Strategic Analysis of the Automation of Container Port Terminals through BOT (Business Observation Tool)

Abstract

1. Introduction

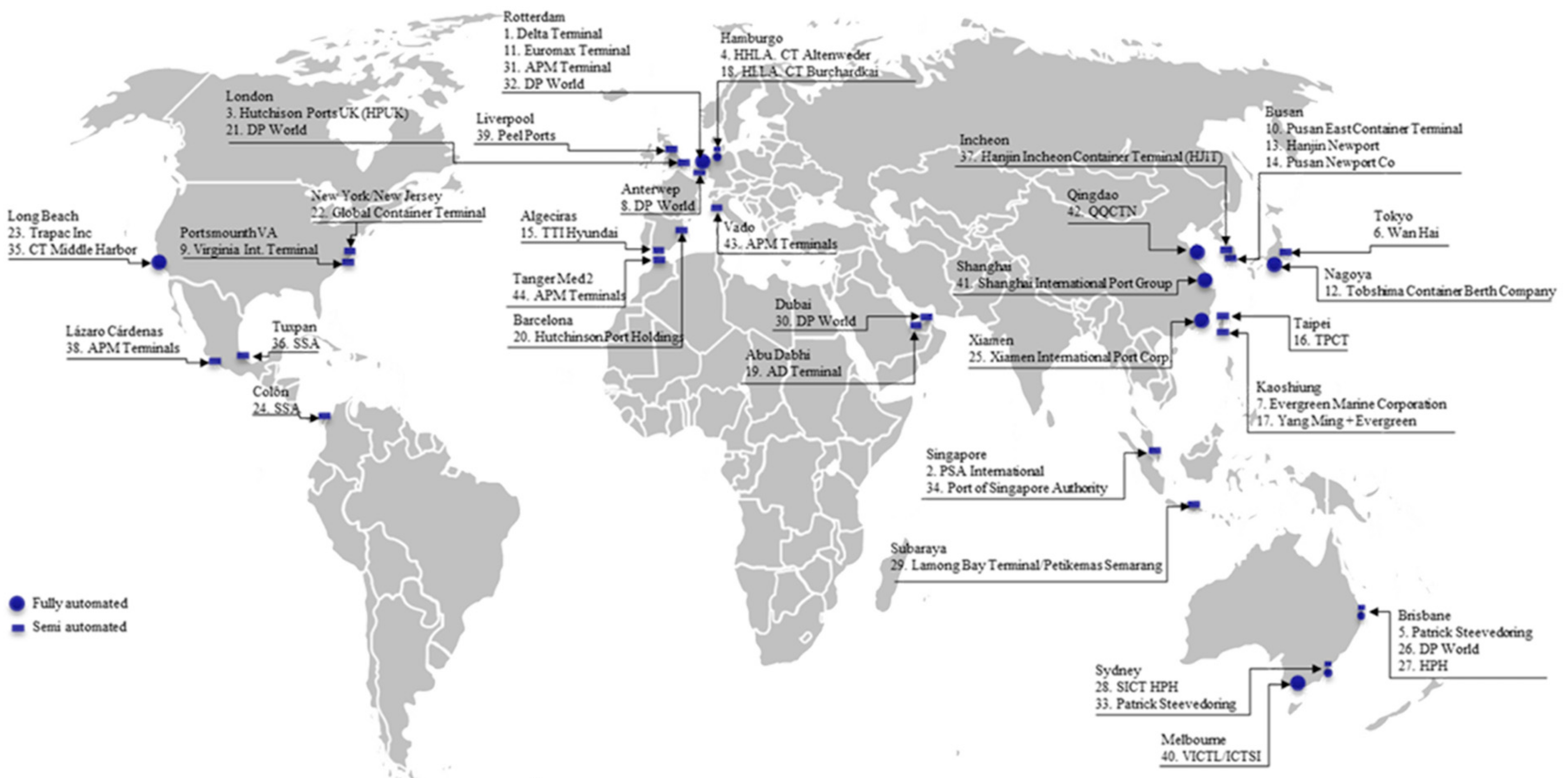

2. Types of Automated Terminals

3. Methodology

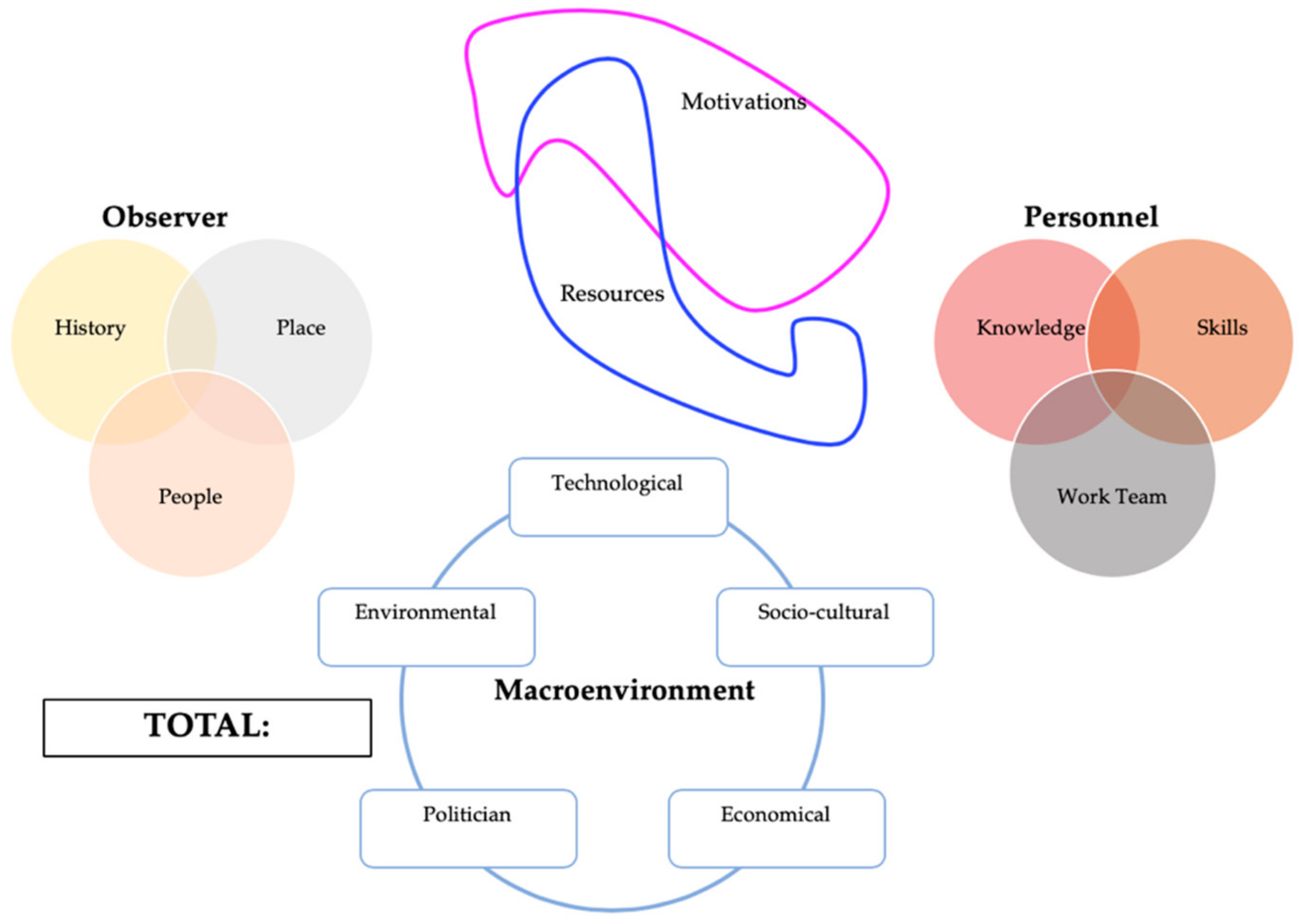

3.1. Step 1: BOT Analysis

3.1.1. Motivations and Resources to Advance

3.1.2. Establishment of the Working Team

3.1.3. Characterize and Understand the Development Environment

3.1.4. Macroenvironment Analysis

3.2. Step 2: Selection of Indicators

3.3. Step 3: Qualitative-Quantitative Analysis

- High degree of achievement: “High”—5

- Medium range: “Medium”—2.5

- Low range: “Low”—1

4. Expected Results and Discussion

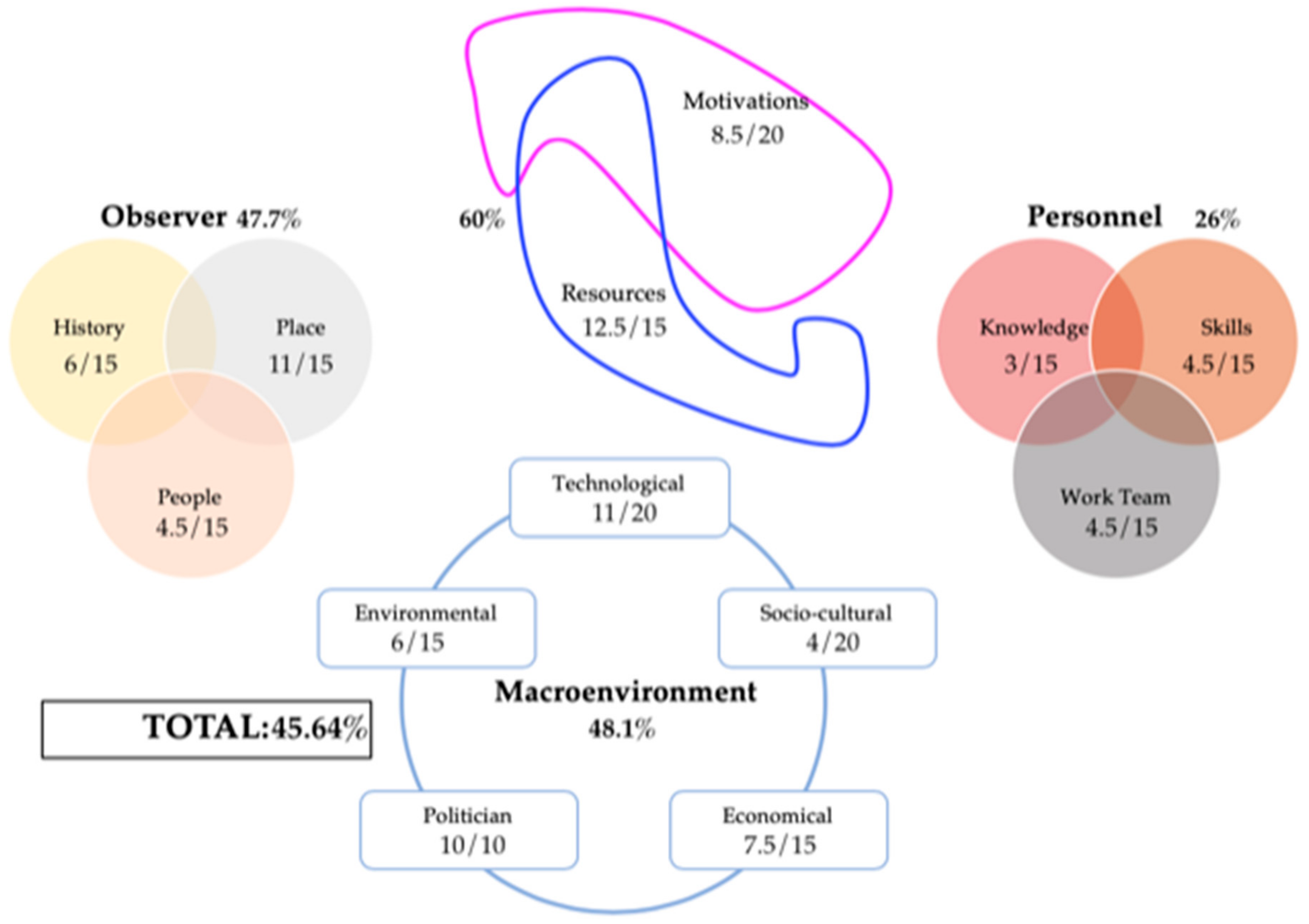

4.1. BOT Analysis

4.1.1. Motivations and Resources to Move Forward

4.1.2. Establishment of the Working Group

4.1.3. Characterize and Understand the Development Environment

4.1.4. Macro-Environment Analysis

- Technological. The automation and rationalization of port procedures has been made possible by digitalization and the integration of information technologies (IT) and innovative information systems (IS). The dynamism of the technological industry requires the establishment of implementation mechanisms that allow the inclusion of the new tools available and adaptation to new developments arising from research, such as the inclusion of autonomous vessels [20].

- Socio-cultural. In a sector with an important trade union strength, the automation of the terminals causes a social conflict, as it implies a reduction in the traditional required labor force.

- Economical. The Spanish port system has established a plan to boost entrepreneurship for innovation in the port sector, endowed with a fund of 25 million euros [21]. On the other hand, the European Sea Ports Organization, ESPO, has developed the "Connect Europe" program (2021-2028), with the aim of financing new port developments. Within this program, it is estimated that European ports will have investment needs of around 48,000 million euros between 2018 and 2027, caused by external factors such as the growth of trade flows, new trends in the maritime industry, decarbonization, digitalization, automation, urban development, and security [22].

- Political. Political actors and institutions advocate the incorporation of automation in maritime transport.

