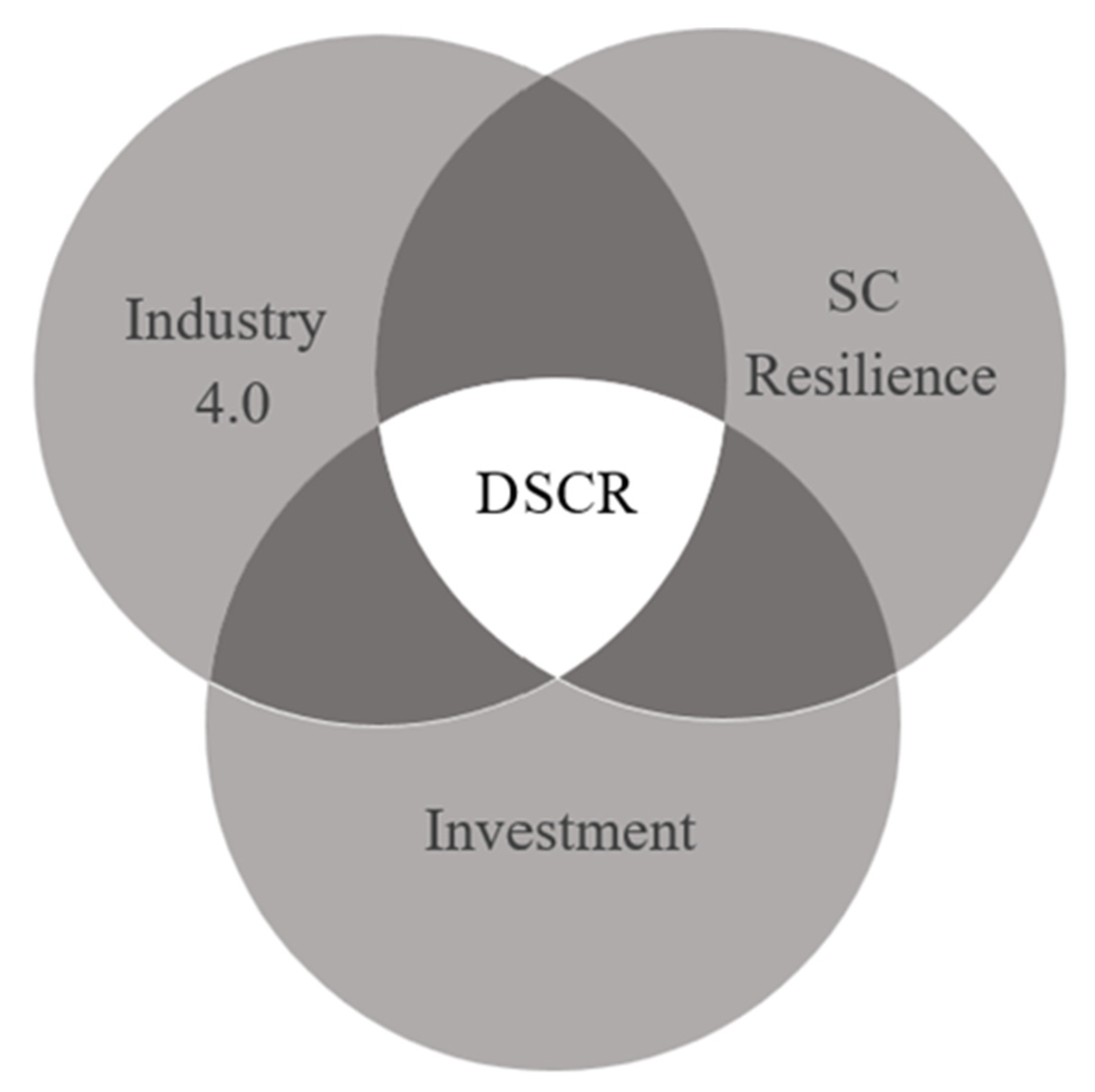

Interconnectedness between Supply Chain Resilience, Industry 4.0, and Investment

Abstract

1. Introduction

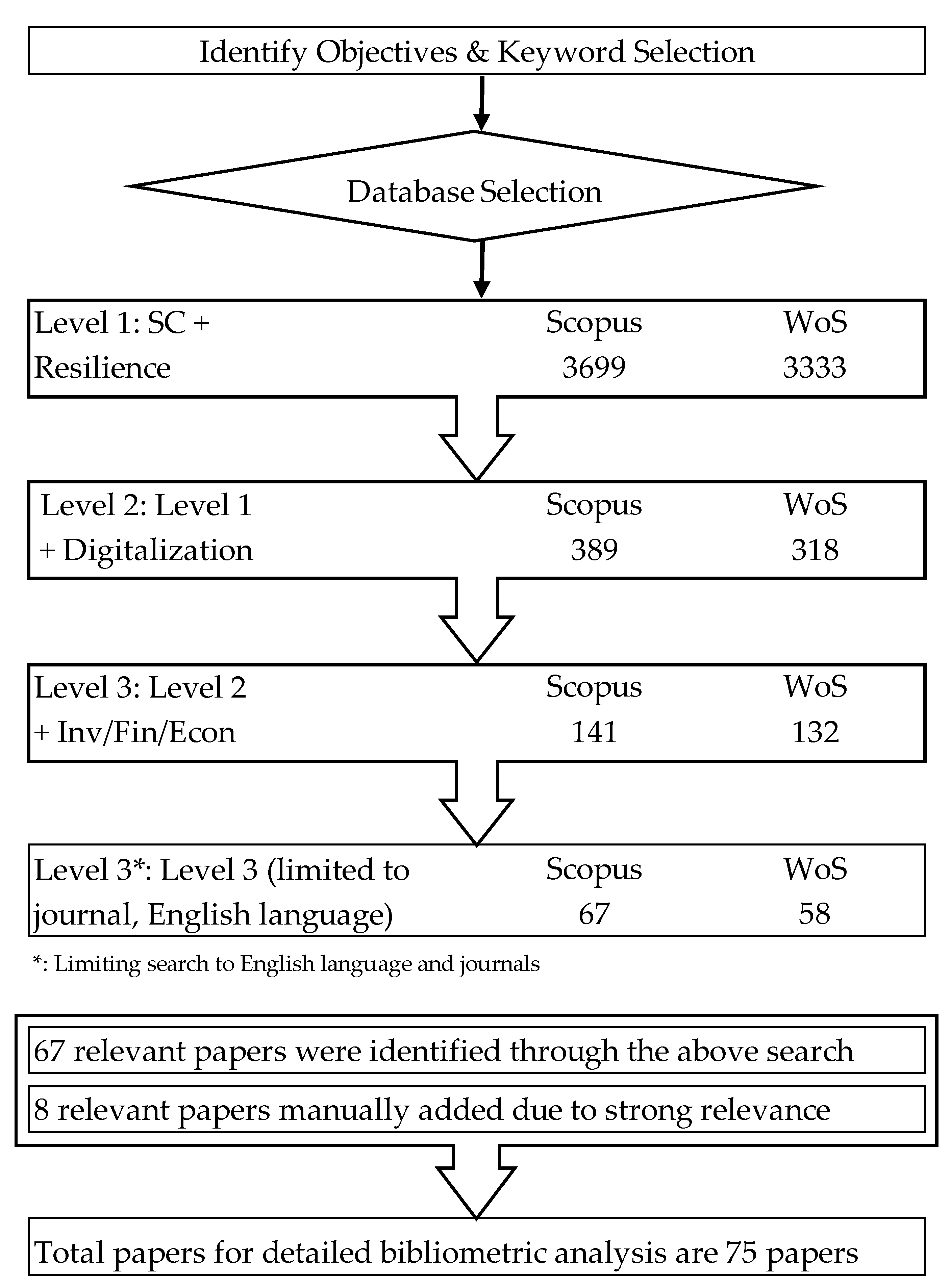

2. Literature Review Methodology

3. Supply Chain Resilience: COVID-19 Scenario, Major Sectors, and Main Building-Blocks

3.1. Building Supply Chain Resilience in the COVID-19 Scenario

