Effect of Brewers’ Spent Grain Addition to a Fermented Form on Dough Rheological Properties from Different Triticale Flour Cultivars

Abstract

1. Introduction

2. Materials and Methods

2.1. Triticale Flour Samples

2.2. Brewers’ Spent Grain Sourdough Fermentation

2.3. Dough Rheological Properties During Mixing and Pasting

2.4. Dough Dynamic Rheological Properties

2.5. Dough Rheological Properties During Extension

2.6. Dough Rheological Properties During Fermentation and Falling Number Values

2.7. Statistical Analysis

3. Results and Discussion

3.1. Dough Rheological Properties During Mixing and Pasting

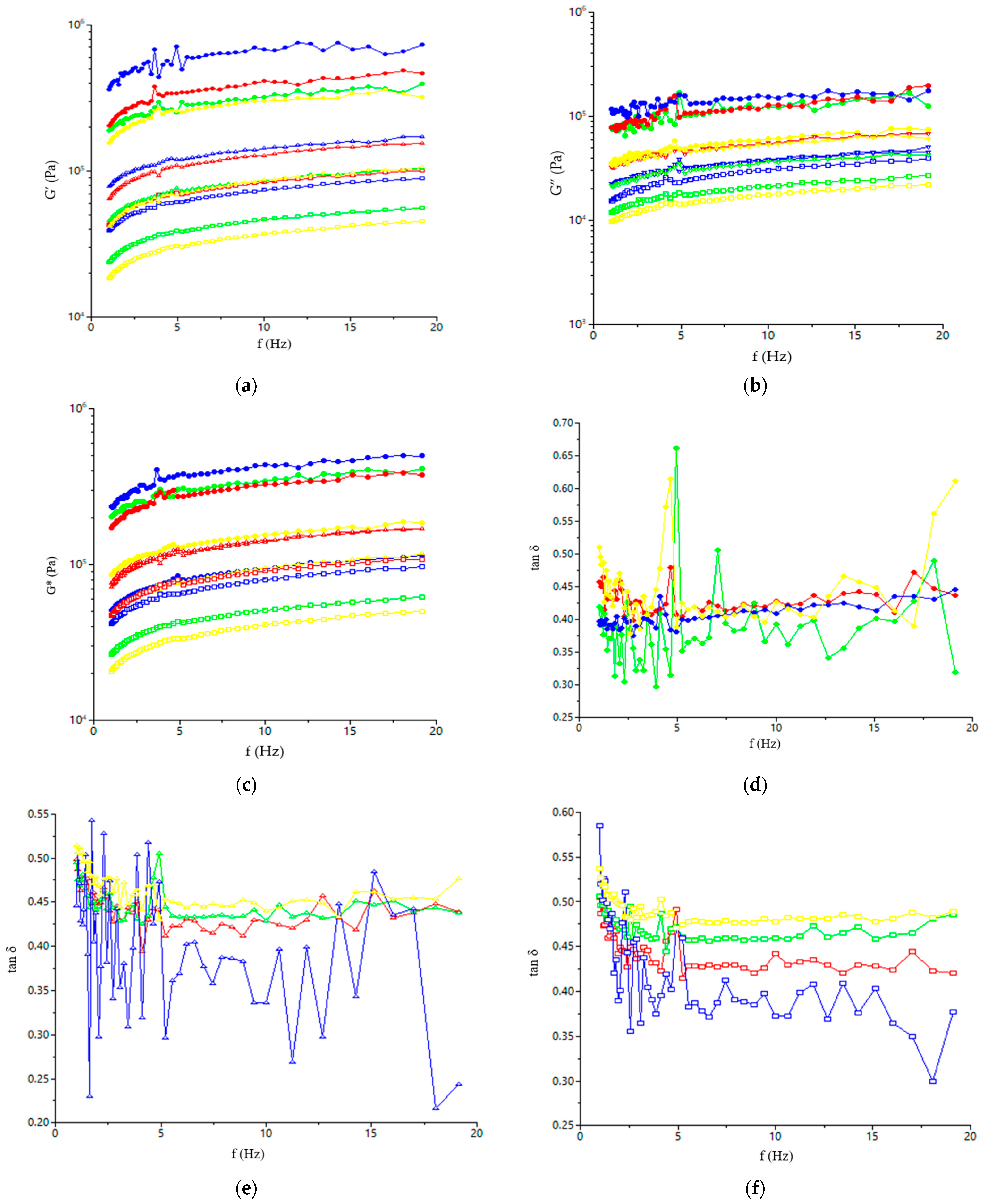

3.2. Dynamic Rheological Properties of Dough Samples

3.3. Dough Rheological Properties During Extension

3.4. Effect of Brewer’s Spent Grain Sourdough Fermentation on pH, Dough Rheological Properties During Fermentation, and Falling Number Values

