The Impact of Technological Innovations on Digital Supply Chain Management: The Mediating Role of Artificial Intelligence: An Empirical Study

Abstract

1. Introduction

1.1. Research Problem

1.2. Research Gap

2. Literature Review

2.1. Efficiency in Digital Supply Chain Management

2.1.1. AI Intermediary

2.1.2. Industry 4.0 and Digital Supply Chains

2.2. Digital Dynamic Capability

2.3. Digital Supply Chain Management and Technological Advancements

2.4. The Role of Artificial Intelligence in Supply Chain Management

2.5. Comparison with Existing Studies

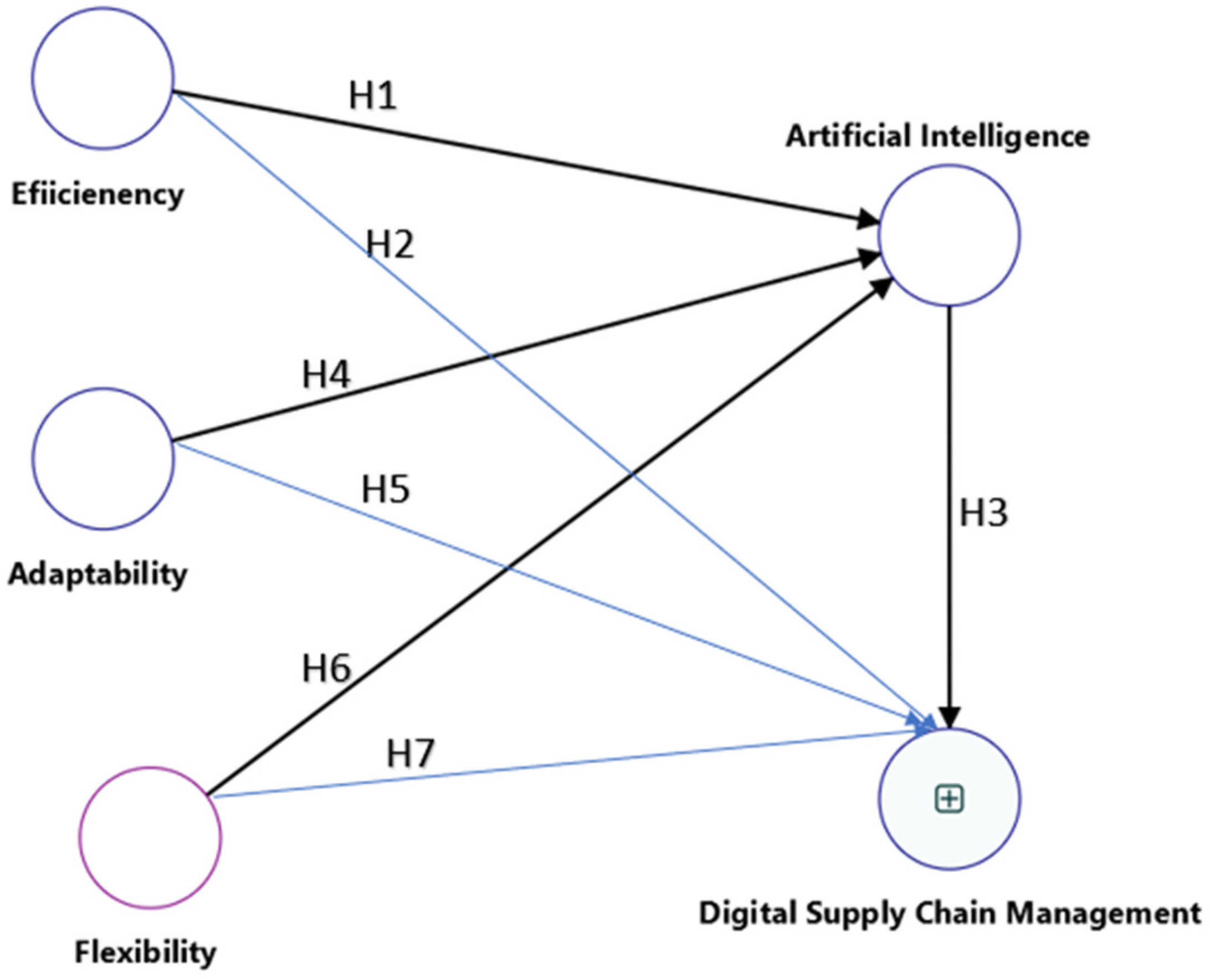

3. Theoretical Framework and Hypothesis Development

4. Research Methodology and Data Analysis

4.1. Research Design and Data Collection

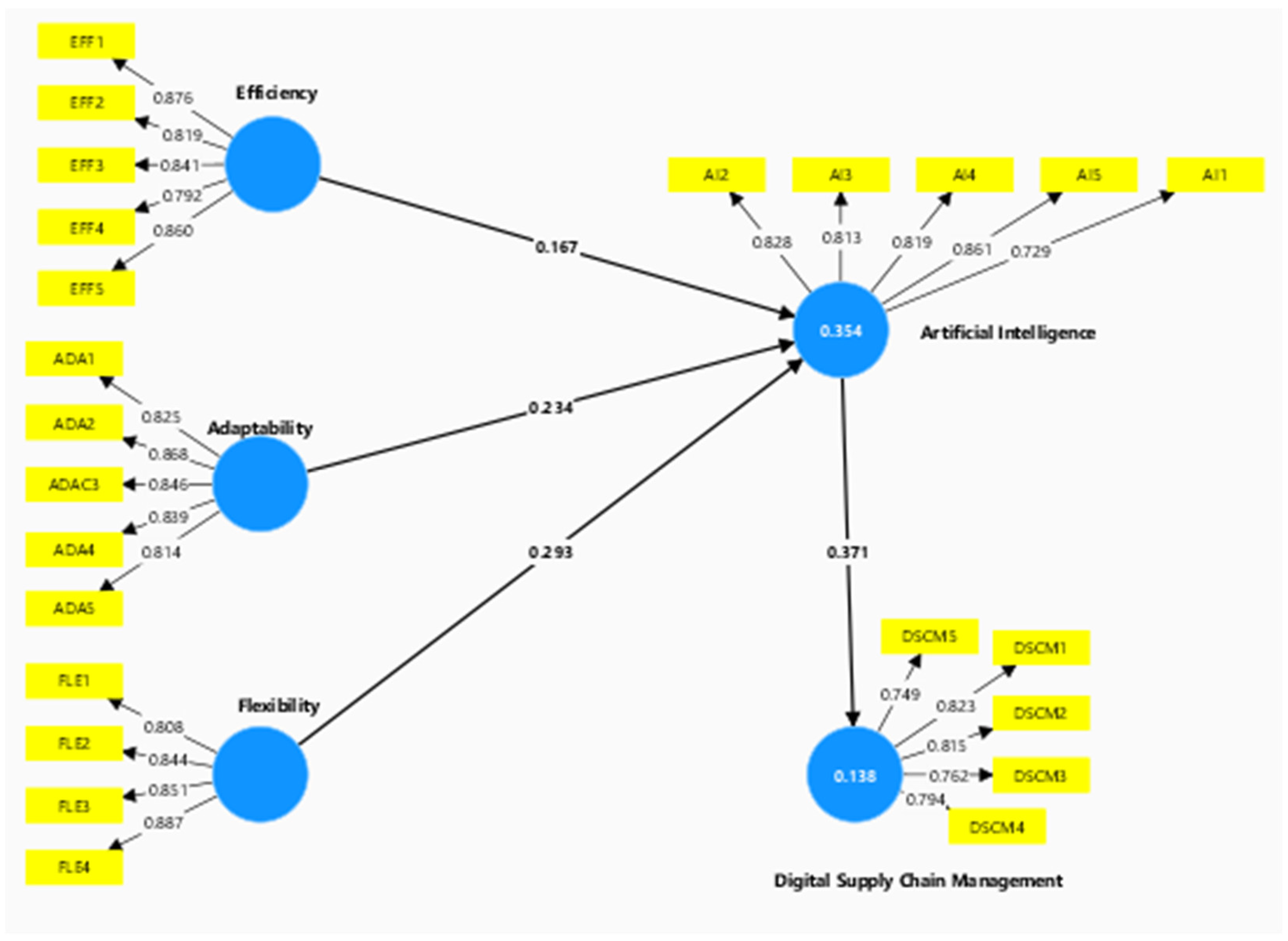

4.2. Data Analysis and Model Validation

4.2.1. Reliability and Convergent Validity

4.2.2. Discriminant Validity (HTMT Ratios)

4.2.3. Discriminant Validity (Fornell–Larcker Criterion)

4.2.4. (R2) Adjusted

4.3. Structural Model

4.3.1. Structural Model Results

4.3.2. Model Fit Indices

5. Findings

5.1. Discussion

5.2. Theoretical Implications

5.3. Managerial Implications

5.4. Strategic Recommendations

5.5. Limitations and Further Research

5.6. Research Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alghizzawi, M.; Omeish, F.; Abdrabbo, T.; Alamro, A.; Al Htibat, A.; Ghani, M.A. The big data analysis and digital marketing. In Opportunities and Risks in AI for Business Development: Volume 2; Springer: Cham, Switzerland, 2024; pp. 1–10. [Google Scholar]

