Abstract

Order picking is a logistics component of warehouse operations where substantial productivity gains are possible. In this study, we investigate implementation processes of collaborative order picking robots (cobots) and focus on the influence of human factors on their implementation in high volume distribution centres. These human factors are: resistance to change; organisational culture; communication on change; and leadership. Four case companies were selected that have experience with testing and introducing several types of cobot and have successfully implemented (at least) one type of cobot over an extended period. In-depth interviews with operational decision-makers led to the identification of 66 critical incidents related to human factors. The results demonstrate the importance of planning the implementation process in phases. Employees are hesitant or resistant to the change due to a lack of information, experience, and communication. The decisive role of the team leader is crucial to implement cobots successfully, and here the individual character traits (e.g., the variance in commitment, character, and motivation) influence the process as well. Although the introduction of cobots is not yet widespread, and the negative impact on the workforce (i.e., concerning job loss) is currently low, one should be aware of the possible future implications when robotisation becomes structurally embedded. Therefore, this article calls for a stronger link between human factors and the future of work, with a specific focus on reskilling and upskilling of logistics professionals in light of robotisation, rather than binary approaches in which robots are primarily seen as a threat to the current workforce.

1. Introduction

Robotisation will increase rapidly in (internal) logistics processes. Whether robots and other fully automatic systems are also the correct answer to future challenges from a business strategy perspective is debatable. Discussions about the human race, subject to slow change, and computers and robots, evolving at a rapid pace [1], lead to tensions and binary interpretations of one versus the other, which inevitably leads to discussions about the influence of robotisation on the future of work. Our study focuses on collaborative order-picking robots and aims to investigate the impact of human factors on their successful implementation in high-volume distribution centres. The order-picking process is essential to warehouse operations and consists of collecting (order picking) items for a specific order. When the items are collected, the order is prepared and sent to the customer. Order picking is an essential process but also a labour-intensive and capital-intensive one [2]. It is estimated that the order-picking costs comprise up to 55% of the total cost of warehousing [3].

Order picking has a significant impact on supply chain productivity, and it is seen as the logistics component where most productivity improvements are possible [4]. This study investigates whether these improvements can be realised by supporting the human operator with a robot during the task and which (human) factors must be considered in robot implementation processes. Collaborative robots are also known as cobots; they come in different versions and are programmed with a computer to perform certain actions automatically. Sensors enable the cobot to detect humans and their environment. The cobot communicates with the human operator, allowing the operator to adjust programming if necessary [1].

Currently, eighty percent of all warehouses operate entirely with people. Fifteen percent of the warehouses are partly automated and only five percent to a large extent. According to ABI Research [5], the collaborative robotics sector was expected to increase roughly tenfold between 2015 and 2020, reaching over $1 billion. The rise of robotisation seems irreversible [6,7].

Multinationals such as Amazon and Google take the lead and invest heavily in robotisation [8]. In 2012, Amazon claimed to have implemented 30,000 robots in 13 fulfilment centres [9]. At the start of 2019, Amazon announced that they had already deployed more than 100,000 robotic systems in more than 25 fulfilment centres across the United States. In June 2019, the company even indicated that this number has grown to 200,000 automated drive robots worldwide [10]. ABI research states that by 2025 more than four million commercial robots will be installed in more than 50,000 warehouses: the need for flexible, efficient, and automated e-commerce fulfilment will drive the rapid increase of cobots as same-day delivery becomes the norm: “Global adoption of warehouse robotics will also be spurred by the increasing affordability and Return on Investment (ROI) of a growing variety of infrastructure-light robots, as they are an attractive and versatile alternative to traditional fixed mechanical automation or manual operations” [11].

An inefficient order-picking process can lead to high operational costs and dissatisfaction among employees and customers. More and more logistics companies are taking the step to (partially) automate the order-picking process. For example, since November 2017, a Dutch logistics company was the first in the world to provide their distribution centre with the iGo Neo from Still [12]. This order-picking cart automatically follows his owner, the human, when collecting orders.

Several challenges can be identified in the rapid evolution of robotisation. First, the implementation requires organisational change (e.g., adjustments in operations). A solid implementation plan should be developed for the machines to work together successfully with the human warehouse operator. Second, employees might be hesitant or resistant to these changes. Robots can support humans in several tasks, but that requires trust and cooperation from the operator [13,14]. Third, increased robotisation impacts the workforce and leads to fears of job loss, thereby negatively affecting the motivation of employees. The existing literature on cobot implementations mainly sets focus on technical issues and success factors (e.g., related to human-robot interaction), and a detailed view on the role of human factors (such as resistance to change) is currently lacking.

Therefore, this study aims to analyse the human factors at play in the implementation of cobots in high volume distribution centres, with a specific focus on resistance to change, organisational culture, communication on change, and leadership. The remainder of this article presents the literature review (Section 2), with a focus on collaborative robots, their application in order picking processes, and issues of Human-Cobot Collaboration. Section 3 provides the materials and methods of our study, thereby highlighting the specificities of the human factors approach in organisational change processes. Detailed information about the critical incidents, which form the basis for our data analysis, is provided in the appendix. Section 4 presents the results, with a specific focus on the cobot implementation process: its drivers and barriers, and the specific human factors influencing this change process. In Section 5, the results of our study are framed within the existing body of knowledge, with specific and critical reflection on the influence of cobot introduction on the future of work and skill requirements. Section 6 concludes our study with the main insights of our research, recommendations for successful cobot implementation, limitations, and recommendations for further research.

2. Literature Review

Interaction between humans and robots is referred to in the literature as Human-Robot Interaction (HRI) or Human-Robot Collaboration (HRC) [15]. According to Sheridan, ref. [1] HRI can be categorized into four areas of application:

- Human supervisory control of robots in the performance of routine tasks. These include handling parts on manufacturing assembly lines and accessing and delivering packages, components, mail, and medicines in warehouses, offices, and hospitals.

- Remote control of space, airborne, terrestrial, and undersea vehicles for non-routine tasks in hazardous or inaccessible environments. Such machines are called “teleoperators”. They perform manipulation and mobility tasks in the remote physical environment in correspondence to the remote human’s continuous control movements. A computer that a human supervisor intermittently reprograms to execute pieces of the overall task is a “telerobot”.

- Automated vehicles in which a human is a passenger, including automated highway and rail vehicles and commercial aircraft.

- Human-robot social interaction, including robot devices that provide entertainment, teaching, comfort, and assistance for children, elderly, and disabled persons.

Our study focuses on the human supervisory control of robots in their performance of routine tasks, as this fits with the order picking process in high volume distribution centres.

2.1. Collaborative Robots

A “cobot” is a collaborative robot used to assist human users at the workplace. It is introduced to ease the work of the employee. In logistics, this can mean that the cobot picks heavy packages, takes on repetitive actions simultaneously, or travels long distances to reduce human walking [8]. For example, Amazon employees walked 18km in the order picking process during a shift. After introducing cobots, the performance improved which led to a reduction of the employees’ walking distance by 40–70% [16].

The principal difference between cobots and industrial robots is the shared workspace. Extensive fencing surrounds a traditional industrial robot so that the human operator cannot get close to the machine. These robots switch off when a person is detected. Collaborative robots, on the other hand, can work safely with people. The human operator is generally “in charge” and can tune the cobot through a programmed computer system. The cobots can detect the presence and movements of people so that they can adjust their behaviour accordingly to prevent accidents. This feature allows collaborative robots to collaborate safely with people [17].

This study focuses on cobots that support the order-picking process. De Weerd [18] concludes that the most significant advantage of working with cobots during order picking is that they take the most arduous work out of the hands of human order pickers, for example, because the cobots move the collected orders into crates themselves. Once an order has been completed, the order picker ensures that the trolley travels to its final destination with a single charge. A new robot then registers with the order picker to maintain continuity in the order picking process.

