Enhancing Supplier Selection for Sustainable Raw Materials: A Comprehensive Analysis Using Analytical Network Process (ANP) and TOPSIS Methods

Abstract

1. Introduction

2. Related Works and Methods

2.1. Supplier Selection

2.2. Sustainable Supplier Selection

- a.

- Economy

- b.

- Environment

- c.

- Social

2.3. Identification of Criteria and Sub-Criteria

- Economic aspects:

- Price: This criterion evaluates the cost of the raw materials provided. The company seeks high-quality raw materials at the lowest possible cost.

- Raw material defect rate: This aspect examines how frequently received raw materials exhibit defects, such as fabric holes, weak thread connections leading to blemishes, stubborn stains, etc.

- Quantity-based discounts: This factor gauges the discounts offered by suppliers to the company when the order quantities increase.

- Proximity: Evaluated by considering the distance between the company and its suppliers.

- Timely delivery: This parameter assesses the punctuality of raw material deliveries from suppliers.

- Material suitability: This criterion considers whether the delivered raw materials align with the required specifications, encompassing aspects like color, material type, and thickness.

- Warranty and vlaims: Assessed through post-transaction services offered in cases where received raw materials are damaged.

- Social aspects:

- Workforce competence: This element evaluates the skill level of the workforce, which directly impacts the company’s productivity.

- Employee satisfaction: This factor assesses the contentment of employees with their work, which can contribute to a smoother workflow.

- Effective communication: This aspect gauges the quality of communication between supervisors and employees, fostering harmony and facilitating clear information flow for streamlined production.

- Flexibility in work arrangements: This criterion examines the ability to adjust work hours based on company orders.

- Safety equipment utilization: This parameter is measured by observing whether employees adhere to safety protocols, reducing the occurrence of workplace accidents.

- Compliance with labor regulations: This factor assesses whether the supplier’s labor practices align with established standards.

- Environmental aspects:

- Use of environmentally friendly materials: This criterion evaluates the utilization of raw materials that do not harm the environment, including elements like fabric dyes.

- Recyclability potential: This aspect assesses whether generated waste can be repurposed or appropriately disposed of.

- Eco-certifications: This parameter examines whether the company possesses certifications related to environmental responsibility.

- Waste management: This criterion assesses how waste is handled, ensuring it follows regulations and guidelines.

3. Results

3.1. Analytical Network Process (ANP)

- Developing a network framework. The process of building the model relies on pre-existing issues, demanding a lucid depiction for structuring a network. It becomes essential to outline control benchmarks and referral criteria, facilitating the assessment of alternative options. Consequently, this phase facilitates the interconnection of individual elements.

- Formulating a matrix for pairwise comparisons. Effective decision-making involves evaluating the significance of elements across various tiers. This evaluation leads to the creation of a matrix A, where the value aij signifies the relative importance of each element. The comparison matrix is defined as follows:

- 3.

- Determining the weight of elements. When the comparisons between pairs are fully completed, the priority vector “w”, also known as the eigenvector, is computed using the following equation:

- 4.

- Calculating the consistency ratio.

- 5.

- Creating a supermatrix.

3.2. TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution)

- Create a decision matrix

- b.

- Create a normalized decision matrixThe equation used to transform each element Xij is:with i = 1,2,3 …, m: and j = 1,2,3 …, n.

- c.

- Create a weighted normalized decision matrixWith weight wi = (w1, w2, w3, …, wn), where wj is the weight of the jth value and wj =1, then normalize the weight matrix V as follows:Vij = Wi × rij

- d.

- Determine the value of positive ideal solutions and negative ideal solutions. The positive ideal solution is denoted A+ while the negative ideal solution is denoted A. The equation for determining the ideal solution can be seen as follows:A+ = (y1+,y2+,……yn+)A− = (y1−,y2−,………yn−)

- e.

- Determine the distance between the value of each alternative with the positive ideal matrix and the negative ideal solution matrix which can be referred to as the separation measure. The following is the mathematical equation of S+ and S.The distance of alternative Si+ to the positive ideal solution is formulated as:The distance of alternative Si− to the negative ideal solution is formulated as:

- f.

- Calculate the preference value of each alternative The preference value of each alternative can be calculated with the equation:

