Logistics Work, Ergonomics and Social Sustainability: Empirical Musculoskeletal System Strain Assessment in Retail Intralogistics

Abstract

1. Introduction

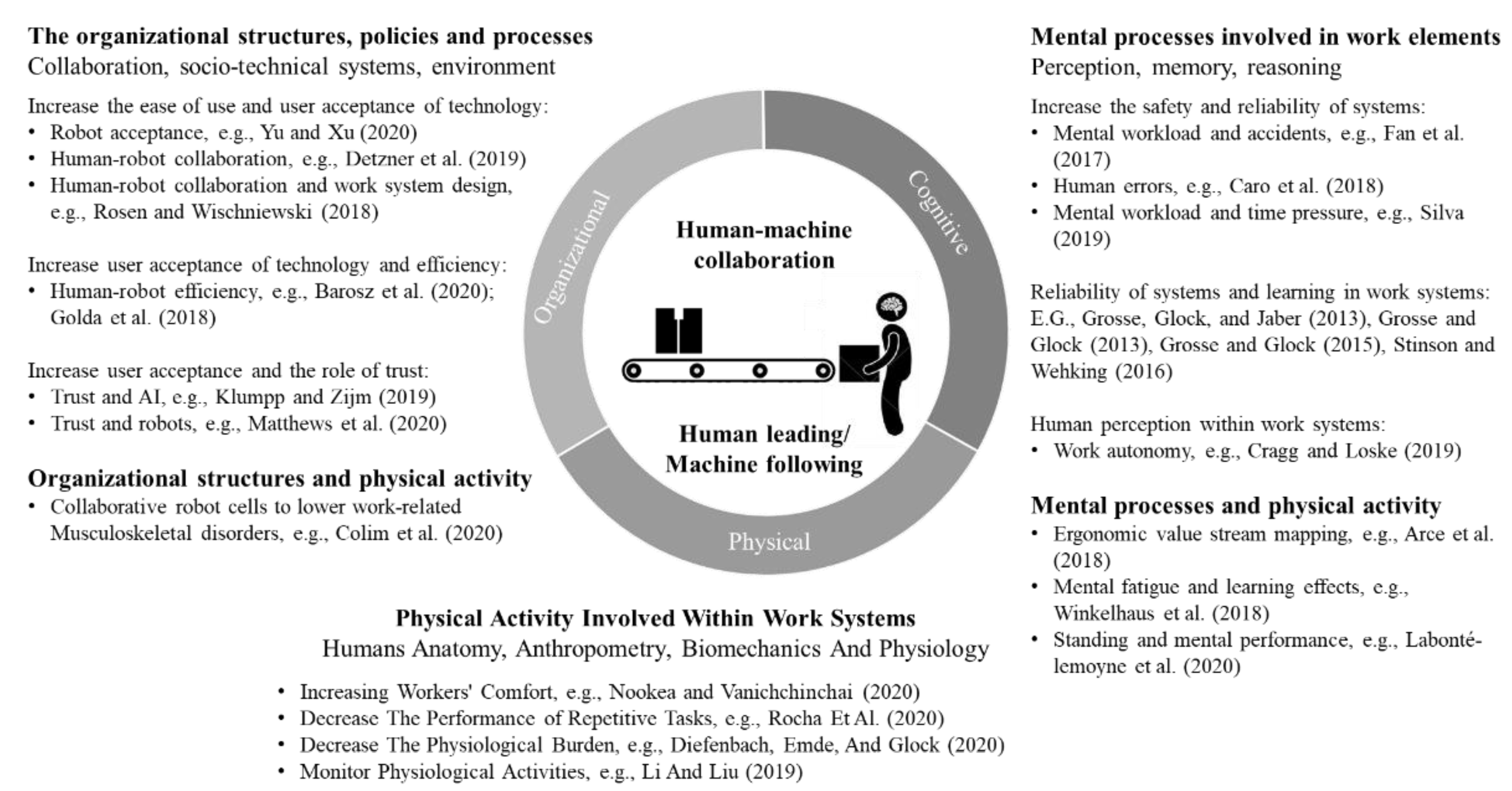

2. Theoretical Framework for Human Factors in Operations

2.1. General Systems Theory and Human-Technology Interaction

2.2. The Human Factor in Human-Machine Collaboration

2.2.1. Organizational Ergonomics

2.2.2. Cognitive Ergonomics

2.2.3. Physical Ergonomics

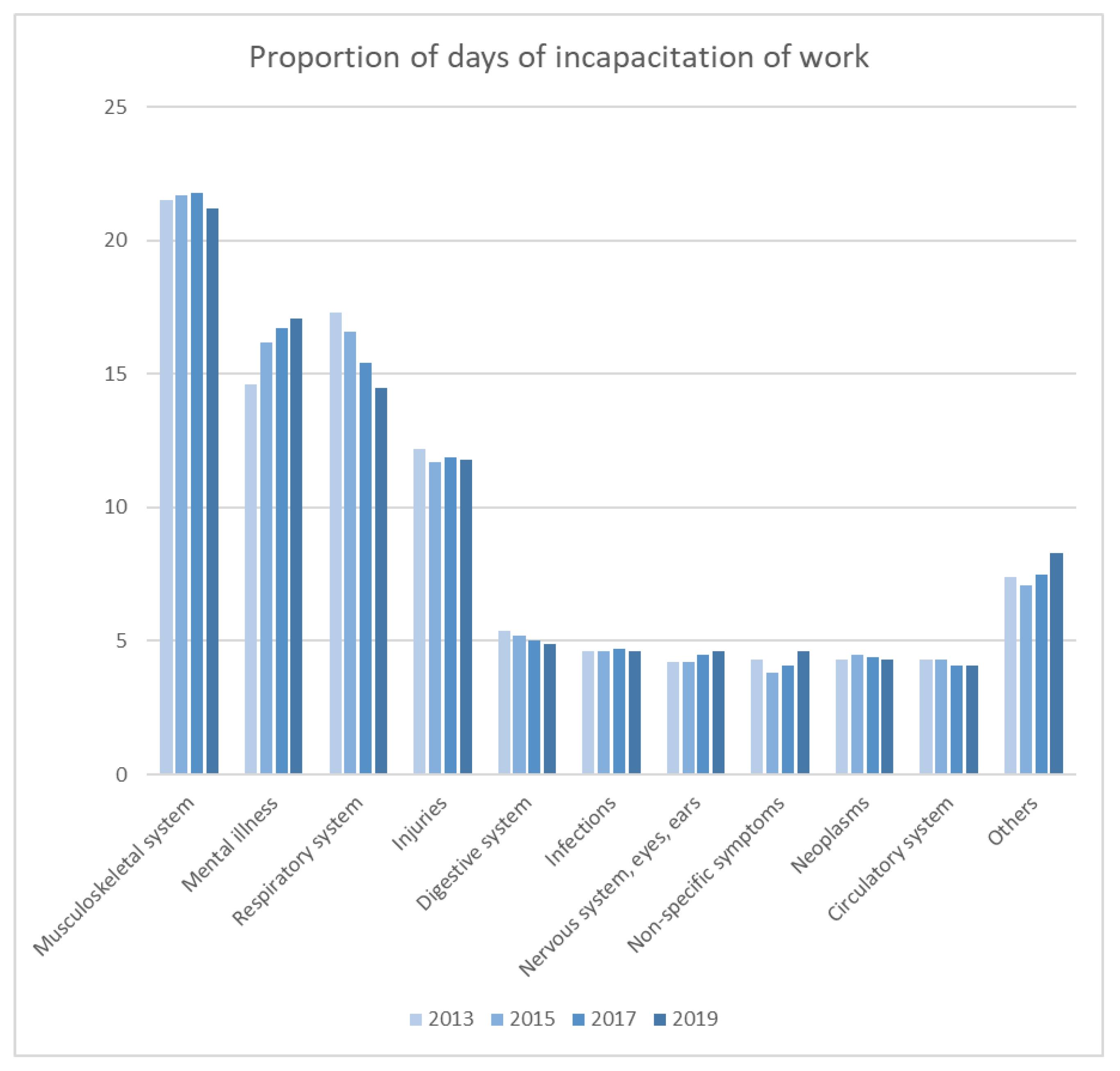

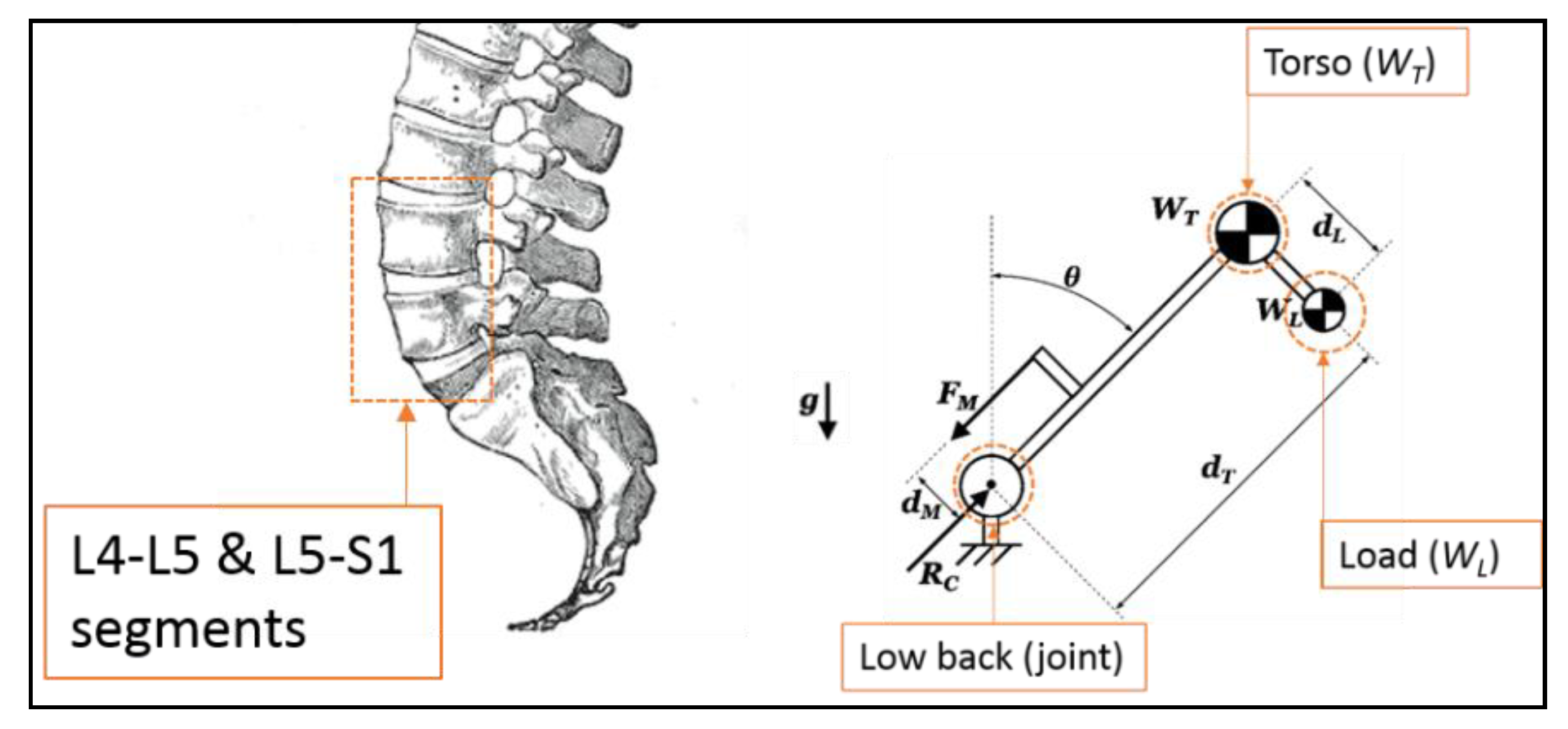

2.2.4. Impact of Low Back Pain

2.3. Low Back Pain and Ergonomics in Retail Operations

3. Research Methods