The automotive industry has been increasingly implementing cobots on assembly lines, but also other industries explore cobots and how they can collaborate with humans [19]. This change is not surprising because cobots offer various advantages to existing industrial robots. A cobot can be placed next to people in small areas. Additionally, they are more programmable than industrial robots and can be used flexibly for repetitive, ergonomically challenging tasks [20].

2.2. Cobots in Order Picking Operations

The order picking process is found in warehouses and consists of collecting (order picking) items for a specific order. When the items are collected, the order is prepared and sent to the customer. Order picking is a basic warehouse process, but it is estimated that picking costs participate with 55% of the total cost of warehousing [3]. Robots are no longer solely used in factory environments; they are also gradually moving to human-populated warehouses. Cobots may prove to be a valuable addition to the order picking process since cost reduction in that area would substantially impact the cost of the entire warehouse process [21,22].

In typical warehouse functions and flows within high volume distribution centres, the main activities include receiving, reserve storage & order picking, accumulation/sortation packing, and shipping [2]. Cobots may provide solutions to different categories of order picking:

- Broken-case or piece-picking is a type of order picking where the individual responsible for picking would pick all the necessary items for one order. They might pick it from the same place or a combination of different shops based on their requirement. The item order picking process is often very repetitive. It is difficult for employers to find upstanding and motivated staff.

- Case-picking is the order-picking of boxes or crates. This picking method is standard in warehouses, especially with retailers; most logistics operations consist of this method of order picking. Case-picking is often performed by a human operator with a pallet truck or roll container. Concerning case-picking, there is generally little diversity in products. The boxes often contain the same products.

- Full-pallet picking is also known as unit-load picking. A pallet is loaded with various items so that the operator can move many items in one go. Picking with a full pallet is often done with different types of (lift) trucks, making pallet picking less labour-intensive than case-picking or piece-picking.

2.3. Human-Cobot Collaboration

Robinette, Wagner, and Howard [23] conclude that robots have incredible potential to assist humans in everyday tasks such as cleaning floors, but also in emergency tasks such as heart surgery and bomb disposal. Although the logistics sector is one of the fastest-growing sectors for robotics [24], many operations still occur manually in this sector. Automation is repeatedly proven difficult by the multitude of variations that have to be taken into account. Cobots should be able to take over the manual activities of man, but the warehouse staff must trust their new helper, and the environment must be ready as well. Hancock et al. [25] presented factors of trust development in human-robot interaction, based on human-related, robot-related, and environmental dimensions. Human-related factors include engagement, expertise, and comfort to work with robots.

Working with cobots is new to many people and, therefore, out of their comfort zone. As shown in studies focusing on automation, trust in HRI is an essential human factor that influences successful implementation [26]. More and more people are open to robotisation. One in three employees is willing to work together with a “robot colleague”. No fewer than 42% of the respondents see a robot as an added value to the work process. The research shows that “time savings” is a major advantage of automation. Of course, some employees do not want to collaborate with robots. For example, in their Global Talent Trends Report, consultancy firm Mercer [27] concludes that 29% of respondents fear job loss. They see the robots as competition. Commitment among human staff will not arise immediately. The time factor likely plays a vital role in the development of engagement. Robots can support humans in several tasks, but many users do not trust them and have a negative prejudice [13]. Such attitudes can subsequently lead to the disuse of these valuable tools [28].

Ogawa et al. [29] analysed to what extent staff is comfortable with teleoperated robots. They received mixed reactions, including fear. People preferred to communicate with a human colleague than a teleoperated robot. Another teleoperated robot study showed that most robot operators reported that they could share their intentions to a reasonable extent. Most people who interacted with the robot saw the behaviour as fairly social [30]. However, robots can also appear threatening. Since the robot already looks different and people are not used to communicating with it, operators may feel uncomfortable if the robot is not doing what is expected of it [31]. Research by Hancock et al. [25] showed that the robot’s performance had more influence on human trust. The better the robot does its job, the more confidence it generates with the user.

Other human factors (also labelled “environmental” factors in the study of Hancock et al. [25]) include ‘communication and culture’ and ‘team collaboration’. The culture and communication within an organisation are also crucial in the implementation of robots. The following example clearly demonstrates this. The SWORD system (Special Weapons Observation Reconnaissance Detection System) was developed by the US Army in Iraq in 2007 to support combat [32]. Although the system worked well, the soldiers never used SWORD because they did not trust the system to safely function as it made unexpected movements due to technical malfunctions [32]. If there is no trust in a company’s culture, the cobot will not be optimally used. “Trust, specifically, has been identified as an important facet in facilitating the correct and appropriate use of a robotic system” [33].

Communicating openly and honestly with the human operators and adequately informing them of the changes that are to come is a key driver for successful implementation processes. With every organisational change process, the team’s willingness to engage in the change process itself is ultimately decisive. Every change brings tension and resistance to change, especially in the beginning phases of the process [34,35].

According to Maurtua et al. [36,37], human-robot collaboration can potentially contribute to the realization of factories of the future. They see these shared workspaces as places where people work together with the robot as a team. The cobots perform repetitive and risky tasks, while the human operators can focus on the critical tasks in the work process, which require their expertise.

3. Materials and Method

This research investigates the role of human acceptance on the cobot implementation process in high-volume distribution centres and is based on multiple case studies. These are most suitable for exploratory research [38] and make it possible to analyse phenomena requiring interaction between investigator and informant, and numerous information sources. Qualitative research is particularly suitable for analysing and comparing different practices in a real-life context. This study contributes to the knowledge gap in the literature concerning human factors influencing the implementation of cobots in logistics and warehousing environments.

Cases were selected based on several criteria: (1) organisation is or has a high-volume distribution centre; (2) organisation is located in the Netherlands; (3) organisation has tested more than one type of collaborative robots in their distribution centre; (4) organisation has successfully introduced at least one type of collaborative robot in their distribution centre. The third criterion was used to select cases that show a certain level of maturity and experience in the introduction of the cobot. The fourth criterion differs from the third. This criterion is focused upon the actual (long-term) implementation and use of cobots in the distribution centre of the case organisation. Both the third and fourth selection criteria proved useful yet strict to find suitable cases for our research. Four case companies were found that met our criteria and were willing to participate in the study. Referring to an earlier study, estimating that only 1 or 2 percent of a sample of 1000 companies had invested in robots [39], our sample seems to fit the qualitative approach and purposes of our research. The general characteristics of the selected cases are presented in Table 1. Due to privacy reasons, the information is anonymised, and so is the link between companies and the specific type of cobots tested and implemented.

Table 1.

Overview of cases.

At least three different types of cobots have been tested and implemented at these case companies, and these have been discussed and focused upon in our study: (1) OPX-L 12 iGo neo (producer: Still); (2) YuMi®—IRB 14,000 (producer: ABB); (3) LOCUSBOTS™ (producer: Locus).

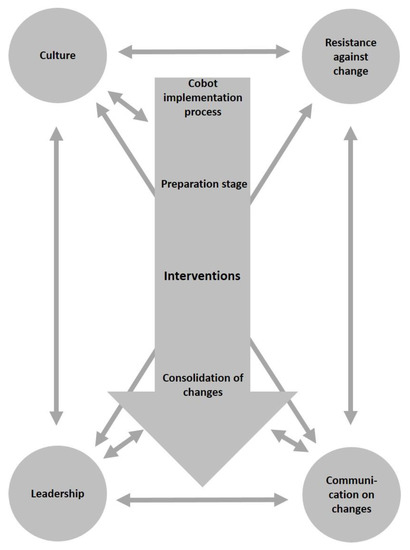

Data was gathered at these four case companies engaged in cobot implementation processes through (1) open and reflective interviews with key stakeholders (with project managers; innovation leads); (2) desk research of relevant documents regarding the implementation process; (3) observations regarding cobot implementation in the respective organisations. Figure 1 presents the research model of this study, which guides the development of the semi-structured interviews (Appendix A. Interview guidelines). The model is based on previously validated models focusing on human factors in organisational change processes [35,40] and represents the innovative change process (in this case: the introduction of cobots), surrounded by several influencing human factors (in this case: resistance to change; communication on changes; leadership; organisational culture). These human factors lead towards open and reflective vital questions to be used during the interviews.

