1. Introduction

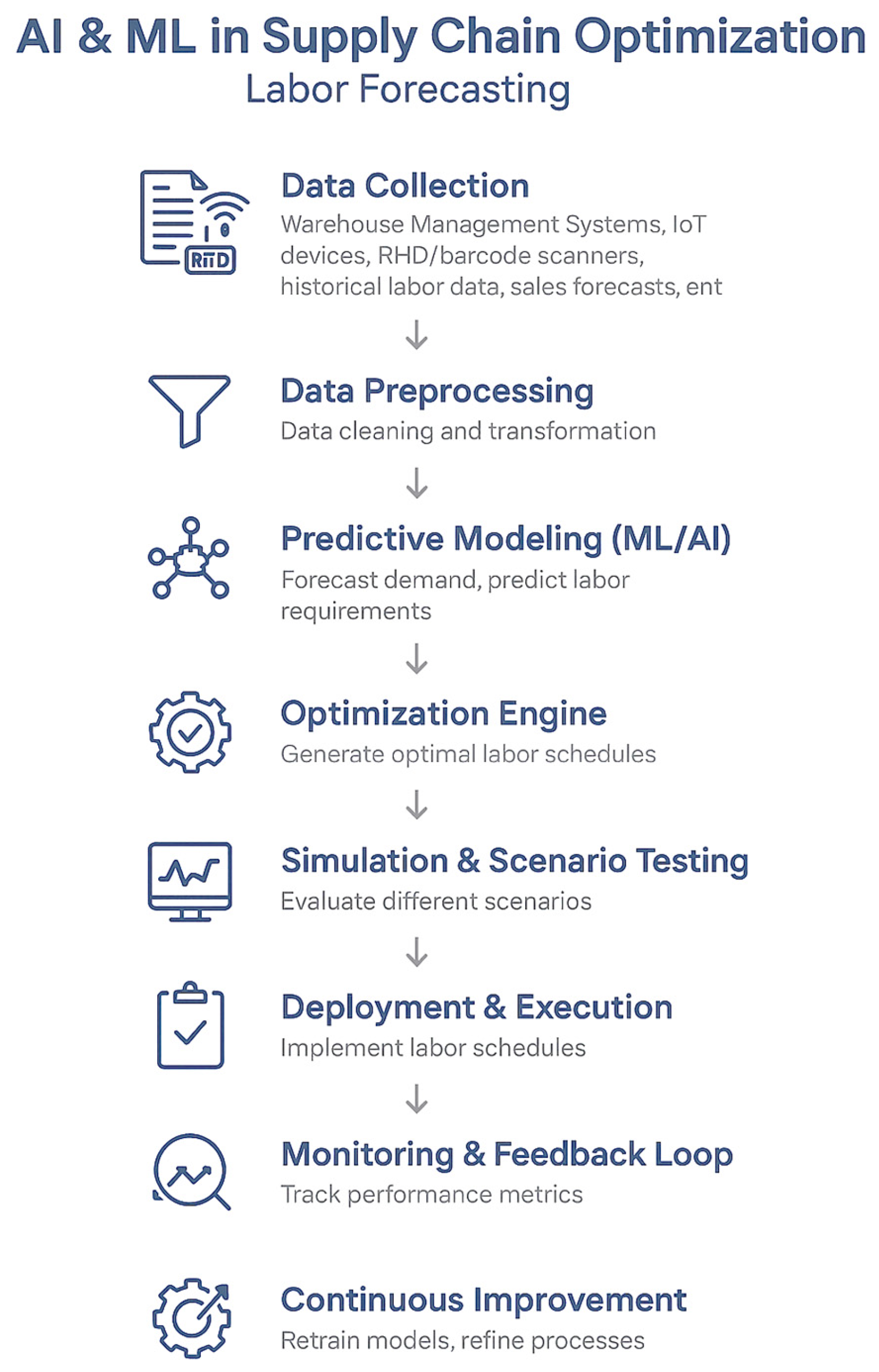

Due to unpredictable customer demand, shortened delivery times, and mounting demands for operational agility, the apparel distribution industry is rapidly changing. As regional microtrends break apart traditional planning models and global fashion cycles quicken, distribution hubs need to adopt data-driven, flexible frameworks instead of static labor methods. Forecasting, scheduling, and supply chain optimization are the main topics of this paper, which examines the relationship between operational growth trends and AI-enhanced labor planning in basic apparel distribution centers. Efficient labor planning is essential in the fast-paced apparel business to maintain operational efficiency and adjust to changing consumer demand. In evolving environments, such as basic apparel distribution centers (DCs), where labor intensity, stock-keeping-unit (SKU) variability, and seasonal demand spikes pose significant challenges, traditional labor forecasting tools which frequently rely on static historical data lack the agility needed [

1]. To solve these issues, artificial intelligence (AI) and machine learning (ML) technologies are increasingly being utilized to enhance labor forecasting and flexible workforce planning. Utilizing real-time data, including order volumes, product assortments, inventory levels, and workforce availability, these systems produce adaptive forecasts that maximize responsiveness and resource allocation [

1,

2,

3]. DCs may respond to the increasing need for speedier fulfillment, individualized customer experiences, and cheaper operational costs by implementing AI-enabled technologies that improve service levels, minimize labor costs, and increase supply chain agility [

4,

5]. Mass data-driven labor planning is becoming an essential component of the apparel industry’s competitiveness and operational resilience as omnichannel retail and fast fashion models gain traction [

6,

7]. Although artificial intelligence (AI) and machine learning (ML) techniques like LSTM, XGBoost, and reinforcement learning are widely used, their use in labor planning for the garment industry is still in its infancy. Contextual sensitivity to SKU complexity, seasonal variations, and staff diversity is sometimes lacking in existing models. Traditional forecasting techniques also do not react to real-time demand signals, and hybrid planning frameworks have trouble scaling over dispersed networks. In order to progress the area, we have identified a number of important issues and research gaps that need to be filled. Current models offer minimal contextualization of AI models. Thus, most of the research presents general algorithms without adjusting them to variables unique to apparel, such as color, size, and fashion turnover. There exist inadequate empirical validation and the usefulness of AI-driven workforce planning in distribution centers has not been adequately illustrated by real-world case studies. Methodology reproducibility is hampered by the fact that many reviews leave out information about database selection, inclusion/exclusion criteria, and review duration. Research on labor forecasting does not address algorithmic bias, data privacy, and human-AI interaction. There exist concerns about generalizability and scalability as AI models frequently work well in isolated pilots but have trouble adapting to a variety of facilities and worker demographics. The goal of this work is to close the gap between theoretical modeling and practical execution by combining structured review processes with a synthesis of recent work. To meet the changing needs of the clothing supply chain, we suggest a framework for ethical, context-aware, and scalable labor planning systems.