4.2. Qualitative-quantitative Analysis

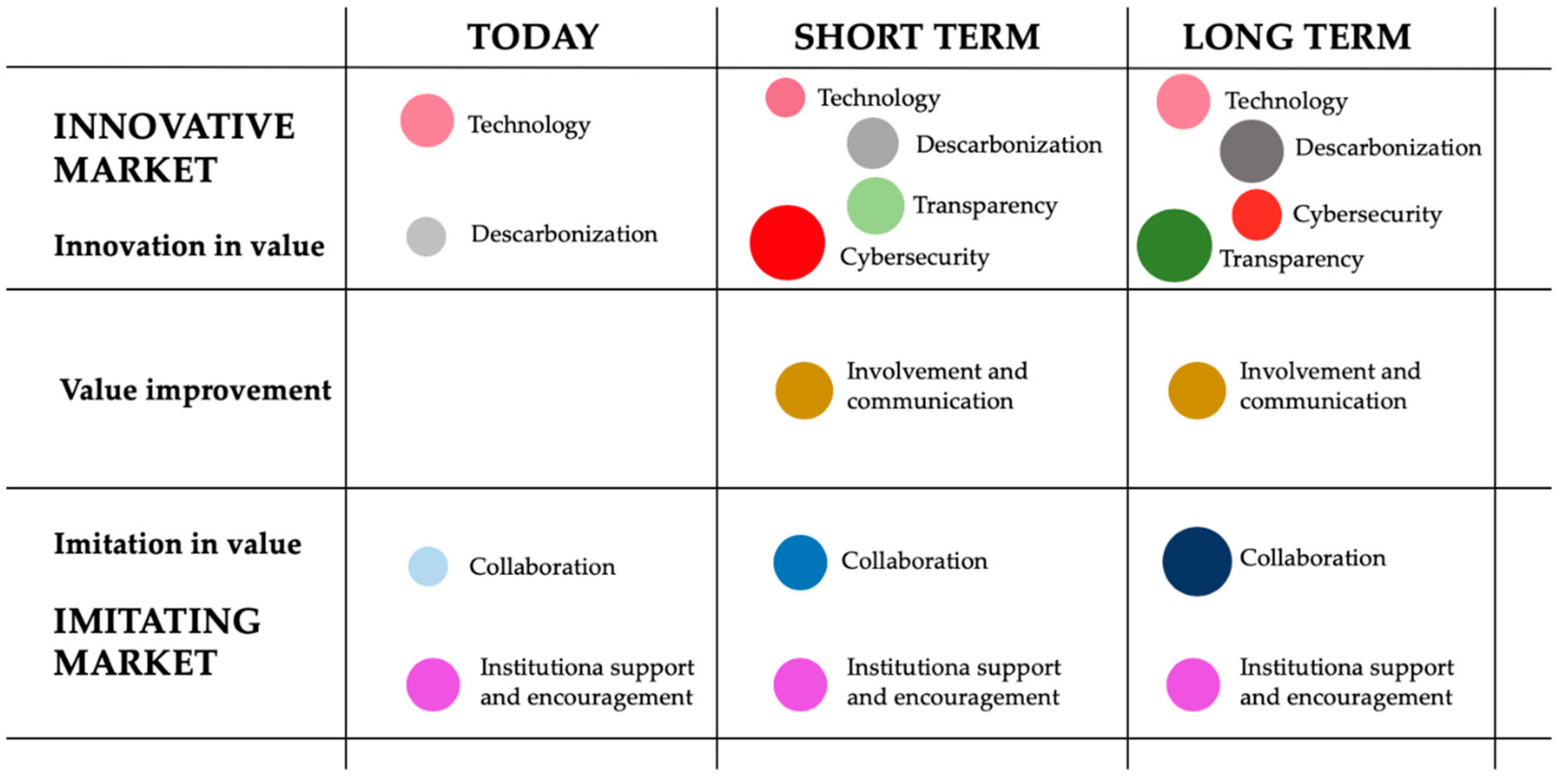

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vis, I.F.; De Koster, R. Transshipment of containers at a container terminal: An overview. Eur. J. Oper. Res. 2003, 147, 1–16. [Google Scholar] [CrossRef]

- Alho, T. Latest Automation Technology Developments for Ports and Terminals. In Proceedings of the ANESCO Automation Coference, Madrid, Spain, 19 February 2019. [Google Scholar]

- Martín-Soberón, A.M.; Monfort, A.; Sapiña, R.; Monterde, N.; Calduch, D. Automation in Port Container Terminals. Procedia Soc. Behav. Sci. 2014, 160, 195–204. [Google Scholar] [CrossRef]