Figure 1.

Human factors research model (based on [35,40]).

The semi-structured interviews with experts and observations in case companies allow for analysis of the influence of human acceptance and the work environment on cobot implementation processes. Through the use of literature-based, semi-structured interview guidelines, internal and content validity is ensured. According to Qu & Dumay [41], semi-structured interviews involve consistent and systematic questioning guided by identified themes, interposed with probes designed to elicit more detailed responses. The schedule was used to interview the operational experts of the four case companies. These interviews were conducted in the respondents’ environment, leading to minimal time investment and respondents feeling entirely at ease.

The collected data were analysed in Microsoft Excel. In an open coding approach, labels derived from the research model and related human factors were attached to the data, which lead to a structured overview of influencing factors in cobot implementation processes: culture, resistance to change, communication, and leadership. Regarding the organisational change process, the following issues received prime focus for the data analysis: (1) adjustments; (2) kick-off and instructions; (3) investment; (4) workforce; (5) preparation; and (6) productivity. Regarding human factors of stakeholders involved (both project managers and warehouse operators), particular attention was provided to the following issues: (1) prejudice; (2) unfamiliarity; (3) curiosity; (4) commitment; (5) character; and (6) motivation. Where possible, relationships between different influencing factors were outlined, clarified, and described (cf. the grey arrows in the research model, as presented in Figure 1), which altogether resulted in a data matrix with 66 critical incidents in the cobot implementation process and the influence of human factors. Appendix B, Table A1 and Table A2 provide an overview of the identified critical incidents.

4. Results

4.1. The Cobot Implementation Process

The implementation of cobots requires innovative organisational changes. The critical incidents identified in the data of the four case companies show that the implementation process is a challenging and often complex process, both from the organisational and the individual perspective. Table 2 presents an overview of the critical incidents and human factors identified concerning the cobot implementation process, with a specific focus on adjustments made, kick-off and instructions, and preparation.

Table 2.

Critical incidents and human factors identified related to adjustments; kick-off; and preparation of the implementation process.

To facilitate cobot implementation, adjustments need to be made in the warehouse or operations. The type of cobot will influence the number of adjustments needed, yet in all cases, we identified resistance to far-reaching adjustments, mainly spurred by management demands or expectations. Minor adjustments are acceptable, to the extent that they do not disrupt the existing processes:

“No, the current process should preferably continue”(Case B)

“Now we think that the cobots work better in an isolated part of the warehouse, which requires adjustment”(Case B)

“An emergency button had to be made to stop the cobot when needed. This was a big adjustment according to the technicians”(Case D)

“No major adjustments were made; that was a requirement from the management”(Case C)

This adherence to business-as-usual and hesitancy to fully adopt cobots in the warehousing operations is in contract with the innovation aspirations as expressed by the respondents. They see innovation as a way to create new opportunities for the organisation to improve its operations and shared various arguments for their choice of cobots:

- Regarding process improvement: by using cobots, goods for multiple customers can be “picked” at the same time so that more orders can be processed.

- Regarding flexibility: organisations requiring a necessary adjustment in the work process can become more flexible. Cobots are mobile and can be deployed in the departments wherever they are most needed.

- Regarding ergonomic development and absenteeism: the introduction of cobots allows for approaches in which warehouse employees are physically relieved. The cobot follows the employee, and the operator can collect the orders. With this development, the organisation tries to reduce the high absenteeism due to illness and physical injuries.

- Regarding scarcity in the labour market: this factor can also be linked to absenteeism. A high-quality workforce with the right skills is hard to find and retain, and cobot implementation can potentially relieve issues related to scarcity on the labour market.

In light of these arguments, it is not surprising that the focus is set on innovation, nor is it strange that this innovation is being sought in robotisation. Causes of hesitancy to fully engage in cobot innovation processes can be found in the financial consequences and investments needed. Yet, the cases in our sample are pioneers, as one expert declared:

“You can keep consulting and calculating, but you just have to start!”(Case B)

According to the experts, a decisive factor during implementation is a clear and solid preparation and instruction (e.g., in a “kick-off & instruction”). By engaging everyone in the process from the start, enthusiasm is created and prejudice reduced. Suppose only a few higher positions are informed, who have to instruct and motivate the other employees. In that case, scepticism arises among the operators, and it will be much more challenging to motivate the employees to work with the cobot. One of the case organisations ensured that all layers of the organisation were aware of the development: from management to the operators, up to the works council. Step by step, person-by-person, employees were informed. The organisation set up an information corner where the project and related technology were explained, which led to an initial “meeting” and familiarisation with the cobots. There was also a monthly meeting where the operators were informed about working with the cobots, and there was time to share experiences. Every operator received training and was rewarded with a certificate if they had mastered the work with the cobot, which made the work with the cobot a fun challenge.

One of the experts admits that his organisation could have included more employees in the preparation. He was confronted by the fact that employees were not open to working with cobots, had much prejudice, and lagged in productivity. Other experts had arranged the preparation very precisely. At the respective companies under their responsibility, the implementation was structured in phases, all layers of the organisation were extensively instructed, and key users were involved in creating support. At these organisations, employees were enthusiastic from the start. Through this way of working, the employer developed trust among the operators and thus tackled issues of resistance to change, a factor that also emerges from our literature study as an indispensable part of an implementation process:

“We ensured that all layers of the organisation were aware of the development. Step-by-step, person-by-person were informed. We set up an information corner. There was also a monthly meeting”(Case B)

“We could have prepared the operators even better”(Case D)

Table 3 presents the critical incidents and human factors identified concerning investments, workforce, and productivity. Regarding the facilitation of cobots in the organisation, both costs and investments are critical organisational factors. Although this study does not explicitly focus on cobot implementations from a financial perspective, this factor cannot be wholly disregarded. According to the experts, cobots are currently an expensive investment. Hence, while there is increased interest, at this moment only a few organisations work with these machines.

Table 3.

Critical incidents and human factors identified related to investments, workforce, and productivity during the implementation process.

Moreover, the number of cobot experts in the Netherlands remains limited. Cobots are seen as an expensive form of innovation. Depending on its features, a cobot costs between €40–90k:

“You actually have to work in two or three shifts for a proper return on investment. That is why I think the deployment of cobots will develop faster at production companies that can produce day and night”(Case B)

The robots earn themselves back sooner in a three- or five-shift operation than in a one-shift operation. Most organisations work with a limited number of cobots. The investment for every cobot is a large one and must be calculated with great care. It is therefore questionable whether the number of cobots will increase spectacularly in the coming years, as mentioned by one of the experts:

“Cobots will really have to become cheaper in the coming years to become attractive for a bigger audience”(Case C)

With a strong focus on the economic dimension of cobot introduction, respondents highlight the importance of checking whether the initial cost of cobot implementation can deliver the desired productivity and output. However, this demands a deeper understanding of the human factors which can aid or hinder cobot implementation.

The use of cobots in logistics is a relatively new development, and not every implementation, so far, has been successful. Since only a few logistics organisations in the Netherlands use cobots, the implementation of these machines is custom-made. During the implementation, technical adjustments are needed before the cobot does precisely what the organisation has in mind. However, the organisation also has to deal with human staff and their emotions, trust, and patience. When the human operator does not fully support the cooperation with the cobot, and the cobot does something different from expected, the operator might become demotivated; this makes the implementation process vulnerable. Here we see how the various human factors influence each other, driving or hindering successful implementation processes.

