Leveraging Machine Learning for Advancing Circular Supply Chains: A Systematic Literature Review

Abstract

1. Introduction

2. Materials and Methods

2.1. Search Strategy

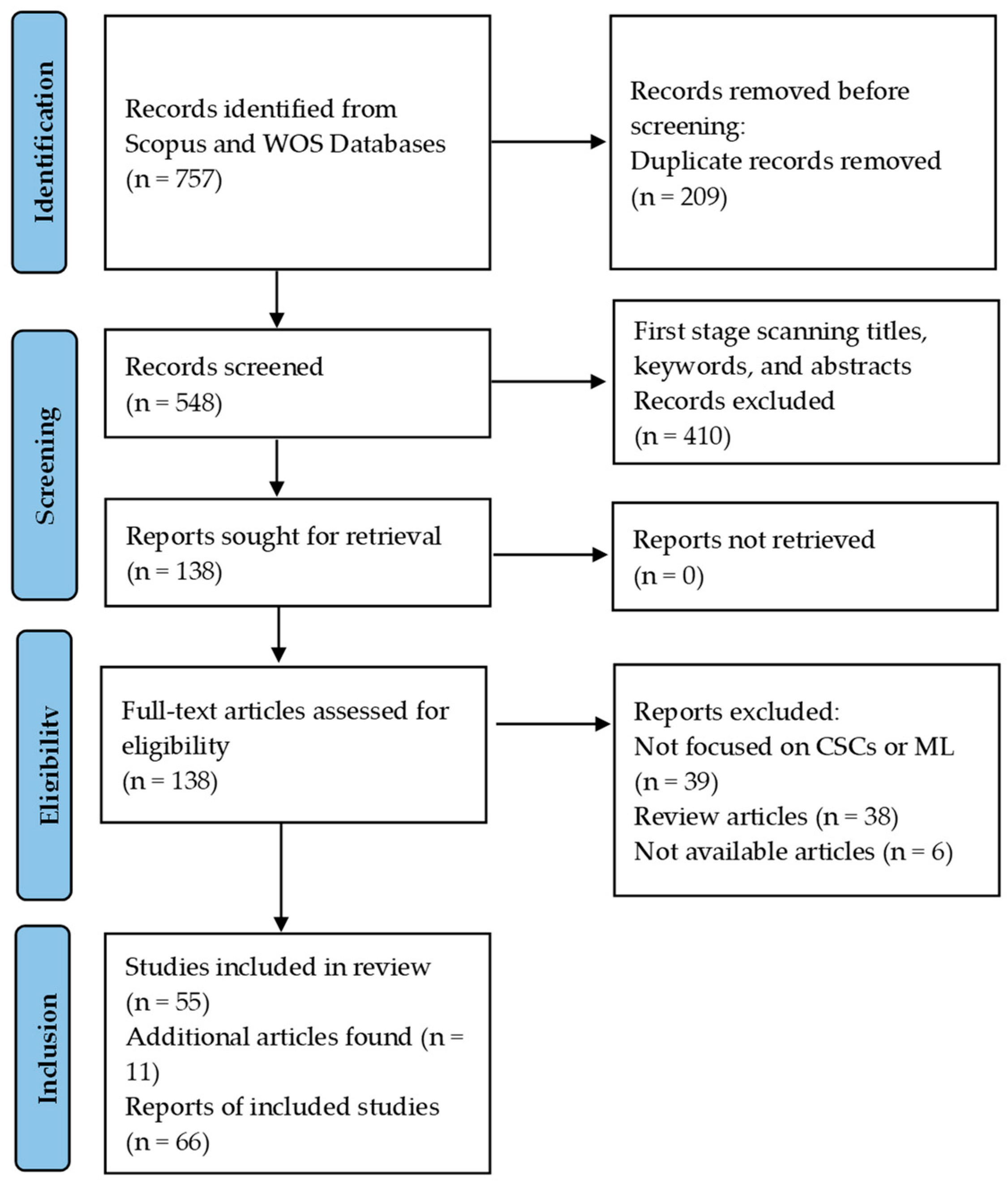

2.2. PRISMA Protocol

- Lack of focus on either ML or CSCs,

- Inaccessibility of full-text versions, or

- The inclusion of articles classified as review papers (which, while useful, were outside the scope of empirical research we aimed to review).