- Al-Ramahi, N.; Kreishan, F.M.; Hussain, Z.; Khan, A.; Alghizzawi, M.; AlWadi, B.M. Unlocking sustainable growth: The role of artificial intelligence adoption in Jordan retail sector, moderated by entrepreneurial orientation. Int. Rev. Manag. Mark. 2024, 14, 143–155. [Google Scholar] [CrossRef]

- Badwan, N.; Al-Khazaleh, S.; Bani Ahmad, A.; AlKhazaleh, A. Impact of board gender diversity on the banking performance sector: Empirical evidence from Palestine. Manag. Sustain. Arab Rev. 2025. [Google Scholar] [CrossRef]

- Salhab, H.A.; Allahham, M.; Abu-Alsondos, I.A.; Frangieh, R.H.; Alkhwaldi, A.F.; Ali, B.J.A. Inventory competition, artificial intelligence, and quality improvement decisions in supply chains with digital marketing. Uncertain Supply Chain Manag. 2023, 11, 1915–1924. [Google Scholar] [CrossRef]

- Rehman, S.U.; Al-Shaikh, M.; Washington, P.B.; Lee, E.; Song, Z.; Abu-AlSondos, I.A.; Shehadeh, M.; Allahham, M. FinTech adoption in SMEs and bank credit supplies: A study on manufacturing SMEs. Economies 2023, 11, 213. [Google Scholar] [CrossRef]

- Hatamlah, H.; Allan, M.; Abu-Alsondos, I.; Shehadeh, M.; Allahham, M. The role of artificial intelligence in supply chain analytics during the pandemic. Uncertain Supply Chain Manag. 2023, 11, 1175–1186. [Google Scholar] [CrossRef]

