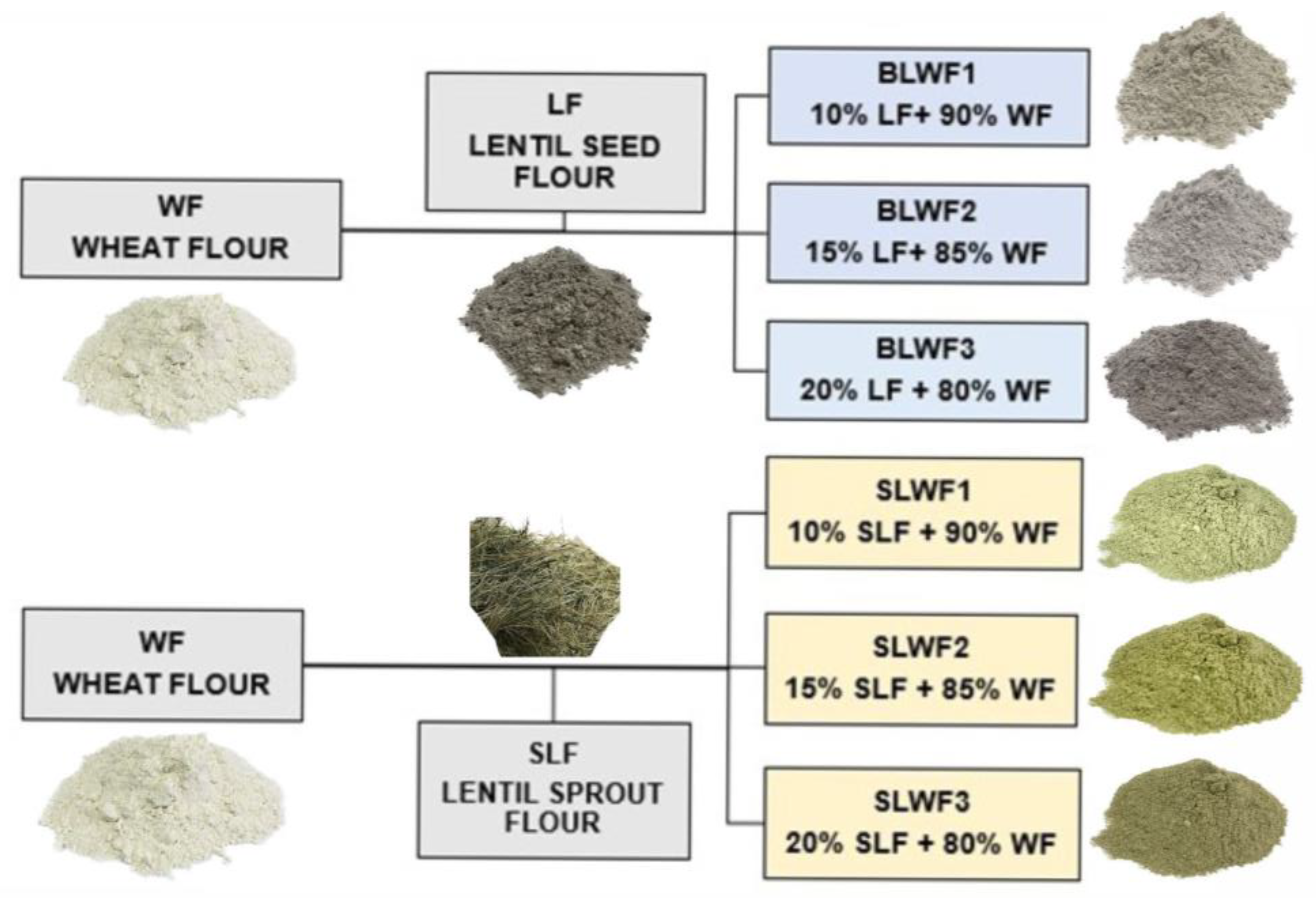

3.1. The Proximate Composition of Composite Flours

The results regarding the proximate composition of the composite flours are presented in

Table 1.

Analysis of the results from

Table 1 reveals that WF had a higher moisture content than the samples with different proportions of black lentil flour, and was in the range of samples with sprouted black lentil flour. WF had a moisture content corresponding to 11.43 ± 0.39%, whereas the moisture content of samples containing black lentil/wheat flour and sprouted black lentil/wheat flour, respectively, ranged from 10.77 ± 0.06% to 9.92 ± 0.13% and from 11.39 ± 0.01% to 11.86 ± 0.02%. These results are similar to those of [

25], who reported that the moisture content of breads obtained with different proportions of black lentils was lower than that of the control bread [

25].

In terms of mineral content, the gradual addition of black lentils and lentil sprouts significantly improved the mineral content of the various flours compared with WF. The mineral content rose from 0.5 ± 0.02% in WF to 2.62 ± 0.03% in BLWF3 and 5.51 ± 0.16% in SLWF3. Similar results were obtained by Hernandez-Aguilar et al., 2020 [

26]. In their study, the mineral content rose from 0.89 to 0.96% between the control sample and the sample with 10% sprouted lentils. Çelik and İlyasoǧlu (2022) revealed an improvement in mineral content between the control sample and that with 20% black lentils [

25]. It can therefore be concluded that the addition of black lentils to wheat flour improves the mineral composition.

It was also found in the present study that flours containing sprouted lentils were richer in minerals than those containing black lentil flour. The protein content followed the same pattern as the mineral content. In fact, as the quantity of black lentils, whether sprouted or not, increased in the composition of the compound flours, so did the protein content. Compound flour samples with black lentils had 12.86 ± 0.02, 13.98 ± 0.09 and 15.06 ± 0.13% protein for BLWF1, BLWF2 and BLWF3, respectively. Samples containing different quantities of sprouted lentils had 11.7 ± 0.11, 12.34 ± 0.2, and 13.31 ± 0.17% protein for SLWF1, SLWF2, and SLWF3, respectively. This suggests that the progressive addition of black lentil flour or sprouted black lentil flour to wheat flour would significantly improve the protein content. Similar results were obtained by other authors [

25,

26]. It should also be noted that flour composed of different proportions of black lentils was richer in protein than flour containing the latter’s sprouts.

Protein supplementation of flour products by adding legumes is an important practice for improving the nutritional value of these products. Flour products, such as bread, biscuits or pasta, are usually high in carbohydrates but low in protein and essential amino acids. The addition of legume flour (chickpeas, lentils, beans, or peas) completes the amino acid profile, especially with lysine, which is missing from cereals [

27,

28]. Protein supplementation promotes a more diversified and sustainable diet, with a positive impact on food security.

In terms of lipids and carbohydrates, the wheat flour provided 1.30 ± 0.02% lipids and 75.63 ± 0.39 g/100 g carbohydrates. The gradual addition of black lentil flour or sprouted black lentil flour to wheat flour would reduce its levels of lipids and carbohydrates. Similar results have been reported by other authors [

12,

22,

25,

26].

