From Supply Chain 4.0 to Supply Chain 5.0: Findings from a Systematic Literature Review and Research Directions

Abstract

:1. Introduction

2. Systematic Literature Review

2.1. Planning the Literature Review

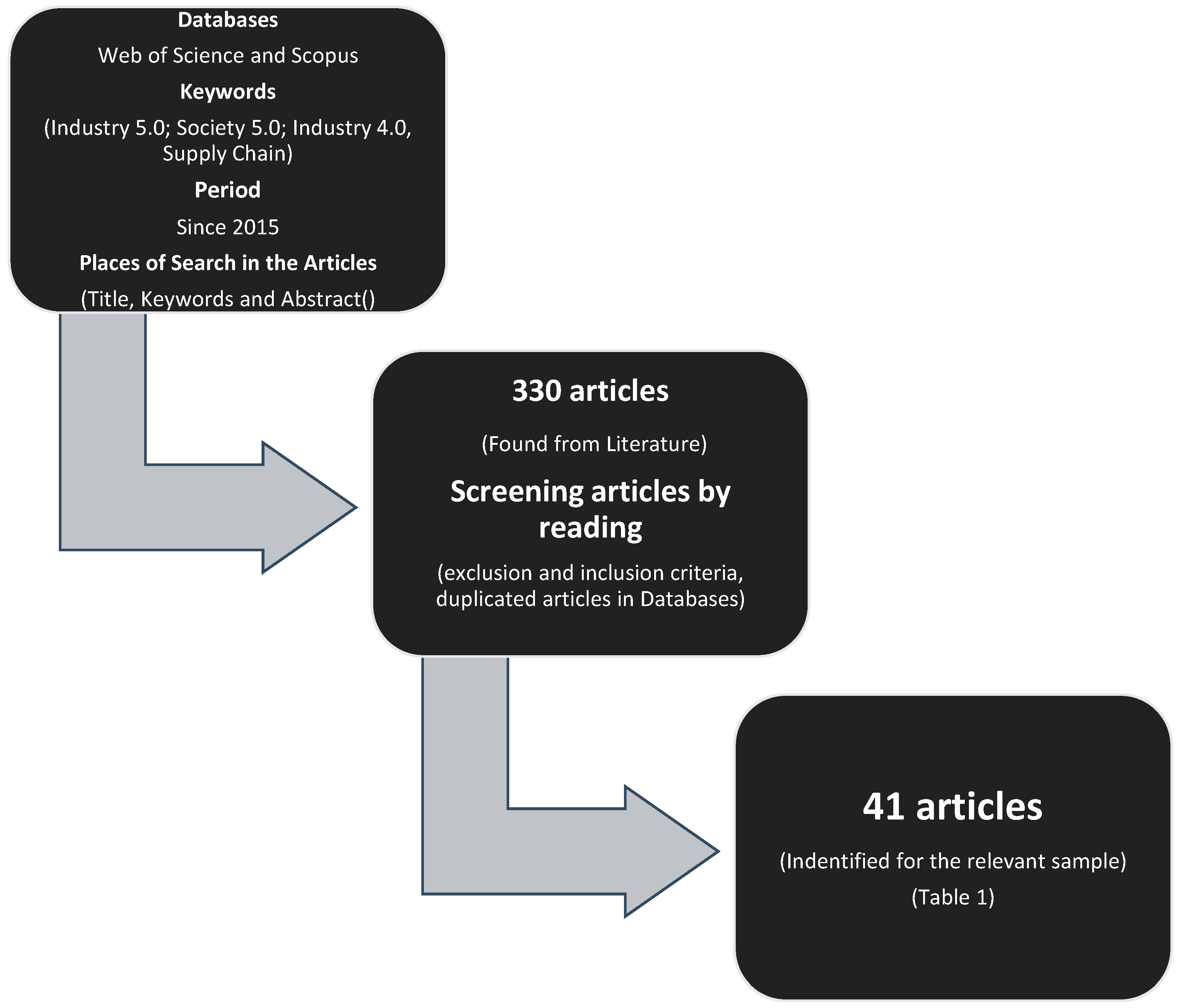

2.2. Conducting the Literature Review

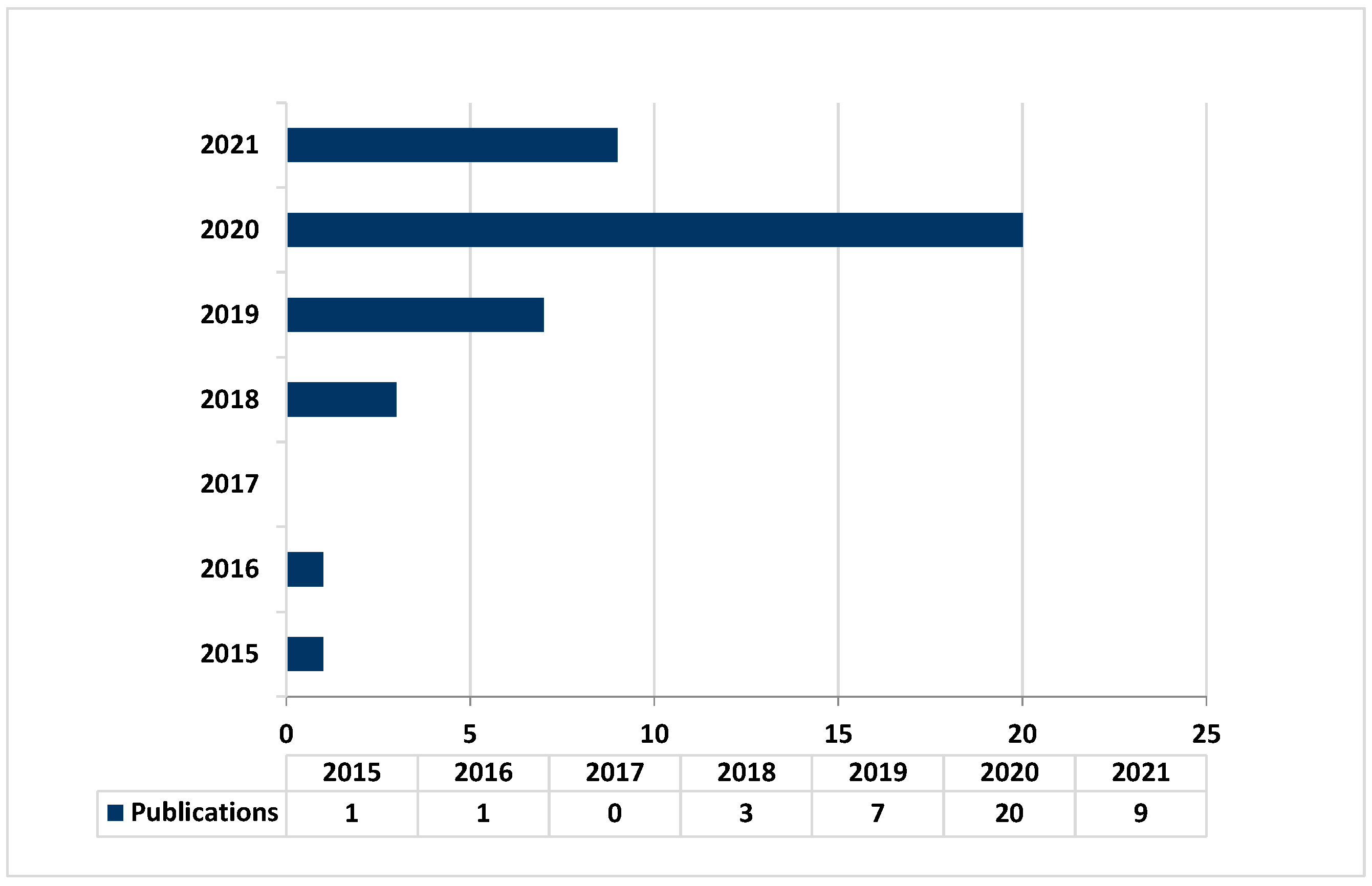

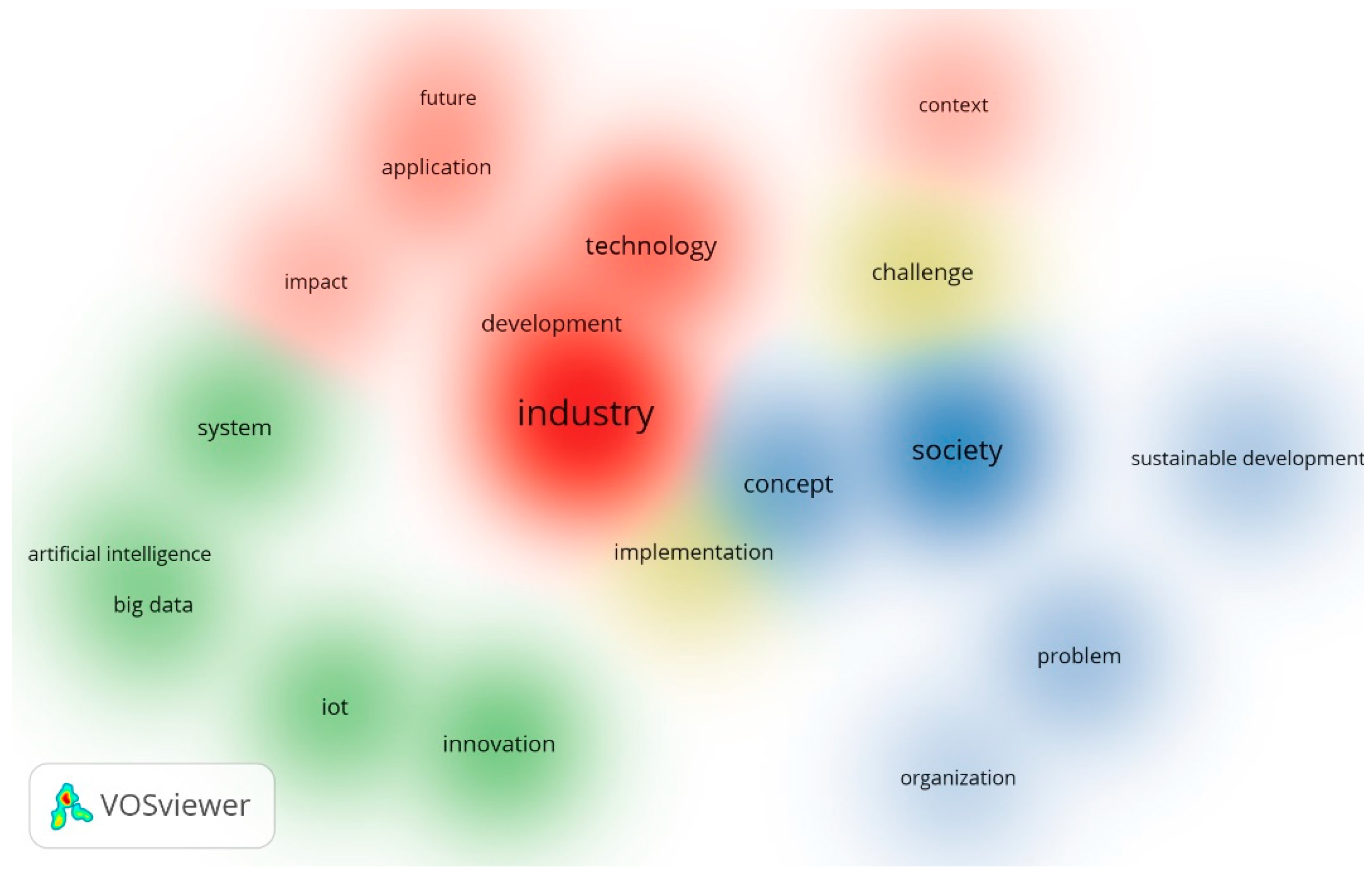

2.3. Reporting the Literature Review

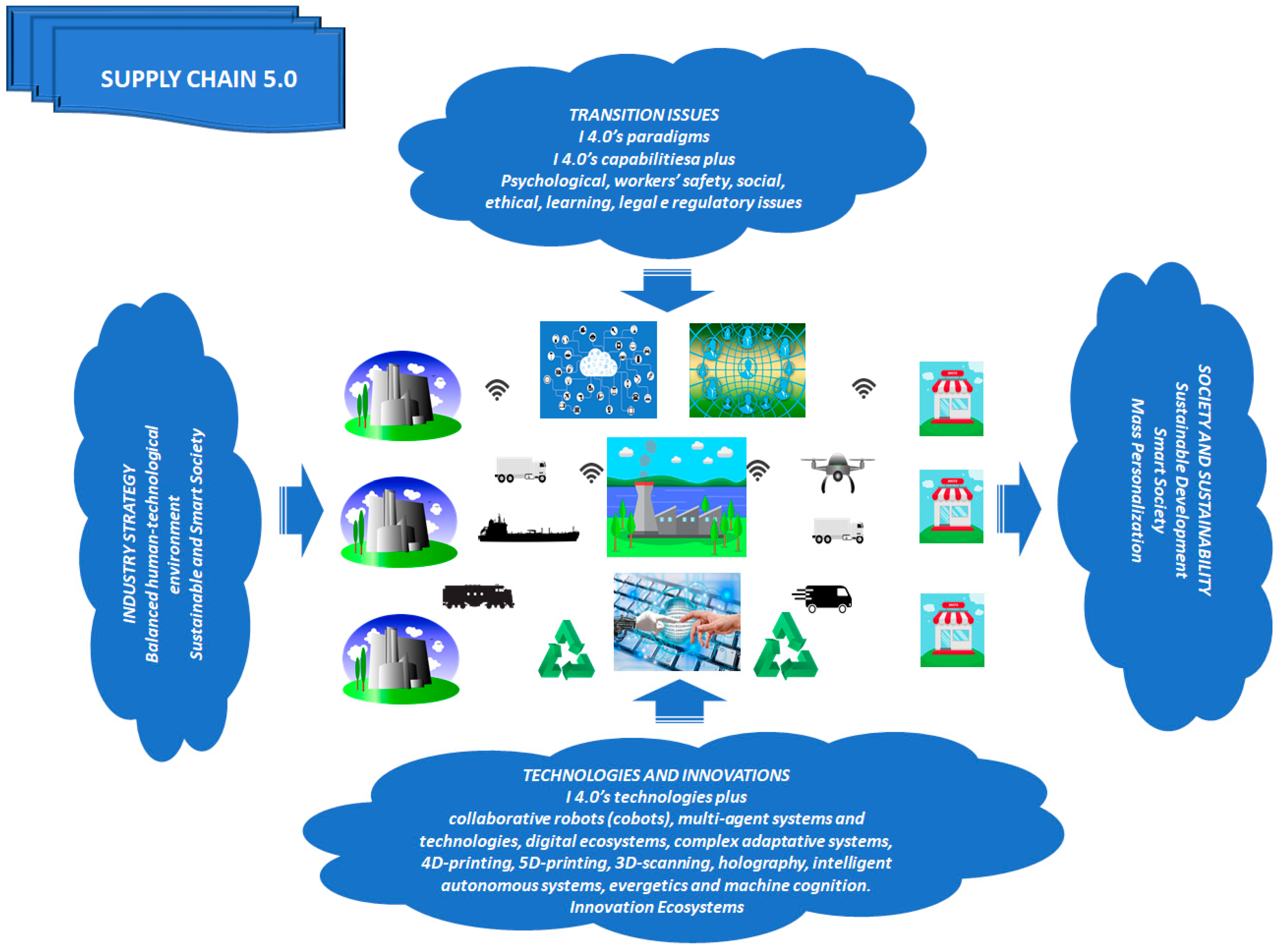

3. Industry 5.0′s Constructs and the Supply Chain Context

3.1. Discussion about the Constructs for Industry 5.0

3.1.1. Construct 1—Industry Strategy

3.1.2. Construct 2—Innovation and Technologies

3.1.3. Construct 3—Society and Sustainability

3.1.4. Construct 4—Transition Issues

3.2. Alignment with the Supply Chain Context

4. Conclusions

