A Systematic Mapping Study on Machine Learning Techniques Applied for Condition Monitoring and Predictive Maintenance in the Manufacturing Sector

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Questions

- RQ 1.

- Which techniques are used and what is their relative frequency?Rationale: This question defines the basis of the study and provides an overview of the current existing ML approaches applied for CM or PdM.

- RQ 2.

- For the identified techniques, which algorithms are used the most?Rationale: Since ML techniques involve diverse algorithms, these approaches have to be identified in order to determine the trend or distribution.

- RQ 3.

- What is the distribution of online and offline algorithms in the identified scenarios?Rationale: Which learning method is used in the present studies? Do the researchers profit from one method in particular?

- RQ 4.

- Are there algorithms that are currently gaining momentum?Rationale: In order to identify and fill gaps of machine learning applied in the manufacturing sector, this question aims to determine potential algorithms for implementation within the research domain by examining their frequency of use in current research.

- RQ 5.

- Which applications are examined to apply condition monitoring or predictive maintenance?Rationale: This question extracts all applications of ML techniques applied for condition monitoring or predictive maintenance. It will show the distribution in the fields of application.

2.2. Search Strategy

2.3. Screening of Papers

2.4. Keywording

- the ML technique;

- the algorithms applied;

- the research type;

- if a framework or case study is proposed;

- the learning type (e.g., online and offline ML).

