A Literature Review on the Sustainable EPQ Model, Focusing on Carbon Emissions and Product Recycling

Abstract

:1. Introduction

- We examined several recent studies on reverse logistics models and EPQ models focused on carbon emissions, product recycling, and imperfect production systems.

- We investigated the existing research trend of the sustainable EPQ model and identified prospective research gaps.

- Based on the potential research gap, we attempted to provide a research path for what we might accomplish in the future for the development of a realistic and sustainable EPQ model.

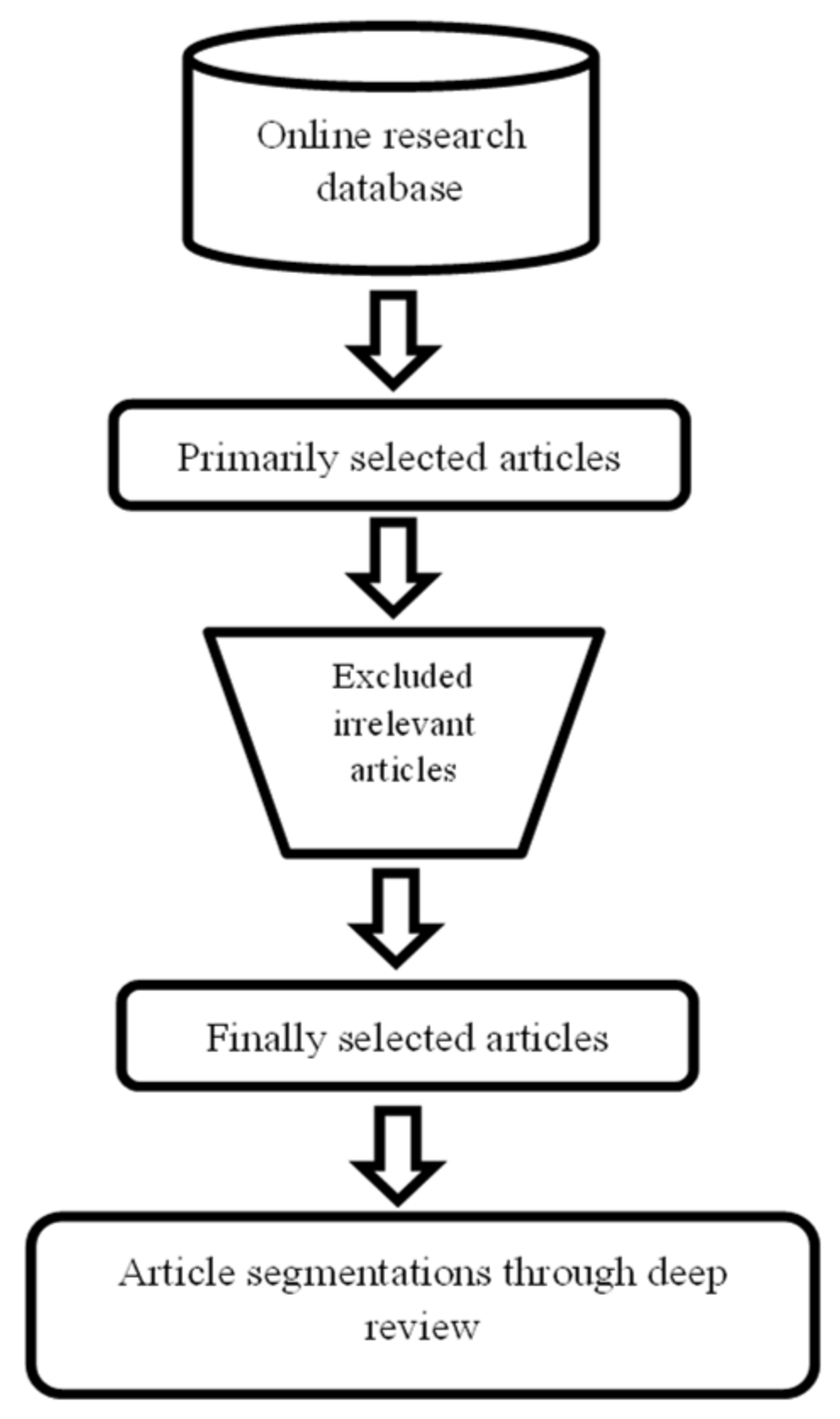

2. Methodology for Reviewing the Literature

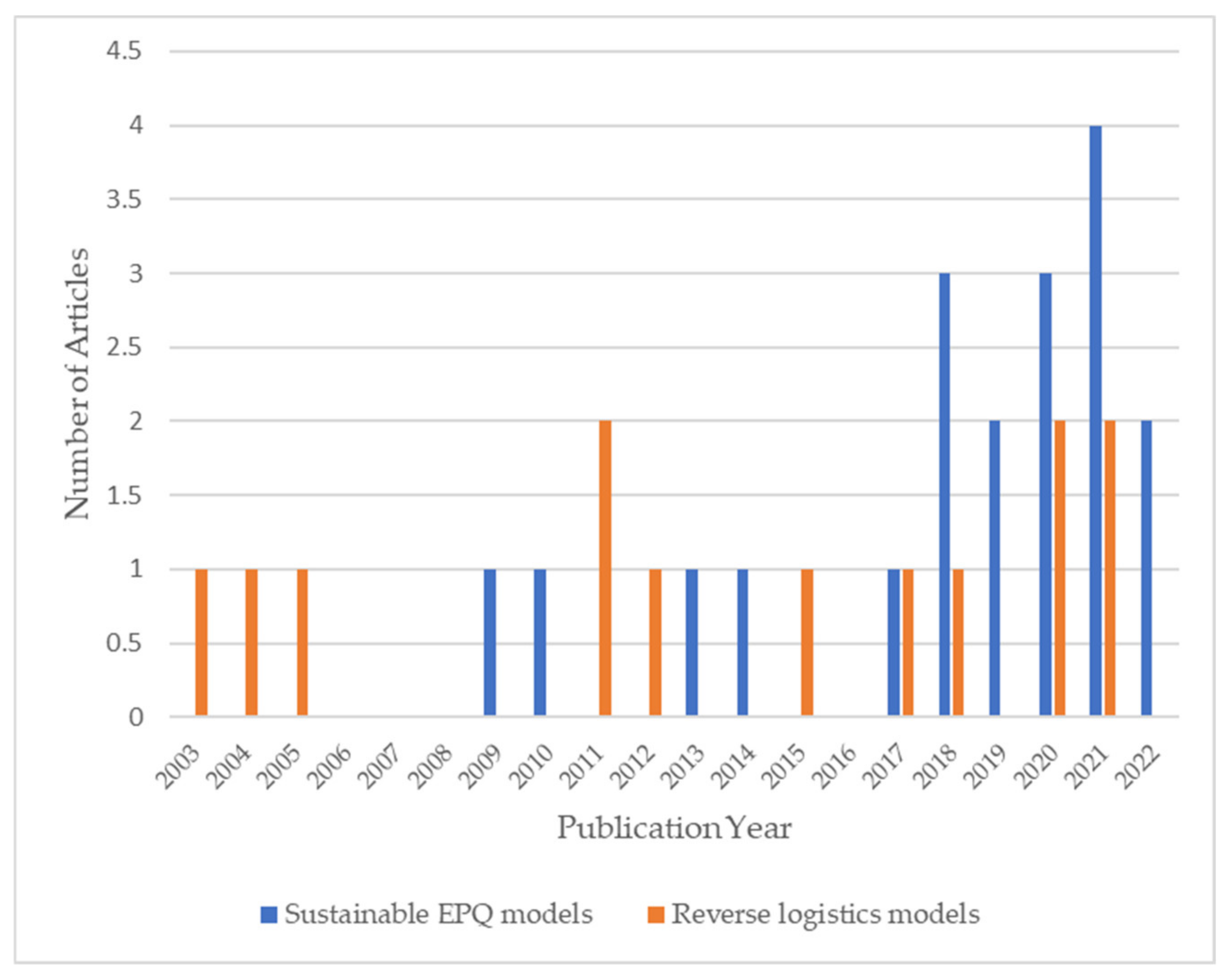