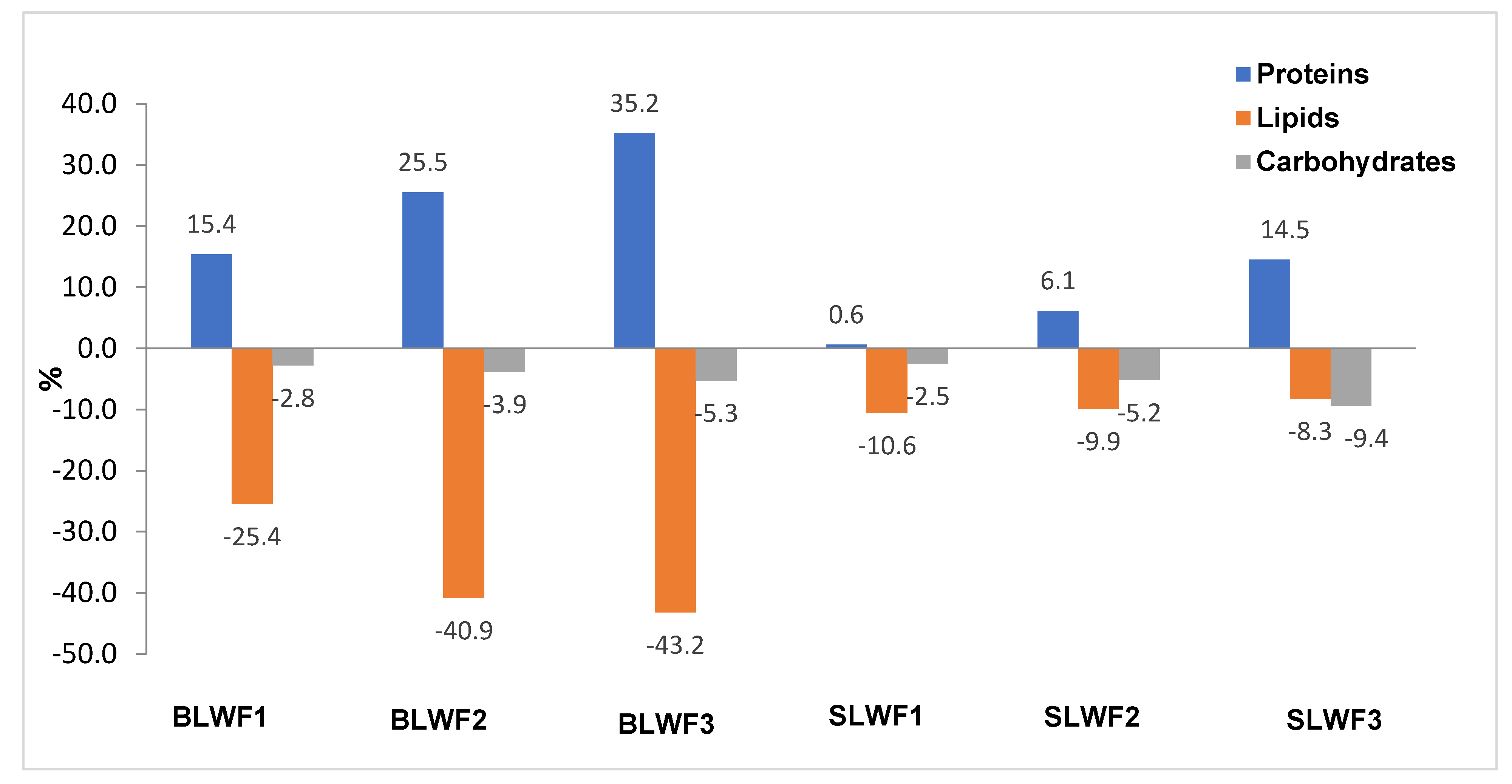

Figure 3 shows the increases/decreases of nutritional parameters in composite flours (BLWF and SLWF) compared to type 650 wheat flour intended for a bakery. There is an important increase in the protein content that varies between 15.4–35.2% depending on the percentage of wheat flour substituted with lentil flour (BLWF), between 0.6–14.5% in the case of fortification with 10–20% of sprouted lentil flour (SLWF). The lipid content, however, decreases with the substituted fraction, the decrease being significant and between 25.4–43.2% depending on the percentage of black lentil flour added, and between 8.3–10.6% when replacing wheat flour with lentil sprout flour.

The carbohydrate intake provided by the consumption of 100 g of composite flour decreased, but in a smaller proportion (2.8–5.3%) compared to the lipid fraction, in the fortified flours with black lentils, with a decrease between 2.5–9.4% of the carbohydrate content for the SLWF samples compared to the intake generated by white flour.

The importance of the use of legumes in flour formulas and their role in controlling metabolic functions and obesity has been highlighted in other studies [

29]. Legumes help reduce the risk of chronic diseases such as type 2 diabetes, cardiovascular disease and obesity due to their high fiber and phytonutrient content [

30]. Fiber and protein from the legume fraction slow down the absorption of carbohydrates, which helps keep blood sugar stable.

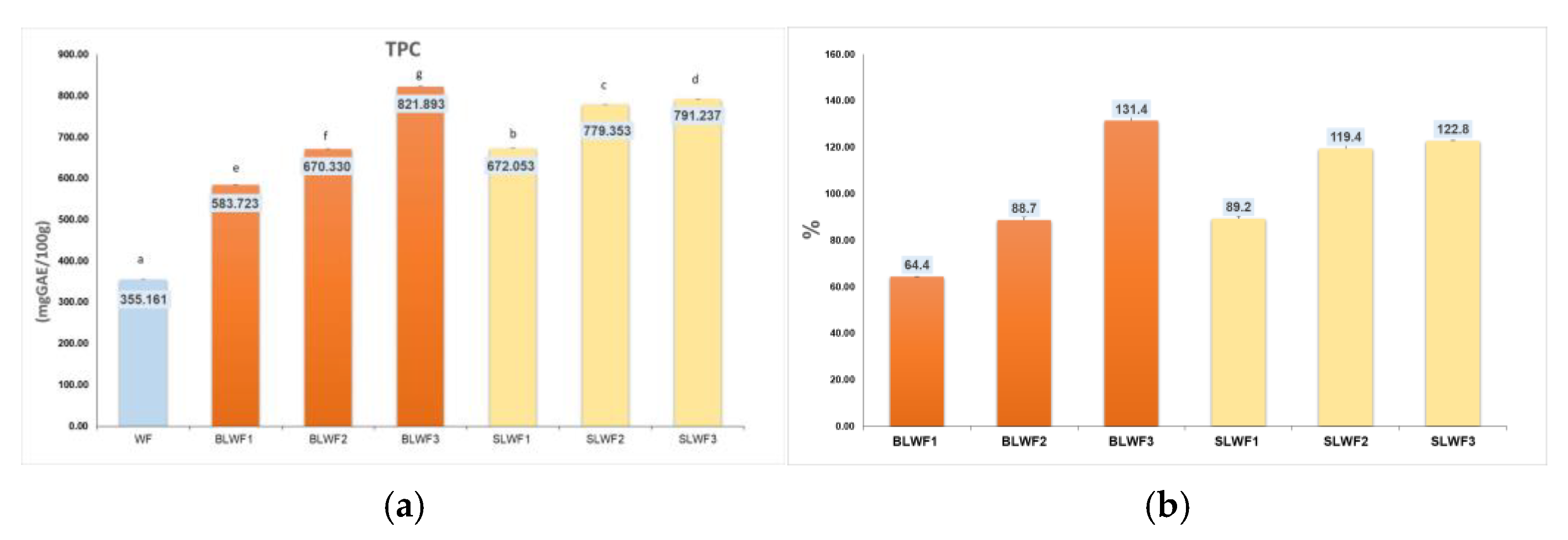

3.2. The Phytochemical Profile of Composite Flours

In the

Figure 4 are presented the values regarding the TPC content of the composite flours and

Table 2 presents the profile of individual polyphenols identified in the BLWF and SLWF mixtures.

The total polyphenol content of the composite flours fortified with sprouted and non-sprouted black lentil flour ranged from 583.723 mg/100 g in the case of the BLWF1 sample to 791.237 mg/100 g in the case of the SLWF3 sample. Through germination, the content of total polyphenols increased, the increase being between 89.22–122.8%. Other authors have reported a content of 379.76 mg/100 g [

31] and 456 mg/100 g [

19] in non-germinated lentil seeds, between 461.28–788.88 mg/100 g [

31] and between 486–614 mg/100 g [

19] in lentil sprouts at different stages of germination. The variety of lentils has a significant influence on the content of total polyphenols. A recent study carried out on different varieties of lentils from Romania showed that yellow lentils are distinguished by a lower content of total polyphenols (69.00 mg/100 g), followed by red lentils (85.89 mg/100 g), brown lentils (247.56 mg/100 g), and black lentils (248.38 mg/100 g), and the highest value was recorded in the case of green lentils (327.31 mg/100 g) [

32].

Much higher values (1200 mg/100 g) for total polyphenol content have been reported in other studies [

10], which emphasizes that sprouting lentils can lead to a significant increase in TPC, with values rising by up to 185% over a 7-day germination period.

In the analyzed composite flours, hydroxycinnamic acids such as rosmarinic, coumaric, ferulic and beta-resorcylic acid were identified, as well as polyphenols from the flavonoid, flavonol and stilbene categories (

Table 2).

Caffeic and gallic acids were not quantified above the minimum detection limit of the method for any of the analyzed samples. In wheat flour (WF), the most abundant hydroxycinnamic acid was beta-resorcylic acid (3.77 mg/kg), followed by rosmarinic acid (1.386 mg/kg), while feluic and coumaric acids were not found in the sample. In composite flours based on wheat flour with the addition of sprouted lentil flour, an increase in the content of hydroxycinnamic acids can be observed with the amount of wheat flour substituted with sprouted lentil flour. The maximum value for hydroxycinnamic acids in the samples of the flour composition with the addition of sprouted lentils was recorded in the sample with 20% sprouted lentil flour, SLW3, with values of 35.280 mg/kg for beta-resorcylic acid, 4.789 mg/kg for coumaric acid, 22.65 mg/kg for ferulic acid and 30.059 mg/kg for rosmarinic acid.

In the composite flour samples based on a mixture of wheat flour and ungerminated lentil flour (BLWF), the content of hydroxycinnamic acids was lower and varied for resorcilic acid from 3.880 mg/kg (BLWF1) to 4.037 mg/kg (BLWF3), from 3.489 mg/kg (BLWF1) to 4.012 mg/kg (BLWF3) for acid coumaric, from 2.316 mg/kg (BLWF1) to 3.981 mg/kg (BLWF3) for ferulic acid, and from 2.614 mg/kg (BLWF1) to 8.490 mg/kg (BLWF3) for rosmarinic acid.

Rosmarinic acid is less common in lentils, but is found in very small amounts, especially in the sprouts. In a 6-day-old sprout, the rosmarinic acid content can reach approximately 28–43 mg/kg, depending on germination conditions [

6]. Ref. [

31] highlights the fact that by germination, the synthesis of rosmarinic acid in the lentil sprouts can be induced.

