The Relationship between Lean Practices and Organizational Performance: An Analysis of Operations Management in a Public Institution

Abstract

1. Introduction

2. Research Background

2.1. Lean Practices in Public Institutions

2.2. Organizational Performance

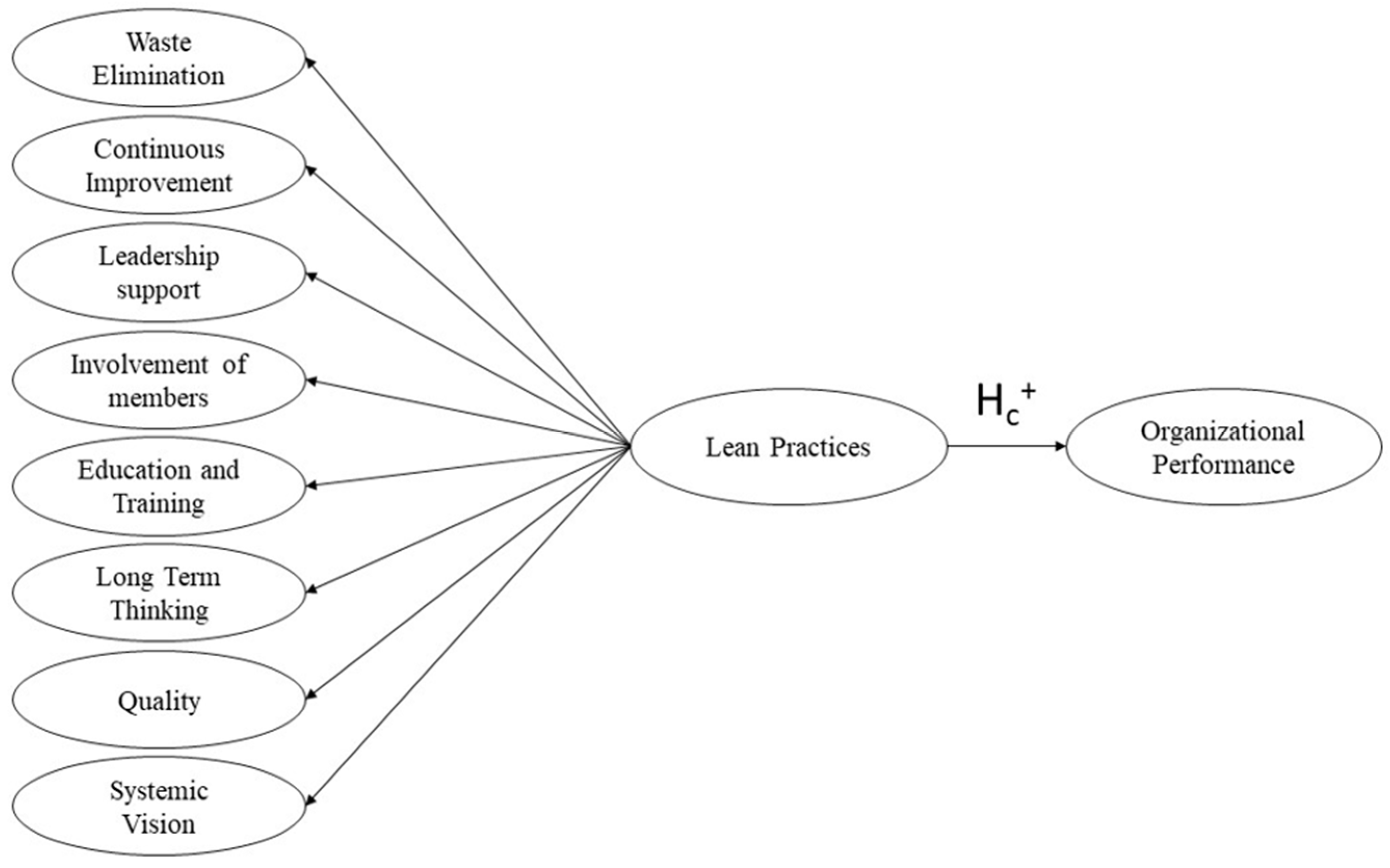