4. Discussion

4.1. Criterion Relationship Results

4.2. Network-Based ANP Model

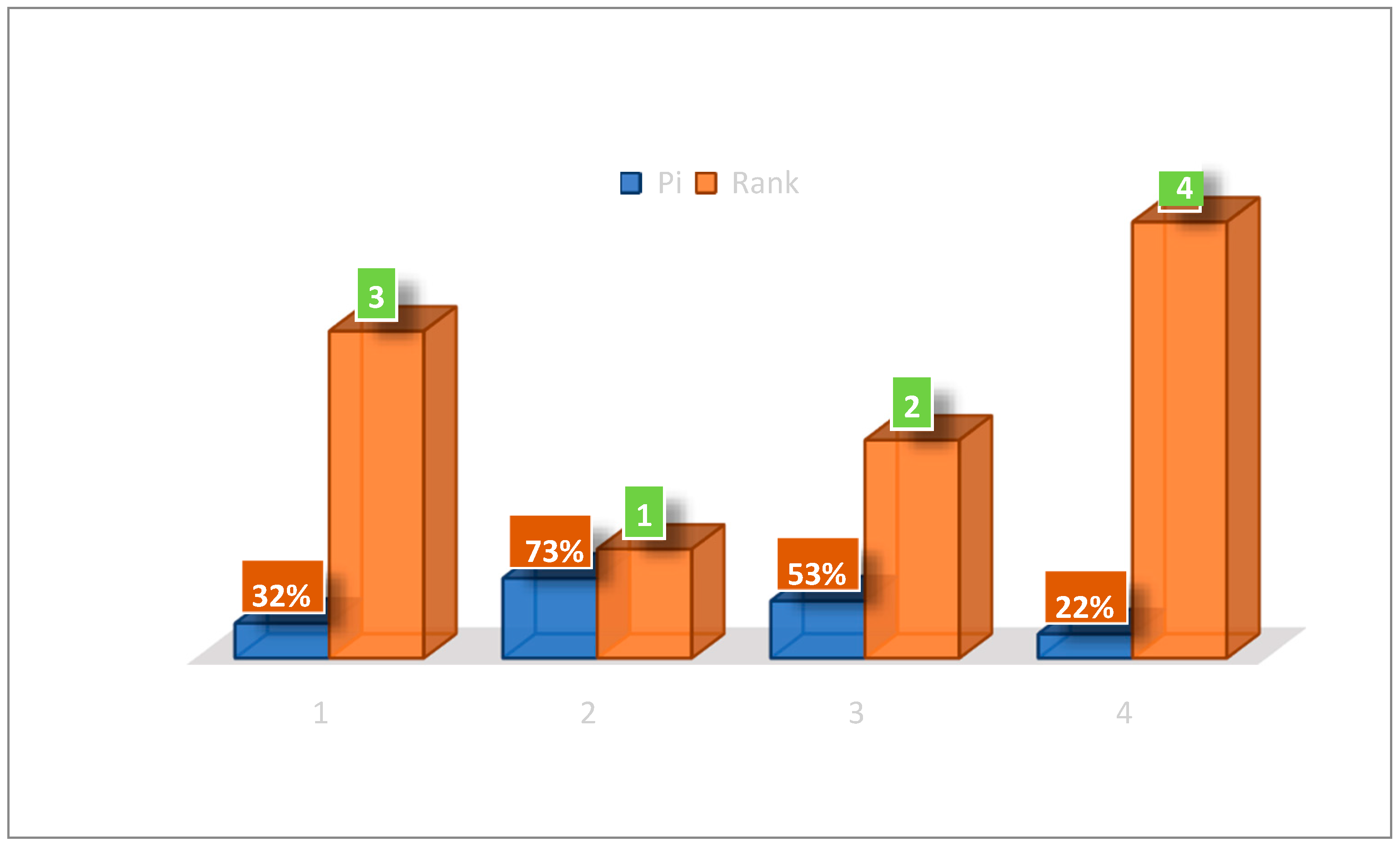

4.3. Prioritization of Alternative Suppliers Based on TOPSIS

4.4. Comparison between the ANP and TOPSIS Methods Based on the Results

4.5. Managerial and Theoretical Implications

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Ming, X.; Zhou, T.; Chang, Y. Sustainable supplier selection for smart supply chain considering internal and external uncertainty: An integrated rough-fuzzy approach. Appl. Soft Comput. 2020, 87, 106004. [Google Scholar] [CrossRef]

- Awasthi, A.; Govindan, K.; Gold, S. Multi-tier sustainable global supplier selection using a fuzzy AHP-VIKOR based approach. Int. J. Prod. Econ. 2018, 195, 106–117. [Google Scholar] [CrossRef]

- Govindan, K. Sustainable consumption and production in the food supply chain: A conceptual framework. Int. J. Prod. Econ. 2018, 195, 419–431. [Google Scholar] [CrossRef]

- Giannakis, M.; Dubey, R.; Vlachos, I.; Ju, Y. Supplier sustainability performance evaluation using the analytic network process. J. Clean. Prod. 2020, 247, 119439. [Google Scholar] [CrossRef]

- Tran, K.; Nguyen, T.; Tran, Y.; Nguyen, A.; Luu, K.; Nguyen, Y. Eco-friendly fashion among generation Z: Mixed-methods study on price value image, customer fulfillment, and pro-environmental behavior. PLoS ONE 2022, 17, e0272789. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar] [CrossRef]

- Govindan, K.; Shankar, K.M.; Kannan, D. Sustainable material selection for construction industry—A hybrid multi criteria decision making approach. Renew. Sustain. Energy Rev. 2016, 55, 1274–1288. [Google Scholar] [CrossRef]

- Hadiguna, R.A. Model penilaian risiko berbasis kinerja untuk rantai pasok kelapa sawit berkelanjutan di Indonesia. J. Tek. Ind. 2012, 14, 13–24. [Google Scholar] [CrossRef][Green Version]

