Nanofillers in Novel Food Packaging Systems and Their Toxicity Issues

Abstract

:1. Introduction

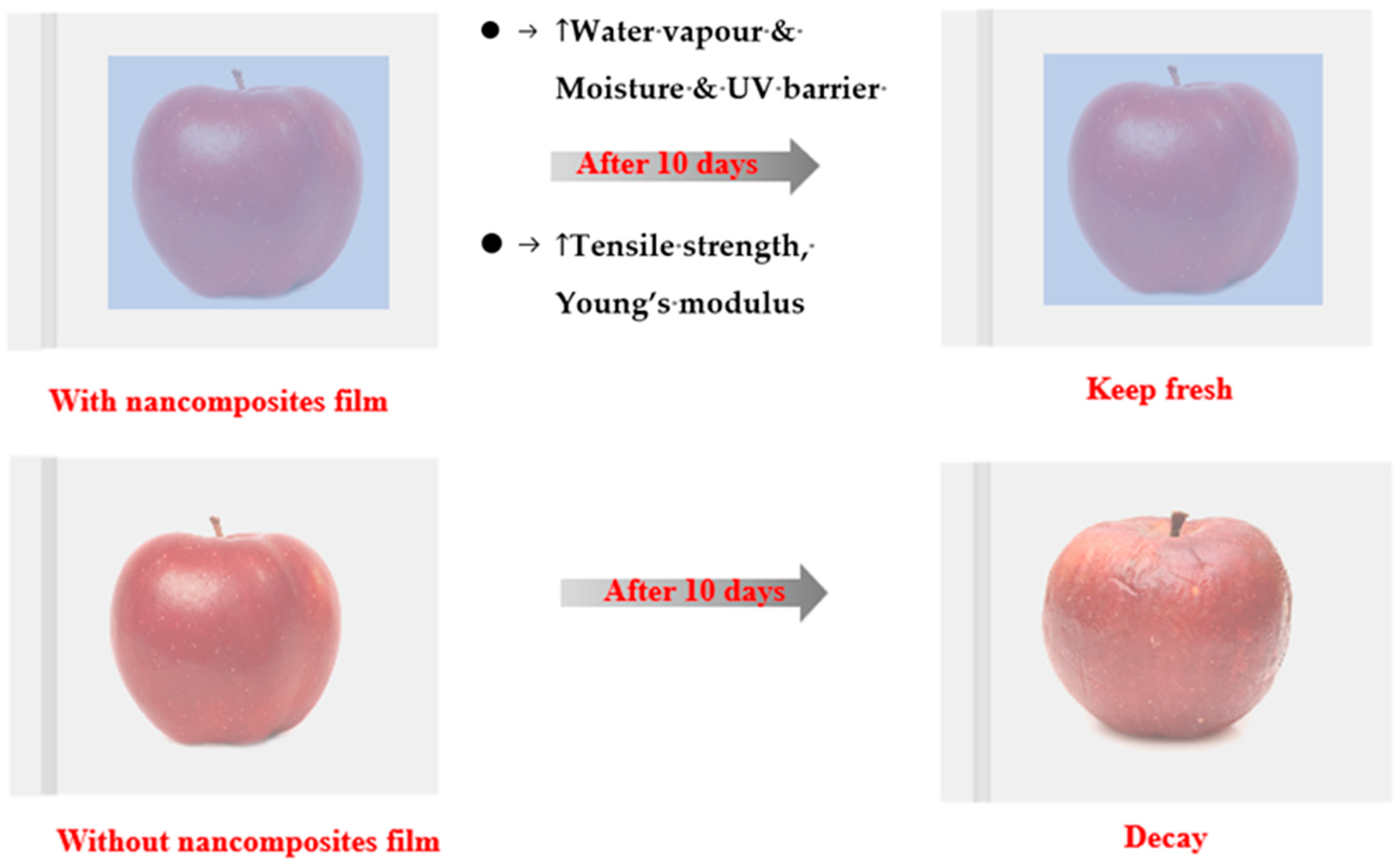

2. Use of Nanofillers for Improvement of Food Packaging

2.1. Nanoclay

2.2. Carbon Nanotubes

2.3. Cellulose-Based Nanofibers or Nanowhiskers

2.4. Starch Nanocrystals

2.5. Chitosan NPs

2.6. Silicon Dioxide NPs (SiO2 NPs)

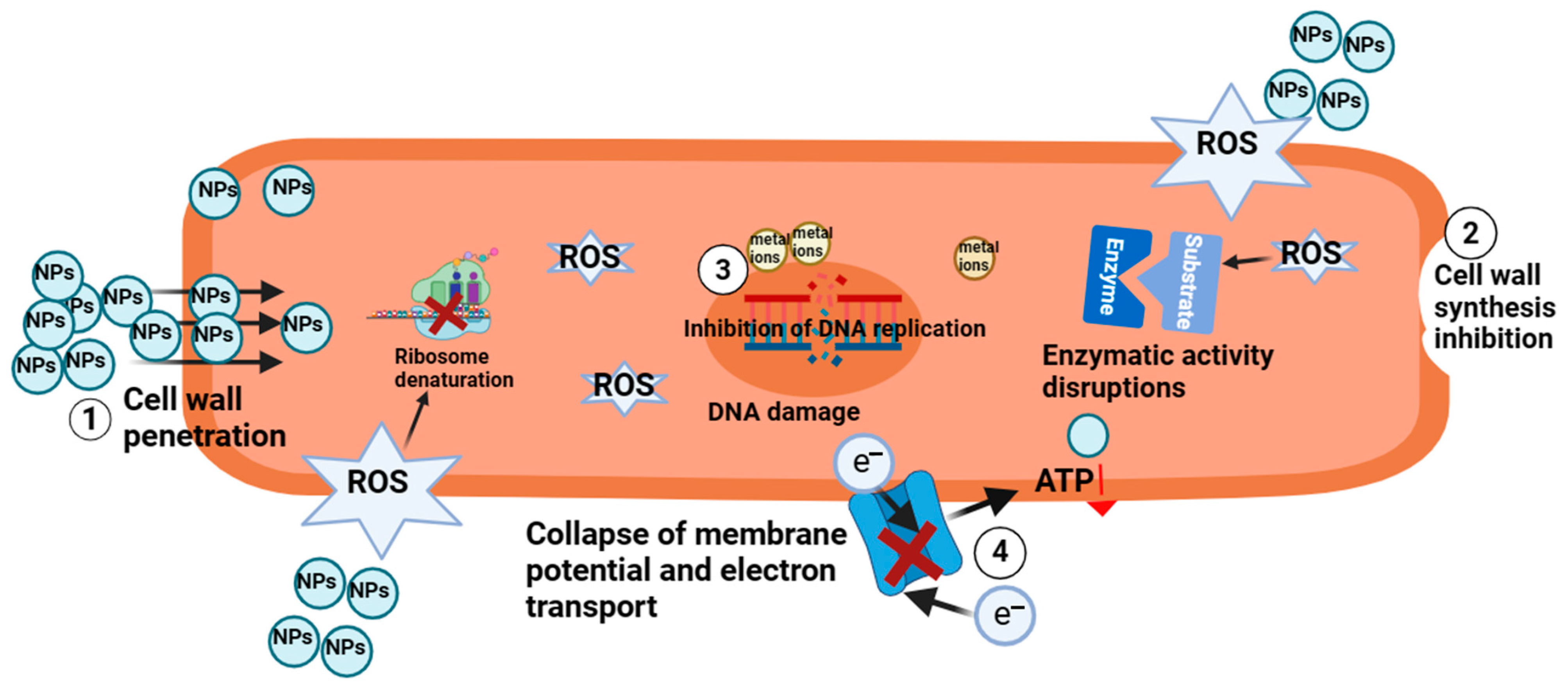

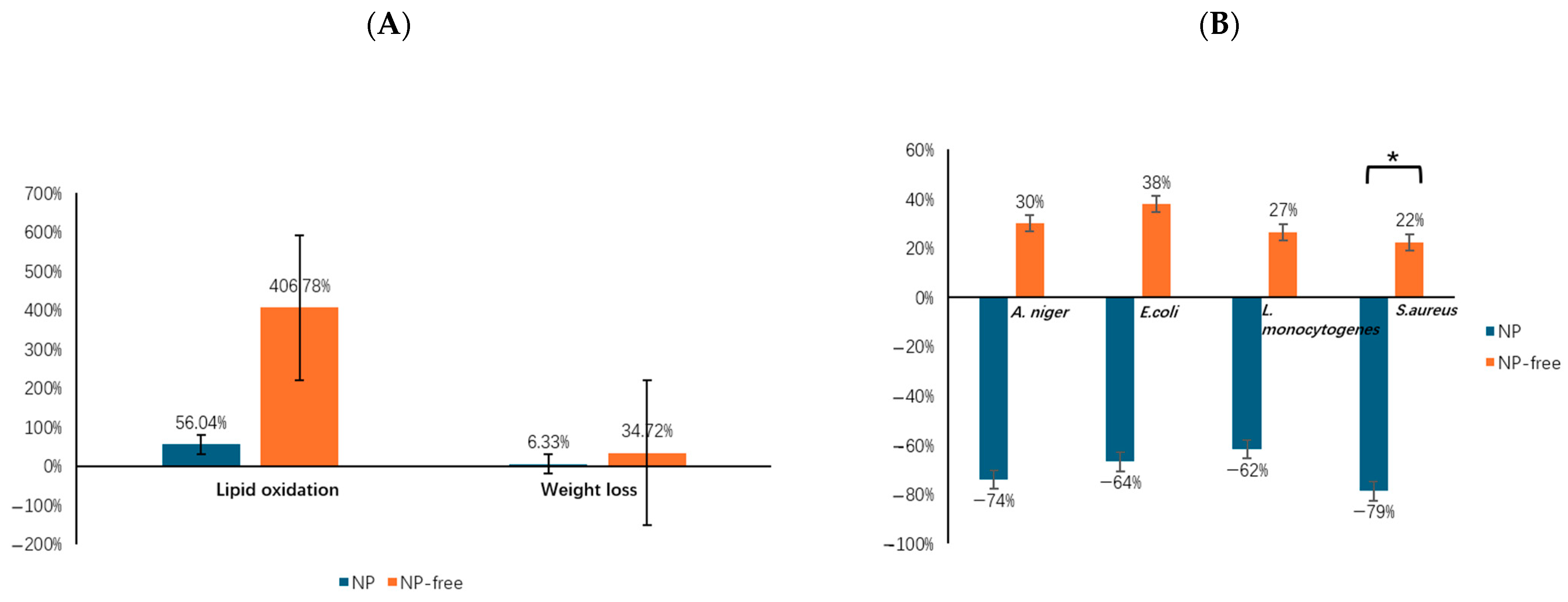

3. Use of Nanofillers in Active Food Packaging

3.1. Silver NPs (Ag NPs)

3.2. Zinc Oxide NPs (ZnO NPs)

3.3. Other NPs

3.4. EO-Loaded Nanoemulsion

3.5. Brief Summary of Antimicrobial Activity of Active Food Packaging

| Nanofillers | Polymeric Matrix | Packaging Form | Findings with Optimal NPs Compared to Non-NPs | Application Product | References | |

|---|---|---|---|---|---|---|

| Concentration/Percentage (%) Weight of Optimal Metal-Based NPs | Types of Metal-Based NPs | |||||