This review sets itself apart by concentrating on AI-driven labor forecasting in basic apparel distribution centers, a field that is frequently disregarded in the literature on supply chains. It presents a scenario-based modeling methodology designed to account for factors unique to the apparel industry, such as labor fluctuations at the shift level, seasonal demand, and SKU complexity. In contrast to previous assessments, the current one incorporates the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA), a body of research-based recommendations aimed at enhancing the quality and transparency of reporting in these types of studies. Researchers can more easily document their technique, from data analysis to literature search and study selection, by using its organized checklist and flow diagram. This makes the researchers’ work more dependable, repeatable, and simple to assess. Utilized extensively in the health sciences and other fields, PRISMA improves the validity of research results and facilitates well-informed decision-making. PRISMA-style transparency standards to improve repeatability and provides a dashboard-ready taxonomy of AI/ML models matched to operational contexts. The study offers a more practical and context-sensitive roadmap for future research and real-world application by addressing empirical gaps, ethical issues, and difficulties with human-AI interaction.

In the PRISMA review we compiled research from a broad range of academic, business, and technology works that discuss workforce and operational planning using AI in basic clothing distribution centers. Scopus, Web of Science, JSTOR, IEEE Xplore, and Google Scholar were the five main databases that were queried using a certain set of phrases. They comprised “supply chain optimization,” “scenario modeling,” “labor forecasting,” “apparel distribution centers,” along with “AI workforce planning.” The review focused on works published between 2016 and 2025 and was restricted to English-language sources. To ensure that theoretical insights and real-world applications were covered, pertinent industry reports were also included to support peer-reviewed findings. A total of 262 articles were surveyed, of which 136 references were narrowed based on relevance to the topic as the inclusion criteria. The entire literature search was conducted over 6 months followed by compilation into judicious sub-topics for this comprehensive review paper.

Figure 1 presents the PRISMA flow chart detailing the systematic review process for AI-based workforce and operational planning in clothing distribution centers. It outlines each phase—from initial database searches to final article selection and thematic categorization (

Supplementary Materials File S1).

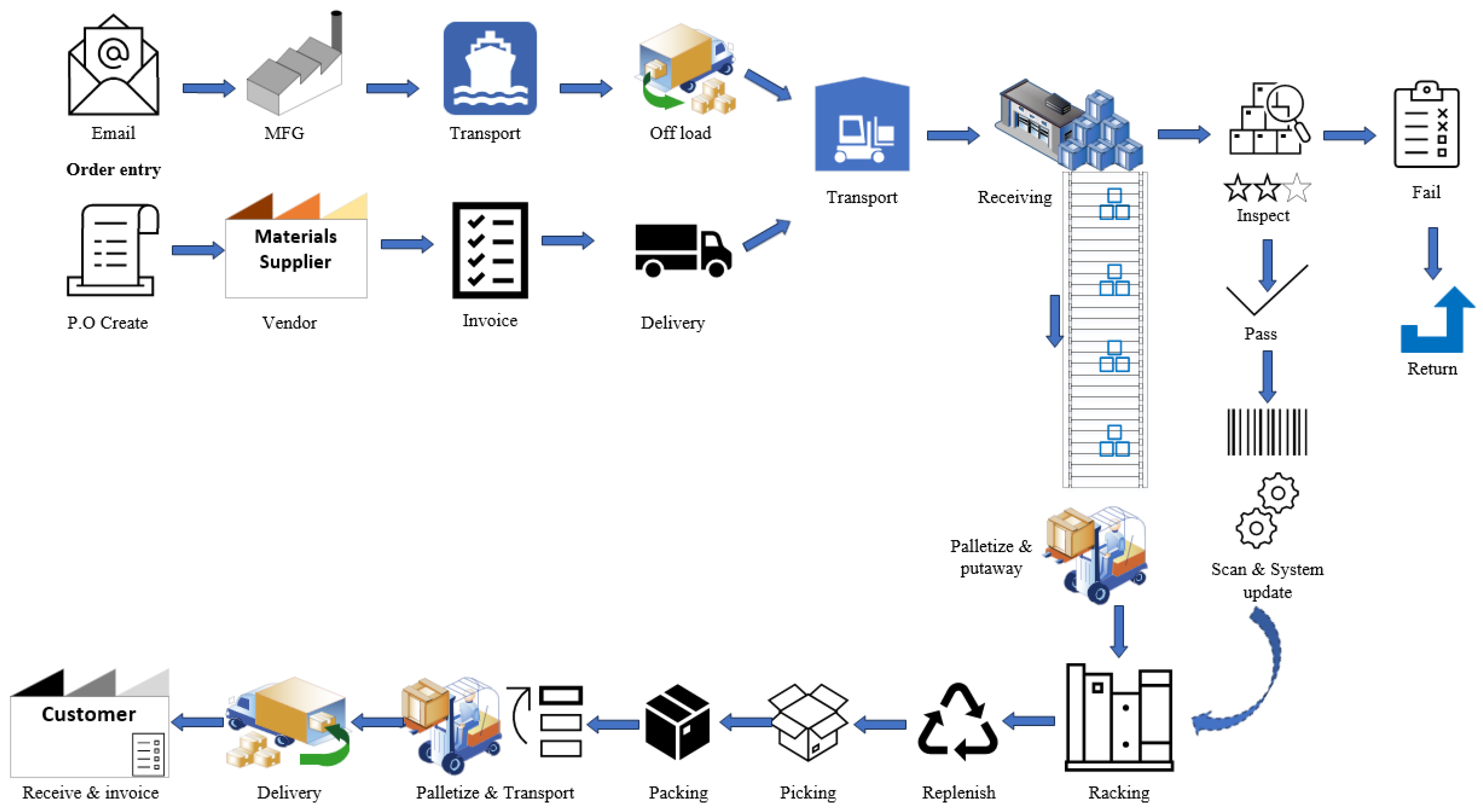

The role of AI in labor forecasting for agile workforce planning in apparel distribution centers is examined in this literature review, which looks at important topics like forecasting models, real-time data use, AI integration, labor efficiency metrics, labor planning strategies, and the effect of employee skill levels on overall performance. The operational schematic of a distribution center is shown in

Figure 2, which gives a visual summary of the main functional areas such as receiving, storage, order picking, packing, and shipping as well as the associated processes between them.

2. Labor Planning Strategies in Apparel Supply Chains

Traditionally, the cornerstones of labor planning in apparel supply chains have been static scheduling, historical data, and experience-based adjustments. Lean and just-in-time (JIT) approaches sometimes fail in highly unpredictable environments, albeit offering some benefit [

8]. To reduce waste and improve responsiveness, the apparel sector needs integrated planning models that link labor, production, and inventory choices. In addition, the logistics of apparel are increasingly adopting agile supply chain solutions, which place an emphasis on responsiveness and adaptability [

9]. Short product life cycles, shifting demand, and worldwide sourcing have made supply chains more complicated, necessitating more flexible and data-driven labor scheduling. To adapt to sudden shifts in demand, these tactics promote proactive workforce planning, decentralized decision-making, and real-time modifications. Because traditional labor planning frequently depends on past trends and static headcount predictions, it cannot adapt to abrupt changes in workforce availability or demand. On the other hand, AI-driven methods offer predictive analytics, real-time data integration, and transformative scenario modeling, which help businesses better identify interruptions, maximize cost-performance, and assign workers. With this change, reactive scheduling will give way to proactive, skills-based labor strategies that are constantly adjusted to meet changing operational requirements. A paradigm shifts in the way apparel distribution centers handle manpower allocation, demand volatility, and operational resilience may be seen in AI-driven labor planning. Real-time, adaptive decision-making is made possible by AI technologies like LSTM for time-series prediction, XGBoost for performance-based staffing, and reinforcement learning for flexible task assignments, in contrast to traditional models that depend on static forecasts and human scheduling. These models use large datasets, such as historical throughput, demand at the SKU level, and productivity at the shift level, to more accurately forecast labor needs [

10]. AI also makes it easier to respond to changes in regional demand, fashion cycles, and promotional spikes, all of which are very erratic in the clothing industry. By matching human resources with operational demand, AI integration enhances prediction accuracy, lowers overtime expenses, and promotes the deployment of ethical labor, according to recent literature [

11]. These features can be integrated into labor planning tools to help distribution centers develop data-driven, scalable workforce strategies that strike a balance between supply chain agility, employee well-being, and cost effectiveness.