3. Results

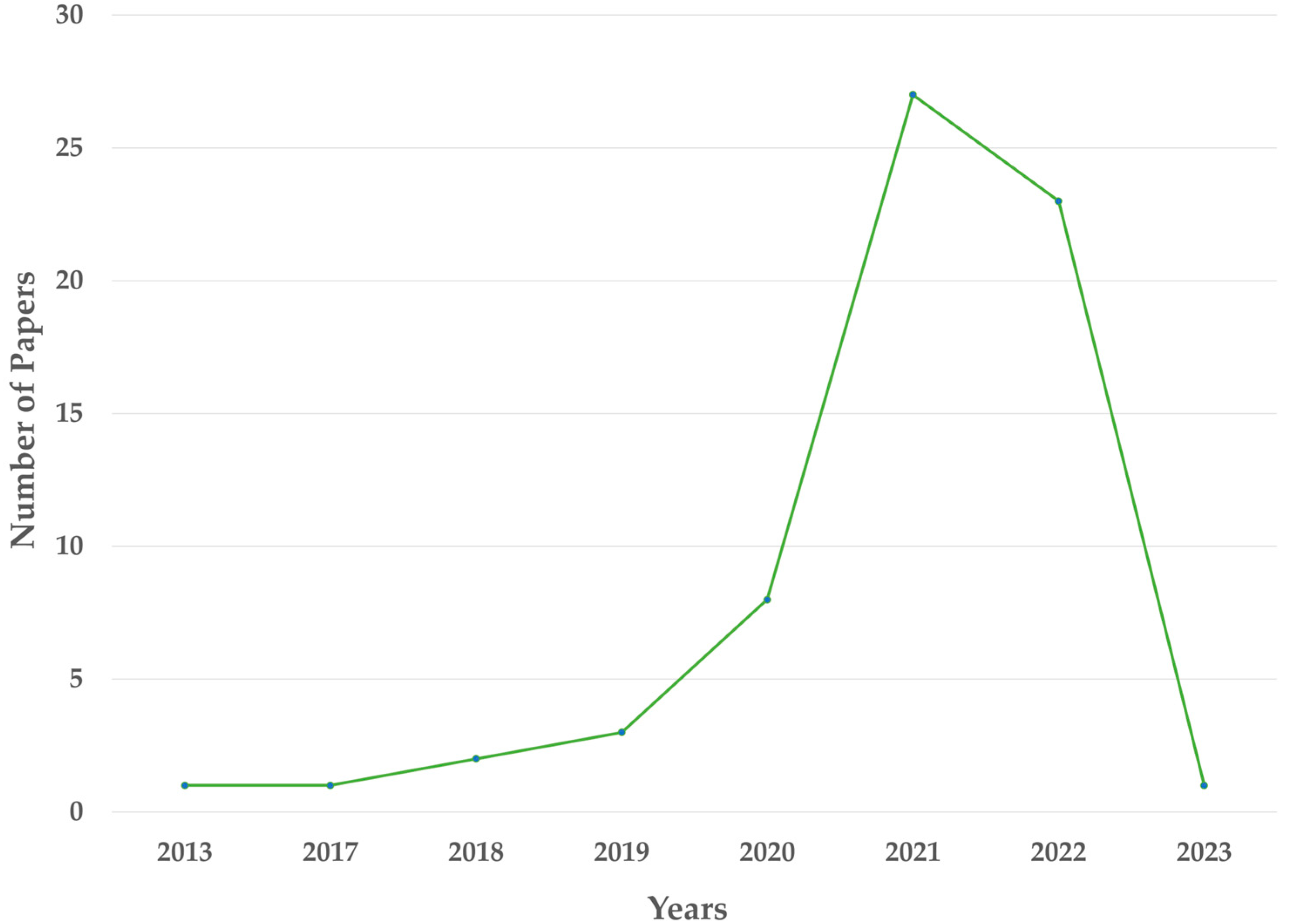

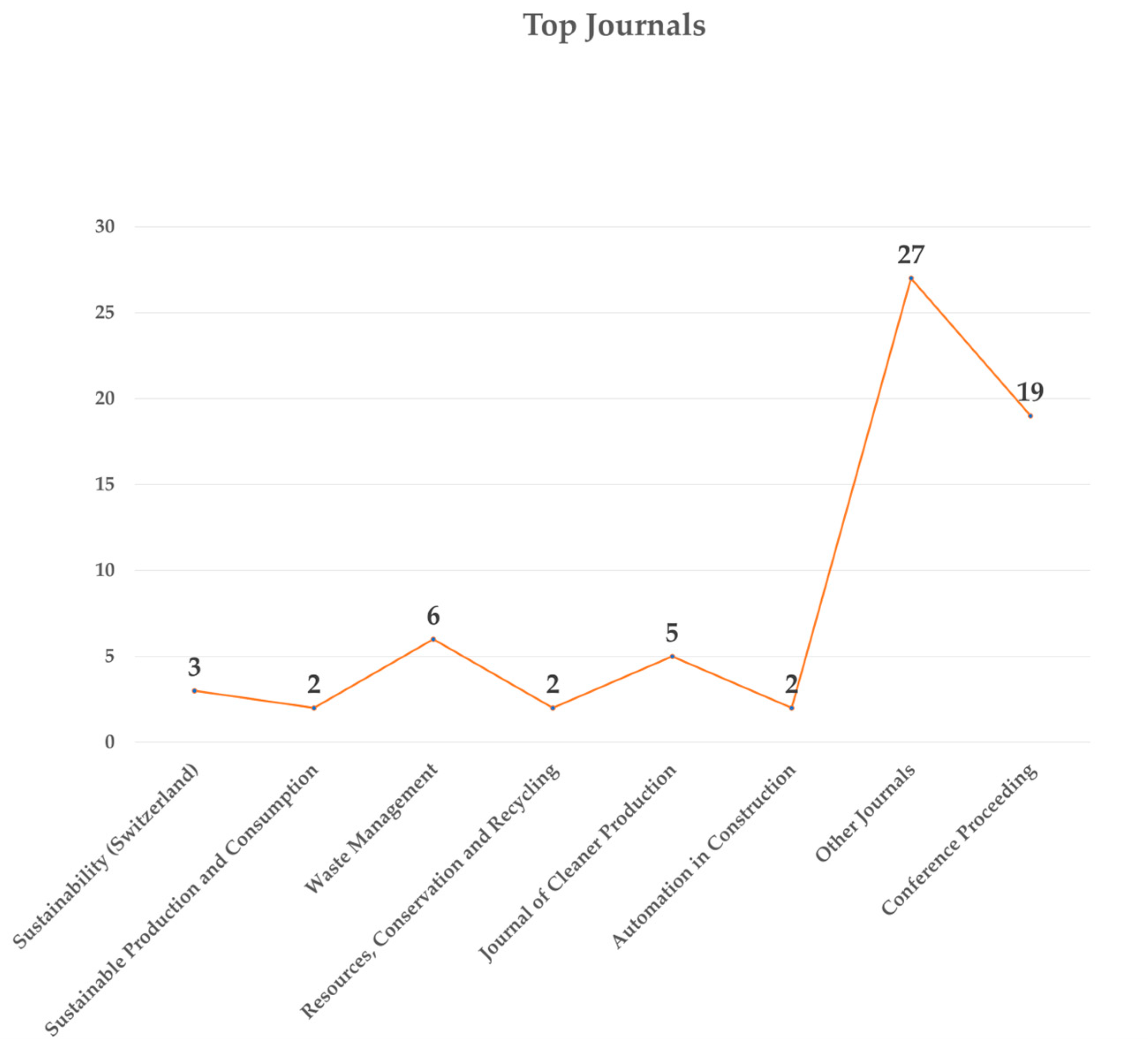

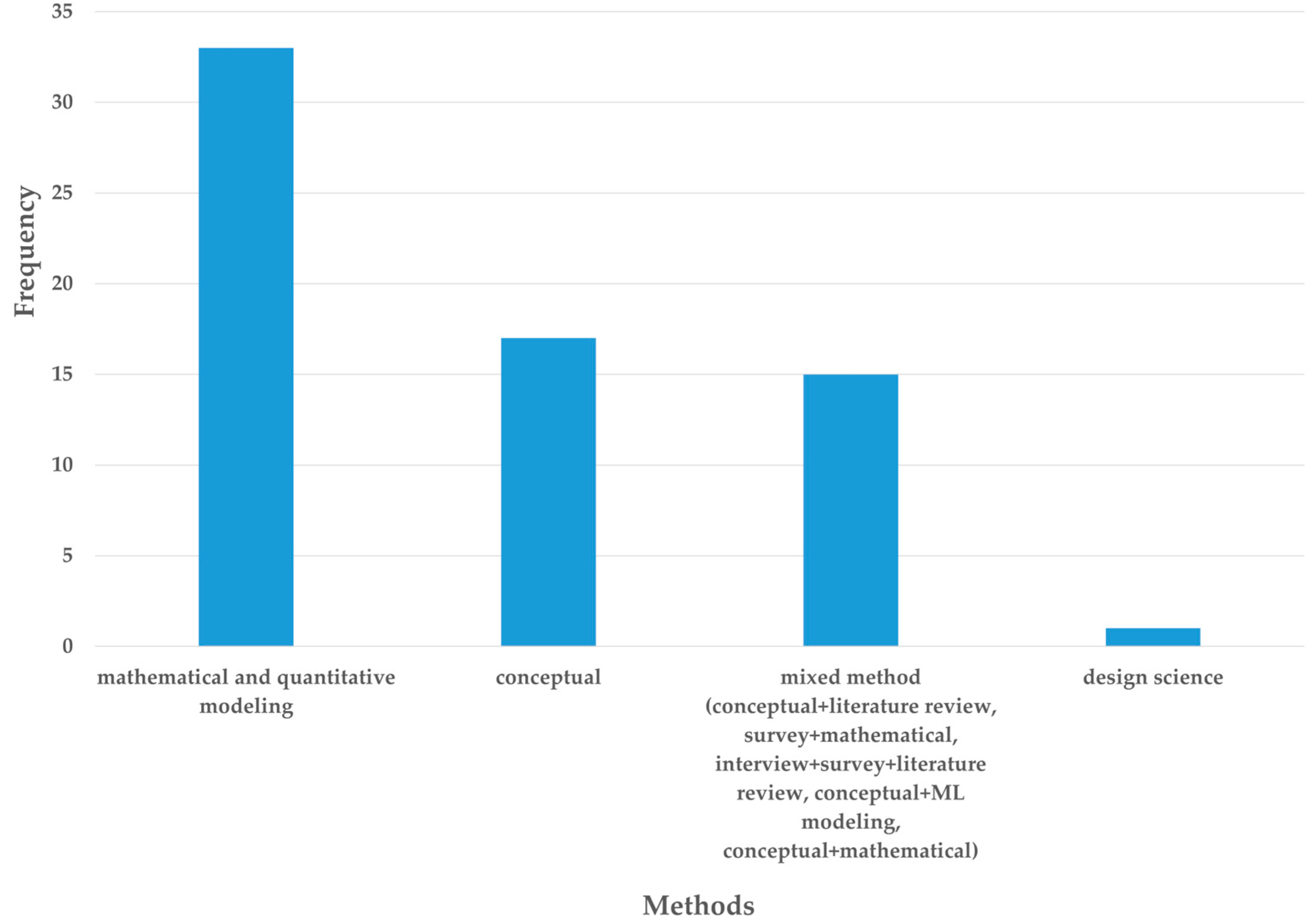

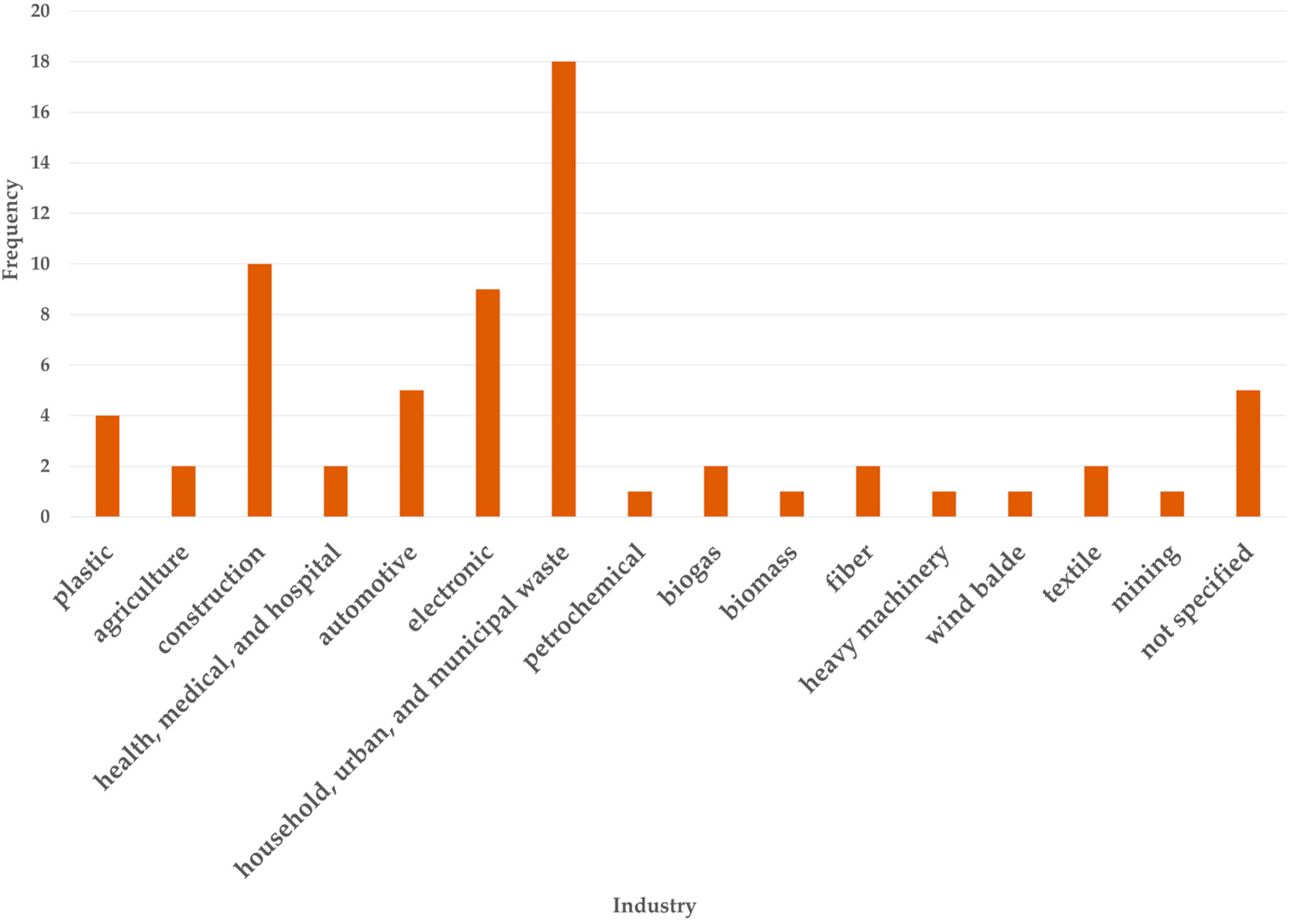

3.1. Descriptive Analysis

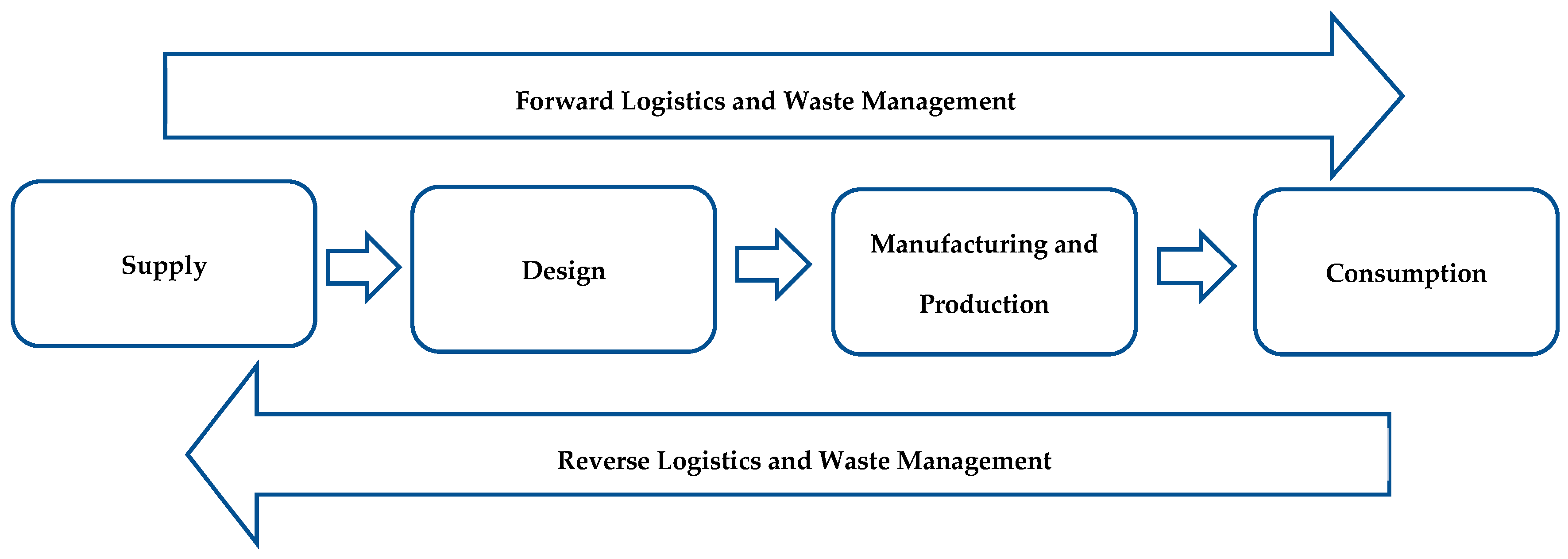

3.2. Content Analysis of ML Technology’s Role in Improving SCs’ Circularity

3.2.1. ML Application: Supply Stage

3.2.2. ML Application: Design Stage

3.2.3. ML Application: Manufacturing and Production Stage

3.2.4. ML Application: Consumption Stage

3.2.5. ML Application: Logistics Stage

3.2.6. ML Application: Waste Management Stage

Construction Industry

Households and Municipalities

Electrical Equipment and Electronics

Other Industries

3.3. Challenges of ML Usage in CSCs

4. Discussion

Synthesis and General Propositions

5. Conclusions

5.1. Further Research Avenues

5.2. Practical Implications

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kühl, C.; Bourlakis, M.; Aktas, E.; Skipworth, H. How Does Servitisation Affect Supply Chain Circularity?–A Systematic Literature Review. J. Enterp. Inf. Manag. 2020, 33, 703–728. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T.; Huisingh, D. Circular Supply Chain Management: A Definition and Structured Literature Review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Mendoza, J.M.F.; Sharmina, M.; Gallego-Schmid, A.; Heyes, G.; Azapagic, A. Integrating Backcasting and Eco-Design for the Circular Economy: The BECE Framework. J. Ind. Ecol. 2017, 21, 526–544. [Google Scholar] [CrossRef]

- Noman, A.A.; Akter, U.H.; Pranto, T.H.; Bahalul, A.K.M. Machine Learning and Artificial Intelligence in Circular Economy: A Bibliometric Analysis and Systematic. Ann. Emerg. Technol. Comput. (AETiC) 2022, 6, 13–40. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Sadeghi, S.; Mooseloo, F.M.; Vandchali, H.R.; Aeini, S. Application of Machine Learning in Supply Chain Management: A Comprehensive Overview of the Main Areas. Math. Probl. Eng. 2021, 2021, 1476043. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Sagnak, M.; Mangla, S.K.; Sezer, M.D.; Pala, M.O. A Fuzzy Based Hybrid Decision Framework to Circularity in Dairy Supply Chains through Big Data Solutions. Technol. Forecast. Soc. Chang. 2021, 170, 120927. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.; Antwi-Afari, P. Adopting Artificial Intelligence for Enhancing the Implementation of Systemic Circularity in the Construction Industry: A Critical Review. Sustain. Prod. Consum. 2022, 35, 509–524. [Google Scholar] [CrossRef]

- Naz, F.; Agrawal, R.; Kumar, A.; Gunasekaran, A.; Majumdar, A.; Luthra, S. Reviewing the Applications of Artificial Intelligence in Sustainable Supply Chains: Exploring Research Propositions for Future Directions. Bus. Strat. Environ. 2022, 31, 2400–2423. [Google Scholar] [CrossRef]

- Kar, A.K.; Choudhary, S.K.; Singh, V.K. How Can Artificial Intelligence Impact Sustainability: A Systematic Literature Review. J. Clean. Prod. 2022, 376, 134120. [Google Scholar] [CrossRef]

- Hallioui, A.; Herrou, B.; Santos, R.S.; Katina, P.F.; Egbue, O. Systems-Based Approach to Contemporary Business Management: An Enabler of Business Sustainability in a Context of Industry 4.0, Circular Economy, Competitiveness and Diverse Stakeholders. J. Clean. Prod. 2022, 373, 133819. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C. Relationships between Industry 4.0, Sustainable Manufacturing and Circular Economy: Proposal of a Research Framework. Int. J. Organ. Anal. 2022, 30, 864–898. [Google Scholar] [CrossRef]

