 and Theme 3 demonstrate substantial negative correlations between clusters, indicating a more pronounced inverse relationship. Theme 2 and Theme 3 also exhibit a negative correlation of −0.47, slightly weaker than the other relationships but still significant. These negative correlations support our previous analysis that as supply chain management gained prominence (especially post-2020), both digital transformation and big data analytics experienced a declining prevalence. This pattern suggests that organizations may allocate limited attention and resources among these competing priorities, resulting in a trade-off effect where focus on one area potentially comes at the expense of others. Alternatively, it could indicate that these themes represent distinct phases in business evolution, with organizations shifting emphasis from data-driven approaches toward physical supply networks as their digital maturity increases, aligning with our study’s objective to understand how organizational priorities shift over time.

6. Classification of Thematic Clusters

Classification of the literature is identified in three major research streams in previous studies, and here we explore the outcomes of research with settings and segments.

6.1. Supply Chain Management

Supply chain management has been substantially affected by the idea of digital transformation, allowing businesses to make use of cutting-edge technology for increased operational effectiveness and better performance. The effects of digital transformation in various contexts and supply chain management sectors have been the subject of several studies. Moghrabi et al. [

45] concentrated on how companies and digital transformations interact. Their research strives to comprehend the dynamics and effects of a company’s digital transformation, especially in the context of algorithm-based methods. In addition, the applicability of enablers for the supply chain’s digital transformation was examined [

46]. They looked at a sequential methodology for implementing key enablers to propel the supply chain’s digital transformation. Additionally, a road mapping taxonomy for digital technologies to alter the supply chain sustainability plan was put up by [

47]. They highlighted the change from a performance-oriented strategy to one that prioritizes sustainable supply chain practices.

However, the pharmaceutical industry’s circular supply networks were discussed in [

48]. They recognized and organized Industry 4.0 Disruptive Technologies (IDTs) and evaluated their effects on circular supply chains for pharmaceuticals. Also, Adel et al. [

49] looked at sectors making the transition from Industry 4.0 to Industry 5.0 and investigated the use of cutting-edge technology in the supply chain and healthcare industries. Big data analytics, the Internet of Things (IoT), collaborative robots, blockchain, digital twins, and forthcoming 6G networks were among the cutting-edge technologies that the report recognized as being essential. The research collaboration patterns and clusters at the intersection of Industry 4.0, circular economy, supply chain management, and quantitative approaches were found [

50,

51]. Their research is intended to comprehend the partnerships and patterns of digital transformation in supply networks with digital capabilities.

On the other hand, Men et al. [

52] examined how Pakistan’s textile industry’s operational effectiveness was impacted by supply chain digitization. They looked at how digital supply chain technologies are being used and how they affect operational effectiveness, including blockchain, the Internet of Things (IoT), and big data analytics. The application of digital technology in green supply chain innovation was examined by [

53]. They underlined the possibility of fostering innovation in green supply chain practices inside manufacturing businesses by looking at the acceptance and application of digital technology. In addition, Latino et al. [

54] concentrated on the idea of the digital twin in the process of the supply chain. The seamless connectivity, real-time capabilities, reliability, quality of service, visibility, and supply chain management efficiency were noted as some of the benefits of the supply chain digital twin model that were emphasized.

Furthermore, the application of digital technology to enable traceability across the supply chain [

55] evaluated a firm that produces organic olive oil. Their architecture made it possible to map supply chain processes, analyze traceability data using digital technologies, and give customers thorough food information. In the context of Saudi Arabia, Hamed et al. [

56] offered insights on the benefits of big data analytics (BDA) in supply chain management (SCM). In their study, they looked specifically at how environmental variables affected the adoption of BDA and its connection to supply chain efficiency in medium-sized supply chain enterprises. Blockchain, business analytics, and mobile-based apps were investigated [

57,

58]) for usage in agricultural and food supply chains. They emphasized how these particular digital tools have helped Sub-Saharan Africa’s food supply networks adopt sustainable practices. Investigating the impact of Industry 4.0 technology on supply chain effectiveness [

59], they discovered that big data analytics, cloud computing, simulation, and modeling-based collaborative supply chain models have a direct impact.

Table 8 below illustrates the details of authors, settings, segments, and outcomes of the digital supply chain management process.

6.2. Digital Transformation in Supply Chain Management

The management of the supply chain through digital transformation is a subject that receives more attention in the current study. Studies have looked at the implications of digital technologies and how they affect many facets of supply chain management. The emergence of health-related issues, the circular economy, sustainable supply chains, consumer adoption of AI, and the use of AI in decision-making were highlighted in an examination of the conceptual structure and evolution of AI research by [

60]. In a similar study, Vasluianu [

61], who focused on sustainable supply chain management, discovered that the application of Industry 4.0 technologies can improve SSCM’s capacity to make precise judgements and encourage circular growth. In addition, Glaros et al. [

62] highlighted the revolutionary implications of agricultural e-commerce technologies on small- and medium-scale farmers, buyers, and market vendors in the context of the local food industry. The use of artificial intelligence (AI) in planning was examined by [

63], who also noted the current ambiguous environment—which is akin to the early phases of computer adoption—and its possible long-term consequences on planning procedures. On the other hand, the possible impacts of Industry 4.0 digital technologies, such as drones, big data analytics, and IoT, on Vietnamese supply chains were examined [

64], with an emphasis on sustainability. Fourteen digital technologies, including big data analytics and predictive health data analysis, that improve the resilience of these supply chains were discovered [

65] after studying the healthcare supply networks.