- Saaty, T.L. Decision Making with Dependence and Feedback: The Analytic Network Process; RWS Publications: Pittsburgh, PA, USA, 1996; Volume 4922. [Google Scholar]

- Sen, D.K.; Datta, S.; Mahapatra, S.S. Sustainable supplier selection in intuitionistic fuzzy environment: A decision-making perspective. Benchmark. Int. J. 2018, 25, 545–574. [Google Scholar] [CrossRef]

- Lu, L.Y.Y.; Wu, C.H.; Kuo, T.C. Environmental principles applicable to green supplier evaluation by using multi-objective decision analysis. Int. J. Prod. Res. 2007, 45, 4317–4331. [Google Scholar] [CrossRef]

- Hadiguna, R.A. Decision support framework for risk assessment of sustainable supply chain. Int. J. Logist. Econ. Glob. 2012, 4, 35–54. [Google Scholar] [CrossRef]

- Scholten, K.; Fynes, B. Risk and Uncertainty Management for Sustainable Supply Chains. In Sustainable Supply Chains: A Research-Based Textbook on Operations and Strategy; Bouchery, Y., Corbett, C.J., Fransoo, J.C., Tan, T., Eds.; Springer International Publishing: Cham, Switherland, 2017; pp. 413–436. [Google Scholar]

- Freeman, J.; Chen, T. Green supplier selection using an AHP-Entropy-TOPSIS framework. Supply Chain. Manag. Int. J. 2015, 20, 327–340. [Google Scholar] [CrossRef]

- Sarkar, B.; Omair, M.; Kim, N. A cooperative advertising collaboration policy in supply chain management under uncertain conditions. Appl. Soft Comput. 2020, 88, 105948. [Google Scholar] [CrossRef]

- Govindan, K.; Mina, H.; Esmaeili, A.; Gholami-Zanjani, S.M. An Integrated Hybrid Approach for Circular supplier selection and Closed loop Supply Chain Network Design under Uncertainty. J. Clean. Prod. 2020, 242, 118317. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Integrating sustainability into supplier selection with grey system and rough set methodologies. Int. J. Prod. Econ. 2010, 124, 252–264. [Google Scholar] [CrossRef]

- Su, C.-M.; Horng, D.-J.; Tseng, M.-L.; Chiu, A.S.F.; Wu, K.-J.; Chen, H.-P. Improving sustainable supply chain management using a novel hierarchical grey-DEMATEL approach. J. Clean. Prod. 2016, 134, 469–481. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kumar, P.; Barua, M.K. Flexible Decision Approach for Analysing Performance of Sustainable Supply Chains Under Risks/Uncertainty. Glob. J. Flex. Syst. Manag. 2014, 15, 113–130. [Google Scholar] [CrossRef]

- Ullah, M.; Sarkar, B. Recovery-channel selection in a hybrid manufacturing-remanufacturing production model with RFID and product quality. Int. J. Prod. Econ. 2020, 219, 360–374. [Google Scholar] [CrossRef]

- Amankou, K.A.C.; Guchhait, R.; Sarkar, B.; Dem, H. Product-specified dual-channel retail management with significant consumer service. J. Retail. Consum. Serv. 2024, 79, 103788. [Google Scholar] [CrossRef]

- Sarkis, J.; Dhavale, D.G. Supplier selection for sustainable operations: A triple-bottom-line approach using a Bayesian framework. Int. J. Prod. Econ. 2015, 166, 177–191. [Google Scholar] [CrossRef]

- Carter, C.R.; Easton, P.L. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Susanty, A.; Purwaninghsih, R.; Puspitasari, N.B.P.N.B.; Siregar, A.R.R.; Arista, A.N. Sustainable Supply Chain Management: Pengukuran Tingkat Keberlanjutan Pada Rantai Pasok Pangan; Fastindo: Semarang, Indonesia, 2020. [Google Scholar]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Wamba, S.F.; Papadopoulos, T. The impact of big data on world-class sustainable manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 631–645. [Google Scholar] [CrossRef]

- Sukmawati, W.; Suparno, O.; Hermawan, A. Keberlanjutan Rantai Pasok Industri Kecil Dan Menengah (Ikm) Alas Kaki Di Kabupaten Dan Kota Bogor. J. Teknol. Ind. Pertan. 2020, 30, 43–52. [Google Scholar]

- Sahoo, B.N.; Panigrahi, S.K. A study on the combined effect of in-situ (TiC-TiB2) reinforcement and aging treatment on the yield asymmetry of magnesium matrix composite. J. Alloys Compd. 2018, 737, 575–589. [Google Scholar] [CrossRef]

- Hall, J.; Matos, S. Incorporating impoverished communities in sustainable supply chains. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 124–147. [Google Scholar] [CrossRef]

- Tayyab, M.; Sarkar, B. An interactive fuzzy programming approach for a sustainable supplier selection under textile supply chain management. Comput. Ind. Eng. 2021, 155, 107164. [Google Scholar] [CrossRef]

