Location Allocation of Biorefineries for a Switchgrass-Based Bioethanol Supply Chain Using Energy Consumption and Emissions

Abstract

1. Introduction

- Locating potential biorefineries using GIS.

- -

- Several studies simplified the identification of potential biorefineries by selecting only centroids, city gates, etc., whereas very few studies used Geographic Information Systems to specify potential locations more realistically. Employing GIS analysis, we considered geographical factors, such as distances from major cities, biomass feedstock suppliers, water sources, highways, and railroads, to locate potential biorefineries.

- Developing a MILP model to maximize the profit while considering the impacts of energy use and carbon emissions throughout the supply chain.

- -

- Our model is significant in considering the joint impacts of carbon emissions and energy consumption on the design of a biofuel supply chain.

- Providing a detailed analysis of how penalties associated with carbon emissions and energy consumption in the supply chain could impact its design and profitability.

- -

- Few studies were conducted that provide detailed supply chain planning and design scenarios based on the penalties set for carbon emissions and energy consumption within biofuel supply chains. In this study, we show how different penalties for energy consumption and carbon emissions can affect location allocation of biorefineries and supply chain planning.

2. Materials and Methods

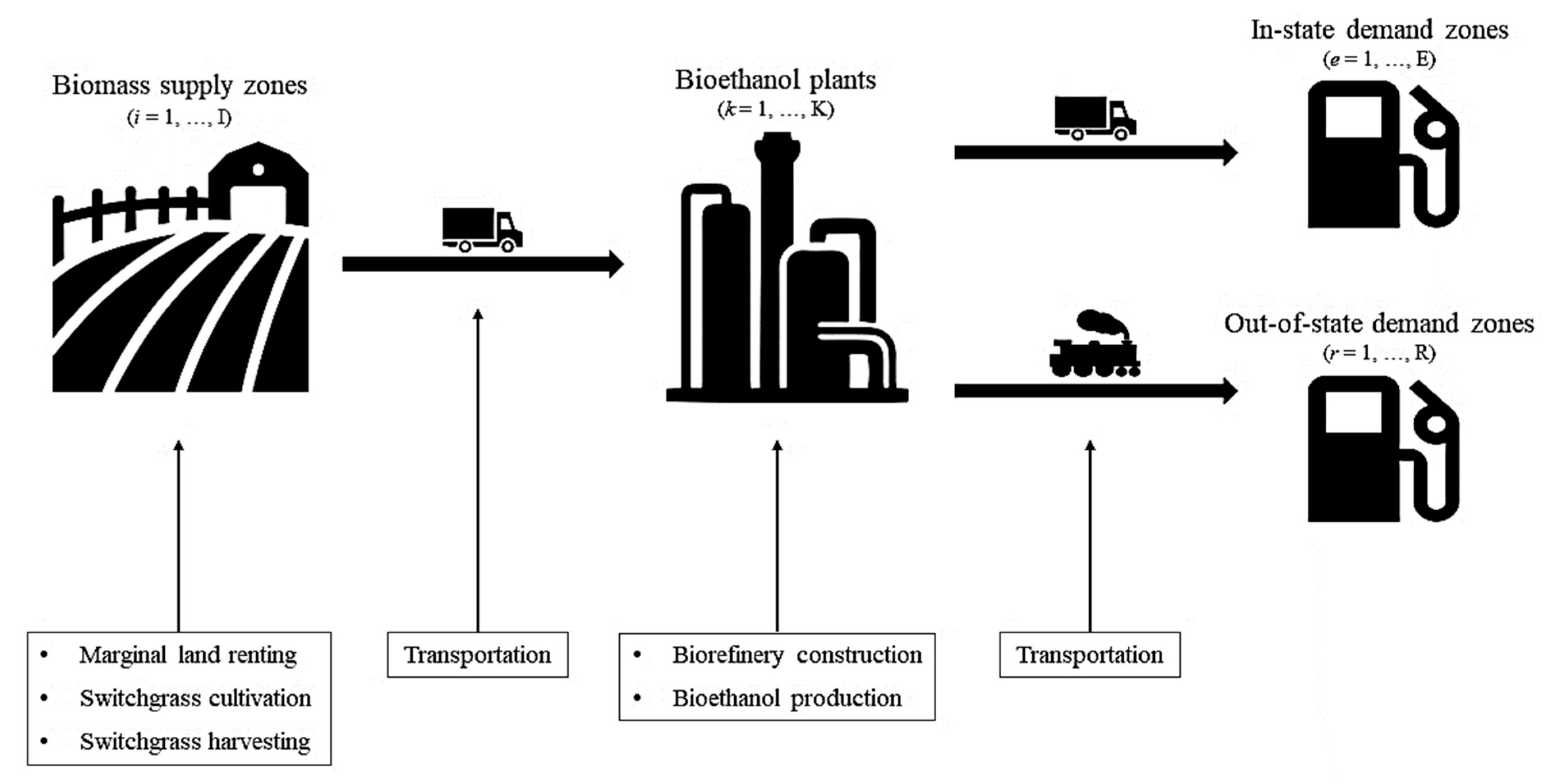

2.1. Problem Statement

2.2. Methodology

- Locations within one mile of a state or federal road transport infrastructure;

- Locations within one mile of a rail transportation network;

- Areas near towns or cities having a population of at least 2000;

- Areas within a quarter-mile and one mile of a waterbody (rivers, lakes, etc.);

- Locations with rich supplies of switchgrass biomass.