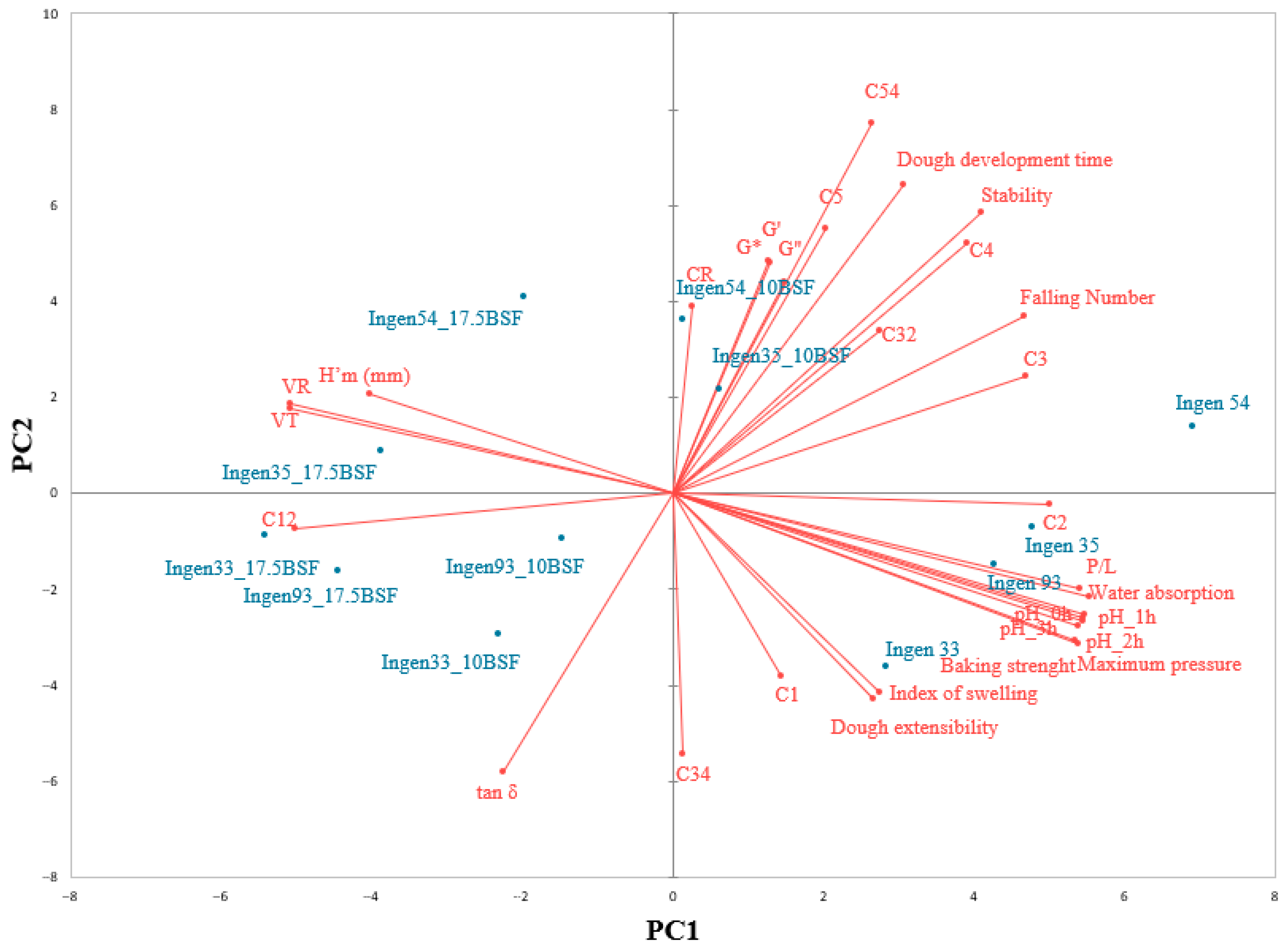

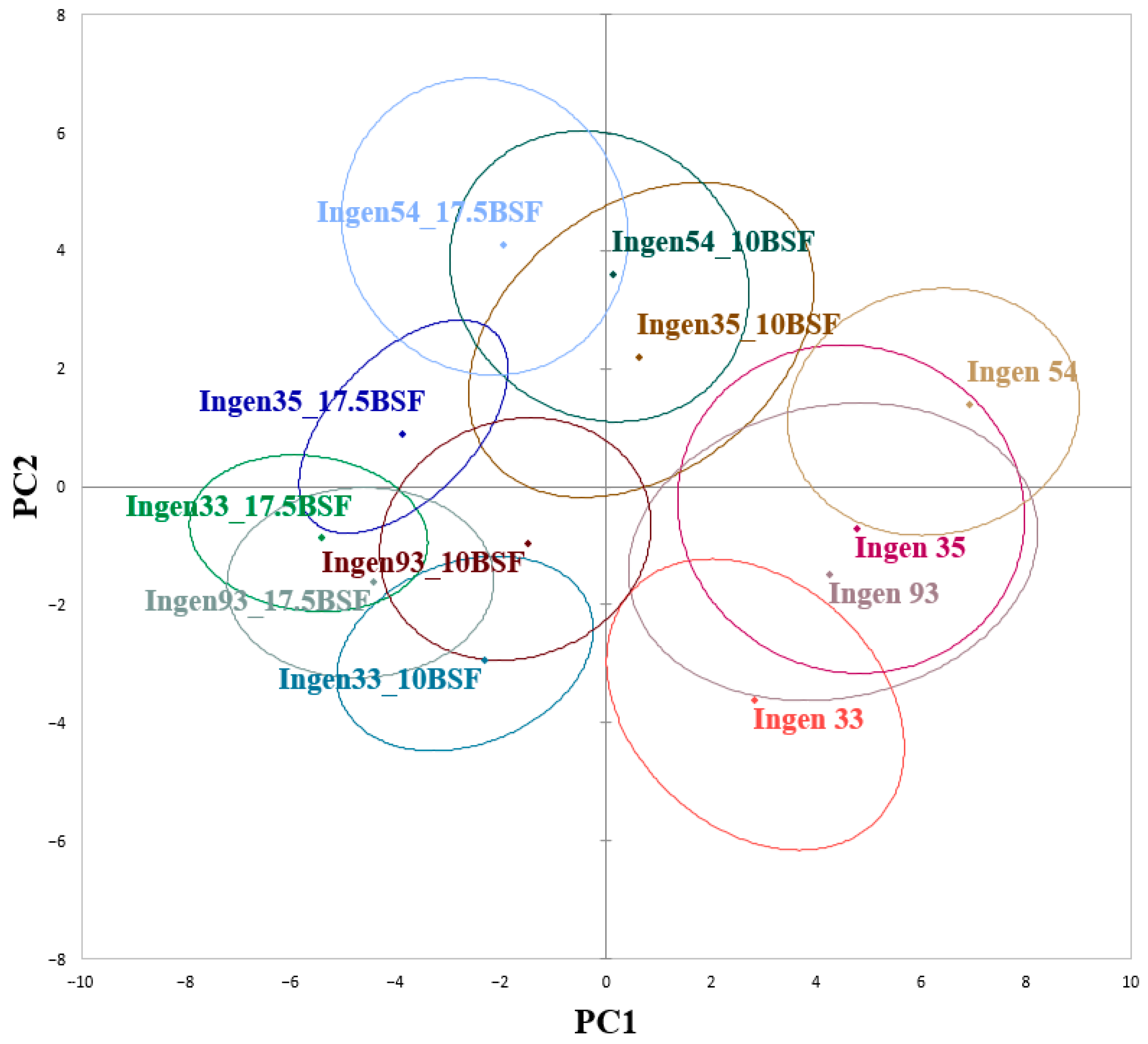

3.5. Relationships Between Triticale Dough Characteristics with Different Levels of Brewer’s Spent Grain Sourdough Fermentation Addition Incorporated into Its Recipe

4. Study’s Limitations

5. Conclusions

6. Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kandrokov, K.R. Effects of triticale flour on the quality of honey cookies. Foods Raw Mater. 2023, 11, 215–222. [Google Scholar] [CrossRef]

- Fraś, A.; Gołębiewska, K.; Gołębiewski, D.; Mańkowski, D.R.; Boros, D.; Szecówka, P. Variability in the chemical composition between triticale grain, flour and bread. J. Cereal Sci. 2016, 71, 66–72. [Google Scholar] [CrossRef]

- Messina, V.; Cano, J.; Silvio, A.; Pattison, A.L.; Roberts, T.H. Wholegrain triticale sourdough: Effects of triticale: Wheat flour ratio and hydration level on bread quality. Food Sci. Nutr. 2024, 12, 3910–3919. [Google Scholar] [CrossRef]

- Kaszuba, J.; Jaworska, G.; Krochmal-Marczak, B.; Kogut, B.; Ku’zniar, P. Effect of bran addition on rheological properties of dough and quality of triticale bread. J. Food Process. Preserv. 2021, 45, e15093. [Google Scholar] [CrossRef]

- Kaszuba, J.; Wo’s, H.; Shchipak, G.V. Bread making quality parameters of some Ukrainian and Polish triticale cultivars. Euphytica 2024, 220, 15. [Google Scholar] [CrossRef]

