Multi-Criteria Decision Support for Sustainable Supplier Evaluation in Mining SMEs: A Fuzzy Logic and TOPSIS Approach

Abstract

1. Introduction

- What are the most relevant sustainability-related criteria for evaluating suppliers in the context of mining SMEs?

- How can a hybrid decision-making framework combining a conventional ranking method and fuzzy logic address the inherent uncertainty and subjectivity in supplier evaluation?

- How do the results of the hybrid framework compare to conventional decision-making methods in selecting the most appropriate supplier?

- What practical insights can be drawn from applying this hybrid framework to a real-world mining SME case study to guide future supplier selection decisions?

2. Literature Review

2.1. Asset Management in the Mining Sector

Computerized Maintenance Management System (CMMS)

2.2. Multi-Criteria Decision Making

3. Materials and Methods

3.1. TOPSIS Model

3.2. FUZZY Model

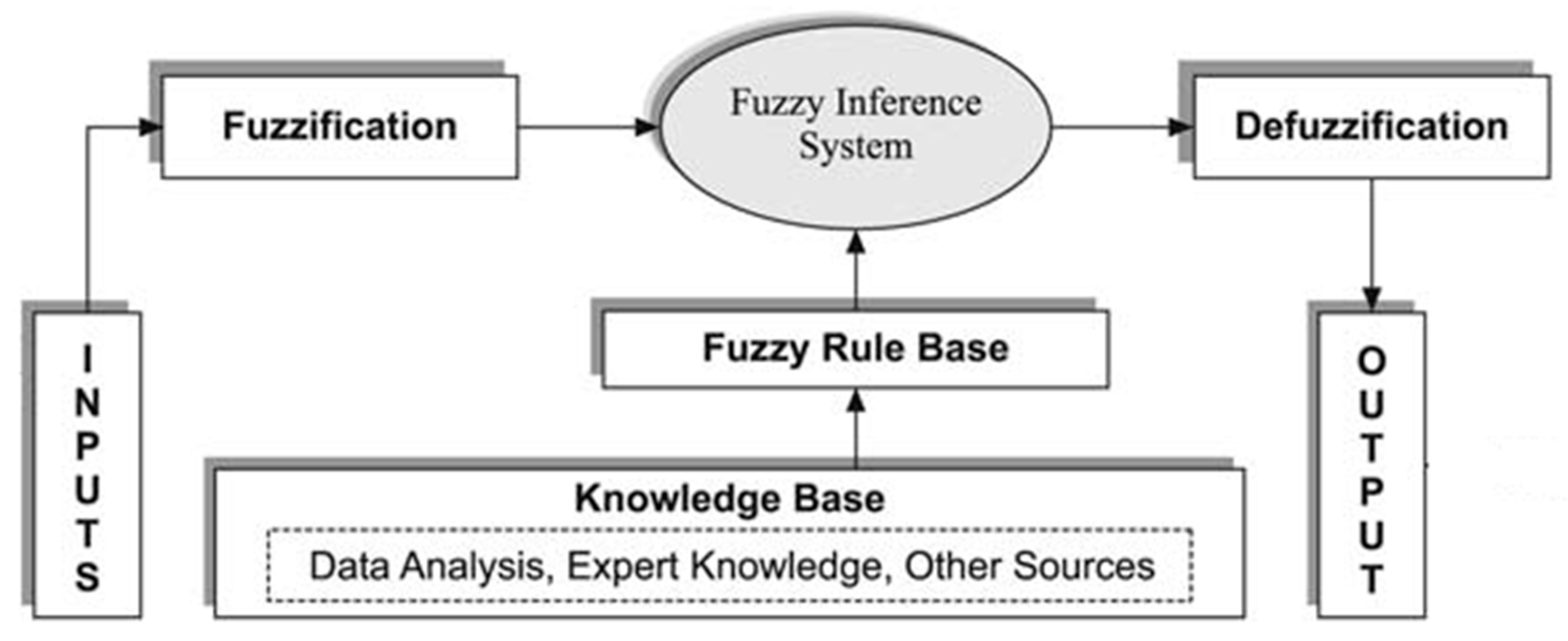

3.2.1. Basic Structure of a Fuzzy Inference System

3.2.2. Fuzzy Model Notation and Formulation

4. Results

4.1. Solution Procedure

Supplier Selection for the Computerized Maintenance Management System (CMMS)