3. Results and Discussion

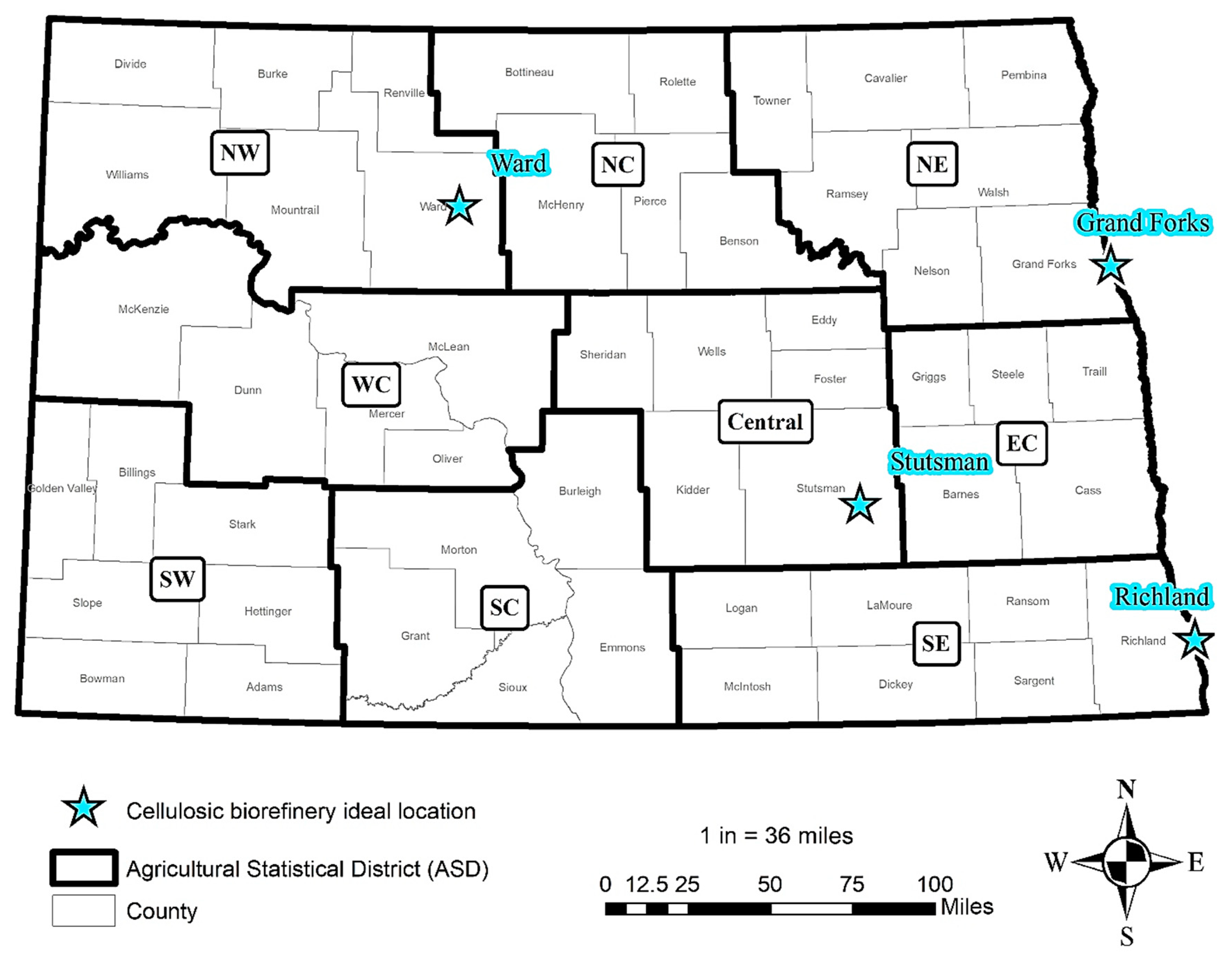

3.1. Location Allocation of Potential Biorefineries with GIS Analysis

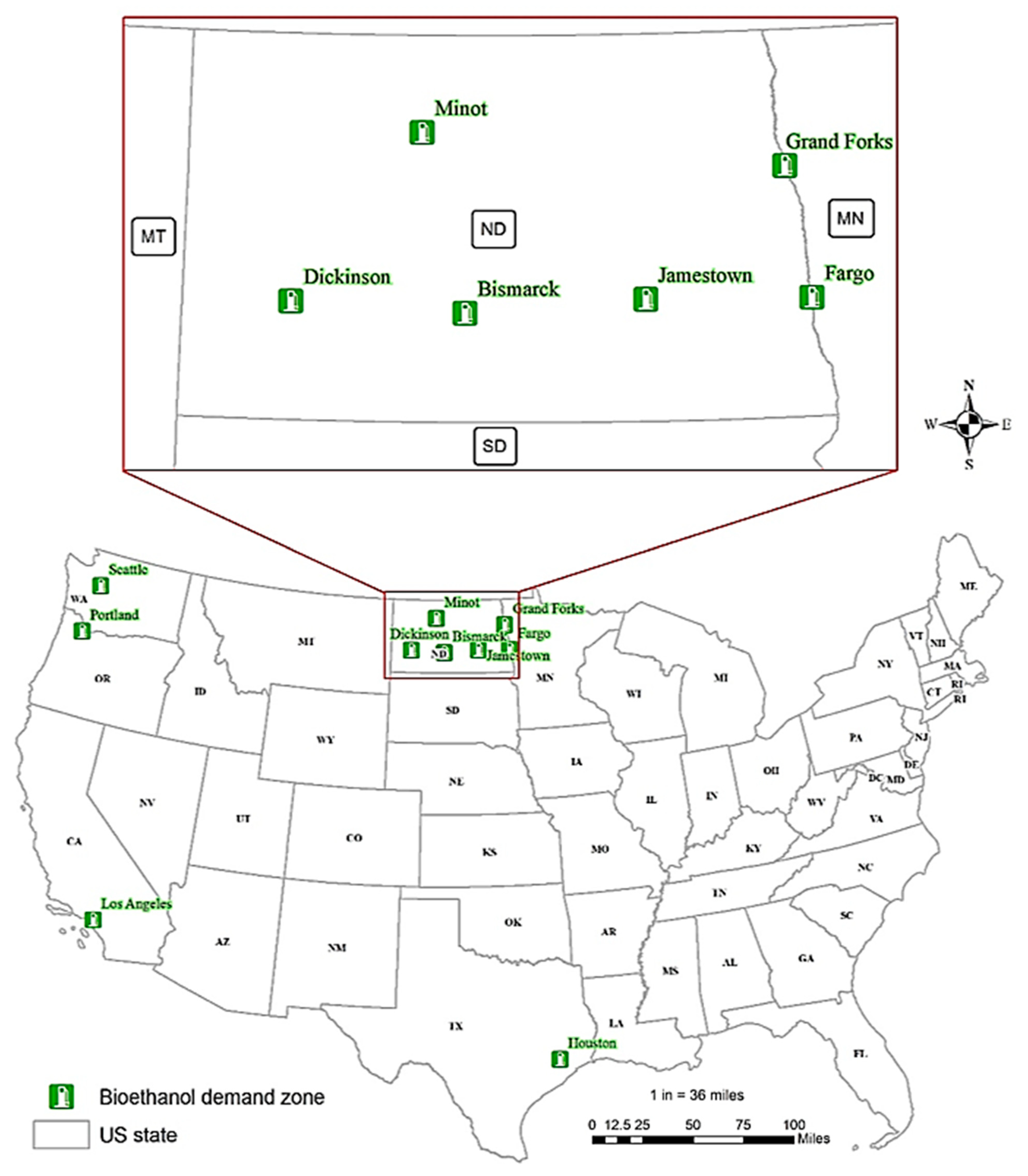

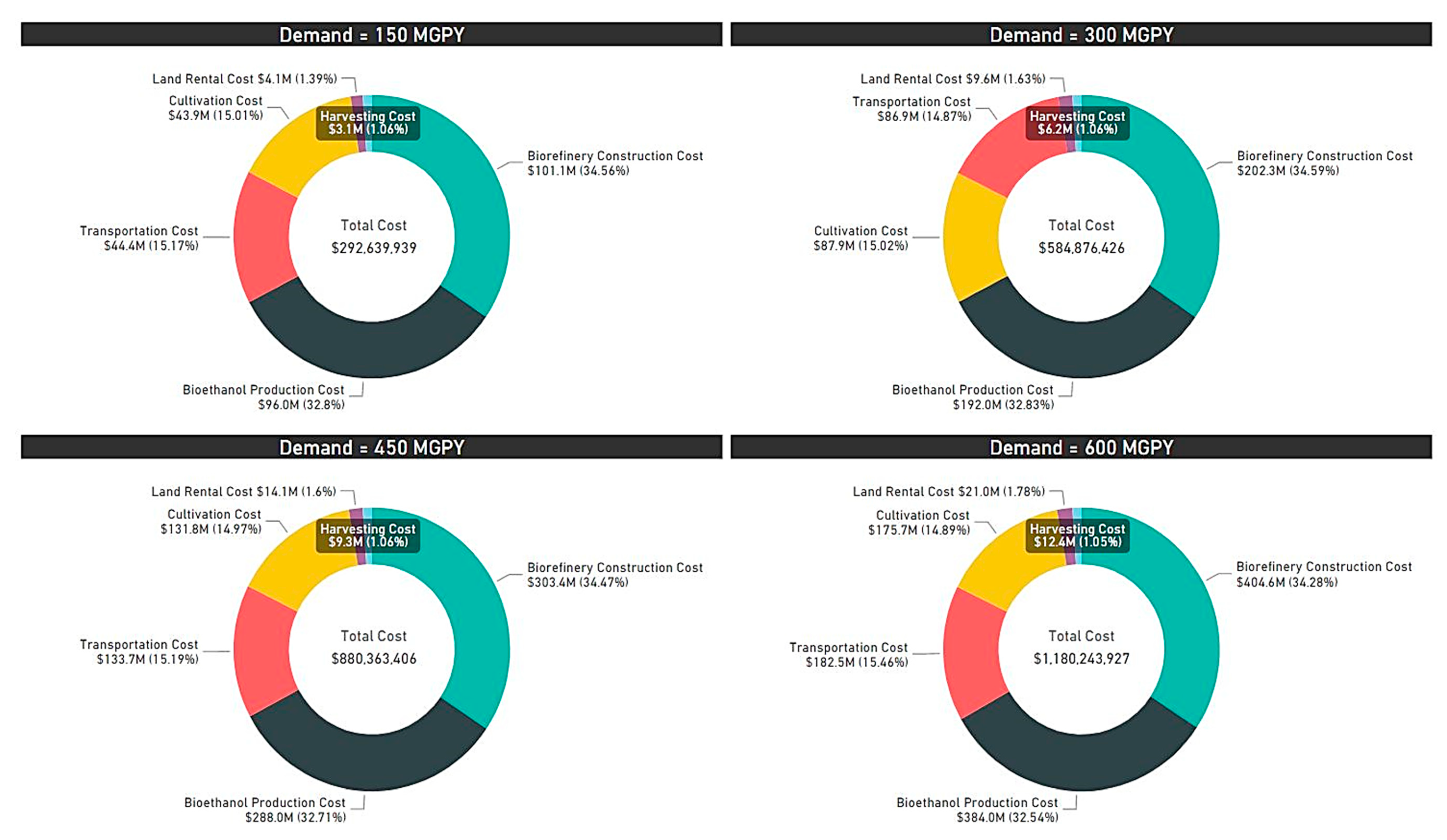

3.2. Maximizing Profit without Emissions and Energy Consumption Penalties

3.3. The Impact of a Carbon Tax on the Supply Chain

3.4. The Impacts of an Energy Consumption Penalty on the Supply Chain

3.5. Analysis with Both Emissions and Energy Consumption Penalties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Input Parameters

| Parameter and Value a | Description | Source |

| = 2.21 | Bioethanol selling price (USD/gal) | [32] |

| = 0.9 | Production cost of bioethanol at biorefinery (USD/gallon) | [2] |

| = 6 | Transportation fixed cost of switchgrass via truck (USD/ton) | [8] |

| = 0.08 | Transportation variable cost of switchgrass via truck (USD/ton-mile) | [8] |

| = 0.01159 | Transportation fixed cost of bioethanol via truck (USD/gallon) | [33] |

| = 0.00024 | Transportation variable cost of bioethanol via truck (USD/gallon-mile) | [33] |