While pointing out obstacles such legacy system integration and high implementation costs, the Raymond 2025 article emphasizes how AI, particularly machine learning and computer vision, improves supply chain resilience, forecasting, and quality control [

12]. Furthermore, Kothapalli demonstrates how AI makes it possible to simulate labor scenarios, optimize cost-performance, and visualize the workforce in real-time for more intelligent planning [

13]. A key aspect often overlooked is human adaptation to AI technologies especially in low-cost labor industries like apparel, where technological adoption tends to lag. Noor’s analysis of AI applications in the clothing sector looks at how the technology is being used to improve operational effectiveness in the face of rising competition and shifting consumer demands. The study emphasizes the application of multi-agent systems, neural networks, and genetic algorithms for tasks including supply chain coordination, production layout optimization, and defect detection. These strategies have limits when it comes to actual implementation, notwithstanding their potential. Noor highlights the necessity of greater research tailored to a particular business and a closer connection between theoretical models and practical implementation [

14]. Siddhu and Mohibi’s recent paper look at how AI is transforming the apparel industry into underdeveloped countries. It highlights AI’s contribution to improved design, production, and supply chain efficiency while addressing challenges like data ethics and employment displacement. They support inclusive innovation and more in-depth research to align AI with local industrial needs [

15]. In addition, An AI-based framework for fashion forecasting is presented in the paper by Banerjee, Mohapatra, and Saha, and it is verified by a case study. It demonstrates how machine learning enhances profit margins, inventory management, and product prediction and advocates for wider usage in the fashion sector [

16]. Moreover, in order to enhance fashion forecasting, Banerjee, Mohapatra, and Saha’s develop a framework of AI for fashion forecasting. It incorporates machine learning methods to improve inventory management, profitability, and product prediction. Through a real-world case study, the methodology is tested and shows quantifiable gains in operational efficiency and forecasting accuracy. The authors urge more widespread use of AI in fashion forecasting and demand that it be further improved to meet industry demands [

17].

Implementing flexible labor methods into practice presents operational difficulties, particularly in labor intensive settings like distribution centers (DCs), where efficiency and flexibility must be balanced. To reduce lead times and enable faster workforce modifications, businesses are increasingly looking for localized or regionalized supply chain nodes, according to H. Moradlou [

18]. This action step could result in higher labor expenses. This change has pushed businesses to embrace workforce models that incorporate flexible shift arrangements, cross-training initiatives, and multiskilled labor pools that can react quickly to interruptions or spikes in demand. Furthermore, workforce planning in agile supply chains needs to consider real-time decision-making and predictive skills in addition to standard productivity measures. Distribution centers may instantly reassign personnel based on real-time workload data and order priority by integrating cloud-based labor management systems, mobile tasking, and intelligent scheduling algorithms [

19]. By enabling managers to rapidly make data-driven labor decisions, these technologies improve agility by lowering bottlenecks and boosting throughput during peak hours. Recent studies by Uzozie investigate the use of AI in design, manufacturing, distribution, and retail [

20]. Using empirical research and a synthesis of the literature, it places a strong emphasis on sustainability, operational effectiveness, and competitive advantage. Robotics, computer vision, and predictive analytics are examples of technologies [

21]. AI-enabled planning for labor disruptions, including supply shocks, demand spikes, and absenteeism, is the main topic of Raymond’s research study. For workforce agility, it suggests resilience modeling and decision-tree frameworks [

12]. Businesses can benefit from using AI in many ways, but there are hazards as well, like data privacy, algorithmic bias, and the challenge of integrating AI with old HR systems and staff skills.