4.2. Detailed Analysis of CMMS Selection Using the TOPSIS Model

4.3. Detailed Analysis of CMMS Selection Using the Fuzzy Model

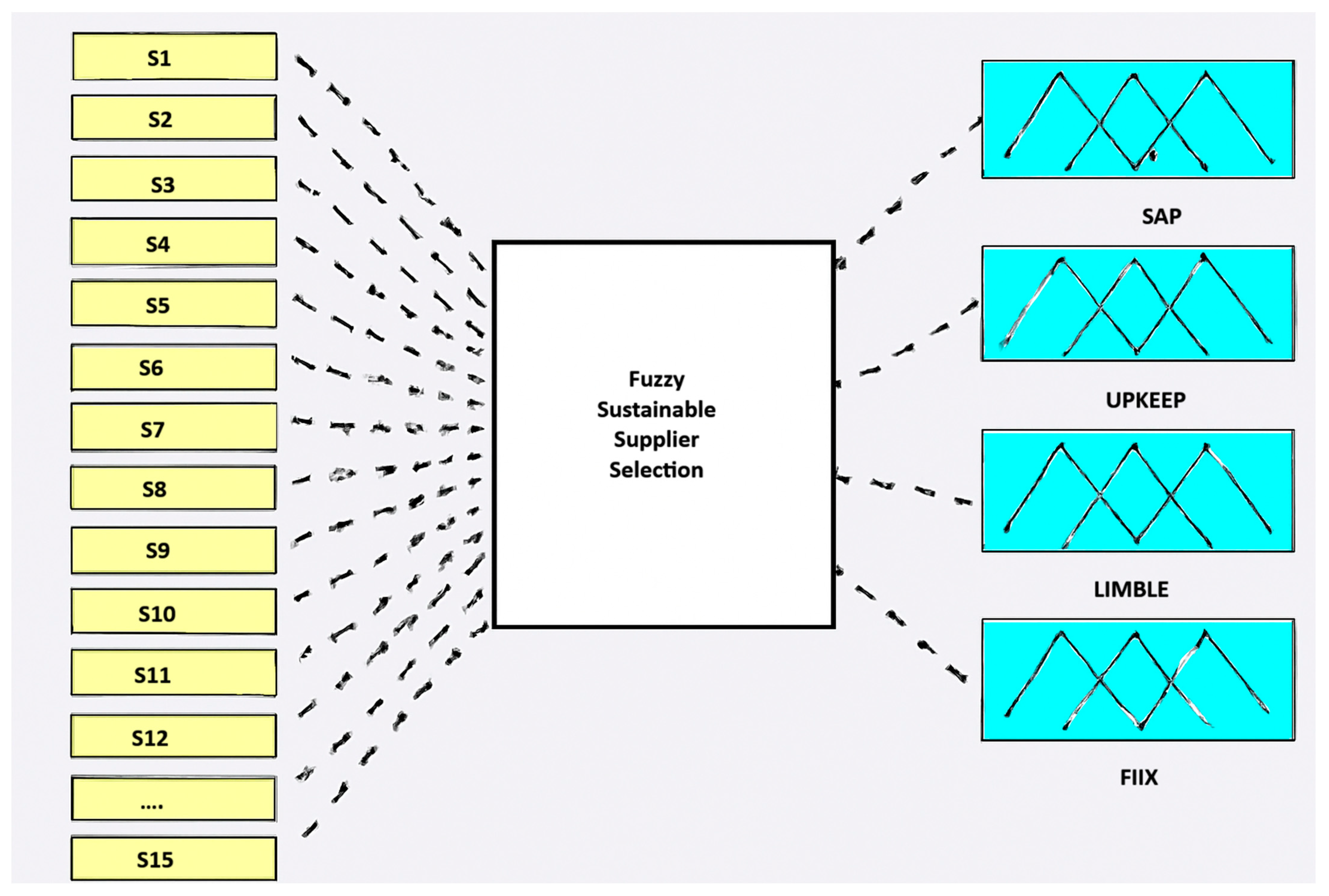

4.3.1. Fuzzy Logic Model Procedure for Sustainable Supplier Selection

4.3.2. Construction of the Fuzzy Decision Matrix

- Purchase Cost (S1) Ratings:

- ○

- SAP = 3 → Fair → (0.25, 0.5, 0.75)

- ○

- UPKEEP = 4 → Good → (0.5, 0.75, 1.0)

- ○

- LIMBLE = 5 → Very Good → (0.75, 1.0, 1.0)