| = 0.06183 | Transportation fixed cost of bioethanol via rail (USD/gallon) | [34] |

| = 0.000069 | Transportation variable cost of bioethanol via rail (USD/gallon-mile) | [34] |

| = 82.63 | Bioethanol conversion rate from switchgrass (gallons/ton) | [2] |

| = 0.0085 | Bioethanol co-product conversion rate (ton/gallon) | [18] |

| = 134 | Bioethanol co-product selling price (USD/ton) | Assumption |

| = 150,000,000 | Capacity of biorefineries (gallons) | [24] |

| = USD 101,145,437 | Annualized fixed capital cost for opening a biorefinery (USD) | [35] (estimate) |

| = 0.00015 | Emission factor of switchgrass acquisition (kg CO2e/ton) | [36] (estimate) |

| = 0.1103 | Emission factor of transporting switchgrass via truck (kg CO2e/ton-mile) | [36] (estimate) |

| = 0.000008 | Emission factor of producing bioethanol from switchgrass (kg CO2e/gallon) | [18] (estimate) |

| = 0.0005624 | Emission factor of transporting bioethanol via truck (kg CO2e/gallon-mile) | [37] (estimate) |

| = 0.0001135 | Emission factor of transporting bioethanol via rail (kg CO2e/gallon-mile) | [37] (estimate) |

| = 16.32 | Mean yield rate of switchgrass (ton/ha) | [2] (estimate) |

| = 395 | Cultivation cost of switchgrass (USD/ha) | [2] |

| = 27.9 | Harvesting cost of (square bale) switchgrass (USD/ha) | [38] |

| = 228.95 | Energy consumed during switchgrass acquisition (MJ/ton) | [39] (estimate) |

| = 171.97 | Energy consumed during transporting switchgrass via truck (MJ/ton-mile) | [39] (estimate) |

| = 13.82 | Energy consumed during bioethanol production (MJ/gal) | [39] (estimate) |

| = 1.58 | Energy consumed during transporting bioethanol via truck (MJ/gallon-mile) | [39] (estimate) |

| = 0.00001279 | Energy consumed during transporting bioethanol via rail (MJ/gallon-mile) | [37] (estimate) |

| = 0.1231 (Regular) | Carbon tax / Environmental cost factor of emissions (USD/kg CO2e) | [30,40] (estimate) |

| = 0.0215 (Regular) | Energy cost factor of fossil fuel consumed (USD/MJ) | [1,31] (estimate) |

Appendix B. Conversion Factors

| 1 mile = 1.609 km |

| 1 ton = 0.907 metric ton |

| 1 gallon = 3.785 L |

References

- Zhang, F.; Wang, J.; Liu, S.; Zhang, S.; Sutherland, J.W. Integrating GIS with Optimization Method for a Biofuel Feedstock Supply Chain. Biomass Bioenergy 2017, 98, 194–205. [Google Scholar] [CrossRef]

- Zhang, J.; Osmani, A.; Awudu, I.; Gonela, V. An Integrated Optimization -Based Model for Switchgrass Bioethanol Supply Chain. Appl. Energy 2013, 102, 1205–1217. [Google Scholar] [CrossRef]

- Haghpanah, T.; Sobati, M.A.; Pishvaee, M.S. Multi-Objective Superstructure Optimization of a Microalgae Biorefinery Considering Economic and Environmental Aspects. Comput. Chem. Eng. 2022, 164, 107894. [Google Scholar] [CrossRef]

- Ren, J.; An, D.; Liang, H.; Dong, L.; Gao, Z.; Geng, Y.; Zhu, Q.; Song, S.; Zhao, W. Life Cycle Energy and CO2 emission Optimization for Biofuel Supply Chain Planning under Uncertainties. Energy 2016, 103, 151–166. [Google Scholar] [CrossRef]

- Hendricks, A.M.; Wagner, J.E.; Volk, T.A.; Newman, D.H.; Brown, T.R. A Cost-Effective Evaluation of Biomass District Heating in Rural Communities. Appl. Energy 2016, 162, 561–569. [Google Scholar] [CrossRef]

- Ghaderi, H.; Moini, A.; Pishvaee, M.S. A Multi-Objective Robust Possibilistic Programming Approach to Sustainable Switchgrass-Based Bioethanol Supply Chain Network Design. J. Clean. Prod. 2018, 179, 368–406. [Google Scholar] [CrossRef]

- Osmani, A.; Zhang, J. Multi-Period Stochastic Optimization of a Sustainable Multi-Feedstock Second Generation Bioethanol Supply Chain—A Logistic Case Study in Midwestern United States. Land Use Policy 2017, 61, 420–450. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Mani, S.; Turhollow, S.; Kumar, A.; Bransby, D.; Lynd, L.; Laser, M. Large-Scale Production, Harvest and Logistics of Switchgrass (Panicum Virgatum L.)—Current Technology and Envisioning a Mature Technology. Biofuels Bioprod. Biorefining 2009, 3, 124–141. [Google Scholar] [CrossRef]

- Larnaudie, V.; Ferrari, M.D.; Lareo, C. Switchgrass as an Alternative Biomass for Ethanol Production in a Biorefinery: Perspectives on Technology, Economics and Environmental Sustainability. Renew. Sustain. Energy Rev. 2022, 158, 112115. [Google Scholar] [CrossRef]

- Zhu, X.; Li, X.; Yao, Q.; Chen, Y. Challenges and Models in Supporting Logistics System Design for Dedicated-Biomass-Based Bioenergy Industry. Bioresour. Technol. 2011, 102, 1344–1351. [Google Scholar] [CrossRef]

- Schnepf, R.; Yacobucci, B.D. Renewable Fuel Standard (RFS): Overview and Issues; Congressional Research Service: Washington, DC, USA, 2013. [Google Scholar]

- Ahi, P.; Searcy, C. An Analysis of Metrics Used to Measure Performance in Green and Sustainable Supply Chains. J. Clean. Prod. 2015, 86, 360–377. [Google Scholar] [CrossRef]