3.1. Case study Description and Task Selection

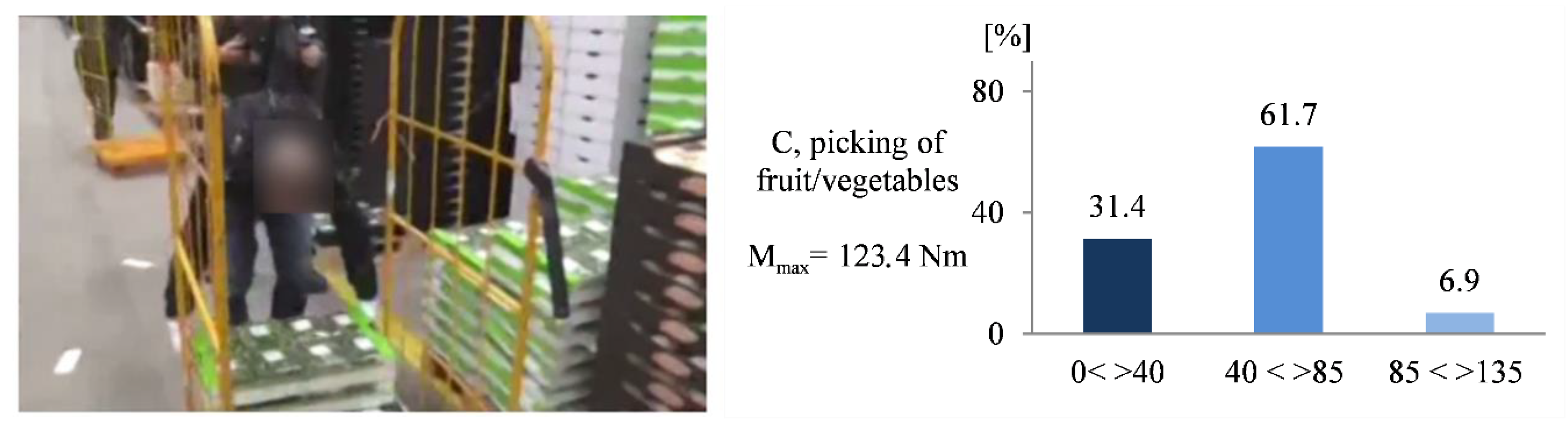

3.2. Methods for Measurements and Evaluation: OWAS and CUELA

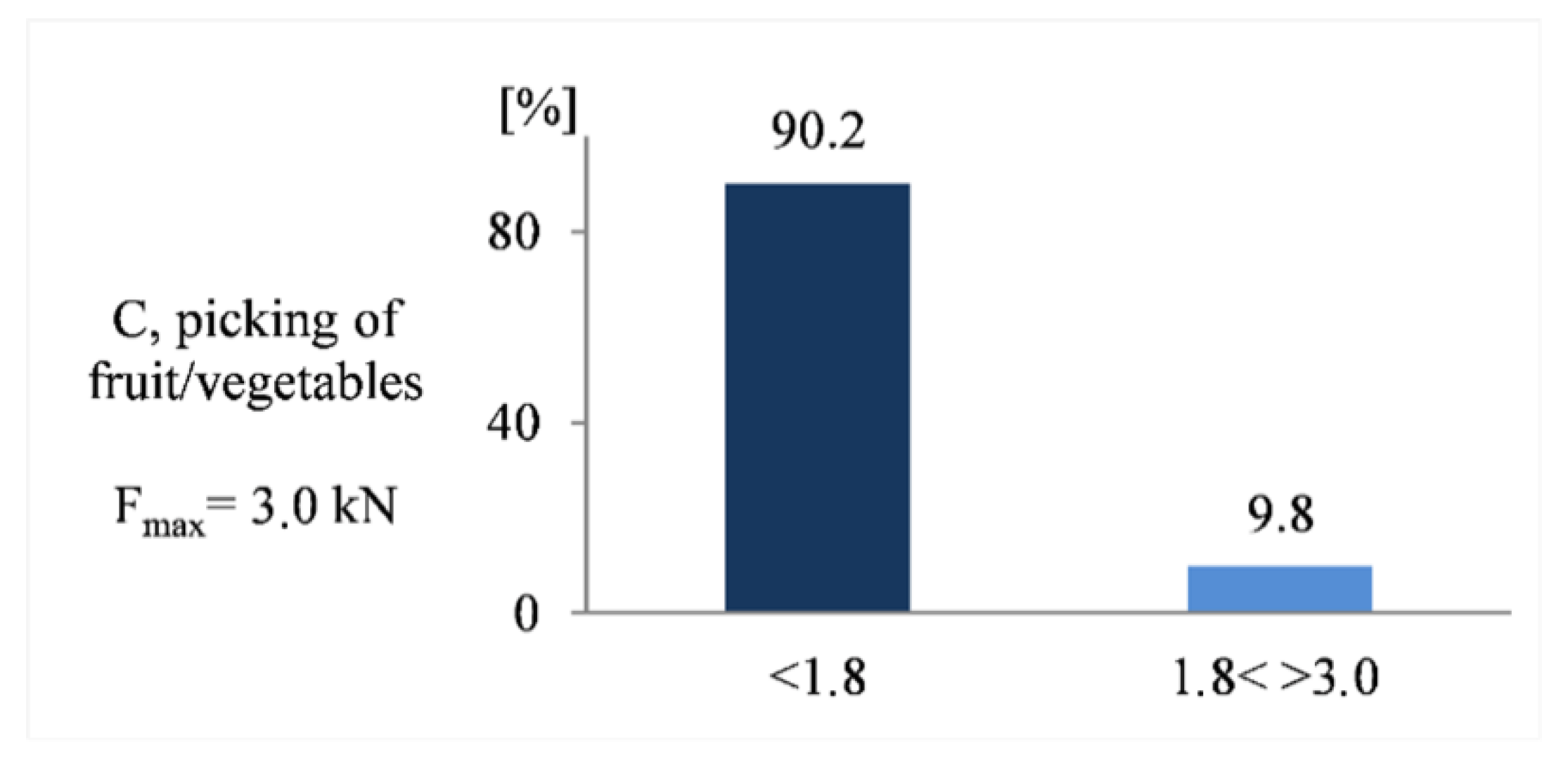

4. Results

5. Discussion

5.1. Areas for Improvement

5.2. Options for Automation and Digitization

5.3. Further Preventive Measures

6. Conclusions and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gualtieri, L.; Palomba, I.; Merati, F.A.; Rauch, E.; Vidoni, R. Design of Human-Centered Collaborative Assembly Workstations for the Improvement of Operators’ Physical Ergonomics and Production Efficiency: A Case Study. Sustainability 2020, 12, 3606. [Google Scholar] [CrossRef]