| 2% | Ag NPs | Agar | Film |

| Fresh beef loin | [115] |

| 2% | Ag NPs | Pullulan-curcumin | Edible film |

| Broiler breast | [154] |

| 0.25% | Ag NPs | HPMC | Film |

| Papaya (Carica papaya L.) | [155] |

| 10% | Ag NPs | Cellulose | Packets |

| Cabbages and tomatoes | [156] |

| 5% | Ag NPs | PLA | Film |

| Strawberry | [157] |

| 5% | Ag NPs (with 10% EOs) | Chitosan | Film |

| Strawberry | [158] |

| 10% | ZnO NPs | PBAT | Film |

| N/A | [159] |

| 12.5% | ZnO NPs | Gelatin/Tapioca starch | Film |

| N/A | [123] |

| 1.5% | ZnO NPs | Pectin | Film |

| N/A | [160] |

| 4 mL | ZnO NPs | HPS/PVA/PA | Film mats |

| N/A | [124] |

| 0.5 g | ZnO NPs | CMC | Film |

| Cherry tomatoes | [161] |

| 100 mg | Cinnamaldehyde | |||||

| 1.5% | ZnO NPs | PLA | Film |

| Fresh fish fillets | [162] |

| 1.5% | ZEO | |||||

| 1.5% | MEO | |||||

| 0.8 g | Ag NPs | Starch/PBAT | Film |

| Peaches and nectarines | [163] |

| 0.2 g | ZnO NPs | |||||

| 0.99 g in 15 mL water | ZnO NPs | Chitosan | Film |

| Grape | [164] |

| 15 mL | Ag NPs | |||||

| 1 mL | citronella EO | |||||

| 0.015% | TiO2 NPs | PLA | Film |

| N/A | [165] |

| 3% | Lycopene | |||||

| 5% | TiO2 NPs | Alginate and aloe vera | Edible coating |

| Tomato | [166] |

| 0.003 g | TiO2 NPs | Starch/PVA | Film |

| Cherry tomato | [167] |

| 0.4 g | elderberry extract | |||||

| 1% | TiO2 NPs | Chitosan | Film |

| Minced meat | [129] |

| 1.5% | Cymbopogon citratus EO | |||||

| 0.3% | Ag NPs | Chitosan/polyethylene oxide | Films |

| N/A | [168] |

| 0.8% | TiO2 NPs | |||||

| 1% | Ag NPs | PLA | Films |

| Fresh mango | [169] |

| 2% | TiO2 NPs | |||||

| 9% | Bergamot EO | |||||

| 3% | CuO NPs | Starch | Film |

| N/A | [133] |

| N/A | Au NPs | PVA/glyoxal | Film |

| Banana | [135] |

| 10% | Fe3O4 NPs | Chitosan/pectin | Film |

| N/A | [170] |

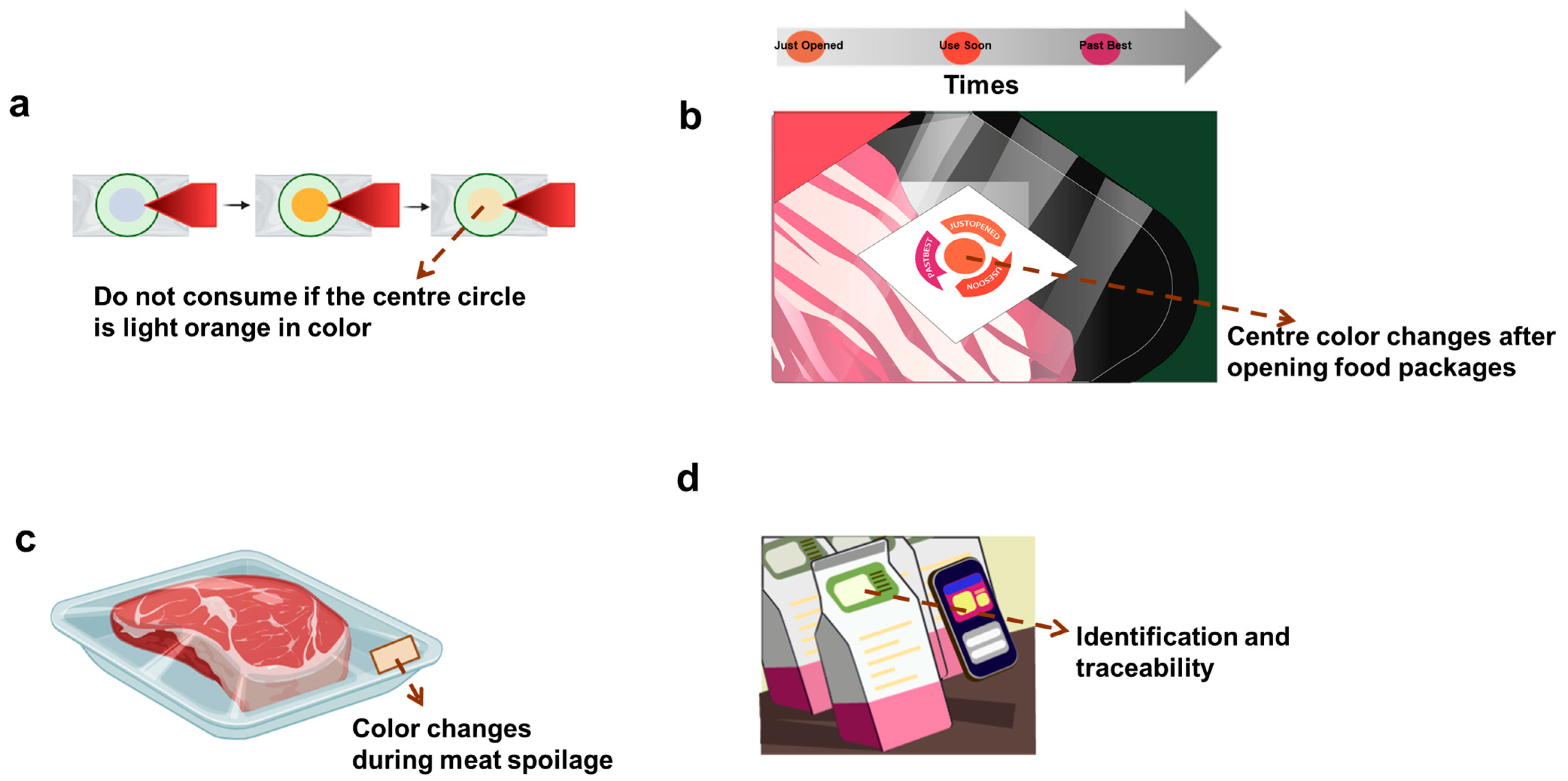

4. Use of Nanofillers in Intelligent Food Packaging

4.1. The Definition of Intelligent Packaging

4.2. Nanocomposites-Based Intelligent Films

4.2.1. Anthocyanins and Their Utility

4.2.2. Other Compounds and Their Application

5. Use of Nanofillers in Photodegradable and Biodegradable Food Packaging

5.1. Photodegradable Food Packaging

5.2. Biodegradable Food Packaging

6. Migration Process

6.1. Factors Affecting the Migration Process

6.2. Assessment Methods for Nanofillers

6.3. Application of Nanofiller to Reduce Migration

7. Toxicological Effects of Nanofillers

7.1. The Cytotoxicity of Migrated Nanofillers

7.2. The Ecotoxicity Effect of Nanofillers

8. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- de Menezes, F.L.G.; de Lima Leite, R.H.; dos Santos, F.K.G.; Aria, A.I.; Aroucha, E.M.M. TiO2-enhanced chitosan/cassava starch biofilms for sustainable food packaging. Colloids Surf. A Physicochem. Eng. Asp. 2021, 630, 127661. [Google Scholar] [CrossRef]

- Ahmad, A.; Qurashi, A.; Sheehan, D. Nano packaging–Progress and future perspectives for food safety, and sustainability. Food Packag. Shelf Life 2023, 35, 100997. [Google Scholar] [CrossRef]

- Pires, J.R.A.; Rodrigues, C.; Coelhoso, I.; Fernando, A.L.; Souza, V.G.L. Current Applications of Bionanocomposites in Food Processing and Packaging. Polymers 2023, 15, 2336. [Google Scholar] [CrossRef] [PubMed]

- WHO. Estimating the Burden of Foodborne Diseases. 2024. Available online: https://www.who.int/publications/i/item/9789240012264 (accessed on 9 May 2024).

- ECHO. Global Food Crisis: What You Need to Know in 2023. 2023. Available online: https://civil-protection-humanitarian-aid.ec.europa.eu/news-stories/stories/global-food-crisis-what-you-need-know-2023_en (accessed on 4 May 2024).

- Souza, V.G.L.; Fernando, A.L. Nanoparticles in food packaging: Biodegradability and potential migration to food—A review. Food Packag. Shelf Life 2016, 8, 63–70. [Google Scholar] [CrossRef]

- Hazer, B.; Karahaliloglu, Z.; Ashby, R.D. Poly (vinyl chloride) Derived Food Packaging Applications with Antioxidative and Anticancer Properties. ACS Food Sci. Technol. 2023, 3, 761–771. [Google Scholar] [CrossRef]

- Hazer, B.; Ashby, R.D. Synthesis of a novel tannic acid-functionalized polypropylene as antioxidant active-packaging materials. Food Chem. 2021, 344, 128644. [Google Scholar] [CrossRef] [PubMed]

- Hazer, B.; Ashby, R.D. Synthesis of poly vinyl chloride/chlorinated polypropylene-active natural substance derivatives for potential packaging materials application. Tannic acid, menthol and lipoic acid. Food Chem. 2023, 403, 134475. [Google Scholar] [CrossRef] [PubMed]

- Venkatesan, R.; Surya, S.; Suganthi, S.; Muthuramamoorthy, M.; Pandiaraj, S.; Kim, S.C. Biodegradable composites from poly (butylene adipate-co-terephthalate) with carbon nanoparticles: Preparation, characterization and performances. Environ. Res. 2023, 235, 116634. [Google Scholar] [CrossRef]

- González-López, M.E.; Calva-Estrada, S.d.J.; Gradilla-Hernández, M.S.; Barajas-Álvarez, P. Current trends in biopolymers for food packaging: A review. Front. Sustain. Food Syst. 2023, 7, 1225371. [Google Scholar] [CrossRef]

- Jiang, S.; Qiao, C.; Liu, R.; Liu, Q.; Xu, J.; Yao, J. Structure and properties of citric acid cross-linked chitosan/poly (vinyl alcohol) composite films for food packaging applications. Carbohydr. Polym. 2023, 312, 120842. [Google Scholar] [CrossRef]

- Mokhena, T.C.; Sadiku, E.R.; Mochane, M.J.; Ray, S.S.; John, M.J.; Mtibe, A. Mechanical properties of cellulose nanofibril papers and their bionanocomposites: A review. Carbohydr. Polym. 2021, 273, 118507. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Kaur, G.; Singh, A.; Kaur, P. Starch based bio-nanocomposite films reinforced with montmorillonite and lemongrass oil nanoemulsion: Development, characterization and biodegradability. J. Food Meas. Charact. 2023, 17, 527–545. [Google Scholar] [CrossRef]

- He, Y.; Li, H.; Fei, X.; Peng, L. Carboxymethyl cellulose/cellulose nanocrystals immobilized silver nanoparticles as an effective coating to improve barrier and antibacterial properties of paper for food packaging applications. Carbohydr. Polym. 2021, 252, 117156. [Google Scholar] [CrossRef]

- Kraśniewska, K.; Galus, S.; Gniewosz, M. Biopolymers-based materials containing silver nanoparticles as active packaging for food applications—A review. Int. J. Mol. Sci. 2020, 21, 698. [Google Scholar] [CrossRef]

- Shankar, S.; Tanomrod, N.; Rawdkuen, S.; Rhim, J. Preparation of pectin/silver nanoparticles composite films with UV-light barrier and properties. Int. J. Biol. Macromol. 2016, 92, 842–849. [Google Scholar] [CrossRef]

- Sani, M.A.; Tavassoli, M.; Salim, S.A.; Azizi-lalabadi, M.; McClements, D.J. Development of green halochromic smart and active packaging materials: TiO2 nanoparticle-and anthocyanin-loaded gelatin/κ-carrageenan films. Food Hydrocoll. 2022, 124, 107324. [Google Scholar] [CrossRef]

- Ashfaq, A.; Khursheed, N.; Fatima, S.; Anjum, Z.; Younis, K. Application of nanotechnology in food packaging: Pros and Cons. J. Agric. Food Res. 2022, 7, 100270. [Google Scholar] [CrossRef]

- Simoneau, C. Applicability of Generally Recognised Diffusion Models for the Estimation of Specific Migration in Support of EU Directive 2002/72/EC. 2010. Available online: https://publications.jrc.ec.europa.eu/repository/bitstream/JRC59476/reqno_jrc59476_mathmod_v10_cs_2010_09_24_final.pdf(1].pdf (accessed on 10 May 2024).