Regarding the impact of cobot implementation on the workforce, cobots are seen as a relevant supplement to human operators. For example, cobots are used for repetitive order picking work, which is tedious and physically demanding for human operators. Cobots have been purchased to work together with humans, and the experts believe there to be enough work to keep both “in service”:

“Still (…) the economy is now growing, so the workforce is growing. However, if the economy slows down, it may indeed be that a cobot is more attractive and cheaper to keep in service than a human operator. That also depends on whether the productivity is high enough for a good return on investment”(Case C)

Regarding the impact of cobot implementation on productivity, the four case companies show mixed results. It is expected that cobots increase the quality of (repetitive) work: they can be switched on and off depending on the workload at that particular moment. Being able to scale up and down flexibly is a crucial issue in logistics. Additionally, the quality of the work that the cobot carries out does not diminish as time goes on. The machine can continue to do the repetitive work in the same way as long as necessary. A human operator is influenced by other factors such as concentration, commitment, and fatigue.

Cobots reduce the workload of the human operator but can also ease the work by taking on heavy and repetitive work, making the order picking work lighter for the operator, resulting in fewer injuries, fitter staff, and lower absenteeism. In turn, the operators can focus on more important and complex work activities in the workplace.

Regarding the link with human factors, it becomes clear from the critical incidents that successful implementation largely depends on the commitment of the operators and team leaders. However, successful implementation processes have not been yielding the expected impact on productivity:

“Because we have instructed the team leaders properly, the operators work correctly with the cobots. However, we are not achieving productivity that we had in mind”(Case B)

“The cobot did not give us the desired result”(Case D)

The logistics supply chain requires distribution centres for flexibility, as it can be hectic in the inbound department while not in other departments. Moreover, this can be completely different the next day. Logistics organisations must deal with this, and cobots allow them to be stationed where they are needed most, making the organisation more flexible when an adjustment to the work process is necessary. However, it appears that this is a bit more complicated in real life since a key user must move the cobot. One of the experts tested this with his staff through a feedback form. It was stated that the moment the cobot is “in the way”, and there is no key user, it cannot be moved, thereby negatively impacting productivity.

4.2. Resistance to Change

Organisational change processes will always cause commotion and fear among employees. Cobots are new and unknown to the people who have to work with them for the first time. Table 4 provides an overview of the results concerning prejudice, unfamiliarity, and curiosity among employees.

Table 4.

Critical incidents and human factors identified related to prejudice, unfamiliarity, and curiosity among employees during the implementation process.

One of the experts indicates that this resistance surprised him (in a negative sense) during his implementation process. The majority of employees are sceptical and often hesitant or resistant when a change is occurring. The role of staff members involved in the implementation process is also important. According to the experts, team leaders were more open to cobots than the average operator because they experience daily problems in staff shortages, process issues, and absenteeism and are jointly responsible for tackling these problems. The decisive role of the team leader is thus highlighted in all cases:

“I was surprised to see how much resistance there was, also among the technicians”(Case D)

“The amount of resistance that arose when people only hear the word “robot” or “cobot” was unprecedented”(Case D)

Some of the experts indicated they had underestimated the difficulty of motivating people. Their organisation’s kick-off program consisted of twenty team leaders, trained by the supplier, who had to explain the work with the cobots to their team. They experienced differences in motivation and character among the team leaders, leading to mixed results in the team performance. The character and the willingness for people to get involved are important factors, and the kick-off must be geared towards motivating all involved team members. Of course, a radical change, such as the implementation of a cobot, has consequences for the work environment. A much-discussed consequence is a change in the workforce, as reflected in professional logistics magazines: will robots take over our jobs in the future? The experts strongly reject this statement:

“There has certainly been some turmoil when we announced that we would focus on robotisation”(Case B)

One of the most important, and at the same time, most difficult objectives mentioned in the various cases is human operators’ acceptance of and their willingness to engage in the introduction of cobots. According to the experts, you gain the acceptance of employees through good preparation and extensive instruction:

“The level of trust was not very high. The first employee was very sceptical”(Case C)

“The character and the will[ingness] of the people are important factors. The kick-off must be effective to motivate all those different characters”(Case B)

“Certain people refuse to work with the cobot”(Case C)

“The amount of resistance that arose when people only hear the word “robot” or “cobot” was unprecedented”(Case D)

These quotes suggest the importance of thoroughly preparing the change process to create support and trust, and lower the resistance to change. Team leaders play a decisive role in these processes, and the cases have even shown differences at team level in the implementation success of cobots.

4.3. Leadership during Cobot Implementation

Table 5 presents the results concerning the commitment, character, and motivation of employees during cobot implementation processes. These constructs all play a role in the human factors occurring and influencing the cobot implementation process and specifically point toward the importance of leadership.

Table 5.

Critical incidents and human factors identified related to the commitment, character, and motivation of employees during the implementation process.

Several experts mentioned that the role of operational manager/supervisor/team leader consists mainly of guiding and motivating the operators. The organisations train these team leaders during implementation to immediately support their team, which makes their role crucial both during and after the implementation phase. A team leader must continue to motivate because:

“Negativity sneaks into a team if a cobot does not work perfectly in one go (…). A test/implementation of a cobot is custom-made and requires many new insights. You need the team leaders to keep on motivating and to really take on their leadership role!”(Case D)

Another expert pointed toward the importance of commitment in light of successful implementation:

“He/she signals the first impressions and feedback. Less commitment from the team leader means less commitment from the operators and ultimately less productivity”(Case C)

When you work with people, you have to deal with differences in character. Operator A may be more open to change than operator B. One operator is more interested in technology than the other, and there is always a difference in willingness to learn something new. One of the key features noticed by the experts is that employees involved are generally curious about cobots. Survey results among their employees (e.g., warehouse operators; order pickers) show that the lights and signals do “trigger” the employees to further explore possibilities to include cobots in their work. Some employees want to test machines by standing in front of them to see how the cobot reacts. It is also important to examine to what extent the human operator is committed to working with the cobot. For example, a temporary worker experiencing a cobot for a day will probably be less committed to the machine than a permanent employee who experiences the benefits in daily operations. To illustrate, one of the experts said:

“It is difficult to motivate people to use the cobots properly. Especially since we also have to deal with new people every day who work for us as flex workers and sometimes do not even speak the Dutch language”(Case C)

“Character plays a major role here too. You see a huge difference in motivation between the team leaders, which also makes the difference in the teams visible. One team leader finds technology and innovation more fun and interesting than the other team leader”(Case D)

Preparation and instructions in advance are necessary to transfer the information to the operators properly. It is also essential that the team leader is convinced and will create support. Every decision made in such a process can be crucial and must be included in the design from the onset and be taken seriously. The team leader should feel that he/she is contributing to and has an influence on these developments. To illustrate, one expert took his team leaders to another company that was already working with robots to create awareness of the possibilities. Character, motivation, and proactivity are essential factors in leadership during cobot implementation:

“Proactivity from the team leaders is so important! You see that if the motivation weakens, the results plummet. As an organisation you have to spend time on this. That really is a learning point for our organisation”(Case D)

These results highlight the pivotal role of motivated, committed, and proactive team leaders in the cobot implementation process; team leaders can ultimately aid or inhibit this process. Thus, it is the organisation’s responsibility to include them in the initial phase of implementation and instruction.

5. Discussion

Our research is an addition to the existing literature on cobot implementations. It aims to fill the gap in the literature on the influence of human factors on cobot implementation processes in high volume distribution centres. Previous research has focused on the technical aspects and possibilities of the implementations, thereby largely ignoring the importance of human factors in these processes. In Section 5.1, we will further elaborate on a specific issue related to these processes, i.e., trust. Section 5.2 provides critical reflections about the influence of robotisation on human factors and the future of work.