- Hatamlah, H.; Allahham, M.; Abu-AlSondos, I.A.; Al-junaidi, A.; Al-Anati, G.M.; Al-Shaikh, M. The role of business intelligence adoption as a mediator of big data analytics in the management of outsourced reverse supply chain operations. Appl. Math. Inf. Sci. 2023, 17, 897–903. [Google Scholar] [CrossRef]

- Hatamlah, H.; Allan, M.; Al-Okaily, M.; Alsharareh, H.; Alzoubi, H.; Al-Dmour, R. Assessing the moderating effect of innovation on the relationship between information technology and supply chain management: An empirical examination. Appl. Math. Inf. Sci. 2023, 17, 889–895. [Google Scholar] [CrossRef]

- Jawabreh, O.; Al-Rawashdeh, B.; Ali, B.J.A.; Al-Afeef, M.A.; Alathamneh, F. The influence of supply chain management strategies on organizational performance in hospitality industry. Appl. Math. Inf. Sci. 2023, 17, 851–858. [Google Scholar] [CrossRef]

- Almustafa, E.; Assaf, A.; Allahham, M. The Impact of Digital Transformation on Supply Chain Resilience and Sustainable Performance: Evidence from the Manufacturing Sector in Jordan. Rev. Gestão Soc. Ambient. 2023, 17, 1–17. [Google Scholar]

- Allahham, M.; Bani Ahmad, A.Y.; Ahmad, M.I.; Al-Okaily, A.; Al-Okaily, M.; Alkhwaldi, A.F. AI-induced anxiety in the assessment of factors influencing the adoption of mobile payment services in supply chain firms: A mental accounting perspective. Int. J. Data Netw. Sci. 2024, 8, 505–514. [Google Scholar] [CrossRef]