- Ertz, M.; Sun, S.; Boily, E.; Kubiat, P.; Quenum, G.G.Y. How Transitioning to Industry 4.0 Promotes Circular Product Lifetimes. Ind. Mark. Manag. 2022, 101, 125–140. [Google Scholar] [CrossRef]

- Rosário, A.T.; Dias, J.C. Sustainability and the Digital Transition: A Literature Review. Sustainability 2022, 14, 4072. [Google Scholar] [CrossRef]

- Agrawal, R.; Wankhede, V.A.; Kumar, A.; Luthra, S.; Majumdar, A.; Kazancoglu, Y. An Exploratory State-of-the-Art Review of Artificial Intelligence Applications in Circular Economy Using Structural Topic Modeling. Oper. Manag. Res. 2021, 15, 609–626. [Google Scholar] [CrossRef]

- Murphy, K.P. Machine Learning: A Probabilistic Perspective; MIT Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Singh, V.; Chen, S.S.; Singhania, M.; Nanavati, B.; Gupta, A. How Are Reinforcement Learning and Deep Learning Algorithms Used for Big Data Based Decision Making in Financial Industries–A Review and Research Agenda. Int. J. Inf. Manag. Data Insights 2022, 2, 100094. [Google Scholar] [CrossRef]

- Liu, J.; Liu, L.; Qian, Y.; Song, S. The Effect of Artificial Intelligence on Carbon Intensity: Evidence from China’s Industrial Sector. Socio-Econ. Plan. Sci. 2022, 83, 101002. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review; Sage Publications Ltd.: Thousand Oaks, CA, USA, 2009; pp. 671–689. [Google Scholar]

- Tiwary, N.K.; Kumar, R.K.; Sarraf, S.; Kumar, P.; Rana, N.P. Impact Assessment of Social Media Usage in B2B Marketing: A Review of the Literature and a Way Forward. J. Bus. Res. 2021, 131, 121–139. [Google Scholar] [CrossRef]

- Ni, D.; Xiao, Z.; Lim, M.K. A Systematic Review of the Research Trends of Machine Learning in Supply Chain Management. Int. J. Mach. Learn. Cybern. 2020, 11, 1463–1482. [Google Scholar] [CrossRef]

- Alavi, B.; Tavana, M.; Mina, H. A Dynamic Decision Support System for Sustainable Supplier Selection in Circular Economy. Sustain. Prod. Consum. 2021, 27, 905–920. [Google Scholar] [CrossRef]

- Laurenti, R.; Sinha, R.; Singh, J.; Frostell, B. Some Pervasive Challenges to Sustainability by Design of Electronic Products–A Conceptual Discussion. J. Clean. Prod. 2015, 108, 281–288. [Google Scholar] [CrossRef]

- Talla, A.; McIlwaine, S. Industry 4.0 and the Circular Economy: Using Design-Stage Digital Technology to Reduce Construction Waste. Smart Sustain. Built Environ. 2022. ahead-of-print. [Google Scholar]

- Płoszaj-Mazurek, M.; Ryńska, E.; Grochulska-Salak, M. Methods to Optimize Carbon Footprint of Buildings in Regenerative Architectural Design with the Use of Machine Learning, Convolutional Neural Network, and Parametric Design. Energies 2020, 13, 5289. [Google Scholar] [CrossRef]

- Ridaura, G.; Llorens-Cervera, S.; Carrillo, C.; Buj-Corral, I.; Riba-Romeva, C. Equipment Suppliers Integration to the Redesign for Emissions Reuse in Industrial Processes. Resour. Conserv. Recycl. 2018, 131, 75–85. [Google Scholar] [CrossRef]

- Khayyam, H.; Naebe, M.; Milani, A.S.; Fakhrhoseini, S.M.; Date, A.; Shabani, B.; Atkiss, S.; Ramakrishna, S.; Fox, B.; Jazar, R.N. Improving Energy Efficiency of Carbon Fiber Manufacturing through Waste Heat Recovery: A Circular Economy Approach with Machine Learning. Energy 2021, 225, 120113. [Google Scholar] [CrossRef]

- Lopez-Garcia, P.; Barrenetxea, X.; García-Arrieta, S.; Sedano, I.; Palenzuela, L.; Usatorre, L. Compounding Process Optimization for Recycled Materials Using Machine Learning Algorithms. Procedia CIRP 2022, 105, 237–242. [Google Scholar] [CrossRef]

- Chiu, M.C.; Wen, C.Y.; Hsu, H.W.; Wang, W.C. Key Wastes Selection and Prediction Improvement for Biogas Production through Hybrid Machine Learning Methods. Sustain. Energy Technol. Assess. 2022, 52, 102223. [Google Scholar] [CrossRef]

- Prioux, N.; Ouaret, R.; Hetreux, G.; Belaud, J.P. Environmental Assessment Coupled with Machine Learning for Circular Economy. Clean Technol. Environ. Policy 2023, 25, 689–702. [Google Scholar] [CrossRef]

- Vondra, M.; Touš, M.; Teng, S.Y. Digestate Evaporation Treatment in Biogas Plants: A Techno-Economic Assessment by Monte Carlo, Neural Networks and Decision Trees. J. Clean. Prod. 2019, 238, 117870. [Google Scholar] [CrossRef]

- González Rodríguez, G.; Gonzalez-Cava, J.M.; Méndez Pérez, J.A. An Intelligent Decision Support System for Production Planning Based on Machine Learning. J. Intell. Manuf. 2020, 31, 1257–1273. [Google Scholar] [CrossRef]

- Lieder, M.; Asif, F.M.; Rashid, A. A Choice Behavior Experiment with Circular Business Models Using Machine Learning and Simulation Modeling. J. Clean. Prod. 2020, 258, 120894. [Google Scholar] [CrossRef]

- Shahidzadeh, M.H.; Shokouhyar, S.; Javadi, F.; Shokoohyar, S. Unscramble Social Media Power for Waste Management: A Multilayer Deep Learning Approach. J. Clean. Prod. 2022, 377, 134350. [Google Scholar] [CrossRef]

- Sun, Q. Research on the Influencing Factors of Reverse Logistics Carbon Footprint under Sustainable Development. Environ. Sci. Pollut. Res. 2017, 24, 22790–22798. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, E.S.; da Rosa Righi, R.; Barbosa, J.L.V.; Alberti, A.M. APTM: A Model for Pervasive Traceability of Agrochemicals. Appl. Sci. 2021, 11, 8149. [Google Scholar] [CrossRef]

- Zec, E.L.; Mogren, O.; Mellquist, A.C.; Fallahi, S.; Algurén, P. Residual Value Prediction Using Deep Learning. In Proceedings of the 2022 IEEE International Conference on Big Data (Big Data), Osaka, Japan, 17–20 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 4560–4567. [Google Scholar]