The way germination takes place also influences the accumulation of hydroxycinnamic acids in the sprouts. It was highlighted that germination in the dark for 6 days induces the highest increase in ferulic acid, reaching a concentration of 82.47 mg/kg DW [

6]. Another study highlighted the increase of ferulic acid from 6.45 mg/kg to 10.32 mg/kg after a 6 day sprouting period [

31].

β-Resorcylic acid (2,4-dihydroxybenzoic acid) is a less common phenolic compound but with notable biological properties, including antioxidant activity, anti-inflammatory and antifungal potential. The content of β-resorcylic acid in dry lentil seeds is usually below 1 mg/100 g dry weight, being a minor compound in the phenolic profile [

5]. Germination causes a modest increase in β-resorcylic acid concentration due to the activation of enzymes that break down cellular components and release bound phenols. The reported values are about 0.5–1.5 mg/100 g dry weight, depending on the duration of germination (3–7 days) [

1].

The caffeic acid content of lentils is about 0.5–2 mg/100 g dry weight [

5] and increases to 5.0 mg/100 g dry weight, depending on the duration of germination [

33]. In our study, caffeic acid was undetectable in agreement with the data reported by other authors [

7,

31].

The coumaric acid content of lentils is about 0.3–1.5 mg/100 g dry weight, and lentil germination can lead to a significant increase in coumaric acid levels, with values of about 1.0–3.0 mg/100 g dry weight [

34]. The content of coumaric acid in brown and black ungerminated lentil seeds

Lentils (

Vicia lens (L.)

Coss. & Germ.), from Greece varied between 12–22 mg/kg and increased from 278 mg/kg to 372 mg/kg after germination, when the sprout length reached 15 cm [

19].

In raw lentils, resveratrol is reported only in trace or very small amounts, below 0.1 mg/100 g dry weight, depending on the variety and growing conditions [

7], while in sprouted lentils the resveratrol content ranges from 0.05–0.2 mg/100 g dry weight, depending on the germination time (3–7 days) and environmental conditions [

1]. Higher concentrations were determined in sprouted lentils (19.00–80.64 mg/kg) depending on the germination conditions [

31].

In our study, the content of resveratrol in flours fortified with germinated and ungerminated lentils was higher in the wheat flour sample and varied between 7.274–34.086 mg/kg for the samples with the addition of ungerminated lentils (BLWF) and between 28.576–64.693 mg/kg for the composite flours with the addition of germinated lentils (SLWF) in agreement with the data reported by Barakat et al., 2022 [

31].

Quercetin is a flavonoid with strong antioxidant, anti-inflammatory and anti-carcinogenic properties, being present in various foods, including legumes. Germinating lentils for 3–5 days leads to an optimal concentration of quercetin, while prolonged germination (>7 days) may result in decreased concentrations. Quercetin is present in raw lentils in amounts of about 0.5–1.5 mg/100 g dry weight and increases to 1.5–3.5 mg/100 g after germination, depending on the environmental conditions (temperature, humidity and light exposure) [

1]. Higher concentrations were reported in the lentil sprouts (35.29–54.12 mg/kg) after 6 days of germination at 20 °C and a relative humidity of 90–93% [

31].

In our study, a higher concentration of quercetin was detected in the raw lentil sprouts (74.919 mg/kg). Wheat flour is poor in quercetin, and its fortification with lentil flour, whether as such or germinated, leads to a significant increase in the level of this bioactive compound. The addition of 20% sprouted lentils leads to a quercetin level of 45.956 mg/kg, while in the version fortified with unsprouted lentils in a proportion of 20%, we found 12.869 mg/kg quercetin.

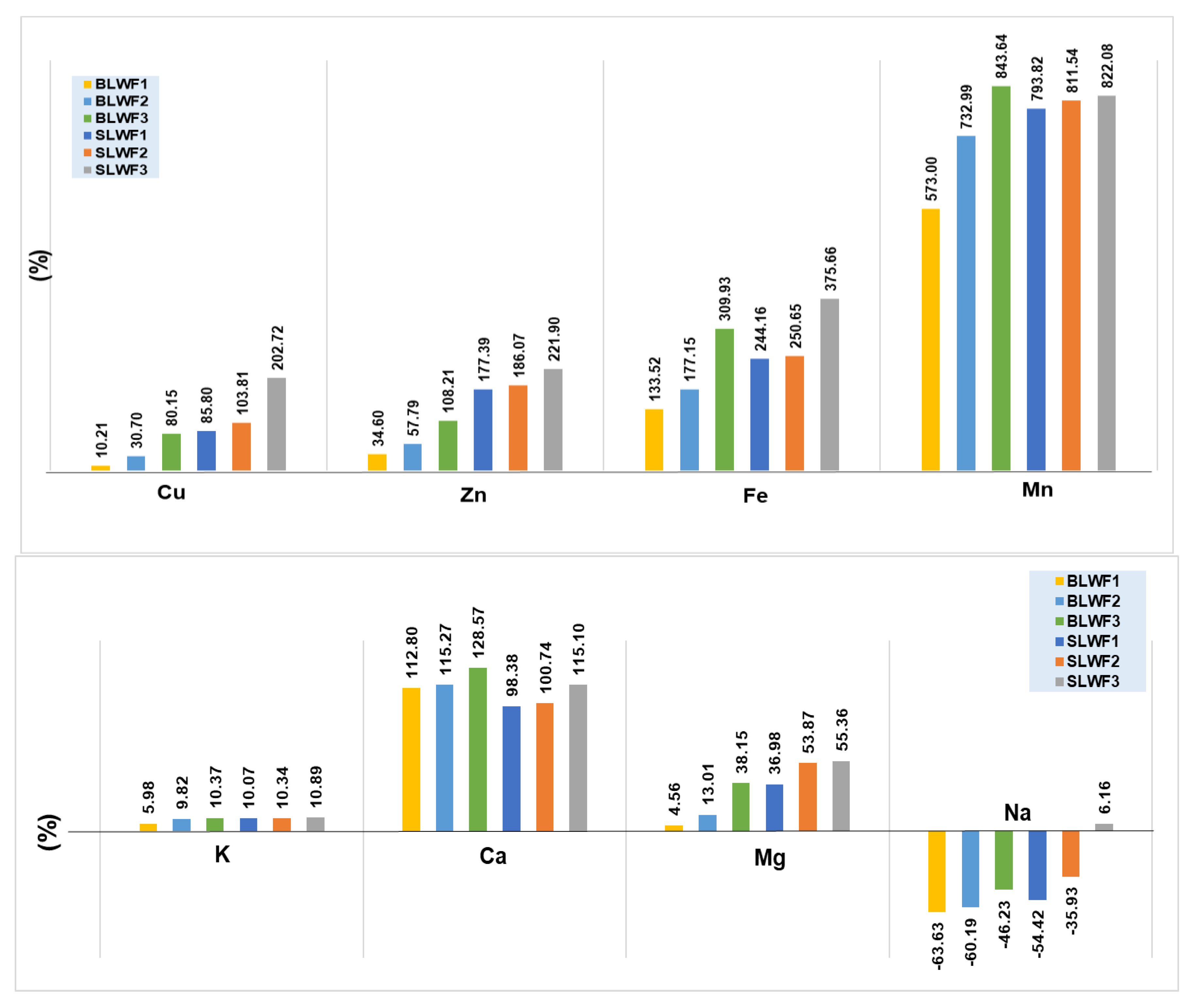

3.3. The Macro and Microelements Composition of Composite Flours

The macro and microelements composition of flours obtained with seed lentil flours and sprouted lentil flours is presented in

Table 3, and the increase is expressed as the percentage of the content of the macro and microelements by fortifying the wheat flour with lentil flour in the two forms as in

Figure 5.

The fortification of wheat flour for baking with black lentil flour, either in ungerminated or germinated form, led to an increase in the contents of macro and micronutrients of the composite flours, which increased with the fraction of substituted wheat flour. With the exception of calcium, for which lower values were recorded for the SLWF1 and two variants fortified with sprouted flour compared to the BLWF1 and two variants based on non-sprouted lentil flour, for all other elements there was an increase in mineral content through the addition of lentil flour in the two forms analyzed. The recorded values were between 302.367–324.777 mg/kg for the varieties of flour fortified with lentil seeds and between 281.884 and 305.635 mg.kg for the composite flour samples based on lentil germinated flour. The increase in calcium content in the composite flour was maximal in the case of the addition of 20% lentil flour from seeds (128.57%) and 115.10% in the case of fortification with sprouted lentil flour (SLWF3).

Sodium is the only macroelement that was found in greater quantity in wheat flour (190.096 mg/kg) compared to composite lentil flour (69.131–102.208 mg/kg) and composite flours with 10–15% lentil sprouts (86.655–121.798 mg/kg) (

Figure 5).

Magnesium recorded values between 419.525 mg/kg for the BLWF1 sample and 623.333 mg/kg, the maximum value recorded for the SLWF3 sample. The increases in Mg content in composite flours by the addition of germinated flour compared to wheat flour for baking were up to 55.36%, and up to 38.15% in the case of substituting wheat flour with 30% black lentil flour, which indicates a possibility of covering the dietary deficit in this macroelement by using composite flours based on germinated or ungerminated lentil flour.

