Industrial Packaging Performance Indicator Using a Group Multicriteria Approach: An Automaker Reverse Operations Case

Abstract

:1. Introduction

2. Literature Review

2.1. Brazilian Automotive Industry

2.2. Packaging in the Automotive Industry

2.3. Packaging Development and Performance in the Automotive Industry

2.4. AHP-GDM

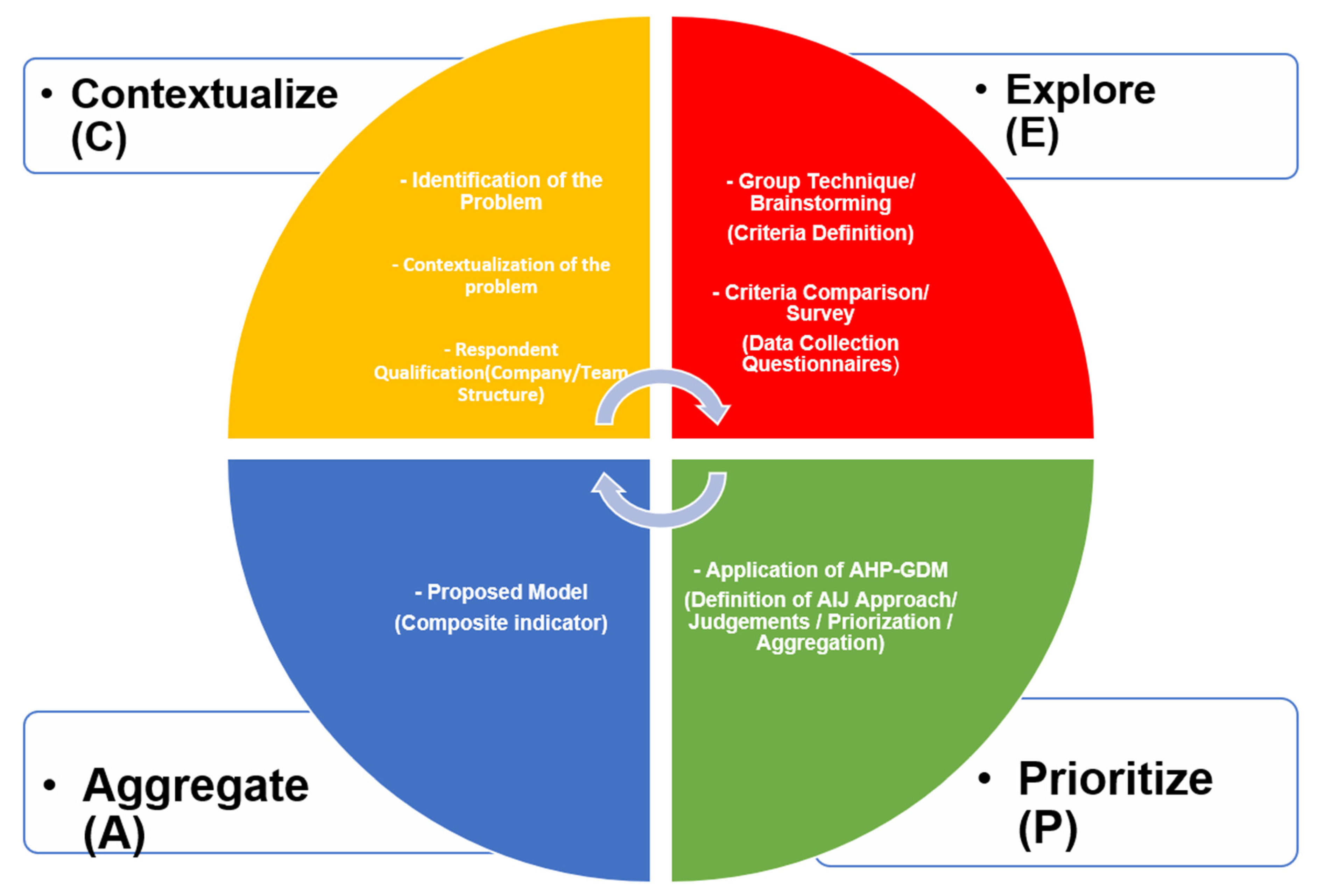

3. Application of the Method

3.1. Background

3.2. Research Method Application Steps

3.3. Current Status

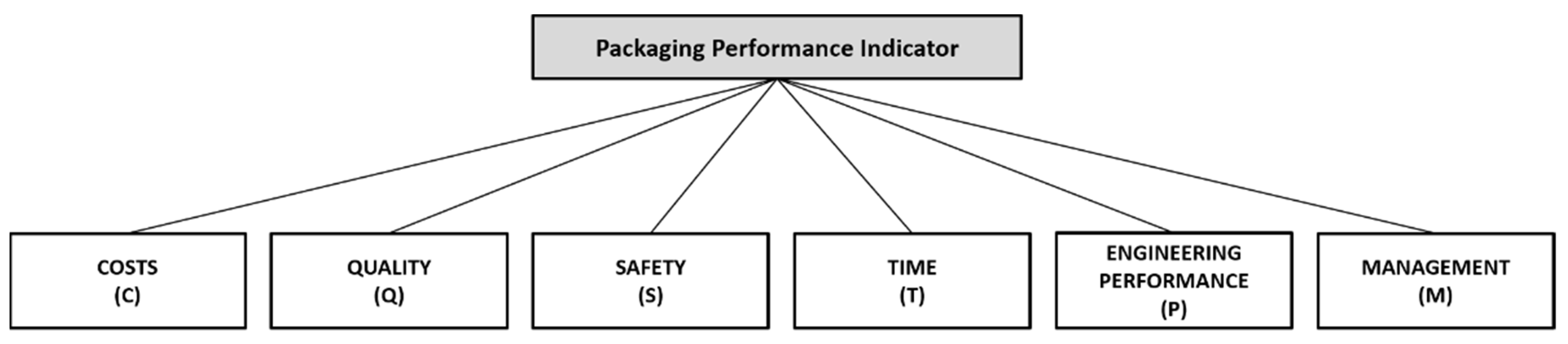

3.4. Modeling (Packaging Performance Indicator)

3.4.1. Group Technique for Defining Criteria (Brainstorming)

- -

- Costs: Refers to the costs involved in the development and the costs incurred during the entire life cycle of these packagings. According to the specialists, the choice of this criterion was made due to its representativeness in the impacts related to the operational profitability of the plant (both in terms of CAPEX and OPEX);

- -

- Quality: This represents the guarantee that the defined packaging protects the quality of the parts transported inside. Its importance is linked to the desire of experts to reduce the number of occurrences of quality breakdown (damage to parts) in which the packaging is considered the root cause;

- -

- Safety: Refers to the definition that the packaging should respect the ergonomics and work safety rules/standards of the company and the local legislation, minimizing the risk of accidents. The specialists chose this criterion in order to avoid and minimize the impacts related to damaged packages during internal movements and to the number of accidents associated with each packaging model, as well as to help follow the internal ergonomic rules;

- -

- Time: Refers to the prioritization of the use of packagings that have reduced times between the phases of a packaging project, which are: prototype, manufacturing in batches, and delivery to the plant. In order to reduce the total time interval that covers from conceptualization to availability and use of the packages in the flow (prototype, manufacturing in batches, and delivery), the specialist team judged that this criterion would bring benefits related to agility and compliance with the deadlines set by the plant regarding the start of the supply of a given part, especially during the launch of a new vehicle or in cases where modernization of a given vehicle model already existing in its production line occurred;

- -