3. Results

3.1. Data Extraction and Mapping Process

3.2. Machine Learning Techniques Used and Their Relative Frequency (RQ 1)

3.3. Algorithms Used (RQ 2)

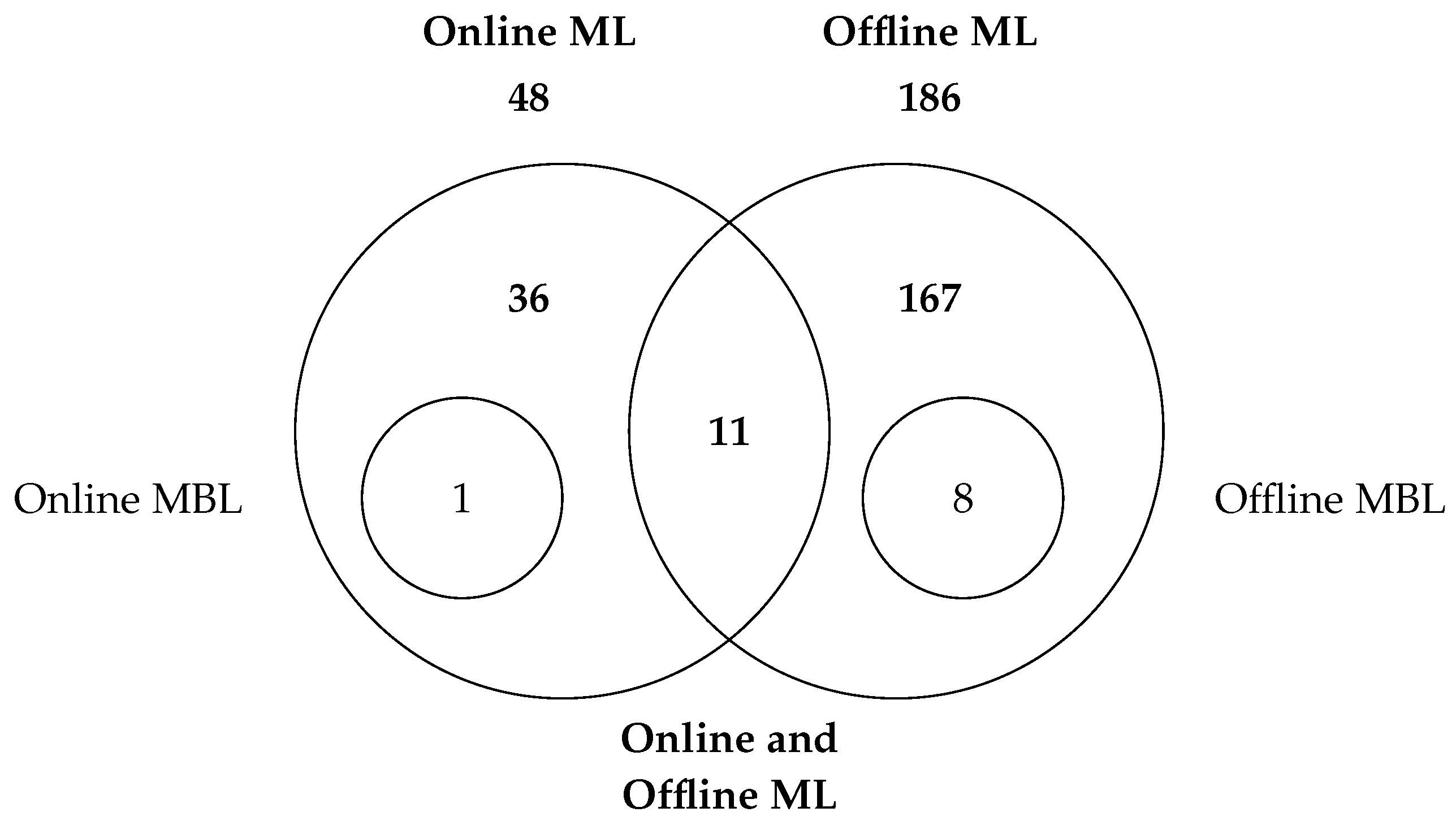

3.4. Distribution of Online and Offline Machine Learning (RQ 3)

3.5. Algorithms Currently Gaining Momentum (RQ 4)

3.6. Applications in Condition Monitoring or Predictive Maintenance (RQ 5)

3.7. High-Level Comparative Analysis and Insight into the Performance of ML Techniques

- data set [64];

- performance metrics used (classification versus regression);

- implementation standards (chance of overfitting);

- distribution of errors.

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| ANN | Artificial neural network |

| CM | Condition monitoring |

| CNN | Convolutional neural network |

| DTN | Deep transfer network |

| ISVR | Iterated support vector regression |

| KNN | K-nearest neighbors |

| LOOCV | Leave-one-out cross validation |

| LSTM | Long short-term memory |

| MAE | Mean absolute error |

| MBL | Mini-batch learning |

| ML | Machine learning |

| MSE | Mean squared error |

| PCA | Principal component analysis |

| PdM | Predictive maintenance |

| RF | Random forest |

| RMSE | Root mean squared error |

| RN | Recurrent neural network |

| RQ | Research question |

| RUL | Remaining useful life |

| SMS | Systematic mapping study |

| SVM | Support vector machine |

| SVR | Support vector regression |

References

- Kagermann, H.; Lukas, W.D.; Wahlster, W. Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. industriellen Revolution. VDI Nachrichten 2011, 13, 2–3. [Google Scholar]

- Thareja, P. Manufacturing paradigms in 2010. In Proceedings of the National Conference on Emerging Trends in Manufacturing Systems, Haryana, India, 15–16 March 2005. [Google Scholar]

- Rao, B.K.N. Handbook of Condition Monitoring; Elsevier Advanced Technology: Amsterdam, The Netherlands, 1996. [Google Scholar]

- Mobley, R.K. An Introduction to Predictive Maintenance; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar] [CrossRef]

- PK, F.A. Learning Outcomes of Classroom Research; Chapter Artificial Intelligence; L ORDINE Nuovo Publication: New Delhi, India, 2021; pp. 65–73. [Google Scholar]

- Bhbosale, S.; Pujari, V.; Multani, Z. Advantages And Disadvantages Of Artificial Intellegence. Aayushi Int. Interdiscip. Res. J. 2020, 77, 227–230. [Google Scholar]

- El Naqa, I.; Murphy, M.J. What Is Machine Learning? In Machine Learning in Radiation Oncology: Theory and Applications; El Naqa, I., Li, R., Murphy, M.J., Eds.; Springer International Publishing: Cham, Switzerland; Berlin, Germany, 2015; pp. 3–11. [Google Scholar] [CrossRef]

- Ren, Y. Optimizing Predictive Maintenance With Machine Learning for Reliability Improvement. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part B Mech. Eng. 2021, 7, 030801. Available online: https://asmedigitalcollection.asme.org/risk/article-pdf/7/3/030801/6733140/risk_007_03_030801.pdf (accessed on 11 November 2021). [CrossRef]

- Nacchia, M.; Fruggiero, F.; Lambiase, A.; Bruton, K. A Systematic Mapping of the Advancing Use of Machine Learning Techniques for Predictive Maintenance in the Manufacturing Sector. Appl. Sci. 2021, 11, 2546. [Google Scholar] [CrossRef]