Potassium did not register significant increases in the composite flours in relation to wheat flour (5.96–10.89%). The maximum value recorded was 559.637 mg/kg in the sample fortified with 20% sprouted lentil flour, while in unfortified wheat flour, the K content was 504.647 mg/kg.

The analysis of the magnesium content of lentil seeds from different varieties has been reported in other studies, identifying values between 850–1060 mg/kg depending on the variety. Lower values, between 671–950 mg/kg, were recorded for potassium, and between 480–1280 mg/kg for calcium [

7]. Other authors reported a level of 900–1000 mg/kg Mg and 700–1000 mg/kg for Ca [

18], while for sprouted lentils a level of 140–400 mg/kg K, 70–90 mg/600 mg/kg Ca and 820 mg/kg Mg [

33].

Our results are in agreement with those reported by other authors regarding the influence of germination on the content of macroelements in lentils [

10], highlighting the fact that the fortification of flour samples with germinated lentils has a greater positive impact on comparative Ca with the other analyzed macroelements (Mg and K). Santos et al., 2020 reported that the magnesium concentration was not affected by sprouting, while Ca and K had percentage increases between 41% and 58%, and 28% and 30%, respectively, in the best performing varieties [

10].

Other studies highlighted that the addition of germinated lupin flour in a proportion of 10–30% in wheat flour for biscuits led to a 50.35% increase in the content of K and 59.64% for Ca [

12], while for composite flours, with the addition of 30% lupin flour, the contents were 615.80 mg/kg Mg, 287.66 mg/kg Ca and 110.67 mg/kg K, which led to a substantial increase in the content of macroelements in the bread obtained based on lupin composite flour [

12]. Lentils are especially rich in essential microelements such as iron, manganese and zinc. Fortifying flour with lentil flour can increase the content of these minerals in baked goods, helping to prevent dietary deficiencies of these minerals.

The increase in micronutrient intake by fortifying wheat flour with black lentil flour in both germinated and ungerminated form was more significant compared to the increases recorded in the case of the main macronutrients (Ca, Na, Mg, K). The micronutrient increases in the composite flours increased in the order: Cu < Zn < Fe < Mn.

Manganese is the microelement that registered the most significant increase, varying between 573.00% in the case of substitution with 10% lentil flour (BLWF1) and 843.64% when 20% lentil flour was added to wheat flour. The recorded value for Mn in the case of type 650 wheat flour was 2.088 mg/kg and it reached a maximum value of 19.700 mg/kg in the BLWF3 variant. Ref. [

10] reported values between 11–25 mg/kg Mn in different varieties of lentils in germinated or ungerminated form [

10].

The second microelement that recorded significant increases through the fortification of wheat flour was Fe, for which increases were recorded between 133.52% for the BLWF1 sample and 375.66% for the SLWF3 sample. These increases in the level of Fe through the partial substitution of wheat flour with germinated or non-germinated lentil flour suggests the possibility of using lentil flour in obtaining functional and dietary foods intended for people with iron deficiency anemia. Previous results reported regarding the Fe content in different varieties of sprouted lentils and lentil seeds indicated an intake of 34–66 mg/kg Fe, with slight increases recorded in the case of sprouted samples [

35]. Martinez et al., 2023, approached the study of the fortification of wheat flour with Fe by adding lentil flour, emphasizing the fact that a substitution of 25% lentil flour for wheat flour led to an increase in the Fe content from 11.97 mg/kg to 26.42 mg Fe [

10].

Flour fortified with sprouted or seeded black lentils increased the Zn content of the samples, the increase being 34.60% in the case of the LWF1 sample and up to 221.90% for the SLWF3 sample. The effect of germination on the Zn content of different lentil varieties indicated values between 36–51 mg/kg in germinated seeds and values between 31–39 mg/kg for non-germinated grains [

18].

3.4. Rheological Properties of Composite Flours

The MIXOLAB CHOPIN Technologies was used to determine the rheological characteristics of the different types of flour used in this study. The MIXOLAB CHOPIN is a dough characterization instrument designed to evaluate flour’s quality and baking performance. It provides a comprehensive view of the dough’s behavior during the baking process and measures several key parameters such as water absorption capacity, mixing stability, initial heat resistance, viscosity variation during heating, viscosity at high temperature, and viscosity during cooling. This instrument simulates real conditions of flour used in bakery products, analyzing dough consistency and protein and starch quality [

24].