- Natalia, C.; Surbakti, I.P.; Oktavia, C.W. Integrated ANP and TOPSIS Method for Supplier Performance Assessment. J. Tek. Ind. 2020, 21, 34–45. [Google Scholar] [CrossRef]

- Memari, A.; Dargi, A.; Jokar, M.R.A.; Ahmad, R.; Rahim, A.R.A. Sustainable supplier selection: A multi-criteria intuitionistic fuzzy TOPSIS method. J. Manuf. Syst. 2019, 50, 9–24. [Google Scholar] [CrossRef]

- Amiri, M.; Hashemi-Tabatabaei, M.; Ghahremanloo, M.; Keshavarz-Ghorabaee, M.; Zavadskas, E.K.; Banaitis, A. A new fuzzy BWM approach for evaluating and selecting a sustainable supplier in supply chain management. Int. J. Sustain. Dev. World Ecol. 2021, 28, 125–142. [Google Scholar] [CrossRef]

- Puska, L.A.; Kozarevic, S.; Stevic, Ž.; Stovrag, J. A new way of applying interval fuzzy logic in group decision making for supplier selection. Econ. Comput. Econ. Cybern. Stud. Res. 2018, 52, 217–234. [Google Scholar]

- Amindoust, A. Supplier selection considering sustainability measures: An application of weight restriction fuzzy-DEA approach. RAIRO-Oper. Res. 2018, 52, 981–1001. [Google Scholar] [CrossRef]

- Khulud, K.; Masudin, I.; Zulfikarijah, F.; Restuputri, D.P.; Haris, A. Sustainable Supplier Selection through Multi-Criteria Decision Making (MCDM) Approach: A Bibliometric Analysis. Logistics 2023, 7, 96. [Google Scholar] [CrossRef]

- Hana, M.; Nurcahyo, R. Kriteria evaluasi pemasok berdasarkan green supply chain management. In Proceedings of the Seminar Dan Konferensi Nasional IDEC, Surakarta, Indonesia, 2–3 May 2019. [Google Scholar]

- Restuputri, D.P.; Amalia, F.; Masudin, I.; Widayat. The influence of industry 4.0, internet of things, and physical-cyber systems on human factors: A case study of workers in Indonesian oil and gas refineries. Theor. Issues Ergon. Sci. 2023, 1–26. [Google Scholar] [CrossRef]

- Restuputri, D.P.; Septira, A.P.; Masudin, I. The Role of Creative Leadership to Improve Organizational Performance Through Organizational Ambidexterity in Creative-Based SMEs. IEEE Trans. Eng. Manag. 2023, 71, 8857–8869. [Google Scholar] [CrossRef]

- Hermawan, A.N.; Masudin, I.; Zulfikarijah, F.; Restuputri, D.P.; Shariff, S.S.R. The effect of sustainable manufacturing on environmental performance through government regulation and eco-innovation. Int. J. Ind. Eng. Oper. Manag. 2023; ahead of print. [Google Scholar] [CrossRef]

- Dzikriansyah, M.A.; Masudin, I.; Zulfikarijah, F.; Jihadi, M.; Jatmiko, R.D. The role of green supply chain management practices on environmental performance: A case of Indonesian small and medium enterprises. Clean. Logist. Supply Chain 2023, 6, 100100. [Google Scholar] [CrossRef]

- Masudin, I.; Fernanda, F.W.; Jie, F.; Restuputri, D.P. A review of sustainable reverse logistics: Approaches and applications. Int. J. Logist. Syst. Manag. 2021, 40, 171–192. [Google Scholar] [CrossRef]

- Sakas, D.P.; Giannakopoulos, N.T.; Kanellos, N.; Christopoulos, C.; Toudas, K.S. Determining Factors for Supply Chain Services Provider Selection and Long-Term Relationship Maintenance: Evidence from Greece. Logistics 2023, 7, 73. [Google Scholar] [CrossRef]

- Çiğdem, Ş.; Meidute-Kavaliauskiene, I.; Yıldız, B. Industry 4.0 and Industrial Robots: A Study from the Perspective of Manufacturing Company Employees. Logistics 2023, 7, 17. [Google Scholar] [CrossRef]

- Letunovska, N.; Offei, F.A.; Junior, P.A.; Lyulyov, O.; Pimonenko, T.; Kwilinski, A. Green Supply Chain Management: The Effect of Procurement Sustainability on Reverse Logistics. Logistics 2023, 7, 47. [Google Scholar] [CrossRef]

- Supriyanto, A.; Masruchah, I. Purchasing Guide: Konsep dan Aplikasi Manejemen Purchasing; Elex Media Komputindo: Central Jakarta, Indonesia, 2008. [Google Scholar]

- Gupta, H.; Barua, M.K. Supplier selection among SMEs on the basis of their green innovation ability using BWM and fuzzy TOPSIS. J. Clean. Prod. 2017, 152, 242–258. [Google Scholar] [CrossRef]

- Wu, C.-R.; Lin, C.-T.; Tsai, P.-H. Analysing alternatives in financial services for wealth management banks: The analytic network process and the balanced scorecard approach. IMA J. Manag. Math. 2009, 20, 303–321. [Google Scholar] [CrossRef]