5.1. Trust

The results confirm that organisations that start a cobot implementation process are confronted with resistance to change, caused by prejudice, scepticism, and unfamiliarity among staff. Our human factors approach confirms earlier research from Sanders et al. [13] into trust and prior experience in HRI. Despite their curious nature, the staff’s trust must be gained before they are willing and confident to work with cobots. Moreover, trust is also linked to the individual characteristics of operators, as they might be sceptical, hesitant, or resistant to change. The lack of experience in working with cobots is also a critical influencing factor in the implementation process. According to the experts, a temporary employee is less committed to the cobot than an operator with a permanent contract. These findings are in line with those of Tsui et al. [42], who state: “Not only does experience lead to increased use, but higher levels of experience also engender more positive attitudes toward robots.”

The results of our study demonstrate that a good instruction plan and the associated kick-off are essential for a successful implementation process. The better the preparation is arranged (structured in phases, all layers of the organisation extensively instructed and key users deployed to create support), the more enthusiastic the employees are about the cobots, hence tackling barriers caused by lack of trust and resistance to change. Central to this is information sharing, communication, and gaining the trust of the operators. According to Maurtua et al. [36,37], employees will only accept a cobot if they feel confident and safe with the cobot and can communicate well with the machine. As confirmed by our results, the interaction between the robot and the employee is crucial.

This study also demonstrates that human acceptance cannot be viewed separately from the work environment during the implementation process of cobots in high-volume distribution centres. Although the physical environment hardly needs adapting to implement a cobot and these “new employees” currently have no direct influence on the workforce, information sharing is an essential success factor for the implementation process. Human factors related to the work environment, organisational culture, and communication need to be taken into account and their interaction and changing nature. This is in line with earlier studies on the changing nature of influencing factors in organisational change processes (e.g., [40]).

A clear and structured instruction contributes to the operator’s trust and increases the chance of acceptance and commitment. Kessler, MacArthur, & Hancock [33] propose a different explanation for this result. In their research, they conclude: “trust has specifically been identified as an important facet in facilitating the correct and appropriate use of a robotic system, which is a defining factor of successful interaction”. Our research has demonstrated that good preparation and instruction can increase trust. Human factors such as resistance to change, prejudice, and unfamiliarity can then be positively influenced, which increases human acceptance. We can conclude from these results that well-prepared operators are more committed to working with cobots than those without any knowledge of the cobots.

5.2. Future of Work

Our results demonstrate that organisational culture is of great importance to the success of an implementation process. Other human factors can influence the culture within an organisation: the behaviour of colleagues (e.g., a lack of trust; resistance to change), but also whether and how team leaders take up their commitment and leadership role. If employees are not open to cooperation, innovation, and new ways of working, there is a low chance of successful implementation [25]. It is plausible that an organisation with a positive culture of improvement is more likely to achieve a successful implementation than an organisation where the culture can be labelled as conservative.

The operational managers, but especially the team leaders, play an important role as they are the ones who have to motivate and guide people, but also because they receive the first signals and feedback. Motivating and involving people in advance and during the process is essential for successful implementation. Calitz et al. [20] declare this in their research into the type of communication required to implement changes. A manager must recognise that human-cobot collaboration requires a different approach than human-human collaboration and that people need the motivation to develop trust in cooperation with cobots. Our results show that in the four case companies at hand, the impact of cobot implementation processes on the workforce has been underestimated. In contrast, its impact on productivity has been overestimated. On the one hand, the impact on the workforce was minimised, yet as case C clearly outlined, its future effects cannot be underestimated. Further research is necessary on how to organize the different elements of work based on whether they are better served by robots or humans (e.g., routinized tasks vs critical thinking). Consequently, this could increase autonomy and satisfaction and, as a result of this, well-being in the workplace, which, in return, could further increase intrinsic motivation and productivity [43,44].

Far-reaching and rapidly changing robotisation processes inevitably influence the future of work. Today’s workforce is insufficiently prepared, affecting employees’ feelings of fear of losing their job and fear of working together with a non-human/non-communicative partner, which is further provoked by binary position-taking (human versus computer) by the management. Such adverse effects on organisational processes have also been documented in other contexts, pointing toward the effect of vicious cycles that hinder innovation [45]. Instead of focusing on job loss and thus encouraging vicious cycles of resistance to change, one should critically reflect on the role of human factors in the future of work. Such a message inevitably includes dimensions of upskilling and reskilling of the workforce to be ready for the future [46]. Further research can address the link between human factors and the future of work, including dimensions of individual resilience, empowerment, and flourishing e.g., [47,48]. Such connections have been laid within the context of education and professionalisation and could inspire business and industrial change as well.

6. Conclusions

This study has shown that different human factors influence the cobot implementation processes and lead to recommendations for the successful implementation of cobots in order picking processes. Resistance to change appeared a crucial human factor and can be divided into three items: (1) Prejudice: pointing to the importance of overcoming initial prejudices and deferring judgment until sufficient information is available; (2) Scepticism: the majority of people is sceptical by nature and often goes into resistance when a change is applied; (3) Unfamiliarity: because most operators are working with a cobot for the first time. These factors show that it is crucial to engage the employees in the changes in advance to turn resistance to change into more trust and willingness to be involved.

Leadership as a human factor plays a decisive role in the implementation process. Team leaders have the responsibility to inform and encourage employees to work with the cobot successfully. Commitment and engagement are needed to get used to the cobot. Our results show that team leaders were more open to cobots than the average operator because they experience daily problems in terms of staff shortages, process issues, and absenteeism, and they are jointly responsible for tackling these problems. Both leadership and resistance to change are inevitably influenced by the other human factors at play: organisational culture and communication on changes.

The results demonstrate, however, two issues that are underexposed within the current debate around robotisation. On the one hand, trust is being viewed from a reductionist and linear perspective from a point where there is a lack of trust, which is then ’solved’ by interventions to increase productivity. On the other hand, the role of robotisation in the future of work is being interpreted as inevitably requiring different and new skills, causing a skills gap in the current workforce. Both issues (trust and/in future of work) are closely related to each other. The expression “robot automation” can evoke feelings of fear in a facility, and employees will be afraid of losing their job. Implementing cobots requires investments that—from the management viewpoint—must be earned back by saving on staff. Such binary interpretations are not only detrimental for human factors in an organisation (leading to vicious cycles with more resistance; thus less productivity), they also neglect the importance of human-robot interaction and the need for re- and upskilling for the future of work.

Our study also has its limitations which lead to recommendations for further research. First, the specific selection criteria have led to a relatively small sample of four case companies. It was important to select only companies with a certain level of maturity in cobot implementation to achieve rich results (as reflected in the 66 identified critical incidents). Although the small sample is in line with recommendations for qualitative research [49], further research with a larger sample and quantitative approaches could lead to other insights into the role and (whether vicious or not) dynamics of human factors in robotisation processes. Second, our choice for the human factors resistance to change, communication, organisational culture, and leadership was informed by earlier research following the human factors approach. Yet, we are aware that more human factors are at play (e.g., as identified by [25]) that could be analysed in-depth, such as empowerment, competence, and mindsets.