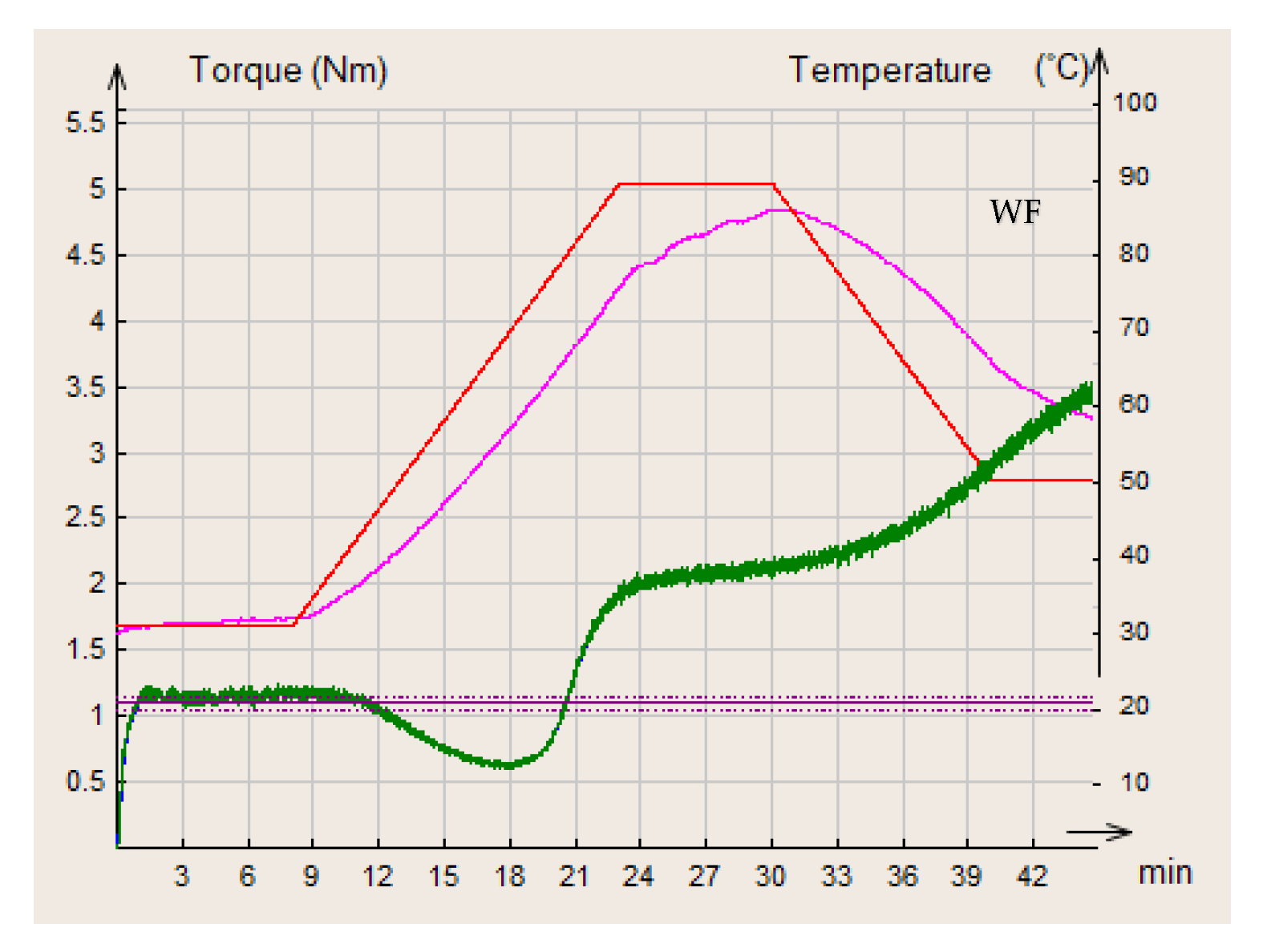

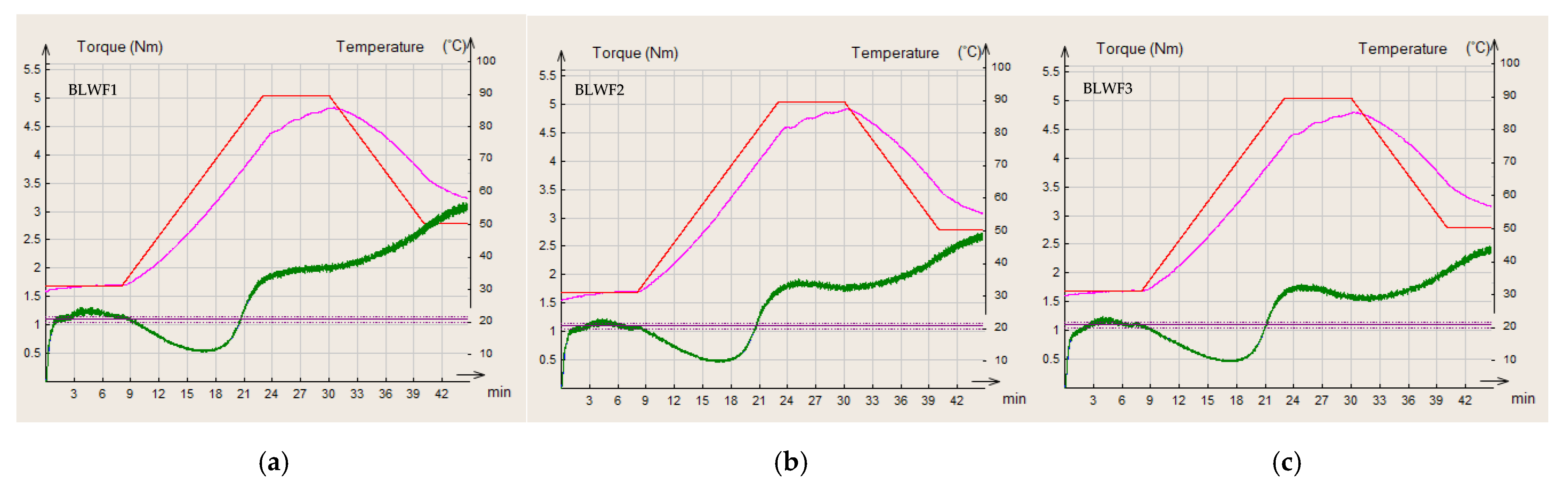

In the present study, wheat flour was used as a control flour compared to different composite flours of wheat/black lentil and wheat/black lentil sprouts. The curves obtained for each of the flours analyzed are presented in

Figure 6,

Figure 7 and

Figure 8.

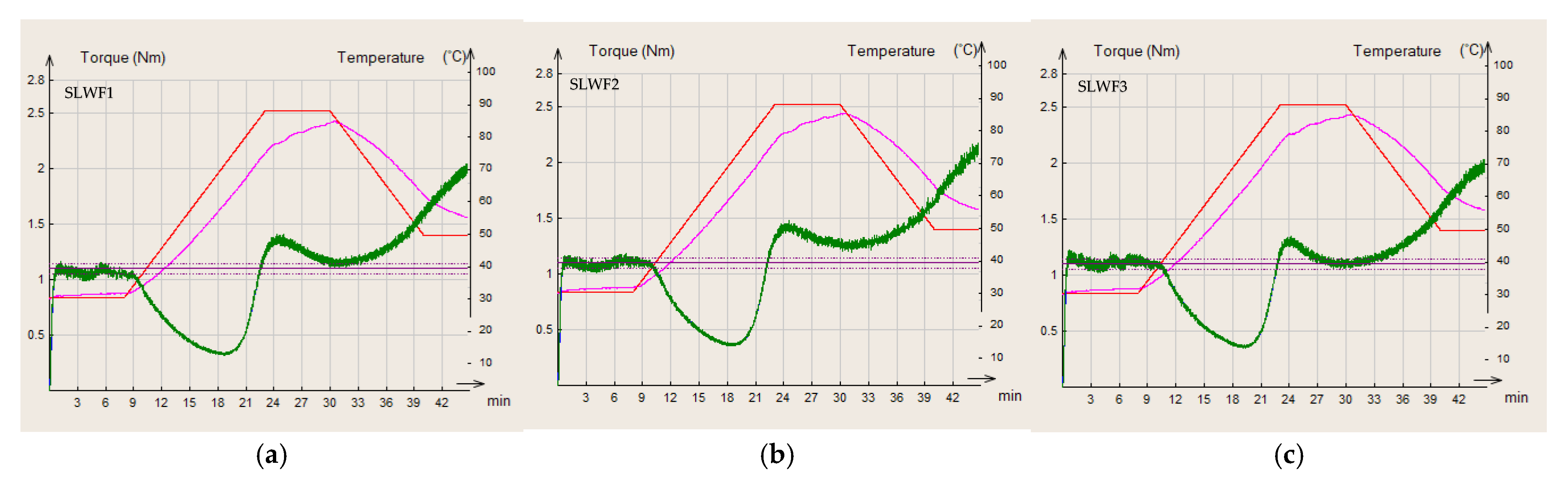

The water absorption of flour is a key parameter that must be strictly observed to obtain good-quality bakery products.

Figure 9 shows the results obtained for water absorption for the different types of composite flours analyzed.

Analysis of the results showed that water absorption was lower for the control sample (WF) than for the other samples with different proportions of black lentil flour and black lentil sprouts. For samples containing black lentil flour, water absorption varied between 59.9% and 60.1%. There was also an increase in the water absorption value with increasing quantities of black lentils in the samples. The same observation was made for composite flours containing various levels of substitution of wheat flour by black lentil sprouts. The water absorption values were 56.9%, 57%, and 58.6%, respectively, for SLWF1, SLWF2, and SLWF3. Similar results were obtained by Dabija et al., 2017 [

36] when studied the effect of yellow pea flour addition on wheat flour dough and bread quality. In this study, the water absorption capacity of composite wheat/yellow pea flours varied from 57.2 to 58.5 for substitution rates ranging from 5 to 20%. The addition of legumes changes the structure and properties of the dough, influencing the final characteristics of bakery products [

36]. Legume flours have a higher water absorption capacity due to their high protein and fiber content, resulting a firmer and less stretchy dough. Adding legumes can prolong the time it takes to get a homogeneous dough, as the proteins in legumes take longer to hydrate [

37].

Figure 10 shows the stability time obtained for each of the doughs produced from different flours.

Analysis of the results from

Figure 10 showed that WF obtained the best stability time (11.45 min). This value is higher than those obtained by [

12,

22,

31,

37], which varied between 8.02 and 9.52. The stability of the dough decreased for composite flours, both those based on lentil flour (BLWF) and those based on sprouted lentils (SLWF) compared to the stability of the dough obtained only from wheat flour type 650. The decrease in the stability of the dough in flours composed with legumes has been highlighted in other studies [

12,

36]. However, in the case of the addition of sprouted lentils, the decrease was less pronounced compared to the BLWF samples, with a slight increase in the stability of the dough through the addition of 30% sprouted lentils (10.52 min), which emphasizes the possibility of processing composite flours based on sprouted lentils in bakeries.

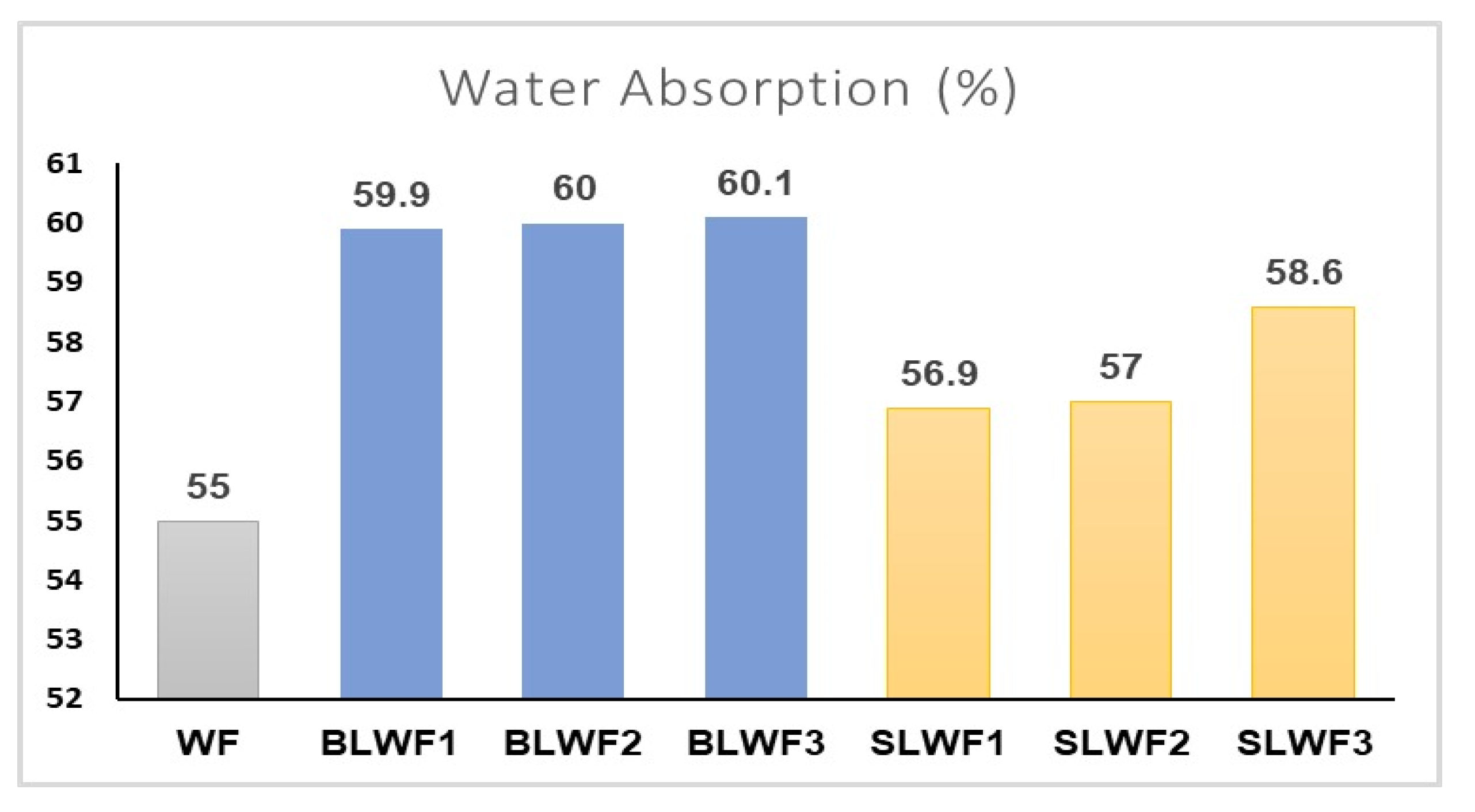

The values of different torques are presented in the

Figure 11 and represent the maximum torque during mixing (C1), protein weakening (C2) caused by mechanical stress and increasing temperature, the rate of starch gelatinization (C3), minimum torque during heating (C4), and torque after cooling to 50 °C (C5).