- Cobuloglu, H.I.; Büyüktahtakın, İ.E. A Mixed-Integer Optimization Model for the Economic and Environmental Analysis of Biomass Production. Biomass Bioenergy 2014, 67, 8–23. [Google Scholar] [CrossRef]

- Ghaderi, H.; Pishvaee, M.S.; Moini, A. Biomass Supply Chain Network Design: An Optimization-Oriented Review and Analysis. Ind. Crops Prod. 2016, 94, 972–1000. [Google Scholar] [CrossRef]

- Babazadeh, R.; Razmi, J.; Rabbani, M.; Pishvaee, M.S. An Integrated Data Envelopment Analysis–Mathematical Programming Approach to Strategic Biodiesel Supply Chain Network Design Problem. J. Clean. Prod. 2017, 147, 694–707. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Haji Esmaeili, S.A.; Sobhani, A.; Szmerekovsky, J. Renewable Jet Fuel Supply Chain Network Design: Application of Direct Monetary Incentives. Appl. Energy 2022, 310, 118569. [Google Scholar] [CrossRef]

- Haji Esmaeili, S.A.; Sobhani, A.; Szmerekovsky, J.; Dybing, A.; Pourhashem, G. First-Generation vs. Second-Generation: A Market Incentives Analysis for Bioethanol Supply Chains with Carbon Policies. Appl. Energy 2020, 277, 115606. [Google Scholar] [CrossRef]

- Gonela, V.; Zhang, J.; Osmani, A.; Onyeaghala, R. Stochastic Optimization of Sustainable Hybrid Generation Bioethanol Supply Chains. Transp. Res. Part E Logist. Transp. Rev. 2015, 77, 1–28. [Google Scholar] [CrossRef]

- Jayarathna, L.; Kent, G.; O’Hara, I. Spatial Optimization of Multiple Biomass Utilization for Large-Scale Bioelectricity Generation. J. Clean. Prod. 2021, 319, 128625. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Optimal Siting and Size of Bioenergy Facilities Using Geographic Information System. Appl. Energy 2012, 94, 192–201. [Google Scholar] [CrossRef]

- Huang, E.; Zhang, X.; Rodriguez, L.; Khanna, M.; de Jong, S.; Ting, K.C.; Ying, Y.; Lin, T. Multi-Objective Optimization for Sustainable Renewable Jet Fuel Production: A Case Study of Corn Stover Based Supply Chain System in Midwestern U.S. Renew. Sustain. Energy Rev. 2019, 115, 109403. [Google Scholar] [CrossRef]

- Sánchez-García, S.; Athanassiadis, D.; Martínez-Alonso, C.; Tolosana, E.; Majada, J.; Canga, E. A GIS Methodology for Optimal Location of a Wood-Fired Power Plant: Quantification of Available Woodfuel, Supply Chain Costs and GHG Emissions. J. Clean. Prod. 2017, 157, 201–212. [Google Scholar] [CrossRef]

- TIGER/Line Shapefiles. Available online: https://www.census.gov/geographies/mapping-files/2020/geo/tiger-line-file.html (accessed on 19 September 2022).

- Kou, N.; Zhao, F. Techno-Economical Analysis of a Thermo-Chemical Biofuel Plant with Feedstock and Product Flexibility under External Disturbances. Energy 2011, 36, 6745–6752. [Google Scholar] [CrossRef]

- NASS Census of Agriculture National Agricultural Statistics Service (NASS). Census of Agriculture; USDA: Washington, DC, USA, 1997.

- ND Studies Energy Curriculum. Available online: https://www.ndstudies.gov/energy/level2/module-5-biofuels-geothermal-recovered/biofuels (accessed on 13 January 2020).

- Zhang, F.; Johnson, D.M.; Johnson, M.A. Development of a Simulation Model of Biomass Supply Chain for Biofuel Production. Renew. Energy 2012, 44, 380–391. [Google Scholar] [CrossRef]

- Haji Esmaeili, S.A.; Szmerekovsky, J.; Sobhani, A.; Dybing, A.; Peterson, T.O. Sustainable Biomass Supply Chain Network Design with Biomass Switching Incentives for First-Generation Bioethanol Producers. Energy Policy 2020, 138, 111222. [Google Scholar] [CrossRef]

- Mason, A.J. OpenSolver—An Open Source Add-In to Solve Linear and Integer Progammes in Excel. In Operations Research Proceedings; Springer: Zurich, Switzerland, 2012; pp. 401–406. [Google Scholar] [CrossRef]

- Nguyen, T.L.T.; Gheewala, S.H. Fossil Energy, Environmental and Cost Performance of Ethanol in Thailand. J. Clean. Prod. 2008, 16, 1814–1821. [Google Scholar] [CrossRef]

- Energy Information Administration (EIA)—Gasoline and Diesel Fuel Update. Available online: https://www.eia.gov/petroleum/gasdiesel/ (accessed on 13 January 2020).

- Mohamed Abdul Ghani, N.M.A.; Vogiatzis, C.; Szmerekovsky, J. Biomass Feedstock Supply Chain Network Design with Biomass Conversion Incentives. Energy Policy 2018, 116, 39–49. [Google Scholar] [CrossRef]

- Searcy, E.; Flynn, P.; Ghafoori, E.; Kumar, A. The Relative Cost of Biomass Energy Transport. Appl. Biochem. Biotechnol. 2007, 137, 639–652. [Google Scholar]

- Kocoloski, M.; Michael Griffin, W.; Scott Matthews, H. Impacts of Facility Size and Location Decisions on Ethanol Production Cost. Energy Policy 2011, 39, 47–56. [Google Scholar] [CrossRef]

- Osmani, A.; Zhang, J. Stochastic Optimization of a Multi-Feedstock Lignocellulosic-Based Bioethanol Supply Chain under Multiple Uncertainties. Energy 2013, 59, 157–172. [Google Scholar] [CrossRef]

- You, F.; Wang, B. Life Cycle Optimization of Biomass-to-Liquid Supply Chains with Distributed-Centralized Processing Networks. Ind. Eng. Chem. Res. 2011, 50, 10102–10127. [Google Scholar] [CrossRef]