Author Contributions

Conceptualization, W.L., L.K. and J.S.; methodology, L.K. and J.S.; validation, W.L. and J.S.; formal analysis, W.L., L.K. and J.S.; investigation, W.L., L.K. and J.S.; writing—original draft preparation, W.L., L.K. and J.S.; writing—review and editing, W.L., J.S.K. and J.S.; supervision, W.L. and J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted according to the guidelines of the Declaration of Helsinki, however Institutional Review Board approval was not requested for this data collection.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Due to the nature of this research, the participants of this study did not agree for their data to be shared publicly.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Interview Guidelines

| General information | Could you tell me about your function and you role in the implementation process? What is the role of your organisation/department in the logistics supply chain? |

| Current order picking process and the choice for robotisation | Order picking is a basic warehousing process, but has an important influence on supply chain’s productivity. Which order picking system types can be found in your warehouse? What made your organisation decide to implement cobots in the order picking process? Which cobot did your organisation choose? Why this cobot? What improvements does this cobot make to the process? |

| Human factors | How did the warehouse employees react to the collaboration with cobots? How would you describe the trust level of warehouse employees during the collaboration with cobots? Do you think that trust influenced the outcomes of the implementation? How? Which factors influenced the trust of the human operator during the implementation of order picking cobots? Has the working environment been adapted for implementation? How? Was a kick-off program initiated at the start of the implementation process? How? Which organisational requirements have been fulfilled during the implementation process? Was there a clear responsibility for each stakeholder in the process? Was this the appropriate way for this implementation process in your opinion? To what extent do you think the operations manager is essential during the implementation of cobots? Why? Can you tell which critical decisions were made during the process? What made these decisions so important? Which factors can be positively influenced by a team leader during the implementation? To what extent have your operations manager succeeded in properly preparing the staff? How did he/she achieve this? |

| Results of the cobot implementation process | Are you satisfied with the outcomes? Why? What were the main learnings from this project? Have jobs been lost as a result of the implementation of cobots? What went well? What should have been done differently/better? |

| (Source: based on [35,40,50]). | |

Appendix B. Critical Incidents Identified in the Data

Table A1.

Critical incidents related to the organisational change process.

Table A1.

Critical incidents related to the organisational change process.

| Case Company | Critical Incident | Quote Interview | Data Label | Human Factor Identified |

|---|---|---|---|---|

| A | 1. Facilitation of cobot introduction | The infrastructure for the supply and removal of materials has been adjusted | Adjustments | Resistance to change |

| 2. Adhering to business-as-usual | But the current process must continue | Adjustments | Resistance to change | |

| 3. Communication and information | Team leaders were trained by the [cobot] supplier, who had to explain the work with the cobots to their team | Kick-off & instructions | Leadership | |

| 4. Costs and investments related to cobot introduction | It is a major investment, which means that we do not purchase multiple cobots | Investment | Culture | |

| 5. Influence of cobot introduction on the workforce | The cobots have no influence on the workforce, but people don’t believe that, so it does affect the culture | Workforce | Culture | |

| 6. Decisive role of team leader | The team leader is there to guide the operators where necessary. We have informed them in advance and have taken them to another company | Preparation | Leadership | |

| 7. Decisive role of team leader | It is their job to explain it to the operators | Preparation | Leadership | |

| 8. Influence of cobot introduction on productivity | There is a lot of difference in motivation and character among the team leaders. Which means that one team works very well with the cobot, and the other much less | Productivity | Resistance to change Leadership | |

| B | 9. Adhering to business-as-usual | No, the current process should preferably continue | Adjustments | Culture Resistance to change |

| 10. Facilitation of cobot introduction | Now we think that the cobots work better in an isolated part of the warehouse, which requires adjustment | Adjustments | Resistance to change Culture | |

| 11. Communication and information | We ensured that all layers of the organization were aware of the development. Step-by-step, person-by-person were informed. We set up an information corner. There was also a monthly meeting. | Kick-off & instructions | Communication | |

| 12. Communication and information | The character and the will[ingness] of the people are important factors. The kick-off must be effective to motivate all those different characters | Kick-off & instructions | Resistance to change Communication | |

| 13. Communication and information | Every operator received training and was rewarded with a certificate if they had mastered the work with the cobot | Kick-off & instructions | Resistance to change Communication Culture | |

| 14. Costs and investments related to cobot introduction | You actually have to work in two or three shifts for a proper return on investment. That is why I think the deployment of cobots will develop faster at production companies that can produce day and night | Investment | Culture | |

| 15. Costs and investments related to cobot introduction | Standing still is going backwards. You can keep consulting and calculating, but you just have to start | Investment | Resistance to change Culture | |

| 16. Influence of cobot introduction on the workforce | Not yet, the amount of work is increasing and the use of cobots is not yet large enough | Workforce | Resistance to change Culture | |

| 17 Decisive role of team leader | The team leaders were closely involved in the design phase. It is important that they feel that they contribute to success | Preparation | Leadership | |

| 18. Influence of cobot introduction on productivity | Because we have instructed the team leaders properly, the operators work correctly with the cobots. However, we are not achieving productivity that we had in mind | Productivity | Leadership Culture | |

| C | 19. Adhering to business-as-usual | No major adjustments were made, that was a requirement from the management | Adjustments | Resistance to change |

| 20. Communication and information | We have not informed everyone in advance. The preparation could have been much better. We have not set up the test phase well enough | Kick-off & instructions | Communication | |

| 21. Costs and investments related to cobot introduction | A cobot is a big investment | Investment | Resistance to change Culture | |

| 22. Costs and investments related to cobot introduction | Cobots will really have to become cheaper in the coming years to become attractive for a bigger audience | Investment | Resistance to change Culture | |

| 23. Influence of cobot introduction on the workforce | No jobs were lost, there is sufficient work | Workforce | Culture | |

| 24. Influence of cobot introduction on the workforce | Still … the economy is now growing, so the workforce is growing. But if the economy slows down, it may indeed be that a cobot is more attractive and cheaper to keep in service than a human operator. | Workforce | Resistance to change Culture | |

| 25. Decisive role of team leader | The team leaders are trained by the [cobot] supplier. They had to introduce the cobot and explain it to the employees | Preparation | Leadership | |

| 26. Influence of cobot introduction on productivity | Less commitment from the team leader means less commitment from the operators and ultimately less productivity | Productivity | Resistance to change Leadership | |

| 27. Influence of cobot introduction on productivity | All cobots have been implemented, but productivity is not being achieved at this time because the preparation should have been better | Productivity | Culture | |

| 28. Influence of cobot introduction on productivity | The productivity that can be achieved with cobots is not achieved | Productivity | Culture | |

| 29. Influence of cobot introduction on productivity | That also depends on whether the productivity is high enough for a good return on investment | Productivity | Culture | |

| D | 30. Facilitation of cobot introduction | An emergency button had to be made to stop the cobot when needed. This was a big adjustment according to the technicians | Adjustments | Resistance to change |

| 31. Communication and information | A project team has been set up and we have taken a number of operators to another company to look at operative cobots. | Kick-off & instructions | Communication | |

| 32. Communication and information | In retrospect it turned out that we could have involved more employees | Kick-off & instructions | Resistance to change Communication | |

| 33. Costs and investments related to cobot introduction | A cobot costs a lot of money, so after a few months we opted for a different robot solution | Investment | Culture | |

| 34. Influence of cobot introduction on the workforce | Replacing jobs is not going that fast, maybe in five or ten years, but fear among staff rules | Workforce | Resistance to change Culture | |

| 35. Decisive role of team leader | The location manager has given a presentation. A project team with operators and team leaders was then established | Preparation | Leadership | |

| 36. Influence of cobot introduction on productivity | You see that if the motivation of a team leader weakens, the results plummet | Productivity | Resistance to change Leadership | |

| 37. Influence of cobot introduction on productivity | The cobot did not give us the desired result. | Productivity | Resistance to change |

Table A2.

Critical incidents related to scepticism, (lack of) commitment and motivation.

Table A2.

