Pandemic, War, Natural Calamities, and Sustainability: Industry 4.0 Technologies to Overcome Traditional and Contemporary Supply Chain Challenges

Abstract

1. Introduction

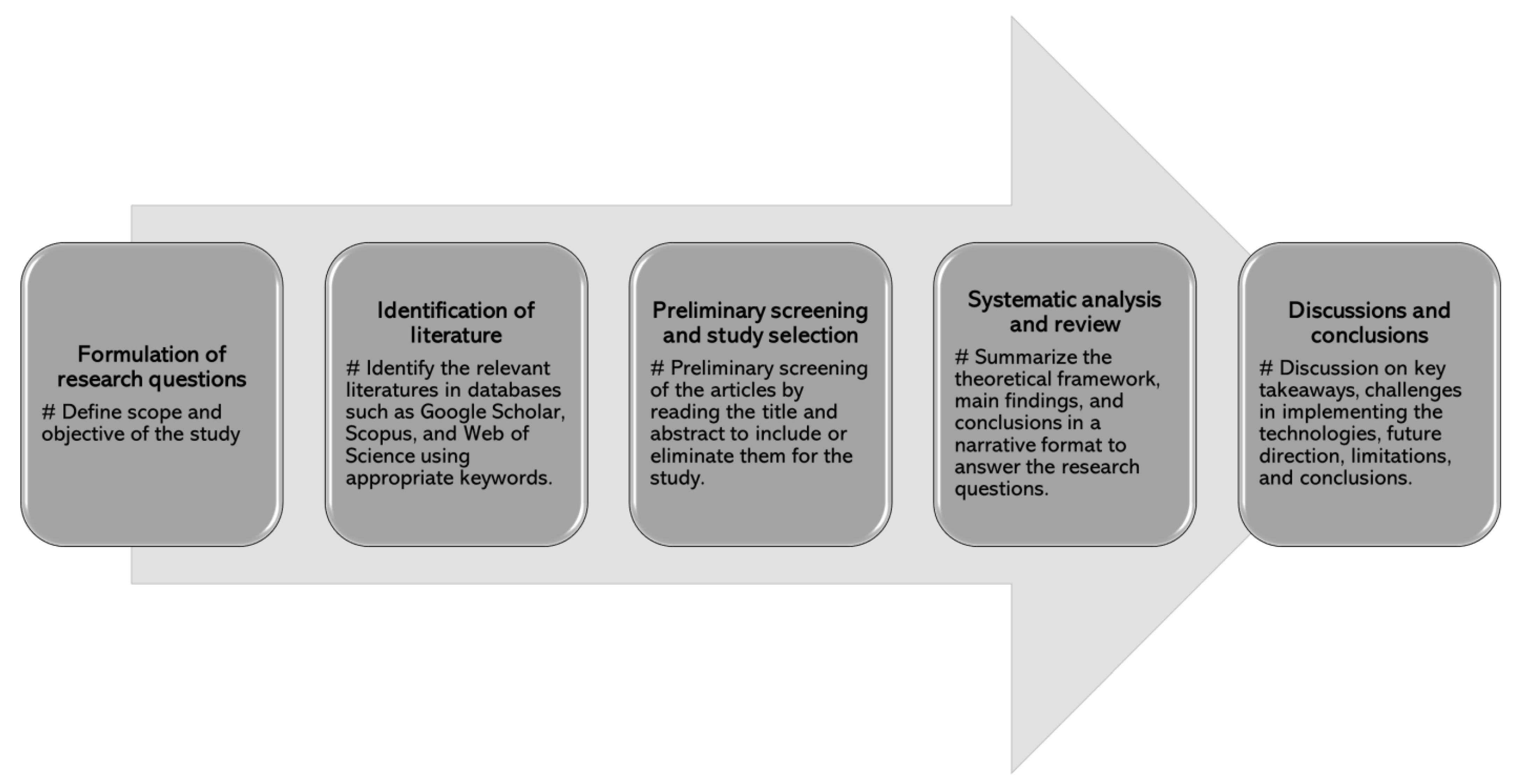

2. Review Methods and Materials

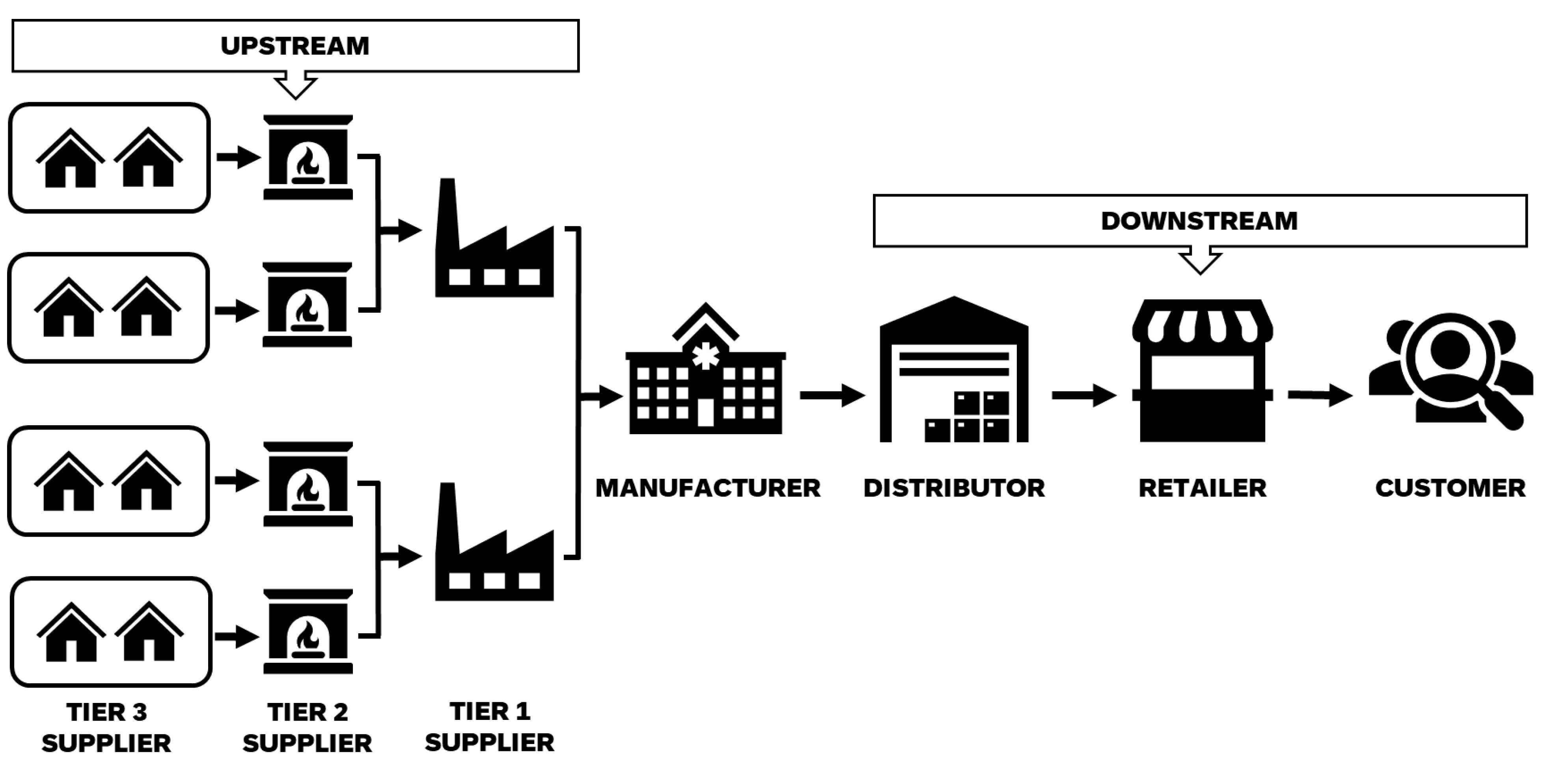

3. Challenges in Supply Chain and Logistics

3.1. Traditional Challenges

3.1.1. Planning and Forecasting

3.1.2. Supplier Relationship Management

3.1.3. Product Quality

3.1.4. Inventory Management

3.1.5. Competitiveness and Customer Service

3.1.6. Risk Identification and Mitigation

3.1.7. Data Accessibility and Management

3.2. Contemporary Challenges

3.2.1. Scarcity of Raw Materials

3.2.2. Increase in Transportation Cost

3.2.3. Demand Forecasting

3.2.4. Logistical Challenges (Port Congestion)

3.2.5. Changes in Consumer Behavior

3.2.6. Labor Shortage

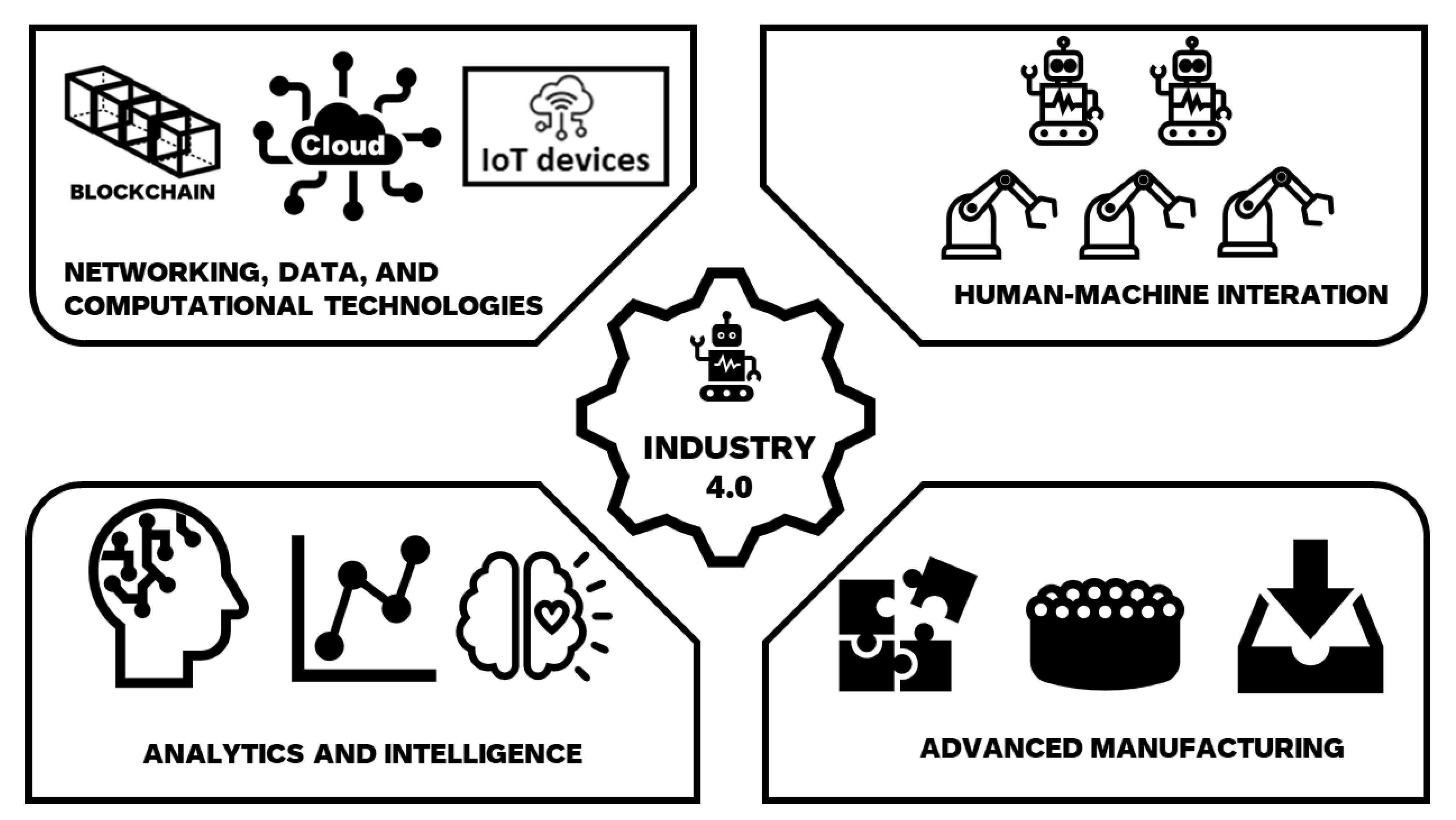

4. Industry 4.0 Technologies in Supply Chain Management

4.1. Artificial Intelligence

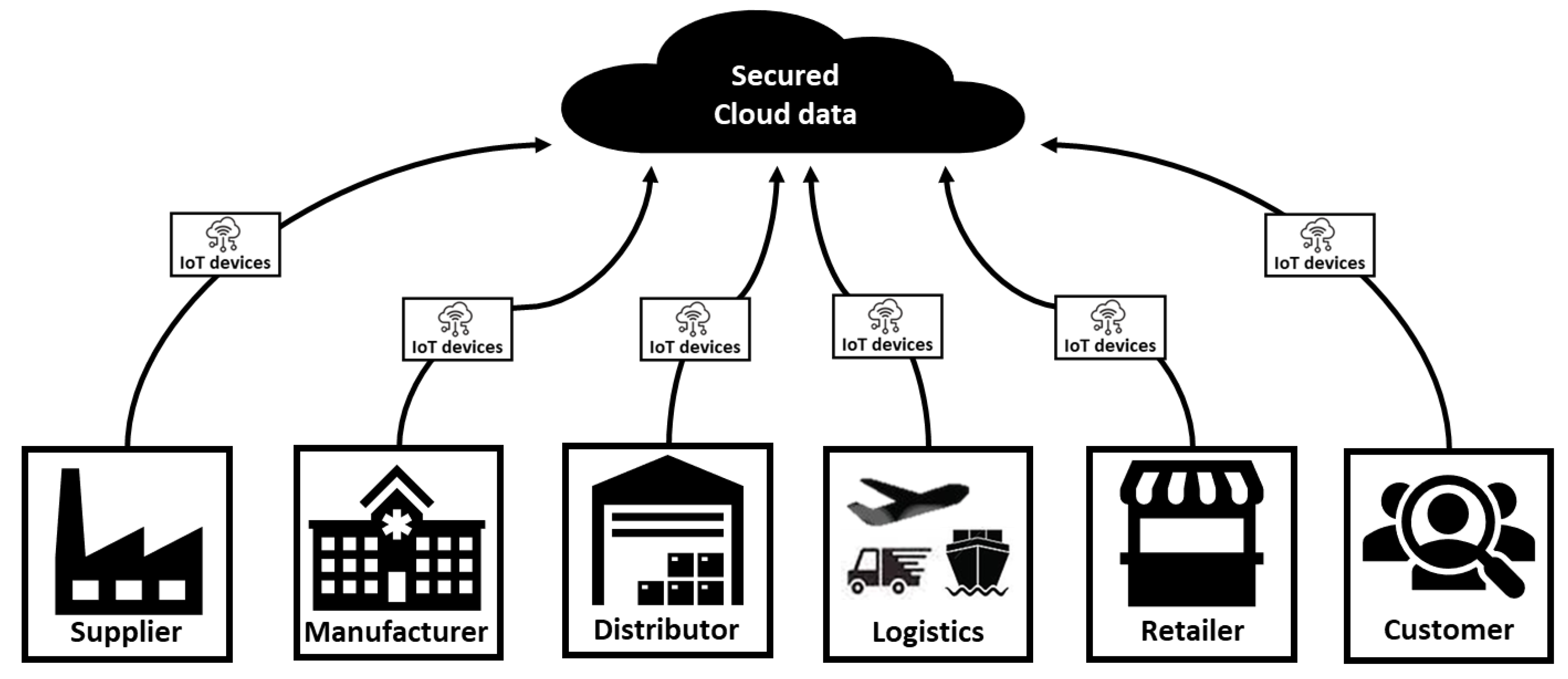

4.2. Internet of Things (IoT)

4.3. Big Data Analytics (BDA)

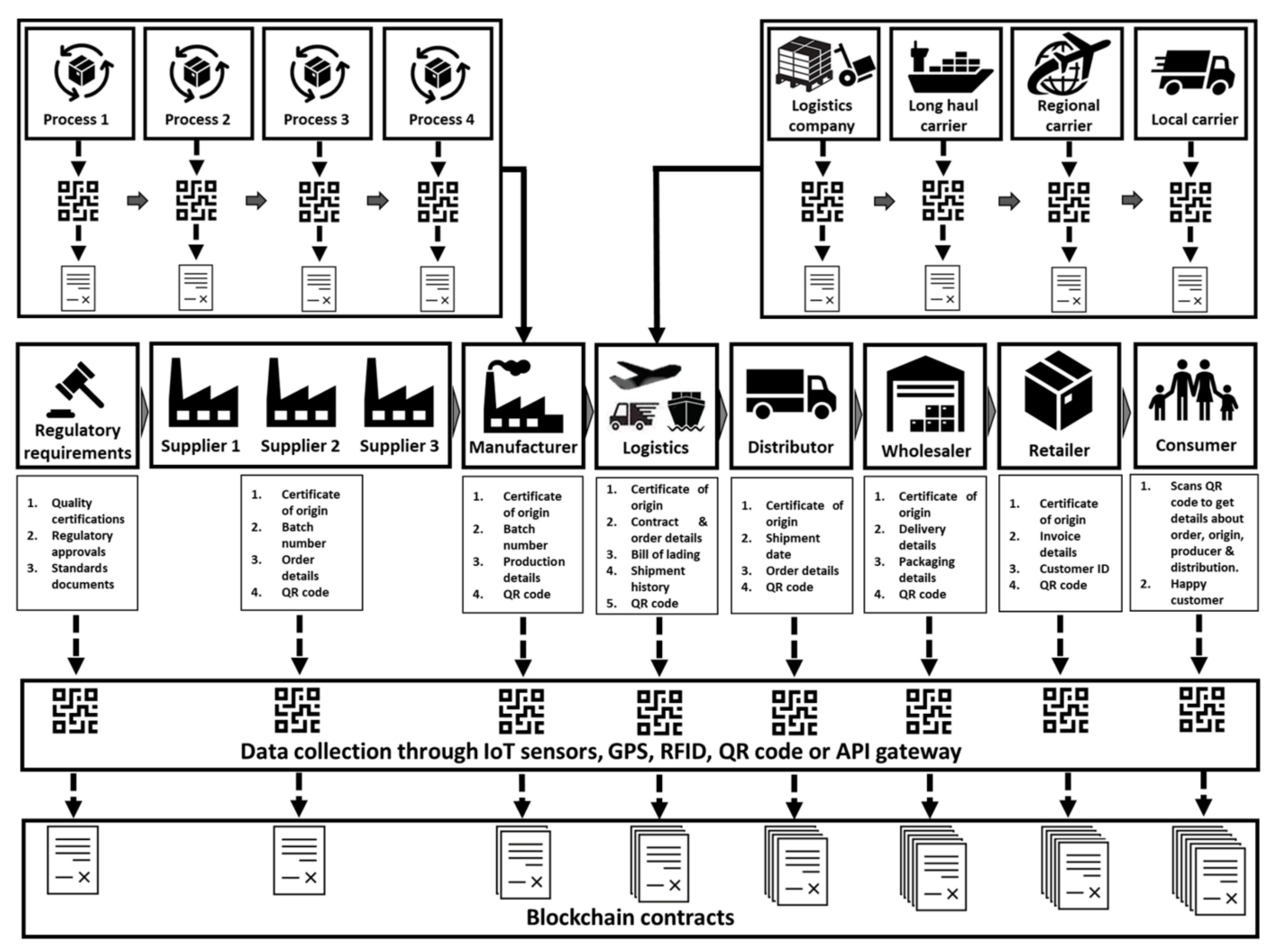

4.4. Blockchain

4.5. Automation and Robotics

4.6. Additive Manufacturing (AM)

5. Sustainable Supply Chain Management

6. Discussion

6.1. Key Takeaways

6.2. Challenges in Adopting Industry 4.0 Technologies

6.3. Future Direction

- o A fully connected supply chain that allows real-time monitoring and improved communication and collaboration between various supply chain participants.

- o Improved flexibility and better visibility of data across the supply chain partners, which can increase productivity, manufacturing efficiency, and profitability in addition to the ability to respond quickly to changing demands.

- o A highly optimized and automated process that can reduce the time to market and improve an organization’s efficiency.

- o A very high level of data transparency and visibility empowers supply chain managers to make effective data-driven decisions.

- o A highly flexible and agile supply chain that can quickly adapt to fluctuations in demand, enable product personalization and customization, and support rapid product development.

- o Enable in-process process monitoring and control that can improve product quality and reduce scrappages, which can make the supply chain sustainable.

- o Enhanced customer experience and customer satisfaction.

- ○