- Zhang, F.; Johnson, D.M.; Wang, J. Life-Cycle Energy and GHG Emissions of Forest Biomass Harvest and Transport for Biofuel Production in Michigan. Energies 2015, 8, 3258–3271. [Google Scholar] [CrossRef]

- Larson, J.A.; Yu, T.; English, B.C.; Mooney, D.F.; Wang, C. Cost Evaluation of Alternative Switchgrass Producing, Harvesting, Storing, and Transporting Systems and Their Logistics in the Southeastern USA. Agric. Financ. Rev. 2010, 70, 184–200. [Google Scholar] [CrossRef]

- Gonela, V.; Zhang, J.; Osmani, A. Stochastic Optimization of Sustainable Industrial Symbiosis Based Hybrid Generation Bioethanol Supply Chains. Comput. Ind. Eng. 2015, 87, 40–65. [Google Scholar] [CrossRef]

- X-Rates. Currency Calculator (US Dollar, Euro). X-Rates Website. 2018. Available online: https://www.x-rates.com/calculator/?from=EUR&to=USD&amount=1 (accessed on 13 January 2020).

| Agricultural Statistical District (ASD) | Available Land for Switchgrass Cultivation (ha) [25] | Marginal Land Rental Cost (USD/ha) [25] |

|---|---|---|

| SE | 76,229 | USD 67.95 |

| EC | 74,394 | USD 49.42 |

| NE | 195,229 | USD 40.77 |

| SC | 65,442 | USD 45.71 |

| CENTRAL | 84,683 | USD 49.42 |

| NC | 88,533 | USD 39.54 |

| SW | 45,013 | USD 35.83 |

| WC | 75,253 | USD 34.59 |

| NW | 102,370 | USD 24.71 |

| Notation | |||

| Indices/Sets | Mean yield rate of switchgrass (tons/ha) | ||

| Cultivation cost of switchgrass (USD/ha) | |||

| Set of suppliers, indexed by i | Harvesting cost of (square bale) switchgrass (USD/ha) | ||

| Set of biorefineries, indexed by k | Marginal land rental cost at supply zone i (USD/ha) | ||

| Set of in-state demand zones, indexed by e | Available marginal land at supply zone i (has) | ||

| Set of out-of-state demand zones, indexed by r | Bioethanol conversion rate from switchgrass (gallons/ton) | ||

| Decision variables | Bioethanol co-product conversion rate at biorefineries (tons/gallon) | ||

| 1 if a biorefinery is opened at location k; 0 otherwise | Emission factor of switchgrass acquisition (kg CO2e/ton) | ||

| Quantity of switchgrass transported from supply area i to biorefinery k via truck (tons) | Emission factor of transporting switchgrass via truck (kg CO2e/ton-mile) | ||

| Decision variables | Parameters | ||

| Quantity of bioethanol transported from biorefinery k to in-state demand zone e via truck (gallons) | Emission factor of bioethanol production from switchgrass (kg CO2e /gallon) | ||

| Quantity of bioethanol transported from biorefinery k to out-of-state demand zone e via rail (gallons) | Emission factor of transporting bioethanol via truck (kg CO2e/gallon-mile) | ||

| Quantity of bioethanol co-products produced at biorefineries (tons) | Emission factor of transporting bioethanol via rail (kg CO2e/gallon-mile) | ||

| Parameters | Energy consumed during switchgrass acquisition (MJ/ton) | ||

| Bioethanol selling price (USD/gallon) | Energy consumed during bioethanol production (MJ/gal) | ||

| Bioethanol co-product selling price (USD/ton) | Energy consumed during transporting switchgrass via truck (MJ/ton-mile) | ||

| Production cost at biorefineries (USD/gallon) | Energy consumed during transporting bioethanol via truck (MJ/gallon-mile) | ||

| Transportation fixed cost of switchgrass via truck (USD/ton) | Energy consumed during transporting bioethanol via rail (MJ/gallon-mile) | ||

| Transportation variable cost of switchgrass via truck (USD/ton-mile) | Carbon tax/Environmental cost factor of emissions (USD/kg CO2e) | ||

| Transportation fixed cost of bioethanol via truck (USD/gallon) | Energy cost factor of fossil fuel consumed (USD/MJ) | ||

| Transportation variable cost of bioethanol via truck (USD/gallon-mile) | Distance from supply zone I to biorefinery k (miles) | ||

| Transportation fixed cost of bioethanol via rail (USD/gallon) | Distance from biorefinery k to in-state demand zone e (miles) | ||

| Transportation variable cost of bioethanol via rail (USD/gallon) | Distance from biorefinery k to out-of-state demand zone e (miles) | ||

| Annualized fixed capital cost for opening a biorefinery (USD) | Annual bioethanol demand level at in-state demand zone e (gallons) | ||

| Capacity of biorefineries (gallons) | Annual bioethanol demand level at out-of-state demand zone r (gallons) | ||

| Demand (MGPY) | Supplier District | Biorefinery | Out-of-State Demand Zone | In-State Demand Zone |

|---|---|---|---|---|

| 150 | NW, NC | Ward | All out-of-state demand zones | All in-state demand zones |

| - | Grand Forks | - | - | |

| - | Richland | - | - | |

| - | Stutsman | - | - | |

| 300 | NW, NC | Ward | Los Angeles, Portland, Seattle | Minot |

| - | Grand Forks | - | - | |

| - | Richland | - | - | |

| CENTRAL, EC | Stutsman | Houston, Los Angeles | Fargo, Jamestown, Grand Forks, Bismarck, Dickinson | |

| 450 | NW, NC | Ward | Los Angeles, Portland, Seattle | Minot |

| NE | Grand Forks | Houston | Fargo, Grand Forks | |

| - | Richland | - | - | |

| CENTRAL, EC | Stutsman | Houston, Los Angeles | Jamestown, Bismarck, Dickinson | |