4.1. Practical and Theoretical Implications

4.2. Limitations and Research Agenda

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the industry 4.0 concept. Procedia Manuf. 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Liao, Y.L.; Deschamps, F.; Rocha Loures, E.F.; Ramos Pereira, F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0; Forschungsunion, acatech: Frankfurt, Germany, 2013; Available online: https://www.acatech.de/Publikation/recommendations-for-implementing-the-strategic-initiative-industrie-4-0-final-report-of-the-industrie-4-0-working-group/ (accessed on 25 May 2021).

- Porter, M.E.; Heppelmann, J.E. How Smart, Connected Products Are Transforming Competition. Harv. Bus. Rev. 2014, 92, 64–88. Available online: https://hbr.org/2014/11/how-smart-connected-products-are-transforming-competition (accessed on 5 April 2020).

- Bongomin, O.; Yemane, A.; Kembabazi, B.; Malanda, C.; Chikonkolo Mwape, M.; Sheron Mpofu, N.; Tigalana, D. Industry 4.0 Disruption and Its Neologisms in Major Industrial Sectors: A State of the Art. J. Eng. 2020, 2020, 8090521. [Google Scholar] [CrossRef]

- Madsen, D.Ø. The Emergence and Rise of Industry 4.0 Viewed through the Lens of Management Fashion Theory. Adm. Sci. 2019, 9, 71. [Google Scholar] [CrossRef] [Green Version]

- Melville, N.P.; Robert, L. The Generative Fourth Industrial Revolution: Features, Affordances, and Implications. 2020. Available online: https://www.researchgate.net/publication/348300945_The_Generative_Fourth_Industrial_Revolution_Features_Affordances_and_Implications (accessed on 5 April 2020).