2.3. Theoretical Research Model

3. Materials and Methods

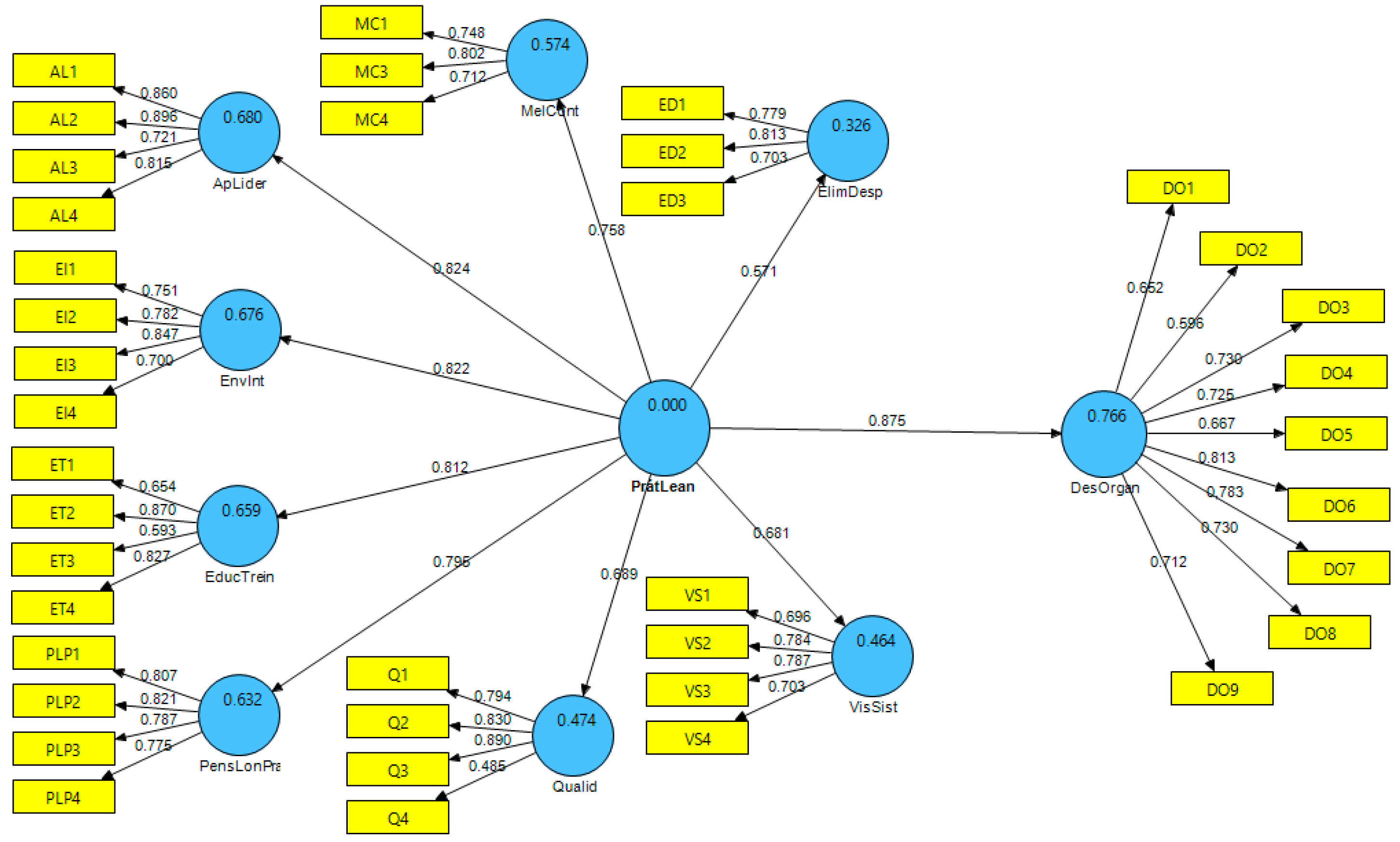

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Juliani, F.; Oliveira, O.J. Lean six sigma in the public sector: Overcoming persistente management challenges. Qual. Manag. J. 2021, 28, 58–75. [Google Scholar] [CrossRef]