- Boer, C.A.; Saanen, Y.A.; Gunther, H.O.; Kim, K.H.; Kopfer, H. Testing, tuning and training terminal operating systems. A modern approach. In Proceedings of the International Conference on Logistics and Maritime Systems (LOGMS), Bremen, Germany, 22–24 August 2012; pp. 25–35. [Google Scholar]

- Heilig, L.; Schwarze, S.; Voss, S. An Analysis of Digital Transformation in the History and Future of Modern Ports. In Proceedings of the 50th Hawaii International Conference on System Sciences, Hawaii, HI, USA, 4–7 January 2017. [Google Scholar]

- Lee, P.T.-W.; Lam, J.S.L.; Lin, C.-W.; Hu, K.-C.; Cheong, I. Developing the fifth generation port concept model: An empirical test. Int. J. Logist. Manag. 2018, 29, 1098–1120. [Google Scholar] [CrossRef]

- Camarero, A.; González, N. Cadenas Integradas de Transporte; Fundación Agustín de Betancourt: Madrid, Spain, 2006. [Google Scholar]

- Camarero, A.; González-Cancelas, N. Logística y Transporte de Contenedores; Fundación Agustín de Betancourt: Madrid, Spain, 2007. [Google Scholar]

- Geerlings, H.; Van Duin, R. A new method for assessing CO2-emissions from container terminals: A promising approach applied in Rotterdam. J. Clean. Prod. 2011, 19, 657–666. [Google Scholar] [CrossRef]

- Zhen, L.; Hu, H.; Wang, W.; Shi, X.; Ma, C. Cranes scheduling in frame bridges based automated container terminals. Transp. Res. Part C Emerg. Technol. 2018, 97, 369–384. [Google Scholar] [CrossRef]

- Zhen, L.; Lee, L.H.; Chew, E.P.; Chang, D.-F.; Xu, Z.-X. A Comparative Study on Two Types of Automated Container Terminal Systems. IEEE Trans. Autom. Sci. Eng. 2011, 9, 56–69. [Google Scholar] [CrossRef]

- Iris, Ç.; Pacino, D.; Røpke, S.; Larsen, A. Integrated Berth Allocation and Quay Crane Assignment Problem: Set partitioning models and computational results. Transp. Res. Part E Logist. Transp. Rev. 2015, 81, 75–97. [Google Scholar] [CrossRef]

- Solórzano, M.C.; Fernández, R.I.; Zambrano, D.C.; Administrativa, V. Plan de marketing en Pymes. In Estrategias Exitosas Para Empresas Comerciales; Universidad Laica Eloy Alfaro de Manabí: Manabí, Ecuador, 2018. [Google Scholar]

- Dorado Gómez, S. Proyecto y Estudio de Viabilidad Económico Financiero y Riesgos de Complejo Hotelero y Resort; Universidad Internacional de la Rioja (UNIR): Logroño, Spain, 2014. [Google Scholar]

- Iris, Ç.; Christensen, J.; Pacino, D.; Ropke, S. Flexible ship loading problem with transfer vehicle assignment and scheduling. Transp. Res. Part B Methodol. 2018, 111, 113–134. [Google Scholar] [CrossRef]

- Morrall, A.; Rainbird, J.; Katsoulakas, T.; Koliousis, I.; Varelas, T. E-Maritime for Automating Legacy Shipping Practices. Transp. Res. Procedia 2016, 14, 143–152. [Google Scholar] [CrossRef]

- Agencia Europea Medio Ambiente. Emissions of Air Pollutants from Transport. 2019. Available online: https://www.eea.europa.eu/data-and-maps/indicators/transport-emissions-of-air-pollutants-8/transport-emissions-of-air-pollutants-6 (accessed on 26 May 2019).

- Iris, Ç.; Lam, J.S.L. A review of energy efficiency in ports: Operational strategies, technologies and energy management systems. Renew. Sustain. Energy Rev. 2019, 112, 170–182. [Google Scholar] [CrossRef]

- Meyer-Larsen, N.; Müller, R. Enhancing the Cybersecurity of Port Community Systems. In Pharmaceutical Supply Chains-Medicines Shortages; Springer Science and Business Media LLC.: Bremen, Germany, 2018; pp. 318–323. [Google Scholar]

- Resolución del Parlamento Europeo, de 15 de enero de 2019, sobre la conducción autónoma en los transportes europeos (2018/2089(INI)). Available online: http://www.europarl.europa.eu/doceo/document/TA-8-2019-0005_ES.html (accessed on 6 March 2019).