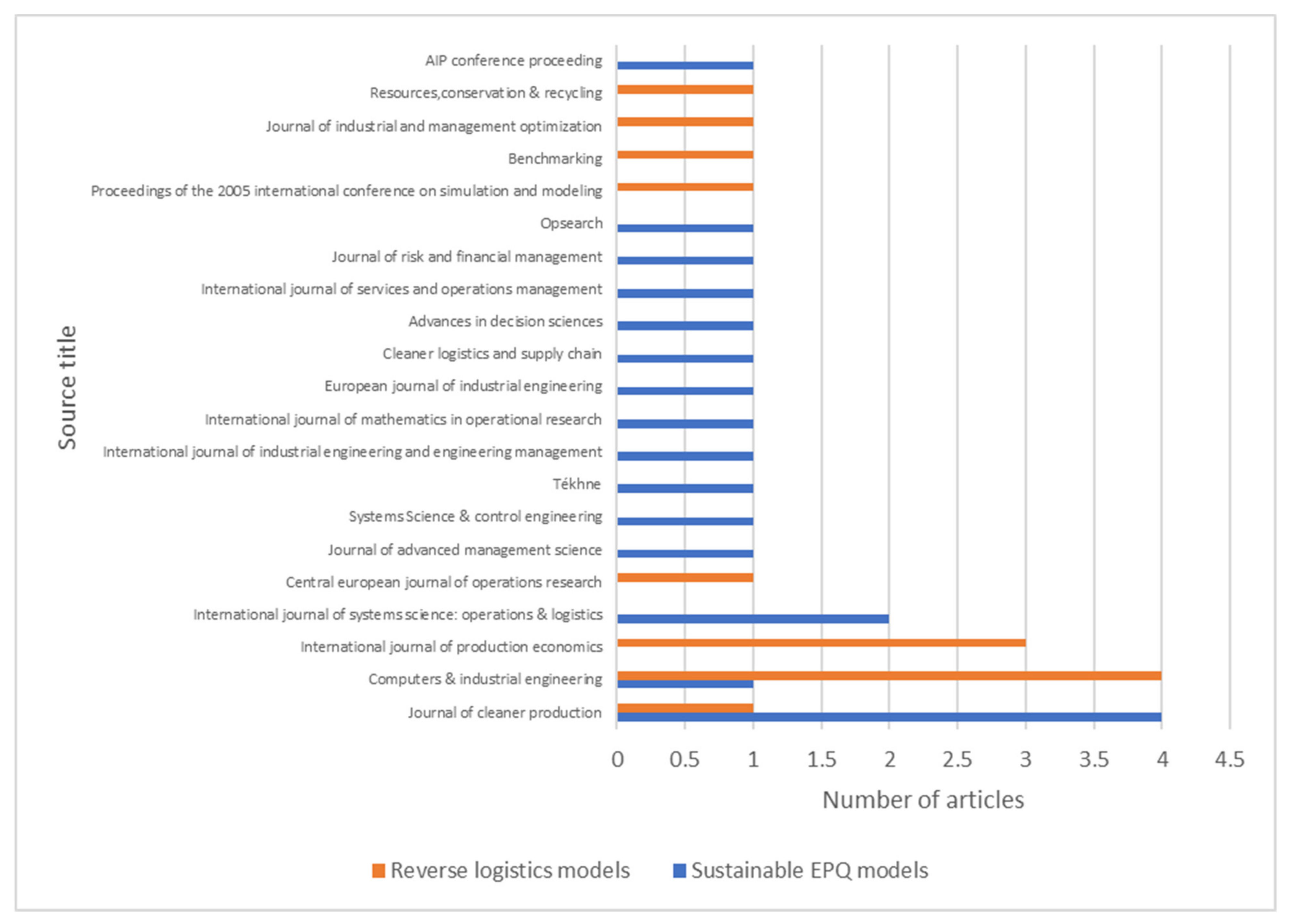

3. Descriptive Analysis

4. Content Analysis

4.1. EPQ Model with Carbon Emission

4.2. Circularity in EPQ Model

4.2.1. EPQ Model with Product Recycling

4.2.2. Reverse Logistics Model

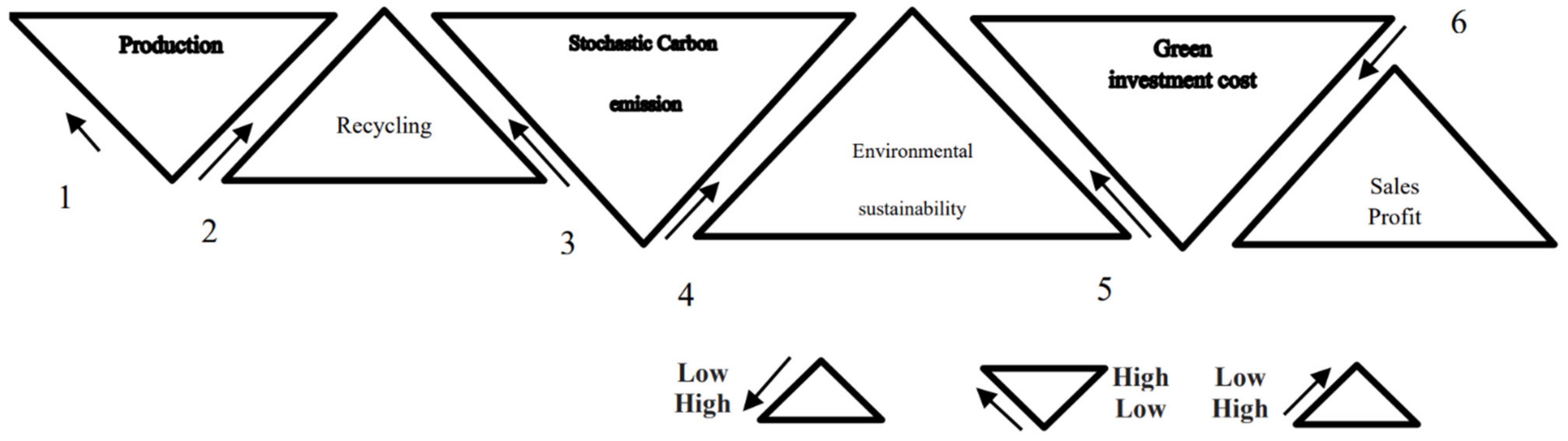

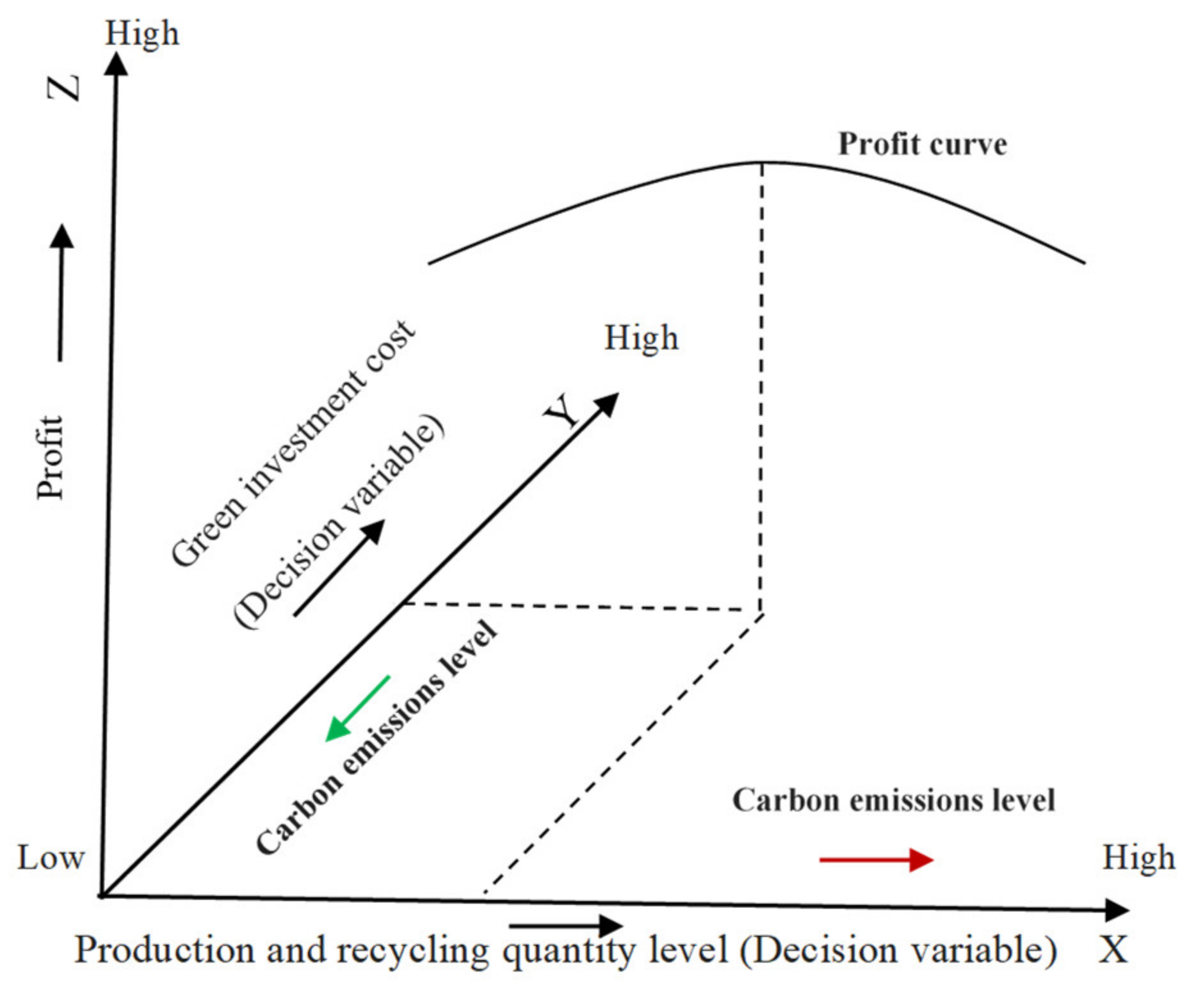

5. Potential Research Gap

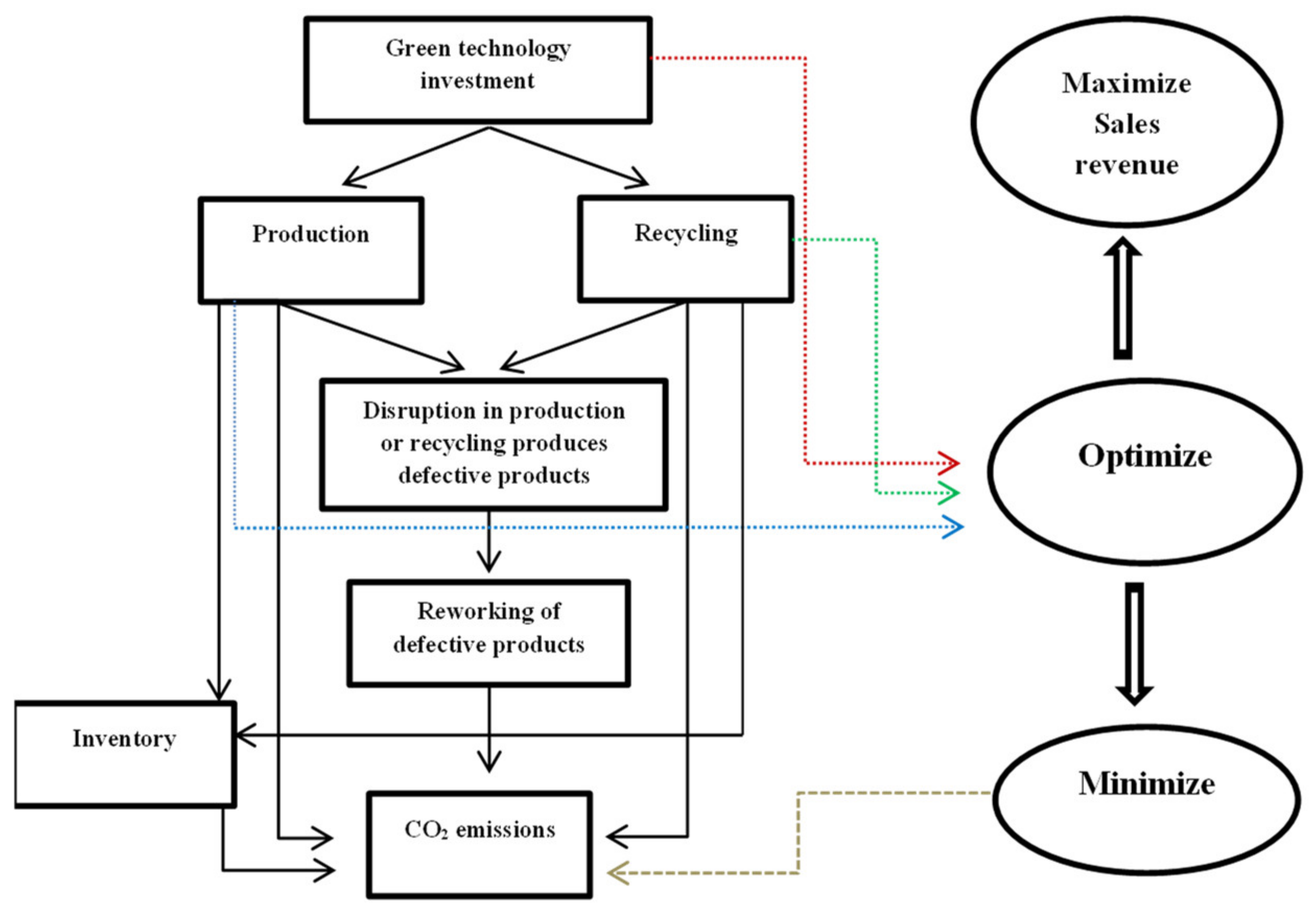

6. Analytical Explanations

7. Conclusions

- Under different carbon emission policies, what are the best strategies concerning production and recycling for a stochastic imperfect production-recycling system that minimizes carbon emissions while maximizing profit or minimizing cost?