- Oesterreich, T.D.; Schuir, J.; Teuteberg, F. The Emperor’s New Clothes or an Enduring IT Fashion? Analyzing the Lifecycle of Industry 4.0 through the Lens of Management Fashion Theory. Sustainability 2020, 12, 8828. [Google Scholar] [CrossRef]

- Santos, K.; Loures, E.; Piechnicki, F.; Canciglieri, O. Opportunities Assessment of Product Development Process in Industry 4.0. Procedia Manuf. 2017, 11, 1358–1365. [Google Scholar] [CrossRef]

- Frederico, G.; Garza-Reyes, J.A.; Kumar, A.; Kumar, V. Performance Measurement for Supply Chains in the Industry 4.0 Era: A Balanced Scorecard Approach. Int. J. Product. Perform. Manag. 2020, 70, 789–807. [Google Scholar] [CrossRef]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2017, 56, 1118–1136. [Google Scholar] [CrossRef] [Green Version]

- Dolgui, A.; Ivanov, D.; Sethi, S.P.; Sokolov, B. Scheduling in production, supply chain and Industry 4.0 systems by optimal control: Fundamentals, state-of-the-art and applications. Int. J. Prod. Res. 2018, 57, 411–432. [Google Scholar] [CrossRef]

- Lin, D.; Lee, C.K.M.; Lau, H.; Yang, Y. Strategic response to Industry 4.0: An empirical investigation on the Chinese automotive industry. Ind. Manag. Data Syst. 2018, 18, 589–605. [Google Scholar] [CrossRef]

- Wilkesmann, M.; Wilkesmann, U. Industry 4.0—organizing routines or innovations? VINE J. Inf. Knowl. Manag. Syst. 2018, 48, 238–254. [Google Scholar] [CrossRef]

- Belinski, R.; Peixe, A.M.; Frederico, G.F.; Garza-Reyes, J.A. Organizational learning and Industry 4.0: Findings from a systematic literature review and research agenda. Benchmarking An. Int. J. 2020, 27, 2435–2457. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process. Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.S.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J. Industry 4.0 Implies Lean Manufacturing: Research Activities in Industry 4.0 Function as Enablers for Lean Manufacturing. J. Ind. Eng. Manag. 2016, 9, 811–833. [Google Scholar] [CrossRef] [Green Version]

- Mrugalska, B.; Wyrwicka, M.K. Towards Lean Production in Industry 4.0. Procedia Manuf. 2017, 182, 466–473. [Google Scholar] [CrossRef]

- Pfohl, H.; Yahsi, B.; Kurnaz, T. The Impact of Industry 4.0 on Supply Chain. In Proceedings of the Hamburg International Conference of Logistics, Hamburg, Germany, 25 September 2015; Available online: https://www.researchgate.net/publication/288466876_The_Impact_of_Industry_40_on_the_Supply_Chain?channel=doi&linkId=56812e5508ae1e63f1edb651&showFulltext=true (accessed on 27 March 2021).

- Kache, F.; Seuring, S. Challenges and opportunities of digital information at the intersection of Big Data Analytics and supply chain management. Int. J. Oper. Prod. Manag. 2017, 37, 10–36. [Google Scholar] [CrossRef]

- Tjahjono, B.; Esplugues, C.; Ares, E.; Pelaez, G. What does Industry 4.0 mean to supply chain. Procedia Manuf. 2017, 13, 1175–1182. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Frederico, G.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, Maturity and Research Agenda. Supply Chain Manag. Int. J. 2019, 25, 262–282. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Pereira, S.C.F.; Telles, R.; Machado, M.C. Industry 4.0 and digital supply chain capabilities A framework for understanding digitalization challenges and opportunities. Benchmarking Int. J. 2019, 28. [Google Scholar] [CrossRef]

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Caballero Morales Aldrette-Malacara, A. Digital supply chain model in Industry 4.0. J. Manuf. Technol. Manag. 2019, 31, 887–933. [Google Scholar] [CrossRef]

- Ghadge, A.; Kara, M.E.; Moradlou, H.; Goswami, M. The impact of Industry 4.0 implementation on supply chains. J. Manuf. Technol. Manag. 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Frederico, G.F. Towards a Supply Chain 4.0 on the post-COVID-19 pandemic: A conceptual and strategic discussion for more resilient supply chains. Rajagiri Manag. J. 2021. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Pacaux-Lemoine, M.P.; Trentesaux, D.; Zambrano Rey, G.; Millot, P. Designing intelligent manufacturing systems through Human-Machine Cooperation principles: A human-centered approach. Comput. Ind. Eng. 2017, 111, 581–595. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Pirola, F.; Pinto, R. Exploring human factors in Logistics 4.0: Empirical evidence from a case study. IFAC-Pap. 2019, 52, 2183–2188. [Google Scholar] [CrossRef]

- Cimini, C.; Pirola, F.; Pinto, R.; Cavalieri, S. A human-in-the-loop manufacturing control architecture for the next generation of production systems. J. Manuf. Syst. 2020, 54, 258–271. [Google Scholar] [CrossRef]

- Fantini, P.; Pinzone, M.; Taisch, M. Placing the operator at the centre of Industry 4.0 design: Modelling and assessing human activities within cyber-physical systems. Comput. Ind. Eng. 2020, 139, 105058. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J.; Taisch, M. The Operator 4.0: Towards socially sustainable factories of the future. Comput. Ind. Eng. 2020, 139, 106128. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Romero, D.; Cavalieri, S.; Stahre, J. Smart Logistics and The Logistics Operator 4.0. In Proceedings of the 21st IFAC World Congress, Berlin, Germany, 12–17 July 2020; Available online: https://www.researchgate.net/publication/340952295_Smart_Logistics_and_ The_Logistics_ Operator_40 (accessed on 2 April 2021).

- Doyle-Kent, M.; Kopacek, P. Doyle-Kent, M.; Kopacek, P. Do We Need Synchronization of the Human and Robotics to Make Industry 5.0 a Success Story? In Digital Conversion on the Way to Industry 4.0. ISPR 2020. Lecture Notes in Mechanical Engineering; Durakbasa, N.M., Gençyılmaz, M.G., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Draper, J.; Bhaneja, B. Towards fusion energy in the industry 5.0 and society 5.0 context: Call for a global commission for urgent action on fusion energy. J. Knowl. Econ. 2020, 1–14. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Vogt, J. Where is the human got to go? Artificial intelligence, machine learning, big data, digitalisation, and human–robot interaction in Industry 4.0 and 5.0. AI Soc. 2021, 1–5. [Google Scholar] [CrossRef]

- Sołtysik-Piorunkiewicz, A.; Zdonek, I. How society 5.0 and industry 4.0 ideas shape the open data performance expectancy. Sustainability 2021, 13, 917. [Google Scholar] [CrossRef]