- Saaty, T.L.; Vargas, L.G. Decision Making with the Analytic Network Process; Springer: Berlin/Heidelberg, Germany, 2006; Volume 282. [Google Scholar]

- Masudin, I.; Mawarni, C.A.; Wardana, R.W.; Restuputri, D.P. Supplier selection using Fuzzy DEA credibility constrained and relative closeness index: A case of Indonesian manufacturing industry. Cogent Bus. Manag. 2023, 10, 2228555. [Google Scholar] [CrossRef]

- Marbun, M.; Sinaga, B. Buku Ajar Sistem Pendukung Keputusan Penilaian Hasil Belajar Dengan Metode Topsis; Rudang Mayang Publisher: Medan, Indonesia, 2018. [Google Scholar]

- Masudin, I.; Pranadika, R.; Wardana, R.W.; Almunawar, M.N. Green Supplier Selection Using D-AHP and TOPSIS Methods for Indonesian Plywood Manufacturing. In Handbook of Research on Promoting Logistics and Supply Chain Resilience through Digital Transformation; Masudin, I., Almunawar, M.N., Restuputri, D.P., Sud-On, P., Eds.; IGI Global: Hershey, PA, USA, 2023; pp. 34–59. [Google Scholar]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Liou, J.J.H.; Chuang, Y.-C.; Zavadskas, E.K.; Tzeng, G.-H. Data-driven hybrid multiple attribute decision-making model for green supplier evaluation and performance improvement. J. Clean. Prod. 2019, 241, 118321. [Google Scholar] [CrossRef]

- Green, C. Best practices in supplier relationship management and response when supply is disrupted by cyber attack: An incident response framework. J. Bus. Contin. Emerg. Plan. 2023, 17, 6–15. [Google Scholar]

- Masudin, I.; Wardana, R.W.; Wijayanti, M.W.T.; Restuputri, D.P. Usability website evaluation for fresh food product in sme’s online business with fuzzy ahp-topsis integration. ASEAN Eng. J. 2023, 13, 71–79. [Google Scholar] [CrossRef]

- Saputro, T.E.; Masudin, I.; Rouyendegh, B.D. A literature review on MHE selection problem: Levels, contexts, and approaches. Int. J. Prod. Res. 2015, 53, 5139–5152. [Google Scholar] [CrossRef]

- Sazvar, Z.; Tavakoli, M.; Ghanavati-Nejad, M.; Nayeri, S. Sustainable-resilient supplier evaluation for high-consumption drugs during COVID-19 pandemic using a data-driven decision-making approach. Sci. Iran. 2022. Available online: https://scientiairanica.sharif.edu/article_23009_eeb818c3a84c91f8763c90868960ff8e.pdf (accessed on 16 June 2024).

- Wang, R.; Zimmerman, J.B. Economic and Environmental Assessment of Office Building Rainwater Harvesting Systems in Various U.S. Cities. Environ. Sci. Technol. 2015, 49, 1768–1778. [Google Scholar] [CrossRef]

- Miceli, A.; Hagen, B.; Riccardi, M.P.; Sotti, F.; Settembre-Blundo, D. Thriving, Not Just Surviving in Changing Times: How Sustainability, Agility and Digitalization Intertwine with Organizational Resilience. Sustainability 2021, 13, 2052. [Google Scholar] [CrossRef]

- Marshall, D.; McCarthy, L.; Heavey, C.; McGrath, P. Environmental and social supply chain management sustainability practices: Construct development and measurement. Prod. Plan. Control 2015, 26, 673–690. [Google Scholar] [CrossRef]

- Ratten, V.; Babiak, K. The role of social responsibility, philanthropy and entrepreneurship in the sport industry. J. Manag. Organ. 2015, 16, 482–487. [Google Scholar] [CrossRef]

- Handfield, R.; Walton, S.V.; Sroufe, R.; Melnyk, S.A. Applying environmental criteria to supplier assessment: A study in the application of the Analytical Hierarchy Process. Eur. J. Oper. Res. 2002, 141, 70–87. [Google Scholar] [CrossRef]

- Wennberg, K.; Wiklund, J.; Hellerstedt, K.; Nordqvist, M. Implications of intra-family and external ownership transfer of family firms: Short-term and long-term performance differences. Strateg. Entrep. J. 2011, 5, 352–372. [Google Scholar] [CrossRef]