- Engineering Performance: Considers the use of optimizable factors related to the packaging construction, such as factors related to packaging with optimized cubic meters, and the increase of the valuable packaging life (durability)—prioritizing the use of returnable elements. This criterion considers the efficiency of the cubic footage occupied/cubic footage available (rate of occupancy of the packaging), the useful life of the packaging (in years), and the type of packaging (disposable or returnable);

- -

- Management: This question is related to using packaging that allows easy operational management (minimum use of accessories) and offers future opportunities for flexibility regarding the use in other flows.

3.4.2. Survey Application (Criteria Comparison)

3.4.3. Choice of Approach (AIJ × AIP)

3.4.4. Individual Responses Obtained (Criteria Comparison Matrix)

3.4.5. Aggregate Model Matrix (Aij)

3.5. Proposed Model

4. Discussion and Practical and Theoretical Implications

5. Conclusions

6. Suggestions for Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moura, R.A.; Banzato, J.M. Embalagem, Unificação & Conteinerização–Série: Manual de Intralogística, 6th ed.; IMAM: São Paulo, Brazil, 2010; Volume 3. [Google Scholar]

- Pålsson, H.; Finnsgård, C.; Wänström, C. Selection of Packaging Systems in Supply Chains from a Sustainability Perspective: The Case of Volvo. Packag. Technol. Sci. 2013, 26, 289–310. [Google Scholar] [CrossRef]

- Hatakeyama, K.; Guarnieri, P. Level of knowledge and formalization of logistics and SCM in the Brazilian automotive industries suppliers. In Complex Systems Concurrent Engineering; Springer: London, UK, 2007; pp. 783–791. [Google Scholar] [CrossRef]

- Zhang, Q.; Segerstedt, A.; Tsao, Y.C.; Liu, B. Returnable packaging management in automotive parts logistics: Dedicated mode and shared mode. Int. J. Prod. Econ. 2015, 168, 234–244. [Google Scholar] [CrossRef]

- Škerlič, S.; Muha, R. A model for managing packaging in the product life cycle in the automotive industry. Sustainability 2020, 12, 9431. [Google Scholar] [CrossRef]

- Veenstra, E.M.; Ellemers, N. Esg indicators as organizational performance goals: Do rating agencies encourage a holistic approach? Sustainability 2020, 12, 10228. [Google Scholar] [CrossRef]

- Julianelli, V.; Caiado, R.G.G.; Scavarda, L.F.; Cruz SP de, M.F. Interplay between reverse logistics and circular economy: Critical success factors-based taxonomy and framework. Resour. Conserv. Recycl. 2020, 158, 104784. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T.; Huisingh, D. Circular supply chain management: A definition and structured literature review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Mura, M.; Longo, M.; Zanni, S. Circular economy in Italian SMEs: A multi-method study. J. Clean. Prod. 2020, 245, 118821. [Google Scholar] [CrossRef]