- ○

- FIIX = 4 → Good → (0.5, 0.75, 1.0)

4.3.3. Normalization of the Fuzzy Decision Matrix

4.3.4. Assigning Fuzzy Weights to Criteria

4.3.5. Fuzzy Weighted Normalized Matrix Computation

4.3.6. Calculation of the Distance from FPIS to FNIS and the Closeness Coefficient

4.3.7. Ranking the Alternatives

5. Conclusions

5.1. Managerial Implications

5.2. Future Direction

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| AHP | Analytic Hierarchy Process |

| ANP | Analytic Network Process |

| CMMS | Computerized Maintenance Management System |

| CSC | Cold Supply Chain |

| DEA | Data Envelopment Analysis |

| DMs | Decision-Makers |

| eMA | Enterprise Asset Management |

| FDEMATEL | Fuzzy Decision-Making Trial and Evaluation Laboratory |

| FAHP | Fuzzy Analytic Hierarchy Process |

| FPIS | Fuzzy Positive Ideal Solution |

| FNIS | Fuzzy Negative Ideal Solution |

| FST | Fuzzy Set Theory or Fuzzy Solution Toolbox |

| H | High |

| IOT | Internet of Things |

| L | Low |

| M | Medium |

| MADM | Multi-Attribute Decision Making |

| MCDM | Multi-Criteria Decision Making |

| O&M | Operations & Maintenance |

| SDGs | Sustainable Development Goals |

| SMEs | Small and Medium Enterprises |

| SS | Supplier Selection |

| TFN | Triangular Fuzzy Number |

| TOPSIS | Technique for Order of Preference by Similarity to Ideal Solution |

| VL or VP | Very Low or Very Poor |

| VH or VG | Very High or Very Good |

References

- Clausen, E.; Sörensen, A. Required and desired: Breakthroughs for future-proofing mineral and metal extraction. Miner. Econ. 2022, 35, 521–537. [Google Scholar] [CrossRef]

- Kim, T.; Shin, J.; Hyung, J.; Kim, K.; Koo, J.; Cha, Y. Willingness to pay for improved water supply services based on asset management: A contingent valuation study in South Korea. Water 2021, 13, 2040. [Google Scholar] [CrossRef]

- Gupta, R. Examining the impact of green logistics practices on supply chain resilience. Res. Square 2024. [Google Scholar] [CrossRef]

- Abdul-Rashid, S.H.; Sakundari, N.; Ghazilla, R.A.R.; Ramayah, T. The impact of sustainable manufacturing practices on sustainability performance. Int. J. Oper. Amp. Prod. Manag. 2017, 37, 182–204. [Google Scholar] [CrossRef]

- Abdulla, A.; Baryannis, G.; Badi, I. An integrated machine learning and MARCOS method for supplier evaluation and selection. Decis. Anal. J. 2023, 9, 100342. [Google Scholar] [CrossRef]

- Ghobadian, A.; Stainer, A.; Liu, J.; Kiss, T. A computerised vendor rating system. In Developments in Logistics Supply Chain Management; Palgrave Macmillan: London, UK, 2016; pp. 103–112. [Google Scholar]

- Azeem, M.; Haleem, A.; Bahl, S.; Javaid, M.; Suman, R.; Nandan, D. Big data applications to take up major challenges across manufacturing industries: A brief review. Mater. Today Proc. 2021, 49, 339–348. [Google Scholar] [CrossRef]

- Gregory, T.D.; Perry, M.L.; Albertus, P. Cost and price projections of synthetic active materials for redox flow batteries. J. Power Sources 2021, 499, 229965. [Google Scholar] [CrossRef]

- Memari, A.; Dargi, A.; Akbari Jokar, M.R.; Ahmad, R.; Abdul Rahim, A.R. Sustainable supplier selection: A multi-criteria intuitionistic fuzzy TOPSIS method. J. Manuf. Syst. 2019, 50, 9–24. [Google Scholar] [CrossRef]

- Buyukozkan, G.; Gocer, F. A novel approach integrating AHP and COPRAS under pythagorean fuzzy sets for digital supply chain partner selection. IEEE Trans. Eng. Manag. 2019, 68, 1486–1503. [Google Scholar] [CrossRef]

- Ali, M.R.; Nipu, S.M.A.; Khan, S.A. A decision support system for classifying supplier selection criteria using machine learning and random forest approach. Decis. Anal. J. 2023, 7, 100238. [Google Scholar] [CrossRef]