- Fondo Puertos 4.0. 2019. Available online: https://www.europapress.es/economia/transportes-00343/noticia-puertos-espanoles-crean-fondo-25-millones-euros-promover-proyectos-innovadores-logisticos-20190408210157.html. (accessed on 24 May 2019).

- O’Reilly, E.; ESPO. The Infraestructura Investement needs and financing challenge of European Ports. In Port Investments Study; ESPO: Brussels, Belgium, 2018; Available online: https://www.espo.be/media/Port%20Investment%20Study%202018_FINAL_1.pdf (accessed on 3 February 2020).

- Venturini, G.; Iris, Ç.; Kontovas, C.A.; Larsen, A. The multi-port berth allocation problem with speed optimization and emission considerations. Transp. Res. Part D Transp. Environ. 2017, 54, 142–159. [Google Scholar] [CrossRef]

- OECD. Descarbonising Maritime Transport: Pathways to Zero-Carbon Shipping by 2035. 2020. Available online: https://www.oecd-ilibrary.org/transport/decarbonising-maritime-transport_b1a7632c-en (accessed on 31 January 2020).

| Terminal | Equipment | Type |

|---|---|---|

| ECT Europa Container Terminal –Rotterdam. Delta Terminal (1993) | 137 ARMG / AGV | A |

| PSA International—Singapur. Pasir Panjang Terminal (1997) | 15 OHBC Manual tractor (M.T.) + chassis | S* |

| Hutchison Ports UK (HPUK)—London Thamesport (2000) | 18 ARMG M.T. + chassis | S |

| HHLA—Hamburgo. CT Altenwerder (CTA) (2001) | 52 ARMG / AGV | A |

| Patrick Steevedoring—Brisbane. Fishermans Island Terminal (2002) | 27 Auto SC / Auto SC | A |

| Wan Hai—Tokyo. Ohi Terminal (2003/06) | 8 CARMG M.T. + chassis | S |

| Evergreen Marine Corporation—Kaoshiung. Evergreen Marine Terminal (2005) | 6 CARMG M.T. + chassis | S |

| DP World—Amberes Antwerp Gateway (2007) | 14 ARMG / ShC manual | S |

| Virginia International Terminal (VIT)—Portsmouth. VA Virginia int. Gateway (2007) | 30 ARMG Manual cassettes | S |

| Pusan East Container Terminal—Busan. Korean Express Brusan CT (2007) | 6 ARMG M.T. + chassis | S |

| ECT Europa Container Terminal—Rotterdam. Euromax terminal (2008) | 58 ARMG / AGV | A |

| Tobshima container berth (TCB) company—Nagoya. Tobishima Pier South (2008) | 12 ARTG AGV | A |

| Hanjin Newport—Hyundai Merchant Marine—Busan. Pusan Newport (2009/10) | 41 + 36 ARMG M.T. + chassis | S |

| Pusan Newport Co (DP World)—Busan. Pusan Newport (2009/12) | 32 + 38 CARMGM.T. + chassis | S |

| TTI Hyunday—Algeciras. Isla Verde (2010) | 32 ARMG / ShC manual | S |

| TPCT—Taipei Port Container Terminal (2010) | 40 CARMG M.T. + chassis | S |

| Yang Ming+Evergreen—Kaoshiung. Kao Ming Container Terminal (2010/11) | 22+40 dual CARMG M.T. + chassis | S |

| HHLA—Hamburgo. CR Burchardkai (CTB) (2010/17) | 15—12 ARMG SHC manual | S |

| AD Terminals—Abu Dhabi. Khalifa Container Terminal (2012) | 42 ARMG / ShC | S |

| Hutchinson Port Holdings—Barcelona. BEST (2012) | 48 ARMG / ShC | S |

| DP World—London Gateway 1,2/3 (2013/2016) | 40 + 20 ARMG / ShC | S |

| Global container Terminal—New York/New Jersey. Global Terminals (2014) | 20 ARMG ShC | S |

| Trapac Inc - Long Beach. Trapac (2014) | 27 ARMG/ ShC | A |

| SSA—Colón Manzanillo Int. Terminal (2014) | 22 ARMG | S |

| Xiamen International Port Corp—Xiamen. Halcang + Fuijang (2014) | 16 ARMG / 18 AGV | A |

| DP WOrld—Brisbane (2014) | 14 ARMG / ShC | S |

| HPH—Brisbane Container Terminal (2014) | 12 ARMG / ShC | S |

| SICT HPH—Sydney Inter. Container Terminal (2014) | 12 ARMG / ShC | S |

| Lamong Bay Terminal/Petikemas Semarang—Surabaya. Pelindo III (2014/16) | 20 ARMG + 11 ARTG | S |