- Savino, M.M.; Riccio, C.; Menanno, M. Empirical study to explore the impact of ergonomics on workforce scheduling. Int. J. Prod. Res. 2020, 58, 415–433. [Google Scholar] [CrossRef]

- Kong, F. Development of metric method and framework model of integrated complexity evaluations of production process for ergonomics workstations. Int. J. Prod. Res. 2019, 57, 2429–2445. [Google Scholar] [CrossRef]

- Hartvigsen, J.; Hancock, M.J.; Kongsted, A.; Louw, Q.; Ferreira, M.L.; Genevay, S.; Hoy, D.; Karppinen, J.; Pransky, G.; Sieper, J.; et al. What low back pain is and why we need to pay attention. Lancet 2018, 391, 2356–2367. [Google Scholar] [CrossRef]

- Bevan, S. Economic impact of musculoskeletal disorders (MSDs) on work in Europe. Best Pract. Res. Clin. Rheumatol. 2015, 29, 356–373. [Google Scholar] [CrossRef] [PubMed]

- Schofield, D.J.; Shrestha, R.N.; Passey, M.E.; Earnest, A.; Fletcher, S.L. Chronic disease and labour force participation among older Australians. Med. J. Aust. 2008, 189, 447–450. [Google Scholar] [CrossRef]

- Marmot, M.; Allen, J.; Bell, R.; Bloomer, E.; Goldblatt, P.; Consortium for the European Review of Social Determinants of Health and the Health Divide. WHO European review of social determinants of health and the health divide. Lancet 2012, 380, 1011–1029. [Google Scholar] [CrossRef]

- Hullegie, P.; Klein, T.J. The effect of private health insurance on medical care utilization and self-assessed health in Germany. Health Econ. 2010, 19, 1048–1062. [Google Scholar] [CrossRef]

- Thomson, S.; Mossialos, E. Choice of public or private health insurance: Learning from the experience of Germany and the Netherlands. J. Eur. Soc. Policy 2006, 16, 315–327. [Google Scholar] [CrossRef]

- Neumann, W.P.; Winkelhaus, S.; Grosse, E.H.; Glock, C.H. Industry 4.0 and the human factor—A systems framework and analysis methodology for successful development. Int. J. Prod. Econ. 2021, 233, 107992. [Google Scholar] [CrossRef]

- International Ergonomics Association. Human Factors/Ergonomics (HF/E): Definition and Applications. 2021. Available online: https://iea.cc/what-is-ergonomics/#:~:text=Ergonomics%20 (accessed on 3 November 2021).

- Skyttner, L. General Systems Theory; World Scientific Publishing Company: Singapore, 2006. [Google Scholar]

- Clegg, C.W. Sociotechnical principles for system design. Appl. Ergon. 2000, 31, 463–477. [Google Scholar] [CrossRef]

- Patriarca, R.; Falegnami, A.; Costantino, F.; Di Gravio, G.; De Nicola, A.; Villani, M.L. WAx: An integrated conceptual framework for the analysis of cyber-socio-technical systems. Saf. Sci. 2021, 136, 105142. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Fragapane, G.; de Koster, R.B.M.; Sgarbossa, F.; Strandhagen, J.O. Planning and control of autonomous mobile robots for intralogistics: Literature review and research agenda. Eur. J. Oper. Res. 2021, 294, 405–426. [Google Scholar] [CrossRef]

- Schmidtler, J.; Knott, V.; Hölzel, C.; Bengler, K. Human Centered Assistance Applications for the working environment of the future. Occup. Ergon. 2015, 12, 83–95. [Google Scholar] [CrossRef]

- Pasparakis, A.; de Vries, J.; de Koster, R.B.M. In Control or under Control?: Human-Robot Collaboration in Warehouse Order Picking. SSRN J. 2021. [Google Scholar] [CrossRef]

- Autor, D.H. Why Are There Still So Many Jobs?: The History and Future of Workplace Automation. J. Econ. Perspect. 2015, 29, 3–30. [Google Scholar] [CrossRef]

- Deschacht, N. The digital revolution and the labour economics of automation: A review. ROBONOMICS J. Autom. Econ. 2021, 1, 8. [Google Scholar]

- Autor, D.H.; Levy, F.; Murnane, R.J. The Skill Content of Recent Technological Change: An Empirical Exploration. Q. J. Econ. 2003, 118, 1279–1333. [Google Scholar] [CrossRef]

- Lewis, M.A. Operations Management: A Research Overview; Routledge Focus; Routledge: London, UK; New York, NY, USA, 2020. [Google Scholar]

- Schmenner, R.W.; Swink, M.L. On theory in operations management. J. Oper. Manag. 1998, 17, 97–113. [Google Scholar] [CrossRef]

- Lee, J.A.; Chang, Y.S.; Choe, Y.H. Assessment and Comparison of Human-Robot Co-work Order Picking Systems Focused on Ergonomic Factors. In Proceedings of the AHFE 2017 International Conference on Safety Management and Human Factors, Los Angeles, CA, USA, 17–21 July 2017; pp. 516–523. [Google Scholar] [CrossRef]

- Gino, F.; Pisano, G.P. Toward a Theory of Behavioral Operations. Manuf. Serv. Oper. Manag. 2008, 10, 676–691. [Google Scholar] [CrossRef]

- Bendoly, E.; Donohue, K.; Schultz, K.L. Behavior in operations management: Assessing recent findings and revisiting old assumptions. J. Oper. Manag. 2006, 24, 737–752. [Google Scholar] [CrossRef]

- Donohue, K.; Özer, Ö.; Zheng, Y. Behavioral Operations: Past, Present, and Future. Manuf. Serv. Oper. Manag. 2020, 22, 191–202. [Google Scholar] [CrossRef]

- Bendoly, E.; Croson, R.; Goncalves, P.; Schultz, K. Bodies of knowledge for research in behavioral operations. Prod. Oper. Manag. 2010, 19, 434–452. [Google Scholar] [CrossRef]

- Loch, C.H.; Wu, Y. Behavioral Operations Management. Found. Trends Technol. Inf. Oper. Manag. 2005, 1, 121–232. [Google Scholar] [CrossRef]

- Patrick Neumann, W.; Dul, J. Human factors: Spanning the gap between OM and HRM. Int. J. Oper. Prod. Manag. 2010, 30, 923–950. [Google Scholar] [CrossRef]

- Setayesh, A.; Grosse, E.H.; Glock, C.H.; Neumann, W.P. Determining the source of human-system errors in manual order picking with respect to human factors. Int. J. Prod. Res. 2021. [Google Scholar] [CrossRef]

- Bau, L.M.S.; Farias, J.P.; Buso, S.A.; Passero, C.R.M. Organizational ergonomics of occupational health methods and processes in a Brazilian oil refinery. Work 2012, 41 (Suppl. 1), 2817–2821. [Google Scholar] [CrossRef]

- Rosen, P.H.; Wischniewski, S. Task Design in Human-Robot-Interaction Scenarios—Challenges from a Human Factors Perspective. Int. Conf. Hum. Factors Syst. Interact. 2017, 592, 71–82. [Google Scholar] [CrossRef]

- Stadnicka, D.; Antonelli, D. Human-robot collaborative work cell implementation through lean thinking. Int. J. Comput. Integr. Manuf. 2019, 32, 580–595. [Google Scholar] [CrossRef]

- Ender, J.; Wagner, J.C.; Kunert, G.; Larek, R.; Pawletta, T.; Guo, F.B. Design of an Assisting Workplace Cell for Human-Robot Collaboration. In Proceedings of the 2019 International Interdisciplinary PhD Workshop (IIPhDW), Wismar, Germany, 15–17 May 2019; pp. 51–56. [Google Scholar] [CrossRef]

- Klumpp, M.; Zijm, H. Logistics Innovation and Social Sustainability: How to Prevent an Artificial Divide in Human-Computer Interaction. J. Bus. Logist. 2019, 40, 265–278. [Google Scholar] [CrossRef]

- Matthews, G.; Lin, J.; Panganiban, A.R.; Long, M.D. Individual Differences in Trust in Autonomous Robots: Implications for Transparency. IEEE Trans. Hum.-Mach. Syst. 2020, 50, 234–244. [Google Scholar] [CrossRef]

- Barosz, P.; Gołda, G.; Kampa, A. Efficiency Analysis of Manufacturing Line with Industrial Robots and Human Operators. Appl. Sci. 2020, 10, 2862. [Google Scholar] [CrossRef]

- Yu, F.; Xu, L. Factors that influence robot acceptance. Chin. Sci. Bull. 2020, 65, 496–510. [Google Scholar] [CrossRef]

- Detzner, P.; Kirks, T.; Jost, J. A Novel Task Language for Natural Interaction in Human-Robot Systems for Warehouse Logistics. In Proceedings of the 14th International Conference on Computer Science and Education, Toronto, ON, Canada, 19–21 August 2019; pp. 725–730. [Google Scholar] [CrossRef]