- Allahham, M.; Sharabati, A.A.A.; Al-Sager, M.; Sabra, S.; Awartani, L.; Khraim, A.S.L. Supply chain risks in the age of big data and artificial intelligence: The role of risk alert tools and managerial apprehensions. Uncertain Supply Chain Manag. 2024, 12, 399–406. [Google Scholar] [CrossRef]

- Allahham, M.; Sharabati, A.A.A.; Hatamlah, H.; Ahmad, A.Y.B.; Sabra, S.; Daoud, M.K. Big data analytics and AI for green supply chain integration and sustainability in hospitals. WSEAS Trans. Environ. Dev. 2023, 19, 1218–1230. [Google Scholar] [CrossRef]

- Alkhazaleh, A.; Assaf, A.; Shehada, M.; Almustafa, E.; Allahham, M. Analysis of the impact of FinTech firms’ lending on the expansion of service base companies in Jordan. Inf. Sci. Lett. 2023, 12, 2891–2902. [Google Scholar] [CrossRef]

- Atieh Ali, A.A.; Sharabati, A.A.A.; Allahham, M.; Nasereddin, A.Y. The relationship between supply chain resilience and digital supply chain and the impact on sustainability: Supply chain dynamism as a moderator. Sustainability 2024, 16, 3082. [Google Scholar] [CrossRef]

- Shehadeh, H.; Shajrawi, A.; Zoubi, M.; Daoud, M. The mediating role of ICT on the impact of supply chain management (SCM) on organizational performance (OP): A field study in pharmaceutical companies in Jordan. Uncertain Supply Chain Manag. 2024, 12, 1251–1266. [Google Scholar] [CrossRef]

- Alrjoub, A.M.S.; Almomani, S.N.; Al-Hosban, A.A.; Allahham, M.I. The impact of financial performance on earnings management practice behavior: An empirical study on financial companies in Jordan. Acad. Strateg. Manag. J. 2021, 20, 1–15. [Google Scholar]

- Sharabati, A.A.A.; Al-Okaily, M.; Al-Kofahi, M.; Alzoubi, H.; Alshurideh, M.; Al-Okaily, A.; Ali, B.J.A. Effects of artificial integration and big data analysis on economic viability of solar microgrids: Mediating role of cost benefit analysis. Oper. Res. Eng. Sci. Theory Appl. 2023, 6, 1–24. [Google Scholar]

- Allahham, M.; Sharabati, A.A.A.; Almazaydeh, L.; Sha-Latony, Q.M.; Frangieh, R.H.; Al-Anati, G.M. The impact of fintech-based eco-friendly incentives in improving sustainable environmental performance: A mediating-moderating model. Int. J. Data Netw. Sci. 2024, 8, 415–430. [Google Scholar] [CrossRef]

- Atieh Ali, A.A.; Sharabati, A.; Alqurashi, D.R.; Shkeer, A.S.; Allahham, M. The impact of artificial intelligence and supply chain collaboration on supply chain resilience: Mediating the effects of information sharing. Uncertain Supply Chain Manag. 2024, 12, 1801–1812. [Google Scholar] [CrossRef]

- Fuqiang, L.; Fan, M.; Hualing, B. Scenario deduction of explosion accidents based on fuzzy dynamic Bayesian network. J. Loss Prev. Process Ind. 2025, 96, 105613. [Google Scholar]

- Sharabati, A.A.A.; Awawdeh, H.Z.; Sabra, S.; Shehadeh, H.K.; Allahham, M.; Ali, A. The role of artificial intelligence on digital supply chain in industrial companies: Mediating effect of operational efficiency. Uncertain Supply Chain Manag. 2024, 12, 1867–1878. [Google Scholar] [CrossRef]

- Sharabati, A.A.A.; Rehman, S.U.; Malik, M.H.; Sabra, S.; Al-Sager, M.; Allahham, M. Is AI biased? Evidence from FinTech-based innovation in supply chain management companies. Int. J. Data Netw. Sci. 2024, 8, 1839–1852. [Google Scholar] [CrossRef]

- Atta, A.A.B.; Ahmad, A.Y.A.B.; Allahham, M.I.; Sisodia, D.R.; Singh, R.R.; Maginmani, U.H. Application of machine learning and blockchain technology in improving supply chain financial risk management. In Proceedings of the International Conference on Contemporary Computing and Informatics, IC3I 2023, Dubai, United Arab Emirates, 20–22 December 2023; IEEE: New York, NY, USA, 2023; pp. 2199–2205. [Google Scholar] [CrossRef]