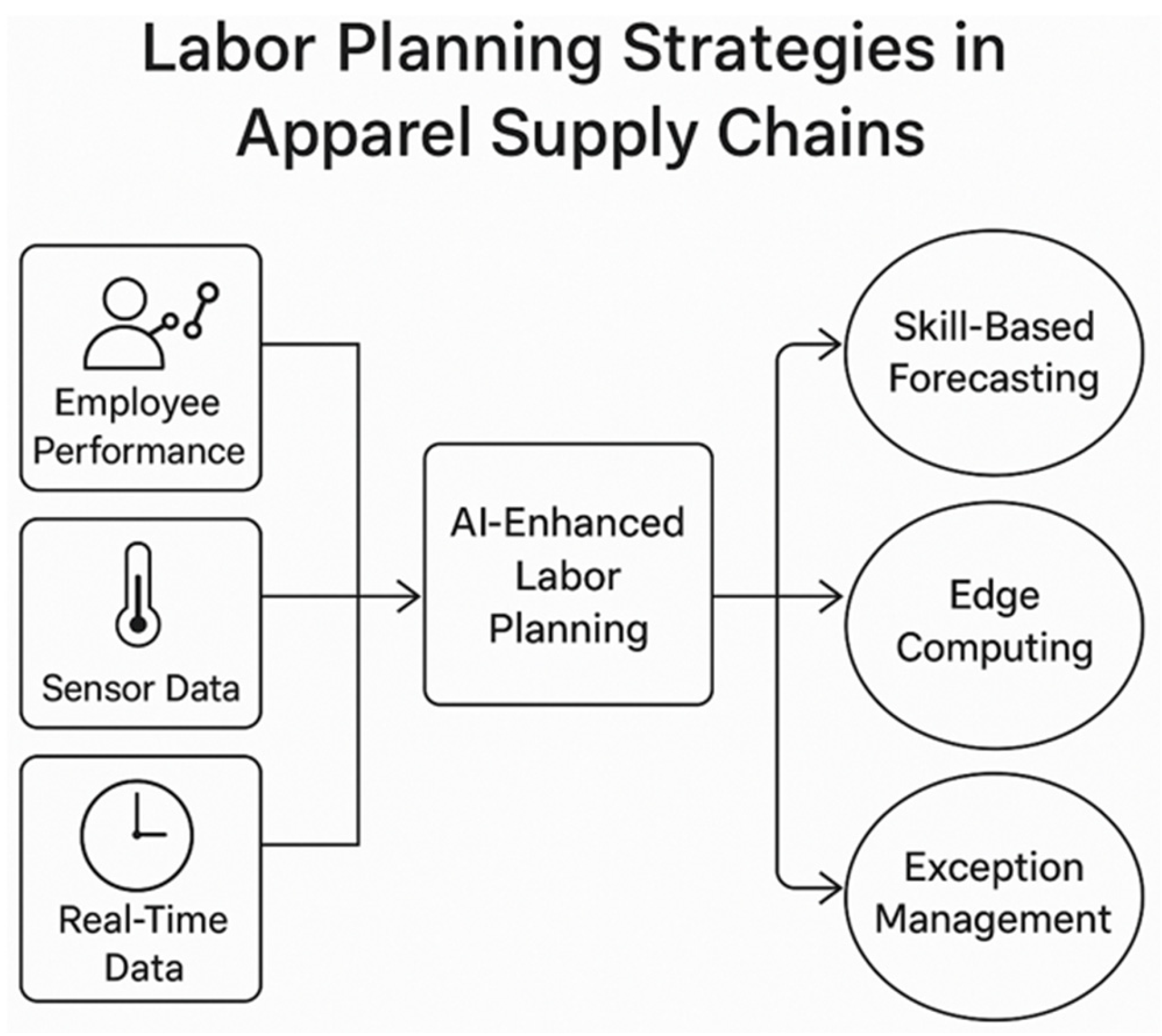

Figure 3 shows how real-time data is used by AI-driven labor planning in clothing supply chains to predict demand, match skills to tasks, and react to interruptions. It allows for quick, data-driven decisions that maximize labor, boost productivity, and preserve service levels in dynamic contexts by utilizing edge computing and predictive analytics.

Agile labor planning further highlights the value of cooperation throughout the supply chain. Ketokivi and Choi (2014) [

25] assert that improving responsiveness and lowering the risk of over- or under-staffing can be achieved by coordinating labor tactics with upstream production and downstream demand signals. Despite the scalable and responsive solutions provided by AI-driven workforce planning, many apparel distribution centers continue to rely on manual coordination and disjointed systems. Siloed platforms frequently house client orders, supplier schedules, and transportation logistics, which restricts visibility and delays decision-making. Excel-based models are not flexible enough to meet changing demands in these settings, while sophisticated AI frameworks are still underutilized because of a lack of expertise, limited infrastructure, and high costs.

Using scalable labor planning tools, such as Excel or AI frameworks like TensorFlow, apparel distribution centers enhance coordination and responsiveness by adjusting staff strategies to changing demand. Effective labor allocation is made possible by utilizing automation, real-time data, and predictive analytics. This enhances customer satisfaction and cost effectiveness while cultivating a workforce that is knowledgeable and flexible [

26,

27]. In their 2025 study, Yanamala effectively describes how generative AI makes it possible to analyze skill gaps, model scenarios, and allocate labor compelling. It highlights the transition to flexible, skill-based workforce strategies from static headcount planning [

28].

Table 1 lists common labor planning techniques used by distribution centers in a variety of industries, emphasizing how they can be utilized practically to manage operational agility and worker efficiency.

3. Demand Forecasting and Workforce Scheduling Models

Linear programming, queuing theory, and statistical forecasting are some of the techniques used in traditional labor scheduling [

37]. However, these models are not flexible enough for changing industries like apparel. Genetic algorithms, simulation-based models, and constraint programming are examples of stochastic and robust optimization techniques that have demonstrated promise for workforce scheduling in the face of uncertainty [

38]. Lin et al. claim that hybrid models improve forecast accuracy and flexibility that may be applied across industries by combining machine learning and operational research methodologies [

39]. Nevertheless, such models are not flexible enough for industries as unstable as clothing. They frequently make assumptions about constant demand or resource availability, which are inconsistent with the regular fluctuations observed in supply chain interruptions, promotional activities, and seasonal product cycles. Consequently, companies are moving toward scheduling systems that are more flexible and impactful.

According to Cordeau et al. [

38], workforce scheduling under uncertainty has demonstrated the potential of effectiveness and stochastic optimization techniques including constraint programming, evolutionary algorithms, and simulation-based models. By taking into consideration variations in job durations, shift preferences, and demand patterns, these methods enable more reliable scheduling choices. Agent-based simulations can be used, for example, to mimic the relationships and behaviors of individual workers to evaluate the effects of scheduling decisions on morale and productivity. The primary elements of personnel scheduling and demand forecasting are described, together with their salient characteristics and contributions to distribution center operations, in

Table 2 below.

Furthermore, forecast accuracy and flexibility are enhanced by hybrid models that combine machine learning and operational research techniques (Lin et al., 2018) [

39]. Hybrid systems employ machine learning to produce operational insights and demand estimates, which are then fed into scheduling optimization solvers. Reinforcement learning is being investigated to self-tune rules through constant feedback, and these systems use historical data to adjust to trends [

41]. Advanced analytics knowledge and AI modeling skills are required for this hybrid strategy, which can be difficult for businesses with limited technological resources. AI-driven scheduling systems dynamically modify labor plans in response to real-time operational parameters by integrating real-time data streams from sources such as WMS, RFID, and IoT enabled equipment. Especially in apparel distribution facilities, where adaptive workforce planning facilitates quicker fulfillment and better alignment with changing demand. This strategy increases responsiveness, decreases downtime, and boosts service efficiency [

42,

43].