- Caro, M.; Quintana, L.; Castillo, M.J.A.; Zea, C. Cognitive Model of a Semi-Mechanized Picking Operation. Rev. Cienc. Salud 2018, 16, 39. [Google Scholar] [CrossRef][Green Version]

- Silva, H.R. Analysis of the Mental Workloads Applied to Press Operators during the Reuse and Recycling of Materials. In Proceedings of the 2nd International Conference on Intelligent Human Systems Integration, San Diego, CA, USA, 7–10 February 2019; Volume 903, pp. 673–678. [Google Scholar] [CrossRef]

- Fan, S.; Yan, X.; Zhang, J.; Wang, J. A review on human factors in maritime transportation using seafarers’ physiological data. In Proceedings of the 4th International Conference on Transportation Information and Safety, Banff, AB, Canada, 8–10 August 2017; pp. 104–110. [Google Scholar] [CrossRef]

- Stinson, M.; Wehking, K.-H. Experimental analysis of manual order picking processes in a Learning Warehouse. Logist. J. Proc. 2016, 2016. [Google Scholar] [CrossRef]

- Grosse, E.H.; Glock, C.H. An experimental investigation of learning effects in order picking systems. J. Manuf. Technol. Manag. 2013, 24, 850–872. [Google Scholar] [CrossRef]

- Grosse, E.H.; Glock, C.H. The effect of worker learning on manual order picking processes. Int. J. Prod. Econ. 2015, 170, 882–890. [Google Scholar] [CrossRef]

- Grosse, E.H.; Glock, C.H.; Jaber, M.Y. The effect of worker learning and forgetting on storage reassignment decisions in order picking systems. Comput. Ind. Eng. 2013, 66, 653–662. [Google Scholar] [CrossRef]

- Shafer, S.M.; Nembhard, D.A.; Uzumeri, M.V. The Effects of Worker Learning, Forgetting, and Heterogeneity on Assembly Line Productivity. Manag. Sci. 2001, 47, 1639–1653. [Google Scholar] [CrossRef]

- Cragg, T.; Loske, D. Perceived work autonomy in order picking systems: An empirical analysis. IFAC-PapersOnLine 2019, 52, 1872–1877. [Google Scholar] [CrossRef]

- Drury, C.G. Global quality: Linking ergonomics and production. Int. J. Prod. Res. 2000, 38, 4007–4018. [Google Scholar] [CrossRef]

- Peters, M.; Quadrat, E.; Nolte, A.; Wolf, A.; Miehling, J.; Wartzack, S.; Leidholdt, W.; Bauer, S.; Fritzsche, L.; Wischniewski, S. Biomechanical Digital Human Models: Chances and Challenges to Expand Ergonomic Evaluation. In Proceedings of the 1st International Conference on Human Systems Engineering and Design, Reims, France, 25–27 October 2018; CHU-Université de Reims Champagne: Ardenne, France; Volume 876, pp. 885–890. [Google Scholar] [CrossRef]

- Li, Y.; Liu, L. Investigation into Ergonomics in Logistics Sorting Equipment. In Proceedings of the IEEE International Conference on Computation, Communication and Engineering, Fujian, China, 8–10 November 2019; pp. 167–169. [Google Scholar] [CrossRef]

- Chaffin, D.B. Improving digital human modelling for proactive ergonomics in design. Ergonomics 2005, 48, 478–491. [Google Scholar] [CrossRef]

- Chaffin, D.B. Human motion simulation for vehicle and workplace design. Hum. Factors Ergon. Manuf. 2007, 17, 475–484. [Google Scholar] [CrossRef]

- Jung, K.; Kwon, O.; You, H. Development of a digital human model generation method for ergonomic design in virtual environment. Int. J. Ind. Ergon. 2009, 39, 744–748. [Google Scholar] [CrossRef]

- Fritzsche, L. Ergonomics risk assessment with digital human models in car assembly: Simulation versus real life. Hum. Factors Ergon. Manuf. 2010, 20, 287–299. [Google Scholar] [CrossRef]

- Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Human Factor Analyser for work measurement of manual manufacturing and assembly processes. Int. J. Adv. Manuf. Technol. 2019, 103, 861–877. [Google Scholar] [CrossRef]

- Sun, X.; Houssin, R.; Renaud, J.; Gerdoni, M. Towards a human factors and ergonomics integration framework in the early product design phase: Function-Task-Behaviour. Int. J. Prod. Res. 2018, 56, 4941–4953. [Google Scholar] [CrossRef]

- van Lingen, P.; van Rhijn, G.; de Looze, M.; Vink, P.; Koningsveld, G.; Tuinzaad, G.; Leskinen, T. ERGOtool for the integral improvement of ergonomics and process flow in assembly. Int. J. Prod. Res. 2002, 40, 3973–3980. [Google Scholar] [CrossRef]

- Ayoub, M.M. Work place design and posture. Hum. Factors 1973, 15, 265–268. [Google Scholar] [CrossRef]

- Jørgensen, K.; Fallentin, N.; Sidenius, B. The strain on the shoulder and neck muscles during letter sorting. Int. J. Ind. Ergon. 1989, 3, 243–248. [Google Scholar] [CrossRef]

- Plonka, F.E. Developing a lean and agile work force. Hum. Factors Ergon. Manuf. 1997, 7, 11–20. [Google Scholar] [CrossRef]

- Rocha, C.; Sousa, I.; Ferreira, F.; Sobreira, H.; Lima, L.; Veiga, G.A.; Moreira, P. Development of an Autonomous Mobile Towing Vehicle for Logistic Tasks. In Robot 2019: Fourth Iberian Robotics Conference; Advances in Intelligent Systems and Computing; Silva, M., Luís Lima, J., Reis, L., Sanfeliu, A., Tardioli, D., Eds.; Springer: Cham, Switzerland, 2020; Volume 1092. [Google Scholar] [CrossRef]

- Diefenbach, H.; Emde, S.; Glock, C.H. Loading tow trains ergonomically for just-in-time part supply. Eur. J. Oper. Res. 2020, 284, 325–344. [Google Scholar] [CrossRef]

- Chander, H.; Burch, R.F.; Talegaonkar, P.; Saucier, D.; Luczak, T.; Ball, J.E.; Turner, A.; Kodithuwakka Arachige, S.N.K.; Caroll, W.; Smith, B.K.; et al. Wearable Stretch Sensors for Human Movement Monitoring and Fall Detection in Ergonomics. Int. J. Environ. Res. Public Health 2020, 17, 3554. [Google Scholar] [CrossRef] [PubMed]

- Nookea, W.; Vanichchinchai, A. An Ergonomics-Based Storage Bin Allocation for Picking Efficiency Improvement. In Proceedings of the 7th International Conference on Industrial Engineering and Applications, Bangkok, Thailand, 16–21 April 2020; pp. 307–310. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Sgarbossa, F.; Calzavara, M.; Grosse, E.H. The effects of human fatigue on learning in order picking: An explorative experimental investigation. IFAC-PapersOnLine 2018, 51, 832–837. [Google Scholar] [CrossRef]

- Labonté-LeMoyne, E.; Jutras, M.-A.; Léger, P.-M.; Senecal, S.; Fredette, M.; Begon, M.; Mathieu, M.-E. Does Reducing Sedentarity with Standing Desks Hinder Cognitive Performance? Hum. Factors 2020, 62, 603–612. [Google Scholar] [CrossRef] [PubMed]

- Arce, A.; Romero-Dessens, L.F.; Leon-Duarte, J.A. Ergonomic Value Stream Mapping: A Novel Approach to Reduce Subjective Mental Workload. In Advances in Social & Occupational Ergonomics, Proceedings of the AHFE 2017 International Conference on Social & Occupational Ergonomics, The Westin Bonaventure Hotel, Los Angeles, CA, USA, 17–21 July 2017; Goosens, R.H.M., Ed.; Springer: Cham, Switzerland, 2018; Volume 605, pp. 307–317. [Google Scholar]

- Colim, A.; Faria, C.; Braga, A.C.; Sousa, N.; Rocha, L.; Carneiro, P.; Costa, N.; Arezes, P. Towards an Ergonomic Assessment Framework for Industrial Assembly Workstations—A Case Study. Appl. Sci. 2020, 10, 3048. [Google Scholar] [CrossRef]

- Gołda, G.; Kampa, A.; Paprocka, I. Analysis of human operators and industrial robots performance and reliability. Manag. Prod. Eng. Rev. 2019, 9, 24–33. [Google Scholar] [CrossRef]

- Hoy, D.; Bain, C.; Williams, G.; March, L.; Brooks, P.; Blyth, F.; Woolf, A.; Vos, T.; Buchbinder, R. A systematic review of the global prevalence of low back pain. Arthritis Rheum. 2012, 64, 2028–2037. [Google Scholar] [CrossRef]

- Kamper, S.J.; Henschke, N.; Hestbaek, L.; Dunn, K.M.; Williams, C.M. Musculoskeletal pain in children and adolescents. Braz. J. Phys. Ther. 2016, 20, 275–284. [Google Scholar] [CrossRef]

- Veale, D.J.; Woolf, A.D.; Carr, A.J. Chronic musculoskeletal pain and arthritis: Impact, attitudes and perceptions. Ir. Med. J. 2008, 101, 208–210. [Google Scholar] [PubMed]

- European Commission. Commission Asks Workers and Employers What Action Should Be Taken to Combat Musculoskeletal Disorders. 2004. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_04_1358 (accessed on 6 April 2020).