- Bataineh, A.Q.; Abu-Alsondos, I.; Salhab, H.A.; Al-Abbas, L.S. A structural equation model for analyzing the relationship between enterprise resource planning and digital supply chain management. Uncertain Supply Chain Manag. 2022, 10, 1289–1296. [Google Scholar] [CrossRef]

- Sahioun, A.; Bataineh, A.Q.; Abu-AlSondos, I.; Haddad, H. The impact of green marketing on consumers’ attitudes: A moderating role of green product awareness. Innov. Mark. 2023, 19, 237. [Google Scholar] [CrossRef]

- Bataineh, A.Q.; Abu-AlSondos, I.; Idris, M.; Mushtaha, A.S.; Qasim, D.M. The role of big data analytics in driving innovation in digital marketing. In Proceedings of the 2023 9th International Conference on Optimization and Applications (ICOA), Benguerir, Morocco, 12–13 May 2023; IEEE: New York, NY, USA, 2023; pp. 1–5. [Google Scholar]

- Fridhi, B. The impact of digital marketing on the performance of firms in Tunisia. Appl. Mark. Anal. 2022, 8, 192–205. [Google Scholar] [CrossRef]

- AlSondos, I.A.A.; Salameh, A.A.M.; Engineer, M. Organizing event ubiquitous with a proposed event mobile application in Bahrain. Int. J. Manag. 2020, 11, 215–224. [Google Scholar]

- Abu AlSondos, I.; Salameh, A.A.M. The effect of system quality and service quality toward using m-commerce service, based on consumer perspective. Manag. Sci. Lett. 2020, 10, 2489–2496. [Google Scholar] [CrossRef]

- Salameh, A.A.; Abu-AlSondos, I.; Abu, N.H.; Harun, A.N. Current knowledge and future possibilities of medical digital technologies based on mobile health. Int. J. Interact. Mob. Technol. 2023, 17, 134–147. [Google Scholar] [CrossRef]

- Alhanatleh, H.; Alghizzawi, M.; Alhawamdeh, Z.; Alkhlaifat, B.; Alabaddi, Z.; Al-Kasasbeh, O. Public value of using fintech services’ mobile applications: Citizens’ perspective in a Jordan setting. Uncertain Supply Chain Manag. 2024, 12, 1317–1330. [Google Scholar] [CrossRef]

- Mukattash, I.L.; Alghizzawi, M.; Hmeidan, T.A.; Alrousan, M.K.; Al Khasawneh, M.; Al-Gasawneh, J.A. Consumer perception towards electric cars: An inductive study with specific reference to the Jordanian market. J. Infrastruct. Policy Dev. 2024, 8, 4690. [Google Scholar] [CrossRef]

- Alqurashi, D.R.; Alghizzawi, M.; Al-Hadrami, A. The role of social media in raising awareness of cybersecurity risks. In Opportunities and Risks in AI for Business Development: Volume 1; Springer: Cham, Switzerland, 2024; pp. 365–376. [Google Scholar]

- Alghizzawi, M.; Ahmed, E.; Ezmigna, I.; Ezmigna, A.A.R.; Omeish, F. The relationship between artificial intelligence and digital marketing in business companies. In The AI Revolution: Driving Business Innovation and Research: Volume 2; Springer: Cham, Switzerland, 2024; pp. 885–895. [Google Scholar]

- Alofan, F.; Khalaf, B.F.; Allahham, M. Strategic drivers of AI-based recruitment system adoption in organizations. Int. J. Innov. Res. Sci. Stud. 2025, 8, 2570–2580. [Google Scholar] [CrossRef]

- Abu-Alhaija, A.S.; Allahham, M.; Alsawaha, A.; Almagharbeh, B.K.; Alsharif, N.A. Crisis logistics: The role of disaster relief in supply chain risk management for emergency response. Int. J. Innov. Res. Sci. Stud. 2025, 8, 700–709. [Google Scholar] [CrossRef]