- Salimova, T.; Guskova, N.; Krakovskaya, I.; Sirota, E. From industry 4.0 to society 5.0: Challenges for sustainable competitiveness of Russian industry. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 497, No. 1; pp. 1–7. [Google Scholar] [CrossRef]

- Potočan, V.; Mulej, M.; Nedelko, Z. Society 5.0: Balancing of industry 4.0, economic advancement and social problems. In Kybernetes; IOP Publishing Ltd.: Saint-Petersburg, Russia, 2020; p. 50. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Critical components of industry 5.0 towards a successful adoption in the field of manufacturing. J. Ind. Integr. Manag. 2020, 5, 327–348. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. Industry 5.0 and its applications in orthopaedics. J. Clin. Orthop. Trauma 2019, 10, 807–808. [Google Scholar] [CrossRef]

- Mihardjo, L.W.W.; Sasmoko Alamsyah, F.; Elidje. Boosting the firm transformation in industry 5.0: Experience-agility innovation model. Int. J. Recent Technol. Eng. 2019, 8, 735–742. [Google Scholar] [CrossRef]

- Aslam, F.; Aimin, W.; Li, M.; Rehman, K.U. Innovation in the era of IoT and industry 5.0: Absolute innovation management (AIM) framework. Information 2020, 11, 124. [Google Scholar] [CrossRef] [Green Version]

- Nahavandi, S. Industry 5.0-a human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef] [Green Version]

- Frederico, G.F. Supply Chain 5.0—The Reconciliation between Humans and Machines! In Supply Chain Management Review, 2nd ed.; Peerless Media: Framingham, MA, USA, 2020; Available online: https://www.scmr.com/article/supply_chain_5.0_the_reconciliation_between_humans_and_machines (accessed on 2 April 2021).

- Wilding, R.; Wagner, B. Special issue: Building theory in supply chain management through “systematic reviews of the literature. Supply Chain Manag. 2014, 19, 355–357. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Literature Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Webster, J.; Watson, R.T. Analysing the past to prepare for the future. MIS Quartely 2002, 26, 8–23. [Google Scholar]

- Carayannis, E.G.; Dezi, L.; Gregori, G.; Calo, E. Smart environments and techno-centric and human-centric innovations for industry and society 5.0: A quintuple helix innovation system view towards smart, sustainable, and inclusive solutions. J. Knowl. Econ. 2021, 1–30. [Google Scholar] [CrossRef]

- Salimova, T.; Vukovic, N.; Guskova, N.; Krakovskaya, I. Industry 4.0 and Society 5.0: Challenges and Opportunities, The Case Study of Russia. IPSI BGD Trans. Internet Res. 2021, 7, 1–7. [Google Scholar]

- Cook, L.L. Insight into the millennial mind-set: Impact of 4IR and society 5.0 on the real estate, construction and other industries. In IOP Conference Series: Earth and Environmental Science; IOPScience: Durban, South Africa, 2021; Volume 654, No. 1. [Google Scholar] [CrossRef]

- Zengin, Y.; Naktiyok, S.; Kaygın, E.; Kavak, O.; Topçuoğlu, E. An investigation upon industry 4.0 and society 5.0 within the context of sustainable development goals. Sustainability 2021, 13, 2682. [Google Scholar] [CrossRef]

- Kumar, R.; Gupta, P.; Singh, S.; Jain, D. Implementation of Industry 4.0 Practices in Indian Organization: A Case Study. In Advances in Industrial and Production Engineering. Lecture Notes in Mechanical Engineering; Phanden, R.K., Mathiyazhagan, K., Kumar, R., Paulo Davim, J., Eds.; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Polat, L.; Erkollar, A. Industry 4.0 vs. Society 5.0. In Digital Conversion on the Way to Industry 4.0. ISPR 2020. Lecture Notes in Mechanical Engineering; Durakbasa, N.M., Gençyılmaz, M.G., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Ul Haq, M.I.; Raina, A.; Suman, R. Industry 5.0: Potential applications in COVID-19. J. Ind. Integr. Manag. 2020, 5, 507–530. [Google Scholar] [CrossRef]

- Sherburne, C. Textile industry 5.0?: Fiber computing coming soon to a fabric near you. AATCC Rev. 2020, 20, 25–30. [Google Scholar] [CrossRef]

- Aquilani, B.; Piccarozzi, M.; Abbate, T.; Codini, A. The role of open innovation and value co-creation in the challenging transition from industry 4.0 to society 5.0: Toward a theoretical framework. Sustainability 2020, 12, 8943. [Google Scholar] [CrossRef]

- Salimova, T.; Vukovic, N.; Guskova, N. Towards Sustainability through Industry 4.0 and Society 5.0. Int. Rev. 2020, 3–4, 48–54. Available online: https://scindeks-clanci.ceon.rs/data/pdf/2217-9739/2020/2217-97392003048S.pdf (accessed on 2 April 2021). [CrossRef]

- Gorodetsky, V.; Larukchin, V.; Skobelev, P. Conceptual model of digital platform for enterprises of industry 5.0. In International Symposium on Intelligent and Distributed Computing 2019; Springer: Cham, Switzerland, 2020; pp. 35–40. [Google Scholar] [CrossRef]

- ElFar, O.A.; Chang, C.; Leong, H.Y.; Peter, A.P.; Chew, K.W.; Show, P.L. Prospects of industry 5.0 in algae: Customization of production and new advance technology for clean bioenergy generation. Energy Convers. Manag. X 2020, 10, 100048. [Google Scholar] [CrossRef]

- Shaddiq, S.; Haryono, S.; Muafi, M.; Isfianadewi, D. Antecedents and consequences of cyberloafing in service provider industries: Industrial revolution 4.0 and society 5.0. J. Asian Financ. Econ. Bus. 2021, 8, 157–167. [Google Scholar] [CrossRef]

- Elim, H.I.; Zhai, G. Control system of multitasking interactions between society 5.0 and industry 5.0: A conceptual introduction & its applications. J. Phys. Conf. Ser. 2020, 1463, 1–8. [Google Scholar] [CrossRef]

- Korneev, N.V. Intelligent complex security management system FEC for the industry 5.0. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 950, pp. 1–9. [Google Scholar] [CrossRef]