- Pereira, A.N.M.; Ribeiro, F.d.M. Stakeholders’ participation in environmental regulation: A case study of the sectoral agreement of packaging reverse logistics in Brazil. Waste Manag. Res. 2021, 39, 1256–1263. [Google Scholar] [CrossRef]

- Grdic, Z.S.; Nizic, M.K.; Rudan, E. Circular economy concept in the context of economic development in EU countries. Sustainability 2020, 12, 3060. [Google Scholar] [CrossRef]

- de Mattos Nascimento, D.L.; Mury Nepomuceno, R.; Caiado, R.G.G.; Maqueira, J.M.; Moyano-Fuentes, J.; Garza-Reyes, J.A. A sustainable circular 3D printing model for recycling metal scrap in the automotive industry. J. Manuf. Technol. Manag. 2022, 33, 876–892. [Google Scholar] [CrossRef]

- Machado, E.; Scavarda, L.F.; Caiado, R.G.G.; Thomé, A.M.T. Barriers and Enablers for the Integration of Industry 4.0 and Sustainability in Supply Chains of MSMEs. Sustainability 2021, 13, 11664. [Google Scholar] [CrossRef]

- Oltra-Badenes, R.; Gil-Gomez, H.; Guerola-Navarro, V.; Vicedo, P. Is It Possible to Manage the Product Recovery Processes in an ERP? Analysis of Functional Needs. Sustainability 2019, 11, 4380. [Google Scholar] [CrossRef]

- Guarnieri, P.; Cerqueira-Streit, J.A.; Batista, L.C. Reverse logistics and the sectoral agreement of packaging industry in Brazil towards a transition to circular economy. Resour. Conserv. Recycl. 2020, 153, 104541. [Google Scholar] [CrossRef]

- Silva, W.D.O.; Morais, D.C. A Group Decision Support System to Share Responsibilities Towards a Circular Economy Transition for Solid Waste Management in Developing Countries. In Proceedings of the 2021 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Melbourne, Australia, 17–20 October 2021; pp. 2221–2226. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Scavarda, L.F.; Azevedo, B.D.; Nascimento, D.L.d.M.; Quelhas, O.L.G. Challenges and Benefits of Sustainable Industry 4.0 for Operations and Supply Chain Management—A Framework Headed toward the 2030 Agenda. Sustainability 2022, 14, 830. [Google Scholar] [CrossRef]

- Akabane, G.K.; Bussola, F.J.; Galhardi, A.C.; Pozo, H.; Neto, J.M. Returnable packaging as a sustainability factor in the automotive chain: A case study. Arch. Bus. Res. 2018, 6, 21–31. [Google Scholar] [CrossRef]

- Moch, B.N.; Rasyad, M. Macroergonomics Approach for Design Improvement of Returnable Rack in Automotive Company. In Proceedings of the 2019 5th International Conference on Industrial and Business Engineering, Hong Kong, 27–29 September 2019; pp. 183–187. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation; McGraw: New York, NY, USA, 1980. [Google Scholar]

- Turón, A.; Aguarón, J.; Escobar, M.T.; Moreno-Jiménez, J.M. A decision support system and visualisation tools for AHP-GDM. Int. J. Decis. Support Syst. Technol. 2019, 11, 1–19. [Google Scholar] [CrossRef]

- Lin, C.; Kou, G.; Peng, Y.; Alsaadi, F.E. Aggregation of the nearest consistency matrices with the acceptable consensus in AHP-GDM. Ann. Oper. Res. 2020. [Google Scholar] [CrossRef]

- Alfurhood, B.; Silaghi, M. A survey of group decision making methods and evaluation techniques. In Proceedings of the Thirty-First International Flairs Conference, Melbourne, FL, USA, 21–23 May 2018; pp. 168–171. [Google Scholar]

- Ramanathan, R.; Ganesh, L.S. Group preference aggregation methods employed in AHP: An evaluation and an intrinsic process for deriving members’ weightages. Eur. J. Oper. Res. 1994, 79, 249–265. [Google Scholar] [CrossRef]

- Hammes, G.; De Souza, E.D.; Taboada Rodriguez, C.M.; Rojas Millan, R.H.; Mojica Herazo, J.C. Evaluation of the reverse logistics performance in civil construction. J. Clean. Prod. 2020, 248, 119212. [Google Scholar] [CrossRef]

- Hummel, J.M.; Bridges, J.F.P.; IJzerman, M.J. Group decision making with the analytic hierarchy process in benefit-risk assessment: A tutorial. Patient 2014, 7, 129–140. [Google Scholar] [CrossRef]

- Saaty, T.L. Who won the Winter 2010 Olympics? A quest into priorities and rankings. J Multi-Criteria Decis Anal. 2010, 17, 25–36. [Google Scholar] [CrossRef]

- de Jesus França, L.C.; Mucida, D.P.; Santana, R.C.; de Morais, M.S.; Gomide, L.R.; de Meneses Bateira, C.V. AHP APPROACH APPLIED TO MULTI-CRITERIA DECISIONS IN ENVIRONMENTAL FRAGILITY MAPPING. FLORESTA 2020, 50, 1623–1632. [Google Scholar] [CrossRef]