- Fiksel, J. Designing Resilient, Sustainable Systems. Environ. Sci. Technol. 2003, 37, 5330–5339. [Google Scholar] [CrossRef]

| Criteria | Sub-Criteria | Code | Sources |

|---|---|---|---|

| Economy (E) | Price | E1 | Memari et al. [31] |

| Product defect rate | E2 | Amiri et al. [32] | |

| Discount on quantity | E3 | Puska et al. [33] | |

| Distance | E4 | Amindoust [34] | |

| On-time delivery | E5 | Puska et al. [33] | |

| Consistent quality | E6 | Khulud et al. [35] | |

| Warranty and claims | E7 | Hana and Nurcahyo [36] | |

| Social (S) | Labor competency | S1 | Restuputri et al. [37] |

| Labor satisfaction | S2 | Memari et al. [31] | |

| Communication fluency | S3 | Amiri et al. [32] | |

| Flexible work arrangements | S4 | Restuputri et al. [38] | |

| Use of safety equipment | S7 | Sukmawati et al. [26] | |

| Compliance with labor regulations | S8 | Hermawan et al. [39] | |

| Environment (E) | Environmentally friendly materials | L1 | Dzikriansyah et al. [40] |

| Recycling potential | L2 | Memari et al. [31] | |

| Eco-friendly certification | L3 | Hana and Nurcahyo [36] | |

| Waste | L4 | Masudin et al. [41] |

| Intensity of Interest | Description |

|---|---|

| 1 | Both elements are equally important |

| 3 | One element is slightly more important than the others |

| 5 | One element is more important than another |

| 7 | One element is clearly more absolutely essential than the others |

| 9 | One element is absolute over another |

| 2,4,6,8 | Values between two adjacent consideration values |

| Scale Value | Description |

|---|---|

| 1 | Very low/Bad |

| 2 | Low/Bad |

| 3 | Medium |

| 4 | High/Good |

| 5 | Very high/Very good |

| Criteria | Economy (E) | Social (S) | Environment (L) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | S1 | S2 | S3 | S4 | S7 | S8 | L1 | L2 | L3 | L4 | ||

| Economy (E) | E1 | √ | √ | √ | √ | √ | ||||||||||||

| E2 | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||

| E3 | √ | √ | ||||||||||||||||

| E4 | √ | √ | √ | √ | ||||||||||||||

| E5 | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| E6 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||

| E7 | √ | √ | √ | √ | √ | √ | ||||||||||||

| Social (S) | S1 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||

| S2 | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||

| S3 | √ | √ | √ | √ | √ | √ | ||||||||||||

| S4 | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| S7 | √ | √ | √ | √ | ||||||||||||||

| S8 | √ | √ | √ | |||||||||||||||

| Environment (L) | L1 | √ | √ | √ | √ | √ | √ | √ | ||||||||||

| L2 | √ | √ | √ | √ | ||||||||||||||

| L3 | √ | √ | ||||||||||||||||

| L4 | √ | √ | √ | √ | ||||||||||||||

| Criteria | Sub Criteria 1 | Sub Criteria 2 | R1 | R2 | R3 | G-Mean |

|---|---|---|---|---|---|---|

| Economic | Price | Product defect rate | 2 | 3 | 4 | 2.884 |

| Discount on quantity | 1 | 2 | 2 | 1.587 | ||

| Distance | 2 | 2 | 2 | 2.000 | ||

| On-time delivery | 1 | 3 | 3 | 2.080 | ||

| Consistent quality | 3 | 2 | 1 | 1.817 | ||

| Warranty and claims | 2 | 0.50 | 2 | 1.260 | ||

| Product defect rate | Discount on quantity | 2 | 2 | 3 | 2.289 | |

| Distance | 1 | 2 | 3 | 1.817 | ||

| On-time delivery | 2 | 1 | 2 | 1.587 | ||

| Consistent quality | 0.50 | 2 | 4 | 1.587 | ||

| Warranty and claims | 1 | 4 | 3 | 2.289 | ||

| Discount on quantity | 2 | 2 | 3 | 2.289 | ||

| Discount on quantity | Distance | 2 | 1 | 1 | 1.260 | |

| On-time delivery | 1 | 2 | 2 | 1.587 | ||

| Consistent quality | 3 | 1 | 0.50 | 1.145 | ||

| Warranty and claims | 2 | 0.33 | 1 | 0.874 | ||

| Distance | On-time delivery | 0.50 | 2 | 2 | 1.260 | |

| Consistent quality | 2 | 1 | 0.50 | 1.000 | ||

| Warranty and claims | 1 | 0.33 | 1 | 0.693 | ||

| On-time delivery | Consistent quality | 0.33 | 2 | 3 | 1.260 | |

| Warranty and claims | 0.50 | 4 | 2 | 1.587 | ||

| Consistent quality | Warranty and claims | 2 | 3 | 0.50 | 1.442 | |

| Social | Workforce competency | Labor satisfaction | 3 | 1 | 2 | 1.817 |

| Communication fluency | 0.50 | 4 | 2 | 1.587 | ||

| Flexible work arrangements | 3 | 0.50 | 2 | 1.442 | ||

| Use of safety equipment | 2 | 0.50 | 2 | 1.260 | ||

| Compliance with labor regulations | 3 | 0.33 | 2 | 1.260 | ||

| Labor satisfaction | Communication fluency | 2 | 4 | 3 | 2.884 | |

| Flexible work arrangements | 1 | 0.50 | 1 | 0.794 | ||

| Use of safety equipment | 2 | 2 | 4 | 2.520 | ||

| Compliance with labor regulation | 1 | 3 | 3 | 2.080 | ||

| Communication fluency | Flexible work arrangements | 2 | 3 | 4 | 2.621 | |

| Use of safety equipment | 1 | 3 | 0.50 | 1.145 | ||

| Compliance with labor regulations | 2 | 2 | 1 | 1.587 | ||

| Flexible work arrangement | Use of safety equipment | 2 | 1 | 4 | 2.000 | |

| Compliance with labor regulations | 1 | 2 | 2 | 1.587 | ||

| Use of safety equipment | Compliance with labor regulations | 2 | 0.50 | 2 | 1.260 | |