| DP World—Dubai. Jebel Ali Container Terminal 3/4 (2014/18) | 60 + 35 ARMG | S |

| APM Terminal—Rotterddam. APMT Maaskvlakte II (2015) | 54 ARGM 36+Lift AGVs | A |

| DP/World—Rotterdam World Gateway (2015) | 32 ARMG / AGV | A |

| Patrick Steevedoring—Sydney Autostrad (2015) | 44 AutoSC / AutoSC | A |

| Port of Singapur Authority—PSA PPT 3-1a T%, 3-1b, 3-2b (2015/2016) | 22+34+72 CARMG M.T. + chassis | S* |

| Long Beach CT Inc.—CT Middle Harbor (2016) | 32 ARMG | A |

| SSA Mexico—Tuxpan Port Terminal (TPT) (2016) | 8 ASC / M.T. + chassis | S |

| Hanjin Incheon Container Terminal—Incheon (2016) | 14 ARMG | S |

| APM Terminals - Veracruz Lázaro Cárdenas T2 (2016) | 22 ARMG | S |

| Peel Ports—Liverpool2 (2016) | 22 CARMG | S* |

| VICTCL/ICTSI—Melbourne. Victoria Int. CT (2016/17) | 32 ARMG / 11 AutoShC | A |

| Shangai International Port Group—Shangai. Yangshan Fase 4 (2017) | 40 ARMG / 50 AGV | A |

| QQCTN—Qingdao. Qianwai CT (2018) | 38 ARMG / 38 AGV | A |

| APM Terminals—VADO. Liguere (2019) | 21 ARMG M.T. + chassis | S |

| APM Terminals—Tanger Med 2 (2019) | 32 ARMG / ShC | S |

| Scenarios | Indicator | Definition |

|---|---|---|

| Motivations | Operational improvement | Increased productivity, thanks to a better occupation and layout of the yard and the development of methodical and orderly operations. Faced with these improvements, the little flexibility they present requires the establishment of mechanisms to facilitate decision-making in unscheduled situations. |

| Economic profitability | Reductions in operating costs should allow the high initial investment required to be amortized. | |

| Safety | The elimination of the human factor makes it possible to reduce errors in the handling of goods, and therefore, an increase in safety. | |

| Sustainability | Sustainability criteria established in the port system, need to decouple the growth of the sector with the negative effects on the social environment and the environment | |

| Resources | Institutional support | Organisms and public entities advocate for the transformation and incorporation of new technologies in order to achieve a more competitive system. |

| Economic agents | Cross investment confluence | |

| Enabling tools | Availability in the market of the necessary technology. | |

| Knowledge | Experience | Personnel not equipped with experience in the performance of new roles |

| Formation | Inadequate and obsolete in the face of new needs | |

| Information | Lack of access to correct information | |

| Skills | Flexibility | Difficulty adapting, reacting and responding.The flexibility comes from a cooperative agreement between the terminal operator and the liner shipping company [15]. |

| Goods handling | Interference of operations. Automation allows to reduce the number of housekeeping movements. | |

| Incident management | Align people with the strategy, communication between the various members and between all levels of the organization | |

| Work Team | Implication | Inclusion and internalization of the project |

| Communication | Align people with the strategy, communication between the various members and between all levels of the organization. | |

| Information processing | Exchange of documents in physical and digital format, with a multitude of interfaces between sender and recipient | |

| History | Paradigm shift | Evolution of the "Port" concept |

| Ports 4.0 | Digital, intelligent and smart ports | |

| Technological Incorporation | Transposition of technology applied to other sectors (blockchain) | |

| People | Multiplicity of agents | Port community conformed of private and public agents. |

| Acceptance of change | Opposition of stevedoring personnel to automation | |

| Collaboration between agents | Disparate objectives that do not converge, resulting in a conflict of interest [16] | |

| Place | Link in logistics chains | Acceptance of the port as a node in the logistics chain, eliminating bottlenecks. |

| Maturity of the port system | Consolidation of ports | |

| Transparency | System opacity | |

| Technological | Technological maturity | Solid fundamentals and verified developed solutions |

| Obsolescence | Emergence of new technologies as a result of research | |

| Implementation mechanisms | Lack of protocols and methodology to facilitate the implementation of technology | |

| Research | Research initiatives must be accompanied by pilot tests certifying their adequacy. | |

| Socio-cultural | Training of personnel | Unskilled personnel |

| Support for trade union strength | The current union strength in the ports and their reluctance to change is a handicap for the adoption of automated terminals. | |