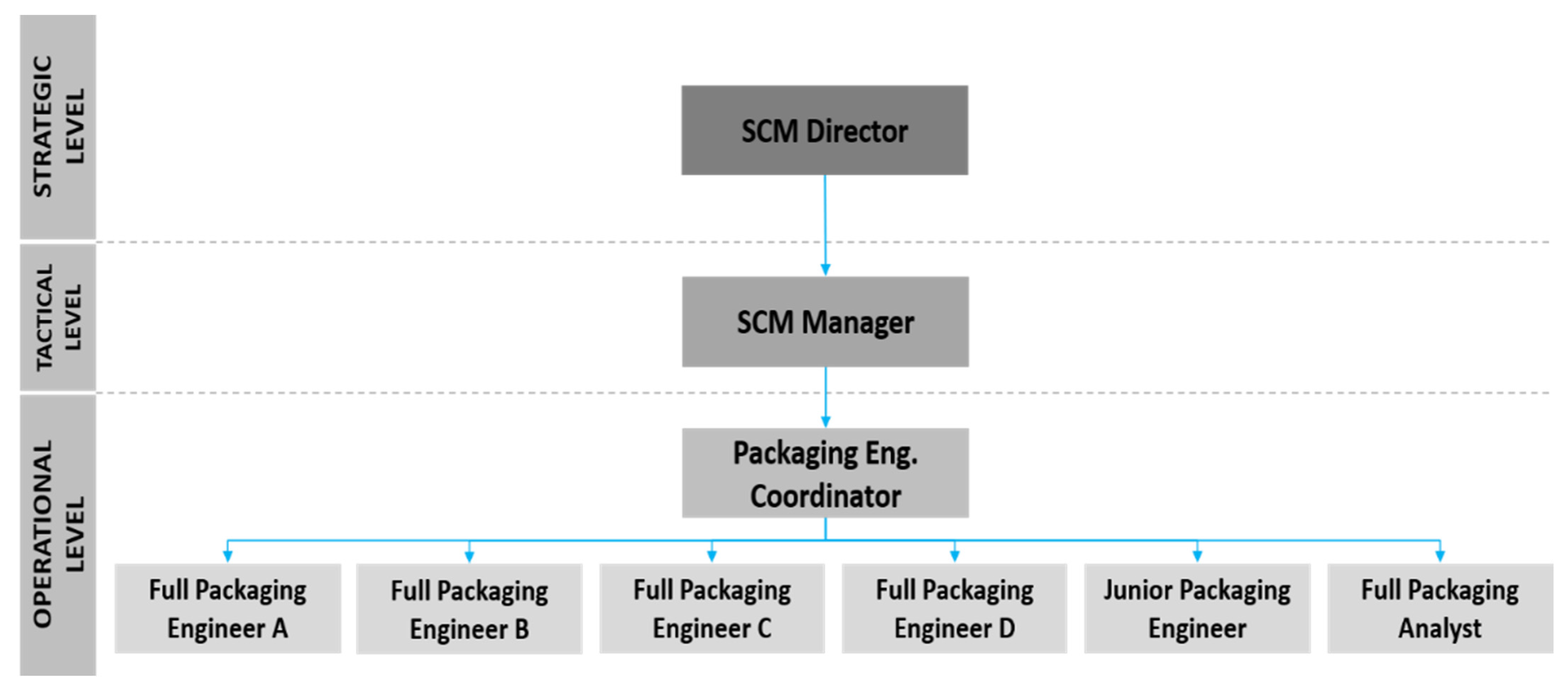

| Function/Job Title | Background | Responsibilities/Activities |

|---|---|---|

| SCM Director | Professional with experience in various areas of the automotive industry. He has international experiences within his sector of activity (SCM), although a few years focused on the direction of the packaging development engineering team. | Acts as a link between the factory and the company’s other plants worldwide. Responsible for steering meetings that involve flow changes and strategic decisions for the organization as a whole. He is very present in decisions that involve new packaging projects. |

| SCM Manager | He has experience in freight scheduling and negotiating transport contracts with carriers and freight forwarders at an international level. He has also worked in studies related to foreign trade (import/export) in several types of models. He has knowledge related to customs and port logistics operations. | Responsible for managing the packaging development team and two other teams related to logistics, one for scheduling and optimizing transportation (inbound logistics) and the other for international logistics (focused on the import and export of materials). |

| Packaging Engineering Coordinator | Professional with experience in transportation scheduling and the area of international freight forwarding, cargo clearance, and customs. | Acts as a link between top management and the packaging engineering team (staff), controlling work demands and piloting current and future projects related to packaging development. |

| Full Packaging Engineer A | He has expertise in developing packaging for metal parts and the external housing of vehicles. He has received international awards related to packaging development within the company. | Responsible for developing packaging for the transportation of metal parts, both for internal and external flow, in addition to being responsible for the maintenance control of all packaging circulating in the plant. |

| Full Packaging Engineer B | He has extensive experience in flow and internal logistics projects (balancing supply and line edge preparation). | Sole direct responsibility for packaging development of the international flow (imported parts), dealing with suppliers and other company plants worldwide. |