- Under different carbon emission policies, what are the best decisions concerning production, recycling, and green technology investment for a stochastic imperfect production-recycling system that minimizes carbon emissions while maximizing profit or minimizing cost?

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ballou, R. Business Logistics Management, 3rd ed.; Prentice Hall: Englewood Cliffs, NJ, USA, 1992. [Google Scholar]

- Darmawan, G.A.; Cipta, W.; Yulianthini, N.N. Application of Economic order quantity (EOQ) in the Management of Flour Raw Material Inventory in Pia Ariawan Business in Banyuning Village in 2013. J. Manaj. Indones. 2015, 3. Available online: https://ejournal.undiksha.ac.id/index.php/JMI/article/view/4585 (accessed on 2 June 2022).

- Fadlil, I.N.; Novitasari, R.; Jauhari, W.A. Sustainable economic production quantity model with rework and product return policy. AIP Conf. Proc. 2020, 2217, 030078. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Kalantari, S.S.; Cárdenas-Barrón, L.E. Pricing and lot sizing for an EPQ inventory model with rework and multiple shipments. Top 2016, 24, 143–155. [Google Scholar] [CrossRef]

- Öztürk, H.J. A deterministic economic production quantity model with partial backordering and outsourcing repair of non-conforming products. Int. J. Syst. Sci. Oper. Logist. 2021, 1–29. [Google Scholar] [CrossRef]

- Öztürk, H. Optimal production run time for an imperfect production inventory system with rework, random breakdowns and inspection costs. Oper. Res. Int. J. 2021, 21, 167–204. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Jaber, M. Economic production quantity model with learning in production, quality, reliability and energy efficiency. Comput. Ind. Eng. 2019, 129, 502–511. [Google Scholar] [CrossRef]

- Sarkar, B.; Sarkar, M.; Ganguly, B.; Cárdenas-Barrón, L.E. Combined effects of carbon emission and production quality improvement for fixed lifetime products in a sustainable supply chain management. Int. J. Prod. Econ. 2021, 231, 107867. [Google Scholar] [CrossRef]

- Kugele, A.S.H.; Ahmed, W.; Sarkar, B. Geometric programming solution of second degree difficulty for carbon ejection controlled reliable smart production system. RAIRO-Oper. Res. 2022, 56, 1013–1029. [Google Scholar] [CrossRef]