- Bott, J.; Störmer, A.; Franz, R. A comprehensive study into the migration potential of nano silver particles from food contact polyolefins. In Chemistry of Food, Food Supplements, and Food Contact Materials: From Production to Plate; ACS Publications: Washington, DC, USA, 2014; pp. 51–70. [Google Scholar]

- Bott, J.; Störmer, A.; Franz, R. A model study into the migration potential of nanoparticles from plastics nanocomposites for food contact. Food Packag. Shelf Life 2014, 2, 73–80. [Google Scholar] [CrossRef]

- Morais, L.d.O.; Macedo, E.V.; Granjeiro, J.M.; Delgado, I.F. Critical evaluation of migration studies of silver nanoparticles present in food packaging: A systematic review. Crit. Rev. Food Sci. Nutr. 2020, 60, 3083–3102. [Google Scholar] [CrossRef] [PubMed]

- Paidari, S.; Tahergorabi, R.; Anari, E.S.; Nafchi, A.M.; Zamindar, N.; Goli, M. Migration of various nanoparticles into food samples: A review. Foods 2021, 10, 2114. [Google Scholar] [CrossRef]

- Huang, J.-Y.; Li, X.; Zhou, W. Safety assessment of nanocomposite for food packaging application. Trends Food Sci. Technol. 2015, 45, 187–199. [Google Scholar] [CrossRef]

- Zhang, W.; Rhim, J. Titanium dioxide (TiO2) for the manufacture of multifunctional active food packaging films. Food Packag. Shelf Life 2022, 31, 100806. [Google Scholar] [CrossRef]

- Nielsen, L.E. Models for the permeability of filled polymer systems. J. Macromol. Sci. Chem. 1967, 1, 929–942. [Google Scholar] [CrossRef]

- Silvestre, C.; Duraccio, D.; Cimmino, S. Food packaging based on polymer nanomaterials. Prog. Polym. Sci. 2011, 36, 1766–1782. [Google Scholar] [CrossRef]

- Bumbudsanpharoke, N.; Ko, S. Nanomaterial-based optical indicators: Promise, opportunities, and challenges in the development of colorimetric systems for intelligent packaging. Nano Res. 2019, 12, 489–500. [Google Scholar] [CrossRef]

- Nath, D.; Santhosh, R.; Pal, K.; Sarkar, P. Nanoclay-based active food packaging systems: A review. Food Packag. Shelf Life 2022, 31, 100803. [Google Scholar] [CrossRef]

- Bai, C.; Ke, Y.; Hu, X.; Xing, L.; Zhao, Y.; Lu, S.; Lin, Y. Preparation and properties of amphiphilic hydrophobically associative polymer/montmorillonite nanocomposites. R. Soc. Open Sci. 2020, 7, 200199. [Google Scholar] [CrossRef] [PubMed]

- Król-Morkisz, K.; Pielichowska, K. Thermal decomposition of polymer nanocomposites with functionalized nanoparticles. In Polymer Composites with Functionalized Nanoparticles; Elsevier: Amsterdam, The Netherlands, 2019; pp. 405–435. [Google Scholar]

- Perera, K.Y.; Hopkins, M.; Jaiswal, A.K.; Jaiswal, S. Nanoclays-containing bio-based packaging materials: Properties, applications, safety, and regulatory issues. J. Nanostruct. Chem. 2024, 14, 71–93. [Google Scholar] [CrossRef]

- Messin, T.; Follain, N.; Lozay, Q.; Guinault, A.; Delpouve, N.; Soulestin, J.; Sollogoub, C.; Marais, S. Biodegradable pla/pbsa multinanolayer nanocomposites: Effect of nanoclays incorporation in multinanolayered structure on mechanical and water barrier properties. Nanomaterials 2020, 10, 2561. [Google Scholar] [CrossRef]

- Radfar, R.; Hosseini, H.; Farhoodi, M.; Ghasemi, I.; Średnicka-Tober, D.; Shamloo, E.; Khaneghah, A.M. Optimization of antibacterial and mechanical properties of an active LDPE/starch/nanoclay nanocomposite film incorporated with date palm seed extract using D-optimal mixture design approach. Int. J. Biol. Macromol. 2020, 158, 790–799. [Google Scholar] [CrossRef]

- Guo, F.; Aryana, S.; Han, Y.; Jiao, Y. A review of the synthesis and applications of polymer–nanoclay composites. Appl. Sci. 2018, 8, 1696. [Google Scholar] [CrossRef]

- Davachi, S.M.; Shekarabi, A.S. Preparation and characterization of antibacterial, eco-friendly edible nanocomposite films containing Salvia macrosiphon and nanoclay. Int. J. Biol. Macromol. 2018, 113, 66–72. [Google Scholar] [CrossRef] [PubMed]

- Naidu, D.S.; John, M.J. Effect of clay nanofillers on the mechanical and water vapor permeability properties of xylan–alginate films. Polymers 2020, 12, 2279. [Google Scholar] [CrossRef] [PubMed]

- Adame, D.; Beall, G.W. Direct measurement of the constrained polymer region in polyamide/clay nanocomposites and the implications for gas diffusion. Appl. Clay Sci. 2009, 42, 545–552. [Google Scholar] [CrossRef]

- Gaume, J.; Taviot-Gueho, C.; Cros, S.; Rivaton, A.; Therias, S.; Gardette, J.L. Optimization of PVA clay nanocomposite for ultra-barrier multilayer encapsulation of organic solar cells. Sol. Energy Mater. Sol. Cells 2012, 99, 240–249. [Google Scholar] [CrossRef]

- Chandio, A.D.; Channa, I.A.; Rizwan, M.; Akram, S.; Javed, M.S.; Siyal, S.H.; Saleem, M.; Makhdoom, M.A.; Ashfaq, T.; Khan, S. Polyvinyl alcohol and nano-clay based solution processed packaging coatings. Coatings 2021, 11, 942. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Mello, I.P.; Khalid, O.; Pires, J.R.A.; Rodrigues, C.; Alves, M.M.; Santos, C.; Fernando, A.L.; Coelhoso, I.J.C. Strategies to improve the barrier and mechanical properties of pectin films for food packaging: Comparing nanocomposites with bilayers. Coatings 2022, 12, 108. [Google Scholar] [CrossRef]

- Oliveira, T.Í.S.; Zea-Redondo, L.; Moates, G.K.; Wellner, N.; Cross, K.; Waldron, K.W.; Azeredo, H.M. Pomegranate peel pectin films as affected by montmorillonite. Food Chem. 2016, 198, 107–112. [Google Scholar] [CrossRef] [PubMed]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Das, R.; Shahnavaz, Z.; Ali, M.E.; Islam, M.M.; Abd Hamid, S.B. Can we optimize arc discharge and laser ablation for well-controlled carbon nanotube synthesis? Nanoscale Res. Lett. 2016, 11, 510. [Google Scholar] [CrossRef] [PubMed]

- Cui, R.; Jiang, K.; Yuan, M.; Cao, J.; Li, L.; Tang, Z.; Qin, Y. Antimicrobial film based on polylactic acid and carbon nanotube for controlled cinnamaldehyde release. J. Mater. Res. Technol. 2020, 9, 10130–10138. [Google Scholar] [CrossRef]

- Wen, Y.-H.; Tsou, C.-H.; de Guzman, M.R.; Huang, D.; Yu, Y.-Q.; Gao, C.; Zhang, X.-M.; Du, J.; Zheng, Y.-T.; Zhu, H. Antibacterial nanocomposite films of poly (vinyl alcohol) modified with zinc oxide-doped multiwalled carbon nanotubes as food packaging. Polym. Bull. 2022, 79, 3847–3866. [Google Scholar] [CrossRef]

- Reig, C.S.; Lopez, A.D.; Ramos, M.H.; Ballester, V.A.C. Nanomaterials: A map for their selection in food packaging applications. Packag. Technol. Sci. 2014, 27, 839–866. [Google Scholar] [CrossRef]

- Garcia, S.; Rubio, L.; Lagaron, J.M. Natural micro and nanobiocomposites with enhanced barrier properties and nove l functionalities for food biopackaging applications. Trends Food Sci. Technol. 2010, 21, 528–536. [Google Scholar] [CrossRef]

- Velichkova, H.; Kotsilkov, S.; Ivanov, E.; Kotsilkova, R.; Gyoshev, S.; Stoimenov, N.; Vitanov, N.K. Release of carbon nanoparticles of different size and shape from nanocomposite poly (lactic) acid film into food simulants. Food Addit. Contam. Part A 2017, 34, 1072–1085. [Google Scholar] [CrossRef]

- Kotsilkov, S.; Ivanov, E.; Vitanov, N.K. Release of graphene and carbon nanotubes from biodegradable poly (lactic acid) films during degradation and combustion: Risk associated with the end-of-life of nanocomposite food packaging materials. Materials 2018, 11, 2346. [Google Scholar] [CrossRef] [PubMed]

- Hui, S.; Das, N.C. Surface modified carbon nanotubes in food packaging. Ind. Appl. 2022, 2, 199–233. [Google Scholar]

- Caroline da Silva Rocha, A.; Rodrigues Menezes, L.; Silva, E.O.D.; Pedrosa, M.C.G. Synergistic effect of carbon nanoparticles on the mechanical and thermal properties of poly (lactic acid) as promising systems for packaging. J. Compos. Mater. 2020, 54, 4133–4144. [Google Scholar] [CrossRef]

- Favier, V.; Canova, G.R.; Cavaillé, J.Y.; Chanzy, H.; Dufresne, A.; Gauthier, C. Nanocomposite materials from latex and cellulose whiskers. Polym. Adv. Technol. 1995, 6, 351–355. [Google Scholar] [CrossRef]

- Le Corre, D.; Bras, J.; Dufresne, A. Starch nanoparticles: A review. Biomacromolecules 2010, 11, 1139–1153. [Google Scholar] [CrossRef]

- Sharma, C.; Dhiman, R.; Rokana, N.; Panwar, H. Nanotechnology: An untapped resource for food packaging. Front. Microbiol. 2017, 8, 1735. [Google Scholar] [CrossRef] [PubMed]

- Janik, M.; Hanula, M.; Khachatryan, K.; Khachatryan, G. Nano-/Microcapsules, Liposomes, and Micelles in Polysaccharide Carriers: Applications in Food Technology. Appl. Sci. 2023, 13, 11610. [Google Scholar] [CrossRef]