- Chen, Y.; Eder, S.; Schubert, S.; Gorgerat, S.; Boschet, E.; Baltensperger, L.; Städeli, C.; Kuster, S.; Fischer, P.; Windhab, E. Influence of Amylase Addition on Bread Quality and Bread Staling. ACS Food Sci. Technol. 2021, 2021, 1143–1150. [Google Scholar] [CrossRef]

- Błaszczak, W.; Sadowska, J.; Rosell, C.M.; Fornal, J. Structural changes in the wheat dough and bread with the addition of alpha-amylases. Eur. Food Res. Technol. 2004, 219, 348–354. [Google Scholar] [CrossRef]

- Seguchi, M.; Ishihara, C.; Yoshino, Y.; Nakatsuka, K.; Yoshihira, T. Breadmaking properties of triticale flour with wheat flour and relationship to amylase activity. J. Food Sci. 1999, 64, 582–586. [Google Scholar] [CrossRef]

- Peña, R.J. Food Uses of Triticale. In Triticale Improvement and Production; Mergoum, M., Gómez-Macpherson, H., Eds.; FAO: Rome, Italy, 2004; pp. 37–48. [Google Scholar]

- Ghendov-Mosanu, A.; Popa, N.; Paiu, S.; Boestean, O.; Bulgaru, V.; Leatamborg, S.; Lupascu, G.; Codină, G.G. Breadmaking Quality Parameters of Different Varieties of Triticale Cultivars. Foods 2024, 13, 1671. [Google Scholar] [CrossRef]

- Karimzadeghan, H.; Mohtarami, F.; Almasi, H. Effect of acorn and triticale flours on physicochemical, textural and sensory properties of biscuit. J. Food Res. 2021, 31, 115–128. [Google Scholar]