However, the environmental sustainability features of sustainable supply chain collaborations were examined [

66]. Although SCC uses digital and Industry 4.0 technologies, their application for sustainability is still in its early phase. According to Mohapatra et al. [

67], who investigated the usage of AI, BDA, and IoT in the manufacturing business, these technologies have the potential to provide just-in-time (JIT) procedures, product diversification, centralized decision-making, efficient supply chains, and revenue generation. In their study on supply chain process management, [

68] focused on the significance of digital transformation in the circular economy and Industry 4.0 technologies, as well as sustainable supply chain management. The potential of certain digital technologies, such as blockchain, big data analytics, and the Internet of Things, to improve competitive advantages, business performance, and sustainable supply chain management was underlined [

69].

Additionally, “Agriculture 4.0” and its effects on supply networks were explored [

70]. To fully appreciate the advantages of the Agriculture 4.0 revolution, which makes use of technologies like the Internet of Things, the Internet of farming, big data analytics, and blockchain, they emphasized the necessity of teaching and training supply chain players, in particular, farmers [

71]. The application of big data analytics (BDA) to handle problems with enormous volumes, high speeds, and a high variety of data in supply chain responsiveness was emphasized [

72] in the context of big data difficulties. The last study, Moghrabi et al. [

45], concentrated on the connection between companies and digital transformations, highlighting the importance of this relationship for organizations.

Overall, these studies show the varied uses and effects of digital transformation in supply chain management, from artificial intelligence (AI) and big data analytics to Industry 4.0 technologies, sustainability, and the circular economy, as well as the transformational effects on various industries like manufacturing, healthcare, and agriculture.

Table 9 below shows the details of authors, settings, segments, and outcomes of the studies.

6.3. Big Data Analytics Impact on Supply Chain Management

Big data analytics (BDA) effects on supply chain management have received a lot of attention lately. The ramifications of BDA in various contexts and supply chain management segments have been examined in several studies. According to AL-Shboul [

73], the role of big data and Information and Communication Technology (ICT) in improving supply chain management is strategic planning. In addition, Alsmairat [

74] looked into how the performance of digital supply chains (DSCs) was affected by supply chain innovation (SCI), big data analytics capabilities (BDACs), and customer relationships (CRs). According to the study, SCI, BDACs, and CRs have positive effects on DSC performance both directly and via the mediating effect of supply chain resilience (SCR). Also, for Tamym et al. [

75], networked enterprises (NEs) and the creation of a Big Data Analytics-Based Approach for Sustainable NEs were their main subjects. They looked at the use of big data analytics to address sustainability issues and boost networked business performance. The use of big data analytics capabilities (BDACs) was specifically examined [

76] in their study of supply chain disruptions and the usage of digital technologies for survival and competitive advantage. The study emphasized the benefits that digital technologies, especially BDA, have given the MSME sector. In addition, Papanagnou et al. [

77] investigated how predictive analytics techniques and big data capabilities promote supply chain resilience in the UK grocery retail industry. In the study, it was determined how well BD capabilities, predictive analytics techniques, and supply chain resilience would match in emergency situations [

78].

On the other hand, Margaritis et al. [

79] investigated the use of big data in the manufacturing, processing, distribution, and retail stages of food supply chain management (FSCM). The work provided a possible research agenda for further study in this area and enhanced the understanding of the role of BD in FSCM. Nagy & Foltin [

80] concentrated on supply chain disruptions and the pertinent hazards posing a danger to supply chains. They offered a strategy for using big data analytics to spot potential disturbances and reduce them, enhancing supply networks’ operational sustainability and resilience. However, in a manufacturing business undergoing a digital transformation, ref. [

81] looked at the development of a digital supply chain. The research placed a particular emphasis on the use of big data analytics for supply chain education and the creation of a systematic strategy for adopting a digital supply chain in the procurement function [

82].

In manufacturing companies, Edwin Cheng et al. [

26] investigated the connection between the circular economy (CE) practices, sustainable supply chain (SSC) adaptability, SSC performance, and big data analytics capabilities. While BDA capabilities do not directly affect the sustainable performance, they can indirectly affect the SSC performance using CE practices and SSC adaptability. In addition, ref. [

83] looked at how artificial intelligence (AI) and big data analytics may be used in the logistics, supply chain, marketing, and manufacturing sectors of the food business. The study emphasized the advantages of real-time optimization in the food industry, which is made feasible by the union of AI and big data analytics. In conclusion, these studies provide light on how big data analytics affects supply chain management in many industries and situations, demonstrating its potential to improve performance, resilience, sustainability, and supply chain decision-making capacities.

Table 10 shows the details of authors, settings, segments, and research outcomes from the big data analytics process in supply chain management.