| Environment | Friendly materials environment | Recycling potential | 1 | 2 | 0.50 | 1.000 |

| Eco-friendly certification | 2 | 0.50 | 1 | 1.0000 | ||

| Waste | 0.50 | 2 | 2 | 1.260 | ||

| Recycling potential | Eco-friendly certification | 2 | 0.33 | 2 | 1.101 | |

| Waste | 2 | 0.33 | 1 | 0.874 | ||

| Friendly certification environment | Waste | 1 | 1 | 0.50 | 0.794 |

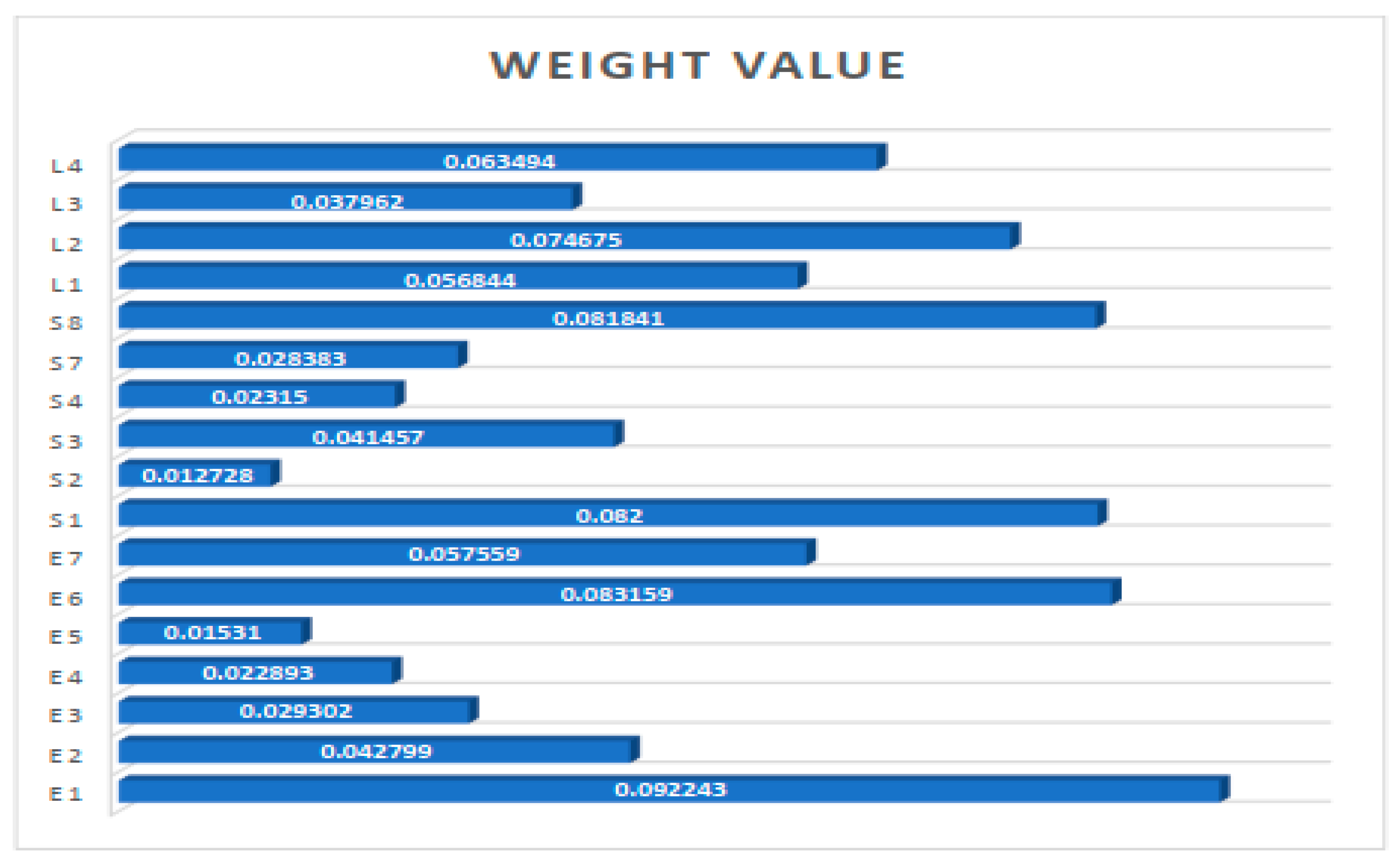

| Criteria | Code | Sub-Criteria | Final Priority Weight | Cluster Normalized Priority Weight |