- Ciecierska, A.; Drywień, M.E.; Hamulka, J.; Sadkowski, T. Nutraceutical functions of beta-glucans. Rocz. Panstw. Zakl. Hig. 2019, 70, 315–324. [Google Scholar] [PubMed]

- Meng, X.; Li, T.; Zhao, J.; Fan, M.; Qian, H.; Li, Y.; Wang, L. Effects of different bran pretreatments on rheological and functional properties of triticale whole-wheat flour. Food Bioprocess. Technol. 2023, 16, 576–588. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Spent Grain: A Functional Ingredient for Food Applications. Foods 2023, 12, 1533. [Google Scholar] [CrossRef]

- Wang, J.; Rosell, C.M.; Benedito de Barber, C. Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem. 2002, 79, 221–226. [Google Scholar] [CrossRef]

- Qamar, H.; Li, Y.; He, R.; Waqas, M.; Song, M.; Deng, D.; Cui, Y.; Yang, P.; Liu, Z.; Qammar, B.; et al. Integrated Metabolomics and Metagenomics Unveiled Biomarkers of Antioxidant Potential in Fermented Brewer’s Grains. Antioxidants 2024, 13, 872. [Google Scholar] [CrossRef]

- Lamas, D.L.; Gende, L.B. Valorisation of Brewers’ Spent Grain for the Development of Novel Beverage and Food Products. Appl. Food Res. 2023, 3, 100314. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Brewer’s Spent Grains: Possibilities of Valorization, a Review. Appl. Sci. 2020, 10, 5619. [Google Scholar] [CrossRef]

- Oyedeji, A.B.; Wu, J. Food-Based Uses of Brewers Spent Grains: Current Applications and Future Possibilities. Food Biosci. 2023, 54, 102774. [Google Scholar] [CrossRef]

- Galoburda, R.; Straumite, E.; Sabovics, M.; Kruma, Z. Dynamics of Volatile Compounds in Triticale Bread with Sourdough: From Flour to Bread. Foods 2020, 9, 1837. [Google Scholar] [CrossRef]

- Siepmann, F.B.; Ripari, V.; Waszczynskyj, N.; Spier, M.R. Overview of Sourdough Technology: From Production to Marketing. Food Bioprocess. Technol. 2018, 11, 242–270. [Google Scholar] [CrossRef]

- Montemurro, M.; Pontonio, E.; Gobbetti, M.; Rizzello, C.G. Investigation of the Nutritional, Functional and Technological Effects of the Sourdough Fermentation of Sprouted Flours. Int. J. Food Microbiol. 2019, 302, 47–58. [Google Scholar] [CrossRef]

- Pérez-Alvarado, O.; Zepeda-Hernández, A.; Garcia-Amezquita, L.E.; Requena, T.; Vinderola, G.; García-Cayuela, T. Role of Lactic Acid Bacteria and Yeasts in Sourdough Fermentation during Breadmaking: Evaluation of Postbiotic-like Components and Health Benefits. Front. Microbiol. 2022, 13, 969460. [Google Scholar] [CrossRef] [PubMed]

- Nataraj, B.H.; Ali, S.A.; Behare, P.V.; Yadav, H. Postbiotics-Parabiotics: The New Horizons in Microbial Biotherapy and Functional Foods. Microb. Cell Fact. 2020, 19, 168. [Google Scholar] [CrossRef] [PubMed]

- De Bondt, Y.; Verdonck, C.; Brandt, M.J.; De Vuyst, L.; Gänzle, M.G.; Gobbetti, M.; Zannini, E.; Courtin, C.M. Wheat Sourdough Breadmaking: A Scoping Review. Annu. Rev. Food Sci. Technol. 2024, 15, 265–282. [Google Scholar] [CrossRef]

- Figueroa, R.H.H.; López-Malo, A.; Mani-López, E. Antimicrobial activity and applications of fermentation from lactic acid bacteria—A review. Sust. Food Technol. 2024, 2, 292–306. [Google Scholar] [CrossRef]

- Erşova, S.; Saitan, O.; Tarna, R.; Rumeus, I.; Codină, G.G.; Ghendov-Mosanu, A. integration of spent grain into food products. J. Eng. Sci. 2024, 31, 130–155. [Google Scholar] [CrossRef]

- International Association for Cereal Science and Technology. ICC Standard Methods (Methods No. 104/1; 136; 105/2; 110/1, 173); ICC: Vienna, Austria, 2005. [Google Scholar]

- SR 90:2007; Făină de Grâu. Metode de Analiză. ASRO Publisher House: Bucharest, Romania, 2007.