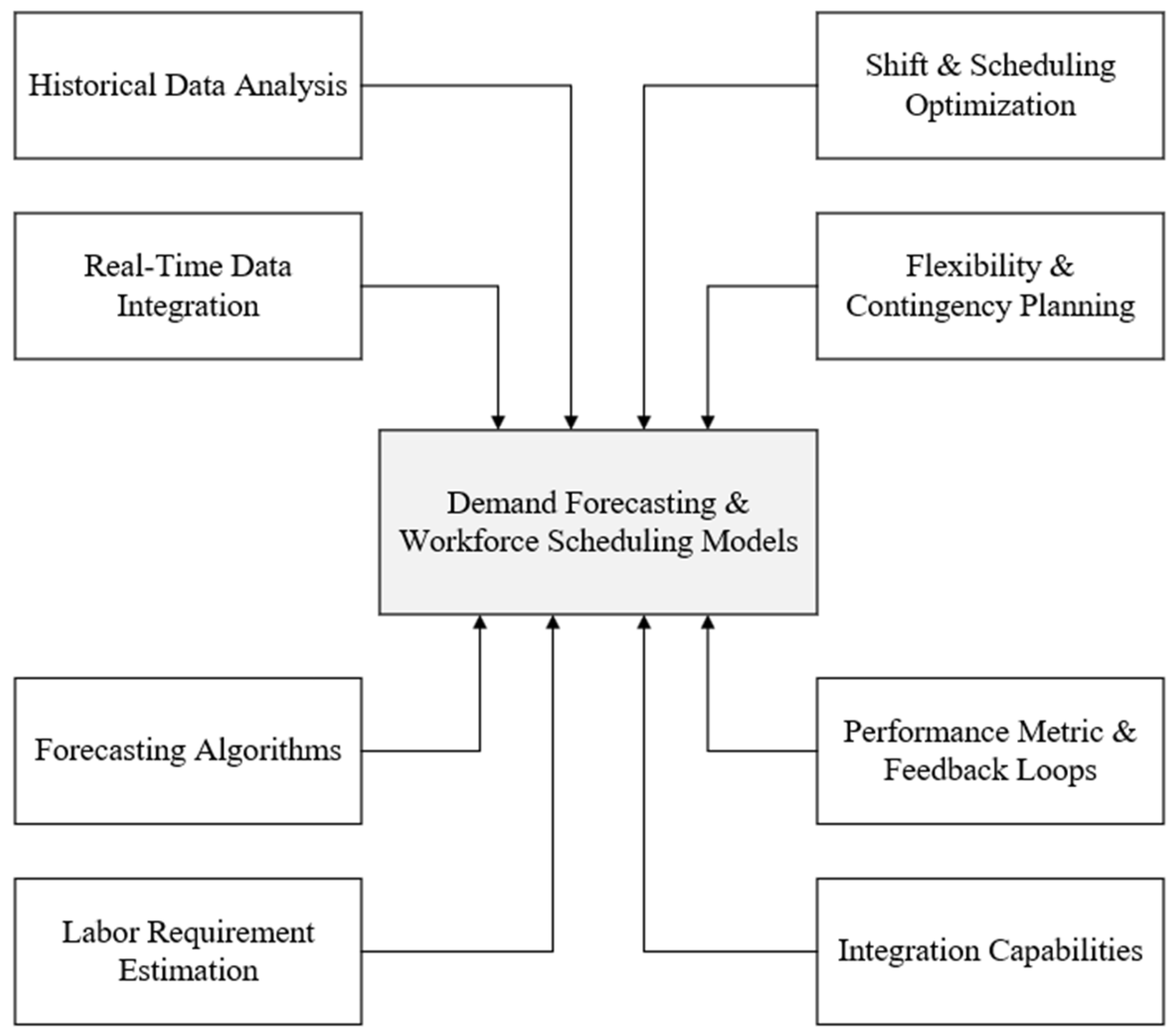

The Demand Forecasting and Workforce Scheduling Models flowchart provides an organized summary of the essential elements that support efficient labor planning in clothing distribution facilities. The core model, which is at the heart of the framework, is impacted by eight interrelated components that work together to improve operational agility and forecasting accuracy. Historical Data Analysis is the first step in the process, which uses historical performance trends to forecast future labor and demand. Real-Time Data Integration complements this, enabling the system to adapt dynamically to the state of operations. The analytical engine that forecasts workforce demands based on both historical and real-time inputs is a forecasting algorithm, which is frequently driven by AI and machine learning. Labor Requirement Estimation determines the required staffing levels after demand projections, and Shift and Scheduling Optimization matches labor availability with workload distribution throughout time periods. Flexibility and Contingency Planning add buffers and alternate methods for managing interruptions like demand spikes or absenteeism to guarantee flexibility. Additionally, the model includes Performance Metrics and Feedback Loops, which analyze throughput, efficiency, and schedule adherence to continuously improve forecasting accuracy. Finally, integration capabilities guarantee that the system may easily connect with larger garment business systems, allowing for end-to-end supply chain function coordination and visibility.

These elements in

Figure 4 work together to create a thorough and adaptable workforce scheduling system that strikes a balance between operational flexibility and predictive analytics to satisfy the changing needs of apparel distribution settings. Demand forecasting methods enable adaptive, closed-loop operations by generating short- and long-term predictions based on market trends, sales data, and promotions, as seen in

Figure 4. Data driven methods are used in demand forecasting and workforce scheduling models to forecast labor requirements and optimize staffing levels, guaranteeing effective operations and flexibility in response to fluctuations in demand.

Although workforce scheduling models and demand predictions provide fundamental insights into labor planning, the limits of hybrid supply chain systems frequently restrict their efficacy. The complexity and volatility of contemporary apparel distribution are difficult for hybrid models that combine lean and agile principles to handle, especially when dealing with short-term trends, variable SKUs, and dispersed supplier networks [

49,

50]. Reactivity and scalability are hampered by these models’ frequent reliance on static assumptions and delayed feedback loops. Therefore, there is a rising need to move toward optimization frameworks driven by AI and machine learning that can simulate various operating scenarios, ingest real-time data, and adapt to dynamic market signals. The next section examines how cutting-edge algorithms like LSTM, XGBoost, and reinforcement learning are being modified to get around these restrictions and enable apparel supply chain planning to reach new heights of accuracy, adaptability, and resilience.

4. AI and Machine Learning in Supply Chain Optimization Models

AI and machine learning tools have been implemented across several fields including manufacturing [

51,

52,

53,

54,

55], biomedical research [

56], oil and gas exploration [

57]. Supply chain optimization has enhanced because of AI and ML’s increased capacity for prediction and decision-making [

58,

59]. In highly variable contexts, labor forecasting methods such as gradient-boosted trees (e.g., XGBoost), neural networks, and support vector machines perform better than conventional models. To provide more contextual forecasts and improve the accuracy of labor planning, AI systems can also incorporate outside variables such as promotions and weather [

27,

44,

45,

46,

47,

48].

Deep learning models and reinforcement learning are becoming popular techniques for ongoing schedule improvement [

42,

60]. By learning from intricate patterns in multi-source data, including sales projections, SKU velocity, order history, and shift logs, these AI-driven models allow for more precise labor forecasting. For instance, long short-term memory (LSTM) architectures and recurrent neural networks (RNNs) are especially well-suited for time-series forecasting, capturing cross-temporal relationships that impact labor requirements [

61]. These models can adjust to fast fashion fads, seasonal variations, and even geographical variations in customer behavior when used in clothing distribution hubs. By gathering data, predicting demand, and improving labor and inventory planning. The effects of AI and machine learning on apparel supply chain operations are depicted in

Figure 5. It draws attention to a powerful feedback loop in which AI models improve workflow over time, increasing output and facilitating more intelligent, instantaneous decision-making. Increased responsiveness and lower operating expenses result from this. Through the integration of sophisticated algorithms in demand forecasting, inventory control, and logistics, AI and ML enable flexible, data-driven supply chain strategies and result in notable efficiency gains.

AI also makes scenario planning and risk-aware forecasting easier. By using methods like Monte Carlo simulations in conjunction with machine learning forecasts, planners may assess workforce requirements under various demand volatility scenarios, improving responsiveness and agility. This is particularly pertinent to the clothing industry, where if not well predicted, demand surges brought on by fashion drops or promotional events may lead to either understaffing or overstaffing. Further democratizing access to advanced analytics has been the incorporation of AI into workforce management systems and cloud-based platforms. AI enhanced dashboards are increasingly widely used by businesses, enabling supply chain managers to identify bottlenecks, simulate labor schedules, and test the effects of changes in real time. The cognitive load on planners is lessened, and decision-making quality is enhanced by these platforms’ frequent predicted alerts and recommendations. The combination of artificial intelligence (AI) with digital twin virtual models of actual distribution settings represents yet another significant breakthrough. Digital twins allow for predictive simulations of labor performance under different demand or scheduling situations by combining AI models with real-time operational data [

65]. This enables distribution centers to find the best configurations prior to implementation and stress-test their workforce plans. Explainability and interpretability are becoming important as AI models develop, particularly in regulated settings [

66,

67,

68].