7. Conclusions

This study set out to investigate the integration of big data analytics with digital technologies for optimizing supply chain management operations. Our three primary objectives were as follows: (1) To identify critical technological enablers and organizational capabilities facilitating digital supply chain transformation; (2) to examine interrelationships between big data analytics capabilities, digital technologies implementation, and supply chain performance outcomes; and (3) to construct a comprehensive framework guiding organizations in their digital transformation journey.

Our findings reveal three distinct yet interconnected research clusters that have evolved in different patterns from 2012 to 2024. Supply chain management emerged as the foundational domain with the highest centrality (14.95), serving as the conceptual anchor connecting various research streams. Digital transformation occupied an intermediate position with moderate centrality (9.50) and high density (101.05), representing the intersection between traditional practices and emerging technologies. Big data analytics demonstrated the highest density (113.22) despite its lower centrality (4.97), characterizing it as a specialized domain with strong internal cohesion. Notably, we identified negative correlations between these themes (−0.48 to −0.54), suggesting organizations shift emphasis from standalone technological initiatives toward integrated approaches as they mature in their digital transformation journey.

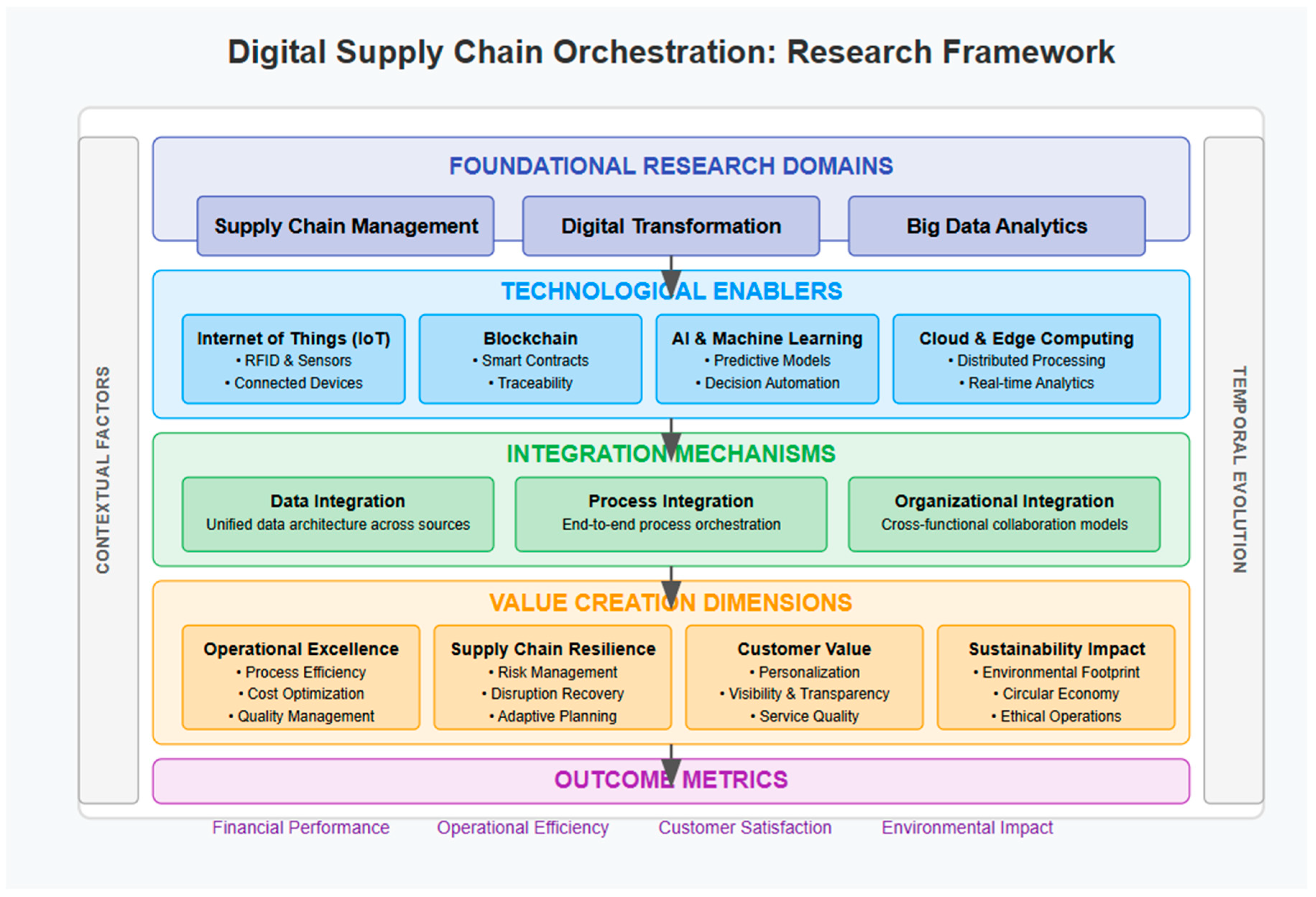

From these findings, we have developed the Digital Supply Chain Orchestration Framework, which makes several significant theoretical contributions to the field. This framework transcends the siloed approach prevalent in the current literature by conceptualizing the digital supply chain transformation as an integrated, multi-layered phenomenon rather than discrete technological implementations. By articulating clear hierarchical relationships between foundational domains, technological enablers, integration mechanisms, and value creation dimensions, our framework provides researchers with a comprehensive theoretical lens to examine complex supply chain transformations. The identification of specific integration mechanisms as a critical mediating layer between technologies and value creation addresses a significant gap in existing theory regarding how organizations translate technological investments into tangible performance outcomes. Our framework’s incorporation of both operational and sustainability dimensions reflects the evolving nature of supply chain objectives beyond traditional efficiency metrics, introducing a more nuanced understanding of value creation that aligns with contemporary stakeholder expectations.