- Aprodu, I.; Simion, A.B.; Banu, I. Valorization of the Brewers’ Spent Grain Through Sourdough Bread Making. Int. J. Food Eng. 2017, 13, 20170195. [Google Scholar] [CrossRef]

- Zhu, F. Triticale: Nutritional composition and food uses. Food Chem. 2018, 241, 468–479. [Google Scholar] [CrossRef]

- Pourmohammadi, K.; Abedi, E. Enzymatic Modifications of Gluten Protein: Oxidative Enzymes. Food Chem. 2021, 356, 129679. [Google Scholar] [CrossRef] [PubMed]

- Maravić, N.; Pajin, B.; Hadnađev, M.; Dapčević-Hadnađev, T.; Pestorić, M.; Škrobot, D.; Tomić, J. Assessment of Whole Grain Ancient Wheat Sourdough in Lyophilised and Native Forms for Cookie Formulation. Foods 2024, 13, 3363. [Google Scholar] [CrossRef]

- Lewko, P.; Wójtowicz, A.; Gancarz, M. Distribution of Arabinoxylans and Their Relationship with Physiochemical and Rheological Properties in Wheat Flour Mill Streams as an Effective Way to Predict Flour Functionality. Appl. Sci. 2023, 13, 5458. [Google Scholar] [CrossRef]

- Jekle, M.; Mühlberger, K.; Becker, T. Starch–gluten interactions during gelatinization and its functionality in dough like model systems. Food Hydrocoll. 2016, 54, 196–201. [Google Scholar] [CrossRef]

- Schirmer, M.; Jekle, M.; Becker, T. Starch gelatinization and its complexity for analysis. Starch 2015, 67, 30–41. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Qian, H.; Zhang, H.; Qi, X. Effects of Different Processing Methods on Starch Properties. J. Food Sci. Biol. 2017, 36, 225–235. [Google Scholar]

- Codină, G.G.; Dabija, A.; Oroian, M. Prediction of Pasting Properties of Dough from Mixolab Measurements Using Artificial Neuronal Networks. Foods 2019, 8, 447. [Google Scholar] [CrossRef] [PubMed]

- De Schepper, C.F.; Buvé, C.; Van Loey, A.M.; Courtin, C.M. A Kinetic Study on the Thermal Inactivation of Barley Malt α-Amylase and β-Amylase during the Mashing Process. Food Res. Int. 2022, 157, 111201. [Google Scholar] [CrossRef] [PubMed]

- Neylon, E.; Arendt, E.K.; Zannini, E.; Sahin, A.W. Fundamental study of the application of brewers spent grain and fermented brewers spent grain on the quality of pasta. Food Struct. 2021, 30, 100225. [Google Scholar] [CrossRef]

- Axentii, M.; Stroe, S.-G.; Codină, G.G. Development and Quality Evaluation of Rigatoni Pasta Enriched with Hemp Seed Meal. Foods 2023, 12, 1774. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Jiang, P.; Zhu, Y.; Zhang, W.; Li, R.; Tan, B. The Effect of Wheat Bran Dietary Fibre and Raw Wheat Bran on the Flour and Dough Properties: A Comparative Study. LWT-Food Sci. Technol. 2023, 173, 114304. [Google Scholar] [CrossRef]

- Ooms, N.; Delcour, J.A. How to impact gluten protein network formation during wheat flour dough making. Curr. Opin. Food Sci. 2019, 25, 88–97. [Google Scholar] [CrossRef]

- Mani, K.; Trägårdh, C.; Eliasson, A.C.; Lindahl, L. Water Content, Water Soluble Fraction, and Mixing Affect Fundamental Rheological Properties of Wheat Flour Doughs. J. Food Sci. 1992, 57, 1198–1209. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Qiao, Y.; Zhang, Y.; Zheng, W.; Zhao, Y.; Huang, Y.; Cui, Z. Improvement of the quality and shelf life of wheat bread by a maltohexaose producing α-amylase. J. Cereal Sci. 2019, 87, 165–171. [Google Scholar] [CrossRef]

- Codină, G.G.; Sarion, C.; Dabija, A. Effects of Dry Sourdough on Bread-Making Quality and Acrylamide Content. Agronomy 2021, 11, 1977. [Google Scholar] [CrossRef]

- Arora, K.; Ameur, H.; Polo, A.; Di Cagno, R.; Rizzello, C.G.; Gobbetti, M. Thirty years of knowledge on sourdough fermentation: A systematic review. Trends Food Sci. Technol. 2021, 108, 71–83. [Google Scholar] [CrossRef]

- Atudorei, D.; Atudorei, O.; Codină, G.G. The Impact of Germinated Chickpea Flour Addition on Dough Rheology and Bread Quality. Plants 2022, 11, 1225. [Google Scholar] [CrossRef] [PubMed]

| Samples | WA (%) | ST (min) | DDT (min) | C1 (N∙m) | C2 (N∙m) | C3 (N∙m) | C4 (N∙m) | C5 (N∙m) | C12 (N∙m) | C32 (N∙m) | C34 (N∙m) | C54 (N∙m) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ingen 33 | 59.0 ± 0.7 g | 2.3 ± 0.05 c | 2.53 ± 0.04 b | 1.137 ± 0.003 g | 0.397 ± 0.002 e | 1.618 ± 0.016 d | 0.364 ± 0.015 c,d | 0.644 ± 0.020 c | 0.740 ± 0.007 b | 1.221 ± 0.006 b | 1.254 ± 0.009 f | 0.280 ± 0.007 b |

| Ingen 33_10BSF | 42.0 ± 0.9 d,e | 2.2 ± 0.06 c | 2.45 ± 0.02 a | 1.076 ± 0.002 b | 0.204 ± 0.005 b | 1.393 ± 0.018 b | 0.142 ± 0.009 a | 0.327 ± 0.025 a | 0.872 ± 0.006 e | 1.189 ± 0.008 a | 1.251 ± 0.005 f | 0.185 ± 0.005 a |