| 600 | NW, NC | Ward | Los Angeles, Portland | Minot |

| NE | Grand Forks | Houston, Los Angeles, Seattle | Grand Forks | |

| SE, EC | Richland | Houston | Fargo | |

| CENTRAL, EC | Stutsman | Los Angeles | Jamestown, Bismarck, Dickinson |

| Carbon Tax | ||||||

|---|---|---|---|---|---|---|

| No Penalty | Regular | Reaction Point | Profit = USD 0 | Another Biorefinery Needed | ||

| Demand (MGPY) | Values | USD 0 | USD 0.1231 | Varied | Varied | Varied |

| 150 | Total profit | USD 70,735,060 | USD 65,895,171 | USD 65,895,171 (carbon tax = USD 1.06) | USD 0 (carbon tax = USD 1.82) | USD (2,487,703,373) (carbon tax = USD 70) |

| Emissions a | 39,316,733 | 39,316,733 | 38,184,906 | 38,184,906 | 36,688,217 | |

| 300 | Total profit | USD 141,873,566 | USD 132,601,966 | USD 125,308,674 (carbon tax = USD 0.22) | USD 0 (carbon tax = USD 1.89) | USD (20,799,938,779) (carbon tax = USD 280) |

| Emissions | 75,317,633 | 75,317,633 | 74,791,924 | 74,791,924 | 74,431,385 | |

| 450 | Total profit | USD 209,761,577 | USD 195,291,611 | USD 185,076,825 (carbon tax = USD 0.21) | USD 0 (carbon tax = USD 1.79) | USD (51,864,095,228) (carbon tax = USD 445) |

| Emissions | 117,546,438 | 117,546,438 | 117,020,730 | 117,020,730 | 116,789,324 | |

| 600 | Total profit | USD 273,256,099 | USD 253,269,524 | - | USD 0 (carbon tax = USD 1.68) | No more biorefineries |

| Emissions | 162,360,481 | 162,360,481 | No changes | 162,360,481 | - | |

| Carbon Tax | ||||||

|---|---|---|---|---|---|---|

| No Penalty | Regular | Reaction Point | Profit = USD 0 | Another Biorefinery Needed | ||

| Demand (MGPY) | Bioethanol Plant | USD 0 | USD 0.1231 | Varied | Varied | Varied |

| 150 | Ward | ✓ | ✓ | - | - | ✓ |

| Grand Forks | - | - | - | - | - | |

| Richland | - | - | - | - | - | |

| Stutsman | - | - | ✓ | ✓ | ✓ | |

| 300 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | - | - | - | - | ✓ | |

| Richland | - | - | - | - | - | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| 450 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Richland | - | - | - | - | ✓ | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| 600 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Richland | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Carbon Tax | |||||

|---|---|---|---|---|---|

| No Penalty | Regular | Reaction Point | Profit = USD 0 | Another Biorefinery Needed | |

| Emissions sources | USD 0 | USD 0.1231 | USD 0.22 | USD 1.89 | USD 280 |

| Biomass acquisition | 545 | 545 | 545 | 545 | 545 |

| Bioethanol production | 2400 | 2400 | 2400 | 2400 | 2400 |

| Transport from supplier to biorefinery | 22,404,399 | 22,404,399 | 21,878,691 | 21,878,691 | 21,927,586 |

| Transport from biorefinery to demand zone | 52,910,289 | 52,910,289 | 52,910,289 | 52,910,289 | 52,500,854 |

| Total * | 75,317,633 | 75,317,633 | 74,791,924 | 74,791,924 | 74,431,385 |

| ECF | ||||||

|---|---|---|---|---|---|---|

| No Penalty | Reaction Point | Profit = USD 0 | Regular | Another Biorefinery Needed | ||

| Demand (MGPY) | Values | USD 0 | Varied | Varied | USD 0.0215 | Varied |

| 150 | Total profit | USD 70,735,060 | USD 60,926,739 (ECF = USD 0.0004) | USD 0 (ECF = USD 0.0032) | USD (393,511,221) | USD (1,609,483,849) (ECF = USD 0.078) |

| Energy (MJ) | 24,631,063,008 | 21,537,344,071 | 21,537,344,071 | 21,537,344,071 | 20,248,379,593 | |

| 300 | Total profit | USD 141,873,566 | USD 135,653,138 (ECF = USD 0.00014) | USD 0 (ECF = USD 0.0033) | USD (795,544,890) | USD (3,389,124,545) (ECF = USD 0.081) |

| Energy (MJ) | 44,489,135,416 | 43,595,413,313 | 43,595,413,313 | 43,595,413,313 | 42,339,964,254 | |

| 450 | Total profit | USD 209,761,577 | USD 203,496,958 (ECF = USD 0.00009) | USD 0 (ECF = USD 0.0031) | USD (1,266,990,598) | USD (11,177,593,949) (ECF = USD 0.1658) |

| Energy (MJ) | 69,611,317,791 | 69,500,191,601 | 68,680,553,671 | 68,680,553,671 | 68,068,426,986 | |

| 600 | Total profit | USD 273,256,099 | USD 264,158,559 (ECF = USD 0.00009) | USD 0 (ECF = USD 0.0028) | USD (1,896,993,394) | No more biorefineries |

| Energy (MJ) | 101,089,408,308 | 100,941,239,825 | 100,941,239,825 | 100,941,239,825 | - | |

| ECF | ||||||

|---|---|---|---|---|---|---|

| No Penalty | Reaction Point | Profit = USD 0 | Regular | Another Biorefinery Needed | ||

| Demand (MGPY) | Bioethanol Plant | USD 0 | Varied | Varied | USD 0.0215 | Varied |

| 150 | Ward | ✓ | - | - | - | ✓ |

| Grand Forks | - | - | - | - | - | |

| Richland | - | - | - | - | - | |

| Stutsman | - | ✓ | ✓ | ✓ | ✓ | |

| 300 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | - | - | - | - | ✓ | |

| Richland | - | - | - | - | - | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| 450 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Richland | - | - | - | - | ✓ | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| 600 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Richland | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| ECF | |||||

|---|---|---|---|---|---|

| No Penalty | Reaction Point | Profit = USD 0 | Regular | Another Biorefinery Needed | |

