Deep-Learning-Based Model Predictive Control of an Industrial-Scale Multistate Counter-Flow Paddy Drying Process

Abstract

:1. Introduction

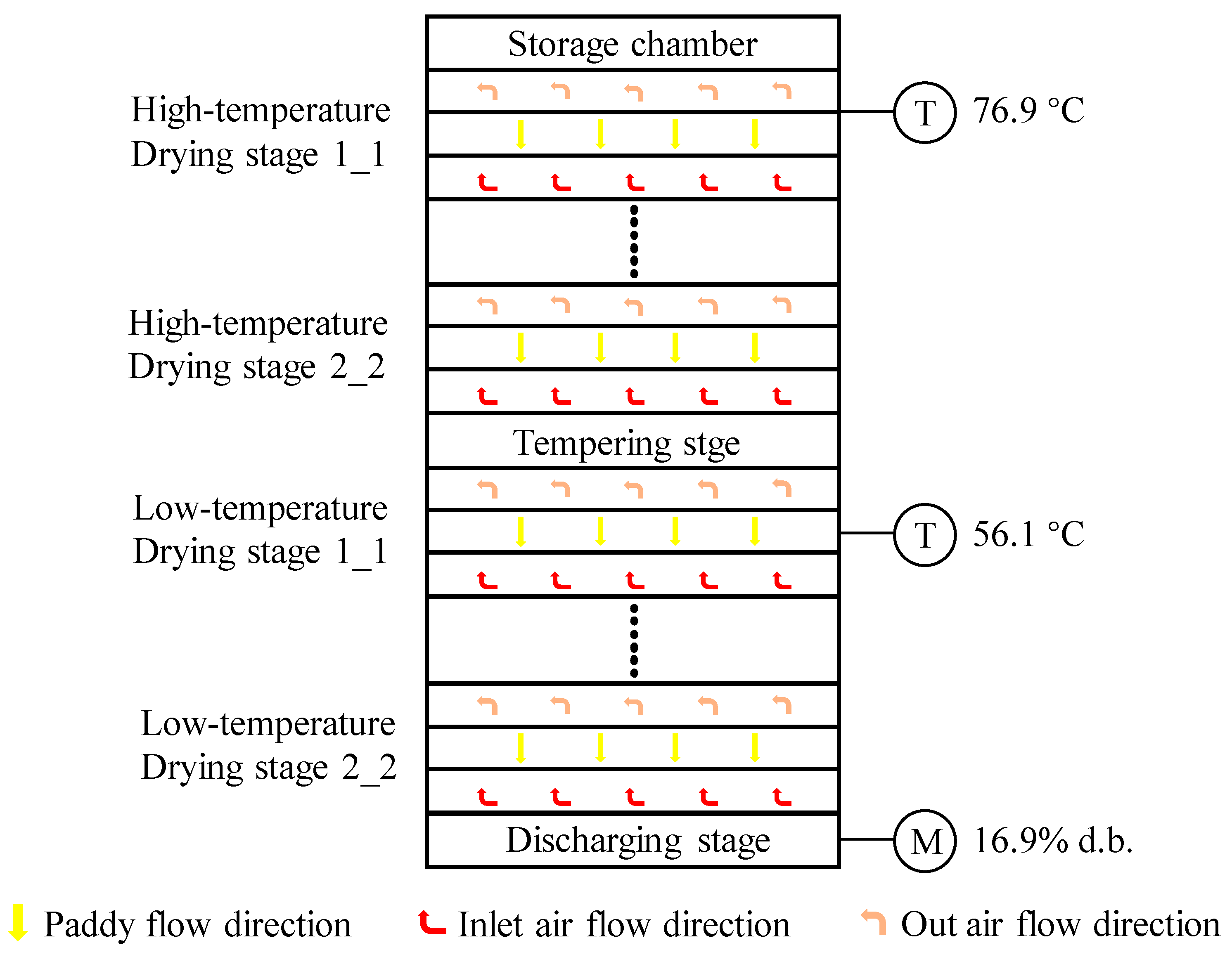

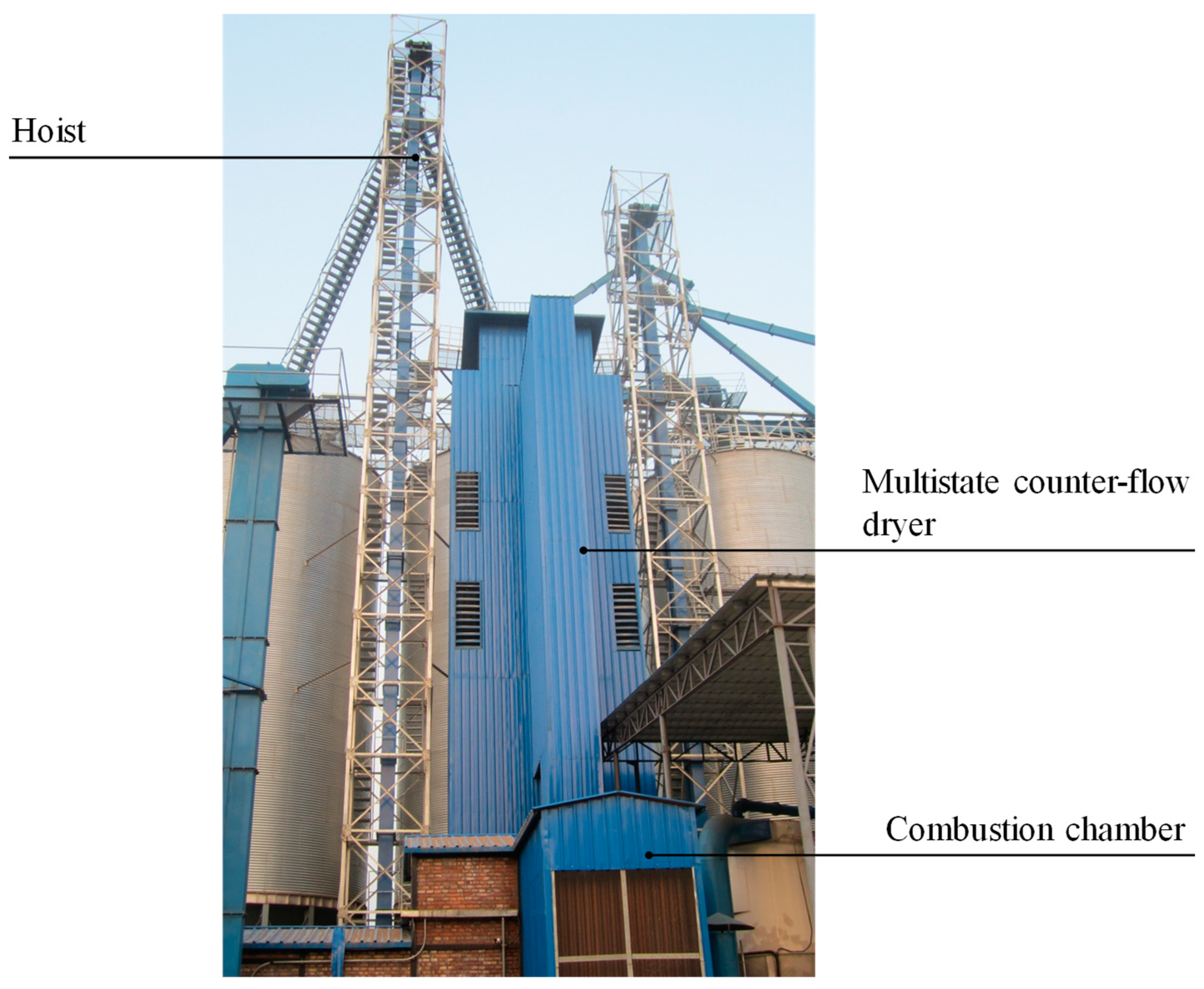