- Begüm, A.; Akbulut, A.; Zaim, A.H. Techniques for Apply Predictive Maintenance and Remaining Useful Life: A Systematic Mapping Study. Bilecik Şeyh Edebali Üniversitesi Fen Bilim. Derg. 2021, 8, 497–511. [Google Scholar]

- Petersen, K.; Feldt, R.; Mujtaba, S.; Mattsson, M. Systematic Mapping Studies in Software Engineering. In Proceedings of the 12th International Conference on Evaluation and Assessment in Software Engineering (EASE’08), Karlskrona, Sweden, 15–16 June 2017; BCS Learning and Development Ltd.: Karlskrona, Sweden, 2008; pp. 68–77. [Google Scholar]

- Oxford English Dictionary. Review. 2022. Available online: https://www.oed.com/view/Entry/164850? (accessed on 5 February 2022).

- Scheuren, F. What is a Survey? American Statistical Association Alexandria: Alexandria, VA, USA, 2004. [Google Scholar]

- Oxford English Dictionary. Manufacturing. 2022. Available online: https://www.oed.com/view/Entry/113773? (accessed on 5 February 2022).

- Oxford English Dictionary. Shop Floor. 2022. Available online: https://www.oed.com/view/Entry/178522? (accessed on 5 February 2022).

- Ahmed, H.; Nandi, A.K. Compressive Sampling and Deep Neural Network (CS-DNN). In Condition Monitoring with Vibration Signals: Compressive Sampling and Learning Algorithms for Rotating Machines; IEEE: Hoboken, NJ, USA, 2019; pp. 361–377. Available online: https://ieeexplore.ieee.org/document/8958910 (accessed on 12 September 2021).

- Russell, S.; Norvig, P. Artificial Intelligence: A Modern Approach; Pearson Education Limited: London, UK, 2009; Volume 3. [Google Scholar]

- Variz, L.; Piardi, L.; Rodrigues, P.J.; Leitão, P. Machine Learning Applied to an Intelligent and Adaptive Robotic Inspection Station. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; Volume 1, pp. 290–295. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Gao, R.X. Transfer learning for enhanced machine fault diagnosis in manufacturing. CIRP Ann. 2020, 69, 413–416. [Google Scholar] [CrossRef]

- Mukherjee, S.; Huang, X.; Rathod, V.T.; Udpa, L.; Deng, Y. Defects Tracking via NDE Based Transfer Learning. In Proceedings of the 2020 IEEE International Conference on Prognostics and Health Management (ICPHM), Detroit, MI, USA, 8–10 June 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Agarwal, S.; Vijaya Saradhi, V.; Karnick, H. Kernel-based online machine learning and support vector reduction. Neurocomputing 2008, 71, 1230–1237. [Google Scholar] [CrossRef]

- Benczúr, A.A.; Kocsis, L.; Pálovics, R. Online Machine Learning in Big Data Streams. arXiv 2018, arXiv:1802.05872. [Google Scholar]

- Li, M.; Zhang, T.; Chen, Y.; Smola, A.J. Efficient Mini-Batch Training for Stochastic Optimization. In Proceedings of the 20th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining (KDD ’14), New York, NY, USA, 24–27 August 2014; Association for Computing Machinery: New York, NY, USA, 2014; pp. 661–670. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, J.; Yan, R.; Mao, K. Machine health monitoring with LSTM networks. In Proceedings of the 2016 10th International Conference on Sensing Technology (ICST), Nanjing, China, 11–13 November 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Wu, H.; Wang, Y.; Yu, Z. In situ monitoring of FDM machine condition via acoustic emission. Int. J. Adv. Manuf. Technol. 2016, 84, 1483–1495. [Google Scholar] [CrossRef]

- Susto, G.A.; Schirru, A.; Pampuri, S.; McLoone, S.; Beghi, A. Machine Learning for Predictive Maintenance: A Multiple Classifier Approach. IEEE Trans. Ind. Inform. 2015, 11, 812–820. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Zhang, Z.; Shi, J.; Wu, D. Prediction of surface roughness in extrusion-based additive manufacturing with machine learning. Robot.-Comput.-Integr. Manuf. 2019, 57, 488–495. [Google Scholar] [CrossRef]

