The truck appointment scheduling problem in CTs has attracted the interest of many researchers in the literature. Although some research studies, articles, and books have been published tackling this problem, some areas still deserve more investigation. For example, ref. [

8] proposed a comprehensive review of the truck appointment scheduling problem and identified the potential research directions related to this problem. The interested readers can refer to the previous study for a wider survey of the published research articles related to the problem in addition to a discussion and comparisons between the identified approaches found in the literature which were used to tackle the external truck appointment scheduling in container terminals. Moreover, readers are encouraged to go through [

9] to identify other aspects of container terminal planning and management models.

The importance of external truck appointment scheduling is concluded from the literature, the surrounded community, and the environmental perspectives. As mentioned previously, many literature review studies discussed how crucial is to schedule the appointments of external trucks in container terminals for all stakeholders involved in these networks such as ref. [

8], which assured that there are still some gaps in this research area. Additionally, many studies have emerged in literature focusing on reducing the harmful emissions on one hand, and scheduling the appointment of external trucks on the other hand as in the work of [

10,

11]. The community perspectives put pressure on addressing the external trucks appointment scheduling, especially in the residential areas next to container terminals’ landside areas because of the congestion of trucks during rush hours [

12]. The previously mentioned reasons motivated the authors to focus on the external truck appointment scheduling in container terminals.

To begin with, studies presenting rudimentary systems to manage the truck arrivals at the terminal gate, ref. [