- Chirau, T.J.; Blaser-Mapitsa, C. How performance management regulations shape evaluation practice in South African municipalities. Eval. Program Plan. 2020, 82, 101831. [Google Scholar] [CrossRef]

- Kates, J.; Marconi, K.; Mannle, T.E., Jr. Developing a performance management system for a Federal public health program: The Ryan White CARE ACT Titles I and II. Eval. Program Plan. 2011, 24, 145–155. [Google Scholar] [CrossRef]

- Montezano, L.; Petry, I.S.; Matos Frossad, L.B.; Isidro, A. Avaliação de competências organizacionais de órgão público federal: Ótica de diferentes atores. RACE-Rev. Adm. Contab. E Econ. 2021, 20, 269–288. [Google Scholar] [CrossRef]

- Garcia, G.A.; Schwantz, P.I.; Moretto Neto, L. Análise do plano de contingência da Fundação Oswaldo Cruz para o enfrentamento do Coronavírus. Ciências Adm. 2021, 23, 24–36. [Google Scholar]

- Almeida, J.P.L.; Galina, S.V.R.; Grande, M.M.; Brum, D.G. Lean thinking: Planning and implementation in the public sector. Int. J. Lean Six Sigma 2017, 8, 390–410. [Google Scholar] [CrossRef]

- Chavez, R.; Gimenez, C.; Fynes, B.; Wiengarten, F.; Yu, W. Internal lean practices and operational performance: The contingency perspective of industry clockspeed. Int. J. Oper. Prod. Manag. 2013, 33, 562–588. [Google Scholar] [CrossRef]

- Sharma, V.; Dixit, A.R.; Qadri, M.A. Impact of lean practices on performance measures in context to Indian machine tool industry. J. Manuf. Technol. Manag. 2015, 26, 1218–1242. [Google Scholar] [CrossRef]

- Habidin, N.F.; Mohd Yusof, S.; Mohd Fuzi, N. Lean Six Sigma, strategic control systems, and organizational performance for automotive suppliers. Int. J. Lean Six Sigma 2016, 7, 110–135. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M.; Fontes, D.B.M.M.; Tan Ching, N. Modeling lean manufacturing success. J. Model. Manag. 2018, 13, 908–931. [Google Scholar] [CrossRef]

- Silva, I.B.; Seraphim, E.C.; Agostinho, O.L.; Lima Junior, O.F.; Batalha, G.F. Lean office in health organization in the Brazilian Army. Int. J. Lean Six Sigma 2015, 6, 2–16. [Google Scholar] [CrossRef]

- Acero, R.; Torralba, M.; Pérez-Moya, R.; Pozo, J.A. Value stream analysis in military logistics: The improvement in order processing procedure. Appl. Sci. 2019, 10, 106. [Google Scholar] [CrossRef]

- Bateman, N.; Hines, P.; Davidson, P. Wider applications for Lean: An examination of the fundamental principles within public sector organisations. Int. J. Product. Perform. Manag. 2014, 63, 550–568. [Google Scholar] [CrossRef]

- Sreedharan, V.R.; Raju, R.J.I.J. A systematic literature review of Lean Six Sigma in different industries. Int. J. Lean Six Sigma 2016, 7, 430–466. [Google Scholar] [CrossRef]

- Karim Suhag, A.; Solangi, S.R.; Larik, R.S.A.; Lakh, M.K.; Tagar, A.H. The relationship of innovation with organizational performance. Int. J. Res.-Granthaalayah 2017, 5, 292–306. [Google Scholar] [CrossRef]

- Urban, W. The Lean Management Maturity Self-Assessment Tool Based on Organizational Culture Diagnosis. Procedia Soc. Behavional Sci. 2015, 213, 728–733. [Google Scholar] [CrossRef]

- Casati, N.M. Current and future global challenges in management and leadership: Finance and quantum computing. In Paradigm Shift in Management Philosophy: Future Challenges in Global Organizations; Palgrave Macmillan: Cham, Switzerland, 2020; pp. 103–131. [Google Scholar]