| Energy consumers | USD 0 | USD 0.00014 | USD 0.0033 | USD 0.0215 | USD 0.081 |

| Biomass acquisition | 831,235,619 | 831,235,619 | 831,235,619 | 831,235,619 | 831,235,619 |

| Bioethanol production | 4,145,999,997 | 4,145,999,997 | 4,145,999,997 | 4,145,999,997 | 4,145,999,997 |

| Transport from supplier to biorefinery | 34,930,956,349 | 34,111,318,419 | 34,111,318,419 | 34,111,318,419 | 34,278,618,010 |

| Transport from biorefinery to demand zone | 4,580,943,452 | 4,506,859,278 | 4,506,859,278 | 4,506,859,278 | 3,084,110,629 |

| Total | 44,489,135,416 | 43,595,413,313 | 43,595,413,313 | 43,595,413,313 | 42,339,964,254 |

| Carbon Tax (USD/kg CO2e) | ||||||

|---|---|---|---|---|---|---|

| No Penalty | Regular | Reaction Point | Profit = USD 0 | Another Biorefinery Needed | ||

| ECF (USD/MJ) | Bioethanol Plant | USD 0 | USD 0.1231 | USD 0.22 | USD 1.89 | USD 280 |

| No Penalty USD 0 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | - | - | - | - | ✓ | |

| Richland | - | - | - | - | - | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Reaction Point USD 0.00014 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | - | - | - | - | ✓ | |

| Richland | - | - | - | - | - | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Profit = USD 0 USD 0.0033 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | - | - | - | - | ✓ | |

| Richland | - | - | - | - | - | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Regular USD 0.0215 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | - | - | - | - | ✓ | |

| Richland | - | - | - | - | - | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Another Biorefinery Needed USD 0.081 | Ward | ✓ | ✓ | ✓ | ✓ | ✓ |

| Grand Forks | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Richland | - | - | - | - | - | |

| Stutsman | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Carbon Tax | ||||||

|---|---|---|---|---|---|---|

| No Penalty | Regular | Reaction Point | Profit = $0 b | Another Biorefinery Needed | ||

| ECF | Values | USD 0 | USD 0.1231 | USD 0.22 | USD 1.89 | USD 280 |

| No Penalty USD 0 | Profit (USD) | 141,873,566 | 132,601,966 | 125,308,674 | 0 | (20,799,938,779) |

| Emissions c (USD/kg CO2e) | 75,317,633 | 75,317,633 | 74,791,924 | 74,791,924 | 74,431,385 | |

| Energy d (MJ) | 44,489,135,416 | 44,489,135,416 | 43,669,497,445 | 43,669,497,445 | 42,595,469,330 | |

| Reaction Point USD 0.00014 | Profit | 135,653,138 | 126,445,922 | 119,198,325 | (5,707,569) | (3,959,758) |

| Emissions (USD/kg CO2e) | 74,794,603 | 74,794,603 | 74,794,603 | 74,791,924 | 74,431,385 | |

| Energy (MJ) | 43,595,413,313 | 43,595,413,313 | 43,595,413,313 | 43,669,497,445 | 42,595,469,330 | |

| Profit = $0 a USD 0.0033 | Profit | 0 | (11,315,584) | (18,563,181) | (143,470,169) | (20,940,503,828) |

| Emissions (USD/kg CO2e) | 74,794,603 | 74,794,603 | 74,794,603 | 74,794,603 | 74,431,385 | |

| Energy (MJ) | 43,595,413,313 | 43,595,413,313 | 43,595,413,313 | 43,595,413,313 | 42,595,469,330 | |

| Regular USD 0.0215 | Profit | (795,544,890) | (804,752,106) | (811,999,703) | (936,906,691) | (21,714,905,113) |

| Emissions (USD/kg CO2e) | 74,794,603 | 74,794,603 | 74,794,603 | 74,794,603 | 74,434,064 | |

| Energy (MJ) | 43,595,413,313 | 43,595,413,313 | 43,595,413,313 | 43,595,413,313 | 42,521,385,198 | |

| Another Biorefinery Needed USD 0.081 | Profit | (3,389,124,545) | (3,398,312,054) | (3,405,544,139) | (3,530,183,780) | (24,244,927,532) |

| Emissions (USD/kg CO2e) | 74,634,515 | 74,634,515 | 74,634,515 | 74,634,515 | 74,434,064 | |

| Energy (MJ) | 42,339,964,254 | 42,339,964,254 | 42,339,964,254 | 42,339,964,254 | 42,521,385,198 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haji Esmaeili, S.A.; Sobhani, A.; Ebrahimi, S.; Szmerekovsky, J.; Dybing, A.; Keramati, A. Location Allocation of Biorefineries for a Switchgrass-Based Bioethanol Supply Chain Using Energy Consumption and Emissions. Logistics 2023, 7, 5. https://doi.org/10.3390/logistics7010005

Haji Esmaeili SA, Sobhani A, Ebrahimi S, Szmerekovsky J, Dybing A, Keramati A. Location Allocation of Biorefineries for a Switchgrass-Based Bioethanol Supply Chain Using Energy Consumption and Emissions. Logistics. 2023; 7(1):5. https://doi.org/10.3390/logistics7010005

Chicago/Turabian StyleHaji Esmaeili, Seyed Ali, Ahmad Sobhani, Sajad Ebrahimi, Joseph Szmerekovsky, Alan Dybing, and Amin Keramati. 2023. "Location Allocation of Biorefineries for a Switchgrass-Based Bioethanol Supply Chain Using Energy Consumption and Emissions" Logistics 7, no. 1: 5. https://doi.org/10.3390/logistics7010005

APA StyleHaji Esmaeili, S. A., Sobhani, A., Ebrahimi, S., Szmerekovsky, J., Dybing, A., & Keramati, A. (2023). Location Allocation of Biorefineries for a Switchgrass-Based Bioethanol Supply Chain Using Energy Consumption and Emissions. Logistics, 7(1), 5. https://doi.org/10.3390/logistics7010005