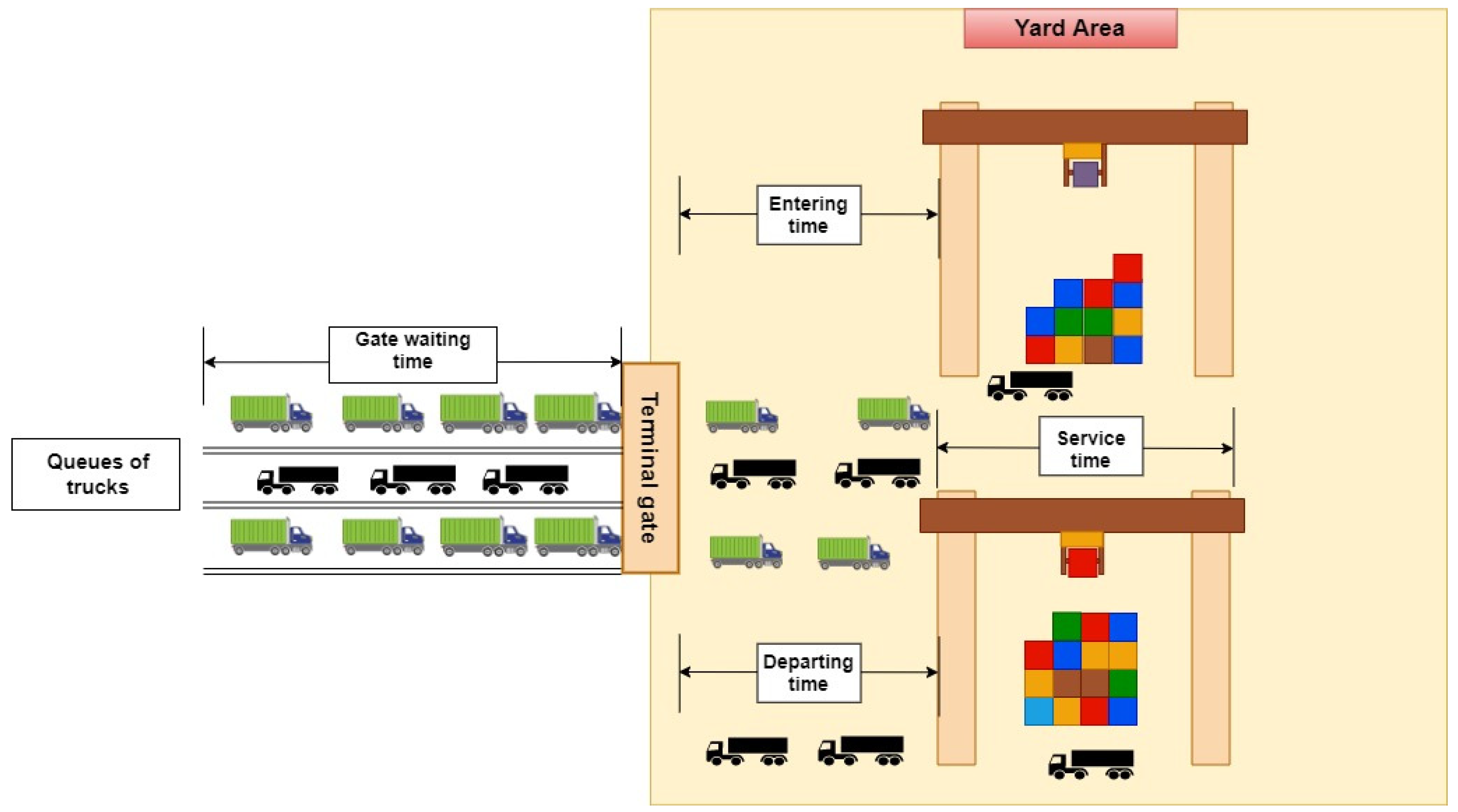

13] have laid the foundation for scheduling trucks using a decision support system to assist the terminal managers in operating the terminal efficiently. Murty et al. proposed a case study in Hong Kong that relied on dividing the working time into time slots at which groups of appointments are assigned. Later, more comprehensive methodologies were implemented to solve the problem, either by formulating the appointment scheduling problem mathematically and solving it with the aid of exact or heuristic algorithms or by simulation software. Simulation packages have witnessed a significant breakthrough nowadays through supporting 3D models that offer real-life representations. This development enables users to get more accurate results and a real description of the studied cases, in addition to determining the key performance indicators of the container terminal systems (e.g., truck turnaround times, queue lengths in the terminal gate and yard area, etc.). Moreover, in some publications, the author’s combined previous approaches to get more efficient and reliable solutions. First of all, ref. [