- As the technologies mature over the years, they can address privacy, security, and cost implications. Hence, industries must openly collaborate with academics to build more successful use cases and address practical problems to exhibit real-life benefits.

- ○

- The creation of an industrial and regulatory framework for some of the novel technologies such as blockchain, reduction in implementation and maintenance costs, and easy availability of technical expertise can make the top management rethink their current strategies and embrace the technologies which will mark the beginning of the transformation of the traditional supply chain into supply chain 4.0.

- ○

- Developing new business models and strategies with the help of these technologies.

- ○

- Developing suitable technology infrastructure for quick implementation and complete digital transformation of legacy manufacturing units.

- ○

- In addition, the impacts of these technologies on sector-specific supply chains should be further explored.

- ○

- Detailed technical studies on various costs involved, breakeven, advantages, and disadvantages of implementing the technologies must be conducted.

- ○

- Apart from cost benefits, the focus of future studies must also be to understand the implications of these technologies on supply chain resilience and sustainability.

6.4. Managerial Implications

6.5. Contributions and limitations of the Study

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Disclaimer

References

- Wu, T.; Blackhurst, J.; O’grady, P. Methodology for supply chain disruption analysis. Int. J. Prod. Res. 2007, 45, 1665–1682. [Google Scholar] [CrossRef]

- Mahajan, K.; Tomar, S. COVID-19 and Supply Chain Disruption: Evidence from Food Markets in India. Am. J. Agric. Econ. 2020, 103, 35–52. [Google Scholar] [CrossRef] [PubMed]

- Oliveira-Dias, D.; Maqueira-Marín, J.M.; Moyano-Fuentes, J. The link between information and digital technologies of industry 4.0 and agile supply chain: Mapping current research and establishing new research avenues. Comput. Ind. Eng. 2022, 167, 108000. [Google Scholar] [CrossRef]

- Li, Y.; Chen, K.; Collignon, S.; Ivanov, D. Ripple effect in the supply chain network: Forward and backward disruption propagation, network health and firm vulnerability. Eur. J. Oper. Res. 2021, 291, 1117–1131. [Google Scholar] [CrossRef] [PubMed]