Critical incidents related to scepticism, (lack of) commitment and motivation.

| Case Company | Critical Incident | Quote Interview | Data Label | Human Factor Identified |

|---|---|---|---|---|

| A | 1. Skepticism among employees | The first employees to use the cobot were skeptical | Prejudice | Resistance to change |

| 2. Lack of experience/gaining experience with cobots | The use of cobots was a real culture shock for our employees | Unfamiliarity | Resistance to change | |

| 3. (Lack of) Committed employees | We should have involved more people from the start | Commitment | Communication | |

| 4. (Lack of) Committed employees | The results became worse because the employees did not work with the cobot | Commitment | Communication Culture | |

| 5. Differences in character among employees | The willingness of employees [to work with the cobot] depends on their character | Character | Resistance to change | |

| 6. (Lack of) motivated employees | You see a huge difference in motivation between the team leaders, which also makes the difference in the teams visible | Motivation | Resistance to change | |

| 7. (Lack of) motivated employees | I underestimated how difficult it is to motivate employees. There is a lot of difference in motivation among the team leaders; with the result that one team works very well with the cobot and the other much less | Motivation | Resistance to change Leadership Culture | |

| B | 8. Skepticism among employees | There has certainly been some turmoil when we announced that we would focus on robotisation | Prejudice | Resistance to change |

| 9. Lack of experience/gaining experience with cobots | Some operators were experimenting, for example, unexpectedly stand in front of the cobot, in order to find out how the cobot would react | Curiosity | Resistance to change Culture | |

| 10. (Lack of) Committed employees | The employees would like to work with the cobots, but we notice that the speed is not yet high enough to make it profitable | Commitment | Culture Leadership | |

| 11. Differences in character among employees | The character and the will[ingness] of the people are important factors. The kick-off must be effective to motivate all those different characters | Character | Resistance to change | |

| 12. (Lack of) motivated employees | The team leader must be convinced of the cobots, because he/she must create support | Motivation | Resistance to change Leadership | |

| 13. (Lack of) motivated employees | The operators were enthusiastic to get started | Motivation | Resistance to change Culture Leadership | |

| C | 14. Skepticism among employees | The level of trust was not very high. The first employee was very skeptical | Prejudice | Resistance to change |

| 15. Lack of experience/gaining experience with cobots | Due to unfamiliarity, the cobots are used too little | Unfamiliarity | Resistance to change Culture Communication | |

| 16. Lack of experience/gaining experience with cobots | The employees were triggered by the lights and the bells on the cobot | Curiosity | Resistance to change Culture | |

| 17. (Lack of) Committed employees | We have to deal with new people every day who work for us as flex workers. They are less committed and sometimes do not even speak the Dutch language | Commitment | Resistance to change Culture | |

| 18. Differences in character among employees | Certain people refuse to work with the cobot | Character | Resistance to change | |

| 19. (Lack of) motivated employees | The team leader reports about the first signals and feedback. You see a lot of differences between team leaders | Motivation | Leadership | |

| D | 20. Skepticism among employees | I was surprised to see how much resistance there was, also among the technicians | Prejudice | Resistance to change |

| 21. Skepticism among employees | The amount of resistance that arose when people only hear the word “robot” or “cobot” was unprecedented | Prejudice | Resistance to change Culture | |

| 22. Lack of experience/gaining experience with cobots | It seems that people are really afraid of the cobots | Unfamiliarity | Resistance to change Culture | |

| 23. Lack of experience/gaining experience with cobots | There was more fear than curiosity | Unfamiliarity Curiosity | Resistance to change Culture | |

| 24. (Lack of) Committed employees | We could have prepared the operators even better | Commitment | Communication Culture | |

| 25. (Lack of) Committed employees | The support was not large, but due to the failure of the cobot the commitment was quickly gone | Commitment | Resistance to change Culture | |

| 26. Differences in character among employees | Character plays a major role here too. You see a huge difference in motivation between the team leaders, which also makes the difference in the teams visible. One team leader finds technology and innovation more fun and interesting than the other team leader | Character | Resistance to change Leadership Culture | |

| 27. (Lack of) motivated employees | Negativity sneaks into a team if a cobot does not work perfectly in one go. A test/implementation of a cobot is custom-made and requires many new insights. | Motivation | Resistance to change Communication Culture | |

| 28. (Lack of) motivated employees | Proactivity from the team leaders is so important! You see that if the motivation weakens, the results plummet. As an organisation you have to spend time on this. That really is a learning point for our organisation | Motivation | Resistance to change Leadership Culture | |

| 29. (Lack of) motivated employees | You need the team leaders to keep on motivating and to really take on their leadership role | Motivation | Leadership |

References

- Sheridan, T.B. Human–robot interaction: Status and challenges. Hum. Factors 2016, 58, 525–532. [Google Scholar] [CrossRef]

- Goetschalckx, M.; Ashayeri, J. Classification and design of order picking systems. Logist. World 1989, 2, 99–106. [Google Scholar] [CrossRef]

- Anđelković, A.; Radosavljević, M. Improving order-picking process through implementation warehouse management system. Strateg. Manag. 2018, 23, 3–10. [Google Scholar] [CrossRef]

- De Koster, R.; Le-Duc, T.; Roodbergen, K.J. Design and control of warehouse order picking: A literature review. Eur. J. Oper. Res. 2007, 182, 481–501. [Google Scholar] [CrossRef]

- ABIresearch. Collaborative Robotics Market Exceeds US$1 Billion by 2020. Available online: https://www.abiresearch.com/press/collaborative-robotics-market-exceeds-us1-billion-/ (accessed on 17 April 2018).

- Dijkhuizen, B. The advance of cobots logistics. Logistic 2017, 12, 6. [Google Scholar]

- Dijkhuizen, B. Robots nemen tilwerk uit handen. Logistiek 2017, 24–25. Available online: www.logistiek.nl (accessed on 10 July 2018).

- Bonkenburg, T. Robotics in logistics. A DPDHL perspective on implications and use cases for the logistics industry. Troisdorf DHL Trendrep. 2016. Available online: https://www.dhl.com/content/dam/downloads/g0/about_us/logistics_insights/dhl_trendreport_robotics.pdf (accessed on 20 May 2021).

- Pepitone, J. Amazon Buys Army of Robots. Available online: https://money.cnn.com/2012/03/20/technology/amazon-kiva-robots/Protime (accessed on 10 July 2018).

- Heater, B. Amazon Debuts a Pair of New Warehouse Robots. Available online: https://techcrunch.com/2019/06/05/amazon-debuts-a-pair-of-new-warehouse-robots/?guccounter=1 (accessed on 23 July 2019).

- ABIresearch. 50,000 Warehouses to Use Robots by 2025 as Barriers to Entry Fall and AI Innovation Accelerates. Available online: https://www.abiresearch.com/press/50000-warehouses-use-robots-2025-barriers-entry-fall-and-ai-innovation-accelerates/ (accessed on 10 April 2019).

- Weerd, P.D. Autonoom als opstap naar automatisering. Logisitiek 2017, 2017, 52–53. [Google Scholar]

- Sanders, T.L.; MacArthur, K.; Volante, W.; Hancock, G.; MacGillivray, T.; Shugars, W.; Hancock, P.A. Trust and Prior Experience in Human-Robot Interaction. In Proceedings of the Human Factors and Ergonomics Society 2017 Annual Meeting, Austin, TX, USA, 9–13 October 2017; pp. 1809–1810. [Google Scholar]

- Vagaš, M.; Galajdová, A.; Šimšík, D. Techniques for Secure Automated Operation with Cobots Participation. In Proceedings of the 2020 21th International Carpathian Control Conference (ICCC), High Tatras, Slovakia, 27–19 October 2020; pp. 1–4. [Google Scholar]

- Michaelis, J.E.; Siebert-Evenstone, A.; Shaffer, D.W.; Mutlu, B. Collaborative or Simply Uncaged? Understanding Human-Cobot Interactions in Automation. In Proceedings of the 2020 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 25–30 April 2020; pp. 1–12. [Google Scholar]

- Allen, V. Walk 11 Miles a Shift and Pick up An Order Every 33 Seconds: Revealed, How Amazon Works Staff ‘to the bone’ [Persbericht]. Available online: http://www.dailymail.co.uk/news/article-2512959/Walk-11-miles-shift-pick-order-33-seconds--Amazon-works-staff-bone.html (accessed on 12 June 2018).