- Qasim, U.; Osman, A.I.; Al-Muhtaseb, A.a.H.; Farrell, C.; Al-Abri, M.; Ali, M.; Vo, D.-V.N.; Jamil, F.; Rooney, D.W. Renewable cellulosic nanocomposites for food packaging to avoid fossil fuel plastic pollution: A review. Environ. Chem. Lett. 2021, 19, 613–641. [Google Scholar] [CrossRef]

- Fotie, G.; Limbo, S.; Piergiovanni, L. Manufacturing of food packaging based on nanocellulose: Current advances and challenges. Nanomaterials 2020, 10, 1726. [Google Scholar] [CrossRef]

- Leung, A.C.; Hrapovic, S.; Lam, E.; Liu, Y.; Male, K.B.; Mahmoud, K.A.; Luong, J.H. Characteristics and properties of carboxylated cellulose nanocrystals prepared from a novel one-step procedure. Small 2011, 7, 302–305. [Google Scholar] [CrossRef] [PubMed]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef]

- Sucinda, E.; Majid, M.A.; Ridzuan, M.; Cheng, E.; Alshahrani, H.; Mamat, N. Development and characterisation of packaging film from Napier cellulose nanowhisker reinforced polylactic acid (PLA) bionanocomposites. Int. J. Biol. Macromol. 2021, 187, 43–53. [Google Scholar] [CrossRef]

- Haghighi, H.; Gullo, M.; La China, S.; Pfeifer, F.; Siesler, H.W.; Licciardello, F.; Pulvirenti, A. Characterization of bio-nanocomposite films based on gelatin/polyvinyl alcohol blend reinforced with bacterial cellulose nanowhiskers for food packaging applications. Food Hydrocoll. 2021, 113, 106454. [Google Scholar] [CrossRef]

- Li, Z.; Guan, J.; Yan, C.; Chen, N.; Wang, C.; Liu, T.; Cheng, F.; Guo, Q.; Zhang, X.; Ye, X.; et al. Corn straw core/cellulose nanofibers composite for food packaging: Improved mechanical, bacteria blocking, ultraviolet and water vapor barrier properties. Food Hydrocoll. 2023, 143, 108884. [Google Scholar] [CrossRef]

- Campelo, P.H.; Sant’Ana, A.S.; Clerici, M.T.P.S. Starch nanoparticles: Production methods, structure, and properties for food applications. Curr. Opin. Food Sci. 2020, 33, 136–140. [Google Scholar] [CrossRef]

- de la Concha, B.B.S.; Agama-Acevedo, E.; Nuñez-Santiago, M.C.; Bello-Perez, L.A.; Garcia, H.S.; Alvarez-Ramirez, J. Acid hydrolysis of waxy starches with different granule size for nanocrystal production. J. Cereal Sci. 2018, 79, 193–200. [Google Scholar] [CrossRef]

- Zhou, J.; Tong, J.; Su, X.; Ren, L.J. Hydrophobic starch nanocrystals preparations through crosslinking modification using citric acid. Int. J. Biol. Macromol. 2016, 91, 1186–1193. [Google Scholar] [CrossRef] [PubMed]

- Martins, P.C.; Latorres, J.M.; Martins, V.G.J.L. Impact of starch nanocrystals on the physicochemical, thermal and structural characteristics of starch-based films. Int. J. Biol. Macromol. 2022, 156, 113041. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Ahmadigol, A.; Khubber, S.; Altintas, Z. Bionanocomposite films with plasticized WPI-jujube polysaccharide/starch nanocrystal blends for packaging fresh-cut carrots. Food Packag. Shelf Life 2023, 36, 101042. [Google Scholar] [CrossRef]

- Dai, L.; Yu, H.; Zhang, J.; Cheng, F. Preparation and characterization of cross-linked starch nanocrystals and self-reinforced starch-based nanocomposite films. Int. J. Biol. Macromol. 2021, 181, 868–876. [Google Scholar] [CrossRef] [PubMed]

- Garavand, F.; Cacciotti, I.; Vahedikia, N.; Rehman, A.; Tarhan, Ö.; Akbari-Alavijeh, S.; Shaddel, R.; Rashidinejad, A.; Nejatian, M.; Jafarzadeh, S.; et al. A comprehensive review on the nanocomposites loaded with chitosan nanoparticles for food packaging. Crit. Rev. Food Sci. Nutr. 2022, 62, 1383–1416. [Google Scholar] [CrossRef] [PubMed]

- Priyadarshi, R.; Rhim, J.W. Chitosan-based biodegradable functional films for food packaging applications. Innov. Food Sci. Emerg. Technol. 2020, 62, 102346. [Google Scholar] [CrossRef]

- Garg, U.; Chauhan, S.; Nagaich, U.; Jain, N.J. Current advances in chitosan nanoparticles based drug delivery and targeting. Adv. Pharm. Bull. 2019, 9, 195. [Google Scholar] [CrossRef] [PubMed]

- Cruz-Romero, M.; Murphy, T.; Morris, M.; Cummins, E.; Kerry, J. Antimicrobial activity of chitosan, organic acids and nano-sized solubilisates for potential use in smart antimicrobially-active packaging for potential food applications. Food Control 2013, 34, 393–397. [Google Scholar] [CrossRef]

- Kong, M.; Chen, X.G.; Xing, K.; Park, H.J. Antimicrobial properties of chitosan and mode of action: A state of the art review. Int. J. Food Microbiol. 2010, 144, 51–63. [Google Scholar] [CrossRef]

- Yu, X.; Liu, Q.; Jin, Z.; Jiao, A. Preparation and characterization of hydroxypropyl methylcellulose/hydroxypropyl starch composite films reinforced by chitosan nanoparticles of different sizes. Mater. Today Commun. 2023, 35, 105714. [Google Scholar] [CrossRef]

- Chang, P.R.; Jian, R.; Yu, J.; Ma, X. Fabrication and characterisation of chitosan nanoparticles/plasticised-starch composites. Food Chem. 2010, 120, 736–740. [Google Scholar] [CrossRef]

- Roy, S.; Min, S.-J.; Biswas, D.; Rhim, J.W. Pullulan/chitosan-based functional film incorporated with curcumin-integrated chitosan nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2023, 660, 130898. [Google Scholar] [CrossRef]

- Kumar, N.; Kumbhat, S. Essentials in Nanoscience and Nanotechnology; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Kaya, M.; Ravikumar, P.; Ilk, S.; Mujtaba, M.; Akyuz, L.; Labidi, J.; Salaberria, A.M.; Cakmak, Y.S.; Erkul, S.K. Production and characterization of chitosan based edible films from Berberis crataegina’s fruit extract and seed oil. Innov. Food Sci. Emerg. Technol. 2018, 45, 287–297. [Google Scholar] [CrossRef]

- Kongkaoroptham, P.; Piroonpan, T.; Pasanphan, W. Chitosan nanoparticles based on their derivatives as antioxidant and antibacterial additives for active bioplastic packaging. Carbohydr. Polym. 2021, 257, 117610. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Ahari, H.; Zhang, Z.; Jafari, S.M. Role of silica (SiO2) nano/micro-particles in the functionality of degradable packaging films/coatings and their application in food preservation. Trends Food Sci. Technol. 2023, 133, 75–86. [Google Scholar] [CrossRef]

- Wu, C.L.; Zhang, M.Q.; Rong, M.Z.; Friedrich, K. Tensile performance improvement of low nanoparticles filled-polypropylene composites. Compos. Sci. Technol. 2002, 62, 1327–1340. [Google Scholar] [CrossRef]

- Vladimirov, V.; Betchev, C.; Vassiliou, A.; Papageorgiou, G.; Bikiaris, D. Dynamic mechanical and morphological studies of isotactic polypropylene/fumed silica nanocomposites with enhanced gas barrier properties. Compos. Sci. Technol. 2006, 66, 2935–2944. [Google Scholar] [CrossRef]

- Tang, S.; Zou, P.; Xiong, H.; Tang, H. Effect of nano-SiO2 on the performance of starch/polyvinyl alcohol blend films. Carbohydr. Polym. 2008, 72, 521–526. [Google Scholar] [CrossRef]

- Hou, X.; Xue, Z.; Xia, Y.; Qin, Y.; Zhang, G.; Liu, H.; Li, K. Effect of SiO2 nanoparticle on the physical and chemical properties of eco-friendly agar/sodium alginate nanocomposite film. Int. J. Biol. Macromol. 2019, 125, 1289–1298. [Google Scholar] [CrossRef]

- Júnior, L.M.; Rodrigues, P.R.; da Silva, R.G.; Vieira, R.P.; Alves, R.M.V. Improving the mechanical properties and thermal stability of sodium alginate/hydrolyzed collagen films through the incorporation of SiO2. Curr. Res. Food Sci. 2022, 5, 96–101. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Xia, Y.; Wang, Y.; Zhao, X.; Xue, Z.; Quan, F.; Geng, C.; Zhao, Z. Preparation and property investigation of crosslinked alginate/silicon dioxide nanocomposite films. J. Appl. Polym. Sci. 2016, 133, 43489. [Google Scholar] [CrossRef]

- Xu, L.; Liu, Y.; Yang, M.; Cao, W.; Zhang, H.; Xia, N.; Li, T.; Zhao, X. Properties of soy protein isolate/nano-silica bilayer films during storage. J. Food Process Eng. 2019, 42, e12984. [Google Scholar] [CrossRef]

- Xu, L.; Cao, W.; Li, R.; Zhang, H.; Xia, N.; Li, T.; Liu, X.; Zhao, X. Properties of soy protein isolate/nano-silica films and their applications in the preservation of Flammulina velutipes. J. Food Process. Preserv. 2019, 43, e14177. [Google Scholar] [CrossRef]

- Dong, W.; Su, J.; Chen, Y.; Xu, D.; Cheng, L.; Mao, L.; Gao, Y.; Yuan, F. Characterization and antioxidant properties of chitosan film incorporated with modified silica nanoparticles as an active food packaging. Food Chem. 2022, 373, 131414. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.W.; Lim, W.S.; Lee, M.H.; Park, H.J. Barrier and structural properties of polyethylene terephthalate film coated with poly (acrylic acid)/montmorillonite nanocomposites. Packag. Technol. Sci. 2021, 34, 141–150. [Google Scholar] [CrossRef]

- Mathew, S.; Snigdha, S.; Mathew, J.; Radhakrishnan, E. Poly (vinyl alcohol): Montmorillonite: Boiled rice water (starch) blend film reinforced with silver nanoparticles; characterization and antibacterial properties. Appl. Clay Sci. 2018, 161, 464–473. [Google Scholar] [CrossRef]

- Risyon, N.P.; Othman, S.H.; Basha, R.K.; Talib, R.A. Characterization of polylactic acid/halloysite nanotubes bionanocomposite films for food packaging. Food Packag. Shelf Life 2020, 23, 100450. [Google Scholar] [CrossRef]

- Sun, M.; Liu, N.; Ni, S.; Bian, H.; Fu, Y.; Chen, X. Poplar hot water extract enhances barrier and antioxidant properties of chitosan/bentonite composite film for packaging applications. Polymers 2019, 11, 1614. [Google Scholar] [CrossRef]

- Mouzahim, M.E.; Eddarai, E.; Eladaoui, S.; Guenbour, A.; Bellaouchou, A.; Zarrouk, A.; Boussen, R. Effect of Kaolin clay and Ficus carica mediated silver nanoparticles on chitosan food packaging film for fresh apple slice preservation. Food Chem. 2023, 410, 135470. [Google Scholar] [CrossRef]

- Cheikh, D.; Martín-Sampedro, R.; Majdoub, H.; Darder, M. Alginate bionanocomposite films containing sepiolite modified with polyphenols from myrtle berries extract. Int. J. Biol. Macromol. 2020, 165, 2079–2088. [Google Scholar] [CrossRef] [PubMed]