Explainable artificial intelligence (XAI) Techniques that enable human users to understand and comprehend AI model decisions are known as explainable artificial intelligence (XAI). Unlike conventional “black-box” models, XAI highlights key characteristics, decision routes, and confidence levels to reveal how predictions are made. Since human planners must verify and implement AI-generated recommendations in practical situations like labor forecasting, this improves trust, accountability, and ethical oversight. In order to assist stakeholders comprehend, audit, and improve model behavior without sacrificing speed, post hoc explanations are made possible by tools like SHAP and LIME [

69]. XAI (Explainable AI) involves producing tools that assist labor planners in comprehending the rationale behind a certain prediction or timetable, promoting trust and enhancing operational decision acceptance. In this context, apparel distribution centers serve as critical components in effective labor planning [

70,

71]. Demand forecasting, task categorization, talent mapping, shift scheduling, performance tracking, and technology integration are some of these. When combined, they create a strategic framework that guarantees efficient production flow and best use of available resources. To maintain operational efficiency and reach production targets in the apparel industry, key pillars such labor forecasting, task assignment, skill alignment, and scheduling are necessary. Together, these components enable data-driven planning and real-time decision-making to increase flexibility, boost efficiency, and match worker capacity with operational demands.

Future modeling initiatives should consider industry-specific factors including SKU complexity, color and size assortments, seasonal fashion cycles, and promotional demand volatility to improve applicability. For instance, time-series data reflecting weekly changes in style preferences can be used to train LSTM models, and real-time inventory turnover across a variety of product categories can be used to improve labor allocation via reinforcement learning. Enhancing forecasting accuracy and operational relevance by including these domain-specific elements will guarantee that AI tools are not only theoretically sound but also customized to the complex dynamics of apparel distribution centers.

5. Use of Real Time Data in Distribution Center Operations

Distribution centers can improve visibility and operational management by utilizing real-time data from RFID tracking, Warehouse Management Systems (WMS), and Internet of Things (IoT) devices [

72]. By enabling the responsive reallocation of labor resources, these systems improve responsiveness to process delays or spikes in demand. By incorporating real-time feeds into forecasting and scheduling systems, advanced analytics platforms facilitate AI-driven decision-making [

73].

Predictive analytics combined with real-time data turns static labor planning into an ongoing, flexible procedure. IoT-enabled wearables and mobile devices, for example, can track the whereabouts of workers, their task completion rates, and their physical states. This information can be used to track performance, detect weariness, and balance labor [

74]. These data streams give shift supervisors the ability to effectively reallocate employees to packing stations or high priority picking zones in an apparel DC setting when order volume increases occur.

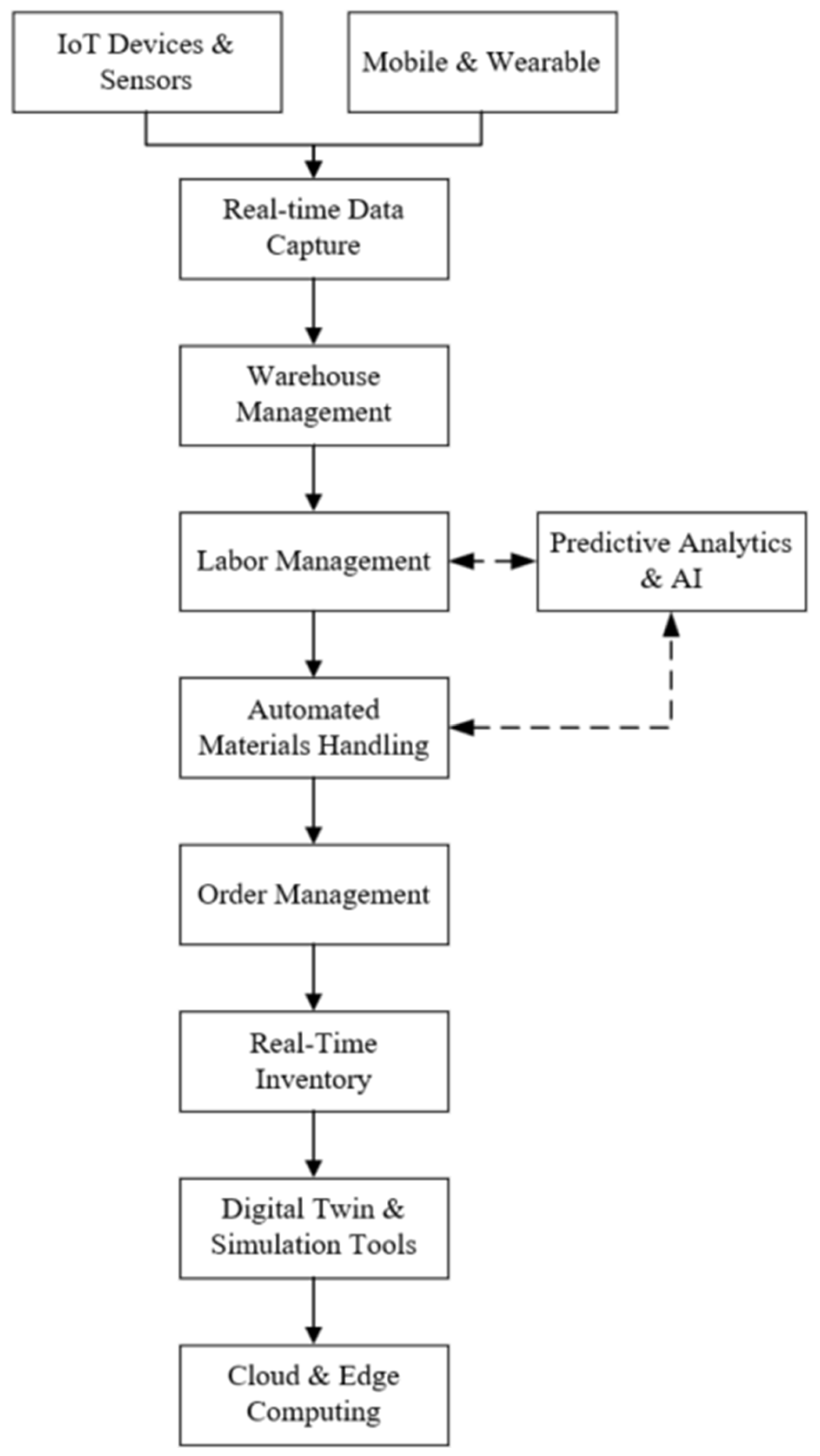

Barcode and RFID scanning also provide insight into SKU-level activity and inventory movement. These technologies cause labor schedule adjustments to be automatically made when combined with AI-based rules engines. For instance, reallocating workers to return processing during busy post-holiday times or sending more staff to inbound docks in the event of a large shipment. A framework for real-time data gathering that facilitates flexible and effective labor planning is shown in

Figure 6. It demonstrates how AI systems gather, analyze, and use labor data continually to facilitate adaptable decision-making. In order to improve system responsiveness and operational management, this design enables smooth data flow capturing, processing, and visualizing information in real time.