- Maniadakis, N.; Gray, A. The economic burden of back pain in the UK. Pain 2000, 84, 95–103. [Google Scholar] [CrossRef]

- Deyo, R.A.; Mirza, S.K.; Turner, J.A.; Brook, I.M. Overtreating chronic back pain: Time to back off? J. Am. Board Fam. Med. JABFM 2009, 22, 62–68. [Google Scholar] [CrossRef]

- Maher, C.; Underwood, M.; Buchbinder, R. Non-specific low back pain. Lancet 2017, 389, 736–747. [Google Scholar] [CrossRef]

- Hartvigsen, J.; Natvig, B.; Ferreira, M. Is it all about a pain in the back? Best practice & research. Clin. Rheumatol. 2013, 27, 613–623. [Google Scholar] [CrossRef]

- Määttä, J.H.; Karppinen, J.; Paananen, M.; Bow, C.; Luk, K.D.K.; Cheung, K.M.C.; Samartzis, D. Refined Phenotyping of Modic Changes: Imaging Biomarkers of Prolonged Severe Low Back Pain and Disability. Medicine 2016, 95, e3495. [Google Scholar] [CrossRef]

- Brinjikji, W.; Diehn, F.E.; Jarvik, J.G.; Carr, C.M.; Kallmes, D.F.; Murad, M.H.; Luetmer, P.H. MRI Findings of Disc Degeneration are More Prevalent in Adults with Low Back Pain than in Asymptomatic Controls: A Systematic Review and Meta-Analysis. AJNR. Am. J. Neuroradiol. 2015, 36, 2394–2399. [Google Scholar] [CrossRef]

- Maas, E.T.; Juch, J.N.S.; Ostelo, R.W.J.G.; Groeneweg, J.G.; Kallewaard, J.W.; Koes, B.W.; Verhagen, A.P.; Huygen, F.J.M.; van Tulder, M.W. Systematic review of patient history and physical examination to diagnose chronic low back pain originating from the facet joints. Eur. J. Pain 2017, 21, 403–414. [Google Scholar] [CrossRef] [PubMed]

- Maas, E.T.; Ostelo Raymond, W.J.G.; Niemisto, L.; Jousimaa, J.; Hurri, H.; Malmivaara, A.; van Tulder, M.W. Radiofrequency denervation for chronic low back pain. Cochrane Database Syst. Rev. 2015. [Google Scholar] [CrossRef] [PubMed]

- Hancock, M.J.; Maher, C.G.; Latimer, J.; Spindler, M.F.; McAuley, J.H.; Laslett, M.; Bogduk, N. Systematic review of tests to identify the disc, SIJ or facet joint as the source of low back pain. Eur. Spine J. 2007, 16, 1539–1550. [Google Scholar] [CrossRef]

- Schousboe, J.T. Epidemiology of Vertebral Fractures. J. Clin. Densitom. Off. J. Int. Soc. Clin. Densitom. 2016, 19, 8–22. [Google Scholar] [CrossRef] [PubMed]

- Stolwijk, C.; van Onna, M.; Boonen, A.; van Tubergen, A. Global Prevalence of Spondyloarthritis: A Systematic Review and Meta-Regression Analysis. Arthritis Care Res. 2016, 68, 1320–1331. [Google Scholar] [CrossRef]

- Lewandrowski, K.-U. Retrospective analysis of accuracy and positive predictive value of preoperative lumbar MRI grading after successful outcome following outpatient endoscopic decompression for lumbar foraminal and lateral recess stenosis. Clin. Neurol. Neurosurg. 2019, 179, 74–80. [Google Scholar] [CrossRef] [PubMed]

- Campbell, P.; Bishop, A.; Dunn, K.M.; Main, C.J.; Thomas, E.; Foster, N.E. Conceptual overlap of psychological constructs in low back pain. Pain 2013, 154, 1783–1791. [Google Scholar] [CrossRef]

- Lee, H.; Hübscher, M.; Moseley, G.L.; Kamper, S.J.; Traeger, A.C.; Mansell, G.; McAuley, J.H. How does pain lead to disability? A systematic review and meta-analysis of mediation studies in people with back and neck pain. Pain 2015, 156, 988–997. [Google Scholar] [CrossRef]

- Frost, H.; Klaber Moffett, J.A.; Moser, J.S.; Fairbank, J.C. Randomised controlled trial for evaluation of fitness programme for patients with chronic low back pain. BMJ (Clin. Res. Ed.) 1995, 310, 151–154. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Statistika. Number of Incapacitation for Work in Days in Germany by Diagnosis for the Years 2013–2019. 2021. Available online: https://de.statista.com/statistik/daten/studie/77239/umfrage/krankheit---hauptursachen-fuer-arbeitsunfaehigkeit/ (accessed on 8 November 2021).

- Garg, A.; Boda, S.; Hegmann, K.T.; Moore, J.S.; Kapellusch, J.M.; Bhoyar, P.; Thiese, M.S.; Merryweather, A.; Deckow-Schaefer, G.; Bloswick, D.; et al. The NIOSH lifting equation and low-back pain, Part 1: Association with low-back pain in the backworks prospective cohort study. Hum. Factors 2014, 56, 6–28. [Google Scholar] [CrossRef]

- Meakin, J.R.; Smith, F.W.; Gilbert, F.J.; Aspden, R.M. The effect of axial load on the sagittal plane curvature of the upright human spine in vivo. J. Biomech. 2008, 41, 2850–2854. [Google Scholar] [CrossRef] [PubMed]

- Richards, G. Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse, 3rd ed.; Kogan Page: London, UK; New York, NY, USA; New Dehli, India, 2018. [Google Scholar]

- Mowrey, C.H.; Parikh, P.J. Mixed-width aisle configurations for order picking in distribution centers. Eur. J. Oper. Res. 2014, 232, 87–97. [Google Scholar] [CrossRef]

- Rao, S.S.; Adil, G.K. Class-based storage with exact S-shaped traversal routeing in low-level picker-to-part systems. Int. J. Prod. Res. 2013, 51, 4979–4996. [Google Scholar] [CrossRef]

- Petersen, C.G.; Aase, G. A comparison of picking, storage, and routing policies in manual order picking. Int. J. Prod. Econ. 2004, 92, 11–19. [Google Scholar] [CrossRef]

- de Koster, R.B.M.; Le-Duc, T.; Roodbergen, K.J. Design and control of warehouse order picking: A literature review. Eur. J. Oper. Res. 2007, 182, 481–501. [Google Scholar] [CrossRef]

- Yang, P.; Zhao, Z.; Guo, H. Order batch picking optimization under different storage scenarios for e-commerce warehouses. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101897. [Google Scholar] [CrossRef]

- Ayres, R.U.; Kneese, A.V. Production, Consumption, and Externalities. Am. Econ. Rev. 1969, 59, 282–297. [Google Scholar]

- Spash, C. The Development of Environmental Thinking in Economics. Environ. Values 1999, 8, 413–435. [Google Scholar] [CrossRef]

- Glock, C.H.; Grosse, E.H.; Abedinnia, H.; Emde, S. An integrated model to improve ergonomic and economic performance in order picking by rotating pallets. Eur. J. Oper. Res. 2019, 273, 516–534. [Google Scholar] [CrossRef]

- Toxiri, S.; Koopman, A.S.; Lazzaroni, M.; Ortiz, J.; Power, V.; de Looze, M.P.; O’Sullivan, L.; Caldwell, D.G. Rationale, Implementation and Evaluation of Assistive Strategies for an Active Back-Support Exoskeleton. Front. Robot. AI 2018, 5, 53. [Google Scholar] [CrossRef]

- Toxiri, S.; Ortiz, J.; Masood, J.; Fernandez, J.; Mateos, L.A.; Caldwell, D.G. A wearable device for reducing spinal loads during lifting tasks: Biomechanics and design concepts. In Proceedings of the 2015 IEEE International Conference on Robotics and Biomimetics (ROBIO), Zhuhai, China, 6–9 December 2015; pp. 2295–2300. [Google Scholar]

- Anderson, C.K.; Chaffin, D.B.; Herrin, G.D.; Matthews, L.S. A biomechanical model of the lumbosacral joint during lifting activities. J. Biomech. 1985, 18, 571–584. [Google Scholar] [CrossRef]

- Reeves, N.P.; Cholewicki, J. Modeling the human lumbar spine for assessing spinal loads, stability, and risk of injury. Crit. Rev. Biomed. Eng. 2003, 31, 73–139. [Google Scholar] [CrossRef]

- Ellegast, R.; Hermanns, I.; Hamburger, R. Long-term measurement and analysis of physical workload with CUELA. In Proceedings of the 12th Joint Conference of the Trade Association for Food and Restaurants and Friedrich Schiller, University of Jena, Jena, Germany, 15 July 2005. [Google Scholar]