| Ingen 33_17.5BSF | 33.0 ± 0.7 a | 1.8 ± 0.08 a | 2.58 ± 0.05 b | 1.070 ± 0.002 a,b | 0.116 ± 0.003 a | 1.346 ± 0.014 a | 0.119 ± 0.006 a | 0.392 ± 0.031 a | 0.954 ± 0.008 f,g | 1.230 ± 0.009 b | 1.227 ± 0.009 e,f | 0.273 ± 0.012 b |

| Ingen 35 | 59.4 ± 0.9 g | 2.9 ± 0.09 f | 3.00 ± 0.01 c | 1.119 ± 0.004 f | 0.365 ± 0.004 d,e | 1.782 ± 0.020 e | 0.515 ± 0.027 e | 0.942 ± 0.018 e | 0.754 ± 0.005 b | 1.417 ± 0.009 e | 1.267 ± 0.012 f | 0.427 ± 0.008 d |

| Ingen 35_10BSF | 48.7 ± 0.8 f | 2.8 ± 0.04 e,f | 3.87 ± 0.06 f | 1.120 ± 0.002 f | 0.340 ± 0.005 d | 1.774 ± 0.017 e | 0.786 ± 0.021 f | 1.325 ± 0.013 g | 0.780 ± 0.007 c | 1.434 ± 0.011 e,f | 0.988 ± 0.011 a | 0.539 ± 0.011 f |

| Ingen 35_17.5BSF | 39.5 ± 0.7 c,d | 2.4 ± 0.05 d | 2.85 ± 0.0 c | 1.113 ± 0.001 e | 0.270 ± 0.002 c | 1.612 ± 0.021 d | 0.491 ± 0.024 e | 0.827 ± 0.028 d | 0.843 ± 0.009 e,d | 1.342 ± 0.006 d | 1.121 ± 0.008 c,d | 0.336 ± 0.008 b,c |

| Ingen 54 | 59.2 ± 0.6 g | 3.8 ± 0.07 h | 4.08 ± 0.02 g | 1.103 ± 0.002 d | 0.418 ± 0.006 f | 1.977 ± 0.023 f | 0.872 ± 0.018 g | 1.527 ± 0.032 h | 0.685 ± 0.010 a | 1.559 ± 0.013 g | 1.105 ± 0.010 c | 0.655 ± 0.011 g,h |

| Ingen 54_10BSG | 42.0 ± 0.4 e | 3.0 ± 0.06 f,g | 3.52 ± 0.03 e | 1.068 ± 0.002 a,b | 0.237 ± 0.004 c | 1.546 ± 0.016 c | 0.478 ± 0.015 e | 0.973 ± 0.027 e | 0.831 ± 0.012 d,e | 1.309 ± 0.007 c | 1.068 ± 0.002 b,c | 0.495 ± 0.006 e |

| Ingen 54_17.5BSF | 37.0 ± 0.8 c | 3.1 ± 0.08 g | 3.03 ± 0.01 c,d | 1.085 ± 0.001 c | 0.209 ± 0.005 b | 1.612 ± 0.023 d | 0.454 ± 0.010 d,e | 1.104 ± 0.024 f | 0.876 ± 0.002 e | 1.403 ± 0.012 e | 1.158 ± 0.007 d | 0.650 ± 0.009 g,h |

| Ingen 93 | 58.3 ± 0.2 g | 2.6 ± 0.05 d,e | 2.85 ± 0.0 c | 1.113 ± 0.001 e | 0.344 ± 0.006 d | 1.765 ± 0.019 e | 0.450 ± 0.014 d,e | 0.817 ± 0.031 d | 0.769 ± 0.008 b,c | 1.421 ± 0.009 e,f | 1.315 ± 0.009 g | 0.367 ± 0.012 c,d |

| Ingen 93_10BSF | 42.0 ± 0.5 e | 2.6 ± 0.04 d,e | 3.07 ± 0.02 d | 1.122 ± 0.001 f | 0.134 ± 0.002 a | 1.781 ± 0.016 e | 0.285 ± 0.012 c | 0.701 ± 0.024 c | 0.988 ± 0.012 g,h | 1.647 ± 0.002 h | 1.496 ± 0.004 h | 0.416 ± 0.008 d |

| Ingen 93_17.5BSF | 35.0 ± 0.8 b | 2.0 ± 0.6 b | 2.45 ± 0.01 a | 1.139 ± 0.002 g | 0.194 ± 0.004 b | 1.365 ± 0.006 a | 0.228 ± 0.024 b | 0.494 ± 0.021 b | 0.945 ± 0.009 f,g | 1.171 ± 0.005 a | 1.137 ± 0.005 d | 0.266 ± 0.005 b |

| Dough Samples | G’ at 10 Hz (Pa) | G” at 10 Hz (Pa) | G* at 10 Hz (Pa) | tan δ at 10 Hz |

|---|---|---|---|---|

| Ingen 33 | 142,400 ± 135 b | 61,010 ± 98 c | 154,900 ± 119 c | 0.428 ± 0.0013 e |

| Ingen 33_10BSF | 128,000 ± 119 b | 54,940 ± 103 c | 139,300 ± 106 b | 0.429 ± 0.0007 e |