- Roehl, C. Know Your Machine: Industrial Robots vs. Cobots [Blogpost]. Available online: https://blog.universal-robots.com/know-your-machine-industrial-robots-vs.-cobots (accessed on 20 January 2019).

- Weerd, P.D. Robots in De Logistiek: Dit is Er, Dit Kunnen Ze. Available online: https://www.logistiek.nl/warehousing/artikel/2018/01/robots-de-logistiek-dit-er-dit-kunnen-ze-101161844 (accessed on 26 June 2018).

- Strohkorb, S.; Huang, C.M.; Ramachandran, A.; Scassellati, B. Establishing Sustained, Supportive Human-Robot Relationships: Building Blocks and Open Challenges. In Proceedings of the AAAI Spring Symposium on Enabling Computing Research in Socially Intelligent Human Robot Interaction, Palo Alto, CA, USA, 21–23 March 2016; pp. 179–182. Available online: https://www.aaai.org/ocs/index.php/SSS/SSS16/paper/.../11942 (accessed on 10 July 2018).

- Calitz, A.P.; Poisat, P.; Cullen, M. The future African workplace: The use of collaborative robots in manufacturing. SA J. Hum. Res. Manag. 2017, 15, 1–11. [Google Scholar] [CrossRef]

- Cao, H.L. A collaborative homeostatic-based behavior controller for social robots in human–Robot interaction experiments. Int. J. Soc. Robot. 2017, 1, 675–690. [Google Scholar] [CrossRef]

- Cohen, Y.; Shoval, S.; Faccio, M.; Minto, R. Deploying cobots in collaborative systems: Major considerations and productivity analysis. Int. J. Prod. Res. 2021, 1–17. [Google Scholar] [CrossRef]

- Robinette, P.; Wagner, A.R.; Howard, A.M. Effect of Robot Performance on Human–Robot Trust in Time-Critical Situations—IEEE Journals & Magazine. Available online: https://ieeexplore.ieee.org/document/7828078 (accessed on 20 December 2020).

- Francis, S. Fast-Growing Sectors within Robotics and Automation. Available online: https://roboticsandautomationnews.com/2018/01/12/fast-growing-sectors-within-robotics-and-automation/15656/ (accessed on 20 December 2018).

- Hancock, A.; Billings, D.R.; Schaefer, K.E.; Chen, J.Y.C.; Visser, E.J.D.; Parasuraman, R. A meta-analysis of factors affecting trust in human-robot interaction. Hum. Factors 2011, 53, 517–527. [Google Scholar] [CrossRef]

- Simões, A.C.; Soares, A.L.; Barros, A.C. Factors influencing the intention of managers to adopt collaborative robots (cobots) in manufacturing organizations. J. Eng. Technol. Manag. 2020, 57, 101574. [Google Scholar] [CrossRef]

- Mercer. Global Talent Trends 2019 (Connectivity in the Human Age). Available online: https://www.mercer.com/content/dam/mercer/attachments/global/Career/gl-2019-global-talent-trends-study.pdf (accessed on 20 May 2021).

- Parasuraman, R.; Riley, V. Humans and automation: Use, misuse, disuse, abuse. Hum. Factors 1997, 39, 230–253. [Google Scholar] [CrossRef]

- Ogawa, K.; Nishio, S.; Koda, K.; Balistreri, G.; Watanabe, T.; Ishiguro, H. Exploring the natural reaction of young and aged person with telenoid in a real world. J. Adv. Comput. Intell. Intell. Inform. 2011, 15, 592–597. [Google Scholar] [CrossRef]

- Sorbello, R.; Chella, A.; Calí, C.; Giardina, M.; Nishio, S.; Ishiguro, H. Telenoidandroid robot as an embodied perceptual social regulation medium engaging natural human humanoid interaction. Robot. Auton. Syst. 2014, 62, 1329–1341. [Google Scholar] [CrossRef]

- Broadbent, E. Interactions with robots: The truths we reveal about ourselves. Ann. Rev. Psychol. 2017, 68, 627–652. [Google Scholar] [CrossRef] [PubMed]

- Ogreten, S.; Lackey, S.; Nicholson, D. Recommended roles for uninhabited team members within mixed-initiative combat teams. In Proceedings of the 2010 International Symposium on Collaborative Technologies and Systems, Chicago, IL, USA, 17–21 May 2010; pp. 531–536. [Google Scholar]

- Kessler, T.; Stowers, K.; Brill, J.C.; Hancock, P.A. Comparisons of human-human trust with other forms of human-technology trust. Proc. Hum. Factors Ergon. Soc. Ann. Meet. 2017, 61, 1303–1307. [Google Scholar] [CrossRef]

- Langley, A.; Smallman, C.; Tsoukas, H.; Van de Ven, A.H. Process studies of change in organisation and management: Unveiling temporality, activity, and flow. Acad. Manag. J. 2013, 56, 1–13. [Google Scholar] [CrossRef]

- Verhulst, E.; Boks, C. The role of human factors in the adoption of sustainable design criteria in business: Evidence from Belgian and Dutch case studies. Int. J. Innov. Sustain. Dev. 2012, 6, 146–163. [Google Scholar] [CrossRef]

- Maurtua, I.; Ibarguren, A.; Kildal, J.; Susperregi, L.; Sierra, B. Human–robot collaboration in industrial applications. Int. J. Adv. Robot. Syst. 2017, 14. [Google Scholar] [CrossRef]

- Maurtua, I.; Fernandez, I.; Tellaeche, A.; Kildal, J.; Susperregi, L.; Ibarguren, A.; Sierra, B. Natural multimodal communication for human–robot collaboration. Int. J. Adv. Robot. Syst. 2017, 14. [Google Scholar] [CrossRef]

- Ghauri, P. Designing and Conducting Case Studies in International Business Research. In Handbook of Qualitative Research Methods for International Business; Marschan-Piekkari, R., Welch, C., Eds.; Edward Elgar: Cheltenham, UK, 2004; pp. 109–124. [Google Scholar]

- Dekker, F. Robot—En ICT-Gebruik in Het Nederlandse Bedrijfsleven, ESB, Jaargang 101, editie 4733. 2016. Available online: https://fabiandekker.nl/_PDF_V2/312313_DEKKER%20(def).pdf (accessed on 10 July 2018).

- Verhulst, E.; Lambrechts, W. Fostering the incorporation of sustainable development in higher education. Lessons learned from a change management perspective. J. Clean. Prod. 2015, 106, 189–204. [Google Scholar] [CrossRef]

- Qu, S.Q.; Dumay, J. The qualitative research interview. Qual. Res. Account. Manag. 2011, 8, 238–264. [Google Scholar] [CrossRef]

- Tsui, K.; Desai, M.A.; Yanco, H.; Cramer, H.; Kemper, N. Measuring attitudes towards telepresence robots. Int. J. Intell. Control Syst. 2011, 16, 1–11. [Google Scholar]

- Hechanova, R.M.; Alampay, R.B.; Franca, E.P. Empowerment, job satisfaction and performance among Filipino service workers. Asian J. Soc. Psychol. 2006, 9, 72–78. [Google Scholar] [CrossRef]

- Kasser, T.; Sheldon, K.M. Time affluence as a path toward personal happiness and ethical business practice: Empirical evidence from four studies. J. Bus. Ethics 2009, 84, 243–255. [Google Scholar] [CrossRef]