3.2. Supply Chain Resilience and the Maritime Shipping Industry

3.3. Supply Chain Resilience and the Food Industry

3.4. Supply Chain Resilience and the Automotive and Logistics Industries

4. Investment and Digital Supply Chain Resilience

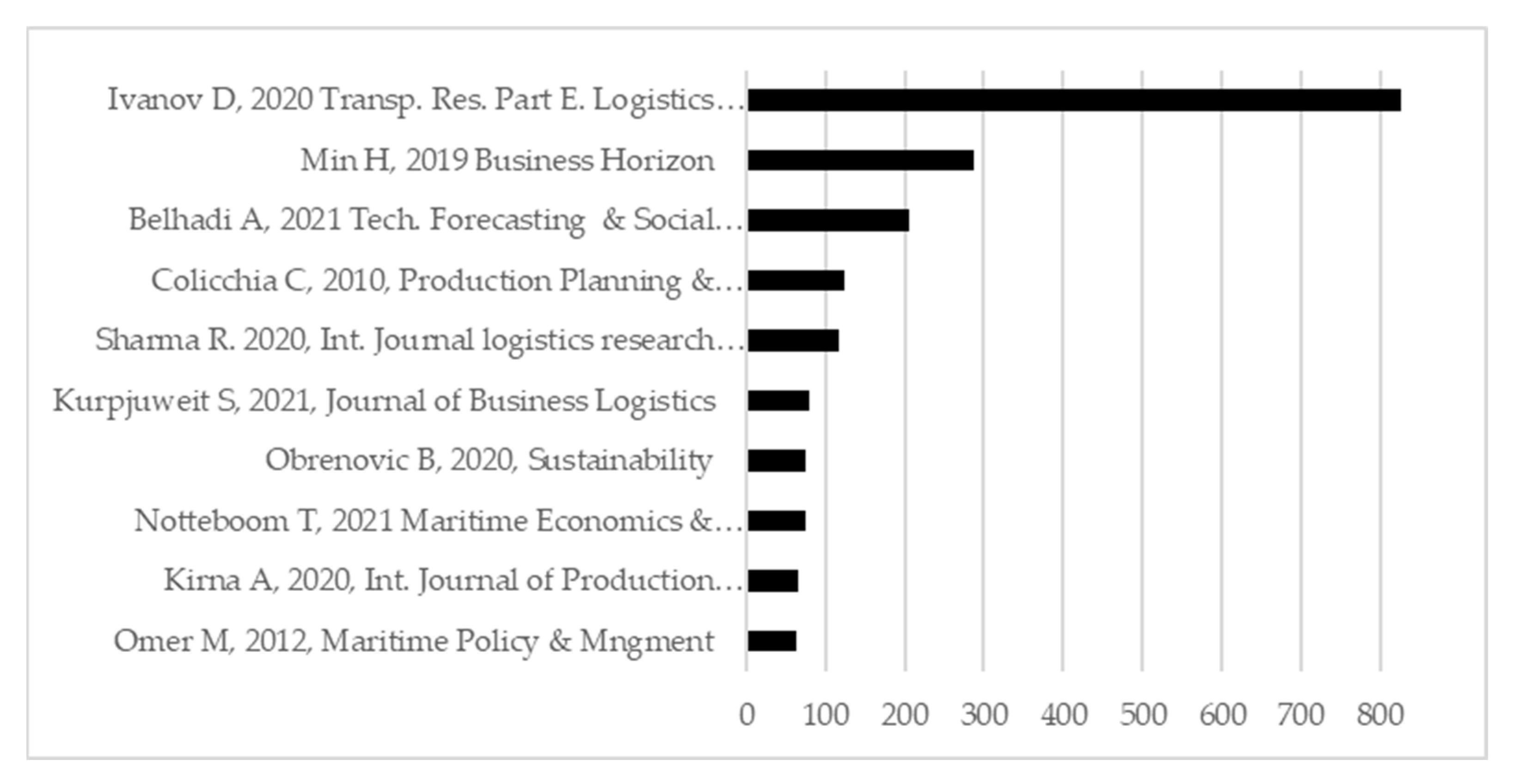

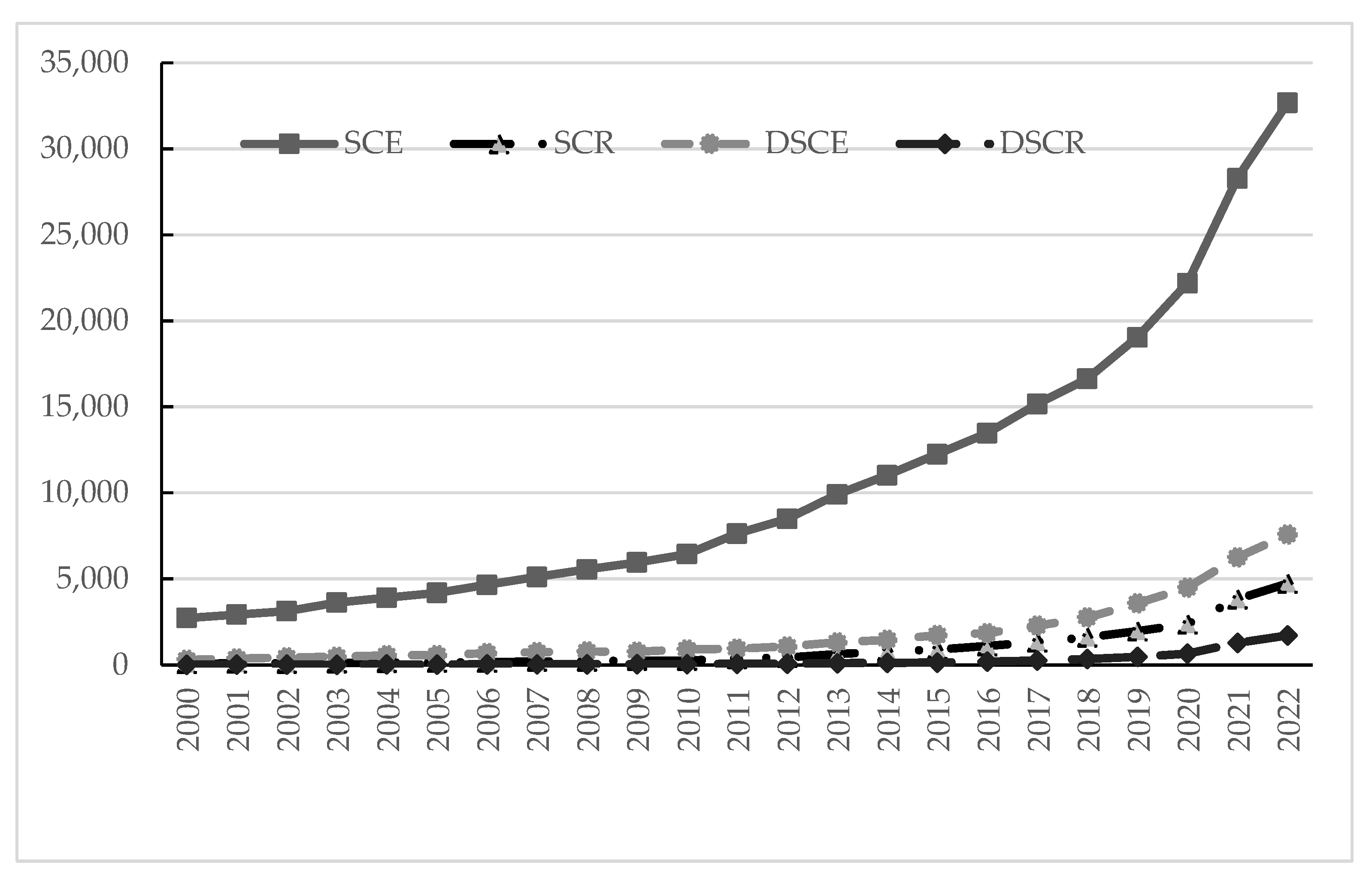

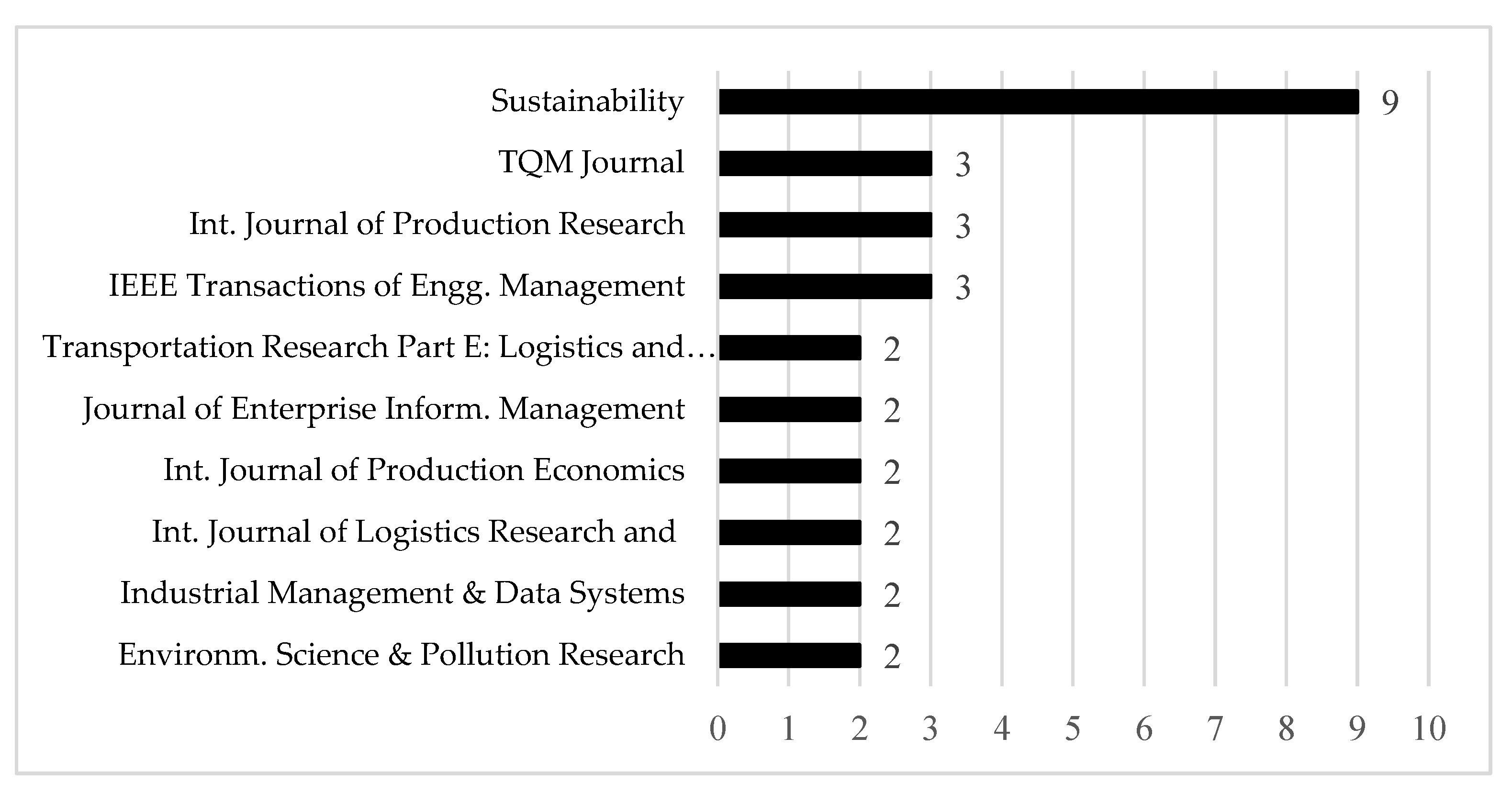