| Reconversion | The change in the management model of the terminals implies a reconversion of the workers to technological profiles | |

| Safety | The elimination of the human factor in operations means an increase in safety, however, in many terminals today people interact with automated and manual equipment, increasing the probability of error | |

| Environmental | Decarbonization | The European Environment Agency (EEA) [17] estimates that shipping has increased its greenhouse gas emissions by 22% from 1990 to 2016. Faced with this increase, the OECD (Organization for Economic Cooperation and Development) has established measures supported by the use of new technologies to achieve the decarbonization of maritime transport by 2035 [5]. |

| Reduction of externalities | Negative externalities, such as congestion, accidents and pollution (atmospheric, acoustic, and visual) can be mitigated with the implementation of automated terminals due to the more rational use of space, the use of electrical equipment, and the programming of removal operations in such a way that they do not intervene in the operation of the terminal. | |

| Energy efficiency | Many ports and terminals endeavor to enhance energy efficiency as energy prices have increased through years and climate change mitigation is a key target for the port industry [18]. | |

| Political | Institutional Impulse | Organisms and public entities advocate for transformation. |

| Regulatory requirements | Hardening of regulations | |

| Economical | Lobbies | Faced with the possibility of a new economic slowdown and the risk of implementing automated terminals, investments have been reduced. |

| Financing | Search for alternative financing | |

| Community aid | European funding with high requirements for its granting. |

| sTAGE | Indicator | Qualitative | Quantitative |

|---|---|---|---|

| Motivations | Operational improvement | Medium | 2.5 |

| Economic profitability | Medium | 2.5 | |

| Safety | Low | 1 | |

| Sustainability | Medium | 2.5 | |

| Resources | Institutional support | High | 5 |

| Economic agents | Medium | 2.5 | |

| Enabling tools | High | 5 | |

| Knowledge | Experience | Low | 1 |

| Formation | Low | 1 | |

| Information | Low | 1 | |

| Skills | Flexibility | Low | 1 |

| Goods handling | Medium | 2.5 | |

| Incident management | Low | 1 | |

| Work Team | Implication | Low | 1 |

| Communication | Low | 1 | |

| Information processing | Medium | 2.5 | |

| History | Paradigm shift | Medium | 2.5 |

| Ports 4.0 | Low | 1 | |

| Technological Incorporation | Medium | 2.5 | |

| Place | Link in logistics chains | High | 5 |

| Maturity of the port system | High | 5 | |

| Transparency | Low | 1 | |

| People | Multiplicity of agents | Medium | 2.5 |

| Acceptance of change | Low | 1 | |

| Collaboration between agents | Low | 1 | |

| Technological | Technological maturity | High | 5 |

| Obsolescence | Medium | 2.5 | |

| Implementation mechanisms | Low | 1 | |

| Research | Medium | 2.5 | |

| Socio-cultural | Training of personnel | Low | 1 |

| Support for trade union strength | Low | 1 | |

| Reconversion | Low | 1 | |

| Safety | Low | 1 | |

| Economical | Lobbies | Medium | 2.5 |

| Financing | Medium | 2.5 | |

| Community aid | Medium | 2.5 | |

| Political | Institutional Impulse | High | 5 |

| Regulatory requirements | High | 5 | |

| Environmental | Decarbonization | Low | 1 |

| Reduction of externalities | Medium | 2.5 | |

| Energy efficiency | Medium | 2.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camarero Orive, A.; Santiago, J.I.P.; Corral, M.M.E.-I.; González-Cancelas, N. Strategic Analysis of the Automation of Container Port Terminals through BOT (Business Observation Tool). Logistics 2020, 4, 3. https://doi.org/10.3390/logistics4010003

Camarero Orive A, Santiago JIP, Corral MME-I, González-Cancelas N. Strategic Analysis of the Automation of Container Port Terminals through BOT (Business Observation Tool). Logistics. 2020; 4(1):3. https://doi.org/10.3390/logistics4010003

Chicago/Turabian StyleCamarero Orive, Alberto, José Ignacio Parra Santiago, María Magdalena Esteban-Infantes Corral, and Nicoletta González-Cancelas. 2020. "Strategic Analysis of the Automation of Container Port Terminals through BOT (Business Observation Tool)" Logistics 4, no. 1: 3. https://doi.org/10.3390/logistics4010003

APA StyleCamarero Orive, A., Santiago, J. I. P., Corral, M. M. E.-I., & González-Cancelas, N. (2020). Strategic Analysis of the Automation of Container Port Terminals through BOT (Business Observation Tool). Logistics, 4(1), 3. https://doi.org/10.3390/logistics4010003