Additionally, by spotting operational disturbances and recommending real-time labor modifications, AI enhanced Warehouse Management Systems (WMS) provide proactive exception management, enhancing efficiency and service levels [

77]. By streamlining exception management, predictive analytics promotes managerial flexibility and expedites fulfillment [

78]. While real-time data-driven solutions, including wearable sensors and automated inventory tracking, improve productivity and visibility, they also present dangers, such as cybersecurity and legacy system integration [

79].

A summary of the main digital tools utilized in apparel distribution centers are stated in

Table 3. Improved visibility, faster fulfillment, and better planning are some benefits of technologies ranging from IoT to AI forecasting and mobile devices. However, challenges still persist which include high costs, complex integration, and data demands.

Furthermore, by processing data locally, edge computing reduces latency and bandwidth consumption, enabling prompt labor planning decisions even in the event of limited cloud access. Workflow optimization and real-time workforce analysis are made possible by decentralizing computation close to data sources, such as automated systems and wearable technology [

84]. Edge-based models that are integrated with AI improve operational resilience and service levels in an unstable situation by automatically adjusting labor allocation, identifying inefficiencies, and enhancing scheduling using predictive analytics [

85].

Supply chain visibility is improved by cloud technologies such as SAP Leonardo, Microsoft Azure IoT, and Oracle SCM Cloud, which offer real-time dashboards and AI-driven analytics. These platforms give labor planners vital performance insights for well-informed decision-making by combining data from WMS, TMS, and IoT devices [

86]. Through intelligent recommendations and predictive alerts, cloud-based control towers enable quick workforce adjustments, increasing agility in the face of interruptions [

87]. Furthermore, multi-site activities are supported by centralized collaboration platforms; nonetheless, issues like data integration and privacy concerns continue to be important factors [

88].

The development of self-optimizing labor systems that continually learn from operational data, anticipate workload shifts, and independently modify labor allocation to maintain optimal flow is made possible by these technologies’ maturing convergence with AI and ML models.

6. Metrics for Evaluating Labor Efficiency and Operational Responsiveness

The labor utilization rate, throughput per work hour, order lead time, and schedule accuracy are key performance indicators (KPIs) that are pertinent to labor forecasting. These parameters are optimized by AI-based systems, which also use them as input to improve algorithms [

89]. AI models with continuous learning capabilities and real-time dashboards improve the capacity to forecast labor requirements and assess the efficacy of labor plans in practical settings.

One important indicator that measures the percentage of scheduled time spent on productive work is the labor utilization rate. In AI enabled environments, labor bottlenecks and high-intensity processes are identified by breaking down utilization at the task level such as picking, packing, replenishment, etc. [

90]. Increased labor tracking granularity dramatically boosts warehouse visibility and resource allocation, according to recent studies [

26].

Throughput per labor hour, or TPLH, is becoming increasingly important, especially in fast-moving apparel DCs where order complexity and SKU diversity shift significantly. TPLH connects task output with labor input and system throughput, going beyond conventional productivity metrics. TPLH can dynamically suggest the best staffing for various order mixes when paired with machine learning algorithms [

26,

91]. Order cycle time, or the period of time between receiving an order and shipping, is crucial for quick fashion and e-commerce fulfillment.

AI enabled workforce planning solutions provide insights into how labor deployment affects customer satisfaction and on-time delivery by correlating labor allocation with cycle time parameters [

92]. In dynamic, AI managed situations, schedule adherence and real-time labor variance are especially crucial. These measurements highlight delays and allow for predictive rescheduling by evaluating how closely real labor execution matches the anticipated timelines. Machine learning models trained in variance data can predict future deviations and proactively recommend modifications, according to research by Ivanov & Dolgui [

92,

93].

Metrics measuring labor efficiency evaluate how well workers’ time and effort are transformed into useful output. Key performance metrics considered in this assessment, such as productivity, utilization rate, extra hours, order fulfillment time, lead time, and on-time delivery rate, are highlighted in

Figure 7. Every statistic is essential for evaluating and improving operational responsiveness and labor efficiency, offering a thorough perspective that aids businesses in pinpointing opportunities for development and streamlining their procedures.

Multi-skilling metrics and the Employee Efficiency Index show an increasing demand for cross-functional labor pools. Worker flexibility and task-switching agility, two essential skills in agile operations are assessed by these indicators. Both workforce readiness and redeployment effectiveness are enhanced by tracking the number of job functions per worker, cross training completion rates, and average task transition timeframes [

97,

98]. By combining workforce flexibility, order fulfillment speed, inventory movement, and task turnaround time, a composite KPI known as the Operational Responsiveness Index (ORI) has surfaced in contemporary DCs analytics. ORI is a strategic guidance for workforce scaling and automation investments when compared across shifts or facilities [

99]. AI Forecast Accuracy offers feedback loops for enhancing predictive labor planning models using statistical metrics such as Mean Absolute Error (MAE) and Root Mean Squared Error (RMSE). Frequent comparison of projected and actual labor demands guarantees ongoing model improvement and flexibility in response to shifting circumstances [

100,

101]. Distribution Center managers and labor planners may react swiftly to operational changes, identify inefficiencies, and promote continuous improvement by integrating these analytics into real-time dashboards and interactive visualization tools. These analytical capabilities are increasingly supported by platforms that use AI and IoT technologies, giving clothing supply chains agility and resilience [

102].

Table 4 outlines the core metrics used to evaluate labor efficiency and operational responsiveness. These indicators such as labor utilization, order fulfillment time, productivity rates, and schedule adherence demonstrate how effectively the workforce adapts to operational demands and maintains performance in real-time environments. The table also illustrates their practical applications in enhancing workforce planning and optimizing overall operational outcomes.

7. Employee Skill Levels and Their Impact on Performance

Task assignment effectiveness, learning curves, and overall productivity in DCs are all impacted by the skill level variety of employees. Flexible job designs and multiskilled labor models are supported by research as ways to maximize labor allocation [

104]. According to Heilala et al. [

105], AI driven task matching and skill-based scheduling systems improve labor utilization by matching tasks with worker competencies. Additionally, the integration of skill matrices into AI systems allows planners to identify capability gaps and enhance training techniques. Multiskilled workforce increases agility by facilitating seamless work reassignment without the need for retraining or supervision. Olhager and Rudberg [

106] assert that skill flexibility makes it possible to use resources more effectively, especially when demand varies, or equipment breaks down. More consistent throughput and more resilience during busy times or disturbances are facilitated by workers who can do a variety of tasks.

AI-powered skill-based scheduling systems that are coupled with labor management systems (LMS) can automatically assign employees to assignments according to their competency profiles, past performance, and degree of fatigue. By assigning the most qualified employees to urgent or high-priority jobs, these systems maximize labor efficiency and lower error rates [

107].

A schematic diagram in

Figure 8 below showing the connection between workers’ skill levels and how they affect performance can be found below. The graphic illustrates how various skill levels basic, intermediate, and advanced affect important performance indicators like output, output quality, efficiency, and creativity. While intermediate skills improve efficiency and creativity, basic skills largely affect productivity and job quality. Advanced skills have a wide-ranging effect, enhancing efficiency, production, and work quality while spurring creativity. This graphic illustration emphasizes how crucial it is to train staff members to maximize organizational effectiveness.