- Gayialis, S.P.; Kechagias, E.P.; Konstantakopoulos, G.D.; Papadopoulos, G.A. A Predictive Maintenance System for Reverse Supply Chain Operations. Logistics 2022, 6, 4. [Google Scholar] [CrossRef]

- Zacharaki, A.; Vafeiadis, T.; Kolokas, N.; Vaxevani, A.; Xu, Y.; Peschl, M.; Ioannidis, D.; Tzovaras, D. RECLAIM: Toward a New Era of Refurbishment and Remanufacturing of Industrial Equipment. Front. Artif. Intell. 2021, 3, 570562. [Google Scholar] [CrossRef] [PubMed]

- Briese, C.; Schlüter, M.; Lehr, J.; Maurer, K.; Krüger, J. Towards Deep Learning in Industrial Applications Taking Advantage of Service-Oriented Architectures. Procedia Manuf. 2020, 43, 503–510. [Google Scholar] [CrossRef]

- Lehr, J.; Schlüter, M.; Krüger, J. Decentralised Identification of Used Exchange Parts with a Mobile Application. Int. J. Sustain. Manuf. 2020, 4, 150–164. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Athanasopoulou, L.; Kampouris, K.; Lagios, P. Designing a Digitalized Cell for Remanufacturing of Automotive Frames. Procedia CIRP 2022, 109, 513–519. [Google Scholar] [CrossRef]

- Schlüter, M.; Lickert, H.; Schweitzer, K.; Bilge, P.; Briese, C.; Dietrich, F.; Krüger, J. AI-Enhanced Identification, Inspection and Sorting for Reverse Logistics in Remanufacturing. Procedia CIRP 2021, 98, 300–305. [Google Scholar] [CrossRef]

- Lickert, H.; Wewer, A.; Dittmann, S.; Bilge, P.; Dietrich, F. Selection of Suitable Machine Learning Algorithms for Classification Tasks in Reverse Logistics. Procedia CIRP 2021, 96, 272–277. [Google Scholar] [CrossRef]

- Çetin, S.; De Wolf, C.; Bocken, N. Circular Digital Built Environment: An Emerging Framework. Sustainability 2021, 13, 6348. [Google Scholar] [CrossRef]

- Davis, P.; Aziz, F.; Newaz, M.T.; Sher, W.; Simon, L. The Classification of Construction Waste Material Using a Deep Convolutional Neural Network. Autom. Constr. 2021, 122, 103481. [Google Scholar] [CrossRef]

- Hoong, J.D.L.H.; Lux, J.; Mahieux, P.Y.; Turcry, P.; Ait-Mokhtar, A. Determination of the Composition of Recycled Aggregates Using a Deep Learning-Based Image Analysis. Autom. Constr. 2020, 116, 103204. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, A.O.; Oyedele, L.O.; Salami, R.O. Deep Learning Model for Demolition Waste Prediction in a Circular Economy. J. Clean. Prod. 2020, 274, 122843. [Google Scholar] [CrossRef]

- Rakhshan, K.; Morel, J.C.; Daneshkhah, A. A Probabilistic Predictive Model for Assessing the Economic Reusability of Load-Bearing Building Components: Developing a Circular Economy Framework. Sustain. Prod. Consum. 2021, 27, 630–642. [Google Scholar] [CrossRef]

- Rakhshan, K.; Morel, J.C.; Daneshkhah, A. Predicting the Technical Reusability of Load-Bearing Building Components: A Probabilistic Approach towards Developing a Circular Economy Framework. J. Build. Eng. 2021, 42, 102791. [Google Scholar] [CrossRef]

- Lu, W.; Lou, J.; Webster, C.; Xue, F.; Bao, Z.; Chi, B. Estimating Construction Waste Generation in the Greater Bay Area, China Using Machine Learning. Waste Manag. 2021, 134, 78–88. [Google Scholar] [CrossRef]

- Wu, P.Y.; Sandels, C.; Mjörnell, K.; Mangold, M.; Johansson, T. Predicting the Presence of Hazardous Materials in Buildings Using Machine Learning. Build. Environ. 2022, 213, 108894. [Google Scholar] [CrossRef]

- Zaman, A. Waste Management 4.0: An Application of a Machine Learning Model to Identify and Measure Household Waste Contamination—A Case Study in Australia. Sustainability 2022, 14, 3061. [Google Scholar] [CrossRef]

- Cîmpeanu, I.A.; Dragomir, D.A.; Zota, R.D. Using Artificial Intelligence for the Benefit of the Circular Economy. In Proceedings of the International Conference on Business Excellence, Bucharest, Romania, 24–26 March 2022; Volume 16, pp. 294–303. [Google Scholar]

- Lühr Sierra, D.V.; Balinos, M.; Gatica, J.; Lagomarsino, C. Ciudad Limpia Valdivia: A Mobile and Web Based Smart Solution Based on Foss Technology to Support Municipal and Household Waste Collection. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2021, 46, 97–102. [Google Scholar] [CrossRef]

- Nafiz, M.S.; Das, S.S.; Morol, M.K.; Al Juabir, A.; Nandi, D. Convowaste: An Automatic Waste Segregation Machine Using Deep Learning. In Proceedings of the 2023 3rd International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), Dhaka, Bangladesh, 7–8 January 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 181–186. [Google Scholar]

- Fasano, F.; Addante, A.S.; Valenzano, B.; Scannicchio, G. Variables Influencing Per Capita Production, Separate Collection, and Costs of Municipal Solid Waste in the Apulia Region (Italy): An Experience of Deep Learning. Int. J. Environ. Res. Public Health 2021, 18, 752. [Google Scholar] [CrossRef]

- Mohammed, M.A.; Abdulhasan, M.J.; Kumar, N.M.; Abdulkareem, K.H.; Mostafa, S.A.; Maashi, M.S.; Khalid, L.S.; Abdulaali, H.S.; Chopra, S.S. Automated Waste-Sorting and Recycling Classification Using Artificial Neural Network and Features Fusion: A Digital-Enabled Circular Economy Vision for Smart Cities. Multimed. Tools Appl. 2022, 82, 39617–39632. [Google Scholar] [CrossRef] [PubMed]

- Chen, X. Machine Learning Approach for a Circular Economy with Waste Recycling in Smart Cities. Energy Rep. 2022, 8, 3127–3140. [Google Scholar] [CrossRef]