- Corne, R.; Nath, C.; El Mansori, M.; Kurfess, T. Study of spindle power data with neural network for predicting real-time tool wear/breakage during inconel drilling. J. Manuf. Syst. 2017, 43, 287–295. [Google Scholar] [CrossRef]

- Huber, S.; Wiemer, H.; Schneider, D.; Ihlenfeldt, S. DMME: Data mining methodology for engineering applications—A holistic extension to the CRISP-DM model. Procedia CIRP 2019, 79, 403–408. [Google Scholar] [CrossRef]

- Painuli, S.; Elangovan, M.; Sugumaran, V. Tool condition monitoring using K-star algorithm. Expert Syst. Appl. 2014, 41, 2638–2643. [Google Scholar] [CrossRef]

- Joshuva, A.; Sugumaran, V. A data driven approach for condition monitoring of wind turbine blade using vibration signals through best-first tree algorithm and functional trees algorithm: A comparative study. ISA Trans. 2017, 67, 160–172. [Google Scholar] [CrossRef]

- Essien, A.; Giannetti, C. A Deep Learning Model for Smart Manufacturing Using Convolutional LSTM Neural Network Autoencoders. IEEE Trans. Ind. Inform. 2020, 16, 6069–6078. [Google Scholar] [CrossRef] [Green Version]

- Langone, R.; Alzate, C.; De Ketelaere, B.; Vlasselaer, J.; Meert, W.; Suykens, J.A. LS-SVM based spectral clustering and regression for predicting maintenance of industrial machines. Eng. Appl. Artif. Intell. 2015, 37, 268–278. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.J.; Wu, H.; Yun, H.; Kim, H.; Jun, M.B.; Sutherland, J.W. Predictive Maintenance of Machine Tool Systems Using Artificial Intelligence Techniques Applied to Machine Condition Data. Procedia CIRP 2019, 80, 506–511. [Google Scholar] [CrossRef]

- Kroll, B.; Schaffranek, D.; Schriegel, S.; Niggemann, O. System Modeling Based on Machine Learning for Anomaly Detection and Predictive Maintenance in Industrial Plants; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Susto, G.A.; Beghi, A. Dealing with time-series data in Predictive Maintenance problems. In Proceedings of the 2016 IEEE 21st International Conference on Emerging Technologies and Factory Automation (ETFA), Berlin, Germany, 6–9 September 2016; Institute of Electrical and Electronics Engineers Inc.: Berlin, Germany, 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Kumar, A.; Shankar, R.; Thakur, L.S. A big data driven sustainable manufacturing framework for condition-based maintenance prediction. J. Comput. Sci. 2018, 27, 428–439. [Google Scholar] [CrossRef]

- Traini, E.; Bruno, G.; D’Antonio, G.; Lombardi, F. Machine Learning Framework for Predictive Maintenance in Milling. IFAC-PapersOnLine 2019, 52, 177–182. [Google Scholar] [CrossRef]

- Gutschi, C.; Furian, N.; Suschnigg, J.; Neubacher, D.; Voessner, S. Log-based predictive maintenance in discrete parts manufacturing. Procedia CIRP 2019, 79, 528–533. [Google Scholar] [CrossRef]

- Panicucci, S.; Nikolakis, N.; Cerquitelli, T.; Ventura, F.; Proto, S.; Macii, E.; Makris, S.; Bowden, D.; Becker, P.; O’mahony, N.; et al. A cloud-to-edge approach to support predictive analytics in robotics industry. Electronics 2020, 9, 492. [Google Scholar] [CrossRef] [Green Version]

- Susto, G.A.; Wan, J.; Pampuri, S.; Zanon, M.; Johnston, A.B.; O’Hara, P.G.; McLoone, S. An adaptive machine learning decision system for flexible predictive maintenance. In Proceedings of the 2014 IEEE International Conference on Automation Science and Engineering (CASE), New Taipei, Taiwan, 18–22 August 2014; pp. 806–811. [Google Scholar] [CrossRef]

- Elangovan, M.; Devasenapati, S.B.; Sakthivel, N.; Ramachandran, K. Evaluation of expert system for condition monitoring of a single point cutting tool using principle component analysis and decision tree algorithm. Expert Syst. Appl. 2011, 38, 4450–4459. [Google Scholar] [CrossRef]

- Klaic, M.; Staroveski, T.; Udiljak, T. Tool wear classification using decision treesin stone drilling applications: A preliminary study. Procedia Eng. 2014, 69, 1326–1335. [Google Scholar] [CrossRef] [Green Version]