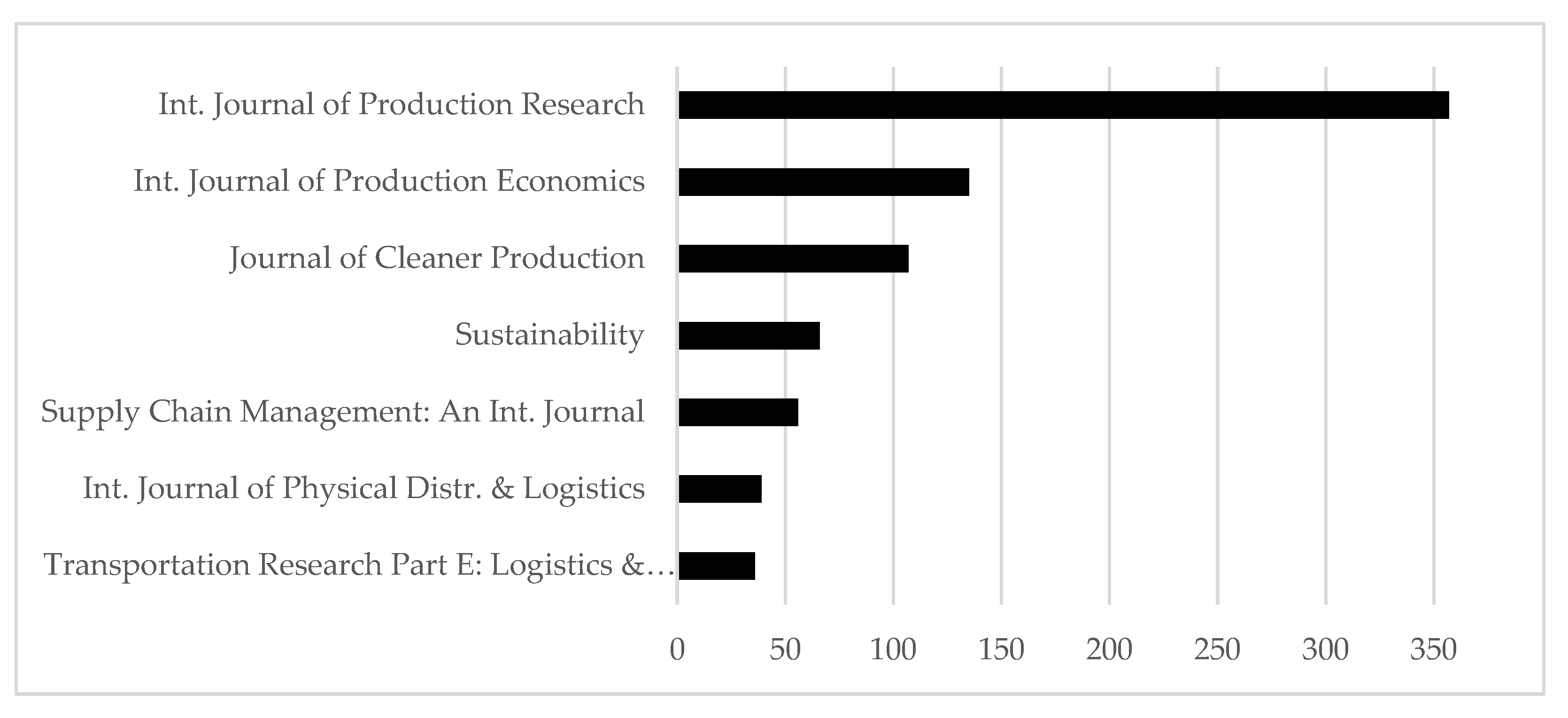

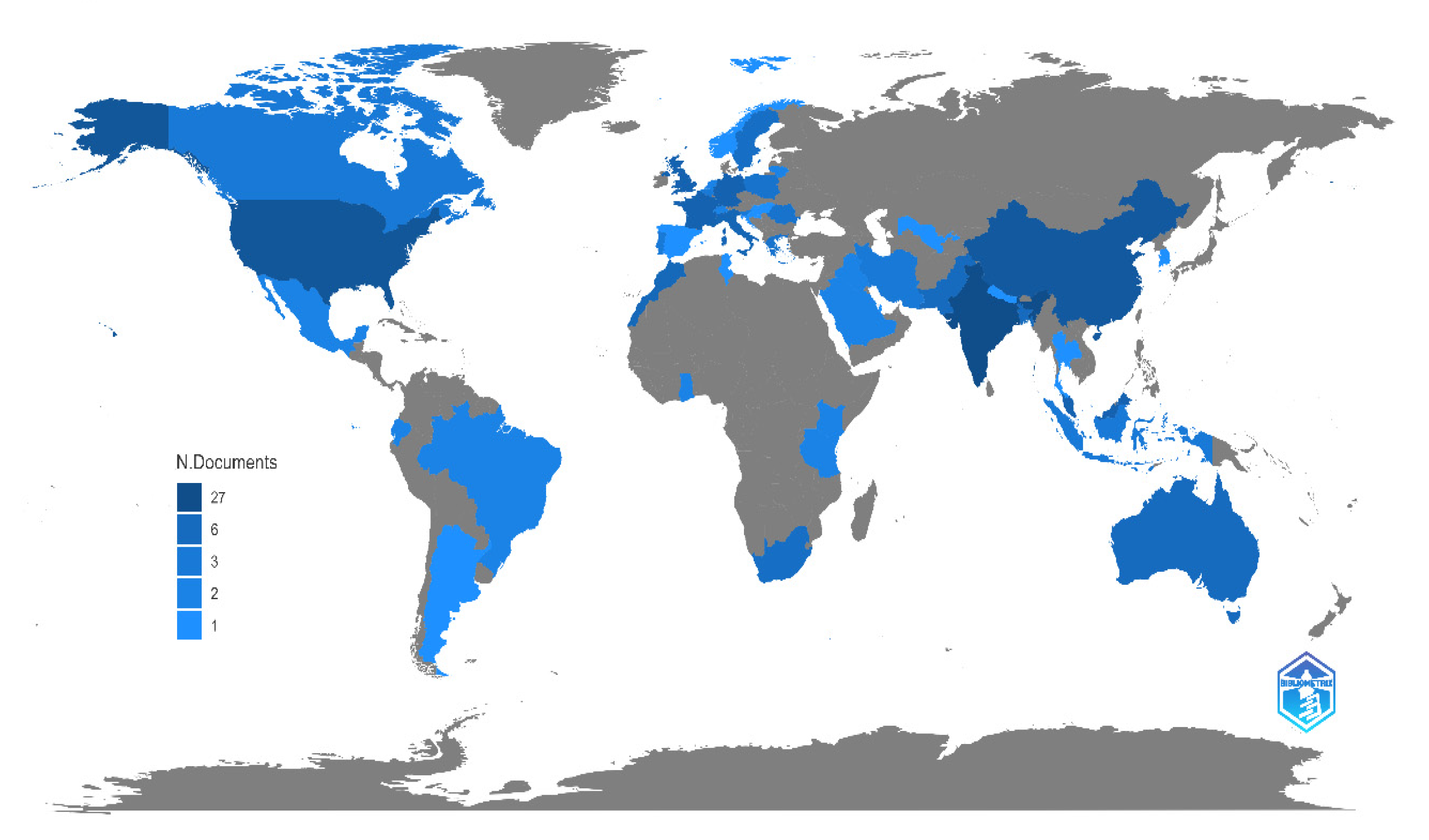

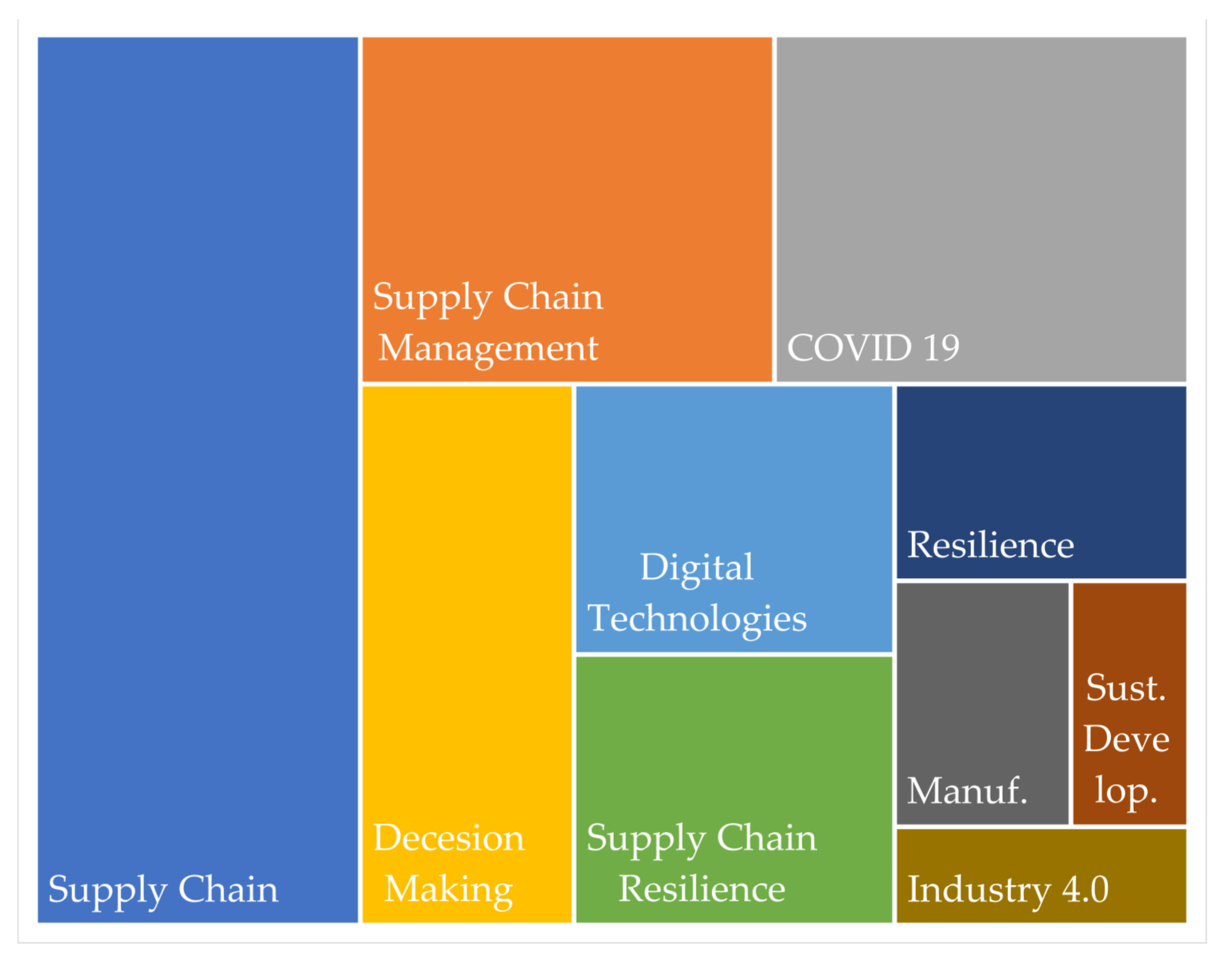

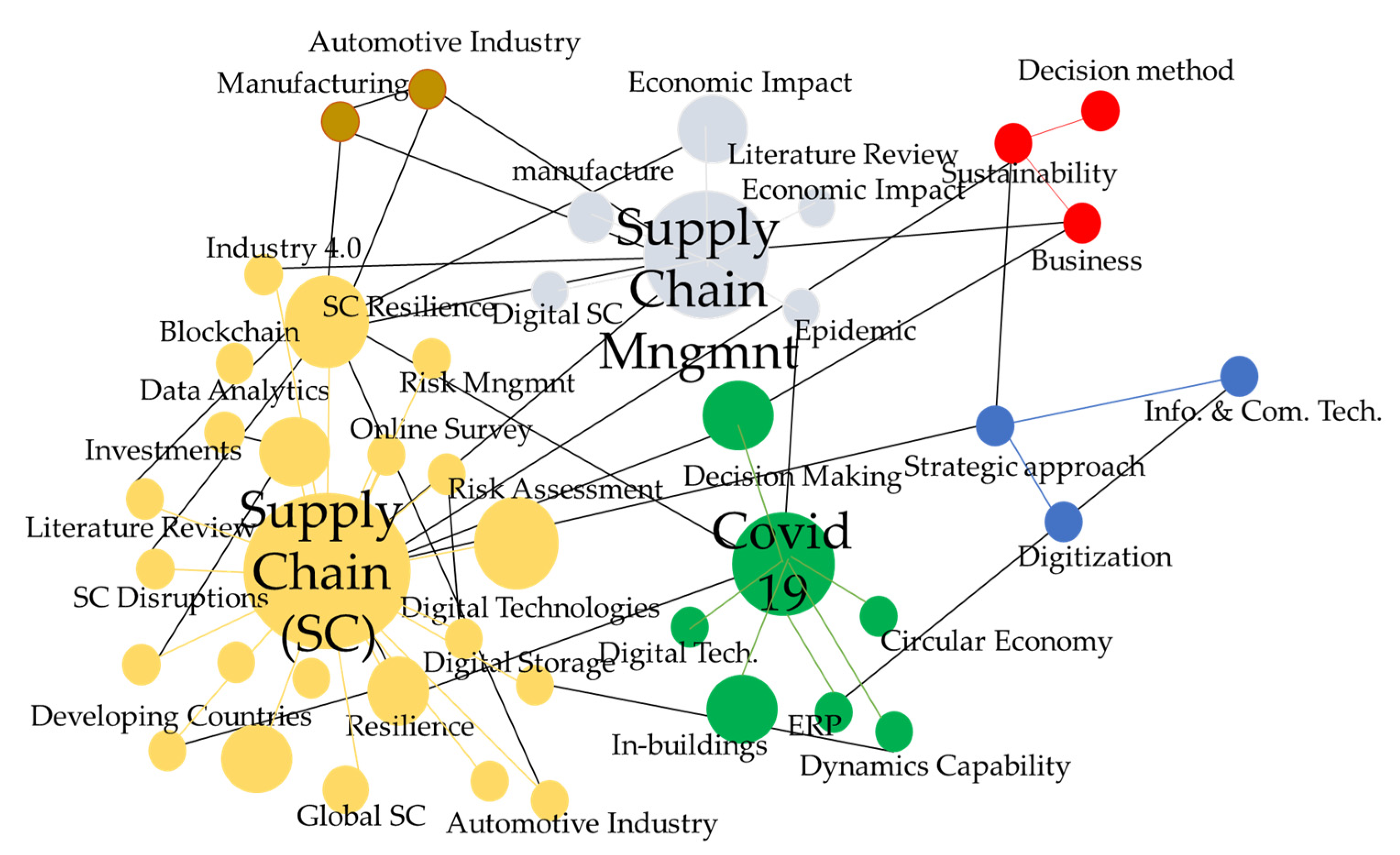

5. Bibliometric Analysis of Supply Chain Resilience Publications

6. Digital Supply Chain Resilience and Additive Manufacturing

7. Securing the Digital Supply Chain: Cybersecurity and Emerging Technologies

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Banna, A.; Franzoi, R.E.; Menezes, B.C.; Al-Enazi, A.; Rogers, S.; Kelly, J.D. Roadmap to digital supply chain resilience. In Computer Aided Chemical Engineering; Yamashita, Y., Kano, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; Volume 49, pp. 571–576. [Google Scholar]