- Gue, I.H.V.; Lopez, N.S.A.; Chiu, A.S.; Ubando, A.T.; Tan, R.R. Predicting Waste Management System Performance from City and Country Attributes. J. Clean. Prod. 2022, 366, 132951. [Google Scholar] [CrossRef]

- Nnamoko, N.; Barrowclough, J.; Procter, J. Solid Waste Image Classification Using Deep Convolutional Neural Network. Infrastructures 2022, 7, 47. [Google Scholar] [CrossRef]

- Wilts, H.; Garcia, B.R.; Garlito, R.G.; Gómez, L.S.; Prieto, E.G. Artificial Intelligence in the Sorting of Municipal Waste as an Enabler of the Circular Economy. Resources 2021, 10, 28. [Google Scholar] [CrossRef]

- Paulauskaite-Taraseviciene, A.; Raudonis, V.; Sutiene, K. Forecasting Municipal Solid Waste in Lithuania by Incorporating Socioeconomic and Geographical Factors. Waste Manag. 2022, 140, 31–39. [Google Scholar] [CrossRef]

- Fan, L.; Abbasi, M.; Salehi, K.; Band, S.S.; Chau, K.W.; Mosavi, A. Introducing an Evolutionary-Decomposition Model for Prediction of Municipal Solid Waste Flow: Application of Intrinsic Time-Scale Decomposition Algorithm. Eng. Appl. Comput. Fluid Mech. 2021, 15, 1159–1175. [Google Scholar] [CrossRef]

- Rosecký, M.; Šomplák, R.; Slavík, J.; Kalina, J.; Bulková, G.; Bednář, J. Predictive Modelling as a Tool for Effective Municipal Waste Management Policy at Different Territorial Levels. J. Environ. Manag. 2021, 291, 112584. [Google Scholar] [CrossRef]

- Wang, C.; Qin, J.; Qu, C.; Ran, X.; Liu, C.; Chen, B. A Smart Municipal Waste Management System Based on Deep-Learning and Internet of Things. Waste Manag. 2021, 135, 20–29. [Google Scholar] [CrossRef]

- Kontokosta, C.E.; Hong, B.; Johnson, N.E.; Starobin, D. Using Machine Learning and Small Area Estimation to Predict Building-Level Municipal Solid Waste Generation in Cities. Comput. Environ. Urban Syst. 2018, 70, 151–162. [Google Scholar] [CrossRef]

- Kannangara, M.; Dua, R.; Ahmadi, L.; Bensebaa, F. Modeling and Prediction of Regional Municipal Solid Waste Generation and Diversion in Canada Using Machine Learning Approaches. Waste Manag. 2018, 74, 3–15. [Google Scholar] [CrossRef] [PubMed]

- Meza, J.K.S.; Yepes, D.O.; Rodrigo-Ilarri, J.; Cassiraga, E. Predictive Analysis of Urban Waste Generation for the City of Bogotá, Colombia, through the Implementation of Decision Trees-Based Machine Learning, Support Vector Machines and Artificial Neural Networks. Heliyon 2019, 5, e02810. [Google Scholar] [CrossRef] [PubMed]

- Magazzino, C.; Mele, M.; Schneider, N.; Sarkodie, S.A. Waste Generation, Wealth and GHG Emissions from the Waste Sector: Is Denmark on the Path towards Circular Economy? Sci. Total Environ. 2021, 755, 142510. [Google Scholar] [CrossRef] [PubMed]

- Abou Baker, N.; Stehr, J.; Handmann, U. Transfer Learning Approach towards a Smarter Recycling. In Proceedings of the International Conference on Artificial Neural Networks and Machine Learning—ICANN 2022, Bristol, UK, 6–9 September 2022; Springer International Publishing: Cham, Switzerland, 2022; pp. 685–696. [Google Scholar]

- Cabri, A.; Masulli, F.; Rovetta, S.; Mohsin, C. Recovering Critical Raw Materials from WEEE Using Artificial Intelligence. In Proceedings of the 21st International Conference on Modeling and Applied Simulation, MAS 2022, Rome, Italy, 19–21 September 2022; pp. 1–5. [Google Scholar]

- D’Morison, F.; Bittencourt, C.; Ferraz, L. Bin Level Detection Based on Wall Entropy Perturbation in Electronic Waste Collection. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 25 October 2013; Volume 1. [Google Scholar]

- Johnson, M.; Khatoon, A.; Fitzpatrick, C. Application of AI and Machine Vision to Improve Battery Detection and Recovery in E-Waste Management. In Proceedings of the 2022 International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Maldives, Maldives, 16–18 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Basia, A.; Simeu-Abazi, Z.; Gascard, E.; Zwolinski, P. Comparison of Data Driven Algorithms for SoH Estimation of Lithium-Ion Batteries. In Proceedings of the 2021 International Conference on Control, Automation and Diagnosis (ICCAD), Grenoble, France, 3–5 November 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Poschmann, H.; Brüggemann, H.; Goldmann, D. Fostering End-of-Life Utilization by Information-Driven Robotic Disassembly. Procedia CIRP 2021, 98, 282–287. [Google Scholar] [CrossRef]

- Deng, S.; Zhou, X.; Huang, A.; Yih, Y.; Sutherland, J.W. Evaluating Economic Opportunities for Product Recycling via the Sherwood Principle and Machine Learning. Resour. Conserv. Recycl. 2021, 167, 105232. [Google Scholar] [CrossRef]

- Scherer, M. Waste Flows Management by Their Prediction in a Production Company. J. Appl. Math. Comput. Mech. 2017, 16, 135–144. [Google Scholar] [CrossRef]

- Majchrowska, S.; Mikołajczyk, A.; Ferlin, M.; Klawikowska, Z.; Plantykow, M.A.; Kwasigroch, A.; Majek, K. Deep Learning-Based Waste Detection in Natural and Urban Environments. Waste Manag. 2022, 138, 274–284. [Google Scholar] [CrossRef]

- Nañez Alonso, S.L.; Reier Forradellas, R.F.; Pi Morell, O.; Jorge-Vázquez, J. Digitalization, Circular Economy and Environmental Sustainability: The Application of Artificial Intelligence in the Efficient Self-Management of Waste. Sustainability 2021, 13, 2092. [Google Scholar] [CrossRef]

- Gruber, F.; Grählert, W.; Wollmann, P.; Kaskel, S. Classification of Black Plastics Waste Using Fluorescence Imaging and Machine Learning. Recycling 2019, 4, 40. [Google Scholar] [CrossRef]