- Chen, K.S.; Wang, C.H.; Tan, K.H. Developing a fuzzy green supplier selection model using six sigma quality indices. Int. J. Prod. Econ. 2019, 212, 1–7. [Google Scholar] [CrossRef]

- Liu, Y.; Eckert, C.; Yannou-Le Bris, G.; Petit, G. A fuzzy decision tool to evaluate the sustainable performance of suppliers in an agrifood value chain. Comput. Ind. Eng. 2019, 127, 196–212. [Google Scholar] [CrossRef]

- Sumrit, D. Supplier selection for vendor-managed inventory in healthcare using fuzzy multi-criteria decision-making approach. Decis. Sci. Lett. 2020, 9, 233–256. [Google Scholar] [CrossRef]

- Liao, C.N.; Kao, H.P. An integrated fuzzy TOPSIS and MCGP approach to supplier selection in supply chain management. Expert Syst. Appl. 2011, 38, 10803–10811. [Google Scholar] [CrossRef]

- Chai, J.; Liu, J.N.; Ngai, E.W. Application of decision-making techniques in supplier selection: A systematic review of literature. Expert Syst. Appl. 2013, 40, 3872–3885. [Google Scholar]

- Cooper, M. Understanding supplier selection criteria: Perspectives from procurement professionals in diverse industries. Preprints 2024, 2024070744. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P.K. Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Zakeri, S.; Chatterjee, P.; Cheikhrouhou, N.; Konstantas, D. Ranking based on optimal points and win-loss-draw multi-criteria decision-making with application to supplier evaluation problem. Expert Syst. Appl. 2022, 191, 116258. [Google Scholar] [CrossRef]

- Dweiri, F.; Kumar, S.; Khan, S.A.; Jain, V. Designing an integrated AHP based decision support system for supplier selection in automotive industry. Expert Syst. Appl. 2016, 62, 273–283. [Google Scholar] [CrossRef]

- Quan, M.Y.; Wang, Z.L.; Liu, H.C.; Shi, H. A hybrid MCDM approach for large group green supplier selection with uncertain linguistic information. IEEE Access 2018, 6, 50372–50383. [Google Scholar] [CrossRef]

- Kannan, D.; Mina, H.; Nosrati-abarghooee, S.; Khosrojerdi, G. Sustainable circular supplier selection: A novel hybrid approach. Sci. Total Environ. 2020, 722, 137936. [Google Scholar] [CrossRef]

- Parra, C.; González-Prida, V.; Candón, E.; Martínez-Galán, P.; Crespo, A. Integration of asset management standard ISO55000 with a maintenance management model. In Proceedings of the World Congress on Engineering Asset Management, Singapore, 28–31 July 2019; Springer: Cham, Switzerland, 2020; pp. 189–200. [Google Scholar]

- Alvarez-Romero, S.O. Use of Building Information Modeling Technology in the Integration of the Handover Process and Facilities Management. Doctoral Dissertation, Worcester Polytechnic Institute, Worcester, MA, USA, 2014. Available online: https://www.wpi.edu/Pubs/ETD/Available/etd-090914…/Disertation_final_SA.pdf (accessed on 10 March 2018).

- Pärn, E.A.; Edwards, D.J.; Sing, M.C.P. The building information modelling trajectory in facilities management: A review. Autom. Constr. 2017, 75, 45–55. [Google Scholar] [CrossRef]

- Lu, Q.; Chen, L.; Lee, S.; Zhao, X. Activity theory-based analysis of BIM implementation in building O&M and first response. Autom. Constr. 2018, 85, 317–332. [Google Scholar]

- Sabol, L. Challenges in Cost Estimating with Building Information Modeling. IFMA World Workplace. 2008, 1, pp. 1–16.

- Sivakumar, R.; Sivakumar, D.; Kannan, P. Murugesan Green vendor evaluation and selection using AHP and Taguchi loss functions in production outsourcing in mining industry. Resour. Policy 2014, 46, 64–75. [Google Scholar] [CrossRef]

- Lin, N.; Devinney, T.M.; Holcomb, T.R. Examining managerial preferences and choices: The role of value creation and value appropriation drivers in strategic outsourcing. Long Range Plan. 2016, 49, 706–722. [Google Scholar] [CrossRef]