- Quatrini, E.; Costantino, F.; Di Gravio, G.; Patriarca, R. Machine learning for anomaly detection and process phase classification to improve safety and maintenance activities. J. Manuf. Syst. 2020, 56, 117–132. [Google Scholar] [CrossRef]

- Madhusudana, C.; Kumar, H.; Narendranath, S. Fault Diagnosis of Face Milling Tool using Decision Tree and Sound Signal. Mater. Today Proc. 2018, 5, 12035–12044. [Google Scholar] [CrossRef]

- Papatheou, E.; Dervilis, N.; Maguire, A.E.; Antoniadou, I.; Worden, K. A Performance Monitoring Approach for the Novel Lillgrund Offshore Wind Farm. IEEE Trans. Ind. Electron. 2015, 62, 6636–6644. [Google Scholar] [CrossRef] [Green Version]

- Krishnakumar, P.; Rameshkumar, K.; Ramachandran, K. Tool Wear Condition Prediction Using Vibration Signals in High Speed Machining (HSM) of Titanium (Ti-6Al-4V) Alloy. Procedia Comput. Sci. 2015, 50, 270–275. [Google Scholar] [CrossRef] [Green Version]

- Sezer, E.; Romero, D.; Guedea, F.; Macchi, M.; Emmanouilidis, C. An Industry 4.0-Enabled Low Cost Predictive Maintenance Approach for SMEs. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Kanawaday, A.; Sane, A. Machine learning for predictive maintenance of industrial machines using IoT sensor data. In Proceedings of the 2017 8th IEEE International Conference on Software Engineering and Service Science (ICSESS), Beijing, China, 24–26 November 2017; pp. 87–90. [Google Scholar] [CrossRef]

- Luo, B.; Wang, H.; Liu, H.; Li, B.; Peng, F. Early Fault Detection of Machine Tools Based on Deep Learning and Dynamic Identification. IEEE Trans. Ind. Electron. 2019, 66, 509–518. [Google Scholar] [CrossRef]

- Amruthnath, N.; Gupta, T. A research study on unsupervised machine learning algorithms for early fault detection in predictive maintenance. In Proceedings of the 2018 5th International Conference on Industrial Engineering and Applications (ICIEA), Singapore, 26–28 April 2018; pp. 355–361. [Google Scholar] [CrossRef]

- Praveenkumar, T.; Saimurugan, M.; Krishnakumar, P.; Ramachandran, K. Fault Diagnosis of Automobile Gearbox Based on Machine Learning Techniques. Procedia Eng. 2014, 97, 2092–2098. [Google Scholar] [CrossRef] [Green Version]

- Ben Ali, J.; Saidi, L.; Harrath, S.; Bechhoefer, E.; Benbouzid, M. Online automatic diagnosis of wind turbine bearings progressive degradations under real experimental conditions based on unsupervised machine learning. Appl. Acoust. 2018, 132, 167–181. [Google Scholar] [CrossRef]

- Shao, S.; Sun, W.; Wang, P.; Gao, R.X.; Yan, R. Learning features from vibration signals for induction motor fault diagnosis. In Proceedings of the 2016 International Symposium on Flexible Automation (ISFA), Cleveland, OH, USA, 1–3 August 2016; pp. 71–76. [Google Scholar] [CrossRef]

- Fan, S.K.S.; Hsu, C.Y.; Tsai, D.M.; He, F.; Cheng, C.C. Data-Driven Approach for Fault Detection and Diagnostic in Semiconductor Manufacturing. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1925–1936. [Google Scholar] [CrossRef]

- Gangadhar, N.; Kumar, H.; Narendranath, S.; Sugumaran, V. Fault Diagnosis of Single Point Cutting Tool through Vibration Signal Using Decision Tree Algorithm. Procedia Mater. Sci. 2014, 5, 1434–1441. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Sarmiento, J.R.; Monroy, J.; Moreno, F.A.; Galindo, C.; Bonelo, J.M.; Gonzalez-Jimenez, J. A predictive model for the maintenance of industrial machinery in the context of industry 4.0. Eng. Appl. Artif. Intell. 2020, 87, 103289. [Google Scholar] [CrossRef]

- Amruthnath, N.; Gupta, T. Fault class prediction in unsupervised learning using model-based clustering approach. In Proceedings of the 2018 International Conference on Information and Computer Technologies (ICICT), DeKalb, IL, USA, 23–25 March 2018; pp. 5–12. [Google Scholar] [CrossRef]