2. Description of Controlled Object

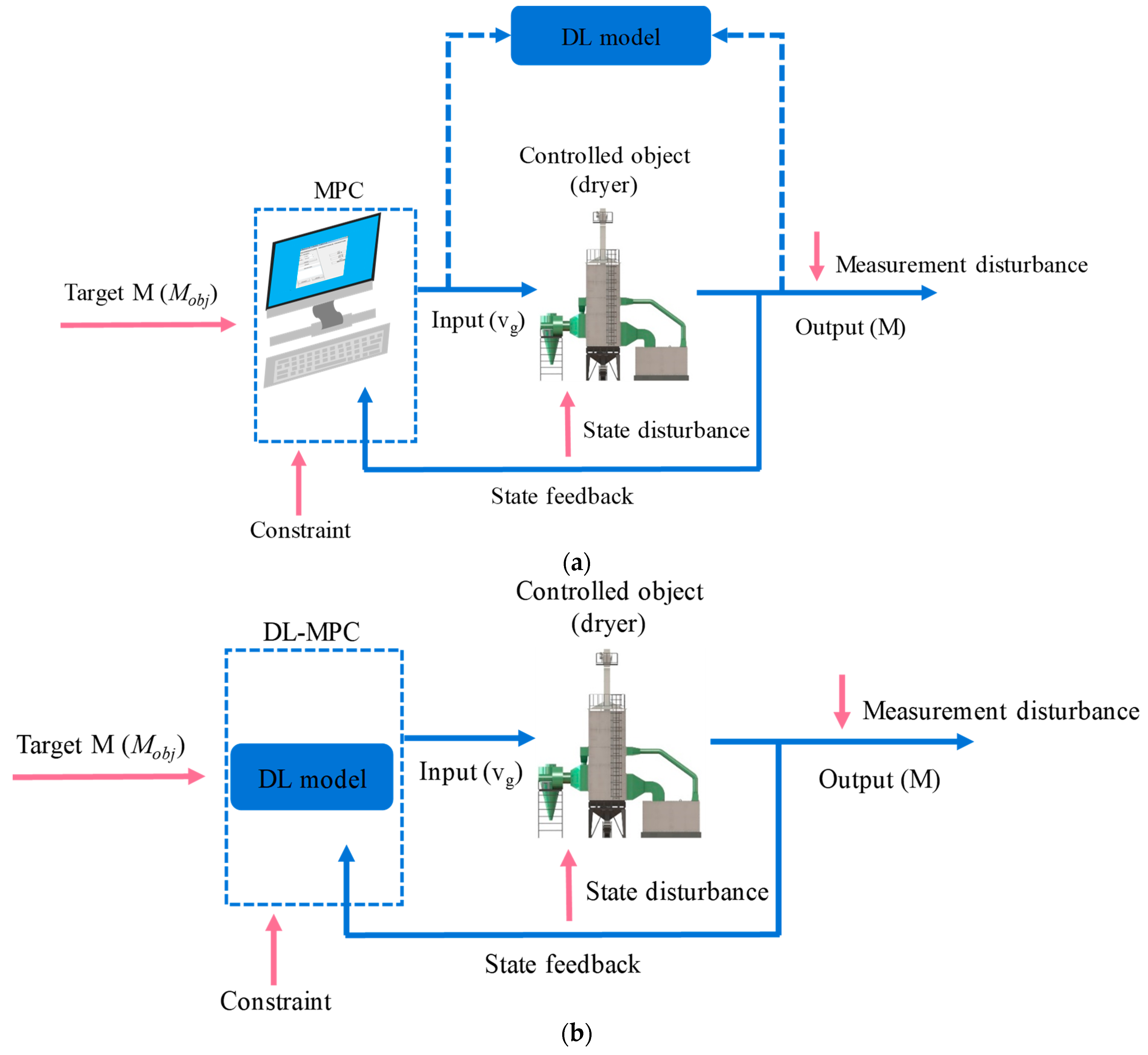

3. Construction of Controller

3.1. Framework of