- Freitag, S.; Ellegast, R.; Dulon, M.; Nienhaus, A. Quantitative measurement of stressful trunk postures in nursing professions. Ann. Occup. Hyg. 2007, 51, 385–395. [Google Scholar] [CrossRef][Green Version]

- Karhu, O.; Kansi, P.; Kuorinka, I. Correcting working postures in industry: A practical method for analysis. Appl. Ergon. 1977, 8, 199–201. [Google Scholar] [CrossRef]

- Zink, K.J.; Fischer, K. Human Factors and Ergonomics: Contribution to Sustainability and Decent Work in Global Supply Chains. In Ergonomics and Human Factors for a Sustainable Future: Current Research and Future Possibilities; Thatcher, A., Yeow, P.H., Eds.; Springer: Singapore, 2018; pp. 243–269. [Google Scholar]

- Aromaa, S.; Väänänen, K. Suitability of virtual prototypes to support human factors/ergonomics evaluation during the design. Appl. Erg. 2016, 56, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Viikari-Juntura, E.; Rauas, S.; Martikainen, R.; Kuosma, E.; Riihimäki, H.; Takala, E.P.; Saarenmaa, K. Validity of self-reported physical work load in epidemiologic studies on musculoskeletal disorders. Scand. J. Work. Environ. Health 1996, 22, 251–259. [Google Scholar] [CrossRef]

- Kant, I.J.; de Jong, L.C.; van Rijssen-Moll, M.; Borm, P.J. A survey of static and dynamic work postures of operating room staff. Int. Arch. Occup. Environ. Health 1992, 63, 423–428. [Google Scholar] [CrossRef] [PubMed]

- Hellig, T.; Mertens, A.; Brandl, C. The interaction effect of working postures on muscle activity and subjective discomfort during static working postures and its correlation with OWAS. Int. J. Ind. Ergon. 2018, 68, 25–33. [Google Scholar] [CrossRef]

- Standard ISO 11226:2000. Ergonomics—Evaluation of Postures at Work; ISO: Geneva, Switzerland, 2000. [Google Scholar]

- Standard EN 1005-4. Human Physical Performance Part 4: Assessment of Postures and Movements When Working on Machines; CEN: Brussels, Belgium, 2009. [Google Scholar]

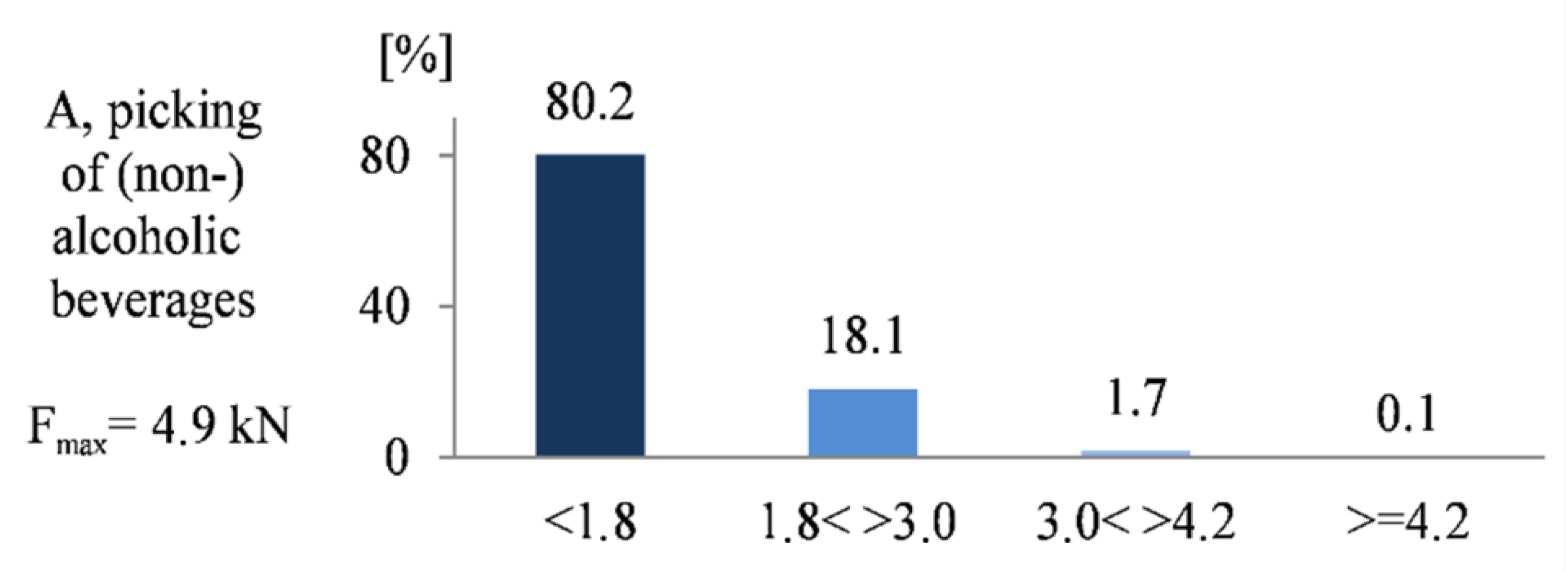

- Jäger, M.; Luttmann, A.; Göllner, R.; Laurig, W. The Dortmunder—Biomechanical Model for Quantification and Assessment of the Load on the Lumbar Spine. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Jäger, M. Die „qRevidierten Dortmunder Richtwerte“. Zent. Arb. Arb. Und Ergon. 2019, 69, 271–289. [Google Scholar] [CrossRef]

- Calzavara, M.; Glock, C.H.; Grosse, E.H.; Persona, A.; Sgarbossa, F. Analysis of economic and ergonomic performance measures of different rack layouts in an order picking warehouse. Comput. Ind. Eng. 2017, 111, 527–536. [Google Scholar] [CrossRef]

- Foster, N.E.; Anema, J.R.; Cherkin, D.; Chou, R.; Cohen, S.P.; Gross, D.P.; Feirreira, P.H.; Fritz, J.M.; Koes, B.W.; Peul, W.; et al. Prevention and treatment of low back pain: Evidence, challenges, and promising directions. Lancet 2018, 391, 2368–2383. [Google Scholar] [CrossRef]

- Straub, N.; Kaczmarek, S.; Hegmanns, T.; Niehues, S. Logistics 4.0—Changing Logistics Processes: Technological Changes in Logistics Systems and their Influence on the Working Environment in the Operative Logistics. Ind. 4.0 Manag. 2017, 33, 47. [Google Scholar]

- Battini, D.; Calzavara, M.; Persona, A.; Sgarbossa, F. Additional effort estimation due to ergonomic conditions in order picking systems. Int. J. Prod. Res. 2017, 55, 2764–2774. [Google Scholar] [CrossRef]

- Battini, D.; Glock, C.H.; Grosse, E.H.; Persona, A.; Sgarbossa, F. Human energy expenditure in order picking storage assignment: A bi-objective method. Comput. Ind. Eng. 2016, 94, 147–157. [Google Scholar] [CrossRef]

- Grosse, E.H.; Glock, C.H.; Jaber, M.Y.; Neumann, W.P. Incorporating human factors in order picking planning models: Framework and research opportunities. Int. J. Prod. Res. 2015, 53, 695–717. [Google Scholar] [CrossRef]

- Cherniack, M.; Dussetschleger, J.; Dugan, A.; Farr, D.; Namazi, S.; Ghaziri, M.E.; Henning, R. Participatory action research in corrections: The HITEC 2 program. Appl. Ergon. 2016, 53 Pt A, 169–180. [Google Scholar] [CrossRef]

- Mangan, J.; Lalwani, C.; Gardner, B. Combining quantitative and qualitative methodologies in logistics research. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 565–578. [Google Scholar] [CrossRef]

- Kovács, G.; Spens, K.M. Abductive reasoning in logistics research. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 132–144. [Google Scholar] [CrossRef]

- Näslund, D. Logistics needs qualitative research—Especially action research. Int. J. Phys. Distrib. Logist. Manag. 2002, 32, 321–338. [Google Scholar] [CrossRef]

- Haslam, R. Targeting ergonomics interventions—Learning from health promotion. Appl. Ergon. 2002, 33, 241–249. [Google Scholar] [CrossRef]

- Oakman, J.; Rothmore, P.; Tappin, D. Intervention development to reduce musculoskeletal disorders: Is the process on target? Appl. Ergon. 2016, 56, 179–186. [Google Scholar] [CrossRef]

- Hensel, R.; Keil, M.; Bawin, S. Field study investigating the Laevo exoskeleton with regard to usability, discomfort and intention to use. In Proceedings of the 64th Spring Conference of the German Ergonomics Society; Gesellschaft für Arbeitswissenschaft, D., Ed.; GfA Summit Essen: Berlin, Germany, 2018. [Google Scholar]

- Gomes-Neto, M.; Lopes, J.M.; Conceição, C.S.; Araujo, A.; Brasileiro, A.; Sousa, C.; Carvalho, V.O.; Arcanjo, F.L. Stabilization exercise compared to general exercises or manual therapy for the management of low back pain: A systematic review and meta-analysis. Phys. Ther. Sport Off. J. Assoc. Chart. Physiother. Sports Med. 2017, 23, 136–142. [Google Scholar] [CrossRef]