- Chikatamarla, L.; Prasad, D.N. Emerging Mining Trends: Preparing Future Mining Professionals. In Proceedings of the International Conference on Emerging Trends in Engineering (ICETE), Hyderabad, India, 22–23 March 2019; Learning and Analytics in Intelligent Systems 2020. Satapathy, S., Raju, K., Molugaram, K., Krishnaiah, A., Tsihrintzis, G., Eds.; Springer: Cham, Switzerland, 2020; Volume 2. [Google Scholar] [CrossRef]

- Sultana, I.; Ahmed, I.; Azeem, A. An integrated approach for multiple criteria supplier selection combining Fuzzy Delphi, Fuzzy AHP & Fuzzy TOPSIS. J. Intell. Fuzzy Syst. 2015, 29, 1273–1287. [Google Scholar] [CrossRef]

- Faisal, M.; Al-Esmael, B.; Sharif, K. Supplier selection for a sustainable supply chain: Triple bottom line (3BL) and analytic network process approach. Benchmarking Int. J. 2017, 24, 1956–1976. [Google Scholar] [CrossRef]

- Ortiz Barrios, M.; Cabarcas Reyes, J.; Ishizaka, A.; Barbati, M.; Jaramillo Rueda, N.; Carrascal Zambrano, G.d.J. A hybrid fuzzy multi criteria decision making model for selecting a sustainable supplier of forklift filters: A case study from the mining industry. Ann. Oper. Res. 2021, 307, 443–481. [Google Scholar] [CrossRef]

- Ishizaka, A.; Nemery, P. Multi-Criteria Decision Analysis; Wiley: Chichester, UK, 2013. [Google Scholar]

- Lo, H.W. A data-driven decision support system for sustainable supplier evaluation in the Industry 5.0 era: A case study for medical equipment manufacturing. Adv. Eng. Inform. 2023, 56, 101998. [Google Scholar] [CrossRef]

- Minardi, F.; Botta-Genoulaz, V.; Mangano, G. A Systematic Review of Sustainable Supply Chain Management Practices in Food Industry. In Proceedings of the Working Conference on Virtual Enterprises, Saint-Étienne, France, 22–24 November 2021; Springer: Cham, Switzerland, 2021; pp. 19–30. [Google Scholar]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2018, 57, 2117–2135. [Google Scholar] [CrossRef]

- Yazdani, M.; Pamucar, D.; Chatterjee, P.; Ebadi, A. A multi-tier sustainable food supplier selection model under uncertainty. Oper. Manag. Res. 2022, 15, 116–145. [Google Scholar] [CrossRef]

- Abdulla, A.; Baryannis, G.; Badi, I. Weighting the key features affecting supplier selection using machine learning techniques. In Proceedings of the 7th International Conference on Transport and Logistics, Niš, Serbia, 6 December 2019; pp. 15–20. [Google Scholar]

- Liou, J.J.; Chang, M.H.; Lo, H.W.; Hsu, M.H. Application of an MCDM model with data mining techniques for green supplier evaluation and selection. Appl. Soft Comput. 2021, 109, 107534. [Google Scholar] [CrossRef]

- Ullah, A.; Yousaf, K. Sustainable supplier selection for the cold supply chain (CSC) in the context of a developing country. Environ. Dev. Sustain. 2021, 23, 13135–13164. [Google Scholar] [CrossRef]

- Nurjanni, K.P.; Carvalho, M.S.; Costa, L. Green supply chain design: A mathematical modeling approach based on a multi-objective optimization model. Int. J. Prod. Econ. 2017, 183, 421–432. [Google Scholar] [CrossRef]

- Shao, Y.; Barnes, D.; Wu, C. External R&D supplier evaluation and selection: A three-stage integrated funnel model. IEEE Trans. Eng. Manag. 2022, 71, 4101–4115. [Google Scholar]

- Wu, C.; Barnes, D. Partner selection in green supply chains using PSO—A practical approach. Prod. Plan. Control 2016, 27, 1041–1061. [Google Scholar] [CrossRef]

- Ghorbani, M.; Arabzad, S.M.; Shahin, A. A novel approach for supplier selection based on the Kano model and fuzzy MCDM. Int. J. Prod. Res. 2013, 51, 5469–5484. [Google Scholar] [CrossRef]

- Lima Junior, F.R.; Osiro, L.; Carpinetti, L.C.R. A comparison between fuzzy AHP and fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Bai, C.; Zhu, Q.; Sarkis, J. Supplier portfolio selection and order allocation under carbon neutrality: Introducing a cooling model. Comput. Ind. Eng. 2022, 170, 108335. [Google Scholar] [CrossRef]