- Ohno, T. O Sistema Toyota de Produção: Além da Produção em Larga Escala; Bookman: Porto Alegre, Brazil, 1997. [Google Scholar]

- Womack, J.P.; Jones, D.T. A Mentalidade Enxuta nas Empresas Lean Thinking: Elimine o Desperdício e Crie Riqueza, 1st ed.; Campus: Rio de Janeiro, Brazil, 2004. [Google Scholar]

- Benkarim, A.; Imbeau, D. Organizational commitment and lean sustainability: Literature review and directions for future research. Sustainability 2021, 13, 3357. [Google Scholar] [CrossRef]

- Velsberg, O.; Westergren, U.H.; Jonsson, K. Exploring smartness in public sector innovation-creating smart public services with the Internet of Things. Eur. J. Inf. Syst. 2020, 29, 350–368. [Google Scholar] [CrossRef]

- Al Yami, M.; Ajmal, M.M. Pursuing sustainable development with knowledge management in public sector. VINE J. Inf. Knowl. Manag. Syst. 2019, 49, 568–593. [Google Scholar] [CrossRef]

- Falcão Junior, M.A.G.; Santos, R.N.M. A gestão de processos na análise das atividades de seleções públicas simplificadas: Estudo de caso em uma prefeitura. Navus Rev. Gestão E Tecnol. 2016, 6, 6–19. [Google Scholar] [CrossRef][Green Version]

- Leontjeva, O.; Trufanova, V. Lean Team Members’ Selection for Public Administration Organisations. Public Adm. Issues 2018, 45–65. [Google Scholar]

- Perna, J.L.S.; Ferraz, F.T. Implantação da Metodologia “Lean” nos setores de Serviços Gerais de uma instituição federal de ensino. In Anais VII Congresso de Sistemas Lean: Contribuições do Lean à Gestão em Tempos de Crise; 10 e 11 de Novembro de; Niterói/Rio de Janeiro, Brazil, 2017; Available online: http://www.producao.uff.br/lean7/anais.html (accessed on 3 August 2023).

- Radnor, Z.; Osborne, S.P. Lean: A failed theory for public ervices? Public Manag. Rev. 2013, 15, 265–287. [Google Scholar] [CrossRef]

- Dibia, I.K.; Dhakal, H.N.; Onuh, S. Lean “Leadership People Process Outcome” (LPPO) implementation model. J. Manuf. Technol. Manag. 2014, 25, 694–711. [Google Scholar] [CrossRef]

- Corrêa, C.S.; Shio, E.; Santos, L.A. O desempenho organizacional por meio da contabilidade gerencial quanto a utilização de ferramentas de gestão. Discip. Sci. 2017, 12, 43–63. [Google Scholar]

- Abdallah, A.B.; Dahiyat, S.E.; Matsui, Y. Lean management and innovation performance. Manag. Res. Rev. 2019, 42, 239–262. [Google Scholar] [CrossRef]

- Atmaja, D.S.; Zaroni, A.N.; Yusuf, M. Actualization of Performance Management Models for the Development of Human Resources Quality, Economic Potential, and Financial Governance Policy in Indonesia Ministry Of Education. Multicult. Educ. 2023, 9, 1–15. [Google Scholar]

- Levinthal, D.A.; Rerup, C. The plural of goal: Learning in a world of ambiguity. Organ. Sci. 2021, 32, 527–543. [Google Scholar] [CrossRef]

- Agostino, D.; Saliterer, I.; Steccolini, I. Digitalization, accounting and accountability: A literature review and reflections on future research in public services. Financ. Account. Manag. 2022, 38, 152–176. [Google Scholar] [CrossRef]

- Ahmed, W.; Najmi, A.; Ikram, M. Steering firm performance through innovative capabilities: A contingency approach to innovation management. Technol. Soc. 2020, 63, 101385. [Google Scholar] [CrossRef]