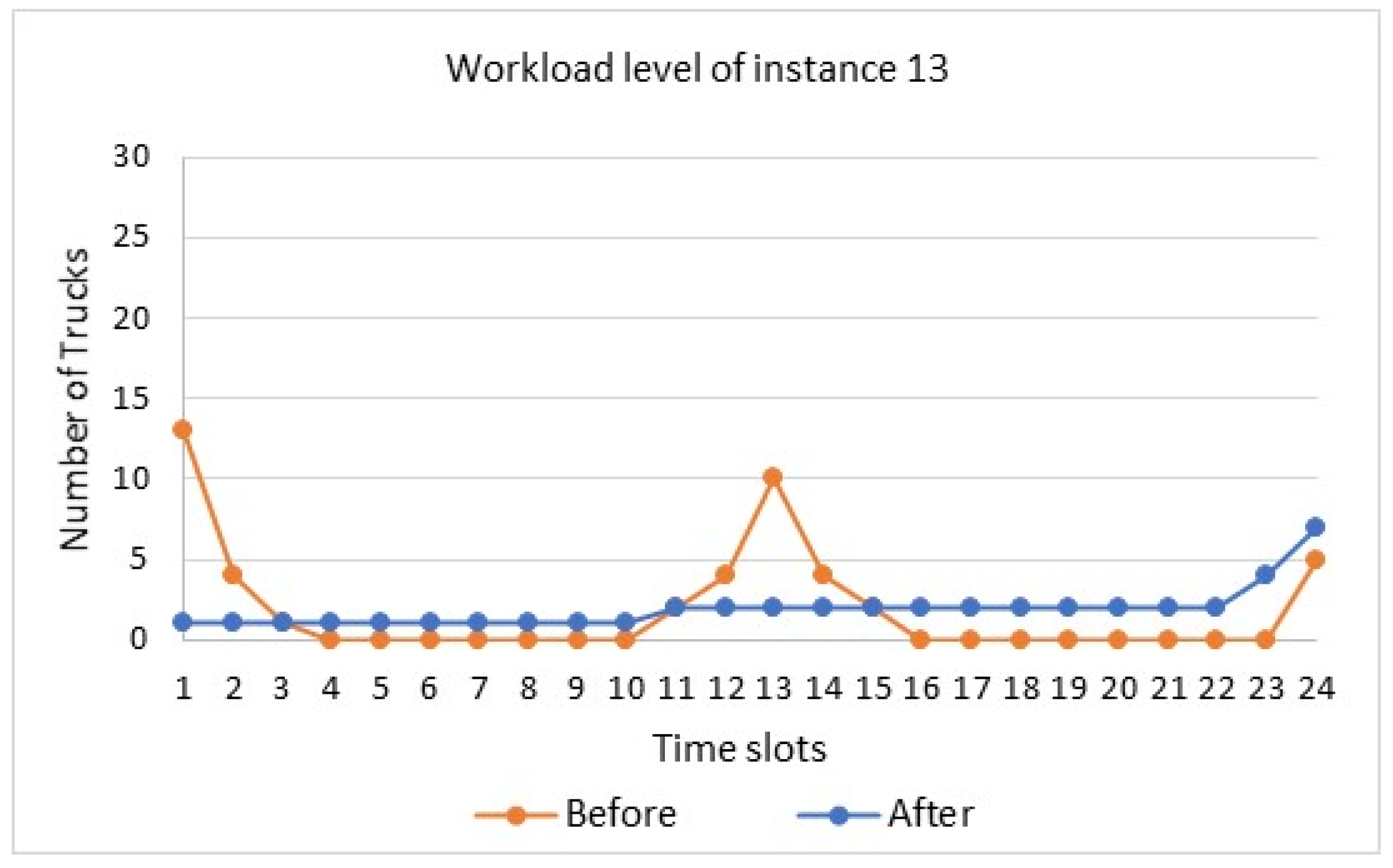

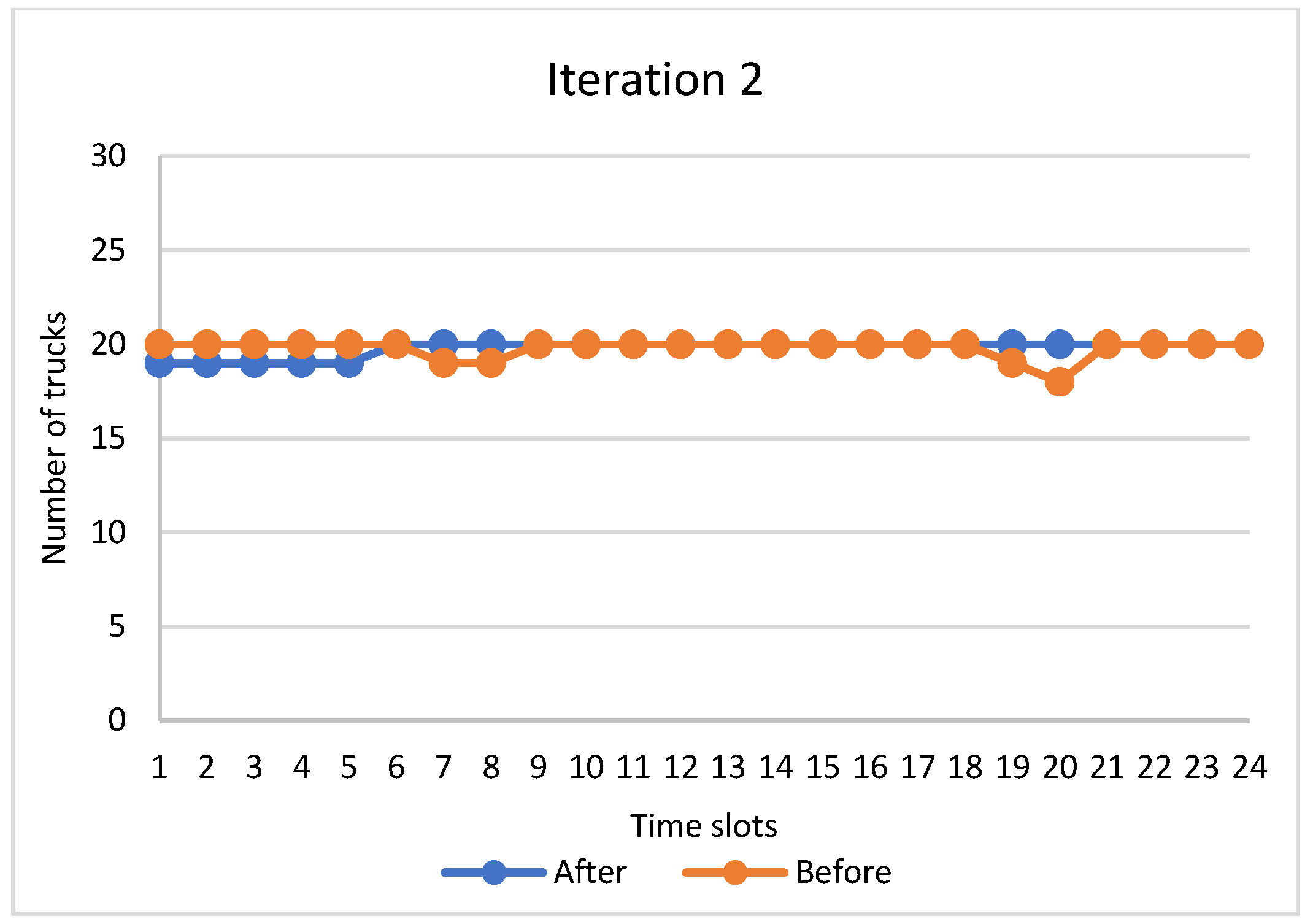

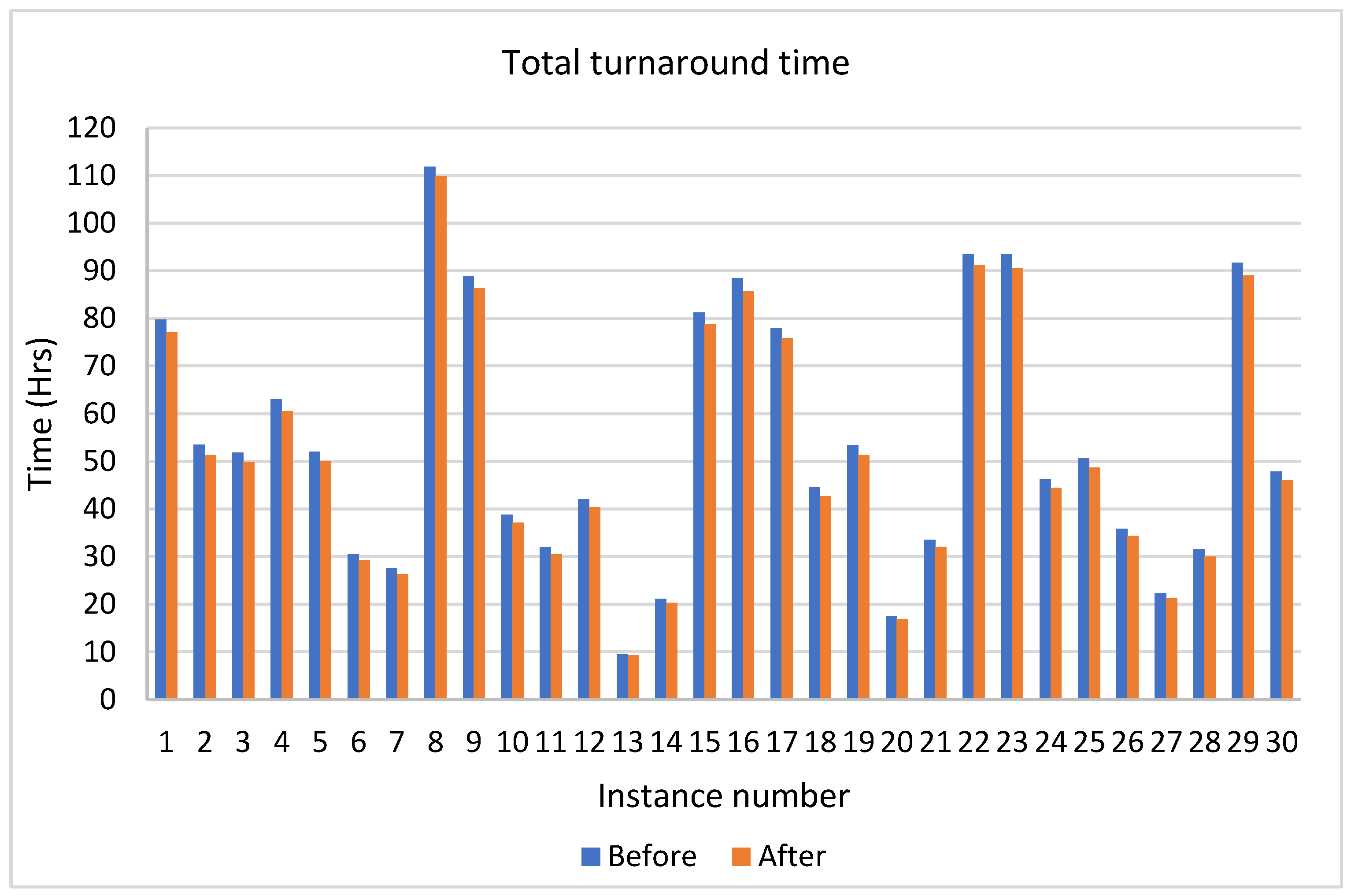

6] conducted a simulation-based optimization study to reduce waiting times experienced by trucks, and dangerous emissions, improve utilization of terminal resources and finally reduce the inconvenience cost of the trucking companies. This cost results from the shifting of appointments from the reserved ones due to the advanced or delayed arrival of trucks. To leverage the collaboration between the CT and trucking companies, they developed a Dynamic Collaborative Truck Appointment System (DCTAS). The integrated model objective is to reduce the turnaround times of trucks considering yard and gate operations. The results revealed better workload levels in the terminal yard, less congestion and queue lengths at the terminal gate, and higher utilization of the terminal equipment. Ref. [