- Candanedo, I.; Nieves, E.; González, S.; Martín, M.; Briones, A. Machine learning predictive model for industry 4.0. Commun. Comput. Inf. Sci. 2018, 877, 501–510. [Google Scholar] [CrossRef]

- Strauß, P.; Schmitz, M.; Wöstmann, R.; Deuse, J. Enabling of Predictive Maintenance in the Brownfield through Low-Cost Sensors, an IIoT-Architecture and Machine Learning. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 1474–1483. [Google Scholar] [CrossRef]

- Zabiński, T.; Maoczka, T.; Kluska, J.; Madera, M.; Sȩp, J. Condition monitoring in Industry 4.0 production systems—The idea of computational intelligence methods application. Procedia CIRP 2019, 79, 63–67. [Google Scholar] [CrossRef]

- Wieringa, R.; Maiden, N.; Mead, N.; Rolland, C. Requirements engineering paper classification and evaluation criteria: A proposal and a discussion. Requir. Eng. 2006, 11, 102–107. [Google Scholar] [CrossRef]

- Grishin, E. Development of intelligent algorithms for the continuous diagnostics and condition monitoring subsystem of the equipment as part of the process control system of a stainless steel pipe production enterprise. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 939. [Google Scholar] [CrossRef]

- Neu, D.A.; Lahann, J.; Fettke, P. A systematic literature review on state-of-the-art deep learning methods for process prediction. Artif. Intell. Rev. 2021, 55, 801–827. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.; Vita, R.; Francisco, R.d.P.; Basto, J.P.; Alcalá, S.G. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Tessaro, I.; Mariani, V.C.; Coelho, L.d.S. Machine learning models applied to predictive maintenance in automotive engine components. Multidiscip. Digit. Publ. Inst. Proc. 2020, 64, 26. [Google Scholar]

- Douglas, P.K.; Harris, S.; Yuille, A.; Cohen, M.S. Performance comparison of machine learning algorithms and number of independent components used in fMRI decoding of belief vs. disbelief. Neuroimage 2011, 56, 544–553. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, W.; Yang, D.; Wang, H. Data-driven methods for predictive maintenance of industrial equipment: A survey. IEEE Syst. J. 2019, 13, 2213–2227. [Google Scholar] [CrossRef]

- Saidi, L.; Ali, J.B.; Fnaiech, F. Application of higher order spectral features and support vector machines for bearing faults classification. ISA Trans. 2015, 54, 193–206. [Google Scholar] [CrossRef] [PubMed]

- Sutrisno, E.; Oh, H.; Vasan, A.S.S.; Pecht, M. Estimation of remaining useful life of ball bearings using data driven methodologies. In Proceedings of the 2012 IEEE Conference on Prognostics and Health Management, Denver, CO, USA, 18–21 June 2012; pp. 1–7. [Google Scholar]

- Ali, J.B.; Saidi, L. A new suitable feature selection and regression procedure for lithium-ion battery prognostics. Int. J. Comput. Appl. Technol. 2018, 58, 102–115. [Google Scholar] [CrossRef]

- Kiangala, K.S.; Wang, Z. An effective predictive maintenance framework for conveyor motors using dual time-series imaging and convolutional neural network in an industry 4.0 environment. IEEE Access 2020, 8, 121033–121049. [Google Scholar] [CrossRef]

- Michau, G.; Hu, Y.; Palmé, T.; Fink, O. Feature learning for fault detection in high-dimensional condition monitoring signals. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2020, 234, 104–115. [Google Scholar] [CrossRef]

- Guo, L.; Gao, H.; Huang, H.; He, X.; Li, S. Multifeatures fusion and nonlinear dimension reduction for intelligent bearing condition monitoring. Shock Vib. 2016, 2016, 4632562. [Google Scholar] [CrossRef] [Green Version]

- Ding, X.; He, Q. Energy-fluctuated multiscale feature learning with deep convnet for intelligent spindle bearing fault diagnosis. IEEE Trans. Instrum. Meas. 2017, 66, 1926–1935. [Google Scholar] [CrossRef]

- Guo, X.; Chen, L.; Shen, C. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement 2016, 93, 490–502. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A new convolutional neural network-based data-driven fault diagnosis method. IEEE Trans. Ind. Electron. 2017, 65, 5990–5998. [Google Scholar] [CrossRef]