- Brewis, C.; Dibb, S.; Meadows, M. Leveraging Big Data for Strategic Marketing: A dynamic capabilities model for incumbent firms. Technol. Forecast. Soc. Chang. 2023, 190, 122402. [Google Scholar] [CrossRef]

- Rehman, S.; Mohamed, R.; Ayoup, H. The mediating role of organizational capabilities between organizational performance and its determinants. J. Glob. Entrep. Res. 2019, 9, 30. [Google Scholar] [CrossRef]

- Saudi, M.H.M.; Juniati, S.; Kozicka, K.; Razimi, M.S.A. Influence of lean practices on supply chain performance. Pol. J. Manag. Stud. 2019, 19, 353–363. [Google Scholar] [CrossRef]

- Parwani, V.; Hu, G. Improving manufacturing supply chain by integrating SMED and production scheduling. Logistics 2021, 5, 4. [Google Scholar] [CrossRef]

- Arca, J.; Prado, J.C. Systematic personnel participation for logistics improvement: A case study. Hum. Fac. Erg. Man. Serv. Ind. 2010, 21, 209–223. [Google Scholar] [CrossRef]

- Singh, J.; Singh, H. Continuous improvement philosophy—literature review and directions. Benchmarking Int. J. 2015, 22, 75–119. [Google Scholar] [CrossRef]

- Waterbury, T. Learning from the pioneers: A multiple-case analysis of implementing Lean in higher education. Int. J. Qual. Reliab. Manag. 2015, 32, 934–950. [Google Scholar] [CrossRef]

- Jabagi, N.; Croteau, A.M.; Audebrand, L.K.; Marsan, J. Gig-workers’ motivation: Thinking beyond carrots and sticks. J. Manag. Psychol. 2019, 34, 192–213. [Google Scholar] [CrossRef]

- Sanchis, R.; Gisbert, M.R.S.; Poler, R. Conceptualisation of the three-dimensional matrix of collaborative knowledge barriers. Sustainability 2020, 12, 1279. [Google Scholar] [CrossRef]

- Sprinkle, T.A.; Urick, M.J. Three generational issues in organizational learning: Knowledge management, perspectives on training and “low-stakes” development. Learn. Organ. 2018, 25, 102–112. [Google Scholar] [CrossRef]

- Bilska, B.; Wrzosek, M.; Krajewska, D.K.; Krajewski, K. Risk of food losses and potential of food recovery for social purposes. Waste Manag. 2016, 52, 269–277. [Google Scholar] [CrossRef]

- Henisz, W.; Koller, T.; Nuttall, R. Five ways that ESG creates value. McKinsey Co. 2019, 1, 1–12. [Google Scholar]

- Santa, R.; Macdonald, J.B.; Ferrer, M. The role of trust in e-Government effectiveness, operational effectiveness and user satisfaction: Lessons from Saudi Arabia in e-G2B. Gov. Inf. Q. 2019, 36, 39–50. [Google Scholar] [CrossRef]

- Lina, R. Improving Product Quality and Satisfaction as Fundamental Strategies in Strengthening Customer Loyalty. Akad. J. Mhs. Ekon. Bisnis 2022, 2, 19–26. [Google Scholar] [CrossRef]

- Joseph, J.; Gaba, V. Organizational structure, information processing, and decision-making: A retrospective and road map for research. Acad. Manag. Ann. 2020, 14, 267–302. [Google Scholar] [CrossRef]

- Gu, M.; Zhang, Y.; Li, D.; Huo, B. The effect of high-involvement human resource management practices on supply chain resilience and operational performance. J. Manag. Sci. Eng. 2023, 8, 176–190. [Google Scholar] [CrossRef]

- Ingelsson, P.; Mårtensson, A. Measuring the importance and practices of Lean values. TQM J. 2014, 26, 463–474. [Google Scholar] [CrossRef]

- Salhieh, L.; Abdallah, A.A. A two-way causal chain between lean management practices and lean values. Int. J. Product. Perform. Manag. 2019, 68, 997–1016. [Google Scholar] [CrossRef]