- Van der Rhee, B.; Verma, R.; Plaschka, G. Understanding trade-offs in the supplier selection process: The role of flexibility, delivery, and value-added services/support. Int. J. Prod. Econ. 2009, 120, 30–41. [Google Scholar] [CrossRef]

- Wu, C.; Barnes, D. Formulating partner selection criteria for agile supply chains: A Dempster–Shafer belief acceptability optimisation approach. Int. J. Prod. Econ. 2010, 125, 284–293. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, J.; Jiang, X.; Zhong, L. Two MAGDM models based on hesitant fuzzy linguistic term sets with possibility distributions: VIKOR and TOPSIS. Inform. Sci. 2019, 473, 101–120. [Google Scholar] [CrossRef]

- Chen, S.M.; Han, W.H. An improved MADM method using interval-valued intuitionistic fuzzy values. Inform. Sci. 2018, 467, 489–505. [Google Scholar] [CrossRef]

- Li, C.C.; Rodríguez, R.M.; Martínez, L.; Dong, Y.; Herrera, F. Consistency of hesitant fuzzy linguistic preference relations: An interval consistency index. Inform. Sci. 2018, 432, 347–361. [Google Scholar] [CrossRef]

- Liu, P.; Chen, S.M. Multiattribute group decision making based on intuitionistic 2-tuple linguistic information. Inform. Sci. 2018, 430, 599–619. [Google Scholar] [CrossRef]

- Islam, S.; Amin, S.H.; Wardley, L.J. Machine learning and optimization models for supplier selection and order allocation planning. Int. J. Prod. Econ. 2021, 242, 108315. [Google Scholar] [CrossRef]

- Khan, M.M.; Bashar, I.; Minhaj, G.M.; Wasi, A.I.; Hossain, N.U.I. Resilient and sustainable supplier selection: An integration of SCOR 4.0 and machine learning approach. Sustain. Resil Infrastruct. 2023, 8, 453–469. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.; Garg, C. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Ishizaka, A. Comparison of fuzzy logic, AHP, FAHP and hybrid fuzzy AHP for new supplier selection and its performance analysis. Int. J. Integr. Supply Manag. 2014, 9, 1–22. [Google Scholar] [CrossRef]

- Barrios, M.; De Felice, F.; Negrete, K.; Romero, B.; Arenas, A.; Petrillo, A. An AHP-Topsis integrated model for selecting the most appropriate tomography equipment. Int. J. Inf. Technol. Decis. Mak. 2016, 15, 861–885. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Zavadskas, E.; Govindan, K.; Antucheviciene, J.; Turskis, Z. Hybrid multiple criteria decision-making methods: A review of applications for sustainability issues. Econ. Res.-Ekon. Istraživanja 2016, 29, 857–887. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Chang, B.; Chang, C.; Wu, C. Fuzzy DEMATEL method for developing supplier selection criteria. Expert Syst. Appl. 2011, 38, 1850–1858. [Google Scholar] [CrossRef]

- Lin, K.-P.; Tseng, M.-L.; Pai, P.-F. Sustainable supply chain management using approximate fuzzy DEMATEL method. Resour. Conserv. Recycl. 2018, 128, 134–142. [Google Scholar] [CrossRef]

- Rashidi, K.; Cullinane, K. A comparison of fuzzy DEA and fuzzy TOPSIS in sustainable supplier selection: Implications for sourcing strategy. Expert Syst. Appl. 2019, 121, 266–281. [Google Scholar] [CrossRef]