By examining employee performance data, skill levels, and contextual elements like demand spikes and absenteeism trends, AI-driven labor forecasting enhances workforce allocation. While reinforcement learning gradually improves labor deployment, machine learning models such as Random Forests and Neural Networks allow for exact scheduling [

108,

109,

110]. By matching activities with individual talents, this strategy supports retention and operational resilience while increasing productivity, decreasing inefficiencies, and improving employee satisfaction [

111].

Figure 8.

Employee skill levels and their impact on performance [

112,

113,

114].

Figure 8.

Employee skill levels and their impact on performance [

112,

113,

114].

By lowering task switch ramp-up times and eliminating downtime brought on by skill mismatches, ongoing training and cross-training initiatives enhance operational responsiveness. AI-powered learning management systems may tailor training programs according to performance data-identified ability gaps, guaranteeing focused skill development for all employees [

115,

116].

The advent of wearable technology and collaborative robots (cobots) has changed the skill needs in high-tech settings, moving the focus from manual work to tech-enabled job management. Workers with digital literacy and the ability to use AI-based interfaces play a crucial role in enabling intelligent distribution systems. Accordingly, in contemporary supply chains, digital upskilling is now regarded as a crucial component of labor planning [

117].

Employee skill levels have a big impact on daily task performance as well as more general corporate outcomes like competitive advantage, cost effectiveness, and operational agility.

Table 5 shows how worker retention and digital transformation are two essential elements for long-term success in clothing distribution centers are facilitated by multiskilling, focused training, job-role alignment, and technological proficiency. Along with increasing operational flexibility and productivity, these capabilities also raise staff engagement. Increased skill proficiency results in improved accuracy, reactivity, and overall efficiency in dynamic work contexts.

In labor-constrained economies, investing in employee training and upskilling increases retention, lowers absenteeism, and boosts productivity. Programs for continuous learning promote engagement and assist employees in adjusting to technology changes [

124]. By efficiently using analytics and predictive models, skilled workers maximize AI-enhanced systems, increasing organizational responsiveness [

125]. Additionally, training encourages people to view AI as a tool for enhancement rather than a replacement. Cross-functional abilities and digital literacy foster creativity, flexibility, and moral technology integration in automated settings [

126].

8. Research Gap and Future Directions

Although labor forecasting with AI has improved, there are still a number of crucial areas that require further study. These include how AI planning is affected by varied and multigenerational workforces, how AI tools and humans interact, how using real-time data affects employment over the long run, and how scalable AI solutions are across complex networks. Closing these gaps will be essential to developing scalable, moral, and inclusive labor planning systems. Several emerging trends influence the future of labor forecasting and agile workforce planning:

Integration with Internet of Things (IoT): IoT devices in DCs can provide real-time operational data to AI models [

47].

Explainable AI: Efforts to make AI decision-making processes transparent and understandable to human managers [

127].

Human-in-the-loop AI: Systems designed to combine AI recommendations with human oversight for better decision quality [

128].

The following table (

Table 6) lists the main research gaps in AI-enhanced labor forecasting in apparel distribution centers. Workforce diversity, human-AI interaction, long-term employment impact, ethical issues with real-time data use, and the scalability of AI solutions are among the areas that have not received enough attention. Closing these gaps is crucial to creating scalable, ethical, and inclusive forecasting systems that promote responsible technology integration, employee well-being, and operational efficiency.

In addition, to help address these identified gaps, the following questions need to be answered:

How can labor scheduling be optimized using reinforcement learning in the face of seasonal demand spikes and SKU volatility?

Which data governance approaches guarantee that employee performance data is used ethically in algorithms for predictive scheduling?

What is the performance of AI-driven labor projections at different facilities with different workforce diversity and automation levels?

In multi-site clothing networks, how do centralized and decentralized labor forecasting models perform differently in real time?

These inquiries serve as a guide for upcoming empirical and modeling studies and represent operational priorities including cost effectiveness, equity, and scalability.

Although the use of AI models for labor forecasting in clothing distribution centers is expanding, it is important to recognize a few significant drawbacks to guarantee ethical implementation. First, the availability of high quality, detailed data such as demand signals at the SKU level, productivity measures at the shift level, and real-time inventory turnover is crucial for these models. This dependence can result in erroneous forecasts and mismatched staffing decisions in fast fashion settings, where trends change every week and prior data may not be useful [

129]. Second, data privacy is still a major issue, especially when predictive systems incorporate biometric, behavioral, or performance-based inputs. AI-driven labor planning runs the danger of breaching employee privacy and undermining confidence in the absence of strong governance frameworks [

130]. Third, the scalability and fairness of many models are limited by their inability to generalize across facilities, labor demographics, and geographical areas. These restrictions highlight the necessity of ethical data handling, transparent model validation, and ongoing performance monitoring to guarantee that AI improves rather than compromises labor equity and operational resilience.

9. Conclusions

Seasonal variations in demand, the proliferation of SKUs, and the emergence of omnichannel fulfillment have made the apparel distribution industry increasingly complex. Because of these factors, traditional labor scheduling techniques are insufficient for handling real-time fluctuations, the deployment of a multiskilled workforce, and ergonomic considerations. This study emphasizes the urgent need for AI-enhanced labor planning tools that boost operational resilience through predictive scheduling and skill-based cross-training. Further enabling inclusive, data-driven workforce strategies in line with performance metrics; and synching workforce capacity with volatile demand cycles. AI-driven labor forecasting is revolutionizing the distribution of apparel by substituting dynamic, data-driven models that use real-time inputs from RFID, WMS, and IoT technologies for static, experience-based scheduling. These solutions increase response to changes in demand, facilitate flexible workforce deployment, and boost flexibility through skill-based planning. Integrated systems specifically designed for apparel logistics are still lacking, despite advancements in discrete fields like analytics and forecasting. More resilient and intelligent supply chain operations are made possible by AI-powered workforce planning, which enhances cost control, service quality, and operational flexibility. Scalable, human-centered AI frameworks that take workforce diversity, ergonomics, and forecasts into account should be the main emphasis of future research.

By connecting theoretical AI frameworks with real-world applications specific to the apparel and fashion industries, especially in emerging economies, this paper makes a unique contribution. This work synthesizes AI approaches across the full value chain, from forecasting and production to retail and sustainability, in contrast to previous studies that concentrate on design or supply chain optimization. The combination of experimental and modeling developments, which are rarely discussed together in literature currently in publication, is a crucial area of originality. The paper lays the groundwork for the adoption of scalable, context-sensitive AI by identifying both methodological innovation and practical problems. A layer of practical relevance that is frequently absent from more general presentations about AI is also added by including case studies and labor forecasting scenarios that are particular to a given region. In addition, the study highlights gaps in existing literature and suggests structured research guideline questions, providing a roadmap for further investigation. The study is positioned as a key resource for academic and industry stakeholders due to its forward-looking viewpoint, emphasis on reproducibility, ethical considerations, and interdisciplinary collaboration.