- Zhang, G.; Yang, Y.; Yang, G. Smart supply chain management in Industry 4.0: The review, research agenda and strategies in North America. Ann. Oper. Res. 2023, 322, 1075–1117. [Google Scholar] [CrossRef] [PubMed]

- Alkaabneh, F.; Shehadeh, K.S.; Diabat, A. Routing and resource allocation in non-profit settings with equity and efficiency measures under demand uncertainty. Transp. Res. Part C Emerg. Technol. 2023, 149, 104023. [Google Scholar] [CrossRef]

- Nakandala, D.; Yang, R.; Lau, H.; Weerabahu, S. Industry 4.0 technology capabilities, resilience and incremental innovation in Australian manufacturing firms: A serial mediation model. Supply Chain. Manag. Int. J. 2023, 28, 760–772. [Google Scholar] [CrossRef]

- Alkaabneh, F.; Diabat, A. A multi-objective home healthcare delivery model and its solution using a branch-and-price algorithm and a two-stage meta-heuristic algorithm. Transp. Res. Part C Emerg. Technol. 2023, 147, 103838. [Google Scholar] [CrossRef]

- Fernando, Y.; Tseng, M.-L.; Wahyuni-Td, I.S.; de Sousa Jabbour, A.B.L.; Chiappetta Jabbour, C.J.; Foropon, C. Cyber supply chain risk management and performance in industry 4.0 era: Information system security practices in Malaysia. J. Ind. Prod. Eng. 2023, 40, 102–116. [Google Scholar] [CrossRef]

- Alkaabneh, F.M.; Lee, J.; Gómez, M.I.; Gao, H.O. A systems approach to carbon policy for fruit supply chains: Carbon tax, technology innovation, or land sparing? Sci. Total Environ. 2021, 767, 144211. [Google Scholar] [CrossRef]

- Pereira, V.; Hadjielias, E.; Christofi, M.; Vrontis, D. A systematic literature review on the impact of artificial intelligence on workplace outcomes: A multi-process perspective. Hum. Resour. Manag. Review 2023, 33, 100857. [Google Scholar] [CrossRef]

- Vrontis, D.; Christofi, M. R&D internationalization and innovation: A systematic review, integrative framework and future research directions. J. Bus. Res. 2019, 128, 812–823. [Google Scholar] [CrossRef]

- Fassin, Y. Research on Covid-19: A disruptive phenomenon for bibliometrics. Scientometrics 2021, 126, 5305–5319. [Google Scholar] [CrossRef]

- Ivanov, D. Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101922. [Google Scholar] [CrossRef]

- Fonseca, L.M.; Azevedo, A.L. COVID-19: Outcomes for Global Supply Chains. Manag. Mark. Chall. Knowl. Soc. 2020, 15, 424–438. [Google Scholar] [CrossRef]

- Obrenovic, B.; Du, J.G.; Godinic, D.; Tsoy, D.; Khan, M.A.S.; Jakhongirov, I. Sustaining Enterprise Operations and Productivity during the COVID-19 Pandemic: “Enterprise Effectiveness and Sustainability Model”. Sustainability 2020, 12, 5981. [Google Scholar] [CrossRef]

- Quayson, M.; Bai, C.; Osei, V. Digital Inclusion for Resilient Post-COVID-19 Supply Chains: Smallholder Farmer Perspectives. IEEE Eng. Manag. Rev. 2020, 48, 104–110. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Jegathesan, N.; Latib, H.; Ioras, F.; Mariapan, M.; Liat, L. Digital marketing during the COVID-19 pandemic: A case study of its adoption by furniture manufacturers in Malaysia. BioResources 2021, 16, 3304–3317. [Google Scholar] [CrossRef]

- Weber, A.N. Responding to supply chain disruptions caused by the covid-19 pandemic: A black swan event for omnichannel retailers. J. Transp. Supply Chain Manag. 2021, 15, 16. [Google Scholar] [CrossRef]

- Corvello, V.; Verteramo, S.; Nocella, I.; Ammirato, S. Thrive during a crisis: The role of digital technologies in fostering antifragility in small and medium-sized enterprises. J. Ambient Intell. Humaniz. Comput. 2022, 1–13. [Google Scholar] [CrossRef]

- Hossain, M.R.; Akhter, F.; Sultana, M.M. SMEs in Covid-19 Crisis and Combating Strategies: A Systematic Literature Review (SLR) and A Case from Emerging Economy. Oper. Res. Perspect. 2022, 9, 100222. [Google Scholar] [CrossRef]

- Song, M.L.; Zheng, C.B.; Wang, J.Q. The role of digital economy in China’s sustainable development in a post-pandemic environment. J. Enterp. Inf. Manag. 2022, 35, 58–77. [Google Scholar] [CrossRef]

- Lee, H.Y. Changing Paradigms in US and EU Supply Chains: Focusing on Sustainability Issues. J. Int. Logist. Trade 2021, 19, 223–236. [Google Scholar] [CrossRef]

- Begum, H.; Abbas, K.; Alam, A.; Song, H.M.; Chowdhury, M.T.; Ghani, A.B.A. Impact of the COVID-19 pandemic on the environment and socioeconomic viability: A sustainable production chain alternative. Foresight 2022, 24, 456–475. [Google Scholar] [CrossRef]

- Cherrafi, A.; Chiarini, A.; Belhadi, A.; El Baz, J.; Benabdellah, A.C. Digital technologies and circular economy practices: Vital enablers to support sustainable and resilient supply chain management in the post-COVID-19 era. TQM J. 2022, 34, 179–202. [Google Scholar] [CrossRef]

- Grzybowska, K.; Stachowiak, A. Global Changes and Disruptions in Supply Chains-Preliminary Research to Sustainable Resilience of Supply Chains. Energies 2022, 15, 4579. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. Cloud supply chain: Integrating Industry 4.0 and digital platforms in the “Supply Chain-as-a-Service”. Transp. Res. Part E Logist. Transp. Rev. 2022, 160, 102676. [Google Scholar] [CrossRef]

- Panwar, R.; Pinkse, J.; De Marchi, V. The Future of Global Supply Chains in a Post-COVID-19 World. Calif. Manag. Rev. 2022, 64, 5–23. [Google Scholar] [CrossRef]

- Ababulgu, N.; Abajobir, N.; Wana, H. The embarking of COVID-19 and the perishable products’ value chain in Ethiopia. J. Innov. Entrep. 2022, 11, 34. [Google Scholar] [CrossRef]

- Tsipoulanidis, A.; Nanos, I. Contemporary Potentials and Challenges of Digital Logistics and Supply Chain Management. Int. J. Innov. Technol. Manag. 2022, 19, 1–14. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Developing a framework for enhancing survivability of sustainable supply chains during and post-COVID-19 pandemic. Int. J. Logist.-Res. Appl. 2022, 25, 433–453. [Google Scholar] [CrossRef]

- Yin, W.; Ran, W. Supply Chain Diversification, Digital Transformation, and Supply Chain Resilience: Configuration Analysis Based on fsQCA. Sustainability 2022, 14, 7690. [Google Scholar] [CrossRef]

- Golan, M.S.; Trump, B.D.; Cegan, J.C.; Linkov, I. Supply chain resilience for vaccines: Review of modeling approaches in the context of the COVID-19 pandemic. Ind. Manag. Data Syst. 2021, 121, 1723–1748. [Google Scholar] [CrossRef]

- Tortorella, G.; Fogliatto, F.S.; Gao, S.; Chan, T.K. Contributions of Industry 4.0 to supply chain resilience. Int. J. Logist. Manag. 2022, 33, 547–566. [Google Scholar] [CrossRef]

- Jerome, J.J.J.; Saxena, D.; Sonwaney, V.; Foropon, C. Procurement 4.0 to the rescue: Catalysing its adoption by modelling the challenges. Benchmarking 2022, 29, 217–254. [Google Scholar] [CrossRef]