| Semantic Attributes | Corresponding Values |

|---|---|

| Very high | 5 |

| High | 4 |

| Moderate | 3 |

| Low | 2 |

| Very low | 1 |

| S/N | Variables | Parameters |

|---|---|---|

| 1 | C1 | Purchase Cost |

| 2 | C2 | Installation/Setup Cost |

| 3 | C3 | Maintenance Cost |

| 4 | C4 | Integration with Organization |

| 5 | C5 | Compatibility with other Software |

| 6 | C6 | Reliability and Efficiency |

| 7 | C7 | Interactiveness and User-friendliness |

| 8 | C8 | Inventory Management |

| 9 | C9 | Calibration Management |

| 10 | C10 | Report Generation |

| 11 | C11 | Billing and Invoicing |

| 12 | C12 | Access Control |

| 13 | C13 | Backup System |

| 14 | C14 | Cloud Solution |

| 15 | C15 | Adoption of IOT Devices and Predictive Maintenance |

| Sustainability Factors | SAP | UPKEEP | LIMBLE | FIIX |

|---|---|---|---|---|

| Purchase Cost (S1) | 3 | 4 | 5 | 4 |

| Installation/Setup Cost (S2) | 3 | 4 | 4 | 4 |

| Maintenance Cost (S3) | 3 | 4 | 5 | 5 |

| Integration with Organization (S4) | 4 | 5 | 3 | 5 |

| Compatibility with other Software (S5) | 4 | 5 | 3 | 4 |

| Reliability and Efficiency (S6) | 5 | 5 | 4 | 4 |

| Interactive and User-friendliness (S7) | 4 | 5 | 4 | 4 |

| Report Generation (S8) | 5 | 5 | 3 | 5 |

| Access Control (S9) | 4 | 5 | 3 | 4 |

| Backup System (S10) | 4 | 4 | 4 | 4 |

| Cloud Solution (S11) | 4 | 4 | 4 | 4 |

| Adoption of IOT Devices and Predictive Maintenance (S12) | 4 | 4 | 3 | 4 |

| Inventory Management (S13) | 4 | 5 | 3 | 4 |

| Billing and Invoicing (S14) | 4 | 5 | 3 | 4 |

| Calibration Management (S15) | 4 | 4 | 3 | 4 |

| Sustainability Factors | SAP | UPKEEP | LIMBLE | FIIX |

|---|---|---|---|---|

| Purchase Cost (S1) | 0.3693 | 0.4924 | 0.6155 | 0.4924 |

| Installation/Setup Cost (S2) | 0.3974 | 0.5298 | 0.5298 | 0.5298 |

| Maintenance Cost (S3) | 0.3464 | 0.4619 | 0.5774 | 0.5774 |

| Integration with Organization (S4) | 0.4619 | 0.5774 | 0.3464 | 0.5774 |

| Compatibility with other Software (S5) | 0.4924 | 0.6155 | 0.3693 | 0.4924 |

| Reliability and Efficiency (S6) | 0.5522 | 0.5522 | 0.4417 | 0.4417 |

| Interactive and User-friendliness (S7) | 0.4682 | 0.5852 | 0.4682 | 0.4682 |

| Report Generation (S8) | 0.5455 | 0.5455 | 0.3273 | 0.5455 |

| Access Control (S9) | 0.4924 | 0.6155 | 0.3693 | 0.4924 |

| Backup System (S10) | 0.5000 | 0.5000 | 0.5000 | 0.5000 |

| Cloud Solution (S11) | 0.5000 | 0.5000 | 0.5000 | 0.5000 |

| Adoption of IOT Devices and Predictive Maintenance (S12) | 0.5298 | 0.5298 | 0.3974 | 0.5298 |

| Inventory Management (S13) | 0.4619 | 0.5774 | 0.3464 | 0.5774 |

| Calibration Management (S15) | 0.4924 | 0.6155 | 0.3693 | 0.4924 |

| Sustainability Factors | SAP | UPKEEP | LIMBLE | FIIX |

|---|---|---|---|---|

| Purchase Cost (S1) | 0.0246 | 0.0328 | 0.0410 | 0.0328 |

| Installation/Setup Cost (S2) | 0.0265 | 0.0353 | 0.0353 | 0.0353 |

| Maintenance Cost (S3) | 0.0231 | 0.0308 | 0.0385 | 0.0385 |

| Integration with Organization (S4) | 0.0308 | 0.0385 | 0.0231 | 0.0385 |

| Compatibility with other Software (S5) | 0.0328 | 0.0410 | 0.0246 | 0.0328 |

| Reliability and Efficiency (S6) | 0.0368 | 0.0368 | 0.0294 | 0.0294 |

| Interactive and User-friendliness (S7) | 0.0312 | 0.0390 | 0.0312 | 0.0312 |

| Report Generation (S8) | 0.0364 | 0.0364 | 0.0218 | 0.0364 |

| Access Control (S9) | 0.0328 | 0.0410 | 0.0246 | 0.0328 |

| Backup System (S10) | 0.0333 | 0.0333 | 0.0333 | 0.0333 |

| Cloud Solution (S11) | 0.0333 | 0.0333 | 0.0333 | 0.0333 |

| Adoption of IOT Devices and Predictive Maintenance (S12) | 0.0353 | 0.0353 | 0.0265 | 0.0353 |