- Sajan, M.P.; Shalij, P.R.; Ramesh, A. Lean manufacturing practices in Indian manufacturing SMEs and their effect on sustainability performance. J. Manuf. Technol. Manag. 2017, 28, 772–793. [Google Scholar]

- Sfakianaki, E.; Kakouris, A. Lean thinking for education: Development and validation of an instrument. Int. J. Qual. Reliab. Manag. 2019, 36, 917–950. [Google Scholar] [CrossRef]

- King, N.C.O.; Lima, E.P.; Costa, S.E.G. Produtividade sistêmica: Conceitos e aplicações. Production 2014, 24, 160–176. [Google Scholar] [CrossRef]

- Alvarez, F.H.B.; Alvarez, L.D.C.H. A aplicação da filosofia Lean Thinking nos setores de saúde: Uma revisão integrativa. Rev. Eletrônica Acervo Saúde 2022, 15, e10065. [Google Scholar] [CrossRef]

- Shenshinov, Y.; Al-Ali, A. The tools of increasing efficiency of human resource in the lean production environment: Conceptual study. Int. J. Core Eng. Manag. 2020, 6, 1–18. [Google Scholar]

- Ringle, C.M.; Silva, D.; Bido, D.S. Modelagem de equações estruturais com utilização do SmartPLS. Rev. Bras. De Mark. 2014, 13, 56–73. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling, 1st ed.; Sage: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Oliveira Neto, G.C.; Tucci, H.N.P.; Correia, J.M.F.; Silva, P.C.; Silva, D.; Amorim, M. Stakeholders’ influences on the adoption of cleaner production practices: A survey of the textile industry. Sustain. Prod. Consum. 2021, 26, 126–145. [Google Scholar] [CrossRef]

- Rönkkö, M.; McIntosh, C.N.; Antonakis, J.; Edwards, J.R. Partial least squares path modeling: Time for some serious second thoughts. J. Oper. Manag. 2016, 47, 9–27. [Google Scholar] [CrossRef]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Richter, N.F.; Sinkovics, R.R.; Ringle, C.M.; Schlägel, C. A critical look at the use of SEM in international business research. Int. Mark. Rev. 2016, 33, 376–404. [Google Scholar] [CrossRef]

- Tenenhaus, M.; Amato, S.; Vinzi, V.V. A global goodness-of-fit index for PLS structural equation modeling. In Proceedings of the XLII SIS Scientific Meeting; CLEUP: Padova, Italy, 2004; Volume 1, pp. 739–742. [Google Scholar]

- Van Assen, M.F. Empowering leadership and contextual ambidexterity–The mediating role of committed leadership for continuous improvement. Eur. Manag. J. 2020, 38, 435–449. [Google Scholar] [CrossRef]

- Sawaean, F.; Ali, K. The impact of entrepreneurial leadership and learning orientation on organizational performance of SMEs: The mediating role of innovation capacity. Manag. Sci. Lett. 2020, 10, 369–380. [Google Scholar] [CrossRef]

- Ershadi, M.J.; Eskandari Dehdazzi, R. Investigating the role of strategic thinking in establishing organizational excellence model: A moderating role of organizational forgetting. TQM J. 2019, 31, 620–640. [Google Scholar] [CrossRef]

- Linden, E. Pandemics and environmental shocks: What aviation managers should learn from COVID-19 for long-term planning. J. Air Transp. Manag. 2021, 90, 101944. [Google Scholar] [CrossRef]

- Ullmann, J.I.; Fumagalli, L.W.A. o feedback como processo de aprendizagem organizacional. Rev. FAE 2018, 21, 137–155. [Google Scholar]

- Kazancoglu, Y.; Ozkan-Ozen, Y.D. Lean in higher education: A proposed model for lean transformation in a business school with MCDM application. Qual. Assur. Educ. 2019, 27, 82–102. [Google Scholar] [CrossRef]

- Jermier, J.M.; Berkes, L.J. Leader behavior in a police command bureaucracy: A closer look at the quasi-military model. Adm. Sci. Q. 1979, 24, 1–23. [Google Scholar] [CrossRef]