- Rahman, A.; Pasanbu, E.; Nugraha, Y.; Khair, F.; Soebandrija, K.E.N.; Wijaya, D.I. Industry 4.0 and society 5.0 through lens of condition based maintenance (CBM) and machine learning of artificial intelligence (MLAI). In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 852, No. 1; pp. 1–6. [Google Scholar] [CrossRef]

- John, K.K.; Adarsh, S.N.; Pattali, V. Workers to super workers: A brief discussion on important technologies for industry 5.0 manufacturing systems. In AIP Conference Proceedings; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 2311. [Google Scholar] [CrossRef]

- Doyle-Kent, M.; Kopacek, P. (2020) Industry 5.0: Is the Manufacturing Industry on the Cusp of a New Revolution. In Lecture Notes in Mechanical Engineering, Proceedings of the International Symposium for Production Research 2019; ISPR 2019; Durakbasa, N., Gençyılmaz, M., Eds.; Springer: Cham, Switzerland. [CrossRef]

- Khaimovich, I.; Ramzaev, V.; Chumak, V. Data modelling for analysis of readness of municipal education in industry 5.0. In CEUR Workshop Proceedings; 2020; Volume 2667, pp. 1–4. Available online: http://ceur-ws:Vol-2667/paper1.pdf (accessed on 30 April 2021).

- Sharma, I.; Garg, I.; Kiran, D. Industry 5.0 and smart cities: A futuristic approach. Eur. J. Mol. Clin. Med. 2020, 7, 2750–2756. Available online: https://ejmcm.com/article_4786.html (accessed on 30 April 2021).

- Saptaningtyas, W.W.E.; Rahayu, D.K. A proposed model for food manufacturing in smes: Facing industry 5.0. In Proceedings of the International Conference on Industrial Engineering and Operations Management 2020, Detroit, MI, USA, 10–14 August 2020; Available online: http://www.ieomsociety:detroit2020/papers/394.pdf (accessed on 30 April 2021).

- Hamdani, N.A.; Herlianti, A.O.; Amin, A.S. Society 5.0: Feasibilities and challenges of the implementation of fintech in small and medium industries. J. Phys. Conf. Ser. 2019, 1402, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Fitzgerald, R.; Wang, E.; Karanassios, V. Smartphone-enabled data acquisition and digital signal processing: From current-output or voltage-output sensors for use on-site, to their use in IoT, in Industry 4.0 and (potentially) in Society 5.0. In Proceedings of the SPIE 10983, Next-Generation Spectroscopic Technologies XII, Baltimore, MD, USA, 13 May 2019; p. 109830A. [Google Scholar] [CrossRef]

- Martynov, V.V.; Shavaleeva, D.N.; Zaytseva, A.A. Information technology as the basis for transformation into a digital society and industry 5.0. In Proceedings of the IEEE International Conference Quality Management, Transport and Information Security, Information Technologies IT and QM and IS 2019, Sochi, Russia, 23–27 September 2019; pp. 539–543. [Google Scholar] [CrossRef]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and human-robot co-working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Özdemir, V.; Hekim, N. Birth of industry 5.0: Making sense of big data with artificial intelligence “the internet of things” and next-generation technology policy. OMICS J. Integr. Biol. 2018, 22, 65–76. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Sun, Q.; Jiang, G.; Tan, K.; Zhang, J.; Hou, J.; Wang, L. Nuclear energy 5.0: New formation and system architecture of nuclear power industry in the new IT era. Zidonghua Xuebao/Acta Autom. Sin. 2018, 44, 922–934. [Google Scholar] [CrossRef]

- Sachsenmeier, P. Industry 5.0—The relevance and implications of bionics and synthetic biology. Engineering 2016, 2, 225–229. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.; Wang, F.; Chen, Y.; Zhao, X. From industries 4.0 to energy 5.0: Concept and framework of intelligent energy systems. Zidonghua Xuebao/Acta Autom. Sin. 2015, 41, 2003–2016. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual. Available online: https://www.vosviewer.com/documentation/Manual_VOSviewer_1.6.8.pdf (accessed on 30 April 2021).

| Authors | Source Title | Purpose | Database | |

|---|---|---|---|---|

| 1 | [56] | Journal of The Knowledge Economy | The purpose is to investigate the implementation of a smart environment for Industry 5.0 and Society 5.0. The case investigated is in the aviation industry sector. | Web of Science and Scopus |

| 2 | [43] | AI & Society | This paper discusses the aspect of human interaction with Industry 4.0’s technologies and the trend towards Industry 5.0. | Web of Science |

| 3 | [44] | Sustainability | Its purpose is to study the use of OD (open data) in Industry 4.0, enabling a Society 5.0. They discovered that the bridge between Industry 4.0 and Society 5.0 is focused on technologies supporting the creation of a physical-to-digital-to-physical loop to ensure the sustainable development of a human-centered society. | Web of Science and Scopus |

| 4 | [57] | IPSI BGD Transactions on Internet Research | This research aimed to identify challenges and opportunities for implementing the concepts of Industry 4.0 and Society 5.0 in Russia, using a case study method. | Web of Science |

| 5 | [58] | IOP Conf. Series: Earth and Environmental Science | This paper brings a discussion regarding the benefits of Industry 4.0 and Society 5.0 for the real state and construction industries. | Scopus |

| 6 | [59] | Sustainability | This work refers to a survey carried out in Turkey, which investigates the relationship between Industry 4.0 and Society 5.0 in the context of Sustainable Development Goals—SDGs. | Scopus |

| 7 | [40] | Lecture Notes in Mechanical Engineering | This article is an investigation regarding human skills required for synchronization of robots in the Industry 5.0 environment. | Scopus |

| 8 | [60] | Lecture Notes in Mechanical Engineering | This research investigated the enablers for Industry 5.0 in the Indian manufacturing sector. | Scopus |

| 9 | [61] | Lecture Notes in Mechanical Engineering | This article presents the main conceptual differences between Industry 5.0 and Society 5.0. | Scopus |

| 10 | [62] | Journal of Industrial Integration and Management-Innovation and Entrepreneurship | This paper explores major technologies of Industry 5.0 which can be applied to the COVID-19 pandemic in the health sector. | Web of Science and Scopus |