- Chin, H.H.; Varbanov, P.S.; Klemeš, J.J. Plastic Waste Categorisation Using Machine Learning Methods-Metals Contaminations. In Proceedings of the 2021 6th International Conference on Smart and Sustainable Technologies (SpliTech), Bol and Split, Croatia, 8–11 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Salim, A.A.; Karnadi, I.; Williamdy, W.; Bastiaan, T.; Steven, E. PLEESE-Plastic Reuse Reminder System Using Computer Vision Deep Learning. In Proceedings of the 2022 1st International Conference on Technology Innovation and Its Applications (ICTIIA), Tangerang, Indonesia, 23 September 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Chin, H.H.; Varbanov, P.S.; You, F.; Sher, F.; Klemeš, J.J. Plastic Circular Economy Framework Using Hybrid Machine Learning and Pinch Analysis. Resour. Conserv. Recycl. 2022, 184, 106387. [Google Scholar] [CrossRef]

- Barraza, R.; Sepúlveda, J.M.; Venegas, J.; Monardes, V.; Derpich, I. A Model for Solving Optimal Location of Hubs: A Case Study for Recovery of Tailings Dams. In International Conference on Computers Communications and Control; Springer International Publishing: Cham, Switzerland, 2020; pp. 304–312. [Google Scholar]

- Walzberg, J.; Cooperman, A.; Watts, L.; Eberle, A.L.; Carpenter, A.; Heath, G.A. Regional Representation of Wind Stakeholders’ End-of-Life Behaviors and Their Impact on Wind Blade Circularity. iScience 2022, 25, 104734. [Google Scholar] [CrossRef] [PubMed]

- Yatim, F.E.; Boumanchar, I.; Srhir, B.; Chhiti, Y.; Jama, C.; Alaoui, F.E.M.H. Waste-to-Energy as a Tool of Circular Economy: Prediction of Higher Heating Value of Biomass by Artificial Neural Network (ANN) and Multivariate Linear Regression (MLR). Waste Manag. 2022, 153, 293–303. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.M.; Mohammed, M.A.; Abdulkareem, K.H.; Damasevicius, R.; Mostafa, S.A.; Maashi, M.S.; Chopra, S.S. Artificial Intelligence-Based Solution for Sorting COVID Related Medical Waste Streams and Supporting Data-Driven Decisions for Smart Circular Economy Practice. Process Saf. Environ. Prot. 2021, 152, 482–494. [Google Scholar] [CrossRef]

- Rudisch, K.; Jüngling, S.; Carrillo Mendoza, R.; Woggon, U.K.; Budde, I.; Malzacher, M.; Pufahl, K. Paving the Road to a Circular Textile Economy with AI. In Proceedings of the Workshop Künstliche Intelligenz in der Umweltinformatik (KIUI-2021), Informatik 2021, Berlin, Germany, 27 September–1 October 2021; Gesellschaft für Informatik: Bonn, Germany, 2021. [Google Scholar]

- Serrano-Munoz, A.; Arana-Arexolaleiba, N.; Chrysostomou, D.; Bøgh, S. Learning and Generalising Object Extraction Skill for Contact-Rich Disassembly Tasks: An Introductory Study. Int. J. Adv. Manuf. Technol. 2021, 124, 3171–3183. [Google Scholar] [CrossRef]

- Tseng, M.L.; Ha, H.M.; Tran, T.P.T.; Bui, T.D.; Chen, C.C.; Lin, C.W. Building a Data-Driven Circular Supply Chain Hierarchical Structure: Resource Recovery Implementation Drives Circular Business Strategy. Bus. Strat. Environ. 2022, 31, 2082–2106. [Google Scholar] [CrossRef]

- Mirzahossein, H.; Gholampour, I.; Sajadi, S.R.; Zamani, A.H. A hybrid deep and machine learning model for short-term traffic volume forecasting of adjacent intersections. IET Intell. Transp. Syst. 2022, 16, 1648–1663. [Google Scholar] [CrossRef]

| Industry | ML Applications | Challenges | Opportunities |

|---|---|---|---|

| Construction | Energy consumption prediction and sustainable design, predicting waste generation and material recovery, waste sorting | Low-quality data, limited access to structural data, overfitting of datasets | Analyzing construction designs and predicting aspects such as the carbon footprint, energy consumption, and potential material waste during the design phase. Estimating recycling, repurposing, and the waste produced during construction and demolition stages in the construction industry. Classifying different types of rubbish through digital images collected from worksite containers in the construction industry. |

| Household and municipal | Predicting waste generation, waste sorting | Unstructured data, inconsistent waste management practices across municipalities | Developing predictive models that can accurately forecast the future generation of municipal waste. By leveraging historical data and relevant variables such as population growth, consumption patterns, and waste production trends, these models can provide valuable insights for efficient resource allocation and effective waste management strategies within the CSC. Classifying waste in smart cities. Efficiently sorting municipal waste in smart cities. Enabling the efficient extraction of recyclable materials from the municipal waste stream. |

| Electronic | E-waste evaluation for repurposing, E-waste collection and monitoring, E-waste sorting | Complexity in sorting, limited availability of data on product composition | Estimating the State of Health (SoH) of Lithium-ion (Li-ion) batteries in E-waste. Predicting fill levels in the bins by integrating a lightweight image processing technique with ML. E-waste classification and systematically identifying and segregating electronic waste materials. |

| Automotive | Identifying and predicting automotive defective parts condition, predicting generated waste | Difficulty in classifying defective parts for remanufacturability, data availability, and quality issues for accurate ML predictions | Classifying automotive defective parts and determining their remanufacturability. Anticipating the quantity of waste produced during various stages of production. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farshadfar, Z.; Mucha, T.; Tanskanen, K. Leveraging Machine Learning for Advancing Circular Supply Chains: A Systematic Literature Review. Logistics 2024, 8, 108. https://doi.org/10.3390/logistics8040108

Farshadfar Z, Mucha T, Tanskanen K. Leveraging Machine Learning for Advancing Circular Supply Chains: A Systematic Literature Review. Logistics. 2024; 8(4):108. https://doi.org/10.3390/logistics8040108

Chicago/Turabian StyleFarshadfar, Zeinab, Tomasz Mucha, and Kari Tanskanen. 2024. "Leveraging Machine Learning for Advancing Circular Supply Chains: A Systematic Literature Review" Logistics 8, no. 4: 108. https://doi.org/10.3390/logistics8040108

APA StyleFarshadfar, Z., Mucha, T., & Tanskanen, K. (2024). Leveraging Machine Learning for Advancing Circular Supply Chains: A Systematic Literature Review. Logistics, 8(4), 108. https://doi.org/10.3390/logistics8040108