- Malešević, S.; Ó Dochartaigh, N. Why combatants fight: The Irish Republican army and the Bosnian Serb army compared. Theory Soc. 2018, 47, 293–326. [Google Scholar] [CrossRef]

- Ţuţuianu, D.E. Discipline and Its Subsequent Benefits for Teaching English in Military Institutions; Bulletin of “Carol I” National Defence University (EN); “Carol I” National Defence University (EN): Bucharest, Romania, 2017; pp. 23–28. [Google Scholar]

- Hall-Clark, B.N.; Wright, E.C.; Fina, B.A.; Blount, T.H.; Evans, W.R.; Carreño, P.K.; Peterson, A.L.; Foa, E.B. Military culture considerations in prolonged exposure therapy with active-duty military service members. Cogn. Behav. Pract. 2019, 26, 335–350. [Google Scholar] [CrossRef]

| Frequency | Valid Percent | ||

|---|---|---|---|

| Age | 19 to 22 years old | 29 | 24.5 |

| 23 to 29 years old | 30 | 25.5 | |

| 30 to 40 years old | 31 | 26.5 | |

| 41 to 55 years old | 26 | 23.5 | |

| Sex | Feminine | 1 | 1.0 |

| Masculine | 115 | 99.0 | |

| Level of education | Elementary | 10 | 5.9 |

| High school | 48 | 43.1 | |

| Graduate | 44 | 39.2 | |

| Specialist | 14 | 11.8 | |

| Length of service | Up to 5 years | 63 | 56.9 |

| From 5 to 10 years | 30 | 23.5 | |

| More than 10 years | 23 | 19.6 |

| Construct | Code | Items | Source |

|---|---|---|---|

| Systemic Vision (SistVis) | VS1 | Interconnected activities between sectors of the organization | [50,51] |

| VS2 | Contribution of the activities to the achievement of the organization’s objectives | ||

| VS4 | Knowledge of the organization’s overall objectives | ||

| VS4 | View of the steps and procedures in the activities | ||

| Waste Elimination (WasEli) | ED1 | Elimination or reduction of waste continuously | [6,52] |

| ED2 | Ability to identify waste in the organization | ||

| ED3 | Reduction of waste in the sector | ||

| ED4 | Solving problems quickly and effectively | ||

| Continuous Improvement (ContImp) | MC1 | Proposing improvements in the organization’s activities | [6,50,51] |

| MC2 | Search for daily improvement | ||

| MC3 | Standardization of activities for continuous improvement | ||

| MC4 | More concerned with improving than finding out who made a mistake | ||

| Leadership support (LidSup) | AL1 | Responsibility for actions and decisions | [40,51] |

| AL2 | Improved ways of working, relationships, and communication | ||

| AL3 | Participation of the leader in the activities | ||

| AL4 | Recognition of the team for achieving objectives and goals | ||

| Involvement of members (InvMem) | EI1 | Autonomy and stimulus for improvement suggestions | [50,51,52,53] |

| EI2 | Feedback on activities and tasks | ||

| EI3 | Involvement in proposing improvements | ||

| EI4 | Autonomy to solve problems | ||

| Education and Training (EduTrai) | ET1 | Strict rules of discipline, respect, and education | [50,51,53] |

| ET2 | Commitment to education and training | ||

| ET3 | Education and Training Resources | ||

| ET4 | Continuous development process | ||

| Long-Term Thinking (LonTerTh) | PLP1 | Common vision in the industry | [6,50,51,52,53] |

| PLP2 | Actions based on long-term thinking | ||

| PLP3 | Understanding long-term returns | ||

| PLP4 | Execution of long-term activities | ||

| Quality (Qual) | Q1 | The quality level of the working group | [50,51] |

| Q2 | Quality of services provided | ||

| Q3 | Continuous quality improvement | ||

| Q4 | Quality of facilities | ||

| Q5 | Quality of the equipment | ||

| Organizational Performance (OrgPer) | DO1 | Productivity Improvement | [54,55,56] |