- Chang, W.-D.; Lin, H.-Y.; Lai, P.-T. Core strength training for patients with chronic low back pain. J. Phys. Ther. Sci. 2015, 27, 619–622. [Google Scholar] [CrossRef] [PubMed]

- Searle, A.; Spink, M.; Ho, A.; Chuter, V. Exercise interventions for the treatment of chronic low back pain: A systematic review and meta-analysis of randomised controlled trials. Clin. Rehabil. 2015, 29, 1155–1167. [Google Scholar] [CrossRef]

- van Middelkoop, M.; Rubinstein, S.M.; Verhagen, A.P.; Ostelo, R.W.; Koes, B.W.; van Tulder, M.W. Exercise therapy for chronic nonspecific low-back pain. Best Pract. Research. Clin. Rheumatol. 2010, 24, 193–204. [Google Scholar] [CrossRef] [PubMed]

- Manniche, C.; Bentzen, L.; Hesselsøe, G.; Christiansen, I.; Lundberg, E. Clinical trial of intensive muscle training for chronic low back pain. Lancet 1988, 332, 1473–1476. [Google Scholar] [CrossRef]

- Thompson, W.R. Worldwide survey of fitness trends for 2017. ACSM’s Health Fit. J. 2016, 20, 8–17. [Google Scholar] [CrossRef]

- Loske, D.; Klumpp, M. Human-AI collaboration in route planning: An empirical efficiency-based analysis in retail logistics. Int. J. Prod. Econ. 2021, 241, 108236. [Google Scholar] [CrossRef]

- Willnat, M.; Lembcke, T.; Harnischmacher, C.; Prinz, C.; Klumpp, M. How Far are You Gonna Go? Understanding Pedestrian Catchment Areas in Shared Mobility Systems. ICIS 2021 Proceedings. Available online: https://aisel.aisnet.org/icis2021/is_sustain/is_sustain/3 (accessed on 8 November 2021).

- Klumpp, M. Artificial Divide: The New Challenge of Human-Artificial Performance in Logistics. In Innovative Produkte und Dienstleistungen in der Mobilität; Proff, H., Fojcik, T., Eds.; Springer: Wiesbaden, Gemmary, 2017. [Google Scholar] [CrossRef]

- Chou, X.; Pietri, N.O.; Loske, D.; Klumpp, M.; Montemanni, R. Optimization Strategies for In-Store Order Picking in Omnichannel Retailing. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems. APMS 2021. IFIP Advances in Information and Communication Technology, 631; Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D., Eds.; Springer Nature: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Loske, D.; Klumpp, M. Learning effects and mental fatigue of forklift operators in food retail logistics: An empirical analysis through the lens of behavioral operations management. IFAC-PapersOnLine 2021, 54, 19–24. [Google Scholar] [CrossRef]

- Awaysheh, A.; Frohlich, M.T.; Flynn, B.B.; Flynn, P.J. To err is human: Exploratory multilevel analysis of supply chain delivery delays. J. Oper. Manag. 2021. [Google Scholar] [CrossRef]

- Klumpp, M.; Ruiner, C. Digital Supply Chains and the Human Factor; Springer Nature: Cham, Switzerland, 2021. [Google Scholar]