- Wenz, L.; Willner, S.; Bierkandt, R.; Levermann, A. Acclimate—A model for economic damage propagation. Part II: A dynamic formulation of the backward effects of disaster-induced production failures in the global supply network. Environ. Syst. Decis. 2014, 34, 525–539. [Google Scholar] [CrossRef]

- Craighead, C.W.; Blackhurst, J.; Rungtusanatham, M.J.; Handfield, R.B. The severity of supply chain disruptions: Design characteristics and mitigation capabilities. Decis. Sci. 2007, 38, 131–156. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Li, Y.; Zobel, C.W. Exploring supply chain network resilience in the presence of the ripple effect. Int. J. Prod. Econ. 2020, 228, 107693. [Google Scholar] [CrossRef]

- Raja Santhi, A.; Muthuswamy, P. Influence of Blockchain Technology in Manufacturing Supply Chain and Logistics. Logistics 2022, 6, 15. [Google Scholar] [CrossRef]

- Sharma, S.; Modgil, S. Supply chain efforts among downstream and upstream: A developed view. Int. J. Eng. Manag. Econ. 2013, 4, 54. [Google Scholar] [CrossRef]

- Serdarasan, S. A review of supply chain complexity drivers. Comput. Ind. Eng. 2013, 66, 533–540. [Google Scholar] [CrossRef]

- Stadtler, H. Supply chain management and advanced planning—Basics, overview and challenges. Eur. J. Oper. Res. 2005, 163, 575–588. [Google Scholar] [CrossRef]

- Bhattacharya, R.; Bandyopadhyay, S. A review of the causes of bullwhip effect in a supply chain. Int. J. Adv. Manuf. Technol. 2011, 54, 1245–1261. [Google Scholar] [CrossRef]

- Sun, H.X.; Ren, Y.T. The impact of forecasting methods on bullwhip effect in supply chain management. In Proceedings of the 2005 IEEE International Engineering Management Conference, St. John’s, NL, Canada, 13 September 2005; pp. 215–219. [Google Scholar] [CrossRef]

- Sheth, J.N.; Sharma, A. Supplier relationships: Emerging issues and challenges. Ind. Mark. Manag. 1997, 26, 91–100. [Google Scholar] [CrossRef]

- Olorunniwo, F.; Jolayemi, J.; Fan, C.; Li, X. Challenges faced in supplier relationship management: Perspectives from practitioners. In Global Conference on Business and Finance Proceedings; The Institute for Business and Finance Research: Hilo, HI, USA, 2011; Volume 6, ISSN 1941-9589. [Google Scholar]

- Ibrahim, A.-Z. Supplier Relationship Management (SRM); Salford University: Manchester, UK, 2019; Available online: https://www.academia.edu/41996920/Supplier_Relationship_Management_SRM (accessed on 15 September 2022).