- Yadav, D.; Singh, R.; Kumar, A.; Sarkar, B. Reduction of Pollution through Sustainable and Flexible Production by Controlling By-Products. J. Environ. Inform. 2022, in press. [Google Scholar] [CrossRef]

- Guo, T.; Li, C.; Chen, Y. Remanufacturing Strategy under Cap-and-Trade Regulation in the Presence of Assimilation Effect. Sustainability 2022, 14, 2878. [Google Scholar] [CrossRef]

- He, P.; Zhang, W.; Xu, X.; Bian, Y. Production lot-sizing and carbon emissions under cap-and-trade and carbon tax regulations. J. Clean. Prod. 2015, 103, 241–248. [Google Scholar] [CrossRef]

- Gharaei, A.; Shekarabi, S.A.H.; Karimi, M.; Pourjavad, E.; Amjadian, A. An integrated stochastic EPQ model under quality and green policies: Generalised cross decomposition under the separability approach. Int. J. Syst. Sci. Oper. Logist. 2021, 8, 119–131. [Google Scholar] [CrossRef]

- Daryanto, Y.; Wee, H.M. Sustainable Economic Production Quantity Models: An Approach toward a Cleaner Production. J. Adv. Manag. Sci. 2018, 6, 206–212. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Goswami, A. Economic production quantity models for imperfect items with pollution costs. Syst. Sci. Control Eng. 2014, 2, 368–378. [Google Scholar] [CrossRef] [Green Version]

- Manna, A.; Das, B.; Dey, J.; Mondal, S. Two layers green supply chain imperfect production inventory model under bi-level credit period. Tékhne 2017, 15, 124–142. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Soleymanfar, V.R.; Govindan, K. Sustainable economic production quantity models for inventory systems with shortage. J. Clean. Prod. 2018, 174, 1011–1020. [Google Scholar] [CrossRef]

- Daryanto, Y.; Wee, H. Low Carbon Economic Production Quantity Model for Imperfect Quality Deteriorating Items. Int. J. Ind. Eng. Eng. Manag. 2019, 1, 1–8. [Google Scholar] [CrossRef]

- Sinha, S.; Modak, N.M. An EPQ model in the perspective of carbon emission reduction. Int. J. Math. Oper. 2019, 14, 338–358. [Google Scholar] [CrossRef]

- Moon, I.; Yun, W.Y.; Sarkar, B. Effects of variable setup cost, reliability, and production costs under controlled carbon emissions in a reliable production system. Eur. J. Ind. Eng. 2022, 16, 371–397. [Google Scholar] [CrossRef]

- Sepehri, A.; Gholamian, M.R. Joint pricing and lot-sizing for a production model under controllable deterioration and carbon emissions. Int. J. Syst. Sci. Oper. Logist. 2021, 1–15. [Google Scholar] [CrossRef]

- Datta, T.K. Effect of Green Technology Investment on a Production-Inventory System with Carbon Tax. Adv. Oper. Res. 2017, 2017, 4834839. [Google Scholar] [CrossRef]

- Mishra, U.; Wu, J.-Z.; Sarkar, B. Optimum sustainable inventory management with backorder and deterioration under controllable carbon emissions. J. Clean. Prod. 2020, 279, 123699. [Google Scholar] [CrossRef]

- Lu, C.-J.; Yang, C.-T.; Yen, H.-F. Stackelberg game approach for sustainable production-inventory model with collaborative investment in technology for reducing carbon emissions. J. Clean. Prod. 2020, 270, 121963. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Zavanella, L.; Jaber, M. Green supply chain with learning in production and environmental investments. IFAC-PapersOnLine 2018, 51, 1738–1743. [Google Scholar] [CrossRef]

- Sarkar, B.; Bhuniya, S. A sustainable flexible manufacturing–remanufacturing model with improved service and green investment under variable demand. Expert Syst. Appl. 2022, 202, 117154. [Google Scholar] [CrossRef]

- Bachar, R.K.; Bhuniya, S.; Ghosh, S.K.; Sarkar, B. Sustainable green production model considering variable demand, partial outsourcing, and rework. AIMS Environ. Sci. 2022, 9, 325–353. [Google Scholar] [CrossRef]

- Mishra, U.; Wu, J.-Z.; Sarkar, B. A sustainable production-inventory model for a controllable carbon emissions rate under shortages. J. Clean. Prod. 2020, 256, 120268. [Google Scholar] [CrossRef]

- Rout, C.; Paul, A.; Kumar, R.S.; Chakraborty, D.; Goswami, A. Cooperative sustainable supply chain for deteriorating item and imperfect production under different carbon emission regulations. J. Clean. Prod. 2020, 272, 122170. [Google Scholar] [CrossRef]

- Sepehri, A.; Mishra, U.; Sarkar, B. A sustainable production-inventory model with imperfect quality under preservation technology and quality improvement investment. J. Clean. Prod. 2021, 310, 127332. [Google Scholar] [CrossRef]

- Priyan, S.; Mala, P.; Palanivel, M. A cleaner EPQ inventory model involving synchronous and asynchronous rework process with green technology investment. Clean. Logist. Supply Chain. 2022, 4, 100056. [Google Scholar] [CrossRef]