- Al Mawahreh, M.A.L.; Momani, R.A.; Allahham, M.; Almagharbeh, B.K.; Bani Ahmad, A.Y. Unlocking organizational productivity through digital marketing: How value proposition strategy shapes success in the service industry. Int. J. Innov. Res. Sci. Stud. 2025, 8, 2667–2676. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Foroughi, B.; Tseng, M.-L.; Nikbin, D.; Khanfar, A.A. Industry 4.0 digital transformation and opportunities for supply chain resilience: A comprehensive review and a strategic roadmap. Prod. Plan. Control 2025, 36, 61–91. [Google Scholar] [CrossRef]

- Khan, T.; Emon, M.M.H. Supply chain performance in the age of Industry 4.0: Evidence from manufacturing sector. Braz. J. Oper. Prod. Manag. 2025, 22, 2434. [Google Scholar] [CrossRef]

- Shahzad, F.; Liu, H.; Zahid, H. Industry 4.0 technologies and sustainable performance: Do green supply chain collaboration, circular economy practices, technological readiness and environmental dynamism matter? J. Manuf. Technol. Manag. 2025, 36, 1–22. [Google Scholar] [CrossRef]

- Dalain, A.F.; Al-Karabsheh, A.; Allahham, M.I.; Almajali, W.I.; Yamin, M.A.Y.; Habboush, T.M. Business resilience as a mediator in the link between digital logistics strategies and competitive advantage: Insights from emerging markets. Logistics 2025, 9, 78. [Google Scholar] [CrossRef]

- Matrouk, K.M.; Selvi, A.; Ahmad Bani Ahmad, A.Y.; Dhurgadevi, M. An adaptive deep learning-based user authentication with digitally signed optimal key-aided encryption for secured mobile edge computing data storage in blockchain. Int. J. Innov. Res. Sci. Stud. 2025, 269, 111482. [Google Scholar] [CrossRef]

- Alsarayrah, T.; Ali, B.J.A. The moderating role of auditor experience on determinants of computer-assisted auditing tools and techniques. J. Risk Financ. Manag. 2025, 18, 206. [Google Scholar] [CrossRef]

- Qeshta, M.H.M.; Ali, B.J.A.; Abdelaziz, M.S.; Almsni, F.M.; Oroud, Y. Optimal board characteristics for making effective decisions affecting financial performance: An examination study. In Proceedings of the 2024 International Conference on Decision Aid Sciences and Applications (DASA), Istanbul, Turkey, 11–12 November 2024; IEEE: New York, NY, USA, 2024; pp. 1–6. [Google Scholar]

- Abdel Latif Al Mawahreh, M.; Alshar, M.M.; Allahham, M.; Bani Ahmad, A.Y.A. The impact of artificial intelligence on purchase intention, the mediating role of digital engagement. In Proceedings of the 2025 1st International Conference, Dubai, United Arab Emirates, 20–22 February 2025; IEEE: New York, NY, USA, 2025. [Google Scholar]

- Bani Ahmad, A.Y.; Kolachina, S.; Rajest, S.S.; Singh, M.; Mishra, A.; Sundar, S.S. Commitment. Int. J. Intell. Enterp. 2025, 12, 1–21. [Google Scholar]

- Sarkar, A.; Guchhait, R.; Sarkar, B. Application of the artificial neural network with multithreading within an inventory model under uncertainty and inflation. Int. J. Fuzzy Syst. 2022, 24, 2318–2332. [Google Scholar] [CrossRef]

- Zhang, Y.; Kumar, A.; Singh, L. An IoT-based digital twin framework for perishables in cold-chain logistics. IEEE Trans. Ind. Inform. 2024, 20, 2345–2356. [Google Scholar] [CrossRef]

- Yuan, S.; Pan, X. The effects of digital technology application and supply chain management on corporate circular economy: A dynamic capability view. J. Environ. Manag. 2023, 341, 118082. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.; Wang, Y.; Zhang, Q.; Lu, J. Emerging opportunities or paradoxes: Assessing the effect of digital technology adoption on corporate carbon performance. J. Environ. Manag. 2025, 391, 126399. [Google Scholar] [CrossRef] [PubMed]