- Lummus, R.; Duclos, L.K.; Vokurka, R. Supply chain flexibility: Building a new model. Glob. J. Flex. Syst. Manag. 2003, 4, 1–13. [Google Scholar]

- Tse, Y.K.; Tan, K.H. Managing product quality risk and visibility in multi-layer supply chain. Int. J. Prod. Econ. 2012, 139, 49–57. [Google Scholar] [CrossRef]

- Yang, Z.B.; Aydýn, G.; Babich, V.; Beil, D.R. Supply Disruptions, Asymmetric Information, and a Backup Production Option. Manag. Sci. 2009, 55, 192–209. [Google Scholar] [CrossRef]

- Lyles, M.; Flynn, B.; Frohlich, M. All Supply Chains Don’t Flow Through: Understanding Supply Chain Issues in Product Recalls. Manag. Organ. Rev. 2008, 4, 167–182. [Google Scholar] [CrossRef]

- Lo, V.H.Y.; Yeung, A. Managing quality effectively in supply chain: A preliminary study. Supply Chain Manag. Int. J. 2006, 11, 208–215. [Google Scholar] [CrossRef]

- Lin, C.; Chow, W.S.; Madu, C.N.; Kuei, C.; Yu, P.P. A structural equation model of supply chain quality management and organizational performance. Int. J. Prod. Econ. 2005, 96, 355–365. [Google Scholar] [CrossRef]

- Gupta, A.; Maranas, C.D.; McDonald, C.M. Mid-term supply chain planning under demand uncertainty: Customer demand satisfaction and inventory management. Comput. Chem. Eng. 2000, 24, 2613–2621. [Google Scholar] [CrossRef]

- Shokouhifar, M.; Ranjbarimesan, M. Multivariate time-series blood donation/demand forecasting for resilient supply chain management during COVID-19 pandemic. Clean. Logist. Supply Chain 2022, 5, 100078. [Google Scholar] [CrossRef]

- Iseri-Say, A.; Toker, A.; Kantur, D. Do popular management techniques improve performance? Evidence from large businesses in Turkey. J. Manag. Dev. 2008, 27, 660–677. [Google Scholar] [CrossRef]

- Agus, A. Supply Chain Management: The Influence of SCM on Production Performance and Product Quality. J. Econ. Bus. Manag. 2015, 3, 1046–1053. [Google Scholar] [CrossRef]

- Lassar, W.; Haar, J.; Montalvo, R.; Hulser, L. Competitive Challenges for Supply Chain Management in Emerging Markets: The Case of Mexico; Florida International University: Miami, FL, USA, 2009. [Google Scholar]

- Chandra, C.; Kumar, S. Supply chain management in theory and practice: A passing fad or a fundamental change? Ind. Manag. Data Syst. 2000, 100, 100–114. [Google Scholar] [CrossRef]

- Supply Chain Vulnerability, Executive Report on Behalf of: Department for Transport, Local Government and the Regions; Cranfield University School of Management: Bedford, UK, 2002.

- Tuncel, G.; Alpan, G. Risk assessment and management for supply chain networks: A case study. Comput. Ind. 2010, 61, 250–259. [Google Scholar] [CrossRef]

- Bhakar, S.S.; Sankpal, S.; Mukherjee, S. Data management issues in the supply chain. In Key Drivers of Organizational Excellence; Excel Books: Delhi, India, 2009; ISBN 817446719X, 9788174467195. [Google Scholar]

- Raut, R.D.; Yadav, V.S.; Cheikhrouhou, N.; Narwane, V.S.; Narkhede, B.E. Big data analytics: Implementation challenges in Indian manufacturing supply chains. Comput. Ind. 2021, 125, 103368. [Google Scholar] [CrossRef]

- Gupta, M.; Abdelmaksoud, A.; Jafferany, M.; Lotti, T.; Sadoughifar, R.; Goldust, M. COVID-19 and economy. Dermatol. Ther. 2020, 33, e13329. [Google Scholar] [CrossRef]

- Cai, M.; Luo, J. Influence of COVID-19 on Manufacturing Industry and Corresponding Countermeasures from Supply Chain Perspective. J. Shanghai Jiaotong Univ. Sci. 2020, 25, 409–416. [Google Scholar] [CrossRef]

- Rahman, T.; Taghikhah, F.; Paul, S.K.; Shukla, N.; Agarwal, R. An agent-based model for supply chain recovery in the wake of the COVID-19 pandemic. Comput. Ind. Eng. 2021, 158, 107401. [Google Scholar] [CrossRef]

- Nicomedes, C.J.C.; Avila, R.M.A. An analysis on the panic during COVID-19 pandemic through an online form. J. Affect. Disord. 2020, 276, 14–22. [Google Scholar] [CrossRef]

- Maffioli, E.M. How Is the World Responding to the Novel Coronavirus Disease (COVID-19) Compared with the 2014 West African Ebola Epidemic? The Importance of China as a Player in the Global Economy. Am. J. Trop. Med. Hyg. 2020, 102, 924–925. [Google Scholar] [CrossRef] [PubMed]

- Nagao, T.; Ijuin, H.; Yamada, T.; Nagasawa, K.; Zhou, L. COVID-19 Disruption Strategy for Redesigning Global Supply Chain Network across TPP Countries. Logistics 2021, 6, 2. [Google Scholar] [CrossRef]

- Shih, W.C. Global Supply Chains in a Post-Pandemic World, Harvard Business Review. 2020. Available online: https://hbr.org/2020/09/global-supply-chains-in-a-post-pandemic-world (accessed on 15 September 2022).

- Burgos, D.; Ivanov, D. Food retail supply chain resilience and the COVID-19 pandemic: A digital twin-based impact analysis and improvement directions. Transp. Res. Part E Logist. Transp. Rev. 2021, 152, 102412. [Google Scholar] [CrossRef]

- Vo, T.D.; Tran, M.D. The impact of covid-19 pandemic on the Global Trade. Int. J. Soc. Sci. Econ. Inven. 2021, 7, 1–7. [Google Scholar] [CrossRef]

- Schork, T. Supply Chain Disruptions Due to Coronavirus: Who Covers the Costs? 20 March 2020. Available online: https://www.aeb.com/intl-en/magazine/articles/coronavirus-supply-chain-delivery-disruption-costs-liability.php (accessed on 15 September 2022).

- Nižetić, S. Impact of coronavirus (COVID-19) pandemic on air transport mobility, energy, and environment: A case study. Int. J. Energy Res. 2020, 44, 10953–10961. [Google Scholar] [CrossRef]

- Chen, C.-F.; De Rubens, G.Z.; Xu, X.; Li, J. Coronavirus comes home? Energy use, home energy management, and the social-psychological factors of COVID-19. Energy Res. Soc. Sci. 2020, 68, 101688. [Google Scholar] [CrossRef]

- Graves, S.C.; Tomlin, B.T.; Willems, S.P. Supply Chain Challenges in the Post-COVID Era. Prod. Oper. Manag. 2022. [Google Scholar] [CrossRef]

- Gui, D.; Wang, H.; Yu, M. Risk Assessment of Port Congestion Risk during the COVID-19 Pandemic. J. Mar. Sci. Eng. 2022, 10, 150. [Google Scholar] [CrossRef]

- Saeed, N.; Song, D.-W.; Andersen, O. Governance mode for port congestion mitigation: A transaction cost perspective. Netnomics Econ. Res. Electron. Netw. 2018, 19, 159–178. [Google Scholar] [CrossRef]

- Taghikhah, F.; Voinov, A.; Shukla, N. Extending the supply chain to address sustainability. J. Clean. Prod. 2019, 229, 652–666. [Google Scholar] [CrossRef]

- Durmaz, Y. The Impact of Psychological Factors on Consumer Buying Behavior and an Empirical Application in Turkey. Asian Soc. Sci. 2014, 10, 194–204. [Google Scholar] [CrossRef]

- Iddris, F. Digital Supply Chain: Survey of the Literature. Int. J. Bus. Res. Manag. 2018, 9, 47–61. [Google Scholar]

- Ellyatt, H. There Are Millions of Jobs, but a Shortage of Workers: Economists Explain Why That’s Worrying. October 2020. Available online: https://www.cnbc.com/2021/10/20/global-shortage-of-workers-whats-going-on-experts-explain.html (accessed on 15 September 2022).

- US Bureau of Labor Statistics. Employment Recovery in the Wake of the COVID-19 Pandemic. December 2020. Available online: https://www.bls.gov/opub/mlr/2020/article/employment-recovery.htm (accessed on 15 September 2022).

- Larue, B. Labor issues and COVID-19. Can. J. Agric. Econ. 2020, 68, 231–237. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Narwane, V.S.; Narkhede, B.E. Applications of industry 4.0 to overcome the COVID-19 operational challenges. Diabetes Metab. Syndr. Clin. Res. Rev. 2020, 14, 1283–1289. [Google Scholar] [CrossRef]

- Aslan, E. How Supply Chain Management Will Change in the Industry 4.0 Era? In Research Anthology on Cross-Industry Challenges of Industry 4.0; Information Resources Management Association, IGI Global: Hershey, PA, USA, 2021; pp. 1015–1035. [Google Scholar] [CrossRef]

- Geodis. A White Paper on Supply Chain Worldwide Survey. 2017. Available online: https://geodis.com/sg//sites/default/files/2019-03/170509_GEODIS_WHITE-PAPER.PDF (accessed on 15 September 2022).