| Full Packaging Engineer C | He has previous experience in the development of specific packaging for metal parts in his former company, and has a lot of know-how in project management with a focus on cost management. | Responsible for the development of packaging in the local flow of suppliers, focused on interior trim parts of the vehicle; also performs the collation and internal analysis of costs related to packaging development (new projects or flow changes). |

| Full Packaging Engineer D | He has a vast background in the area of development of packaging for automotive parts, being the most experienced professional in the sector when it comes to the development of packaging, has a very analytical and broad vision of the entire development process of new projects, and is always consulted by the other team members about making decisions related to the theme. | Responsible for the analysis/study of new logistics projects, reporting directly to the management and direction of the sector. |

| Junior Packaging Engineer | He has experience in transportation flow analysis, scheduling, and freight forwarding, with recent experience in packaging development. | Responsible for the development of packaging related to the flow of parts for the final assembly of the vehicles and performing the studies related to freight costs and cubage improvement of the packaging developed by the rest of the team. |

| Full Packaging Analyst | He has previous experience in developing packaging for automotive parts and the production line supply flow at other assembly plants. | Responsible for the development of packaging for the assembly parts of the engines produced in the plant; also acts as the team’s quality manager, responding to possible problems related to process failures involving packaging. |

| Function/Job Title | Industry in General | Length of Experience Automobile Industry | Packaging Development |

|---|---|---|---|

| SCM Director | 19 years | 19 years | 2 years |

| SCM Manager | 10 years | 4 years | 3 years |

| Packaging Eng. Coord. | 18 years | 18 years | 2 years |

| Full Packaging Eng. A | 9 years | 9 years | 5 years |

| Full Packaging Eng. B | 5 years | 3.5 years | 1.5 years |

| Full Packaging Eng. C | 10 years | 10 years | 7 years |

| Full Packaging Eng. D | 10 years | 10 years | 6 years |

| Junior Packaging Eng. | 10 years | 8 years | 8 years |

| Full Packaging Analyst | 16.5 years | 14.5 years | 12.5 years |

| Criteria | |||

|---|---|---|---|

| volume | quality | development time | operational |

| cost | part quality | performance | locking system |

| acquisition cost | transport costs | engineering performance | use of moving parts |

| packaging type | disposable costs | maintenance costs | storage area costs |

| handling | inventory discrepancies | inventory losses | load and loading limitations |

| ergonomics | package durability | packaging management | frequency (packaging turnover) |

| safety | time | management | depreciation |

| Intensity | Definition | Explanation |

|---|---|---|

| 1 | Equal importance | Two activities contribute equally to the objective |

| 3 | Slight importance | Experience and judgment slightly favor one activity over another |

| 5 | Strong importance | Experience and judgment strongly favor one activity over another |

| 7 | Very strong importance | An activity is favored very strongly over another; its dominance demonstrated in practice |

| 9 | Absolute importance | The evidence favoring one activity over another is of the highest possible order of affirmation |

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 0.14285 | 1.00000 | 3.00000 | 0.14285 | 0.20000 | 0.48009 | 0.05996 |

| (Q) | 7.00000 | 1.00000 | 1.00000 | 5.00000 | 3.00000 | 7.00000 | 3.00410 | 0.37519 |

| (S) | 1.00000 | 1.00000 | 1.00000 | 5.00000 | 1.00000 | 1.00000 | 1.30766 | 0.16332 |

| (T) | 0.33333 | 0.20000 | 0.20000 | 1.00000 | 0.14285 | 0.14285 | 0.25456 | 0.03179 |

| (P) | 7.00000 | 0.33333 | 1.00000 | 7.00000 | 1.00000 | 0.14285 | 1.15167 | 0.14383 |

| (M) | 5.00000 | 0.14285 | 1.00000 | 7.00000 | 7.00000 | 1.00000 | 1.80860 | 0.22588 |

| Σ (Sum) | 21.33333 | 2.81904 | 5.20000 | 28.00000 | 12.28571 | 9.48571 | 8.00669 | 1.00000 |

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 0.20000 | 0.20000 | 7.00000 | 1.00000 | 7.00000 | 1.11869 | 0.11746 |

| (Q) | 5.00000 | 1.00000 | 0.20000 | 5.00000 | 7.00000 | 5.00000 | 2.36505 | 0.24833 |

| (S) | 5.00000 | 5.0000 | 1.00000 | 7.00000 | 7.00000 | 7.00000 | 4.52417 | 0.47505 |

| (T) | 0.14286 | 0.20000 | 0.14286 | 1.00000 | 0.20000 | 0.33333 | 0.25456 | 0.02672 |

| (P) | 1.00000 | 0.14286 | 0.14286 | 5.00000 | 1.00000 | 5.00000 | 0.89390 | 0.09386 |

| (M) | 0.14286 | 0.20000 | 0.14286 | 3.00000 | 0.20000 | 1.00000 | 0.36713 | 0.03855 |

| Σ (Sum) | 12.28571 | 6.74285 | 1.82857 | 28.00000 | 16.40000 | 25.33333 | 9.52350 | 1.00000 |