14] proposed a study to investigate the effect of putting a cap on the truck density inside the terminal using a TAS by allowing a certain number of trucks to come during each time slot. They used mathematical modeling and simulation to illustrate the effect of employing a TAS on the truck turnaround time and the utilization of the terminal resources. The problems resulting from the lack of organization and miscommunication between quay cranes and yard trucks were investigated by [

15]. A mixed-integer linear programming model was developed to reduce the idle time spent executing two consecutive tasks and was solved by a particle swarm optimization-based solution method. In order to balance the workload in the terminal, ref. [

16] proposed a mixed integer programming model to determine the appointment quota optimally, regarding the appointments of vessels, barges, trains, and trucks, and the obtained results were validated using Discrete Event Simulation (DES). Ref. [

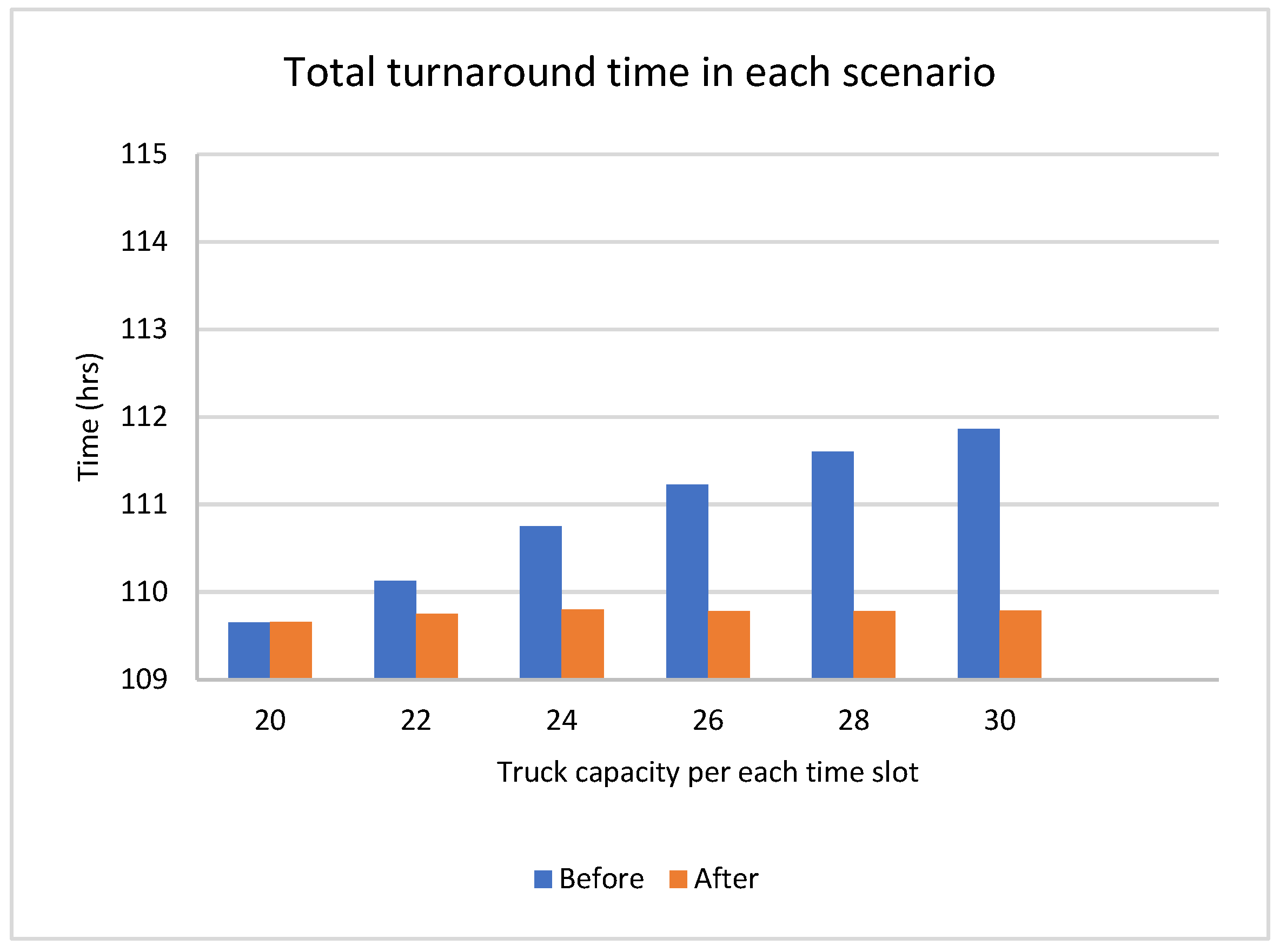

17] presented a DES approach to identify the effect of arrival patterns of external trucks on the turnaround time. The results of this study showed that there is a direct impact on the waiting time by changing the arrival patterns of external trucks. Furthermore, they recommended some considerations for terminal managers to reduce the time spent by trucks at the terminal gate and yard without affecting the working hours of the terminal gate. A TAS was designed by [