C1 is a characteristic for the first part of the MIXOLAB profile that defines the mixing parameters at 30 °C; for this parameter, there were no significant differences among the values obtained for WF, BLWF2, BLWF3, and SLWF3.

The second stage is the first heating stage and corresponds to the weakening of the protein network of the dough. The combined effect of mechanical shear stresses and the temperature constraint induces a decrease in the C2 torque, which represents the minimum value of the torque produced by the passage of the dough subjected to mechanical and thermal constraints due to the beginning of protein destabilization [

12]. Compared to WF, the BLWF and SLWF composite flours were characterized by a lower C2 torque, values that were significantly lower in the case of SLWF (C2: 0.332–0.366 Nm) compared to BLWF (C2: 0.545–0.471 Nm). Similar results regarding the behavior of composite flours based on a wheat–triticale flour mixture have been reported in other studies [

38].

In the third stage of the MIXOLAB profile, starch gelatinization takes place. Heating the dough induces the swelling of the starch granules and increases the viscosity of the dough. The boiling phase describes the behavior of the starch and is characterized by a maximum torque produced during the heating phase (C3) [

39]. This parameter also registers significant decreases due to the addition of a legume matrix, especially in the case of SLWF samples (C3: 1.302–1.426 Nm) compared with WF (C3:1.917 Nm).

C4 is calculated as the ratio of torque after a holding time at 90 °C and the maximum torque during the heating period [

24] and reflects the enzymatic activity of the dough. A high content of alpha-amylase induces an increase in the value of C4 and β [

40]. The C4 value decreases in composite flours in this order: WF > BLWF > SLWF, which reflects a low alpha-amylase activity, leading to a lower cleavage of starch into fermentable sugars during the dough fermentation process.

In the stage 4, the dough is subjected to the double action of mixing and enzymatic activity. A decrease in consistency may be observed at this stage. Cooling of the dough (step 5) leads to the degradation of the starch and the stiffness of the dough increases. C5 is the difference between the torque produced after cooling to 50 °C and that after the heating period and was at its maximum for WF (C5 = 3.490 Nm) and minimum for SWFL (C5 = 2.007 Nm).