| DO2 | Fair and Equitable Treatment of Employees | ||

| DO3 | Recurrence of errors | ||

| DO4 | Cost reduction | ||

| DO5 | Fulfillment of industry goals | ||

| DO6 | The efficiency of activities and processes | ||

| DO7 | Efficient activities at low cost | ||

| DO8 | New procedures and/or practices | ||

| DO9 | Achieving the organization’s goals and objectives |

| Construct | AVE | Composite Reliability | Cronbach’s Alpha |

|---|---|---|---|

| LidSup | 0.681591 | 0.894817 | 0.842137 |

| EduTrai | 0.554940 | 0.829635 | 0.721602 |

| WasEli | 0.586519 | 0.809108 | 0.750911 |

| InvMem | 0.596304 | 0.854686 | 0.776840 |

| ContImp | 0.569822 | 0.798626 | 0.721403 |

| LonTerTh | 0.636170 | 0.874856 | 0.809274 |

| Qual | 0.585874 | 0.844664 | 0.743514 |

| SistVis | 0.552011 | 0.830916 | 0.731571 |

| OrgPer | 0.510700 | 0.903220 | 0.818311 |

| LidSup | EduTrai | WasEli | InvMem | ContImp | LonTerTh | Qual | SistVis | |

|---|---|---|---|---|---|---|---|---|

| LidSup | 0.82559 | -- | ||||||

| EduTrai | 0.63780 | 0.74494 | -- | |||||

| WasEli | 0.28838 | 0.38713 | 0.76585 | |||||

| InvMem | 0.63848 | 0.65110 | 0.36183 | 0.77221 | ||||

| ContImp | 0.64672 | 0.51279 | 0.37878 | 0.61347 | 0.75487 | |||

| LonTerTh | 0.58923 | 0.69024 | 0.36919 | 0.61179 | 0.55512 | 0.79760 | ||

| Qual | 0.49704 | 0.45843 | 0.46594 | 0.48901 | 0.38805 | 0.40027 | 0.76542 | |

| SistVis | 0.56190 | 0.44558 | 0.40285 | 0.53801 | 0.41708 | 0.39528 | 0.44895 | 0.74297 |

| Construct | Q² | f² |

|---|---|---|

| LidSup | 0.630494 | 0.630494 |

| EduTrai | 0.488381 | 0.488381 |

| WasEli | 0.468079 | 0.468079 |

| InvMem | 0.619947 | 0.619947 |

| ContImp | 0.585209 | 0.585209 |

| LonTerTh | 0.574580 | 0.574580 |

| Qual | 0.502305 | 0.502305 |

| SistVis | 0.582152 | 0.582152 |

| Construct | β | p-Value |

|---|---|---|

| LidSup | 0.824 | 0.000 |

| EduTrai | 0.812 | 0.010 |

| WasEli | 0.571 | 0.000 |

| InvMem | 0.822 | 0.015 |

| ContImp | 0.758 | 0.000 |

| LonTerTh | 0.796 | 0.013 |

| Qual | 0.689 | 0.000 |

| SistVis | 0.681 | 0.005 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schwantz, P.I.; Klein, L.L.; Simonetto, E.d.O. The Relationship between Lean Practices and Organizational Performance: An Analysis of Operations Management in a Public Institution. Logistics 2023, 7, 52. https://doi.org/10.3390/logistics7030052

Schwantz PI, Klein LL, Simonetto EdO. The Relationship between Lean Practices and Organizational Performance: An Analysis of Operations Management in a Public Institution. Logistics. 2023; 7(3):52. https://doi.org/10.3390/logistics7030052

Chicago/Turabian StyleSchwantz, Patricia Inês, Leander Luiz Klein, and Eugênio de Oliveira Simonetto. 2023. "The Relationship between Lean Practices and Organizational Performance: An Analysis of Operations Management in a Public Institution" Logistics 7, no. 3: 52. https://doi.org/10.3390/logistics7030052

APA StyleSchwantz, P. I., Klein, L. L., & Simonetto, E. d. O. (2023). The Relationship between Lean Practices and Organizational Performance: An Analysis of Operations Management in a Public Institution. Logistics, 7(3), 52. https://doi.org/10.3390/logistics7030052