| Class | Code | Posture |

|---|---|---|

| Back | 1 | Straight |

| 2 | bent (forward/backward) | |

| 3 | turned or bent sideways (left/right) | |

| 4 | turned and bent or bent sideways and forward | |

| Arms | 1 | both below shoulder height |

| 2 | one arm at shoulder height or above | |

| 3 | both arms at shoulder height or above | |

| Legs | 1 | sitting |

| 2 | standing, both legs straight | |

| 3 | standing on one leg | |

| 4 | standing, knees bent | |

| 5 | standing, one knee bent | |

| 6 | kneeling (one or both legs) | |

| 7 | walking/moving | |

| Load | 1 | <10 kg (≈100 N) |

| 2 | 10 to 20 kg (≈100–200 N) | |

| 3 | >20 kg (≈200 N) |

| Evaluation (Boundaries in °, Absolute Values) | |||

|---|---|---|---|

| Parameter | Acceptable | Cond. Acceptable | Not Acceptable |

| Head tilt | 0 to 25 | 25 to 85 | >85 (flexion) |

| <0 (extension) | |||

| Head tilt (side) | 10 | >10 | |

| Neck torsion | 45 | >45 | |

| Neck bend | 0 to 25 | >25 (flexion) | |

| <0 (extension) | |||

| Trunk inclination | 0 to 20 | 20 to 60 | >60 (flexion) |

| <0 (extension) | |||

| Trunk inclination (side) | 10 | 10 to 20 | >20 |

| Back bend | 0 to 20 | 20 to 40 | >40 (flexion) |

| <0 (extension) | |||

| Back torsion | 10 | 10 to 20 | >20 |

| Shoulder joint | 0 to 20 | −20 to −60 | <−60 (abduction) |

| (abduction/adduction) | >0 (adduction) | ||

| Shoulder joint | 0 to 20 | 20 to 60 | <0 (extension) |

| (flexion/extension) | >0 (flexion) | ||

| Boundaries in Nm | |||

| L5/S1 external moment | 0 to 40 | 40 to 85 | 85 to 135 |

| L5/S1 compressive forces (men) | 0.7 to 2.3 | 2.3 to 3.2 | >3.2 |

| L5/S1 compressive forces(women) | 0.7 to 1.8 | 1.8 to 2.5 | >2.5 |

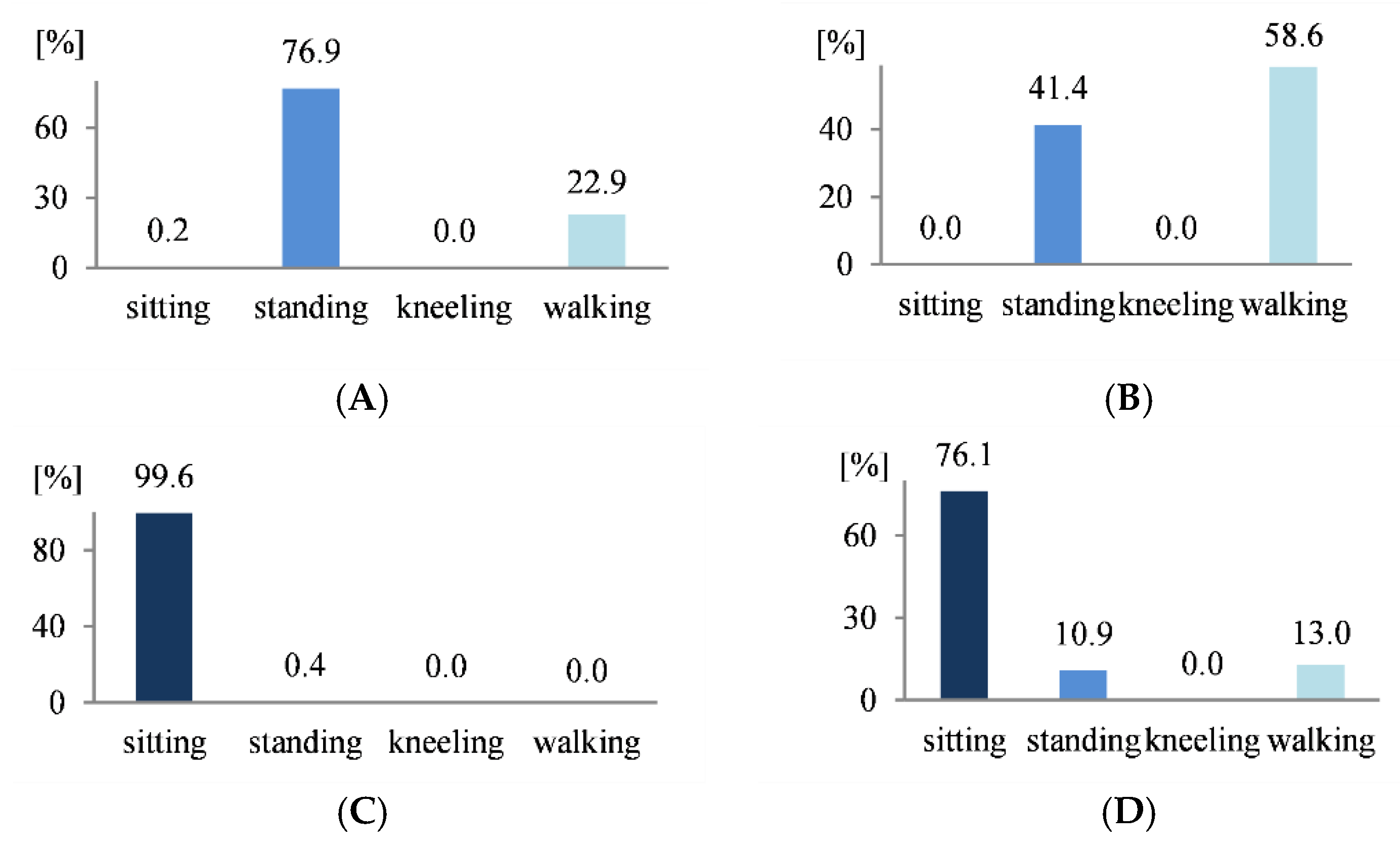

| Ratios per Activity (%) | ||||||

|---|---|---|---|---|---|---|

| Class | Code | Posture | A | B | C | D |

| Back | 1 | Straight | 75.0 | 92.1 | 84.4 | 92.2 |

| 2 | bent (forward/backward) | 16.1 | 1.8 | 8.9 | 4.9 | |

| 3 | turned or bent sideways (left/right) | 8.5 | 6.0 | 6.2 | 2.8 | |

| 4 | turned and bent or bent sideways and forward | 0.3 | 0.0 | 0.5 | 0.1 | |

| Arms | 1 | both below shoulder height | 94.7 | 96.6 | 92.9 | 97.6 |

| 2 | one arm at shoulder height or above | 4.7 | 3.3 | 5.8 | 2.4 | |

| 3 | both arms at shoulder height or above | 0.6 | 0.2 | 1.4 | 0.0 | |

| Legs | 1 | Sitting | 0.2 | 99.6 | 0.0 | 76.1 |

| 2 | standing, both legs straight | 65.4 | 0.4 | 40.7 | 8.2 | |

| 3 | standing on one leg | 0.0 | 0.0 | 0.0 | 0.0 | |

| 4 | standing, knees bent | 11.5 | 0.0 | 0.7 | 2.7 | |

| 5 | standing, one knee bent | 0.0 | 0.0 | 0.0 | 0.0 | |

| 6 | kneeling (one or both legs) | 0.0 | 0.0 | 0.0 | 0.0 | |

| 7 | walking/moving | 22.9 | 0.0 | 58.6 | 13.0 | |

| Load | 1 | <10 kg (≈100 N) | 99.5 | 100.0 | 100.0 | 99.8 |

| 2 | 10 to 20 kg (≈100–200 N) | 0.5 | 0.0 | 0.0 | 0.2 | |

| 3 | >20 kg (≈200 N) | 0.0 | 0.0 | 0.0 | 0.0 | |

| Activity (Example) | Example Postures (OWAS, CUELA) | Thresholds | Ergonomic Measures (Example) |

|---|---|---|---|

| Operation of warehouse vehicle, sitting, facing shelves | 3111 | Head tilt (side) > 10° | Variations in rack layouts and pallet storage systems [119] |

| Picking | 2141, 2142 | For 2141: Shoulder joint flexion > 60° For 2142: weight > 10 kg or shoulder joint flexion > 20° | Variations in rack layouts and pallet storage systems [119] |

| Picking, Carrying of loads (walking) | 217x, e.g., 2171 | Trunk inclination > 20° and/or weight > 10 kg; any back curvature > 20° | Exoskeletons |

| Field of Activity | Measures in Operational Health Management Program |

|---|---|

| Workplace | Warehouse layout optimization with regard to the average weight of SKU, e.g., article placement always in the storage place best accessible in an ergonomic human perspective Opening of a fitness room for free use to enable warm-up stretching and stretch breaks, as well as a workplace athlete training |

| Workforce | Implementation of a job rotation mechanism to avoid that order pickers are only employed in warehouse areas with a disproportionately high average weight per SKU Implementation of a voluntarily and free of charge education program for employees focusing on proper lifting techniques |

| Work object | Relocation of articles in the dry assortment with a high average weight per SKU and at the same time moderate turnover to a semi-automated central warehouse Integration of SKUs weight and stability into a continuous improvement process regarding packaging design trademarks and branded products Increasing the usage of industrial trucks for order picker to decrease the distance traveled on foot |

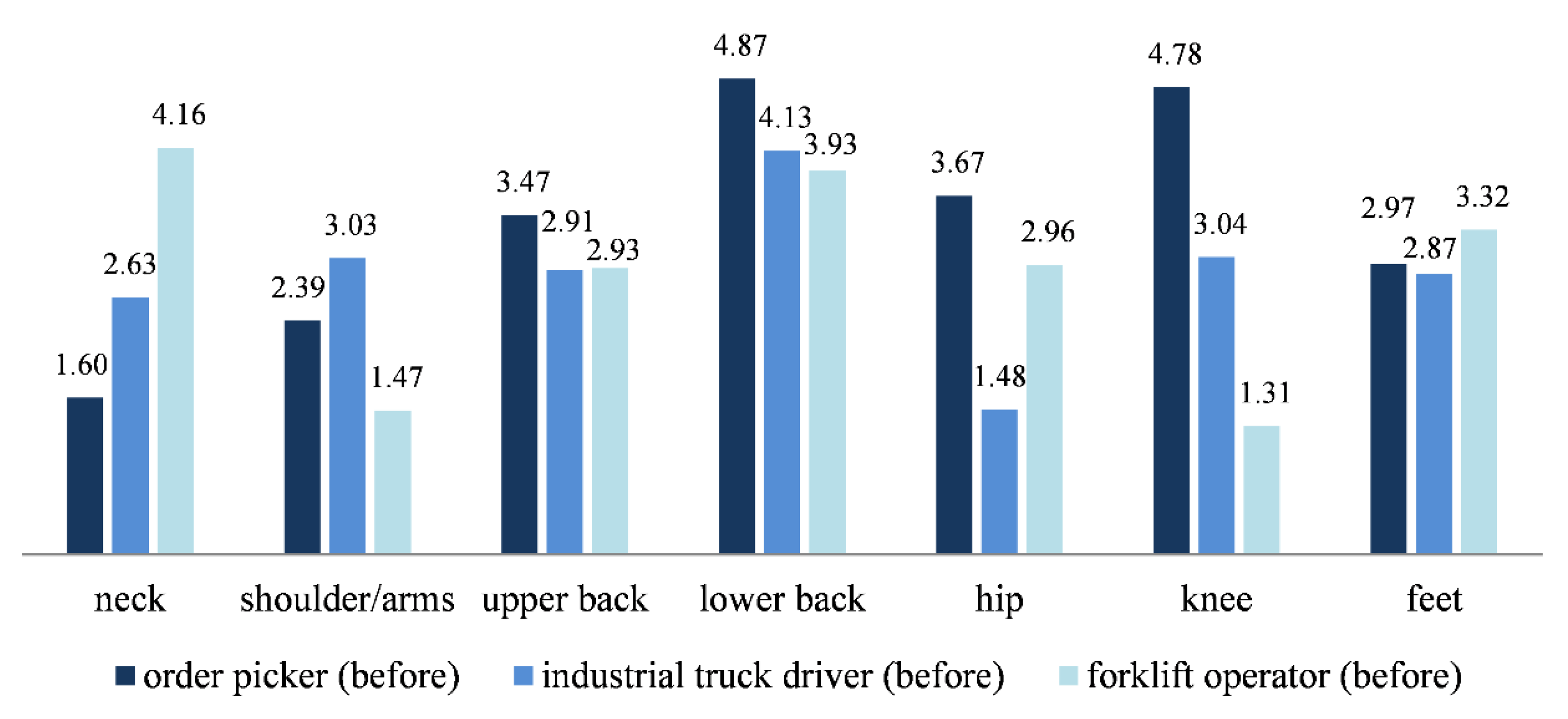

| Order Picker (Before, t0) | Order Picker (After, t1) | Industrial Truck Driver (Before) | Industrial Truck Driver (After) | Forklift Operator (Before) | Forklift Operator (After) | |

|---|---|---|---|---|---|---|

| neck | 1.60 | 2.12 | 2.63 | 1.71 | 4.16 | 2.17 |

| shoulder/arms | 2.39 | 1.89 | 3.03 | 3.66 | 1.47 | 1.60 |

| upper back | 3.47 | 3.16 | 2.91 | 1.80 | 2.93 | 1.87 |

| lower back | 4.87 | 2.75 | 4.13 | 3.62 | 3.93 | 2.31 |

| hip | 3.67 | 3.06 | 1.48 | 1.90 | 2.96 | 2.71 |

| knee | 4.78 | 3.89 | 3.04 | 2.26 | 1.31 | 1.97 |

| feet | 2.97 | 2.01 | 2.87 | 1.62 | 3.32 | 1.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loske, D.; Klumpp, M.; Keil, M.; Neukirchen, T. Logistics Work, Ergonomics and Social Sustainability: Empirical Musculoskeletal System Strain Assessment in Retail Intralogistics. Logistics 2021, 5, 89. https://doi.org/10.3390/logistics5040089

Loske D, Klumpp M, Keil M, Neukirchen T. Logistics Work, Ergonomics and Social Sustainability: Empirical Musculoskeletal System Strain Assessment in Retail Intralogistics. Logistics. 2021; 5(4):89. https://doi.org/10.3390/logistics5040089

Chicago/Turabian StyleLoske, Dominic, Matthias Klumpp, Maria Keil, and Thomas Neukirchen. 2021. "Logistics Work, Ergonomics and Social Sustainability: Empirical Musculoskeletal System Strain Assessment in Retail Intralogistics" Logistics 5, no. 4: 89. https://doi.org/10.3390/logistics5040089

APA StyleLoske, D., Klumpp, M., Keil, M., & Neukirchen, T. (2021). Logistics Work, Ergonomics and Social Sustainability: Empirical Musculoskeletal System Strain Assessment in Retail Intralogistics. Logistics, 5(4), 89. https://doi.org/10.3390/logistics5040089