|---|---|---|---|---|

| Economy (0.0652) | E1 | 1. Price | 0.0922 | 0.2695 |

| E2 | 2. Product defect rate | 0.0418 | 0.1221 | |

| E3 | 3. Discount on quantity | 0.0293 | 0.0856 | |

| E4 | 4. Distance | 0.0229 | 0.0669 | |

| E5 | 5. Timely delivery | 0.0820 | 0.0447 | |

| E6 | 6. Consistent quality | 0.0832 | 0.2430 | |

| E7 | 7. Warranty and claims | 0.0576 | 0.1682 | |

| Social (0.0343) | S1 | 1. Labor competency | 0.0862 | 0.3137 |

| S2 | 2. Labor satisfaction | 0.0127 | 0.0463 | |

| S3 | 3. Smoothness of communication | 0.0425 | 0.1545 | |

| S4 | 4. Flexible work arrangements | 0.0232 | 0.0843 | |

| S7 | 7. Use of safety equipment | 0.0284 | 0.103 | |

| S8 | 8. Compliance with labor regulations | 0.0153 | 0.2979 | |

| Environment (0.0503) | L1 | 1. Environmentally friendly materials | 0.0568 | 0.2440 |

| L2 | 2. Recycling potential | 0.0747 | 0.3205 | |

| L3 | 3. Eco-friendly certification | 0.0380 | 0.1629 | |

| L4 | 4. Waste | 0.0635 | 0.2725 |

| Criteria | Code | Linkage Relationship | Inconsistency Value |

|---|---|---|---|

| Economy | E1 | E2, E3, E4, E5, E6, E7 L1, L2, L3, L4 | 0.0176 0.0454 |

| E2 | E1, E3, E4, E5, E6 L1, L4 S1, S2, S3, S4, S7, S8 | 0.0195 0.0000 0.0350 | |

| E3 | E1, E2, E4, E5, E6 | 0.016 | |

| E4 | E1, E2, E3, E5, E6 | 0.0202 | |

| E5 | E1, E2, E3, E4, E7 | 0.0202 | |

| E6 | E1, E2, E3, E4, E5, E7 L1, L2, L3, L4 S1, S2, S3, S4, S7, S8 | 0.0184 0.0454 0.0357 | |

| E7 | E1, E2, E3, E4, E5, E6, L1, L2, L3, L4 | 0.0200 0.0454 | |

| Social | S1 | E1, E2, E6 S2, S3, S4, S7, S8 L2, L4 | 0.0085 0.0000 0.0260 |

| S2 | E2, E6 S1, S3, S4, S7, S8 | 0.0000 0.0326 | |

| S3 | E2, E6 S1, S2, S4, S7, S8 | 0.0000 0.0460 | |

| S4 | E2, E6 S1, S2, S3, S7, S8 L1, L2 | 0.0000 0.0530 0.0000 | |

| S7 | E2, E6 S1, S2, S3, S4, S8 | 0.0000 0.0270 | |

| S8 | E2, E6, E7 S1, S2, S3, S4, S7 L1, L2, L3, L4 | 0.0080 0.0454 0.027 | |

| Environment | L1 | E1, E6, E7 L2, L3, L4 | 0.051 0.051 |

| L2 | E1, E2, E6, E7 S1, S4, S8 | 0.026 0.051 | |

| L3 | E1, E6, E7 L1, L2, L4 S4, S8 | 0.051 0.051 0.000 | |

| L4 | E1, E2, E6, E7 L1, L2, L3 S1, S8 | 0.026 0.051 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masudin, I.; Habibah, I.Z.; Wardana, R.W.; Restuputri, D.P.; Shariff, S.S.R. Enhancing Supplier Selection for Sustainable Raw Materials: A Comprehensive Analysis Using Analytical Network Process (ANP) and TOPSIS Methods. Logistics 2024, 8, 74. https://doi.org/10.3390/logistics8030074

Masudin I, Habibah IZ, Wardana RW, Restuputri DP, Shariff SSR. Enhancing Supplier Selection for Sustainable Raw Materials: A Comprehensive Analysis Using Analytical Network Process (ANP) and TOPSIS Methods. Logistics. 2024; 8(3):74. https://doi.org/10.3390/logistics8030074

Chicago/Turabian StyleMasudin, Ilyas, Isna Zahrotul Habibah, Rahmad Wisnu Wardana, Dian Palupi Restuputri, and S. Sarifah Radiah Shariff. 2024. "Enhancing Supplier Selection for Sustainable Raw Materials: A Comprehensive Analysis Using Analytical Network Process (ANP) and TOPSIS Methods" Logistics 8, no. 3: 74. https://doi.org/10.3390/logistics8030074

APA StyleMasudin, I., Habibah, I. Z., Wardana, R. W., Restuputri, D. P., & Shariff, S. S. R. (2024). Enhancing Supplier Selection for Sustainable Raw Materials: A Comprehensive Analysis Using Analytical Network Process (ANP) and TOPSIS Methods. Logistics, 8(3), 74. https://doi.org/10.3390/logistics8030074