| 11 | [63] | AATCC Review | This article presents the development of functional fiber computing for the textile industry in the context of Industry 5.0. | Web of Science and Scopus |

| 12 | [64] | Sustainability | This study examines how Industry 4.0 features and enabling technologies can support the transition to Society 5.0. It also investigates the roles of both open innovation and value co-creation within this transition. | Web of Science and Scopus |

| 13 | [41] | Journal of Knowledge Economy | This article presents a discussion regarding nuclear fusion energy through the lens of Industry 5.0 and Society 5.0. | Web of Science and Scopus |

| 14 | [47] | Journal of Industrial Integration and Management-Innovation and Entrepreneurship | This paper is a discussion about Industry 4.0 and Industry 5.0 and presents the main capabilities and elements needed to implement Industry 5.0 in the manufacturing industry. | Web of Science and Scopus |

| 15 | [42] | Applied Sciences-Basel | This paper covers the value-oriented and ethical technology engineering aspects of Industry 5.0, evidencing the findings through a survey of industry leaders from different companies. | Web of Science and Scopus |

| 16 | [46] | Kybernetes | This article discusses the relationship between Society 5.0, Industry 4.0, responsible economic development, and social problems solutions through the enhancement of corporate social responsibility (CSR) in organizations. | Web of Science and Scopus |

| 17 | [50] | Information | This research presents an innovation management framework—absolute innovation management (AIM)—as an innovation ecosystem for the Industry 5.0 context. | Web of Science and Scopus |

| 18 | [65] | International Review | This article provides a general view regarding actual development directions of the concepts of Industry 4.0 and Society 5.0, taking into consideration the context of sustainable development. | Web of Science |

| 19 | [66] | Intelligent Distributed Computing XIII | This article presents a conceptual model of an advanced digital platform for adaptive management of enterprises considering the context of Industry 5.0. | Web of Science and Scopus |

| 20 | [67] | Energy Conversion and Management: X | It considers aspects of the transition from Industry 4.0 to Industry 5.0 in the algae industry. | Scopus |

| 21 | [68] | Journal of Asian Finance, Economics and Business | The article is a discussion regarding cyberloafing effects through the lens of Industry 4.0 and Society 5.0. | Scopus |

| 22 | [69] | Journal of Physics: Conference Series | This work demonstrates a conceptual approach of a control system of multitasking between Society 5.0 and Industry 5.0. | Scopus |

| 23 | [70] | IOP Conference Series: Materials Science and Engineering | This paper presents the intelligent complex security management system for Industry 5.0 (FEC—fuel and energy complex), based on the Russian human–machine concept. | Scopus |

| 24 | [71] | IOP Conference Series: Materials Science and Engineering | This article provides an approach related to condition-based maintenance (CBM) and machine learning of artificial intelligence (MLAI) considering the context of Industry 4.0 and Society 5.0. | Scopus |

| 25 | [72] | AIP Conference Proceedings | This paper discusses the main technologies for the Industry 5.0 manufacturing systems design. | Scopus |

| 26 | [73] | Lecture Notes in Mechanical Engineering | This article proposes some areas that will need to be addressed with regard to the Industry 5.0 trend. | Scopus |

| 27 | [74] | CEUR Workshop Proceedings | The purpose of this study was to determine the level of readiness of municipalities in the Samara Oblast area to introduce Industry 5.0 technologies. | Scopus |

| 28 | [75] | European Journal of Molecular & Clinical Medicine | This article presents the main current technological developments of Industry 4.0 and future modifications for the Industry 5.0 context. | Scopus |

| 29 | [76] | Proceedings of the 5th North America International Conference on Industrial Engineering and Operations Management | This paper proposes a model of food product innovation for food manufacturing SMEs considering the trends of Industry 5.0 and Society 5.0. | Scopus |

| 30 | [51] | Sustainability | This paper introduces the concept of Industry 5.0 as well as presents key features and concerns related to Industry 5.0. | Web of Science and Scopus |

| 31 | [45] | International Scientific Conference Digital Transformation on Manufacturing, Infrastructure and Service | This paper presents the relationship between the objectives and goals of sustainable development and the concepts of Industry 4.0 and Society 5.0. | Web of Science and Scopus |

| 32 | [77] | 4th Annual Applied Science and Engineering Conference | This research investigates the feasibilities and challenges of the implementation of fintech in small and medium industries in the Society 5.0 era. | Web of Science and Scopus |

| 33 | [78] | Next-Generation Spectroscopic Technologies XII | This paper explores the use of smartphone applications in Industry 4.0 or Society 5.0 applications. | Web of Science and Scopus |

| 34 | [79] | Proceedings of the 2019 IEEE International Conference of Quality Management, Transport and Information Security, Information Technologies | This article discusses the main technologies and approaches which will contribute to the transition from Industry 4.0 to Industry 5.0. | Scopus |

| 35 | [80] | Procedia Computer Science | This article presents a discussion related to Industry 5.0, especially linked to the human–robot co-working issues from an organizational and human relations perspective. | Scopus |

| 36 | [49] | International Journal of Recent Technology and Engineering | This study presents an innovative model to support the transition from Industry 4.0 to Industry 5.0. | Scopus |

| 37 | [81] | OMICS-A Journal of Integrative Biology | This paper presents a vision of Industry 5.0 based on big data, the internet of things, and artificial intelligence. | Web of Science and Scopus |

| 38 | [48] | Journal of Clinical Orthopedics and Trauma | This article discusses the main applications of Industry 5.0 and their benefits to the medical industry. | Scopus |

| 39 | [82] | Zigonghua Xuebao/Acta Automatica Sinica | This paper proposes a system architecture for the nuclear power industry considering the Industry 5.0 context. | Scopus |

| 40 | [83] | Engineering | This research investigates how Industry 5.0 may impact the development of bionics (synthetic biology) | Web of Science and Scopus |

| 41 | [84] | Zigonghua Xuebao/Acta Automatica Sinica | In this paper, a new framework called Energy 5.0 is proposed, taking into consideration interactions and trends of energy and industry development as well as other advances. | Scopus |

| Word | Cluster | Weight <Occurrences> | Weight <Links> | Weight <Total Link Strength> |