- Oh, J.W.; Jeong, J. Convolutional neural network and 2-D image based fault diagnosis of bearing without retraining. In Proceedings of the 2019 3rd International Conference on Compute and Data Analysis, Kahului, HI, USA, 14–16 March 2019; pp. 134–138. [Google Scholar]

- Shao, S.; McAleer, S.; Yan, R.; Baldi, P. Highly accurate machine fault diagnosis using deep transfer learning. IEEE Trans. Ind. Inform. 2018, 15, 2446–2455. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L. A transfer convolutional neural network for fault diagnosis based on ResNet-50. Neural Comput. Appl. 2020, 32, 6111–6124. [Google Scholar] [CrossRef]

- Zhao, M.; Zhong, S.; Fu, X.; Tang, B.; Dong, S.; Pecht, M. Deep residual networks with adaptively parametric rectifier linear units for fault diagnosis. IEEE Trans. Ind. Electron. 2020, 68, 2587–2597. [Google Scholar] [CrossRef]

- Marei, M.; El Zaatari, S.; Li, W. Transfer learning enabled convolutional neural networks for estimating health state of cutting tools. Robot.-Comput.-Integr. Manuf. 2021, 71, 102145. [Google Scholar] [CrossRef]

- Han, T.; Liu, C.; Yang, W.; Jiang, D. Deep transfer network with joint distribution adaptation: A new intelligent fault diagnosis framework for industry application. ISA Trans. 2020, 97, 269–281. [Google Scholar] [CrossRef] [Green Version]

- Agogino, A.; Goebel, K. NASA Ames Prognostics Data Repository. 2007. Available online: https://ti.arc.nasa.gov/tech/dash/groups/pcoe/prognostic-data-repository/ (accessed on 27 August 2021).

- Saxena, A.; Goebel, K. Turbofan Engine Degradation Simulation Data Set. 2008. Available online: https://ti.arc.nasa.gov/tech/dash/groups/pcoe/prognostic-data-repository/#turbofan (accessed on 3 September 2021).

- Jia, L.; Zhao, Q.; Tong, L. Retail pricing for stochastic demand with unknown parameters: An online machine learning approach. In Proceedings of the 2013 51st Annual Allerton Conference on Communication, Control, and Computing (Allerton), Monticello, IL, USA, 2–4 October 2013; pp. 1353–1358. [Google Scholar] [CrossRef]

- van Otterlo, M.; Wiering, M. Reinforcement Learning and Markov Decision Processes. In Reinforcement Learning: State-of-the-Art; Wiering, M., van Otterlo, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 3–42. [Google Scholar] [CrossRef]

- Smart, W.D.; Kaelbling, L.P. Practical reinforcement learning in continuous spaces. In Proceedings of the ICML ’00: Proceedings of the Seventeenth International Conference on Machine Learning, San Francisco, CA, USA, 9 June–2 July 2000; pp. 903–910. [Google Scholar]

- Wu, J.; He, H.; Peng, J.; Li, Y.; Li, Z. Continuous reinforcement learning of energy management with deep Q network for a power split hybrid electric bus. Appl. Energy 2018, 222, 799–811. [Google Scholar] [CrossRef]

- Dominey, P.F. Complex sensory-motor sequence learning based on recurrent state representation and reinforcement learning. Biol. Cybern. 1995, 73, 265–274. [Google Scholar] [CrossRef]

- Oliff, H.; Liu, Y.; Kumar, M.; Williams, M.; Ryan, M. Reinforcement learning for facilitating human-robot-interaction in manufacturing. J. Manuf. Syst. 2020, 56, 326–340. [Google Scholar] [CrossRef]