| Ingen 33_17.5BSF | 83,050 ± 106 b | 36,670 ± 58 b | 90,790 ± 78 b | 0.441 ± 0.0011 f |

| Ingen 35 | 319,600 ± 98 c | 125,500 ± 127 d | 343,300 ± 101 d | 0.392 ± 0.0025 c |

| Ingen 35_10BSF | 86,650 ± 103 b | 37,150 ± 89 b | 94,280 ± 173 b | 0.428 ± 0.0016 e |

| Ingen 35_17.5BSF | 46,290 ± 120 a | 21,280 ± 78 a | 50,950 ± 115 a | 0.459 ± 0.0027 g |

| Ingen 54 | 141,900 ± 109 b | 63,200 ± 113 b | 258,500 ± 98 b | 0.445 ± 0.0019 d |

| Ingen 54_10BSF | 123,400 ± 201 e | 58,400± 106 f | 158,000 ± 131 f | 0.473 ± 0.0003 a |

| Ingen 54_17.5BSF | 89,800 ± 114 d | 42,700 ± 27 e | 97,400 ± 96 e | 0.475 ± 0.0009 b |

| Ingen 93 | 301,200 ± 127 c | 128,500 ± 76 d | 327,500 ± 125 d | 0.426 ± 0.0015 e |

| Ingen 93_10BSF | 87,690 ± 128 b | 38,580 ± 49 b | 95,800 ± 76 b | 0.439 ± 0.0021 f |

| Ingen 93_17.5BSF | 37,000 ± 101 a | 17,690 ± 38 a | 41,010 ± 81 a | 0.478 ± 0.0018 h |

| Dough Samples | P (mm) | L (mm) | G | W (10−4 J) | P/L |

|---|---|---|---|---|---|

| Ingen 33 | 100 ± 1.5 e | 37 ± 0.6 g | 13.5 ± 0.01 g | 114 ± 2 e | 2.70 ± 0.10 d |

| Ingen 33_10BSF | 53 ± 1.0 c | 39 ± 0.8 h | 13.9 ± 0.04 g | 51 ± 2 c | 1.35 ± 0.09 b |

| Ingen 33_17.5BSF | 32 ± 0.7 a | 28 ± 0.5 d | 11.8 ± 0.03 d | 33 ± 1 b | 1.14 ± 0.02 a |

| Ingen 35 | 102 ± 2.0 e | 31 ± 0.7 e,f | 12.4 ± 0.06 d | 112 ± 2 e | 3.29 ± 0.05 f |

| Ingen 35_10BSF | 50 ± 1.6 c | 24 ± 0.4 b | 10.9 ± 0.03 b,c | 47 ± 1 c | 2.08 ± 0.06 c |

| Ingen 35_17.5BSF | 27 ± 1.3 a | 19 ± 0.1 a | 9.7 ± 0.01 a | 18 ± 1 a | 1.42 ± 0.02 b |

| Ingen 54 | 106 ± 1.8 e | 32 ± 0.5 f | 12.6 ± 0.05 e,f | 129 ± 4 f | 3.31 ± 0.03 f |

| Ingen 54_10BSF | 43 ± 0.6 b | 33 ± 0.2 f | 12.8 ± 0.04 e,f | 45 ± 2 c | 1.30 ± 0.06 b |

| Ingen 54_17.5BSF | 26 ± 1.0 a | 25 ± 0.4 c | 11.1 ± 0.01 c | 20 ± 1 a | 1.04 ± 0.02 a |

| Ingen 93 | 95 ± 1.7 d | 32 ± 0.6 f | 12.6 ± 0.03 e,f | 99 ± 2 d | 2.97 ± 0.03 e |

| Ingen 93_10BSF | 41 ± 1.1 b | 30 ± 0.5 e | 12.2 ± 0.04 e | 47 ± 2 c | 1.37 ± 0.02 b |

| Ingen 93_17.5BSF | 25 ± 0.8 a | 23 ± 0.3 a | 10.7 ± 0.02 b | 23 ± 1 a | 1.08 ± 0.01 a |

| Samples | pH | |||

|---|---|---|---|---|

| 0 h | 1 h | 2 h | 3 h | |

| Ingen 33 | 6.15 ± 0.02 j,k | 6.04 ± 0.03 h,i | 5.98 ± 0.01 g,h | 5.95 ± 0.02 g |

| Ingen 33_10BSF | 5.74 ± 0.04 e,f | 5.71 ± 0.02 d,e | 5.67 ± 0.03 d,e | 5.64 ± 0.03 c,d |

| Ingen 33_17.5BSF | 5.64 ± 0.03 c,d | 5.60 ± 0.03 b,c | 5.55 ± 0.04 b,c | 5.51 ± 0.04 a,b |

| Ingen 35 | 6.10 ± 0.02 i,j | 6.02 ± 0.01 h | 5.97 ± 0.01 g | 5.94 ± 0.01 g |

| Ingen 35_10BSF | 5.70 ± 0.01 d,e | 5.68 ± 0.03 d,e | 5.62 ± 0.02 c,d | 5.59 ± 0.03 b,c |

| Ingen 35_17.5BSF | 5.58 ± 0.02 b,c | 5.55 ± 0.02 b | 5.52± 0.04 a,b | 5.48 ± 0.02 a |