Figure 10 below illustrates the integrated framework contributed by the study.

The practical implications of our findings align with several Sustainable Development Goals, particularly SDG 9 (Industry, Innovation, and Infrastructure) and SDG 12 (Responsible Consumption and Production). The integrated framework provides organizations with a structured approach to assess digital maturity, identify technological gaps, and develop implementation roadmaps that enhance efficiency while reducing resource consumption. Furthermore, our findings on supply chain resilience support SDG 8 (Decent Work and Economic Growth) by helping organizations maintain operations during disruptions, thereby protecting employment and economic stability. Our Digital Supply Chain Orchestration Framework delivers targeted value across the transformation ecosystem. Organizational leaders gain a strategic assessment tool for evaluating digital maturity, identifying technological gaps, and developing evidence-based implementation roadmaps that optimize resource allocation and risk management.

Limitations and Future Agenda

This study acknowledges several methodological limitations. The bibliometric approach inherently privileges established publications, potentially underrepresenting emerging research areas and recent technological developments. While our systematic review encompassed 96 publications across diverse contexts, it cannot capture the complete spectrum of relevant research, particularly cutting-edge applications and industry innovations. Additionally, our structural topic modeling reveals correlational patterns between research clusters but cannot establish causal mechanisms underlying the observed negative relationships (−0.48 to −0.54), limiting explanatory power regarding organizational transformation pathways.

Future research should pursue multiple complementary directions to advance digital supply chain understanding. Empirical validation through longitudinal case studies examining organizations at different digital maturity stages would test our framework’s practical applicability and refinement needs. Technology integration studies exploring emerging technologies—particularly generative AI, digital twins, and advanced blockchain applications—with existing supply chain capabilities would illuminate next-generation transformation possibilities. Interdisciplinary collaboration incorporating insights from organizational behavior, data science, and sustainability studies would better address the socio-technical dynamics of digital transformation. Mechanism-focused research should examine specific integration mechanisms mediating between technological implementations and value creation, particularly investigating how orchestration capabilities develop and evolve. Cross-cultural studies exploring framework applicability across different economic, regulatory, and cultural contexts would enhance global generalizability. Finally, performance measurement research developing comprehensive metrics for evaluating orchestration effectiveness would support evidence-based digital transformation strategies.

Author Contributions

Conceptualization, N.K. and M.I.Q.; methodology design and PRISMA implementation, N.K., M.K. and S.J.; systematic literature search and database screening, S.J., M.K. and N.K.; data extraction and quality assessment, N.K., S.J. and M.F.; bibliometric and statistical analysis using R Studio, N.K. and M.K.; digital supply chain orchestration framework development, N.K., M.I.Q. and S.H.B.; original draft preparation, N.K.; critical review, editing, and intellectual content contribution, S.H.B., M.I.Q., M.F. and M.K.; data visualization and figure preparation, N.K. and M.F.; methodology validation and theoretical framework refinement, S.H.B. and M.I.Q.; research supervision and strategic guidance, S.H.B. and M.I.Q.; project coordination and administration, S.H.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article and

Supplementary Material. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Farivar, S.; Golmohammadi, A.; Ramirez, A. Analytics Capability and Firm Performance in Supply Chain Organizations: The Role of Employees’ Analytics Skills. Analytics 2022, 1, 1–14. [Google Scholar] [CrossRef]

- Agrawal, T.K.; Kumar, V.; Pal, R.; Wang, L.; Chen, Y. Blockchain-based framework for supply chain traceability: A case example of textile and clothing industry. Comput. Ind Eng. 2021, 154, 107130. [Google Scholar] [CrossRef]

- Attaran, M. Digital technology enablers and their implications for supply chain management. Supply Chain. Forum Int. J. 2020, 21, 158–172. [Google Scholar] [CrossRef]

- Notteboom, T.; van der Lugt, L.; van Saase, N.; Sel, S.; Neyens, K. The Role of Seaports in Green Supply Chain Management: Initiatives, Attitudes, and Perspectives in Rotterdam, Antwerp, North Sea Port, and Zeebrugge. Sustainability 2020, 12, 1688. [Google Scholar] [CrossRef]

- Sheng, J.; Amankwah-Amoah, J.; Khan, Z.; Wang, X. COVID-19 Pandemic in the New Era of Big Data Analytics: Methodological Innovations and Future Research Directions. Br. J. Manag. 2021, 32, 1164–1183. [Google Scholar] [CrossRef]

- Nweje, U.; Taiwo, M. Leveraging Artificial Intelligence for predictive supply chain management, focus on how AI-driven tools are revolutionizing demand forecasting and inventory optimization. Int. J. Sci. Res. Arch. 2025, 14, 230–250. [Google Scholar] [CrossRef]