- Top 5 Supply Chain Management Challenges and How to Overcome Them (With Real-Life Examples). 8 April 2021. Available online: https://www.easyecom.io/blog/top-5-supply-chain-management-challenges-and-how-to-overcome-them-with-real-life-examples/ (accessed on 15 September 2022).

- Muthuswamy, P.; Shunmugesh, K. Artificial intelligence based tool condition monitoring for digital twins and industry 4.0 applications. Int. J. Interact. Des. Manuf. 2022. [Google Scholar] [CrossRef]

- McCulloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial intelligence in supply chain management: A systematic literature review. J. Bus. Res. 2021, 122, 502–517. [Google Scholar] [CrossRef]

- Mobarakeh, N.A.; Shahzad, M.K.; Baboli, A.; Tonadre, R. Improved Forecasts for uncertain and unpredictable Spare Parts Demand in Business Aircraft’s with Bootstrap Method. IFAC-PapersOnLine 2017, 50, 15241–15246. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Choy, K.L.; Wu, C.H.; Ho, G.T.S.; Lam, C.H.Y.; Koo, P.S. An Internet of Things (IoT)-based risk monitoring system for managing cold supply chain risks. Ind. Manag. Data Syst. 2018, 118, 1432–1462. [Google Scholar] [CrossRef]

- Ignaciuk, P.; Wieczorek, Ł. Continuous Genetic Algorithms in the Optimization of Logistic Networks: Applicability Assessment and Tuning. Appl. Sci. 2020, 10, 7851. [Google Scholar] [CrossRef]

- Ferreira, L.; Borenstein, D. Normative agent-based simulation for supply chain planning. J. Oper. Res. Soc. 2011, 62, 501–514. [Google Scholar] [CrossRef]

- Naz, F.; Kumar, A.; Majumdar, A.; Agrawal, R. Is artificial intelligence an enabler of supply chain resiliency post COVID-19? An exploratory state-of-the-art review for future research. Oper. Manag. Res. 2022, 15, 378–398. [Google Scholar] [CrossRef]

- Sohrabpour, V.; Oghazi, P.; Toorajipour, R.; Nazarpour, A. Export sales forecasting using artificial intelligence. Technol. Forecast. Soc. Change 2021, 163, 120480. [Google Scholar] [CrossRef]

- Ketter, W.; Collins, J.; Gini, M.; Gupta, A.; Schrater, P. Real-Time Tactical and Strategic Sales Management for Intelligent Agents Guided by Economic Regimes. Inf. Syst. Res. 2012, 23, 1263–1283. [Google Scholar] [CrossRef]

- O’Donnell, T.; Humphreys, P.; McIvor, R.; Maguire, L. Reducing the negative effects of sales promotions in supply chains using genetic algorithms. Expert Syst. Appl. 2009, 36, 7827–7837. [Google Scholar] [CrossRef]

- Shakya, S.; Chin, C.M.; Owusu, G. An AI-based system for pricing diverse products and services. Knowl.-Based Syst. 2010, 23, 357–362. [Google Scholar] [CrossRef]

- Casabayó, M.; Agell, N.; Sánchez-Hernández, G. Improved market segmentation by fuzzifying crisp clusters: A case study of the energy market in Spain. Expert Syst. Appl. 2015, 42, 1637–1643. [Google Scholar] [CrossRef]

- Sarvari, P.A.; Ustundag, A.; Takci, H. Performance evaluation of different customer segmentation approaches based on RFM and demographics analysis. Kybernetes 2016, 45, 1129–1157. [Google Scholar] [CrossRef]

- Stalidis, G.; Karapistolis, D.; Vafeiadis, A. Marketing Decision Support Using Artificial Intelligence and Knowledge Modeling: Application to Tourist Destination Management. Procedia-Soc. Behav. Sci. 2015, 175, 106–113. [Google Scholar] [CrossRef]

- Rekha, A.G.; Abdulla, M.S.; Asharaf, S. Artificial Intelligence Marketing: An application of a novel Lightly Trained Support Vector Data Description. J. Inf. Optim. Sci. 2016, 37, 681–691. [Google Scholar] [CrossRef]

- Martínez-López, F.J.; Casillas, J. Artificial intelligence-based systems applied in industrial marketing: An historical overview, current and future insights. Ind. Mark. Manag. 2013, 42, 489–495. [Google Scholar] [CrossRef]

- Kwong, C.K.; Jiang, H.; Luo, X.G. AI-based methodology of integrating affective design, engineering, and marketing for defining design specifications of new products. Eng. Appl. Artif. Intell. 2016, 47, 49–60. [Google Scholar] [CrossRef]

- Taratukhin, V.; Yadgarova, Y. Towards a socio-inspired multiagent approach for new generation of product life cycle management. Procedia Comput. Sci. 2018, 123, 479–487. [Google Scholar] [CrossRef]

- Cardoso, R.N.; Pereira, B.L.; Fonseca, J.P.S.; Ferreira, M.V.M.; Tavares, J.J.P.Z.S. Automated Planning Integrated with Linear Programming Applied in the Container Loading Problem. IFAC Proc. Vol. 2013, 46, 153–158. [Google Scholar] [CrossRef]

- Wang, T.; Ramik, D.M.; Sabourin, C.; Madani, K. Intelligent systems for industrial robotics: Application in logistic field. Ind. Robot. 2012, 39, 251–259. [Google Scholar] [CrossRef]

- Knoll, D.; Prüglmeier, M.; Reinhart, G. Predicting Future Inbound Logistics Processes Using Machine Learning. Procedia CIRP 2016, 52, 145–150. [Google Scholar] [CrossRef]

- Klumpp, M. Automation and artificial intelligence in business logistics systems: Human reactions and collaboration requirements. Int. J. Logist. Res. Appl. 2018, 21, 224–242. [Google Scholar] [CrossRef]

- Eslikizi, S.; Ziebuhr, M.; Kopfer, H.; Buer, T. Shapley-based side payments and simulated annealing for distributed lot-sizingÕ. IFAC-PapersOnLine 2015, 48, 1592–1597. [Google Scholar] [CrossRef]

- Lee, C.K.M.; Ho, W.; Ho, G.T.S.; Lau, H.C.W. Design and development of logistics workflow systems for demand management with RFID. Expert Syst. Appl. 2011, 38, 5428–5437. [Google Scholar] [CrossRef]

- Kucukkoc, I.; Zhang, D.Z. A mathematical model and genetic algorithm-based approach for parallel two-sided assembly line balancing problem. Prod. Plan. Control 2015, 26, 874–894. [Google Scholar] [CrossRef]

- Sanders, D.; Gegov, A. AI tools for use in assembly automation and some examples of recent applications. Assem. Autom. 2013, 33, 184–194. [Google Scholar] [CrossRef]

- Olsson, E.; Funk, P. Agent-based monitoring using case-based reasoning for experience reuse and improved quality. J. Qual. Maint. Eng. 2009, 15, 179–192. [Google Scholar] [CrossRef]

- Gligor, A.; Dumitru, C.-D.; Grif, H.-S. Artificial intelligence solution for managing a photovoltaic energy production unit. Procedia Manuf. 2018, 22, 626–633. [Google Scholar] [CrossRef]

- Ennen, P.; Reuter, S.; Vossen, R.; Jeschke, S. Automated Production Ramp-up Through Self-Learning Systems. Procedia CIRP 2016, 51, 57–62. [Google Scholar] [CrossRef]

- Sousa, A.R.; Tavares, J.J.P.Z.S. Toward Automated Planning Algorithms Applied to Production and Logistics. IFAC Proc. Vol. 2013, 46, 165–170. [Google Scholar] [CrossRef]

- Quiñónez-Gámez, O.P.; Camacho-Velázquez, R.G. Validation of production data by using an AI-based classification methodology; a case in the Gulf of Mexico. J. Nat. Gas Sci. Eng. 2011, 3, 729–734. [Google Scholar] [CrossRef]

- Bravo, C.; Castro, J.A.; Saputelli, L.; Ríos, A.; Aguilar-Martin, J.; Rivas, F. An implementation of a distributed artificial intelligence architecture to the integrated production management. J. Nat. Gas Sci. Eng. 2011, 3, 735–747. [Google Scholar] [CrossRef]

- Mayr, A.; Weigelt, M.; Masuch, M.; Meiners, M.; Hüttel, F.; Franke, J. Application Scenarios of Artificial Intelligence in Electric Drives Production. Procedia Manuf. 2018, 24, 40–47. [Google Scholar] [CrossRef]

- Martinez-Barbera, H.; Herrero-Perez, D. Development of a flexible AGV for flexible manufacturing systems. Ind. Robot. 2010, 37, 459–468. [Google Scholar] [CrossRef]

- Kasie, F.M.; Bright, G.; Walker, A. Decision support systems in manufacturing: A survey and future trends. J. Model. Manag. 2017, 12, 432–454. [Google Scholar] [CrossRef]