- Dem, H.; Prasher, L. Imperfect Production System under Reverse Logistics in Stock-Out Situation: EPQ Model. Adv. Decis. Sci. 2013, 2013, 915675. [Google Scholar] [CrossRef]

- Konstantaras, I.; Skouri, K.; Jaber, M.Y. Lot sizing for a recoverable product with inspection and sorting. Comput. Ind. Eng. 2010, 58, 452–462. [Google Scholar] [CrossRef]

- Hwang, H.; Ko, Y.D.; Yune, S.H.; Ko, C.S. A closed-loop recycling system with a minimum allowed quality level on returned products. Int. J. Serv. Oper. Manag. 2009, 5, 758. [Google Scholar] [CrossRef]

- AlArjani, A.; Miah, M.; Uddin, S.; Mashud, A.; Wee, H.-M.; Sana, S.; Srivastava, H. A Sustainable Economic Recycle Quantity Model for Imperfect Production System with Shortages. J. Risk Financ. Manag. 2021, 14, 173. [Google Scholar] [CrossRef]

- Mashud, A.H.M.; Roy, D.; Daryanto, Y.; Chakraborty, R.K.; Tseng, M.L. A controllable carbon emission and deterioration inventory model with advance payments scheme. J. Clean. Prod. 2021, 296, 126608. [Google Scholar] [CrossRef]

- Mishra, U.; Mashud, A.; Tseng, M.-L.; Wu, J.-Z. Optimizing a Sustainable Supply Chain Inventory Model for Controllable Deterioration and Emission Rates in a Greenhouse Farm. Mathematics 2021, 9, 495. [Google Scholar] [CrossRef]

- Kundu, S.; Chakrabarti, T. Impact of carbon emission policies on manufacturing, remanufacturing and collection of used item decisions with price dependent return rate. Opsearch 2018, 55, 532–555. [Google Scholar] [CrossRef]

- Jaber, M.Y.; El Saadany, A.M. An economic production and remanufacturing model with learning effects. Int. J. Prod. Econ. 2011, 131, 115–127. [Google Scholar] [CrossRef]

- Dobos, I.; Richter, K. A production/recycling model with stationary demand and return rates. Cent. Eur. J. Oper. Res. 2003, 11, 35–46. [Google Scholar] [CrossRef]

- Dobos, I.; Richter, K. An extended production/recycling model with stationary demand and return rates. Int. J. Prod. Econ. 2004, 90, 311–323. [Google Scholar] [CrossRef]

- Hwang, H.; Oh, Y.; Gen, M. An inventory policy for recycling system. In Proceedings of the 2005 International Conference on Simulation and Modeling, Bangkok, Thailand, 17–19 January 2005; pp. 17–19. [Google Scholar]

- Karmakar, S.; De, S.K.; Goswami, A. A pollution sensitive remanufacturing model with waste items: Triangular dense fuzzy lock set approach. J. Clean. Prod. 2018, 187, 789–803. [Google Scholar] [CrossRef]

- Khara, B.; Dey, J.K.; Mondal, S.K. Sustainable recycling in an imperfect production system with acceptance quality level dependent development cost and demand. Comput. Ind. Eng. 2020, 142, 106300. [Google Scholar] [CrossRef]

- Wang, X.; Han, S. Optimal operation and subsidies/penalties strategies of a multi-period hybrid system with uncertain return under cap-and-trade policy. Comput. Ind. Eng. 2020, 150, 106892. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; El Saadany, A.M. Carbon emissions and energy effects on manufacturing–remanufacturing inventory models. Comput. Ind. Eng. 2015, 88, 307–316. [Google Scholar] [CrossRef]

- Arora, R.; Singh, A.P.; Sharma, R.; Chauhan, A. A remanufacturing inventory model to control the carbon emission using cap-and-trade regulation with the hexagonal fuzzy number. Benchmarking Int. J. 2021, 1–29. [Google Scholar] [CrossRef]

- Yan, G.; Song, Q.; Ni, Y.; Yang, X. Pricing, carbon emission reduction and recycling decisions in a closed-loop supply chain under uncertain environment. J. Ind. Manag. Optim. 2021, 1–22. [Google Scholar] [CrossRef]

- Krikke, H. Impact of closed-loop network configurations on carbon footprints: A case study in copiers. Resour. Conserv. Recycl. 2011, 55, 1196–1205. [Google Scholar] [CrossRef]

- Sarkar, B.; Ullah, M.; Kim, N. Environmental and economic assessment of closed-loop supply chain with remanufacturing and returnable transport items. Comput. Ind. Eng. 2017, 111, 148–163. [Google Scholar] [CrossRef]

- Chaabane, A.; Ramudhin, A.; Paquet, M. Design of sustainable supply chains under the emission trading scheme. Int. J. Prod. Econ. 2012, 135, 37–49. [Google Scholar] [CrossRef]