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 0.20000 | 0.11111 | 0.11111 | 0.11111 | 0.11111 | 0.17674 | 0.01570 |

| (Q) | 5.00000 | 1.00000 | 0.20000 | 0.14286 | 0.11111 | 0.11111 | 0.34759 | 0.03087 |

| (S) | 9.00000 | 5.00000 | 1.00000 | 0.20000 | 0.11111 | 0.11111 | 0.69336 | 0.06158 |

| (T) | 9.00000 | 7.00000 | 5.00000 | 1.00000 | 0.20000 | 0.11111 | 1.38309 | 0.12285 |

| (P) | 9.00000 | 9.00000 | 9.00000 | 5.00000 | 1.00000 | 0.20000 | 3.00000 | 0.26646 |

| (M) | 9.00000 | 9.00000 | 9.00000 | 9.00000 | 5.00000 | 1.00000 | 5.65792 | 0.50254 |

| Σ (Sum) | 42.00000 | 31.20000 | 24.31111 | 15.45397 | 6.53333 | 1.64444 | 11.25870 | 1.00000 |

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 0.20000 | 0.11111 | 5.00000 | 0.33333 | 0.33333 | 0.48075 | 0.04961 |

| (Q) | 5.00000 | 1.00000 | 0.11111 | 3.00000 | 5.00000 | 3.00000 | 1.70998 | 0.17648 |

| (S) | 9.00000 | 9.00000 | 1.00000 | 9.00000 | 7.00000 | 5.00000 | 5.42583 | 0.55996 |

| (T) | 0.20000 | 0.33333 | 0.11111 | 1.00000 | 0.33333 | 0.33333 | 0.30613 | 0.03159 |

| (P) | 3.00000 | 0.20000 | 0.14286 | 3.00000 | 1.00000 | 0.33333 | 0.66401 | 0.06853 |

| (M) | 3.00000 | 0.33333 | 0.20000 | 3.00000 | 3.00000 | 1.00000 | 1.10292 | 0.11383 |

| Σ (Sum) | 21.20000 | 11.06667 | 1.67619 | 24.00000 | 16.66667 | 10.00000 | 9.68962 | 1.00000 |

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 7.00000 | 9.00000 | 0.20000 | 0.20000 | 0.20000 | 0.89208 | 0.08426 |

| (Q) | 0.14286 | 1.00000 | 7.00000 | 0.11111 | 0.11111 | 0.14286 | 0.34759 | 0.03283 |

| (S) | 0.11111 | 0.14286 | 1.00000 | 0.11111 | 0.11111 | 0.11111 | 0.16710 | 0.01578 |

| (T) | 5.00000 | 9.00000 | 9.00000 | 1.00000 | 9.00000 | 5.00000 | 5.12993 | 0.48453 |

| (P) | 5.00000 | 9.00000 | 9.00000 | 0.11111 | 1.00000 | 0.20000 | 1.44225 | 0.13622 |

| (M) | 5.00000 | 7.00000 | 9.00000 | 0.20000 | 5.00000 | 1.00000 | 2.60847 | 0.24637 |

| Σ (Sum) | 16.25397 | 33.14286 | 44.00000 | 1.73333 | 15.42222 | 6.65397 | 10.58742 | 1.00000 |

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 0.20000 | 0.11111 | 5.00000 | 1.00000 | 5.00000 | 0.90668 | 0.08284 |

| (Q) | 5.00000 | 1.00000 | 0.11111 | 7.00000 | 7.00000 | 7.00000 | 2.39885 | 0.21916 |

| (S) | 9.00000 | 9.00000 | 1.00000 | 9.00000 | 9.00000 | 9.00000 | 6.24025 | 0.57012 |

| (T) | 0.20000 | 0.14286 | 0.11111 | 1.00000 | 0.20000 | 1.00000 | 0.29317 | 0.02678 |

| (P) | 1.00000 | 0.14286 | 0.11111 | 5.00000 | 1.00000 | 3.00000 | 0.78727 | 0.07193 |

| (M) | 0.20000 | 0.14286 | 0.11111 | 1.00000 | 0.33333 | 1.00000 | 0.31922 | 0.02916 |

| Σ (Sum) | 16.40000 | 10.62857 | 1.55556 | 28.00000 | 18.53333 | 26.00000 | 10.94545 | 1.00000 |

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 1.00000 | 0.11111 | 3.00000 | 1.00000 | 1.00000 | 0.83268 | 0.08253 |

| (Q) | 1.00000 | 1.00000 | 0.11111 | 7.00000 | 1.00000 | 1.00000 | 0.95898 | 0.09505 |

| (S) | 9.00000 | 9.00000 | 1.00000 | 9.00000 | 9.00000 | 9.00000 | 6.24025 | 0.61850 |

| (T) | 0.33333 | 0.14286 | 0.11111 | 1.00000 | 0.20000 | 0.20000 | 0.24412 | 0.02420 |

| (P) | 1.00000 | 1.00000 | 0.11111 | 5.00000 | 1.00000 | 1.00000 | 0.90668 | 0.08986 |

| (M) | 1.00000 | 1.00000 | 0.11111 | 5.00000 | 1.00000 | 1.00000 | 0.90668 | 0.08986 |

| Σ (Sum) | 13.33333 | 13.14286 | 1.55556 | 30.00000 | 13.20000 | 13.20000 | 10.08939 | 1.00000 |