- Abbasi, A.; Zahedi, F.M.; Zeng, D.; Chen, Y.; Chen, H.; Nunamaker, J.F. Enhancing Predictive Analytics for Anti-Phishing by Exploiting Website Genre Information. J. Manag. Inf. Syst. 2015, 31, 109–157. [Google Scholar] [CrossRef]

- Shah, N.U.; Naeem, S.B.; Bhatti, R.; Khan, A.; Wang, X. Impact of big data and data analytics on the provision of data services in academic libraries. Electron. Libr. 2024, 42, 1039–1054. [Google Scholar] [CrossRef]

- Ageron, B.; Bentahar, O.; Gunasekaran, A. Digital supply chain: Challenges and future directions. Supply Chain. Forum Int. J. 2020, 21, 133–138. [Google Scholar] [CrossRef]

- Tay, H.L.; Loh, H.S. Digital transformations and supply chain management: A Lean Six Sigma perspective. J. Asia Bus. Stud. 2022, 16, 340–353. [Google Scholar] [CrossRef]

- Barbosa, M.W.; de la Calle Vicente, A.; Ladeira, M.B.; de Oliveira, M.P.V. Managing supply chain resources with Big Data Analytics: A systematic review. Int. J. Logist. Res. Appl. 2017, 21, 177–200. [Google Scholar] [CrossRef]

- Khan, N.; Falahat, M.; Ullah, I.; Sikandar, H.; Van, N.T. Integrating halal tourism with sustainable development goals through Islamic values environmental responsibility and technological innovation. Discov. Sustain. 2025, 6, 648. [Google Scholar] [CrossRef]

- Deichmann, U.; Goyal, A.; Mishra, D. Will digital technologies transform agriculture in developing countries? Agric. Econ. 2016, 47, 21–33. [Google Scholar] [CrossRef]

- Mohsen, B.M. Developments of Digital Technologies Related to Supply Chain Management. Procedia Comput. Sci. 2023, 220, 788–795. [Google Scholar] [CrossRef]

- Chehbi-Gamoura, S.; Derrouiche, R.; Damand, D.; Barth, M. Insights from big Data Analytics in supply chain management: An all-inclusive literature review using the SCOR model. Prod. Plan. Control. 2019, 31, 355–382. [Google Scholar] [CrossRef]

- Goh, Y.M.; Micheler, S.; Sanchez-Salas, A.; Case, K.; Bumblauskas, D.; Monfared, R. A variability taxonomy to support automation decision-making for manufacturing processes. Prod. Plan. Control. 2020, 31, 383–399. [Google Scholar] [CrossRef]

- Gunasekara, L.; Robb, D.J.; Zhang, A. Used product acquisition, sorting and disposition for circular supply chains: Literature review and research directions. Int. J. Prod. Econ. 2023, 260, 108844. [Google Scholar] [CrossRef]

- Zurayk, R. Pandemic and Food Security: A View from the Global South. J. Agric. Food Syst. Community Dev. 2020, 9, 17–21. [Google Scholar] [CrossRef]

- Tan, K.H.; Zhan, Y.Z.; Ji, G.; Ye, F.; Chang, C. Harvesting big data to enhance supply chain innovation capabilities: An analytic infrastructure based on deduction graph. Int. J. Prod. Econ. 2015, 165, 223–233. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, G.; Sun, B. A comprehensive literature review of the demand forecasting methods of emergency resources from the perspective of artificial intelligence. Nat. Hazards 2019, 97, 65–82. [Google Scholar] [CrossRef]

- Jamnick, N.A.; Pettitt, R.W.; Granata, C.; Pyne, D.B.; Bishop, D.J. An Examination and Critique of Current Methods to Determine Exercise Intensity. Sports Med. 2020, 50, 1729–1756. [Google Scholar] [CrossRef]

- Bonafiglia, J.T.; Preobrazenski, N.; Islam, H.; Walsh, J.J.; Ross, R.; Johannsen, N.M.; Martin, C.K.; Church, T.S.; Slentz, C.A.; Ross, L.M.; et al. Exploring Differences in Cardiorespiratory Fitness Response Rates Across Varying Doses of Exercise Training: A Retrospective Analysis of Eight Randomized Controlled Trials. Sports Med. 2021, 51, 1785–1797. [Google Scholar] [CrossRef]

- McCarthy, S.F.; Leung, J.M.P.; Hazell, T.J. Is a verification phase needed to determine V˙ O2max across fitness levels? Eur. J. Appl. Physiol. 2021, 121, 861–870. [Google Scholar] [CrossRef]

- Pauwels, K.; Aksehirli, Z. Big data analytics democratized with clean collaboration and customer privacy choice. J. Bus. Res. 2025, 188, 115112. [Google Scholar] [CrossRef]

- AlNuaimi, B.K.; Khan, M.; Ajmal, M.M. The role of big data analytics capabilities in greening e-procurement: A higher order PLS-SEM analysis. Technol Forecast. Soc. Change 2021, 169, 120808. [Google Scholar] [CrossRef]

- Edwin Cheng, T.C.; Kamble, S.S.; Belhadi, A.; Ndubisi, N.O.; Lai, K.; Kharat, M.G. Linkages between big data analytics, circular economy, sustainable supply chain flexibility, and sustainable performance in manufacturing firms. Int. J. Prod. Res. 2021, 60, 6908–6922. [Google Scholar] [CrossRef]