- Wendler-Bosco, V.; Nicholson, C. Port disruption impact on the maritime supply chain: A literature review. Sustain. Resilient Infrastruct. 2020, 5, 378–394. [Google Scholar] [CrossRef]

- Colicchia, C.; Dallari, F.; Melacini, M. Increasing supply chain resilience in a global sourcing context. Prod. Plan. Control 2010, 21, 680–694. [Google Scholar] [CrossRef]

- Omer, M.; Mostashari, A.; Nilchiani, R.; Mansouri, M. A framework for assessing resiliency of maritime transportation systems. Marit. Policy Manag. 2012, 39, 685–703. [Google Scholar] [CrossRef]

- He, Y.; Yang, Y.C.; Wang, M.M.; Zhang, X.D. Resilience Analysis of Container Port Shipping Network Structure: The Case of China. Sustainability 2022, 14, 9489. [Google Scholar] [CrossRef]

- Li, W.J.; Asadabadi, A.; Miller-Hooks, E. Enhancing resilience through port coalitions in maritime freight networks. Transp. Res. Part A-Policy Pract. 2022, 157, 1–23. [Google Scholar] [CrossRef]

- Notteboom, T.; Pallis, T.; Rodrigue, J.P. Disruptions and resilience in global container shipping and ports: The COVID-19 pandemic versus the 2008-2009 financial crisis. Marit. Econ. Logist. 2021, 23, 179–210. [Google Scholar] [CrossRef]

- Grzelakowski, A. The Covid 19 Pandemic—Challenges for Maritime Transport and Global Logistics Supply Chains. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2022, 16, 71–77. [Google Scholar] [CrossRef]

- Hägele, S.; Grosse, E.; Ivanov, D. Supply chain resilience: A tertiary study. Int. J. Integr. Supply Manag. 2022, 16, 52–81. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Abdollahi, A.; Zailani, S.; Iranmanesh, M.; Ghobakhloo, M. Digitalization in Food Supply Chains: A Bibliometric Review and Key-Route Main Path Analysis. Sustainability 2022, 14, 83. [Google Scholar] [CrossRef]

- Hobbs, J.E. The COVID-19 pandemic and meat supply chains. Meat Sci. 2021, 181, 108459. [Google Scholar] [CrossRef] [PubMed]

- Hobbs, J.E. Food supply chain resilience and the COVID-19 pandemic: What have we learned? Can. J. Agric. Econ. 2021, 69, 189–196. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Ponce, P.; Tanveer, M.; Aguirre-Padilla, N.; Mahmood, H.; Shah, S.A.A. Technological innovation and circular economy practices: Business strategies to mitigate the effects of COVID-19. Sustainability 2021, 13, 8479. [Google Scholar] [CrossRef]

- Nchanji, E.B.; Lutomia, C.K. Regional impact of COVID-19 on the production and food security of common bean smallholder farmers in Sub-Saharan Africa: Implication for SDG’s. Glob. Food Secur. 2021, 29, 100524. [Google Scholar] [CrossRef] [PubMed]

- Joshi, S.; Sharma, M. Digital technologies (DT) adoption in agri-food supply chains amidst COVID-19: An approach towards food security concerns in developing countries. J. Glob. Oper. Strateg. Sourc. 2022, 15, 262–282. [Google Scholar] [CrossRef]

- Sridhar, A.; Balakrishnan, A.; Jacob, M.M.; Sillanpaa, M.; Dayanandan, N. Global impact of COVID-19 on agriculture: Role of sustainable agriculture and digital farming. Environ. Sci. Pollut. Res. 2022, 30, 42509–42525. [Google Scholar] [CrossRef]

- Taylor, E. Explainer: Tesla’s Self-Driving Ambitions Get a Reboot. Available online: https://www.reuters.com/article/us-tesla-results-selfdriving-explainer-idUSKBN2762M5 (accessed on 5 November 2020).

- Wahlman, A. Tesla Is Decades Away from Full Self-Driving Cars. Available online: https://www.thestreet.com/investing/tesla-is-decades-away-from-full-self-driving-cars-14853271 (accessed on 7 December 2020).

- Calabrese, G.G.; Vervaeke, M. Strategies for facing the crisis: The case of the car design/style supply chain in France and in Italy. Int. J. Prod. Dev. 2017, 22, 21–37. [Google Scholar] [CrossRef]

- Spieske, A.; Birkel, H. Improving supply chain resilience through industry 4.0: A systematic literature review under the impressions of the COVID-19 pandemic. Comput. Ind. Eng. 2021, 158, 22. [Google Scholar] [CrossRef]

- Gruchmann, T.; Melkonyan, A.; Krumme, K. Logistics Business Transformation for Sustainability: Assessing the Role of the Lead Sustainability Service Provider (6PL). Logistics 2018, 2, 25. [Google Scholar] [CrossRef]

- Pishdar, M.; Shakib, M.D.; Antucheviciene, J.; Vilkonis, A. Interval Type-2 Fuzzy Super SBM Network DEA for Assessing Sustainability Performance of Third-Party Logistics Service Providers Considering Circular Economy Strategies in the Era of Industry 4.0. Sustainability 2021, 13, 6497. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.; Jabbour, C.J.C.; Gunasekaran, A.; Ndubisi, N.O.; Venkatesh, M. Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technol. Forecast. Soc. Chang. 2021, 163, 120447. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Modgil, S.; Meissonier, R.; Dwivedi, Y.K. Artificial Intelligence and Information System Resilience to Cope with Supply Chain Disruption. IEEE Trans. Eng. Manag. 2021, 1–11. [Google Scholar] [CrossRef]

- Gupta, H.; Yadav, A.K.; Kusi-Sarpong, S.; Khan, S.A.; Sharma, S.C. Strategies to overcome barriers to innovative digitalisation technologies for supply chain logistics resilience during pandemic. Technol. Soc. 2022, 69, 101970. [Google Scholar] [CrossRef]

- Carrillo, J.; Vallejo, B.; Gomis, R. COVID-19 and industrial resilience in the Global South. A case study on the auto parts sector in Mexico. Int. J. Automot. Technol. Manag. 2022, 22, 82–105. [Google Scholar] [CrossRef]

- Herold, D.M.; Nowicka, K.; Pluta-Zaremba, A.; Kummer, S. COVID-19 and the pursuit of supply chain resilience: Reactions and “lessons learned” from logistics service providers (LSPs). Supply Chain Manag. 2021, 26, 702–714. [Google Scholar] [CrossRef]

- Eldem, B.; Kluczek, A.; Baginski, J. The COVID-19 Impact on Supply Chain Operations of Automotive Industry: A Case Study of Sustainability 4.0 Based on Sense-Adapt-Transform Framework. Sustainability 2022, 14, 5855. [Google Scholar] [CrossRef]

- Gilchrist, S.; Himmelberg, C. Investment: Fundamentals and Finance; NBER: Cambridge, MA, USA, 1999. [Google Scholar]

- Ioannou, A.; Angus, A.; Brennan, F. Parametric CAPEX, OPEX, and LCOE expressions for offshore wind farms based on global deployment parameters. Energy Sources Part B Econ. Plan. Policy 2018, 13, 281–290. [Google Scholar] [CrossRef]

- Nipa, T.J.; Kermanshachi, S.; Karthick, S. Analysis of Investment Decision-Making Factors in Resilience Improvement of Transportation Infrastructure. In Proceedings of the Construction Research Congress 2022, Arlington, VA, USA, 9–12 March 2022. [Google Scholar]

- Zouari, D.; Ruel, S.; Viale, L. Does digitalising the supply chain contribute to its resilience? Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 149–180. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Min, H. Blockchain technology for enhancing supply chain resilience. Bus. Horiz. 2019, 62, 35–45. [Google Scholar] [CrossRef]

- Sharma, R.; Shishodia, A.; Kamble, S.; Gunasekaran, A.; Belhadi, A. Agriculture supply chain risks and COVID-19: Mitigation strategies and implications for the practitioners. Int. J. Logist.-Res. Appl. 2020, 1–27. [Google Scholar] [CrossRef]

- Kurpjuweit, S.; Schmidt, C.G.; Klockner, M.; Wagner, S.M. Blockchain in Additive Manufacturing and its Impact on Supply Chains. J. Bus. Logist. 2021, 42, 46–70. [Google Scholar] [CrossRef]

- Aria, M.; Misuraca, M.; Spano, M. Mapping the Evolution of Social Research and Data Science on 30 Years of Social Indicators Research. Soc. Indic. Res. 2020, 149, 803–831. [Google Scholar] [CrossRef]

- Radhakrishnan, R.; Hashem, A.; Abd_Allah, E.F. Bacillus: A Biological Tool for Crop Improvement through Bio-Molecular Changes in Adverse Environments. Front. Physiol. 2017, 8, 667. [Google Scholar] [CrossRef]