| Ingen 54 | 6.18 ± 0.03 j,k | 6.08 ± 0.02 i | 6.04 ± 0.01 h,i | 5.97 ± 0.01 g |

| Ingen 54_10BSF | 5.76 ± 0.01 e,f | 5.73 ± 0.03 e,f | 5.70 ± 0.02 d,e | 5.67 ± 0.03 d,e |

| Ingen 54_17.5BSF | 5.66 ± 0.02 d | 5.63 ± 0.04 c,d | 5.58 ± 0.02 b,c | 5.54 ± 0.03 a,b |

| Ingen 93 | 6.12 ± 0.02 i,j | 6.00 ± 0.01 h | 5.97 ± 0.01 g | 5.94 ± 0.01 g |

| Ingen 93_10BSF | 5.72 ± 0.01 e | 5.70 ± 0.03 d,e | 5.65 ± 0.03 c,d | 5.62 ± 0.02 c,d |

| Ingen 93_17.5BSF | 5.61 ± 0.03 d,e | 5.58 ± 0.04 b,c | 5.54 ± 0.02 b | 5.49 ± 0.02 a |

| Dough Samples | H’m (mm) | VT (mL) | VR (mL) | CR (%) | FN (s) |

|---|---|---|---|---|---|

| Ingen 33 | 87.1 ± 0.7 a,b | 1647 ± 17 a | 1640 ± 5 a | 99.5 ± 0.02 f | 73 ± 1 b |

| Ingen 33_10BSF | 87.9 ± 0.5 b | 1879 ± 21 c | 1864 ± 0 c | 99.2 ± 0.04 c | 68 ± 2 a,b |

| Ingen 33_17.5BSF | 98.4 ± 0.1 f | 2120 ± 10 g | 2109 ± 3 g | 99.5 ± 0.01 d,e | 64 ± 2 a |

| Ingen 35 | 88.7 ± 0.3 b,c | 1921 ± 15 d | 1907 ± 4 c | 99.2 ± 0.02 c | 102 ± 1 e |

| Ingen 35_10BSF | 89.2 ± 0.2 c | 2042 ± 18 e,f | 2013 ± 3 e | 98.6 ± 0.01 a | 77 ± 2 c |

| Ingen 35_17.5BSF | 100.0 ± 0.9 g | 2213 ± 15 h | 2198 ± 8 h | 99.3 ± 0.03 d | 68 ± 1 a,b |

| Ingen 54 | 87.4 ± 0.3 a,b | 1631 ± 12 a | 1620 ± 5 a | 99.3 ± 0.01 d | 136 ± 2 h |

| Ingen 54_10BSF | 87.8 ± 0.3 b | 1948 ± 15 d | 1933 ± 3 c | 99.2 ± 0.2 c | 111 ± 1 f |

| Ingen 54_17.5BSF | 89.1 ± 0.2 c | 1983 ± 13 e | 1968 ± 8 d | 99.2 ± 0.01 c | 93 ± 1 d |

| Ingen 93 | 87.2 ± 0.1 a | 1743 ± 2 b | 1727 ± 5 b | 99.1 ± 0.02 b | 120 ± 1 g |

| Ingen 93_10BSF | 90.8 ± 0.5 d | 2024 ± 9 e | 2009 ± 4 d,e | 99.3 ± 0.03 d | 70 ± 2 b |

| Ingen 93_17.5BSF | 94.0 ± 0.1 e | 2128 ± 11 g | 2115 ± 3 g | 99.4 ± 0.02 e | 64 ± 1 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghendov-Mosanu, A.; Ropciuc, S.; Dabija, A.; Saitan, O.; Boestean, O.; Paiu, S.; Rumeus, I.; Leatamborg, S.; Lupascu, G.; Codină, G.G. Effect of Brewers’ Spent Grain Addition to a Fermented Form on Dough Rheological Properties from Different Triticale Flour Cultivars. Foods 2025, 14, 41. https://doi.org/10.3390/foods14010041

Ghendov-Mosanu A, Ropciuc S, Dabija A, Saitan O, Boestean O, Paiu S, Rumeus I, Leatamborg S, Lupascu G, Codină GG. Effect of Brewers’ Spent Grain Addition to a Fermented Form on Dough Rheological Properties from Different Triticale Flour Cultivars. Foods. 2025; 14(1):41. https://doi.org/10.3390/foods14010041

Chicago/Turabian StyleGhendov-Mosanu, Aliona, Sorina Ropciuc, Adriana Dabija, Olesea Saitan, Olga Boestean, Sergiu Paiu, Iurie Rumeus, Svetlana Leatamborg, Galina Lupascu, and Georgiana Gabriela Codină. 2025. "Effect of Brewers’ Spent Grain Addition to a Fermented Form on Dough Rheological Properties from Different Triticale Flour Cultivars" Foods 14, no. 1: 41. https://doi.org/10.3390/foods14010041

APA StyleGhendov-Mosanu, A., Ropciuc, S., Dabija, A., Saitan, O., Boestean, O., Paiu, S., Rumeus, I., Leatamborg, S., Lupascu, G., & Codină, G. G. (2025). Effect of Brewers’ Spent Grain Addition to a Fermented Form on Dough Rheological Properties from Different Triticale Flour Cultivars. Foods, 14(1), 41. https://doi.org/10.3390/foods14010041