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 0.33333 | 0.33333 | 5.00000 | 1.00000 | 0.33333 | 0.75498 | 0.09841 |

| (Q) | 3.00000 | 1.00000 | 1.00000 | 5.00000 | 1.00000 | 0.33333 | 1.30766 | 0.17044 |

| (S) | 3.00000 | 1.00000 | 1.00000 | 5.00000 | 1.00000 | 0.33333 | 1.30766 | 0.17044 |

| (T) | 0.20000 | 0.20000 | 0.20000 | 1.00000 | 0.11111 | 0.20000 | 0.23713 | 0.03091 |

| (P) | 1.00000 | 1.00000 | 1.00000 | 9.00000 | 1.00000 | 0.20000 | 1.10292 | 0.14376 |

| (M) | 3.00000 | 3.00000 | 3.00000 | 5.00000 | 5.00000 | 1.00000 | 2.96177 | 0.38604 |

| Σ (Sum) | 11.20000 | 6.53333 | 6.53333 | 30.00000 | 9.11111 | 2.40000 | 7.67211 | 1.00000 |

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 3.00000 | 0.20000 | 5.00000 | 5.00000 | 1.00000 | 1.57042 | 0.19034 |

| (Q) | 0.33333 | 1.00000 | 0.33333 | 7.00000 | 0.33333 | 3.00000 | 0.95898 | 0.11623 |

| (S) | 5.00000 | 3.00000 | 1.00000 | 9.00000 | 5.00000 | 5.00000 | 3.87298 | 0.46941 |

| (T) | 0.20000 | 0.14286 | 0.11111 | 1.00000 | 0.20000 | 1.00000 | 0.29317 | 0.03553 |

| (P) | 0.20000 | 3.00000 | 0.20000 | 5.00000 | 1.00000 | 1.00000 | 0.91839 | 0.11131 |

| (M) | 1.00000 | 0.33333 | 0.20000 | 1.00000 | 1.00000 | 1.00000 | 0.63677 | 0.07718 |

| Σ (Sum) | 7.73333 | 10.47619 | 2.04444 | 28.00000 | 12.53333 | 12.00000 | 8.25071 | 1.00000 |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Random Index (RI) | 0.00 | 0.00 | 0.58 | 0.98 | 1.12 | 1.24 | 1.32 | 1.41 |

| Function/Position | Consistency Index (CI = μ) | Consistency Ratio (CR = CI/RI) | Status (CR ≤ 0.10000) | |