- Khachatryan, G.; Khachatryan, K.; Szczepankowska, J.; Krzan, M.; Krystyjan, M. Design of Carbon Nanocomposites Based on Sodium Alginate/Chitosan Reinforced with Graphene Oxide and Carbon Nanotubes. Polymers 2023, 15, 925. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, A.M.; Abou Elfadl, A.; El Sayed, A.M.; Ibrahim, I.M. Improving the optical, dielectric properties and antimicrobial activity of Chitosan–PEO by GO/MWCNTs: Nanocomposites for energy storage and food packaging applications. Polymer 2023, 267, 125650. [Google Scholar] [CrossRef]

- Singh, P.; Kaur, G.; Singh, A.; Sharma, T.; Dar, B. Improved mechanical, functional and antimicrobial properties of corn starch-based biodegradable nanocomposites films reinforced with lemongrass oil nanoemulsion and starch nano-crystal. Mater. Chem. Phys. 2023, 308, 128267. [Google Scholar] [CrossRef]

- Velásquez-Castillo, L.E.; Leite, M.A.; Tisnado, V.J.A.; Ditchfield, C.; Sobral, P.J.d.A.; Moraes, I.C.F. Cassava Starch Films Containing Quinoa Starch Nanocrystals: Physical and Surface Properties. Foods 2023, 12, 576. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Gutiérrez, M.; Bascón-Villegas, I.; Espinosa, E.; Carrasco, E.; Pérez-Rodríguez, F.; Rodríguez, A. Cellulose nanofibers from olive tree pruning as food packaging additive of a biodegradable film. Foods 2021, 10, 1584. [Google Scholar] [CrossRef] [PubMed]

- Tibolla, H.; Czaikoski, A.; Pelissari, F.; Menegalli, F.; Cunha, R.L. Starch-based nanocomposites with cellulose nanofibers obtained from chemical and mechanical treatments. Int. J. Biol. Macromol. 2020, 161, 132–146. [Google Scholar] [CrossRef]

- de Souza Coelho, C.C.; Silva, R.B.S.; Carvalho, C.W.P.; Rossi, A.L.; Teixeira, J.A.; Freitas-Silva, O.; Cabral, L.M.C. Cellulose nanocrystals from grape pomace and their use for the development of starch-based nanocomposite films. Int. J. Biol. Macromol. 2020, 159, 1048–1061. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, W.; Tu, Y.; Zhao, Y. Gelatin-based nanocomposite film with bacterial cellulose–MgO nanoparticles and its application in packaging of preserved eggs. Coatings 2021, 11, 39. [Google Scholar] [CrossRef]

- Othman, S.H.; Othman, N.F.L.; Shapi’i, R.A.; Ariffin, S.H.; Yunos, K.F.M. Corn starch/chitosan nanoparticles/thymol bio-nanocomposite films for potential food packaging applications. Polymers 2021, 13, 390. [Google Scholar] [CrossRef]

- Shapi’i, R.A.; Othman, S.H.; Basha, R.K.; Naim, M.N. Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles. Nanotechnol. Rev. 2022, 11, 1464–1477. [Google Scholar] [CrossRef]

- Lu, W.; Cui, R.; Zhu, B.; Qin, Y.; Cheng, G.; Li, L.; Yuan, M. Influence of clove essential oil immobilized in mesoporous silica nanoparticles on the functional properties of poly (lactic acid) biocomposite food packaging film. J. Mater. Res. Technol. 2021, 11, 1152–1161. [Google Scholar] [CrossRef]

- Mahmud, J.; Sarmast, E.; Shankar, S.; Lacroix, M. Advantages of nanotechnology developments in active food packaging. Food Res. Int. 2022, 154, 111023. [Google Scholar] [CrossRef]

- Singh, R.; Smitha, M.; Singh, S.P. The role of nanotechnology in combating multi-drug resistant bacteria. J. Nanosci. Nanotechnol. 2014, 14, 4745–4756. [Google Scholar] [CrossRef] [PubMed]

- Emamifar, A.; Kadivar, M.; Shahedi, M.; Soleimanian-Zad, S. Evaluation of nanocomposite packaging containing Ag and ZnO on shelf life of fresh orange juice. Innov. Food Sci. Emerg. Technol. 2010, 11, 742–748. [Google Scholar] [CrossRef]

- Simbine, E.O.; Rodrigues, L.d.C.; Lapa-Guimaraes, J.; Kamimura, E.S.; Corassin, C.H.; OLIVEIRA, C.A.F.d. Application of silver nanoparticles in food packages: A review. Food Sci. Technol. 2019, 39, 793–802. [Google Scholar] [CrossRef]

- Cui, Y.; Zhao, Y.; Tian, Y.; Zhang, W.; Lü, X.; Jiang, X. The molecular mechanism of action of bactericidal gold nanoparticles on Escherichia coli. Biomaterials 2012, 33, 2327–2333. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Li, P.J.; Xie, R.S.; Cao, X.Y.; Su, D.L.; Shan, Y. Biosynthesis of silver nanoparticle composites based on hesperidin and pectin and their synergistic antibacterial mechanism. Int. J. Biol. Macromol. 2022, 214, 220–229. [Google Scholar] [CrossRef]

- Hong, S.I.; Cho, Y.; Rhim, J.W. Effect of Agar/AgNP composite film packaging on refrigerated beef loin quality. Membranes 2021, 11, 750. [Google Scholar] [CrossRef]

- Grisoli, P.; De Vita, L.; Milanese, C.; Taglietti, A.; Diaz Fernandez, Y.; Bouzin, M.; D’Alfonso, L.; Sironi, L.; Rossi, S.; Vigani, B. PVA films with mixed silver nanoparticles and gold nanostars for intrinsic and photothermal antibacterial action. Nanomaterials 2021, 11, 1387. [Google Scholar] [CrossRef]

- Raghav, G.; Nagarajan, K.; Palaninatharaja, M.; Karthic, M.; Ganesh, M.A. Reuse of used paper egg carton boxes as a source to produce hybrid AgNPs-carboxyl nanocellulose through bio-synthesis and its application in active food packaging. Int. J. Biol. Macromol. 2023, 249, 126119. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Liu, B.; Ma, J.; Wei, S.; Wang, L.; Yin, S.; Yang, X. Development of Gliadin@ AgNPs hybrid nanoparticles as building blocks for constructing antimicrobial protein-based porous materials. Chem. Eng. J. 2024, 482, 148924. [Google Scholar] [CrossRef]

- Pallavicini, P.; Dacarro, G.; Taglietti, A. Self-assembled monolayers of silver nanoparticles: From intrinsic to switchable inorganic antibacterial surfaces. Eur. J. Inorg. Chem. 2018, 45, 4846–4855. [Google Scholar] [CrossRef]

- Girase, B.; Depan, D.; Shah, J.; Xu, W.; Misra, R. Silver–clay nanohybrid structure for effective and diffusion-controlled antimicrobial activity. Mater. Sci. Eng. C 2011, 31, 1759–1766. [Google Scholar] [CrossRef]

- Szczepanowicz, K.; Stefanska, J.; Socha, R.P.; Warszynski, P. Preparation of silver nanoparticles via chemical reduction and their antimicrobial activity. Physicochem. Probl. Min. Process. 2010, 45, 85–98. [Google Scholar]

- Sirelkhatim, A.; Mahmud, S.; Seeni, A.; Kaus, N.H.M.; Ann, L.C.; Bakhori, S.K.M.; Hasan, H.; Mohamad, D. Review on zinc oxide nanoparticles: Antibacterial activity and toxicity mechanism. Nano-Micro Lett. 2015, 7, 219–242. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.A.; Sarbon, N.M. A comparative study: Physical, mechanical and antibacterial properties of bio-composite gelatin films as influenced by chitosan and zinc oxide nanoparticles incorporation. Food Biosci. 2021, 43, 101250. [Google Scholar] [CrossRef]

- Hashem, A.H.; El-Naggar, M.E.; Abdelaziz, A.M.; Abdelbary, S.; Hassan, Y.R.; Hasanin, M.S. Bio-based antimicrobial food packaging films based on hydroxypropyl starch/polyvinyl alcohol loaded with the biosynthesized zinc oxide nanoparticles. Int. J. Biol. Macromol. 2023, 249, 126011. [Google Scholar] [CrossRef]

- Mohd Yusof, H.; Abdul Rahman, N.A.; Mohamad, R.; Hasanah Zaidan, U.; Samsudin, A.A.J.A. Antibacterial potential of biosynthesized zinc oxide nanoparticles against poultry-associated foodborne pathogens: An in vitro study. Animals 2021, 11, 2093. [Google Scholar] [CrossRef]

- Adeyeye, S.A.O.; Ashaolu, T.J. Applications of nano-materials in food packaging: A review. J. Food Process Eng. 2021, 44, e13708. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Park, S.J. TiO2 photocatalyst for water treatment applications. J. Ind. Eng. Chem. 2013, 19, 1761–1769. [Google Scholar] [CrossRef]

- Koysuren, O.; Koysuren, H.N. Photocatalytic activity of polyvinyl borate/titanium dioxide composites for UV light degradation of organic pollutants. J. Macromol. Sci. Part A 2018, 55, 401–407. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.; Partovi, R.; Talebi, F.; Babaei, A. Chitosan/TiO2 nanoparticle/Cymbopogon citratus essential oil film as food packaging material: Physico-mechanical properties and its effects on microbial, chemical, and organoleptic quality of minced meat during refrigeration. J. Food Process. Preserv. 2020, 44, e14536. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Mohammadian, E.; McClements, D.J. Eco-friendly active packaging consisting of nanostructured biopolymer matrix reinforced with TiO2 and essential oil: Application for preservation of refrigerated meat. Food Chem. 2020, 322, 126782. [Google Scholar] [CrossRef]

- Dey, A.; Pandey, G.; Rawtani, D. Functionalized nanomaterials driven antimicrobial food packaging: A technological advancement in food science. Food Control 2022, 131, 108469. [Google Scholar] [CrossRef]

- Saravanakumar, K.; Sathiyaseelan, A.; Mariadoss, A.V.A.; Xiaowen, H.; Wang, M.H. Physical and bioactivities of biopolymeric films incorporated with cellulose, sodium alginate and copper oxide nanoparticles for food packaging application. Int. J. Biol. Macromol. 2020, 153, 207–214. [Google Scholar] [CrossRef] [PubMed]

- Peighambardoust, S.J.; Peighambardoust, S.H.; Pournasir, N.; Pakdel, P.M. Properties of active starch-based films incorporating a combination of Ag, ZnO and CuO nanoparticles for potential use in food packaging applications. Food Packag. Shelf Life 2019, 22, 100420. [Google Scholar] [CrossRef]

- Hoseinnejad, M.; Jafari, S.M.; Katouzian, I. Inorganic and metal nanoparticles and their antimicrobial activity in food packaging applications. Crit. Rev. Microbiol. 2018, 44, 161–181. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, S.; Teoh, Y.L.; Ong, K.M.; Zaidi, N.S.R.; Mah, S.K. Poly (vinyl) alcohol crosslinked composite packaging film containing gold nanoparticles on shelf life extension of banana. Food Packag. Shelf Life 2020, 24, 100463. [Google Scholar] [CrossRef]

- Su, C. Environmental implications and applications of engineered nanoscale magnetite and its hybrid nanocomposites: A review of recent literature. J. Hazard. Mater. 2017, 322, 48–84. [Google Scholar] [CrossRef]