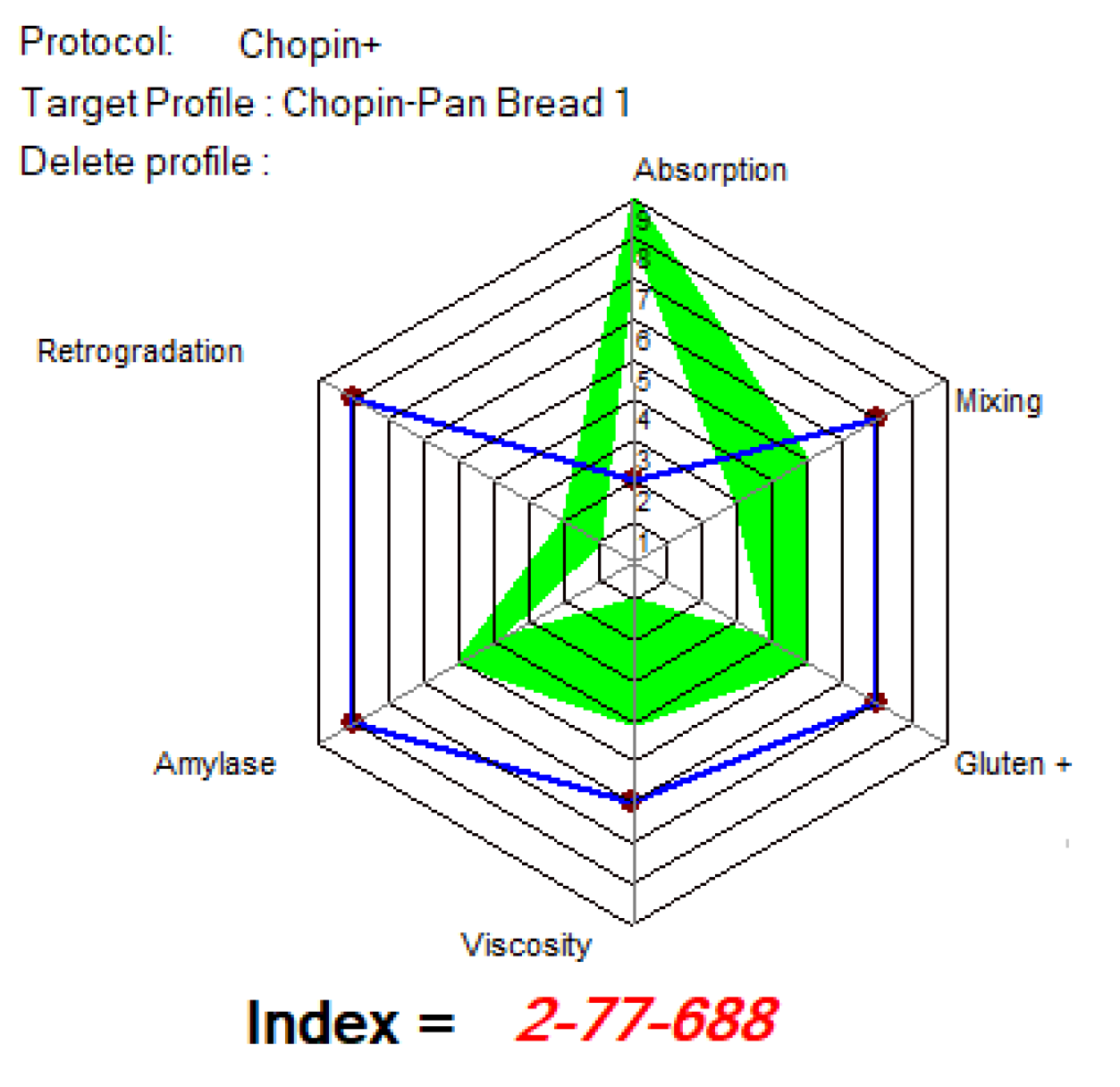

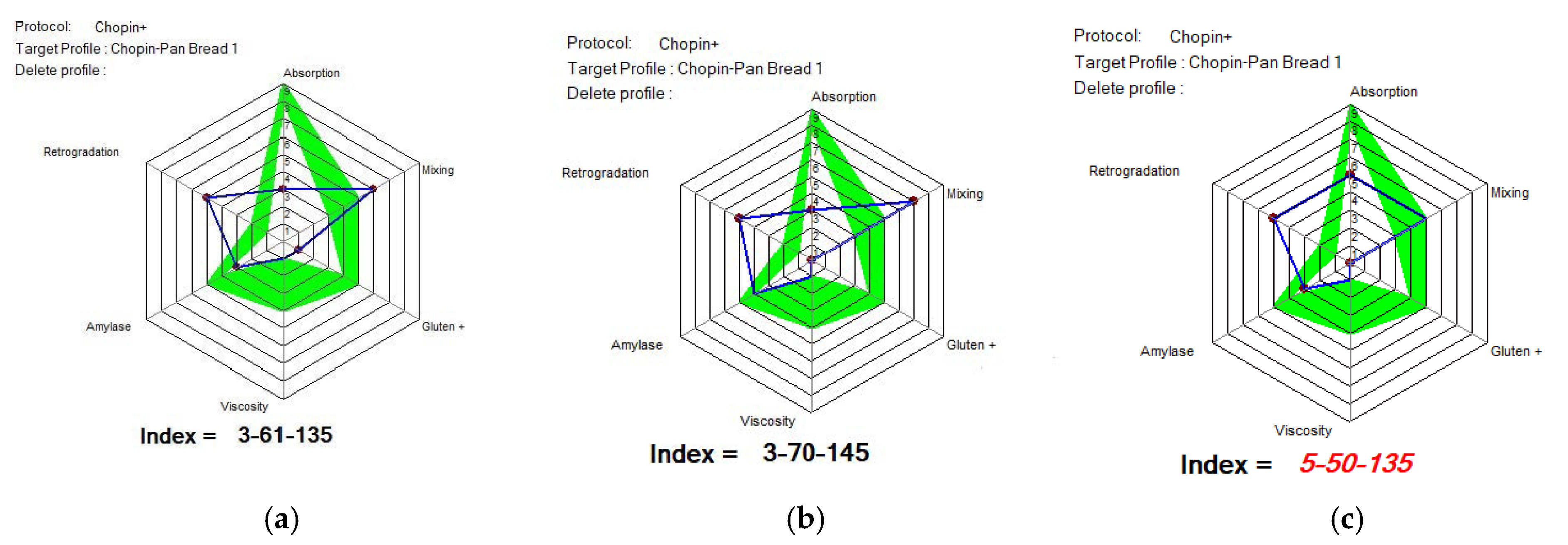

Figure 12,

Figure 13 and

Figure 14 show the indices of WF’s MIXOLAB profile for samples of flours blended with black lentil and black lentil sprouts, compared with the indices recommended by MIXOLAB for bread production. Analysis of these figures showed that the absorption index recommended by MIXOLAB for bread production was between eight and nine. Of all the flours analyzed, only those with different proportions of black lentils (BLWF) had an absorption index close to that recommended by MIXOLAB. There was no change from one sample to the next. They all obtained an index equivalent to seven. On the other hand, the composite flours with different proportions of black lentil sprouts (SLWF) obtained an index equivalent to three. Given that the absorption index is the MIXOLAB parameter used to measure a flour’s water absorption capacity [

24,

39], the composite flours with different proportions of black lentils would have a water absorption capacity very close to that required for bread production, compared with flours composed of different proportions of black lentil sprouts.

According to the MIXOLAB handbook [

24], the mixing index is a parameter that measures the stability of the dough and, in particular, the development time and weakening of the dough during kneading at 30 °C. Analysis of the results obtained in the present study showed that flours with different proportions of lentil flours obtained mixing index values within the range recommended by MIXOLAB for bread production. The same observation was made for the gluten index and for viscosity where only the SLWF3 sample reached the optimal value. On the other hand, for samples with different proportions of black lentil sprouts (SLWF), only the 20% sample (SLWF3) obtained the recommended value for the mixing index. Also, the amylase index was in the range of optimal values for all SLWF samples. For the rest of the indices studied, none of the samples reached a recommended value, including the control sample. Hernandez-Aguilar et al., 2020 [

26], in their study regarding the use of lentil sprouts as a nutraceutical alternative for the elaboration of bread, highlighted that the bread obtained with the addition of increasing amounts of black lentil sprouts was harder and less cohesive than the control bread. In addition, the quality of the dough and flour was modified by the addition of sprouted lentils and this effect increased with an increasing concentration of sprouted lentils [

24]. Similar results were also obtained by Turfani et al., 2017 [

41], who studied the technological properties of wheat bread enriched with lentil or carob flours. That study concluded that lentil flour reduces the toughness, stability and resistance of wheat dough [

26].

Considering the results obtained by comparing the MIXOLAB profile of the analyzed samples with that of the optimal rheological profile for bread making, we can say that the BLWF3 sample with 20% lentil flour, which overlaps four of the three analyzed indices, is optimal from the point of view of the rheological behavior of the dough used in bakeries.

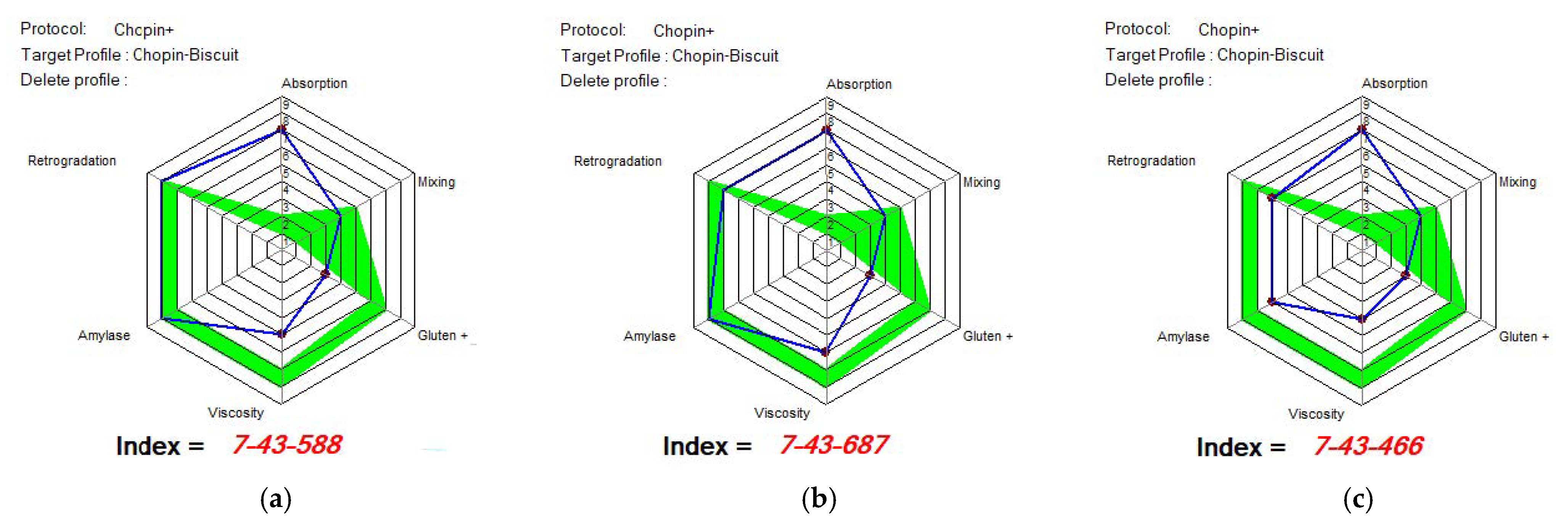

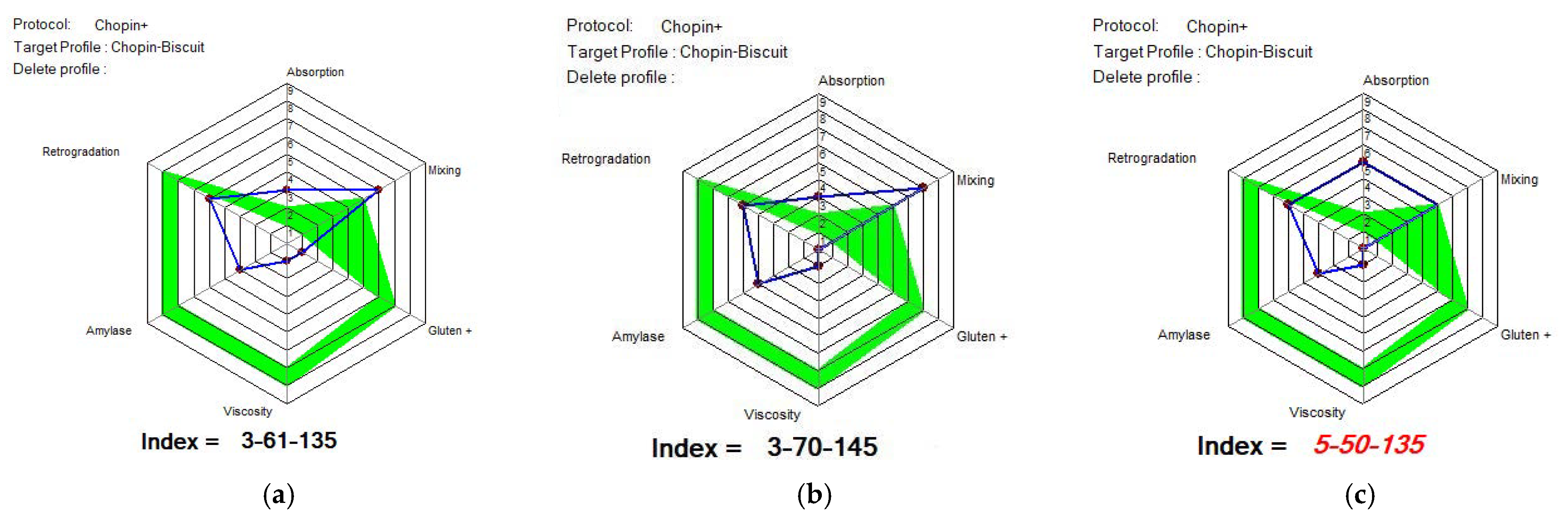

Figure 15,

Figure 16 and

Figure 17 show the indices recommended by MIXOLAB for the production of biscuits for each sample. WF would be a good flour for the production of biscuits, since it would have obtained very good values for each of the indices studied, especially for the absorption, gluten, amylase and retrogradation indices. As for the samples with different proportions of lentil flour, all the samples obtained a good mixing index for biscuit production up to 15%; the samples had good amylase and retrogradation indices. Black lentil flour, although having a higher absorption index than that recommended for biscuit production, would improve the stability of the dough and the development time and weakening of the dough in composite flours. On the other hand, black lentil sprouted flour overlapped with the optimal model for the retrograde index for all experimental variants and for the mixing parameter for the SLWF3 variant.