- Lee, Y.-h.; Lee, Y.; Seong, J.C.; Stanescu, A.; Hwang, C.S. A Comparison of Network Clustering Algorithms in Keyword Network Analysis: A Case Study with Geography Conference Presentations. J. Geospat. Environ. Res. 2020, 7, 1. [Google Scholar]

- Saengchai, S.; Jermsittiparsert, K. Coping strategy to counter the challenges towards implementation of Industry 4.0 in Thailand: Role of supply chain agility and resilience. Int. J. Supply Chain Manag. 2019, 8, 733–744. [Google Scholar]

- Amjad, M.S.; Rafique, M.Z.; Hussain, S.; Khan, M.A. A new vision of LARG Manufacturing—A trail towards Industry 4.0. CIRP J. Manuf. Sci. Technol. 2020, 31, 377–393. [Google Scholar] [CrossRef]

- Berawi, M.A.; Suwartha, N.; Asvial, M.; Harwahyu, R.; Suryanegara, M.; Setiawan, E.A.; Surjandari, I.; Zagloel, T.Y.M.; Maknun, I.J. Digital Innovation: Creating Competitive Advantages. Int. J. Technol. 2020, 11, 1076–1080. [Google Scholar] [CrossRef]

- Kinra, A.; Ivanov, D.; Das, A.; Dolgui, A. Ripple effect quantification by supplier risk exposure assessment. Int. J. Prod. Res. 2020, 58, 5559–5578. [Google Scholar] [CrossRef]

- Mithani, M.A.; Narula, R.; Surdu, I.; Verbeke, A. Unique Implications of Crises and Disruptions for International Business: How Established MNEs Are Exposed to Crises and Mitigate Their Effects. In Crises and Disruptions in International Business: How Multinational Enterprises Respond to Crises, Mithani, M.A., Narula, R., Surdu, I., Verbeke, A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 3–18. [Google Scholar]

- Sharma, A.; Pilli, E.S.; Mazumdar, A.P.; Gera, P. Towards trustworthy Internet of Things: A survey on Trust Management applications and schemes. Comput. Commun. 2020, 160, 475–493. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Zacharia, Z.G.; Swami, S. Supply chain resilience for managing the ripple effect in Industry 4.0 for green product diffusion. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 897–930. [Google Scholar] [CrossRef]

- Hussain, A.; Farooq, M.U.; Habib, M.S.; Masood, T.; Pruncu, C.I. COVID-19 Challenges: Can Industry 4.0 Technologies Help with Business Continuity? Sustainability 2021, 13, 11971. [Google Scholar] [CrossRef]

- Kalaboukas, K.; Rožanec, J.; Košmerlj, A.; Kiritsis, D.; Arampatzis, G. Implementation of cognitive digital twins in connected and agile supply networks-an operational model. Appl. Sci. 2021, 11, 4103. [Google Scholar] [CrossRef]

- Kaur, H.; Singh, S.P. Multi-stage hybrid model for supplier selection and order allocation considering disruption risks and disruptive technologies. Int. J. Prod. Econ. 2021, 231, 25. [Google Scholar] [CrossRef]

- Miceli, A.; Hagen, B.; Riccardi, M.P.; Sotti, F.; Settembre-Blundo, D. Thriving, Not Just Surviving in Changing Times: How Sustainability, Agility and Digitalization Intertwine with Organizational Resilience. Sustainability 2021, 13, 2052. [Google Scholar] [CrossRef]

- Tamym, L.; Benyoucef, L.; Nait Sidi Moh, A.; El Ouadghiri, M.D. A big data based architecture for collaborative networks: Supply chains mixed-network. Comput. Commun. 2021, 175, 102–111. [Google Scholar] [CrossRef]

- Akram, S.V.; Malik, P.K.; Singh, R.; Gehlot, A.; Juyal, A.; Ghafoor, K.Z.; Shrestha, S. Implementation of Digitalized Technologies for Fashion Industry 4.0: Opportunities and Challenges. Sci. Program. 2022, 2022, 1–17. [Google Scholar] [CrossRef]

- Asante, M.; Epiphaniou, G.; Maple, C.; Al-Khateeb, H.; Bottarelli, M.; Ghafoor, K.Z. Distributed Ledger Technologies in Supply Chain Security Management: A Comprehensive Survey. IEEE Trans. Eng. Manag. 2022, 70, 713–739. [Google Scholar] [CrossRef]

- Asante Boakye, E.; Zhao, H.; Ahia, B.N.K. Blockchain technology prospects in transforming Ghana’s economy: A phenomenon-based approach. Inf. Technol. Dev. 2022, 1–30. [Google Scholar] [CrossRef]

- Badakhshan, E.; Ball, P. Applying digital twins for inventory and cash management in supply chains under physical and financial disruptions. Int. J. Prod. Res. 2022, 1–23. [Google Scholar] [CrossRef]

- Chari, A.; Niedenzu, D.; Despeisse, M.; Machado, C.G.; Azevedo, J.D.; Boavida-Dias, R.; Johansson, B. Dynamic capabilities for circular manufacturing supply chains-Exploring the role of Industry 4.0 and resilience. Bus. Strateg. Environ. 2022, 31, 2500–2517. [Google Scholar] [CrossRef]

- Hsu, C.H.; He, X.; Zhang, T.Y.; Chang, A.Y.; Liu, W.L.; Lin, Z.Q. Enhancing Supply Chain Agility with Industry 4.0 Enablers to Mitigate Ripple Effects Based on Integrated QFD-MCDM: An Empirical Study of New Energy Materials Manufacturers. Mathematics 2022, 10, 1635. [Google Scholar] [CrossRef]

- Melnyk, S.A.; Schoenherr, T.; Speier-Pero, C.; Peters, C.; Chang, J.F.; Friday, D. New challenges in supply chain management: Cybersecurity across the supply chain. Int. J. Prod. Res. 2022, 60, 162–183. [Google Scholar] [CrossRef]

- Minculete, G.; Stan, S.E.; Ispas, L.; Virca, I.; Stanciu, L.; Milandru, M.; Mănescu, G.; Bădilă, M.I. Relational Approaches Related to Digital Supply Chain Management Consolidation. Sustainability 2022, 14, 10727. [Google Scholar] [CrossRef]

- Mukherjee, A.A.; Singh, R.K.; Mishra, R.; Bag, S. Application of blockchain technology for sustainability development in agricultural supply chain: Justification framework. Oper. Manag. Res. 2022, 15, 46–61. [Google Scholar] [CrossRef]

- Sahu, A.K.; Sharma, M.; Raut, R.D.; Sahu, A.K.; Sahu, N.K.; Antony, J.; Tortorella, G.L. Decision-making framework for supplier selection using an integrated MCDM approach in a lean-agile-resilient-green environment: Evidence from Indian automotive sector. TQM J. 2022, 35, 964–1006. [Google Scholar] [CrossRef]

- Meyer, M.M.; Glas, A.H.; Eßig, M. Achieving Supply Chain Resilience Through Additive Manufacturing. In Supply Chain Resilience: Insights from Theory and Practice; Kummer, S., Wakolbinger, T., Novoszel, L., Geske, A.M., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 233–245. [Google Scholar]

- Linke, R. Additive Manufacturing, Explained. Available online: https://mitsloan.mit.edu/ideas-made-to-matter/additive-manufacturing-explained (accessed on 2 November 2020).