- El-Khawaga, A.M.; Farrag, A.A.; Elsayed, M.A.; El-Sayyad, G.S.; El-Batal, A.I. Antimicrobial and photocatalytic degradation activities of chitosan-coated magnetite nanocomposite. J. Clust. Sci. 2021, 32, 1107–1119. [Google Scholar] [CrossRef]

- Saedi, S.; Shokri, M.; Priyadarshi, R.; Rhim, J.-W. Silver ion loaded 3-aminopropyl trimethoxysilane-modified Fe3O4 nanoparticles for the fabrication of carrageenan-based active packaging films. Colloids Surf. B Biointerfaces 2021, 208, 112085. [Google Scholar] [CrossRef] [PubMed]

- Cai, N.; Li, C.; Han, C.; Luo, X.; Shen, L.; Xue, Y.; Yu, F. Tailoring mechanical and antibacterial properties of chitosan/gelatin nanofiber membranes with Fe3O4 nanoparticles for potential wound dressing application. Appl. Surf. Sci. 2016, 369, 492–500. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Chen, Y.; Du, L.; Zhang, B.; Zhang, H.; Liu, J.; Wang, K. Preparation and characterization of novel polyethersulfone hybrid ultrafiltration membranes bending with modified halloysite nanotubes loaded with silver nanoparticles. Ind. Eng. Chem. Res. 2012, 51, 3081–3090. [Google Scholar] [CrossRef]

- Calabretta, M.K.; Kumar, A.; McDermott, A.M.; Cai, C. Antibacterial activities of poly (amidoamine) dendrimers terminated with amino and poly (ethylene glycol) groups. Biomacromolecules 2007, 8, 1807–1811. [Google Scholar] [CrossRef] [PubMed]

- Perera, K.Y.; Jaiswal, S.; Jaiswal, A.K. A review on nanomaterials and nanohybrids based bio-nanocomposites for food packaging. Food Chem. 2022, 376, 131912. [Google Scholar] [CrossRef] [PubMed]

- Hanula, M.; Pogorzelska-Nowicka, E.; Pogorzelski, G.; Szpicer, A.; Wojtasik-Kalinowska, I.; Wierzbicka, A.; Półtorak, A. Active packaging of button mushrooms with zeolite and açai extract as an innovative method of extending its shelf life. Agriculture 2021, 11, 653. [Google Scholar] [CrossRef]

- Marzano-Barreda, L.A.; Yamashita, F.; Bilck, A.P. Effect of biodegradable active packaging with zeolites on fresh broccoli florets. J. Food Sci. Technol. 2021, 58, 197–204. [Google Scholar] [CrossRef] [PubMed]

- Mahmud, J.; Khan, R. Characterization of natural antimicrobials in food system. Adv. Microbiol. 2018, 8, 894. [Google Scholar] [CrossRef]

- Khachatryan, G.; Khachatryan, K.; Krystyjan, M.; Krzemińska-Fiedorowicz, L.; Lenart-Boroń, A.; Białecka, A.; Krupka, M.; Krzan, M.; Blaszyńska, K.; Hanula, M.; et al. Synthesis and Investigation of Physicochemical and Biological Properties of Films Containing Encapsulated Propolis in Hyaluronic Matrix. Polymers 2023, 15, 1271. [Google Scholar] [CrossRef]

- Nile, S.H.; Baskar, V.; Selvaraj, D.; Nile, A.; Xiao, J.; Kai, G. Nanotechnologies in food science: Applications, recent trends, and future perspectives. Nano-Micro Lett. 2020, 12, 45. [Google Scholar] [CrossRef] [PubMed]

- Jamali, S.N.; Assadpour, E.; Feng, J.; Jafari, S.M. Natural antimicrobial-loaded nanoemulsions for the control of food spoilage/pathogenic microorganisms. Adv. Colloid Interface Sci. 2021, 295, 102504. [Google Scholar] [CrossRef]

- Donsì, F.; Ferrari, G. Essential oil nanoemulsions as antimicrobial agents in food. J. Biotechnol. 2016, 233, 106–120. [Google Scholar] [CrossRef]

- Fallah, A.A.; Sarmast, E.; Dehkordi, S.H.; Isvand, A.; Dini, H.; Jafari, T.; Soleimani, M.; Khaneghah, A.M. Low-dose gamma irradiation and pectin biodegradable nanocomposite coating containing curcumin nanoparticles and ajowan (Carum copticum) essential oil nanoemulsion for storage of chilled lamb loins. Meat Sci. 2022, 184, 108700. [Google Scholar] [CrossRef]

- Faustman, C.; Cassens, R. The biochemical basis for discoloration in fresh meat: A review. J. Muscle Foods 1990, 1, 217–243. [Google Scholar] [CrossRef]

- Liu, D.; Li, H.; Zhou, G.; Yuan, M.; Qin, Y. Biodegradable poly (lactic-acid)/poly (trimethylene-carbonate)/laponite composite film: Development and application to the packaging of mushrooms (Agaricus bisporus). Polym. Adv. Technol. 2015, 26, 1600–1607. [Google Scholar] [CrossRef]

- Dakal, T.C.; Kumar, A.; Majumdar, R.S.; Yadav, V. Mechanistic basis of antimicrobial actions of silver nanoparticles. Front. Microbiol. 2016, 7, 1831. [Google Scholar] [CrossRef]

- Khan, M.J.; Ramiah, S.K.; Selamat, J.; Shameli, K.; Sazili, A.Q.; Mookiah, S. Utilisation of pullulan active packaging incorporated with curcumin and pullulan mediated silver nanoparticles to maintain the quality and shelf life of broiler meat. Ital. J. Anim. Sci. 2022, 21, 244–262. [Google Scholar] [CrossRef]

- Vieira, A.C.F.; de Matos Fonseca, J.; Menezes, N.M.C.; Monteiro, A.R.; Valencia, G.A. Active coatings based on hydroxypropyl methylcellulose and silver nanoparticles to extend the papaya (Carica papaya L.) shelf life. Int. J. Biol. Macromol. 2020, 164, 489–498. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.; Sahareen, T. Investigation of cellulosic packets impregnated with silver nanoparticles for enhancing shelf-life of vegetables. LWT 2017, 86, 116–122. [Google Scholar] [CrossRef]

- Zhang, C.; Li, W.; Zhu, B.; Chen, H.; Chi, H.; Li, L.; Qin, Y.; Xue, J. The quality evaluation of postharvest strawberries stored in nano-Ag packages at refrigeration temperature. Polymers 2018, 10, 894. [Google Scholar] [CrossRef]

- Shankar, S.; Khodaei, D.; Lacroix, M. Effect of chitosan/essential oils/silver nanoparticles composite films packaging and gamma irradiation on shelf life of strawberries. Food Hydrocoll. 2021, 117, 106750. [Google Scholar] [CrossRef]

- Venkatesan, R.; Rajeswari, N. ZnO/PBAT nanocomposite films: Investigation on the mechanical and biological activity for food packaging. Polym. Adv. Technol. 2017, 28, 20–27. [Google Scholar] [CrossRef]

- Hari, K.D.; Garcia, C.V.; Shin, G.-H.; Kim, J.T. Improvement of the UV barrier and antibacterial properties of crosslinked pectin/zinc oxide bionanocomposite films. Polymers 2021, 13, 2403. [Google Scholar] [CrossRef]

- Guo, X.; Chen, B.; Wu, X.; Li, J.; Sun, Q. Utilization of cinnamaldehyde and zinc oxide nanoparticles in a carboxymethylcellulose-based composite coating to improve the postharvest quality of cherry tomatoes. Int. J. Biol. Macromol. 2020, 160, 175–182. [Google Scholar] [CrossRef]

- Heydari-Majd, M.; Ghanbarzadeh, B.; Shahidi-Noghabi, M.; Najafi, M.A.; Hosseini, M. A new active nanocomposite film based on PLA/ZnO nanoparticle/essential oils for the preservation of refrigerated Otolithes ruber fillets. Food Packag. Shelf Life 2019, 19, 94–103. [Google Scholar] [CrossRef]

- Zhai, X.; Zhou, S.; Zhang, R.; Wang, W.; Hou, H. Antimicrobial starch/poly (butylene adipate-co-terephthalate) nanocomposite films loaded with a combination of silver and zinc oxide nanoparticles for food packaging. Int. J. Biol. Macromol. 2022, 206, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Motelica, L.; Ficai, D.; Ficai, A.; Truşcă, R.D.; Ilie, C.I.; Oprea, O.C.; Andronescu, E. Innovative antimicrobial chitosan/ZnO/Ag NPs/citronella essential oil nanocomposite—Potential coating for grapes. Foods 2020, 9, 1801. [Google Scholar] [CrossRef] [PubMed]

- Asadi, S.; Pirsa, S. Production of biodegradable film based on polylactic acid, modified with lycopene pigment and TiO2 and studying its physicochemical properties. J. Polym. Environ. 2020, 28, 433–444. [Google Scholar] [CrossRef]

- Salama, H.E.; Aziz, M.S.A. Optimized alginate and Aloe vera gel edible coating reinforced with nTiO2 for the shelf-life extension of tomatoes. Int. J. Biol. Macromol. 2020, 165, 2693–2701. [Google Scholar] [CrossRef]

- Jayakumar, A.; Radoor, S.; Kim, J.T.; Rhim, J.W.; Parameswaranpillai, J.; Nandi, D.; Srisuk, R.; Siengchin, S. Titanium dioxide nanoparticles and elderberry extract incorporated starch based polyvinyl alcohol films as active and intelligent food packaging wraps. Food Packag. Shelf Life 2022, 34, 100967. [Google Scholar] [CrossRef]

- Abutalib, M.M.; Rajeh, A. Enhanced structural, electrical, mechanical properties and antibacterial activity of Cs/PEO doped mixed nanoparticles (Ag/TiO2) for food packaging applications. Polym. Test. 2021, 93, 107013. [Google Scholar] [CrossRef]

- Chi, H.; Song, S.; Luo, M.; Zhang, C.; Li, W.; Li, L.; Qin, Y. Effect of PLA nanocomposite films containing bergamot essential oil, TiO2 nanoparticles, and Ag nanoparticles on shelf life of mangoes. Sci. Hortic. 2019, 249, 192–198. [Google Scholar] [CrossRef]

- Zarandona, I.; Correia, D.M.; Moreira, J.; Costa, C.M.; Lanceros-Mendez, S.; Guerrero, P.; De la Caba, K. Magnetically responsive chitosan-pectin films incorporating Fe3O4 nanoparticles with enhanced antimicrobial activity. Int. J. Biol. Macromol. 2023, 227, 1070–1077. [Google Scholar] [CrossRef] [PubMed]

- Kalpana, S.; Priyadarshini, S.; Leena, M.M.; Moses, J.; Anandharamakrishnan, C. Intelligent packaging: Trends and applications in food systems. Trends Food Sci. Technol. 2019, 93, 145–157. [Google Scholar] [CrossRef]

- Zheng, D.; Cao, S.; Li, D.; Wu, Y.; Duan, P.; Liu, S.; Li, X.; Zhang, X.; Chen, Y. Fabrication and characterization of chitosan/anthocyanin intelligent packaging film fortified by cellulose nanocrystal for shrimp preservation and visual freshness monitoring. Int. J. Biol. Macromol. 2024, 264, 130692. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, Y.; Yong, H.; Qin, Y.; Liu, J.; Liu, J. Development of multifunctional food packaging films based on chitosan, TiO2 nanoparticles and anthocyanin-rich black plum peel extract. Food Hydrocoll. 2019, 94, 80–92. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, C.; Pu, Y.; Chen, S.; Liu, L.; Cui, Z.; Zhong, Y. Recent advances in pH-responsive freshness indicators using natural food colorants to monitor food freshness. Foods 2022, 11, 1884. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Tang, Q.; Xu, Z.; Huang, K.; Li, H.; Zou, Z. Development of novel Co-MOF loaded sodium alginate based packaging films with antimicrobial and ammonia-sensitive functions for shrimp freshness monitoring. Food Hydrocoll. 2023, 135, 108193. [Google Scholar] [CrossRef]