- Park, I.B.; Huh, J.; Kim, J.; Park, J. A Reinforcement Learning Approach to Robust Scheduling of Semiconductor Manufacturing Facilities. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1420–1431. [Google Scholar] [CrossRef]

| Database | Search Results | Search Results Since 2011 |

|---|---|---|

| IEEExplore | 219 | 205 |

| ScienceDirect | 94 | 91 |

| Scopus | 506 | 453 |

| Sum | 819 | 749 |

| Inclusion | published in 2011 or later |

| written in English | |

| available/accessible online | |

| Exclusion | purely medical issues |

| purely network issues | |

| issues not belonging to the manufacturing sector | |

| issues not belonging to CM or PdM | |

| other systematic mapping studies | |

| systematic literature reviews |

| Geographical Provenance | Number of Papers | Proportion |

|---|---|---|

| Canada | 5 | 1.97% |

| China | 29 | 11.42% |

| Germany | 29 | 11.42% |

| Greece | 6 | 2.36% |

| India | 31 | 12.20% |

| Italy | 9 | 3.54% |

| Singapore | 8 | 3.15% |

| Spain | 10 | 3.94% |

| Sweden | 5 | 1.97% |

| United Kingdom | 16 | 6.30% |

| USA | 20 | 7.87% |

| Countries with 1 paper each | 15 | 5.91% |

| Countries with 2 papers each | 18 | 7.09% |

| Countries with 3 papers each | 12 | 4.72% |

| Countries with 4 papers each | 28 | 11.02% |

| No Information | 13 | 5.12% |

| Total | 254 | 100% |

| Technique | Algorithm | No. of Publications | Sum |

|---|---|---|---|

| Classification | Support vector machine | 48 | 119 |

| k-nearest neighbor | 20 | ||

| C4.5 decision tree | 14 | ||

| Other | 37 | ||

| Neural Nets and | Multi-layered perceptron | 23 | 104 |

| Deep Learning | Long short-term memory | 17 | |

| Convolutional neural network | 15 | ||

| Other | 49 | ||

| Ensemble | Random forest | 34 | 63 |

| Methods | Gradient boosting machine | 8 | |

| Adaboost | 4 | ||

| Isolation forest | 4 | ||

| Other | 13 | ||

| Regression | Support vector regression | 13 | 55 |

| Logistic regression | 9 | ||

| Linear regression | 7 | ||

| Other | 26 | ||

| Dimensionality | Principal component analysis | 25 | 39 |

| Reduction | Linear discriminant analysis | 4 | |

| Multidimensional analysis | 2 | ||

| Other | 8 | ||

| Clustering | k-means clustering | 14 | 38 |

| Gaussian mixture model | 9 | ||

| Agglomerative clustering | 3 | ||

| DBSCAN | 3 | ||

| Other | 9 | ||

| Transfer Learning | 5 | ||

| Reinforcement | Deep Q network | 1 | 3 |

| Learning | Double deep Q-learning | 1 | |

| Multi-objective reinforcement | 1 | ||

| Total | 426 |

| Application | Most Cited Publications |

|---|---|

| CM | [24,25,30,31,32] |

| PdM | [26,33,34,35,36] |

| RUL Estimation/Prediction | [37,38,39,40,41] |

| Classification/Identification | [29,42,43,44,45] |

| Prediction | [27,28,46,47,48] |

| Fault Detection | [33,49,50,51,52] |

| Fault Diagnosis | [45,53,54,55,56] |

| Failure Prediction | [28,39,49,57,58] |

| Anomaly Detection | [35,44,59,60,61] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phan, T.L.J.; Gehrhardt, I.; Heik, D.; Bahrpeyma, F.; Reichelt, D. A Systematic Mapping Study on Machine Learning Techniques Applied for Condition Monitoring and Predictive Maintenance in the Manufacturing Sector. Logistics 2022, 6, 35. https://doi.org/10.3390/logistics6020035

Phan TLJ, Gehrhardt I, Heik D, Bahrpeyma F, Reichelt D. A Systematic Mapping Study on Machine Learning Techniques Applied for Condition Monitoring and Predictive Maintenance in the Manufacturing Sector. Logistics. 2022; 6(2):35. https://doi.org/10.3390/logistics6020035

Chicago/Turabian StylePhan, Thuy Linh Jenny, Ingolf Gehrhardt, David Heik, Fouad Bahrpeyma, and Dirk Reichelt. 2022. "A Systematic Mapping Study on Machine Learning Techniques Applied for Condition Monitoring and Predictive Maintenance in the Manufacturing Sector" Logistics 6, no. 2: 35. https://doi.org/10.3390/logistics6020035

APA StylePhan, T. L. J., Gehrhardt, I., Heik, D., Bahrpeyma, F., & Reichelt, D. (2022). A Systematic Mapping Study on Machine Learning Techniques Applied for Condition Monitoring and Predictive Maintenance in the Manufacturing Sector. Logistics, 6(2), 35. https://doi.org/10.3390/logistics6020035