- Camarillo, A.; Ríos, J.; Althoff, K. Knowledge-based multi-agent system for manufacturing problem solving process in production plants. J. Manuf. Syst. 2018, 47, 115–127. [Google Scholar] [CrossRef]

- Taylan, O.; Darrab, I.A. Fuzzy control charts for process quality improvement and product assessment in tip shear carpet industry. J. Manuf. Technol. Manag. 2012, 23, 402–420. [Google Scholar] [CrossRef]

- Brandenburger, J.; Colla, V.; Nastasi, G.; Ferro, F.; Schirm, C.; Melcher, J. Big Data Solution for Quality Monitoring and Improvement on Flat Steel Production. IFAC-PapersOnLine 2016, 49, 55–60. [Google Scholar] [CrossRef]

- Tsafarakis, S.; Saridakis, C.; Baltas, G.; Matsatsinis, N. Hybrid particle swarm optimization with mutation for optimizing industrial product lines: An application to a mixed solution space considering both discrete and continuous design variables. Ind. Mark. Manag. 2013, 42, 496–506. [Google Scholar] [CrossRef]

- Ma, Z.; Leung, J.Y.; Zanon, S. Integration of artificial intelligence and production data analysis for shale heterogeneity characterization in steam-assisted gravity-drainage reservoirs. J. Pet. Sci. Eng. 2018, 163, 139–155. [Google Scholar] [CrossRef]

- Trentesaux, D.; Thomas, A. Product-Driven Control: A State of the Art and Future Trends. IFAC Proc. Vol. 2012, 45, 716–721. [Google Scholar] [CrossRef]

- Munguia, J.; Bernard, A.; Erdal, M. Proposal and evaluation of a KBE-RM selection system. Rapid Prototyp. J. 2011, 17, 236–246. [Google Scholar] [CrossRef]

- Amirkolaii, K.N.; Baboli, A.; Shahzad, M.K.; Tonadre, R. Demand Forecasting for Irregular Demands in Business Aircraft Spare Parts Supply Chains by using Artificial Intelligence (AI). IFAC-PapersOnLine 2017, 50, 15221–15226. [Google Scholar] [CrossRef]

- Florez, J.V.; Lauras, M.; Okongwu, U.; Dupont, L. A decision support system for robust humanitarian facility location. Eng. Appl. Artif. Intell. 2015, 46, 326–335. [Google Scholar] [CrossRef]

- Vahdani, B.; Iranmanesh, S.H.; Mousavi, S.M.; Abdollahzade, M. A locally linear neuro-fuzzy model for supplier selection in cosmetics industry. Appl. Math. Model. 2012, 36, 4714–4727. [Google Scholar] [CrossRef]

- Zhang, X.; Chan, F.T.S.; Adamatzky, A.; Mahadevan, S.; Yang, H.; Zhang, Z.; Deng, Y. An intelligent physarum solver for supply chain network design under profit maximization and oligopolistic competition. Int. J. Prod. Res. 2016, 55, 244–263. [Google Scholar] [CrossRef]

- Sinha, A.K.; Zhang, W.Z.; Tiwari, M. Co-evolutionary immuno-particle swarm optimization with penetrated hyper-mutation for distributed inventory replenishment. Eng. Appl. Artif. Intell. 2012, 25, 1628–1643. [Google Scholar] [CrossRef]

- Zgaya, H.; Zoghlami, N.; Hammadi, S.; Bretaudeau, F. Negotiation Model in a Multi-Agent Supply Chain System for The Crisis Management. IFAC Proc. Vol. 2009, 42, 1026–1031. [Google Scholar] [CrossRef]

- Dias, J.C.Q.; Calado, J.M.F.; Osório, A.L.; Morgado, L.F. RFID together with multi-agent systems to control global value chains. Annu. Rev. Control 2009, 33, 185–195. [Google Scholar] [CrossRef]

- Pino, R.; Fernández, I.; De la Fuente, D.; Parreño, J.; Priore, P. Supply chain modelling using a multi-agent system. J. Adv. Manag. Res. 2010, 7, 149–162. [Google Scholar] [CrossRef]

- Min, H. Artificial intelligence in supply chain management: Theory and applications. Int. J. Logist. Res. Appl. 2009, 13, 13–39. [Google Scholar] [CrossRef]

- Chong, A.Y.-L.; Bai, R. Predicting open IOS adoption in SMEs: An integrated SEM-neural network approach. Expert Syst. Appl. 2013, 41, 221–229. [Google Scholar] [CrossRef]

- Yanqing, D.; Edwards, J.S.; Yogesh, K.D. Artificial intelligence for decision making in the era of Big Data – evolution, challenges and research agenda. Int. J. Inf. Manage. 2019, 48, 63–71. [Google Scholar] [CrossRef]

- Regal, T.; Pereira, C.E. Ontology for Conceptual Modelling of Intelligent Maintenance Systems and Spare Parts Supply Chain Integration. IFAC-PapersOnLine 2018, 51, 1511–1516. [Google Scholar] [CrossRef]

- Merlino, M.; Sproģe, I. The Augmented Supply Chain. Procedia Eng. 2017, 178, 308–318. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742. [Google Scholar] [CrossRef]

- Ross, D.F.; Weston, F.S.; Stephen, W. Introduction to Supply Chain Management Technologies; CRC Press: Boca Raton, FL, USA, 2010; ISBN 1439837538, 9781439837535. [Google Scholar]

- Salehi-Amiri, A.; Jabbarzadeh, A.; Hajiaghaei-Keshteli, M.; Chaabane, A. Utilizing the Internet of Things (IoT) to address uncertain home health care supply chain network. Expert Syst. Appl. 2022, 208, 118239. [Google Scholar] [CrossRef]

- Shokouhifar, M.; Sabbaghi, M.M.; Pilevari, N. Inventory management in blood supply chain considering fuzzy supply/demand uncertainties and lateral transshipment. Transfus. Apher. Sci. 2021, 60, 103103. [Google Scholar] [CrossRef]

- Sohrabi, M.; Zandieh, M.; Afshar-Nadjafi, B. A simple empirical inventory model for managing the processed corneal tissue equitably in hospitals with demand differentiation. Comput. Appl. Math. 2021, 40, 281. [Google Scholar] [CrossRef]

- APICS. Supply Chain Operations Reference Model, Version 12.0. 2017. Available online: http://www.apics.org/docs/default-source/scor-p-toolkits/apics-scc-scor-quick-reference-guide.pdf?sfvrsn=2 (accessed on 15 September 2022).

- Verdouw, C.N.; Beulens, A.J.M.; Van der Vorst, J.G.A.J. Virtualisation of floricultural supply chains: A review from an Internet of Things perspective. Comput. Electron. Agric. 2013, 99, 160–175. [Google Scholar] [CrossRef]

- Ng, I.; Scharf, K.; Pogrebna, G.; Maull, R. Contextual variety, Internet-of-Things and the choice of tailoring over platform: Mass customisation strategy in supply chain management. Int. J. Prod. Econ. 2015, 159, 76–87. [Google Scholar] [CrossRef]

- Yu, J.; Subramanian, N.; Ning, K.; Edwards, D. Product delivery service provider selection and customer satisfaction in the era of internet of things: A Chinese e-retailers’ perspective. Int. J. Prod. Econ. 2015, 159, 104–116. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.F.; Zang, D.X. Real-Time Visibility and Traceability Framework for Discrete Manufacturing Shopfloor. In Proceedings of the 22nd International Conference on Industrial Engineering and Engineering Management 2015; Springer: Singapore, 2015; pp. 763–772. [Google Scholar]

- Rymaszewska, A.; Helo, P.; Gunasekaran, A. IoT powered servitization of manufacturing—An exploratory case study. Int. J. Prod. Econ. 2017, 192, 92–105. [Google Scholar] [CrossRef]

- Putnik, G.D.; Varela, M.L.R.; Carvalho, C.; Alves, C.; Shah, V.; Castro, H.; Ávila, P. Smart Objects Embedded Production and Quality Management Functions. Int. J. Qual. Res. 2015, 9, 151–166. [Google Scholar]

- Ondemir, O.; Gupta, S.M. Quality management in product recovery using the Internet of Things: An optimization approach. Comput. Ind. 2014, 65, 491–504. [Google Scholar] [CrossRef]

- Chukwuekwe, D.O.; Schjoelberg, P.; Roedseth, H.; Stuber, A. Reliable, Robust and Resilient Systems: Towards Development of a Predictive Maintenance Concept within the Industry 4.0 Environment. In Proceedings of the EFNMS Euro Maintenance Conference, Athens, Greece, 30 May 2016. [Google Scholar]

- Reaidy, P.J.; Gunasekaran, A.; Spalanzani, A. Bottom-up approach based on Internet of Things for order fulfillment in a collaborative warehousing environment. Int. J. Prod. Econ. 2015, 159, 29–40. [Google Scholar] [CrossRef]