| Constructs | Cronbach’s Alpha | C.R. | (AVE) |

|---|---|---|---|

| Adaptability | 0.894 | 0.896 | 0.922 |

| Artificial Intelligence | 0.869 | 0.87 | 0.906 |

| Efficiency | 0.894 | 0.898 | 0.922 |

| Flexibility | 0.87 | 0.873 | 0.911 |

| Construct Pair | HTMT Ratio |

|---|---|

| Adaptability—Artificial Intelligence | 0.42 |

| Adaptability—Digital Supply Chain Mgmt. | 0.35 |

| Adaptability—Efficiency | 0.28 |

| Adaptability—Flexibility | 0.30 |

| Artificial Intelligence—Digital SCM | 0.47 |

| Artificial Intelligence—Efficiency | 0.40 |

| Artificial Intelligence—Flexibility | 0.36 |

| Digital SCM—Efficiency | 0.33 |

| Digital SCM—Flexibility | 0.29 |

| Efficiency—Flexibility | 0.31 |

| Adaptability—Artificial Intelligence | 0.42 |

| Adaptability—Digital Supply Chain Mgmt. | 0.35 |

| Adaptability | Artificial Intelligence | Digital Supply Chain Management | Efficiency | Flexibility | |

|---|---|---|---|---|---|

| Adaptability | 0.838 | ||||

| Artificial Intelligence | 0.483 | 0.811 | |||

| Digital Supply Chain Management | 0.388 | 0.371 | 0.789 | ||

| Efficiency | 0.585 | 0.511 | 0.541 | 0.838 | |

| Flexibility | 0.516 | 0.532 | 0.587 | 0.707 | 0.848 |

| Variable | R2 | R2 Adjusted |

|---|---|---|

| Artificial Intelligence | 0.354 | 0.347 |

| Digital Supply Chain Management | 0.138 | 0.134 |

| Hypo | Relationships | Beta | Standard Error | T Statistics | p Values | Decision |

|---|---|---|---|---|---|---|

| H1 | Adaptability -> Artificial Intelligence | 0.234 | 0.069 | 3.373 | 0.001 | Supported |

| H2 | Adaptability -> Digital Supply Chain Management | 0.087 | 0.032 | 2.75 | 0.006 | Supported |

| H3 | Artificial Intelligence -> Digital Supply Chain Management | 0.371 | 0.086 | 4.291 | 0 | Supported |

| H4 | Efficiency -> Artificial Intelligence | 0.167 | 0.081 | 2.058 | 0.04 | Supported |

| H5 | Efficiency -> Digital Supply Chain Management | 0.062 | 0.036 | 1.71 | 0.087 | Unsupported |

| H6 | Flexibility -> Artificial Intelligence | 0.293 | 0.083 | 3.529 | 0 | Supported |

| H7 | Flexibility -> Digital Supply Chain Management | 0.109 | 0.044 | 2.456 | 0.014 | Supported |

| Hypo | Relationships | Standardized Beta | Standard Error | T Statistics | p Values | Decision |

|---|---|---|---|---|---|---|

| H8 | Adaptability -> Digital Supply Chain Management | 0.087 | 0.032 | 2.75 | 0.006 | Supported |

| H9 | Efficiency -> Digital Supply Chain Management | 0.062 | 0.036 | 1.71 | 0.087 | Unsupported |

| H10 | Flexibility -> Digital Supply Chain Management | 0.109 | 0.044 | 2.456 | 0.014 | Supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dalain, A.F.; Alnadi, M.; Allahham, M.I.; Yamin, M.A. The Impact of Technological Innovations on Digital Supply Chain Management: The Mediating Role of Artificial Intelligence: An Empirical Study. Logistics 2025, 9, 138. https://doi.org/10.3390/logistics9040138

Dalain AF, Alnadi M, Allahham MI, Yamin MA. The Impact of Technological Innovations on Digital Supply Chain Management: The Mediating Role of Artificial Intelligence: An Empirical Study. Logistics. 2025; 9(4):138. https://doi.org/10.3390/logistics9040138

Chicago/Turabian StyleDalain, Ali F., Mohammad Alnadi, Mahmoud Izzat Allahham, and Mohammad Ali Yamin. 2025. "The Impact of Technological Innovations on Digital Supply Chain Management: The Mediating Role of Artificial Intelligence: An Empirical Study" Logistics 9, no. 4: 138. https://doi.org/10.3390/logistics9040138

APA StyleDalain, A. F., Alnadi, M., Allahham, M. I., & Yamin, M. A. (2025). The Impact of Technological Innovations on Digital Supply Chain Management: The Mediating Role of Artificial Intelligence: An Empirical Study. Logistics, 9(4), 138. https://doi.org/10.3390/logistics9040138