- Sun, J.; Jiang, H.; Wu, H.; Tong, C.; Pang, J.; Wu, C. Multifunctional bionanocomposite films based on konjac glucomannan/chitosan with nano-ZnO and mulberry anthocyanin extract for active food packaging. Food Hydrocoll. 2020, 107, 105942. [Google Scholar] [CrossRef]

- Wang, F.; Xie, C.; Tang, H.; Hao, W.; Wu, J.; Sun, Y.; Sun, J.; Liu, Y.; Jiang, L. Development, characterization and application of intelligent/active packaging of chitosan/chitin nanofibers films containing eggplant anthocyanins. Food Hydrocoll. 2023, 139, 108496. [Google Scholar] [CrossRef]

- Duan, M.; Yu, S.; Sun, J.; Jiang, H.; Zhao, J.; Tong, C.; Hu, Y.; Pang, J.; Wu, C. Development and characterization of electrospun nanofibers based on pullulan/chitin nanofibers containing curcumin and anthocyanins for active-intelligent food packaging. Int. J. Biol. Macromol. 2021, 187, 332–340. [Google Scholar] [CrossRef] [PubMed]

- Bhargava, N.; Sharanagat, V.S.; Mor, R.S.; Kumar, K. Active and intelligent biodegradable packaging films using food and food waste-derived bioactive compounds: A review. Trends Food Sci. Technol. 2020, 105, 385–401. [Google Scholar] [CrossRef]

- Rachmelia, D.; Imawan, C. Time temperature indicator label using black corn extract and chitosan matrix. J. Phys. Conf. Ser. 2018, 1120, 012041. [Google Scholar] [CrossRef]

- Amiri, R.; Piri, H.; Akbari, M.; Moradi, G. The fabrication and kinetic modeling of a new time–temperature label based on paraffin wax and black carrot anthocyanin for monitoring fish products. Anal. Methods 2020, 12, 544–551. [Google Scholar] [CrossRef]

- Eskandarabadi, S.M.; Mahmoudian, M.; Farah, K.R.; Abdali, A.; Nozad, E.; Enayati, M. Active intelligent packaging film based on ethylene vinyl acetate nanocomposite containing extracted anthocyanin, rosemary extract and ZnO/Fe-MMT nanoparticles. Food Packag. Shelf Life 2019, 22, 100389. [Google Scholar] [CrossRef]

- Pan, K.; Luo, Y.; Gan, Y.; Baek, S.J.; Zhong, Q. pH-driven encapsulation of curcumin in self-assembled casein nanoparticles for enhanced dispersibility and bioactivity. Soft Matter 2014, 10, 6820–6830. [Google Scholar] [CrossRef]

- Wu, C.; Zhu, Y.; Wu, T.; Wang, L.; Yuan, Y.; Chen, J.; Hu, Y.; Pang, J. Enhanced functional properties of biopolymer film incorporated with curcurmin-loaded mesoporous silica nanoparticles for food packaging. Food Chem. 2019, 288, 139–145. [Google Scholar] [CrossRef] [PubMed]

- Salarbashi, D.; Tafaghodi, M.; Bazzaz, B.S.F.; Mohammad Aboutorabzade, S.; Fathi, M. pH-sensitive soluble soybean polysaccharide/SiO2 incorporated with curcumin for intelligent packaging applications. Food Sci. Nutr. 2021, 9, 2169–2179. [Google Scholar] [CrossRef]

- Chen, J.; Guo, Y.; Zhang, X.; Liu, J.; Gong, P.; Su, Z.; Fan, L.; Li, G. Emerging nanoparticles in food: Sources, application, and safety. J. Agric. Food Chem. 2023, 71, 3564–3582. [Google Scholar] [CrossRef]

- Rahman, S.; Chowdhury, D. Guar gum-sodium alginate nanocomposite film as a smart fluorescence-based humidity sensor: A smart packaging material. Int. J. Biol. Macromol. 2022, 216, 571–582. [Google Scholar] [CrossRef]

- Zhai, X.; Li, Z.; Shi, J.; Huang, X.; Sun, Z.; Zhang, D.; Zou, X.; Sun, Y.; Zhang, J.; Holmes, M. A colorimetric hydrogen sulfide sensor based on gellan gum-silver nanoparticles bionanocomposite for monitoring of meat spoilage in intelligent packaging. Food Chem. 2019, 290, 135–143. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.; Ko, S. Colorimetric freshness indicator based on cellulose nanocrystal–silver nanoparticle composite for Intelligent Food Packaging. Polymers 2022, 14, 3695. [Google Scholar] [CrossRef]

- Mohammadi-Alamuti, M.; Shahabi-Ghahfarrokhi, I.; Shaterian, M. Photo–degradable and recyclable starch/Fe3O4/TiO2 nanocomposites: Feasibility of an approach to reduce the recycling labor cost in plastic waste management. Environ. Sci. Pollut. Res. 2023, 30, 2740–2753. [Google Scholar] [CrossRef]

- Goñi-Ciaurriz, L.; Senosiain-Nicolay, M.; Vélaz, I. Aging Studies on Food Packaging Films Containing β-Cyclodextrin-Grafted TiO2 Nanoparticles. Int. J. Mol. Sci. 2021, 22, 2257. [Google Scholar] [CrossRef]

- Goudarzi, V.; Shahabi-Ghahfarrokhi, I. Photo-producible and photo-degradable starch/TiO2 bionanocomposite as a food packaging material: Development and characterization. Int. J. Biol. Macromol. 2018, 106, 661–669. [Google Scholar] [CrossRef] [PubMed]

- Perera, K.Y.; Jaiswal, A.K.; Jaiswal, S. Biopolymer-Based Sustainable Food Packaging Materials: Challenges, Solutions, and Applications. Foods 2023, 12, 2422. [Google Scholar] [CrossRef]

- Ludueña, L.N.; Vazquez, A.; Alvarez, V.A. Effect of the type of clay organo-modifier on the morphology, thermal/mechanical/impact/barrier properties and biodegradation in soil of polycaprolactone/clay nanocomposites. J. Appl. Polym. Sci. 2013, 128, 2648–2657. [Google Scholar] [CrossRef]

- Oyeoka, H.C.; Ewulonu, C.M.; Nwuzor, I.C.; Obele, C.M.; Nwabanne, J.T. Packaging and degradability properties of polyvinyl alcohol/gelatin nanocomposite films filled water hyacinth cellulose nanocrystals. J. Bioresour. Bioprod. 2021, 6, 168–185. [Google Scholar] [CrossRef]

- Indumathi, M.; Sarojini, K.S.; Rajarajeswari, G. Antimicrobial and biodegradable chitosan/cellulose acetate phthalate/ZnO nano composite films with optimal oxygen permeability and hydrophobicity for extending the shelf life of black grape fruits. Int. J. Biol. Macromol. 2019, 132, 1112–1120. [Google Scholar] [CrossRef]

- Yeasmin, S.; Yeum, J.H.; Yang, S.B. Fabrication and characterization of pullulan-based nanocomposites reinforced with montmorillonite and tempo cellulose nanofibril. Carbohydr. Polym. 2020, 240, 116307. [Google Scholar] [CrossRef] [PubMed]

- Oliver-Ortega, H.; Vandemoortele, V.; Bala, A.; Julian, F.; Méndez, J.A.; Espinach, F.X. Nanoclay effect into the biodegradation and processability of poly (lactic acid) nanocomposites for food packaging. Polymers 2021, 13, 2741. [Google Scholar] [CrossRef] [PubMed]

- Ediyilyam, S.; George, B.; Shankar, S.S.; Dennis, T.T.; Wacławek, S.; Černík, M.; Padil, V.V. Chitosan/gelatin/silver nanoparticles composites films for biodegradable food packaging applications. Polymers 2021, 13, 1680. [Google Scholar] [CrossRef] [PubMed]

- Perera, K.Y.; Sharma, S.; Duffy, B.; Pathania, S.; Jaiswal, A.K.; Jaiswal, S. An active biodegradable layer-by-layer film based on chitosan-alginate-TiO2 for the enhanced shelf life of tomatoes. Food Packag. Shelf Life 2022, 34, 100971. [Google Scholar] [CrossRef]

- Luo, Y.; Lin, Z.; Guo, G. Biodegradation assessment of poly (lactic acid) filled with functionalized titania nanoparticles (PLA/TiO 2) under compost conditions. Nanoscale Res. Lett. 2019, 14, 56. [Google Scholar] [CrossRef] [PubMed]

- Castro-Aguirre, E.; Auras, R.; Selke, S.; Rubino, M.; Marsh, T. Impact of nanoclays on the biodegradation of poly (lactic acid) nanocomposites. Polymers 2018, 10, 202. [Google Scholar] [CrossRef] [PubMed]

- Ahari, H.; Lahijani, L.K. Migration of silver and copper nanoparticles from food coating. Coatings 2021, 11, 380. [Google Scholar] [CrossRef]

- Cheng, F.L. Research of mathematical model for plastic packaging materials migration. J. Jilin Inst. Chem. Technol. 2011, 7, 25. [Google Scholar]

- Bott, J.; Störmer, A.; Franz, R. Migration of nanoparticles from plastic packaging materials containing carbon black into foodstuffs. Food Addit. Contam. Part A 2014, 31, 1769–1782. [Google Scholar] [CrossRef]

- Cushen, M.; Kerry, J.; Morris, M.; Cruz-Romero, M.; Cummins, E. Nanotechnologies in the food industry–Recent developments, risks and regulation. Trends Food Sci. Technol. 2012, 24, 30–46. [Google Scholar] [CrossRef]

- Félix, J.S.; Manzoli, J.E.; Padula, M.; Monteiro, M. Evaluation of different conditions of contact for caprolactam migration from multilayer polyamide films into food simulants. Packag. Technol. Sci. 2014, 27, 457–466. [Google Scholar] [CrossRef]

- Chang, N.; Zhang, C.-h.; Zheng, F.-e.; Huang, Y.-l.; Zhu, J.-y.; Zhou, Q.; Zhou, X.; Ji, S.-j. Migration of toluene through different plastic laminated films into food simulants. Food Control 2016, 59, 164–171. [Google Scholar] [CrossRef]

- Al-Ali, R.M.; Al-Hilifi, S.A.; Rashed, M. Fabrication, characterization, and anti-free radical performance of edible packaging-chitosan film synthesized from shrimp shell incorporated with ginger essential oil. J. Food Meas. Charact. 2021, 15, 2951–2962. [Google Scholar] [CrossRef]

- Honarvar, Z.; Hadian, Z.; Mashayekh, M. Nanocomposites in food packaging applications and their risk assessment for health. Electron. Physician 2016, 8, 2531. [Google Scholar] [CrossRef] [PubMed]

- Pasias, I.; Raptopoulou, K.; Proestos, C. Migration from Metal Packaging into Food; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Shamhari, N.M.; Wee, B.S.; Chin, S.F.; Kok, K.Y. Synthesis and characterization of zinc oxide nanoparticles with small particle size distribution. Acta Chim. Slov. 2018, 65, 578–585. [Google Scholar] [CrossRef] [PubMed]

- Cussler, E.; Hughes, S.E.; Ward, W.J., III; Aris, R. Barrier membranes. J. Membr. Sci. 1988, 38, 161–174. [Google Scholar] [CrossRef]