| Inventory Management (S13) | 0.0308 | 0.0385 | 0.0231 | 0.0385 |

| Calibration Management (S15) | 0.0328 | 0.0410 | 0.0246 | 0.0328 |

| SAP | UPKEEP | LIMBLE | FIIX | |

|---|---|---|---|---|

| Positive ideal solution (P+) | 0.0195 | 0.0143 | 0.0485 | 0.0264 |

| Negative ideal solution (P−) | 0.0364 | 0.0435 | 0.0000 | 0.0333 |

| (P+) + (P−) | 0.0560 | 0.0578 | 0.0485 | 0.0598 |

| Closeness coefficient (A) | 0.6510 | 0.7525 | 0.0000 | 0.5576 |

| Ranking | 2 | 1 | 4 | 3 |

| S/N | Linguistic Term | Fuzzy Number/Triangular |

|---|---|---|

| 1 | Very Poor (VP)/VL | 0.0, 0.0, 0.25/0.0, 0.1, 0.3 |

| 2 | Poor (P)/L | 0.0, 0.25, 0,5/0.1, 0.3, 0.5 |

| 3 | Fair (F)/M | 0.25, 0.5, 0.75/0.3, 0.5, 0.7 |

| 4 | Good (G)/H | 0.5, 0.75, 1.0/0.5, 0.7, 0.9 |

| 5 | Very Good (VG)/VH | 0.75, 1.0, 1.0/0.7, 0.9, 1 |

| S/N | Criterion | Code | Importance Level | Triangular Fuzzy Number |

|---|---|---|---|---|

| 1 | Purchase Cost | S1 | High | (0.5, 0.7, 0.9) |

| 2 | Installation/Setup Cost | S2 | Medium | (0.3, 0.5, 0.7) |

| 3 | Maintenance Cost | S3 | High | (0.5, 0.7, 0.9) |

| 4 | Integration with Organization | S4 | Very | (0.7, 0.9, 1.0) |

| 5 | Compatibility with other Software | S5 | High | (0.5, 0.7, 0.9) |

| 6 | Reliability and Efficiency | S6 | Very high | (0.7, 0.9, 1.0) |

| 7 | Interactive and User-friendliness | S7 | Medium | (0.3, 0.5, 0.7) |

| 8 | Report Generation | S8 | Medium | (0.3, 0.5, 0.7) |

| 9 | Access Control | S9 | Medium | (0.3, 0.5, 0.7) |

| 10 | Backup System | S10 | Low | (0.1, 0.3, 0.5) |

| 11 | Cloud Solution | S11 | Medium | (0.3, 0.5, 0.7) |

| 12 | Adoption of IoT Devices and Predictive Maintenance | S12 | High | (0.5, 0.7, 0.9) |

| 13 | Inventory Management | S13 | High | (0.5, 0.7, 0.9) |

| 14 | Billing and Invoicing | S14 | Medium | (0.3, 0.5, 0.7) |

| 15 | Calibration Management | S15 | Low | (0.1, 0.3, 0.5) |

| S/N | CMMS | CCi | Rank |

|---|---|---|---|

| 1 | UPKEEP | Highest | 1st (Best) |

| 2 | SAP | Second Highest | 2nd |

| 3 | FIIX | Third highest | 3rd |

| 4 | LIMBLE | Lowest | 4th (Least) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gidiagba, J.O.; Okwu, M.; Tartibu, L. Multi-Criteria Decision Support for Sustainable Supplier Evaluation in Mining SMEs: A Fuzzy Logic and TOPSIS Approach. Logistics 2025, 9, 132. https://doi.org/10.3390/logistics9030132

Gidiagba JO, Okwu M, Tartibu L. Multi-Criteria Decision Support for Sustainable Supplier Evaluation in Mining SMEs: A Fuzzy Logic and TOPSIS Approach. Logistics. 2025; 9(3):132. https://doi.org/10.3390/logistics9030132

Chicago/Turabian StyleGidiagba, Joachim O., Modestus Okwu, and Lagouge Tartibu. 2025. "Multi-Criteria Decision Support for Sustainable Supplier Evaluation in Mining SMEs: A Fuzzy Logic and TOPSIS Approach" Logistics 9, no. 3: 132. https://doi.org/10.3390/logistics9030132

APA StyleGidiagba, J. O., Okwu, M., & Tartibu, L. (2025). Multi-Criteria Decision Support for Sustainable Supplier Evaluation in Mining SMEs: A Fuzzy Logic and TOPSIS Approach. Logistics, 9(3), 132. https://doi.org/10.3390/logistics9030132