- Radanliev, P.; De Roure, D. New and emerging forms of data and technologies: Literature and bibliometric review. Multimed. Tools Appl. 2023, 82, 2887–2911. [Google Scholar] [CrossRef]

- Menezes, B.C.; Kelly, J.D.; Leal, A.G.; Le Roux, G.C. Predictive, Prescriptive and Detective Analytics for Smart Manufacturing in the Information Age. IFAC-PapersOnLine 2019, 52, 568–573. [Google Scholar] [CrossRef]

- Rana, Z.A.; Khor, C.S.; Zabiri, H. Computational Experience with Piecewise Linear Relaxations for Petroleum Refinery Planning. Processes 2021, 9, 1624. [Google Scholar] [CrossRef]

| References | Article Type | Industry/Focus Area | Main Idea | Methodology | I4.0 Technologies Used/Recommended | |||

|---|---|---|---|---|---|---|---|---|

| Research | Review | Conceptual/ Theoretical | Empirical | Mathematical/Simulation | ||||

| [34] | ✓ | Maritime | SCR in global sourcing context | ✓ | ✓ | |||

| [35] | ✓ | Maritime | Maritime transportation resilience | ✓ | ||||

| [50] | ✓ | Automotive | Strategies for facing a crisis | ✓ | ✓ | |||

| [52] | ✓ | Logistics | Logistics business transformation for sustainability | ✓ | ✓ | ✓ | ||

| [65] | ✓ | Business | Enhancing SCR | ✓ | ✓ (Blockchain) | |||

| [71] | ✓ | Manufacturing | SC agility and resilience | ✓ | ✓ | |||

| [72] | ✓ | Manufacturing | Lean, Agile, Resilient, and Green (LARG) Manufacturing | ✓ | ✓ | |||

| [33] | ✓ | Maritime | Impact of port disruption on maritime SC | ✓ | ||||

| [73] | ✓ | Business | Competitive advantages through digital innovation | ✓ | ✓ | |||

| [7] | ✓ | Business | COVID-19 outcomes for global SCs | ✓ | ✓ | |||

| [12] | ✓ | Business | Predicting the impacts of COVID-19 on global SCs | ✓ | ✓ (Digital twins) | |||

| [74] | ✓ | Business | Ripple effect quantification | ✓ | ||||

| [75] | ✓ | Business | Organizational adaptation in growing risks | ✓ | ||||

| [14] | ✓ | Business | Operational sustainability and productivity during COVID-19 | ✓ | ✓ (ICT, Intranet) | |||

| [16] | ✓ | Agriculture | Resilient post-COVID-19 SCs | ✓ | ✓ | |||

| [17] | ✓ | Furniture | SMEs surviving the COVID-19 | ✓ | ✓ | |||

| [76] | ✓ | Business | SC quality management systems | ✓ | ✓ | |||

| [66] | ✓ | Agriculture | SC risks | ✓ | ✓ | |||

| [54] | ✓ | Automotive | SCR to the COVID-19 outbreak | ✓ | ✓ | ✓ (Big Data) | ||

| [77] | ✓ | Additive Manufacturing | SCR for managing the ripple effect in I4.0 | ✓ | ✓ | |||

| [38] | ✓ | Maritime/Ports | Disruptions and resilience in global container shipping and ports | ✓ | ||||

| [30] | ✓ | Healthcare | SCR—modeling approaches | ✓ | ✓ (AI, digital twins) | |||

| [56] | ✓ | Automotive | Coping with SC disruptions | ✓ | ✓ (AI) | |||

| [58] | ✓ | Logistics | SCR during COVID-19 | ✓ | ✓ | |||

| [42] | ✓ | Food | Meat SCs during the pandemic | ✓ | ✓ | |||

| [43] | ✓ | Food | SCR during the pandemic | ✓ | ✓ | |||

| [78] | ✓ | Business | COVID-19 challenges and I4.0 solutions | ✓ | ✓ | ✓ | ✓ | |

| [79] | ✓ | Business | Agile supply networks | ✓ | ✓ (Digital twins) | |||

| [80] | ✓ | Business | Supplier selection and order allocation under disruptions | ✓ | ✓ | |||

| [44] | ✓ | Food | Strategies to mitigate outbreak effects | ✓ | ✓ | |||

| [67] | ✓ | Additive Manufacturing | Blockchain in Additive Manufacturing and its Impact on SCs | ✓ | ✓ (Blockchain) | |||

| [21] | ✓ | Global changing paradigms and sustainability issues | ✓ | ✓ | ||||

| [81] | ✓ | Business | Organizational resilience in changing times | ✓ | ✓ | ✓ | ||

| [45] | ✓ | Agriculture | Regional impact of SC disruptions | ✓ | ✓ | ✓ | ||

| [53] | ✓ | Logistics | Strategies for circular economy | ✓ | ✓ | |||

| [51] | ✓ | Automotive | Improving SCR through I4.0 | ✓ | ✓ (Big Data) | |||

| [82] | ✓ | Business | SCR using Big Data | ✓ | ✓ | ✓ (Big Data) | ||

| [11] | ✓ | Business | Coping with SC disruptions | ✓ | ✓ | |||

| [83] | ✓ | Fashion | Opportunities and challenges with respect to I4.0 | ✓ | ✓ | |||

| [84,85] | ✓ | Business | SC security | ✓ | ✓ (Blockchain) | |||

| [86] | ✓ | Business | Inventory and cash management under physical and financial SC disruptions | ✓ | ✓ (Digital twins) | |||

| [22] | ✓ | Manufacturing | Sustainable production alternatives | ✓ | ✓ | |||

| [67] | ✓ | Additive Manufacturing | SCR and efficiency building | ✓ | ✓ | ✓ | ||

| [57] | ✓ | Automotive | SCR during COVID-19 | ✓ | ✓ | |||

| [87] | ✓ | Manufacturing | Role of I4.0 and resilience in circular SCs | ✓ | ✓ | ✓ | ||

| [23] | ✓ | Business | Digital technologies and circular economy practices | ✓ | ✓ | |||

| [12] | ✓ | Business | SCR during a crisis | ✓ | ✓ | |||

| [59] | ✓ | Automotive | COVID-19 impact on SC operations | ✓ | ✓ | |||

| [18] | ✓ | Business | Global changes and disruptions in SC | ✓ | ✓ | |||

| [39] | ✓ | Maritime/Logistics | COVID-19 challenges | ✓ | ✓ | |||

| [34] | ✓ | Maritime | SCR | ✓ | ✓ | |||

| [36] | ✓ | Maritime/Port | Resilience analysis | ✓ | ✓ | |||

| [37] | ✓ | Maritime/Port | Resilience enhancement through port coalitions | ✓ | ||||

| [50] | ✓ | Logistics | Overcoming digitalization barriers for SCR | ✓ | ✓ | |||

| [19] | ✓ | Business | SCR during COVID-19 | ✓ | ✓ | |||

| [88] | ✓ | Manufacturing | I4.0 enablers to mitigate ripple effects | ✓ | ✓ | |||

| [83] | ✓ | Textile | Resilient SC model | ✓ | ✓ | |||

| [25] | ✓ | Business | Digital SC management and technology to enhance resilience | ✓ | ✓ | ✓ | ||

| [24] | ✓ | Business | Cloud SC | ✓ | ✓ | |||

| [32] | ✓ | Healthcare | Procurement 4.0 | ✓ | ✓ | |||

| [46] | ✓ | Agriculture | Digital technologies and food security | ✓ | ✓ | |||

| [89] | ✓ | Business | Cybersecurity | ✓ | ✓ | |||

| [86] | ✓ | Additive Manufacturing | SC disruptions from COVID-19 | ✓ | ✓ | |||

| [90] | ✓ | Business | Digital SC management | ✓ | ✓ | ✓ | ||

| [91] | ✓ | Agriculture | Sustainability development in agricultural SC | ✓ | ✓ (Blockchain) | |||

| [92] | ✓ | Business | SC viability in COVID-19 perspective | ✓ | ✓ | |||

| [26] | ✓ | Business | Global SC in post-COVID-19 scenario | ✓ | ✓ | |||

| [36] | ✓ | Food | Digitalization in food SCs | ✓ | ✓ | |||

| [93] | ✓ | Automotive | LARG Manufacturing | ✓ | ✓ | |||

| [28] | ✓ | Business | Survivability of sustainable SCs during and post-COVID-19 | ✓ | ✓ | |||

| [19] | ✓ | Business | Sustainable development post COVID-19 disruptions | ✓ | ✓ | ✓ | ||

| [47] | ✓ | Agriculture | Agriculture and digital farming | ✓ | ✓ | |||

| [31] | ✓ | Healthcare | Development of resilience and digitalization | ✓ | ✓ | |||

| [27] | ✓ | Logistics | Digital logistics and SC management | ✓ | ✓ | ✓ | ||

| [29] | ✓ | Business | DT to achieve SCR | ✓ | ✓ | ✓ | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Banna, A.; Rana, Z.A.; Yaqot, M.; Menezes, B. Interconnectedness between Supply Chain Resilience, Industry 4.0, and Investment. Logistics 2023, 7, 50. https://doi.org/10.3390/logistics7030050

Al-Banna A, Rana ZA, Yaqot M, Menezes B. Interconnectedness between Supply Chain Resilience, Industry 4.0, and Investment. Logistics. 2023; 7(3):50. https://doi.org/10.3390/logistics7030050

Chicago/Turabian StyleAl-Banna, Adnan, Zaid Ashraf Rana, Mohammed Yaqot, and Brenno Menezes. 2023. "Interconnectedness between Supply Chain Resilience, Industry 4.0, and Investment" Logistics 7, no. 3: 50. https://doi.org/10.3390/logistics7030050

APA StyleAl-Banna, A., Rana, Z. A., Yaqot, M., & Menezes, B. (2023). Interconnectedness between Supply Chain Resilience, Industry 4.0, and Investment. Logistics, 7(3), 50. https://doi.org/10.3390/logistics7030050