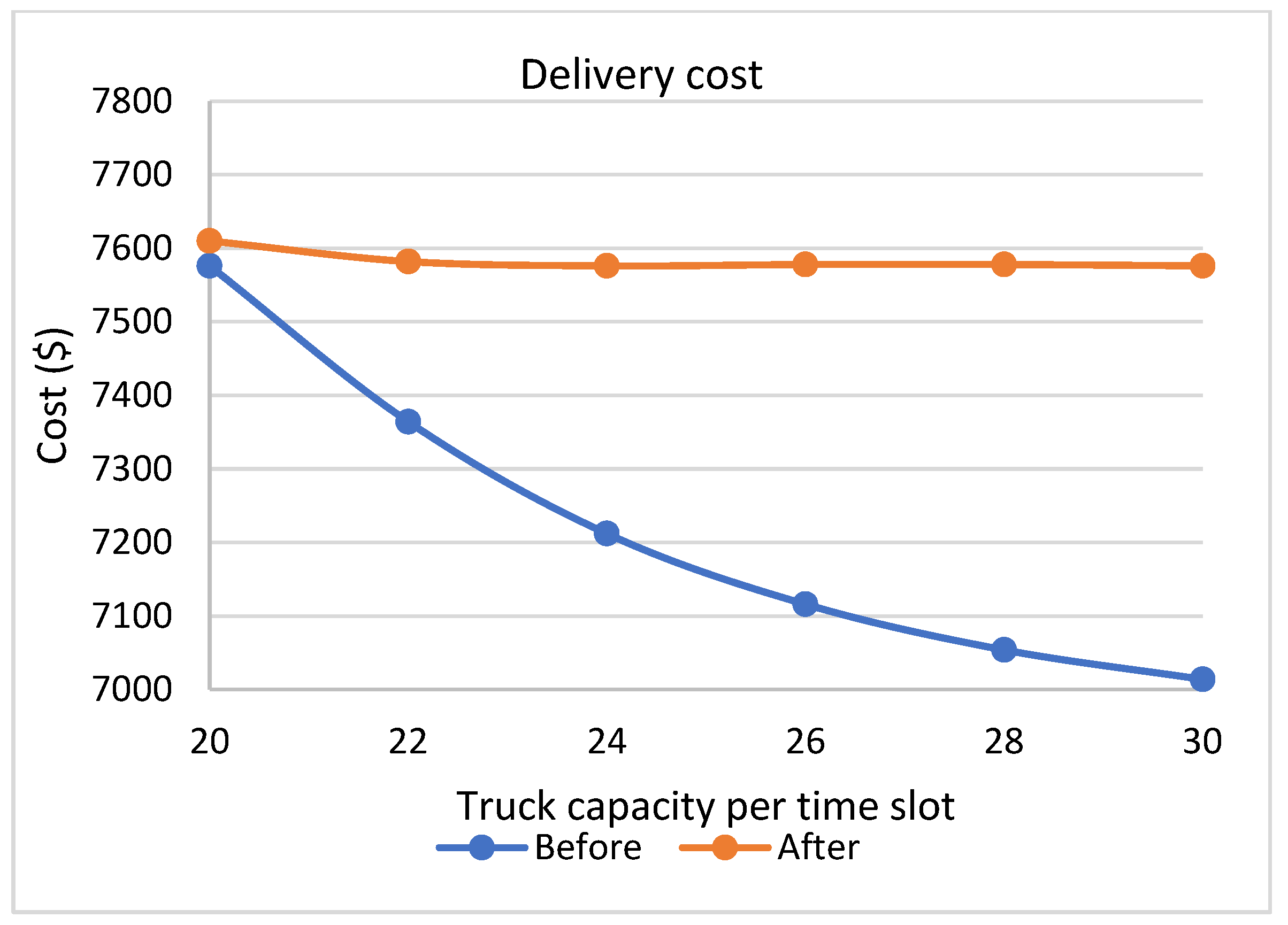

18] to achieve a reciprocal benefit for both the terminal and trucking companies. A mixed-integer nonlinear programming model was formulated to optimize the optimum quota per each time slot aiming at reducing truck densities in the gate and yard areas, in addition to providing the best schedule for the trucking companies to send their trucks without deviation from the reserved appointments. The obtained results revealed that the container transportation costs declined by 11.5%. Ref. [