- Mithas, S.; Chen, Z.L.; Saldanha, T.J.V.; De Oliveira Silveira, A. How will artificial intelligence and Industry 4.0 emerging technologies transform operations management? Prod. Oper. Manag. 2022, 31, 4475–4487. [Google Scholar] [CrossRef]

- Mithas, S.; Chen, Y.; Lin, Y.; De Oliveira Silveira, A. On the causality and plausibility of treatment effects in operations management research. Prod. Oper. Manag. 2022, 31, 4558–4571. [Google Scholar] [CrossRef]

- Pessot, E.; Zangiacomi, A.; Fornasiero, R. Unboxing the hyper-connected supply chain: A case study in the furniture industry. Prod. Plan. Control. 2022, 35, 580–598. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Saldanha, T.; Mithas, S.; Khuntia, J.; Whitaker, J.; Melville, N. How Green Information Technology Standards and Strategies Influence Performance: Role of Environment, Cost and Dual Focus. MIS Q. 2022, 46, 2367–2386. [Google Scholar] [CrossRef]

- Bigliardi, B.; Filippelli, S.; Petroni, A.; Tagliente, L. The digitalization of supply chain: A review. Procedia Comput. Sci. 2022, 200, 1806–1815. [Google Scholar] [CrossRef]

- da Costa, T.P.; Gillespie, J.; Cama-Moncunill, X.; Ward, S.; Condell, J.; Ramanathan, R.; Murphy, F. A Systematic Review of Real-Time Monitoring Technologies and Its Potential Application to Reduce Food Loss and Waste: Key Elements of Food Supply Chains and IoT Technologies. Sustainability 2023, 15, 614. [Google Scholar] [CrossRef]

- Ivanov, D. Digital Supply Chain Management and Technology to Enhance Resilience by Building and Using End-to-End Visibility During the COVID-19 Pandemic. IEEE Trans. Eng. Manag. 2021, 71, 10485–10495. [Google Scholar] [CrossRef]

- Sakas, D.P.; Giannakopoulos, N.T.; Terzi, M.C.; Kanellos, N.; Liontakis, A. Digital Transformation Management of Supply Chain Firms Based on Big Data from DeFi Social Media Profiles. Electronics 2023, 12, 4219. [Google Scholar] [CrossRef]

- Mamun, M.M. Circular Economy and Digital Supply Chain: The Role of Emerging Technologies for Facilitating Sustainability. 2025. Available online: https://osuva.uwasa.fi/handle/10024/19511 (accessed on 22 July 2025).

- Dey, R.K. The Role of Intelligent Supply Chain Management in Optimizing Financial Operations and Risk Control in Logistics Firms. 2025. Available online: http://www.theseus.fi/handle/10024/887500 (accessed on 22 July 2025).

- Mustapha, I.; Khan, N.; Qureshi, M.I. Is Technology Affecting the Way Our Minds Operate? Digital Psychology of Users in the Era of Digitalization. Adv. Struct. Mater. 2022, 174, 71–92. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Prisma Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, 336–341. [Google Scholar] [CrossRef]

- Cahlik, T. Search for fundamental articles in economics. Scientometrics 2000, 49, 389–402. [Google Scholar] [CrossRef]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. An approach for detecting, quantifying, and visualizing the evolution of a research field: A practical application to the Fuzzy Sets Theory field. J. Informetr. 2011, 5, 146–166. [Google Scholar] [CrossRef]

- Tamakloe, R.; Park, D. Discovering latent topics and trends in autonomous vehicle-related research: A structural topic modelling approach. Transp. Policy 2023, 139, 1–20. [Google Scholar] [CrossRef]

- Sharma, A.; Rana, N.P.; Nunkoo, R. Fifty years of information management research: A conceptual structure analysis using structural topic modeling. Int. J. Inf. Manag. 2021, 58, 102316. [Google Scholar] [CrossRef]

- Roberts, M.E.; Stewart, B.M.; Tingley, D. Stm: An R Package for Structural Topic Models. J. Stat. Softw. 2019, 91, 1–40. [Google Scholar] [CrossRef]

- Moghrabi, I.A.R.; Bhat, S.A.; Szczuko, P.; AlKhaled, R.A.; Dar, M.A. Digital Transformation and Its Influence on Sustainable Manufacturing and Business Practices. Sustainability 2023, 15, 3010. [Google Scholar] [CrossRef]

- Agrawal, P.; Narain, R. Analysis of enablers for the digitalization of supply chain using an interpretive structural modelling approach. Int. J. Product. Perform. Manag. 2023, 72, 410–439. [Google Scholar] [CrossRef]

- Huo, X.; Ma, G.; Tong, X.; Zhang, X.; Pan, Y.; Nguyen, T.N.; Yuan, G.; Han, H.; Chen, W.; Wei, M.; et al. Trial of Endovascular Therapy for Acute Ischemic Stroke with Large Infarct. N. Engl. J. Med. 2023, 388, 1272–1283. [Google Scholar] [CrossRef]