- Sarkar, B.; Joo, J.; Kim, Y.; Park, H.; Sarkar, M. Controlling defective items in a complex multi-phase manufacturing system. RAIRO-Oper. Res. 2022, 56, 871–889. [Google Scholar] [CrossRef]

- Li, Y.-H.C.; Sy, L.L.; Lomibao, K.C.; German, J.D.; Wee, H.M. A Survey on Multi-Product Sustainable Economic Production Quantity Model Considering Wastewater Emission Costs. IOP Conf. Ser. Mater. Sci. Eng. 2020, 730, 012068. [Google Scholar]

- Shi, H.; Peng, S.; Liu, Y.; Zhong, P. Barriers to the implementation of cleaner production in Chinese SMEs: Government, industry and expert stakeholders’ perspectives. J. Clean. Prod. 2008, 16, 842–852. [Google Scholar] [CrossRef]

- Gagnon, R.; Morgan, S. A Literature Review of Remanufacturing Production Planning and Control. In Proceedings of the Annual Meeting of the Decision Sciences Institute, Seattle, WA, USA, 21–24 November 2015. [Google Scholar]

- Atasu, A.; Wassenhove, L.N. An Operations Perspective on Product Take-Back Legislation for E-Waste: Theory, Practice, and Research Needs. Prod. Oper. Manag. 2011, 21, 407–422. [Google Scholar] [CrossRef]

| References | Research Considerations | ||||||

|---|---|---|---|---|---|---|---|

| EPQ | Modeling Approach | Carbon Emission | Recycling /Remanufacturing | Imperfect Manufacturing System | Green Technology Investment | ||

| Deterministic | Stochastic | ||||||

| Taleizadeh et al. [4] | √ | √ | √ | ||||

| Öztürk [5] | √ | √ | √ | ||||

| Öztürk [6] | √ | √ | √ | ||||

| Dem and Prasher [32] | √ | √ | √ | √ | |||

| Gharaei et al. [13] | √ | √ | √ | √ | |||

| Sinha and Modak [19] | √ | √ | √ | ||||

| Fadlil et al. [3] | √ | √ | √ | √ | |||

| Daryanto and Wee [14] | √ | √ | √ | ||||

| Daryanto and Wee [18] | √ | √ | √ | √ | |||

| Konstantaras et al. [33] | √ | √ | |||||

| Sepehri et al. [30] | √ | √ | √ | √ | √ | ||

| Mishra et al. [28] | √ | √ | √ | √ | |||

| Priyan et al. [31] | √ | √ | √ | √ | √ | ||

| Sarkar et al. [8] | √ | √ | √ | ||||

| Hwang et al. [34] | √ | √ | √ | ||||

| Wang et al. [45] | √ | √ | √ | ||||

| Bazan et al. [46] | √ | √ | √ | ||||

| Karmakar et al. [43] | √ | √ | √ | ||||

| Khara et al. [44] | √ | √ | √ | ||||

| Kundu and Chakrabarti [38] | √ | √ | √ | √ | |||

| Kugele et al. [9] | √ | √ | √ | ||||

| Sarkar et al. [52] | √ | √ | |||||

| Bachar et al. [27] | √ | √ | √ | ||||

| Future research consideration | √ | √ | √ | √ | √ | √ | |

| References | Research Considerations | ||

|---|---|---|---|

| Modeling Approach | Stochastic Parameter | Probability Distribution | |

| Stochastic | |||

| Taleizadeh et al. [4] | EPQ | The portion of faulty goods | Uniform distibution |

| Öztürk [5] | EPQ | The fraction of nonconform- ing items | Uniform distibution |

| Öztürk [6] | EPQ | The proportion of faulty goods, the proportion of scrap goods, the time to breakdown | Uniform distibution |

| Gharaei et al. [13] | EPQ | Resources | Normal distribution |

| Hwang et al. [34] | EPQ | The quality of returned goods | Uniform distibution |

| Wang et al. [45] | Multi-period hybrid manufacturing/ remanufacturing model |

|

|

| Sarkar et al. [52] | Multi-phase manufacturing model | The portion of defective goods | Uniform distibution |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karim, R.; Nakade, K. A Literature Review on the Sustainable EPQ Model, Focusing on Carbon Emissions and Product Recycling. Logistics 2022, 6, 55. https://doi.org/10.3390/logistics6030055

Karim R, Nakade K. A Literature Review on the Sustainable EPQ Model, Focusing on Carbon Emissions and Product Recycling. Logistics. 2022; 6(3):55. https://doi.org/10.3390/logistics6030055

Chicago/Turabian StyleKarim, Rubayet, and Koichi Nakade. 2022. "A Literature Review on the Sustainable EPQ Model, Focusing on Carbon Emissions and Product Recycling" Logistics 6, no. 3: 55. https://doi.org/10.3390/logistics6030055

APA StyleKarim, R., & Nakade, K. (2022). A Literature Review on the Sustainable EPQ Model, Focusing on Carbon Emissions and Product Recycling. Logistics, 6(3), 55. https://doi.org/10.3390/logistics6030055