- Dardmeh, N.; Khosrowshahi, A.; Almasi, H.; Zandi, M. Study on effect of the polyethylene terephthalate/nanoclay nanocomposite film on the migration of terephthalic acid into the yoghurt drinks simulant. J. Food Process Eng. 2017, 40, e12324. [Google Scholar] [CrossRef]

- de Abreu, D.A.P.; Cruz, J.M.; Angulo, I.; Losada, P.P. Mass transport studies of different additives in polyamide and exfoliated nanocomposite polyamide films for food industry. Packag. Technol. Sci. Int. J. 2010, 23, 59–68. [Google Scholar] [CrossRef]

- Garofalo, E.; Scarfato, P.; Di Maio, L.; Incarnato, L. Tuning of co-extrusion processing conditions and film layout to optimize the performances of PA/PE multilayer nanocomposite films for food packaging. Polym. Compos. 2018, 39, 3157–3167. [Google Scholar] [CrossRef]

- Seray, M.; Hadj-Hamou, A.S. Synergistic effect of combining metallic and mineral nanoparticles on the improvement of the performance of active poly (butylene adipate-co-terephthalate) packaging films. Polym. Compos. 2024, 45, 4031–4050. [Google Scholar] [CrossRef]

- Farhoodi, M.; Mohammadifar, M.A.; Mousavi, M.; Sotudeh-Gharebagh, R.; Emam-Djomeh, Z. Migration kinetics of ethylene glycol monomer from PET bottles into acidic food simulant: Effects of nanoparticle presence and matrix morphology. J. Food Process Eng. 2017, 40, e12383. [Google Scholar] [CrossRef]

- Farhoodi, M. Nanocomposite materials for food packaging applications: Characterization and safety evaluation. Food Eng. Rev. 2016, 8, 35–51. [Google Scholar] [CrossRef]

- Dimitrijevic, M.; Karabasil, N.; Boskovic, M.; Teodorovic, V.; Vasilev, D.; Djordjevic, V.; Kilibarda, N.; Cobanovic, N. Safety aspects of nanotechnology applications in food packaging. Procedia Food Sci. 2015, 5, 57–60. [Google Scholar] [CrossRef]

- Thakur, A.; Kumar, A. Ecotoxicity Analysis and Risk Assessment of Nanomaterials for the Environmental Remediation. In Proceedings of the Macromolecular Symposia, Chandigarh, India, 18–22 October 2021; p. 2100438. [Google Scholar]

- Rozhina, E.; Batasheva, S.; Miftakhova, R.; Yan, X.; Vikulina, A.; Volodkin, D.; Fakhrullin, R. Comparative cytotoxicity of kaolinite, halloysite, multiwalled carbon nanotubes and graphene oxide. Appl. Clay Sci. 2021, 205, 106041. [Google Scholar] [CrossRef]

- Das, S.K.; Sen, K.; Ghosh, B.; Ghosh, N.; Sinha, K.; Sil, P.C. Molecular mechanism of nanomaterials induced liver injury: A review. World J. Hepatol. 2024, 16, 566. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Chen, Z.; Ba, T.; Pu, J.; Chen, T.; Song, Y.; Gu, Y.; Qian, Q.; Xu, Y.; Xiang, K. Susceptibility of young and adult rats to the oral toxicity of titanium dioxide nanoparticles. Small 2013, 9, 1742–1752. [Google Scholar] [CrossRef] [PubMed]

- Gupta, N.; Yadav, K.K.; Kumar, V.; Kumar, S.; Chadd, R.P.; Kumar, A. Trace elements in soil-vegetables interface: Translocation, bioaccumulation, toxicity and amelioration—A review. Sci. Total Environ. 2019, 651, 2927–2942. [Google Scholar] [CrossRef] [PubMed]

- Wong, S.W.; Leung, K.M.; Djurišić, A. A comprehensive review on the aquatic toxicity of engineered nanomaterials. Rev. Nanosci. Nanotechnol. 2013, 2, 79–105. [Google Scholar] [CrossRef]

- Adeyemi, J.O.; Fawole, O.A. Metal-based nanoparticles in food packaging and coating technologies: A review. Biomolecules 2023, 13, 1092. [Google Scholar] [CrossRef]

- Primožič, M.; Knez, Ž.; Leitgeb, M.J.N. (Bio) Nanotechnology in food science—Food packaging. Nanomaterials 2021, 11, 292. [Google Scholar] [CrossRef]

- Sarfraz, J.; Gulin-Sarfraz, T.; Nilsen-Nygaard, J.; Pettersen, M.K. Nanocomposites for food packaging applications: An overview. Nanomaterials 2020, 11, 10. [Google Scholar] [CrossRef] [PubMed]

| Study | Nanofillers | Polymer Matrix and Added Components | Mechanical Properties | Barrier Features | Thermal Characteristics | ||||

|---|---|---|---|---|---|---|---|---|---|

| TS (MPa) | EAB (%) | Young’s Modulus (MPa) | WVP (g m−1 Pa−1 s−1) | OP (cc Mil m−2 Day Atm) | Light Transmittance (%) | Mobility (Tg (°C) | |||

| [92] | MMT | PET, PAA | N/A | N/A | N/A | 2.50 × 10−12 → 2.26 × 10−12 (−9.60%) | 1.01 × 10−16 → 1.7 × 10−18 (−98.32%) | N/A | N/A |

| [93] | MMT | PVA boiled rice starch | 16.8 → 33.5 (+99.40%) | 257 → 4.6 (−98.21%) | 290.0 → 2220.0 (+665.51%) | N/A | N/A | N/A | N/A |

| [94] | Halloysite nanotubes | PLA | 22.5 → 37 (+64.44%) | 2.1 → 1.4 (−33.33%) | 1800.0 → 4200.0 (+ 133.33%) | 1.62 × 10−10→ 1.27 × 10−10 (−21.60%) | 1.06 × 10−13 → 7.08 × 10−14 (−33.33%) | N/A | 58.49 → 57.42 (−1.83%) |

| [95] | Bentonitte | Chitosan, poplar hot water extract | 39.3 → 52.9 (+34.69%) | 11.7 → 7.9 (−32.28%) | N/A | 8.71 × 10−11 → 6.72 × 10−11 (−22.85%) | 3.36 × 10−8 → 1.63 × 10−18 (−51.48%) | 280 nm: 35 → 28 (−20%) | N/A |

| [96] | Kaolinite | Chitosan | 17.0 → 12.0 (−29.41%) | 14.8 → 10.0 (−32.43%) | N/A | 9.61 × 10−11 → 7.92 × 10−11 (−17.58%) | N/A | 400 nm: 87 → 77 (−11.49%) | N/A |

| [97] | Sepiolite | Alginate, sepiolite-myrtle berries extract | 38.0 → 117.0 (+207.89%) | 3.8 → 3.2 (−15.79%) | 2.0 → 4.3 (116.08%) | 1.79 × 10−6 → 1.62 × 10−6 (−9.49%) | N/A | 600 nm: 90 → 73.8 (−18.00%) | N/A |

| [47] | ZnO-doped MWCNTs | PVA | (+116.00%) | (+81.00%) | N/A | (−25.93%) | N/A | 250 nm (−15.18%) | 74.3 → 76.9 (+3.50%) |

| [98] | CNTs | Sodium alginate/chitosan | 17.5 → 24.2 (+38.29%) | 16.9 → 21.8 (+28.99%) | N/A | N/A | N/A | N/A | N/A |

| [99] | MWCNTs | GO, Ch.–PEO | N/A | N/A | N/A | N/A | N/A | 400 nm: 76% → 21% (−72.37%) | N/A |

| [100] | Starch nanocrystals | Corn starch | 17.4 → 20.3 (+16.67%) | 16.7 → 10.6 (−36.52%) | N/A | 3.58 × 10−14 → 2.89 × 10−14 (−19.27%) | N/A | 800 nm: 74.8 → 54.0 (−27.80%) | N/A |

| [101] | Quinoa Starch nanocrystals | Cassava starch | 6.5 → 16.5 (+153.85%) | 10.2 → 7.1 (−30.39%) | 2.8 → 6.6 (+135.71%) | 1.5 × 10−7 → 1.2 × 10−7 (−16.67%) | N/A | N/A | 15.0 → 23.1 (+54.00%) |

| [102] | CNFs | PVA | 52.5 → 69.8 (+32.95%) | 99.0 → 84.7 (−14.44%) | 3578.0 → 4263.0 (+19.14%) | 6.97 × 10−7 → 2.82 × 10−7 (−59.54%) | (−99.46%) | 5.7 → 48.8 | N/A |

| [103] | CNFs | Starch | 8.9 → 16.5 (+85.39%) | 83.2 → 9.0 (−89.18%) | 289.0 → 743.0 (+157.09%) | 12.0 × 10−11→ 8.65 × 10−11 (−27.91%) | N/A | 380 nm: 72.2→ 40.0 (−44.60%) | N/A |

| [104] | CNCs | Starch | 16.2 → 24.6 (+51.85%) | 13.1 → 3.6 (−72.51%) | 12.9 → 21.0 (+62.35%) | 2.08 × 10−10 → 1.84 × 10−10 (−11.54%) | N/A | N/A | N/A |

| [105] | BC | Gelatin | 3.2 → 1.1 (−65.63%) | 102.07 → 186.04 (+82.27%) | 50.1 → 0.9 (−98.30%) | 3.06 × 10−9 → 2.47 × 10−9 (−19.28%) | N/A | N/A | N/A |

| [106] | CNP | Corn starch, thymol | 7.7 →13.7 (+77.92%) | 139.0 → 157.0 (+12.94%) | 33.7 → 63.6 (+88.72%) | N/A | N/A | N/A | N/A |

| [107] | CNP | Starch | 1.1 → 10.0 (+79.55%) | 67.0 → 90.8 (+35.48%) | 6.0 → 39.9 (+568.96%) | 3.06 × 10−15 →1.75 × 10−15 (−42.81%) | (−48.12%) | N/A | N/A |

| [91] | SiO2 NPs | Chitosan | 101.3 → 131.9 (+30.21%) | 4.8 → 2.3 (−52.08%) | N/A | 1.34 × 10−11 →1.06 × 10−11 (−20.90%) | N/A | 400 nm: (−85.19%) | N/A |

| [108] | SiO2 NPs | PLA | 43.3 → 34.7 (−19.86%) | 2.6 → 2.9 (+11.54%) | 1775.8 → 1840.6 (−3.65%) | 3.81 × 10−3 →2.53 × 10−3 (−33.60%) | N/A | N/A | 51.4 → 51.6 (−0.39%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Zhou, X.; Zhou, L.; Jia, M.; Xiong, Y. Nanofillers in Novel Food Packaging Systems and Their Toxicity Issues. Foods 2024, 13, 2014. https://doi.org/10.3390/foods13132014

Zhou X, Zhou X, Zhou L, Jia M, Xiong Y. Nanofillers in Novel Food Packaging Systems and Their Toxicity Issues. Foods. 2024; 13(13):2014. https://doi.org/10.3390/foods13132014

Chicago/Turabian StyleZhou, Xiangyu, Xiaoyu Zhou, Longli Zhou, Ming Jia, and Ying Xiong. 2024. "Nanofillers in Novel Food Packaging Systems and Their Toxicity Issues" Foods 13, no. 13: 2014. https://doi.org/10.3390/foods13132014

APA StyleZhou, X., Zhou, X., Zhou, L., Jia, M., & Xiong, Y. (2024). Nanofillers in Novel Food Packaging Systems and Their Toxicity Issues. Foods, 13(13), 2014. https://doi.org/10.3390/foods13132014