|---|---|---|---|---|

| SCM Director | 7.98623 | 0.39725 | 0.32036 | inconsistency |

| SCM Manager | 7.25073 | 0.25015 | 0.20173 | inconsistency |

| Packaging Eng. Coordinator | 7.58549 | 0.31710 | 0.25572 | inconsistency |

| Full Packaging Engineer A | 6.98206 | 0.19641 | 0.15840 | inconsistency |

| Full Packaging Engineer B | 7.73218 | 0.34644 | 0.27938 | inconsistency |

| Full Packaging Engineer C | 7.41608 | 0.28322 | 0.22840 | inconsistency |

| Full Packaging Engineer D | 6.41001 | 0.08200 | 0.06613 | consistency |

| Junior Packaging Engineer | 6.49279 | 0.09856 | 0.07948 | consistency |

| Full Packaging Analyst | 6.96541 | 0.19308 | 0.15571 | inconsistency |

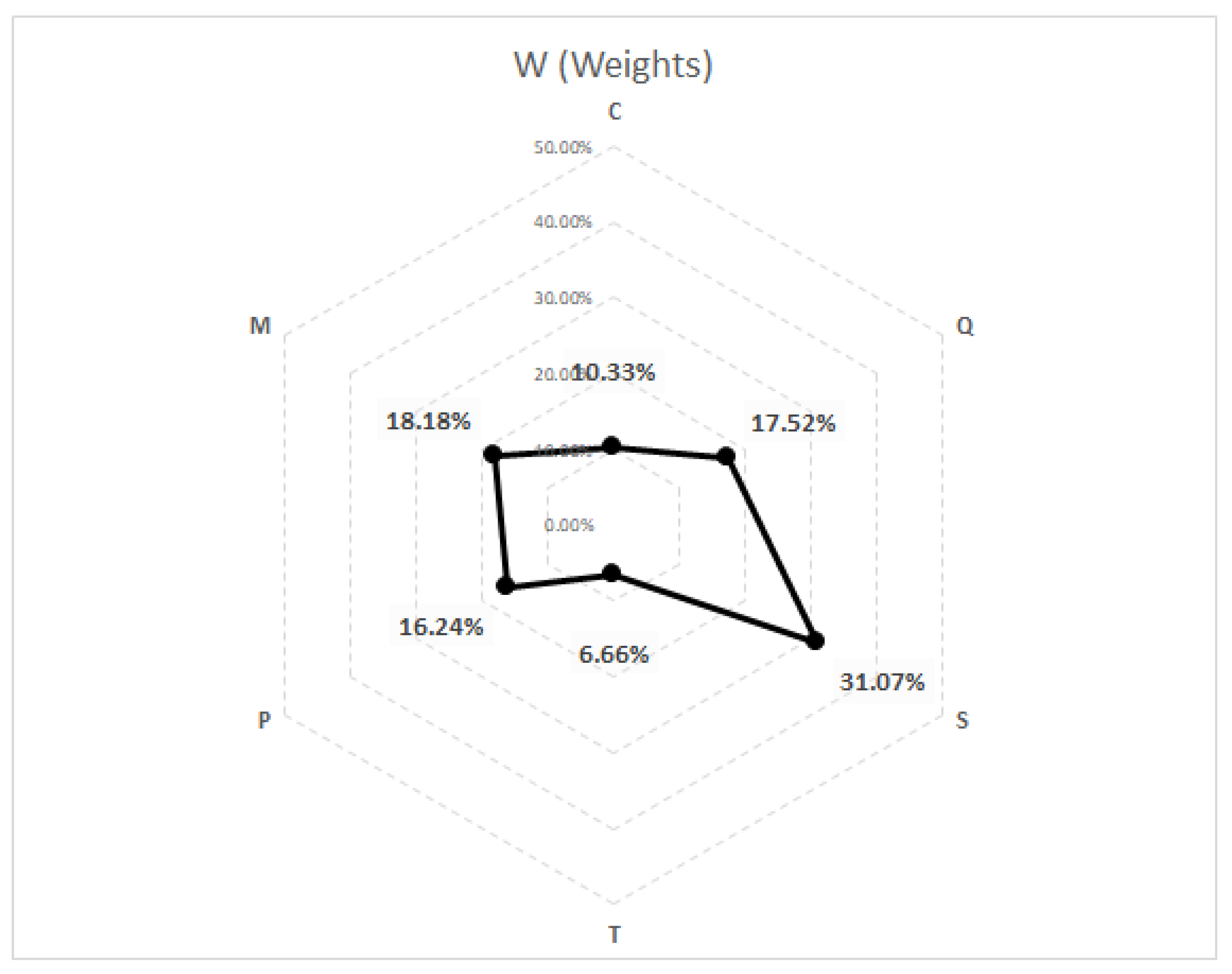

| Criteria | (C) | (Q) | (S) | (T) | (P) | (M) | Eigenvector | W (Weights) |

|---|---|---|---|---|---|---|---|---|

| (C) | 1.00000 | 0.48904 | 0.29756 | 2.12270 | 0.55854 | 0.63706 | 0.69211 | 0.10330 |

| (Q) | 2.04481 | 1.00000 | 0.36938 | 2.33225 | 1.13086 | 1.31386 | 1.17393 | 0.17521 |

| (S) | 3.36063 | 2.70720 | 1.00000 | 3.08776 | 1.84273 | 1.57113 | 2.08150 | 0.31068 |

| (T) | 0.47109 | 0.42876 | 0.32385 | 1.00000 | 0.29158 | 0.41341 | 0.44614 | 0.06659 |

| (P) | 1.79035 | 0.88428 | 0.54267 | 3.42949 | 1.00000 | 0.56334 | 1.08812 | 0.16241 |

| (M) | 1.56970 | 0.76111 | 0.63648 | 2.41889 | 1.77511 | 1.00000 | 1.21800 | 0.18179 |

| Σ (Sum) | 10.23660 | 6.27041 | 3.16996 | 14.39111 | 6.59884 | 5.49881 | 6.69982 | 1.00000 |

| Matrix | Consistency Index (CI = μ) | Consistency Ratio (CR = CI/RI) | Status (CR ≤ 0.10000) | |

|---|---|---|---|---|

| Aggregate Matrix (Group) | 6.17071 | 0.03414 | 0.02753 | consistency |

| Results | Criteria | Total (∑) | |||||

|---|---|---|---|---|---|---|---|

| (C) | (Q) | (S) | (T) | (P) | (M) | ||

| W (Pesos) | 0.10330 | 0.17521 | 0.31068 | 0.06659 | 0.16241 | 0.18179 | 1.00000 |

| % | 10.33% | 17.52% | 31.07% | 6.66% | 16.24% | 18.18% | 100.00% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Cruz, M.M.; Caiado, R.G.G.; Santos, R.S. Industrial Packaging Performance Indicator Using a Group Multicriteria Approach: An Automaker Reverse Operations Case. Logistics 2022, 6, 58. https://doi.org/10.3390/logistics6030058

da Cruz MM, Caiado RGG, Santos RS. Industrial Packaging Performance Indicator Using a Group Multicriteria Approach: An Automaker Reverse Operations Case. Logistics. 2022; 6(3):58. https://doi.org/10.3390/logistics6030058

Chicago/Turabian Styleda Cruz, Marcelo Miguel, Rodrigo Goyannes Gusmão Caiado, and Renan Silva Santos. 2022. "Industrial Packaging Performance Indicator Using a Group Multicriteria Approach: An Automaker Reverse Operations Case" Logistics 6, no. 3: 58. https://doi.org/10.3390/logistics6030058

APA Styleda Cruz, M. M., Caiado, R. G. G., & Santos, R. S. (2022). Industrial Packaging Performance Indicator Using a Group Multicriteria Approach: An Automaker Reverse Operations Case. Logistics, 6(3), 58. https://doi.org/10.3390/logistics6030058