19] presented a mixed-integer programming model combined with DES to obtain a smooth workload distribution during all working hours and reduce the congested trucks at the terminal. They indicated that the collaboration between the terminal and the trucking companies improves the key performance indicators (e.g., vessel and truck turnaround times). Furthermore, the previous study deduced a more efficient TAS compared with the one proposed by ref. [

20], which is why this system is more convenient to apply in reality. In this regard, ref. [

21] presented an integrated DCTAS aiming at helping both the trucking companies and container terminals in sharing the decision-making process. Trucking companies are encouraged to participate in selecting their preferable arrival appointments while guaranteeing that the workload of the terminal is balanced. The proposed approach incorporated a DES model and a mixed-integer programming model to solve the problem while considering the uncertainties related to the problem. The obtained results showed that adopting DCTAS can benefit both the CT and trucking companies to improve various key performance indicators such as queue lengths and truck turnaround times. Ref. [

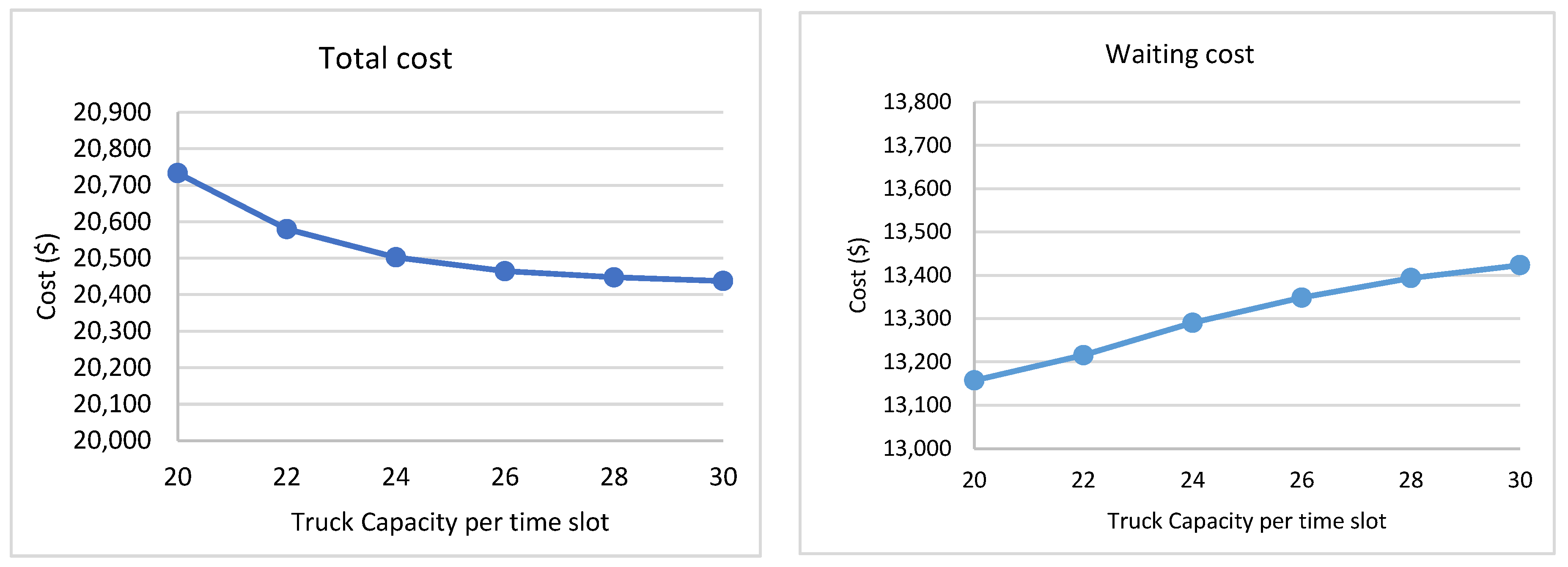

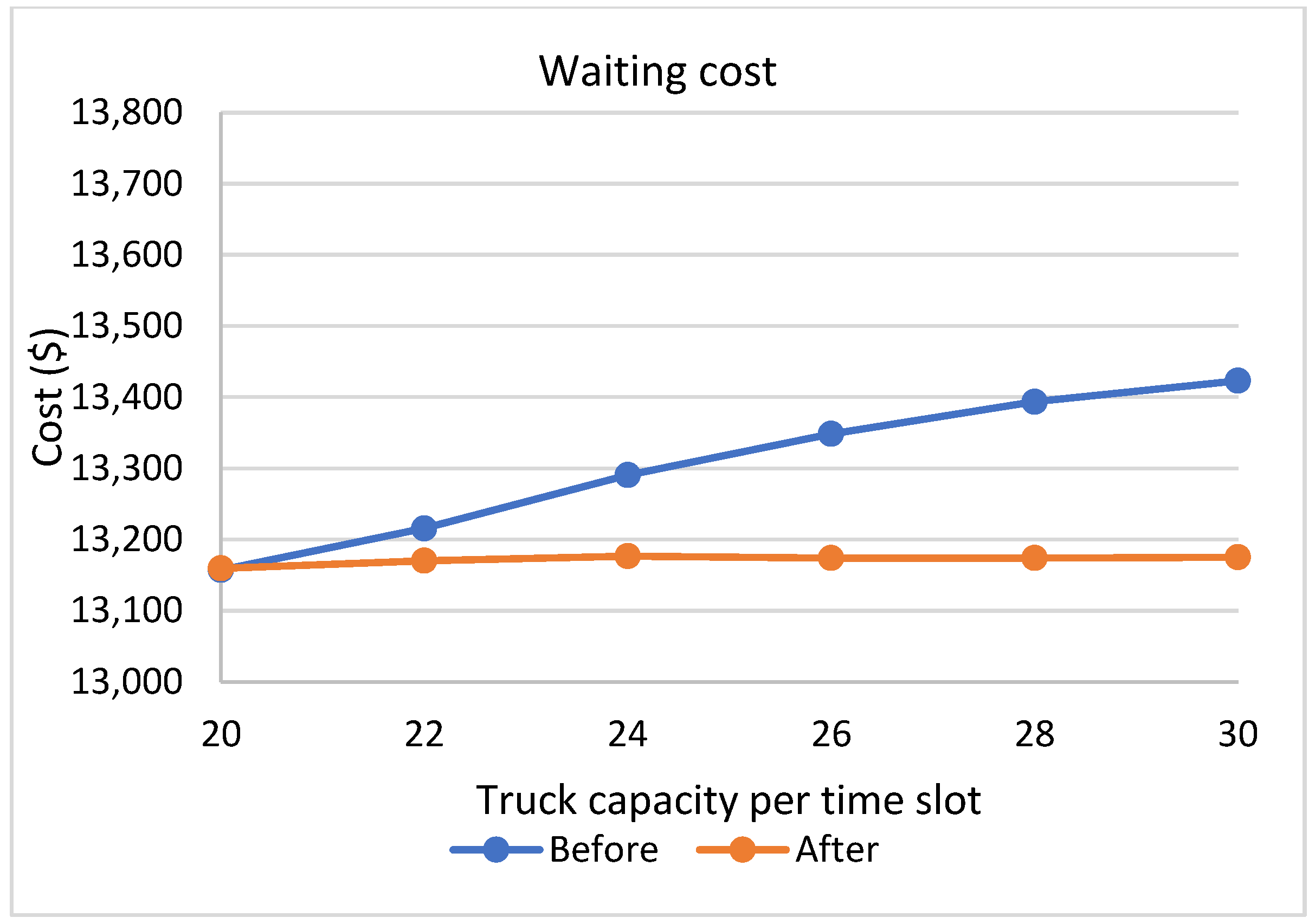

22] used the concept of non-stationary queuing models to design a TAS in order to limit the over-crowdedness of trucks in the terminal yard by calculating the optimum number of appointments per time slot. Besides, using the yard cranes efficiently for managing the workload. The results showed a considerable reduction in the total operating cost. Ref. [

12] implemented an integer linear programming model to obtain the best schedule for the received appointments of trucks. They aimed at minimizing the total cost by reducing the shifted appointments due to the delayed arrival of trucks. The presented models tested to check its performance using several scenarios from the literature. The obtained results showed a considerable reduction in truck turnaround times.

In this work, an extension of the work of ref. [

23] considers more parameters, and a modified objective function is proposed. This study differs from the work of ref. [

23] by introducing a linear objective function to reduce the total costs resulting from dispatching tasks of containers. Moreover, a new formulation of the problem is proposed considering more constraints to level the workload inside the terminal. The binary programming model is used to schedule the appointments of the trucks arriving at the terminal to manage the workload levels inside the terminal to avoid bottlenecks. The model will help in reducing the total costs related to the dispatch of containers from/to the terminal, in addition, it will distribute the workload evenly among all the working hours, which provides better utilization of the terminal resources, reduced turnaround times, and congestion in front of the gate and the yard areas.