- Amoozad Mahdiraji, H.; Hafeez, K.; Kord, H.; Abbasi Kamardi, A.A. Analysing the voice of customers by a hybrid fuzzy decision-making approach in a developing country’s automotive market. Manag. Decis. 2022, 60, 399–425. [Google Scholar] [CrossRef]

- Adel, M.; Ahmed, M.A.; Elabiad, M.A.; Mohamed, A.A. Removal of heavy metals and dyes from wastewater using graphene oxide-based nanomaterials: A critical review. Environ. Nanotechnol. Monit. Manag. 2022, 18, 100719. [Google Scholar] [CrossRef]

- Hettiarachchi, B.D.; Brandenburg, M.; Seuring, S. Connecting additive manufacturing to circular economy implementation strategies: Links, contingencies and causal loops. Int. J. Prod. Econ. 2022, 246, 108414. [Google Scholar] [CrossRef]

- Zou, Y.; Xiao, G.; Li, Q.; Biancardo, S.A. Intelligent Maritime Shipping: A Bibliometric Analysis of Internet Technologies and Automated Port Infrastructure Applications. J. Mar. Sci. Eng. 2025, 13, 979. [Google Scholar] [CrossRef]

- Men, Y.; Su, X.; Li, P.; Tan, Y.; Ge, C.; Jia, S.; Li, L.; Wang, J.; Cheng, G.; Zhuang, L.; et al. Oxygen-Inserted Top-Surface Layers of Ni for Boosting Alkaline Hydrogen Oxidation Electrocatalysis. J. Am. Chem. Soc. 2022, 144, 12661–12672. [Google Scholar] [CrossRef]

- Rahmanzadeh, S.; Pishvaee, M.S.; Govindan, K. Emergence of open supply chain management: The role of open innovation in the future smart industry using digital twin network. Ann. Oper. Res. 2022, 329, 979–1007. [Google Scholar] [CrossRef]

- Latino, M.E.; Menegoli, M.; Lazoi, M.; Corallo, A. Voluntary traceability in food supply chain: A framework leading its implementation in Agriculture 4.0. Technol. Forecast. Soc. Change 2022, 178, 121564. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Internet of things for smart factories in industry 4.0, a review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204. [Google Scholar] [CrossRef]

- Hamed, A.; Bohari, A.M. Adoption of big data analytics in medium-large supply chain firms in Saudi Arabia. Knowl. Perform. Manag. 2022, 6, 62–74. [Google Scholar] [CrossRef]

- Abban, R.; Abebe, G.K. Exploring digitalization and sustainable practices in African agribusinesses and food supply chains: A literature review. Int. J. Food Syst. Dyn. 2022, 13, 470–474. [Google Scholar] [CrossRef]

- Lu, Q.; Jiang, Y.; Wang, Y. How can digital technology deployment empower supply chain financing? A resource orchestration perspective. Supply Chain. Manag. Int. J. 2024, 29, 804–819. [Google Scholar] [CrossRef]

- Patrucco, A.S.; Trabucchi, D.; Frattini, F.; Lynch, J. The impact of COVID-19 on innovation policies promoting Open Innovation. RD Manag. 2022, 52, 273–293. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Kshetri, N.; Hughes, L.; Slade, E.L.; Jeyaraj, A.; Kar, A.K.; Baabdullah, A.M.; Koohang, A.; Raghavan, V.; Ahuja, M.; et al. “So what if ChatGPT wrote it?” Multidisciplinary perspectives on opportunities, challenges and implications of generative conversational AI for research, practice and policy. Int. J. Inf. Manag. 2023, 71, 102642. [Google Scholar] [CrossRef]

- Vasluianu, F.A.; Seizinger, T.; Timofte, R.; Cui, S.; Huang, J.; Tian, S.; Fan, M.; Zhang, J.; Zhu, L.; Wei, X.; et al. NTIRE 2023 Image Shadow Removal Challenge Report. Available online: https://openaccess.thecvf.com/content/CVPR2023W/NTIRE/papers/Vasluianu_NTIRE_2023_Image_Shadow_Removal_Challenge_Report_CVPRW_2023_paper.pdf (accessed on 22 July 2025).

- Glaros, A.; Nost, E.; Nelson, E.; Klerkx, L.; Fraser, E.D.G. Contested definitions of digital agri-food system transformation: A webpage and network analysis. Int. J. Food Des. 2023, 8, 35–60. [Google Scholar] [CrossRef]

- Swen, J.J.; van der Wouden, C.H.; Manson, L.E.; Abdullah-Koolmees, H.; Blagec, K.; Blagus, T.; Böhringer, S.; Cambon-Thomsen, A.; Cecchin, E.; Cheung, K.-C.; et al. A 12-gene pharmacogenetic panel to prevent adverse drug reactions: An open-label, multicentre, controlled, cluster-randomised crossover implementation study. Lancet 2023, 401, 347–356. [Google Scholar] [CrossRef]

- Akbari, M.; Hopkins, J.L. Digital technologies as enablers of supply chain sustainability in an emerging economy. Oper. Manag. Res. 2021, 15, 689–710. [Google Scholar] [CrossRef]