- Qiu, X.; Luo, H.; Xu, G.; Zhong, R.; Huang, G.Q. Physical assets and service sharing for IoT-enabled Supply Hub in Industrial Park (SHIP). Int. J. Prod. Econ. 2015, 159, 4–15. [Google Scholar] [CrossRef]

- Choy, K.L.; Ho, G.T.S.; Lee, C.K.H. A RFID-based storage assignment system for enhancing the efficiency of order picking. J. Intell. Manuf. 2017, 28, 111–129. [Google Scholar] [CrossRef]

- Kong, X.T.R.; Chen, J.; Luo, H.; Huang, G.Q. Scheduling at an auction logistics centre with physical internet. Int. J. Prod. Res. 2015, 54, 2670–2690. [Google Scholar] [CrossRef]

- Yao, J. Optimisation of one-stop delivery scheduling in online shopping based on the physical Internet. Int. J. Prod. Res. 2017, 55, 358–376. [Google Scholar] [CrossRef]

- Mathaba, S.; Adigun, M.; Oladosu, J.; Oki, O. On the Use of the Internet of Things and Web 2.0 in Inventory management. J. Intell. Fuzzy Syst. 2017, 32, 3091–3101. [Google Scholar] [CrossRef]

- Gu, Y.; Liu, Q. Research on the Application of the Internet of Things in Reverse Logistics Information Management. J. Ind. Eng. Manag. 2013, 6, 963–973. [Google Scholar] [CrossRef]

- Parry, G.C.; Brax, S.A.; Maull, R.S.; Ng, I.C.L. Operationalising IoT for reverse supply: The development of use-visibility measures. Supply Chain Manag. Int. J. 2016, 21, 228–244. [Google Scholar] [CrossRef]

- Thürer, M.; Pan, Y.H.; Qu, T.; Luo, H.; Li, C.D.; Huang, G.Q. Internet of Things (IoT) driven kanban system for reverse logistics: Solid waste collection. J. Intell. Manuf. 2019, 30, 2621–2630. [Google Scholar] [CrossRef]

- Balaji, M.S.; Roy, S.K. Value co-creation with Internet of things technology in the retail industry. J. Mark. Manag. 2017, 33, 7–31. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Darvazeh, S.S.; Vanani, I.R.; Musolu, F.M. Big Data Analytics and Its Applications in Supply Chain Management. In New Trends in the Use of Artificial Intelligence for the Industry 4.0; Martínez, L.R., Rios, R.A.O., Prieto, M.D., Eds.; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef][Green Version]

- Geunes, J.; Chang, B. Operations Research Models for Supply Chain Management and Design. In Encyclopedia of Optimization; Floudas, C., Pardalos, P., Eds.; Springer: Boston, MA, USA, 2008. [Google Scholar] [CrossRef]

- Wang, G.; Gunasekaran, A.; Ngai, E.W.T.; Papadopoulos, T. Big data analytics in logistics and supply chain management: Certain investigations for research and applications. Int. J. Prod. Econ. 2016, 176, 98–110. [Google Scholar] [CrossRef]

- Murugesan, S.; Sudharsanan, T.; Murugesan, V.; Muthuswamy, P. Overall Equipment Effectiveness (OEE) analysis and improvement in a spinning unit. Int. J. Appl. Eng. Res. 2015, 10, 3791–3796. [Google Scholar] [CrossRef]

- Richey, R.G.; Morgan, T.R.; Lindsey-Hall, K.; Adams, F.G. A global exploration of Big Data in the supply chain. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 710–739. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Significant Applications of Big Data in Industry 4.0. J. Ind. Integr. Manag. 2021, 6, 429–447. [Google Scholar] [CrossRef]

- Arunachalam, D.; Kumar, N.; Kawalek, J.P. Understanding big data analytics capabilities in supply chain management: Unravelling the issues, challenges and implications for practice. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 416–436. [Google Scholar] [CrossRef]

- Yaga, D.; Mell, P.; Roby, N.; Scarfone, K. Blockchain technology overview. arXiv 2019, arXiv:1906.11078. [Google Scholar] [CrossRef]

- Klapita, V. Implementation of Electronic Data Interchange as a Method of Communication Between Customers and Transport Company. Transp. Res. Procedia 2021, 53, 174–179. [Google Scholar] [CrossRef]

- Azzi, R.; Chamoun, R.K.; Sokhn, M. The power of a blockchain-based supply chain. Comput. Ind. Eng. 2019, 135, 582–592. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Khan, S.; Suman, R. Blockchain technology applications for Industry 4.0: A literature-based review. Blockchain Res. Appl. 2021, 2, 100027. [Google Scholar] [CrossRef]

- Hellani, H.; Sliman, L.; Samhat, A.E.; Exposito, E. On Blockchain Integration with Supply Chain: Overview on Data Transparency. Logistics 2021, 5, 46. [Google Scholar] [CrossRef]

- Tucker, M. Sourcing Minerals Responsibly with Blockchain Technology. Available online: https://www.ibm.com/case-studies/rcs-global-blockchain/ (accessed on 30 November 2021).

- Almutairi, K.; Dehshiri, S.J.H.; Hoa, A.X.; Dhanraj, J.A.; Mostafaeipour, A.; Issakhov, A.; Techato, K. Blockchain Technology Application Challenges in Renewable Energy Supply Chain Management. Environ. Sci. Pollut. Res. 2022, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Dehshiri, S.J.H.; Emamat, M.S.M.M.; Amiri, M. A novel group BWM approach to evaluate the implementation criteria of blockchain technology in the automotive industry supply chain. Expert Syst. Appl. 2022, 198, 116826. [Google Scholar] [CrossRef]

- Kagermann, H. Change through digitization: Value creation in the age of Industry 4.0. In Management of Permanent Change; Pinkwart, A., Reichwald, R., Albach, H., Meffert, H., Eds.; Gabler: Wiesbaden, Germany, 2015; pp. 23–45. [Google Scholar]

- Hofmann, E.; Sternberg, H.; Chen, H.; Pflaum, A.; Prockl, G. Supply chain management and Industry 4.0: Conducting research in the digital age. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 945–955. [Google Scholar] [CrossRef]

- Tantawi, K.H.; Sokolov, A.; Tantawi, O. Advances in Industrial Robotics: From Industry 3.0 Automation to Industry 4.0 Collaboration. In Proceedings of the 2019 4th Technology Innovation Management and Engineering Science International Conference (TIMES-iCON), Bangkok, Thailand, 11–13 December 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Flämig, H. Autonomous vehicles and autonomous driving in freight transport. In Autonomous Driving; Maurer, M., Gerdes, J.C., Lenz, B., Winner, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 365–385. [Google Scholar]

- Jennings, D.; Figliozzi, M. Study of sidewalk autonomous delivery robots and their potential impacts on freight efficiency and travel. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 317–326. [Google Scholar] [CrossRef]

- Padmakumar, M. Additive Manufacturing of Tungsten Carbide Hardmetal Parts by Selective Laser Melting (SLM), Selective Laser Sintering (SLS) and Binder Jet 3D Printing (BJ3DP) Techniques. Lasers Manuf. Mater. Process. 2020, 7, 338–371. [Google Scholar] [CrossRef]

- Muthuswamy, P. Influence of powder characteristics on properties of parts manufactured by metal additive manufacturing. Lasers Manuf. Mater. Process. 2022, 9, 312–337. [Google Scholar] [CrossRef]

- Kunovjanek, M.; Knofius, N.; Reiner, G. Additive manufacturing and supply chains—A systematic review. Prod. Plan. Control 2020, 33, 1231–1251. [Google Scholar] [CrossRef]

- Ashima, R.; Haleem, A.; Bahl, S.; Javaid, M.; Mahla, S.K.; Singh, S. Automation and manufacturing of smart materials in additive manufacturing technologies using Internet of Things towards the adoption of industry 4.0. Mater. Today Proc. 2021, 45, 5081–5088. [Google Scholar] [CrossRef]

- Wagoner, D. How Additive Manufacturing is Transforming the Supply Chain. Available online: https://www.pinionglobal.com/additive-manufacturing-supply-chain/ (accessed on 15 September 2022).

- US Air Force and GE Reach Next Milestone in Pacer Edge Program. Available online: https://www.3dprintingmedia.network/us-air-force-ge-next-milestone-pacer-edge-program/ (accessed on 15 September 2022).