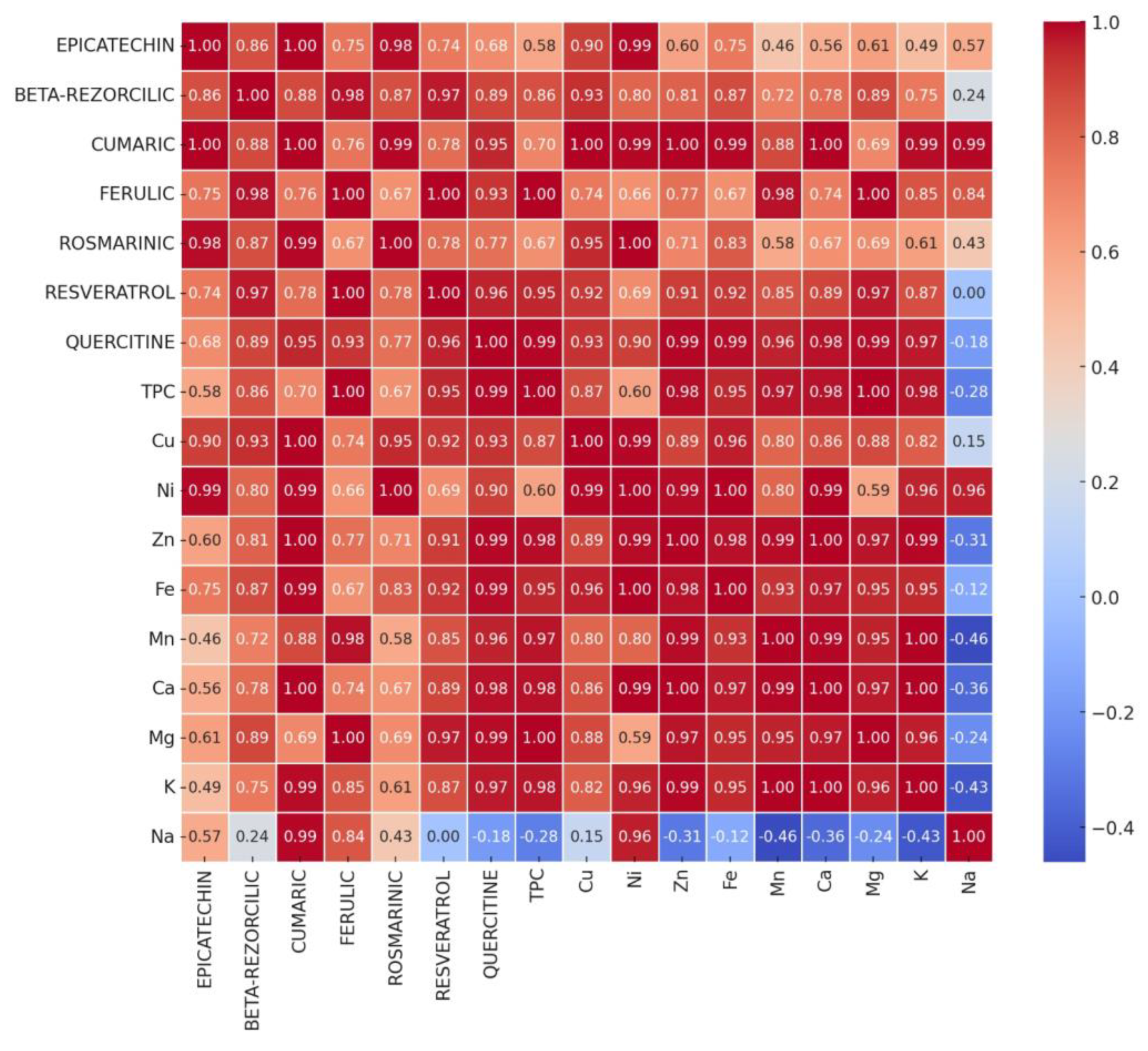

3.5. Correlation Between Analyzed Compounds

Figure 18 and

Figure 19 present the Pearson correlation matrix between individual polyphenol contents and macro and microelement contents for composite flours BLWF (

Figure 18) and SLWF (

Figure 19).

The analysis of the Pearson correlations between the studied variables: individual polyphenols and macro and microelements related to wheat flour-based composite flours mixed with lentil flour in a proportion of 10–20% (BLWF experimental variants) indicated that there was a strongly positive correlation between: TPC and epicatechin (r = 0.94), TPC and quercetin (r = 0.96), TPC and ferulic acid (r = 0.96), TPC and rosmarinic acid (r = 0.93) and TPC and coumaric acid (r = 0.96), which demonstrated that these polyphenols contribute significantly to the total polyphenols determined. Conversely, there was a strong negative correlation (r = −0.33) between TPC and rosmarinic acid.

Regarding the correlations between the analyzed macroelements and the individual polyphenols, it was observed that Ca has strong positive correlations with variables such as quercetin (r = 0.92), coumaric acid (r = 1:00) and resveratrol (r = 1.00), which indicates a synergistic relationship between calcium and these compounds.

Mg had a profile similar to Ca and showed strong positive correlations with the same phenolic compounds. K showed significant positive correlations with epicatechin (r = 1:00), ferulic acid (r = 0.96), rosemary acid (r = 0.98) and quercetin (r = 0.93), indicating an essential role in samples with high antioxidant activity.

The microelements analyzed (Zn, Fe, Mn, and Cu) generally presented strongly positive correlations with the majority of individual polyphenols, except for beta-resorcilic acid, which presented negative or weakly positive correlations with all microelements.

In the case of SLWF composite flours there were also positive correlations between the analyzed components, but these were weaker compared to those obtained in the case of BLWF variants. Thus, between macroelements and polyphenolic compounds there were strongly positive correlations between the pairs: K/coumaric acid (r = 0.99), K/quercetin (r = 0.97), K/TPC (r = 0.98), and K/ferulic acid (r = 0.85). Mg was strongly positively correlated with TPC and ferulic acid (r = 1), resveratrol (r = 0.97), and quercetin (r = 0.98), and Ca was strongly positively correlated with coumaric (r = 1), TPC and quercetin (r = 0.98).

Among the microelements, Fe, Zn, Mn, Cu were strongly positively correlated (r > 0.85) with TPC, coumaric acid, quercetin and resveratrol, while Cu and Ni showed strongly positive correlations with epicatechin (r > 0.9).

Na was the macroelement that showed negative correlations with most of the other parameters analyzed, which indicates that samples with a high sodium content have lower levels of polyphenols and essential macroelements and microelements.

In addition, the multi-parametric statistical evaluation method using PCA (

Figure 20 and

Figure 21), were used for further analysis of the data regarding individual polyphenols and macro and microelements. Based on a linear correlation matrix, PCA was applied to the mean values of the measured traits to study which parameters contributed the most to the total data variation. For the individual polyphenols evaluation, Principal Component 1 (PC1) accounted for 87.383% of the total variance, while Principal Component 2 (PC2) accounted for 8.674% of the variance. It was observed that variables such as resveratrol and quercetin were the most influential in the differentiation of samples, having long vectors oriented toward positive PC1, with the caffeic, coumaric, beta-resorcilic and ferulic variables having a lower impact on differentiation with short vectors.

From

Figure 20 it can be observed that the WF sample is positioned far on the negative side of PC1, which indicates a low content of polyphenols. BLWF1, BLWF2, and BLWF3 are grouped near the origin, in the central area of the graph, indicating a balanced content of polyphenols such as coumaric, beta-resorcilic, and ferulic. SLWF1 and SLWF2 are positioned on the negative side of PC2 and they show differences from BLWF, but they remain closer in terms of chemical composition, while SLWF3 is distinct, indicating a high content of major polyphenols. Vectors that form a small angle to each other (e.g., resveratrol and quercetin) indicate a strong positive correlation between these variables, while variables with opposite or perpendicular vectors have a low or negative correlation.

The PCA analysis of the projection of the macro and microelement parameters of the composite flours (

Figure 21) indicates that PC1 explains 65.593% of the variance and PC2 explains 30.449% of the variance, reflecting the secondary variation.

From the interpretation of the biplot, it can be seen that WF is located in the negative part of Component 1 and Component 2, suggesting a low content of the variables related to these vectors (K, Mg, and Fe). Samples BLWF1, BLWF2, and BLWF3 are grouped in the negative part of PC2, indicating chemical similarities, their content being more balanced in trace elements such as Zn and Fe. SLWF3 is clearly positioned in the positive part of PC1 and PC2, indicating a high content of Mg, K, and other elements. SLWF2 also lies on the positive side of PC1, suggesting a similar but less extreme profile than SLWF3. SLWF1 is positioned between BLWF and SLWF3, indicating an intermediate composition. The vectors of the Mg, K, and Ca variables are long, which suggests a significant influence on the variation explained by Component 1, while Na is positioned almost perpendicular to Component 2, which indicates a more modest influence on PC2. Zn and Fe contribute to the differentiation of the samples on Component 2, having vectors oriented in the direction of the BLWF samples.