|---|---|---|---|---|

| Industry | 1 | 74 | 18 | 955 |

| Society | 3 | 30 | 17 | 506 |

| Technology | 1 | 21 | 18 | 387 |

| Concept | 3 | 14 | 18 | 230 |

| Innovation | 2 | 12 | 15 | 227 |

| Challenge | 4 | 11 | 15 | 186 |

| Development | 1 | 10 | 15 | 141 |

| IoT | 2 | 10 | 13 | 164 |

| System | 2 | 10 | 16 | 167 |

| Application | 1 | 8 | 15 | 114 |

| Implementation | 4 | 8 | 14 | 137 |

| Big data | 2 | 7 | 12 | 132 |

| Problem | 3 | 7 | 13 | 184 |

| Context | 1 | 5 | 11 | 71 |

| Impact | 1 | 5 | 15 | 78 |

| Sustainable Development | 3 | 5 | 9 | 85 |

| Artificial intelligence | 2 | 4 | 12 | 79 |

| Future | 1 | 4 | 10 | 62 |

| Organization | 3 | 3 | 10 | 139 |

| Industry Strategy (Cluster 1) | Innovation and Technologies (Cluster 2) | Social and Sustainability (Cluster 3) | Transition Issues (Cluster 4) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Authors/Words | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| [56] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | |||||

| [43] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | |||

| [44] | * | * | * | * | * | * | * | * | * | * | * | * | |||||||

| [57] | * | * | * | * | * | * | * | * | * | ||||||||||

| [58] | * | * | * | * | * | * | * | ||||||||||||

| [59] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||

| [40] | * | * | * | * | * | * | * | * | * | * | * | ||||||||

| [60] | * | * | * | * | * | * | * | * | * | * | * | ||||||||

| [61] | * | * | * | * | * | * | |||||||||||||

| [62] | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||

| [63] | * | * | * | * | * | * | * | * | * | ||||||||||

| [64] | * | * | * | * | * | * | * | * | * | * | * | ||||||||

| [41] | * | * | * | * | * | * | * | * | * | ||||||||||

| [47] | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||

| [42] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | |||||

| [46] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | |||||

| [50] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||

| [65] | * | * | * | * | * | * | * | ||||||||||||

| [66] | * | * | * | * | * | * | * | * | * | * | |||||||||

| [67] | * | * | * | * | * | * | * | ||||||||||||

| [68] | * | * | * | * | * | ||||||||||||||

| [69] | * | * | * | * | * | * | * | * | * | * | * | ||||||||

| [70] | * | * | * | * | * | * | * | * | * | ||||||||||

| [71] | * | * | * | * | * | * | |||||||||||||

| [72] | * | * | * | * | * | * | * | * | * | * | * | * | |||||||

| [73] | * | * | * | * | * | * | * | * | * | * | |||||||||

| [74] | * | * | * | * | * | * | * | * | * | * | * | ||||||||

| [75] | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||

| [76] | * | * | * | * | * | * | * | * | * | * | * | * | |||||||

| [51] | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||

| [45] | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||

| [77] | * | * | * | * | * | ||||||||||||||

| [78] | * | * | * | * | * | * | * | * | * | * | |||||||||

| [79] | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||

| [80] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | ||

| [49] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | |||||

| [81] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | |||||

| [48] | * | * | * | * | * | * | * | * | * | * | * | * | * | * | |||||

| [82] | * | * | * | * | * | * | * | * | * | * | * | * | |||||||

| [83] | * | * | * | * | * | * | * | * | * | ||||||||||

| [84] | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||

| Industry 5.0′s Constructs | Research Questions—Industry 5.0 and Supply Chains |

|---|---|

| Industry Strategy | * How to deploy Supply Chain 5.0′s strategy amid the paradigms of Industry 4.0? * How mature should organizations be before the rollout of the Supply Chain 5.0 strategy? * How to get alignment with the supply chain’s members to develop a Supply Chain 5.0 program? * What are the strategic impacts of implementing a Supply Chain 5.0 program (e.g., sustainability, mass personalization, digital society)? * How can stakeholders in the supply chain get competitive advantages by implementing joint initiatives regarding Supply Chain 5.0?” |

| Innovation and Technologies | * What are the most beneficial technologies to create a Supply Chain 5.0 impact? * What are the key technologies of Industry 4.0 to create a proper scaffolding for the implementation of Industry 5.0′s technologies? * How can technologies of Industry 5.0 be interoperable across the supply chain and interplay with society? * How can innovation ecosystems foster the deployment of Industry 5.0 programs in supply chains? |

| Society and Sustainability | * How can Supply Chain 5.0 interplay with society, to help the development of a super-smart society? * What are the benefits of the Supply Chain 5.0 approach for circular supply chains? * What are the benefits generated for individuals who interact with a Supply Chain 5.0? * How can Supply Chain 5.0 enhance the achievement of climate goals, helping to create a more sustainable environment? What is the role of the supply chain’s members in the development of Society 5.0 and sustainable development? |

| Transition Issues | * What are the main barriers to the transition from Supply Chain 4.0 to Supply Chain 5.0? * Which capabilities must be developed before the implementation of Supply Chain 5.0′s programs? * What are the triggers to implement a transition strategy from Supply Chain 4.0 to Supply Chain 5.0? * How can the stakeholders involved in supply chains impact a transition program? |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frederico, G.F. From Supply Chain 4.0 to Supply Chain 5.0: Findings from a Systematic Literature Review and Research Directions. Logistics 2021, 5, 49. https://doi.org/10.3390/logistics5030049

Frederico GF. From Supply Chain 4.0 to Supply Chain 5.0: Findings from a Systematic Literature Review and Research Directions. Logistics. 2021; 5(3):49. https://doi.org/10.3390/logistics5030049

Chicago/Turabian StyleFrederico, Guilherme F. 2021. "From Supply Chain 4.0 to Supply Chain 5.0: Findings from a Systematic Literature Review and Research Directions" Logistics 5, no. 3: 49. https://doi.org/10.3390/logistics5030049

APA StyleFrederico, G. F. (2021). From Supply Chain 4.0 to Supply Chain 5.0: Findings from a Systematic Literature Review and Research Directions. Logistics, 5(3), 49. https://doi.org/10.3390/logistics5030049