- Furstenau, L.B.; Zani, C.; Terra, S.X.; Sott, M.K.; Choo, K.K.R.; Saurin, T.A. Resilience capabilities of healthcare supply chain and supportive digital technologies. Technol. Soc. 2022, 71, 102095. [Google Scholar] [CrossRef]

- Kunkel, S.; Matthess, M.; Xue, B.; Beier, G. Industry 4.0 in sustainable supply chain collaboration: Insights from an interview study with international buying firms and Chinese suppliers in the electronics industry. Resour. Conserv. Recycl. 2022, 182, 106274. [Google Scholar] [CrossRef]

- Mohapatra, B.; Tripathy, S.; Singhal, D.; Saha, R. Significance of digital technology in manufacturing sectors: Examination of key factors during COVID-19. Res. Transp. Econ. 2022, 93, 101134. [Google Scholar] [CrossRef]

- Tavana, M.; Shaabani, A.; Vanani, I.R.; Gangadhari, R.K. A Review of Digital Transformation on Supply Chain Process Management Using Text Mining. Processes 2022, 10, 842. [Google Scholar] [CrossRef]

- Joshi, S.; Sharma, M. Sustainable Performance through Digital Supply Chains in Industry 4.0 Era: Amidst the Pandemic Experience. Sustainability 2022, 14, 16726. [Google Scholar] [CrossRef]

- Sozinova, A.A.; Daribekova, A.S.; Lapteva, I.P.; Makarova, M.V. A New Level of Food Security as a Result of the Transition of Food-Importing Countries to Agriculture 4.0 Based on Deep Learning. In Food Security in the Economy of the Future; Springer: Berlin/Heidelberg, Germany, 2023; pp. 85–92. [Google Scholar]

- Jellason, N.P.; Robinson, E.J.Z.; Ogbaga, C.C.; García-Mateos, G. Agriculture 4.0: Is Sub-Saharan Africa Ready? Appl. Sci. 2021, 11, 5750. [Google Scholar] [CrossRef]

- Conde, M.V.; Zamfir, E.; Timofte, R.; Motilla, D.; Liu, C.; Zhang, Z.; Peng, Y.; Lin, Y.; Guo, J.; Zou, X.; et al. Efficient Deep Models for Real-Time 4K Image Super-Resolution. NTIRE 2023 Benchmark and Report. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Vancouver, BC, Canada, 18–22 June 2023; pp. 1495–1521. [Google Scholar]

- AL-Shboul, M.A. Better understanding of technology effects in adoption of predictive supply chain business analytics among SMEs: Fresh insights from developing countries. Bus. Process Manag. J. 2023, 29, 159–177. [Google Scholar] [CrossRef]

- Alsmairat, M.A.K. Big data analytics capabilities, SC innovation, customer readiness, and digital SC performance: The mediation role of SC resilience. Int. J. Adv. Oper. Manag. 2023, 15, 82. [Google Scholar]

- Tamym, L.; Benyoucef, L.; Moh, A.N.S.; El Ouadghiri, M.D. Big data analytics-based approach for robust, flexible and sustainable collaborative networked enterprises. Adv. Eng. Inform. 2023, 55, 101873. [Google Scholar] [CrossRef]

- Ciampi, F.; Faraoni, M.; Ballerini, J.; Meli, F. The co-evolutionary relationship between digitalization and organizational agility: Ongoing debates, theoretical developments and future research perspectives. Technol. Forecast. Soc. Change 2022, 176, 121383. [Google Scholar] [CrossRef]

- Papanagnou, C.; Seiler, A.; Spanaki, K.; Papadopoulos, T.; Bourlakis, M. Data-driven digital transformation for emergency situations: The case of the UK retail sector. Int. J. Prod. Econ. 2022, 250, 108628. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Sharma, A.; Rana, N.P.; Giannakis, M.; Goel, P.; Dutot, V. Evolution of artificial intelligence research in Technological Forecasting and Social Change: Research topics, trends, and future directions. Technol Forecast. Soc. Change 2023, 192, 122579. [Google Scholar] [CrossRef]

- Margaritis, I.; Madas, M.; Vlachopoulou, M. Big Data Applications in Food Supply Chain Management: A Conceptual Framework. Sustainability 2022, 14, 4035. [Google Scholar] [CrossRef]

- Nagy, J.; Foltin, P. Increase supply chain resilience by applying early warning signals within big-data analysis. Ekon. Vjesn. 2022, 35, 467–481. [Google Scholar] [CrossRef]

- Tahir, S.; Ramish, A. Xarasoft (Pvt) Ltd.—Vision 2027 to implement a digital supply chain for industry 4.0. Emerald Emerg. Mark. Case Stud. 2022, 12, 1–22. [Google Scholar] [CrossRef]

- Narwane, V.S.; Raut, R.D.; Yadav, V.S.; Cheikhrouhou, N.; Narkhede, B.E.; Priyadarshinee, P. The role of big data for Supply Chain 4.0 in manufacturing organisations of developing countries. J. Enterp. Inf. Manag. 2021, 34, 1452–1480. [Google Scholar] [CrossRef]

- Sharma, S.; Gahlawat, V.K.; Rahul, K.; Mor, R.S.; Malik, M. Sustainable Innovations in the Food Industry through Artificial Intelligence and Big Data Analytics. Logistics 2021, 5, 66. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).