- Kazancoglu, Y.; Ozbiltekin-Pala, M.; Sezer, M.D.; Ekren, B.Y.; Kumar, V. Assessing the Impact of COVID-19 on Sustainable Food Supply Chains. Sustainability 2022, 14, 143. [Google Scholar] [CrossRef]

- Chalmeta, R.; Santos-deLeón, N.J. Sustainable Supply Chain in the Era of Industry 4.0 and Big Data: A Systematic Analysis of Literature and Research. Sustainability 2020, 12, 4108. [Google Scholar] [CrossRef]

- Mphela, T.; Savage, C.J.; Gutierrez, A. Enabling Sustainable Supply Chains in the Industrial 4.0 Era. In Supply Chain–Recent Advances and New Perspectives in the Industry 4.0 Era; Bányai, T., Bányai, Á., Kaczmar, I., Eds.; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Mastos, T.D.; Nizamis, A.; Vafeiadis, T.; Alexopoulos, N.; Ntinas, C.; Gkortzis, D.; Papadopoulos, A.; Ioannidis, D.; Tzovaras, D. Industry 4.0 sustainable supply chains: An application of an IoT enabled scrap metal management solution. J. Clean. Prod. 2020, 269, 122377. [Google Scholar] [CrossRef]

- Chkanikova, O.; Mont, O. Corporate Supply Chain Responsibility: Drivers and Barriers for Sustainable Food Retailing. Corp. Soc. Responsib. Environ. Manag. 2012, 22, 65–82. [Google Scholar] [CrossRef]

- Giunipero, L.C.; Hooker, R.E.; Denslow, D. Purchasing and supply management sustainability: Drivers and barriers. J. Purch. Supply Manag. 2012, 18, 258–269. [Google Scholar] [CrossRef]

- Ethical Supply: The Search for Cobalt Beyond the Congo. 2 September 2020. Available online: https://www.visualcapitalist.com/sp/ethical-supply-the-search-for-cobalt-beyond-the-congo/ (accessed on 15 September 2022).

- Vafeiadis, T.; Nizamis, A.; Pavlopoulos, V.; Giugliano, L.; Rousopoulou, V.; Ioannidis, D.; Tzovaras, D. Data Analytics Platform for the Optimization of Waste Management Procedures. In Proceedings of the 2019 15th International Conference on Distributed Computing in Sensor Systems (DCOSS), Santorini, Greece, 29–31 May 2019; pp. 333–338. [Google Scholar] [CrossRef]

- Ramirez-Peña, M.; Sotano, A.J.S.; Pérez-Fernandez, V.; Abad, F.J.; Batista, M. Achieving a sustainable shipbuilding supply chain under I4.0 perspective. J. Clean. Prod. 2020, 244, 118789. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Wu, L.; Yue, X.; Jin, A.; Yen, D.C. Smart supply chain management: A review and implications for future research. Int. J. Logist. Manag. 2016, 27, 395–417. [Google Scholar] [CrossRef]

- De Vass, T.; Shee, H.; Miah, S. IoT in Supply Chain Management: Opportunities and Challenges for Businesses in Early Industry 4.0 Context. Oper. Supply Chain Manag. Int. J. 2021, 14, 148–161. [Google Scholar] [CrossRef]

- Prause, M. Challenges of Industry 4.0 Technology Adoption for SMEs: The Case of Japan. Sustainability 2019, 11, 5807. [Google Scholar] [CrossRef]

- Martins, F.C.; Simon, A.T.; Campos, R.S. Supply Chain 4.0 challenges. Gestão Produção 2020, 27, e5427. [Google Scholar] [CrossRef]

- Rad, F.F.; Oghazi, P.; Palmié, M.; Chirumalla, K.; Pashkevich, N.; Patel, P.C.; Sattari, S. Industry 4.0 and supply chain performance: A systematic literature review of the benefits, challenges, and critical success factors of 11 core technologies. Ind. Mark. Manag. 2022, 105, 268–293. [Google Scholar] [CrossRef]

- Xin, L.; Lang, S.; Mishra, A.R. Evaluate the challenges of sustainable supply chain 4.0 implementation under the circular economy concept using new decision making approach. Oper. Manag. Res. 2022, 1–20. [Google Scholar] [CrossRef]

- Abdirad, M.; Krishnan, K. Industry 4.0 in Logistics and Supply Chain Management: A Systematic Literature Review. Eng. Manag. J. 2021, 33, 187–201. [Google Scholar] [CrossRef]

- Kiers, J.; Seinhorst, J.; Zwanenburg, M.; Stek, K. Which Strategies and Corresponding Competences Are Needed to Improve Supply Chain Resilience: A COVID-19 Based Review. Logistics 2022, 6, 12. [Google Scholar] [CrossRef]

- Industry 4.0 Readiness Report. Available online: https://www2.deloitte.com/za/en/pages/about-deloitte/articles/industry-4-0-readiness-report.html (accessed on 15 September 2022).

- Rasouli, M.R. Intelligent process-aware information systems to support agility in disaster relief operations: A survey of emerging approaches. Int. J. Prod. Res. 2019, 57, 1857–1872. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control 2021, 32, 775–788. [Google Scholar] [CrossRef]

| Field of Research | Subfield and Related Literature |

|---|---|

| Marketing | Sales forecasting [67], Sales management [68], Sales promotions [69], Pricing models [70], Market segmentation [71], Customer segmentation [72], Marketing decision support [73], Direct marketing [74], and Industrial marketing [75] |

| Product design | Design specifications of new products [76] and Product life-cycle management [77] |

| Logistics | Container terminal management [78], General logistics [79], Inbound logistics processes [80], Logistics systems automation [81], Lot-sizing [82], and Logistics workflow [83] |

| Production | Assembly line balancing [84], Assembly automation [85], Production monitoring [86], Production forecasting [87], Production systems [88], Production planning and scheduling [89], Production data management [90], Integrated production management [91], General production management [92], Flexible manufacturing systems [93], Decision support systems [94], Manufacturing problem solving [95], Quality control and improvement [96], Quality monitoring [97], Product line optimization [98], Workflow management [99], Product-driven control [100], and Low-volume production [101] |

| Supply chain | Demand forecasting [102], Facility location [103], Supplier selection [104], Supply chain network design [105], Supply chain risk management [63], Inventory replenishment [106], Crisis management [107], Global value chains [108], Supply chain process management [109], General supply chain management [110], Supply chain integration [111], Supply chain planning [112], Maintenance systems [113], and Sustainable supply chain [114] |

| Process | Role of IoT | Relevant Literature |

|---|---|---|

| Source |

| Verdouw et al. [121], Ng et al. [122], Yu et al. [123]. |

| Make |

| Wang et al. [124], Rymaszewska et al. [125], Putnik et al. [126], Ondemir et al. [127], Chukwuekwe et al. [128]. |

| Deliver |

| Reaidy et al. [129], Qiu et al. [130], Choy et al. [131], Kong et al. [132], Yao [133], Mathaba et al. [134]. |

| Return |

| Gu and Liu [135], Parry et al. [136], Thürer et al. [137]. |

| Field of Research | Subfield and Related Literature |

|---|---|

| Plan | Process integration and simplification to reduce overall lead time in planning. |

| Source | Lesser inventory and transportation lead time due to reduced assembly parts. |

| Make | Reduction in raw material usage, lesser assemblies, and highly customizable parts to meet customer demand. |

| Deliver | Reduction in the dependency on multiple suppliers can reduce delivery lead time. |

| Return | Reduction in scrap and recycling of unused AM material. |

| Characteristics | Details |

|---|---|

| Instrumented | Systems integrated with sensors, RFID tags, and other data collection techniques to make data-driven decisions. |

| Interconnected | Fully connected supply chain participants with a seamless flow of data between them. |

| Intelligent | Intelligent system that can make collect and process a huge volume of data that can independently make decisions. |

| Automated | A high level of automation reduces manual labor, which can lower overall lead time and improve quality. |

| Integrated | A high level of collaboration across the supply chain participants with transparent and fool-proof visibility to data for decision making. |

| Innovative | Capability to collect and analyze data to support innovative process techniques and arrive at an efficient solution. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raja Santhi, A.; Muthuswamy, P. Pandemic, War, Natural Calamities, and Sustainability: Industry 4.0 Technologies to Overcome Traditional and Contemporary Supply Chain Challenges. Logistics 2022, 6, 81. https://doi.org/10.3390/logistics6040081

Raja Santhi A, Muthuswamy P. Pandemic, War, Natural Calamities, and Sustainability: Industry 4.0 Technologies to Overcome Traditional and Contemporary Supply Chain Challenges. Logistics. 2022; 6(4):81. https://doi.org/10.3390/logistics6040081

Chicago/Turabian StyleRaja Santhi, Abirami, and Padmakumar Muthuswamy. 2022. "Pandemic, War, Natural Calamities, and Sustainability: Industry 4.0 Technologies to Overcome Traditional and Contemporary Supply Chain Challenges" Logistics 6, no. 4: 81. https://doi.org/10.3390/logistics6040081

APA StyleRaja Santhi, A., & Muthuswamy, P. (2022). Pandemic, War, Natural Calamities, and Sustainability: Industry 4.0 Technologies to Overcome Traditional and Contemporary Supply Chain Challenges. Logistics, 6(4), 81. https://doi.org/10.3390/logistics6040081