Model Predictive Control

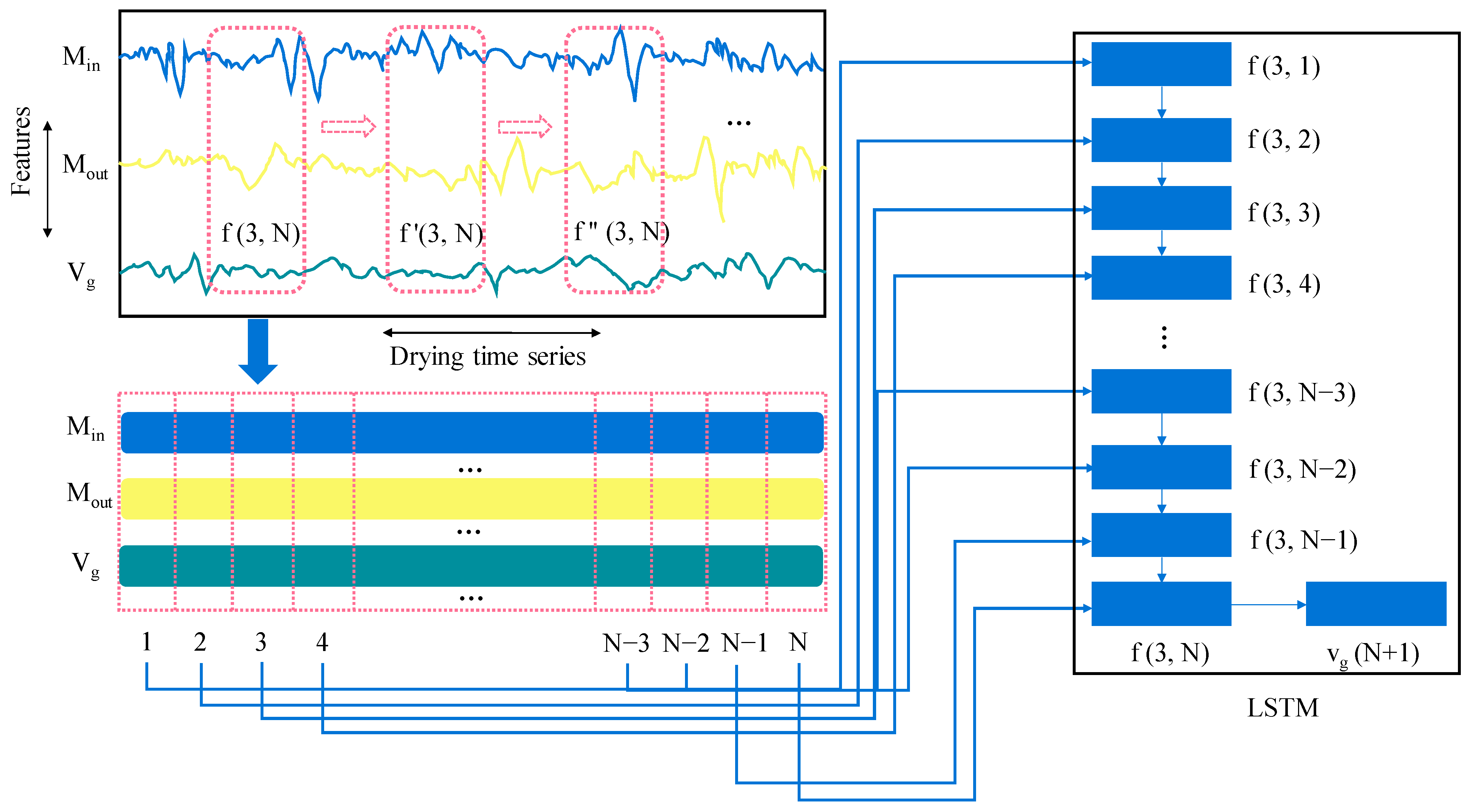

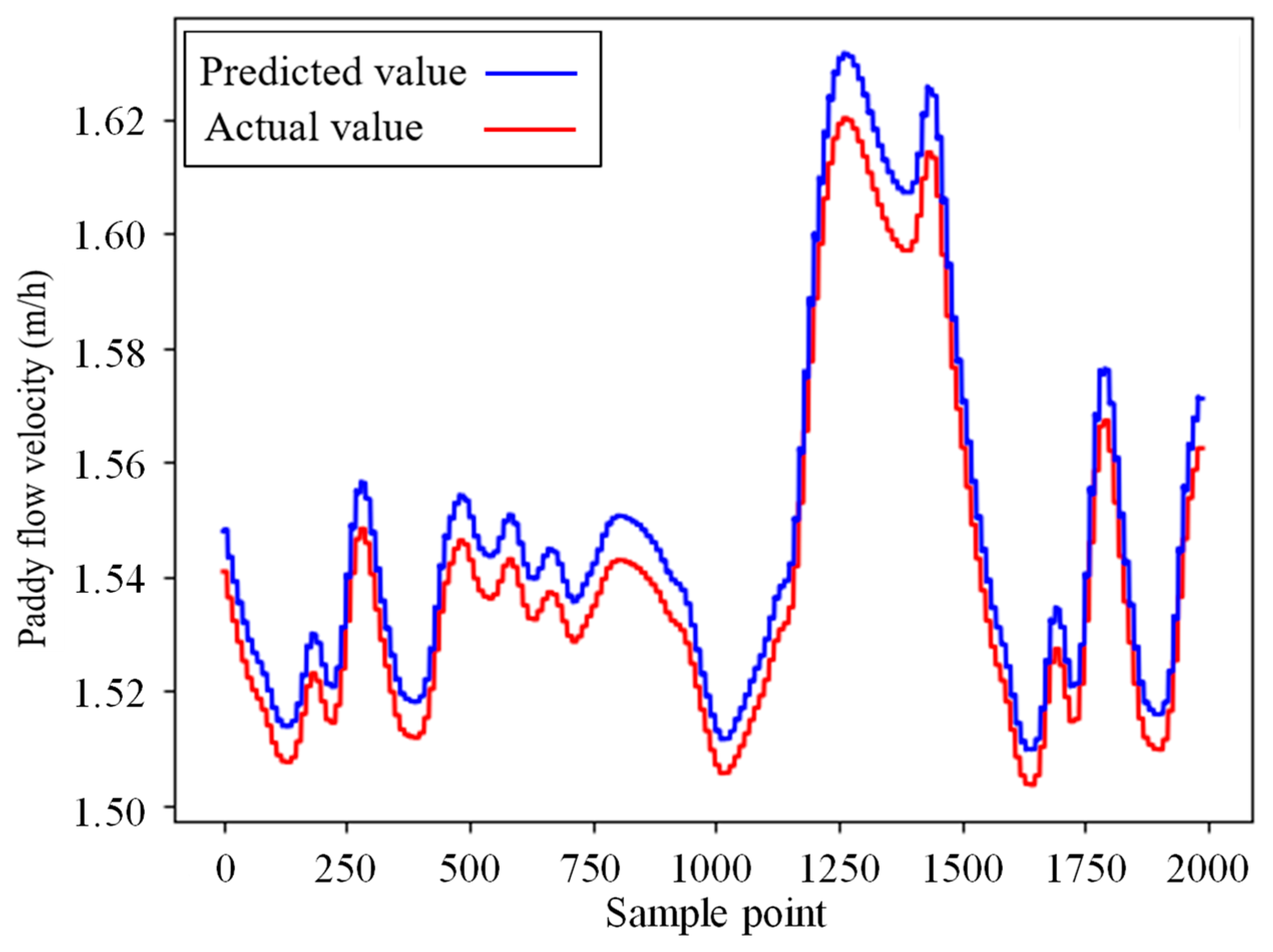

3.2. Deep-Learning-Based MPC

3.3. Analytical Model for Data Generation and Collection

3.4. Statistical Analysis

4. Simulation

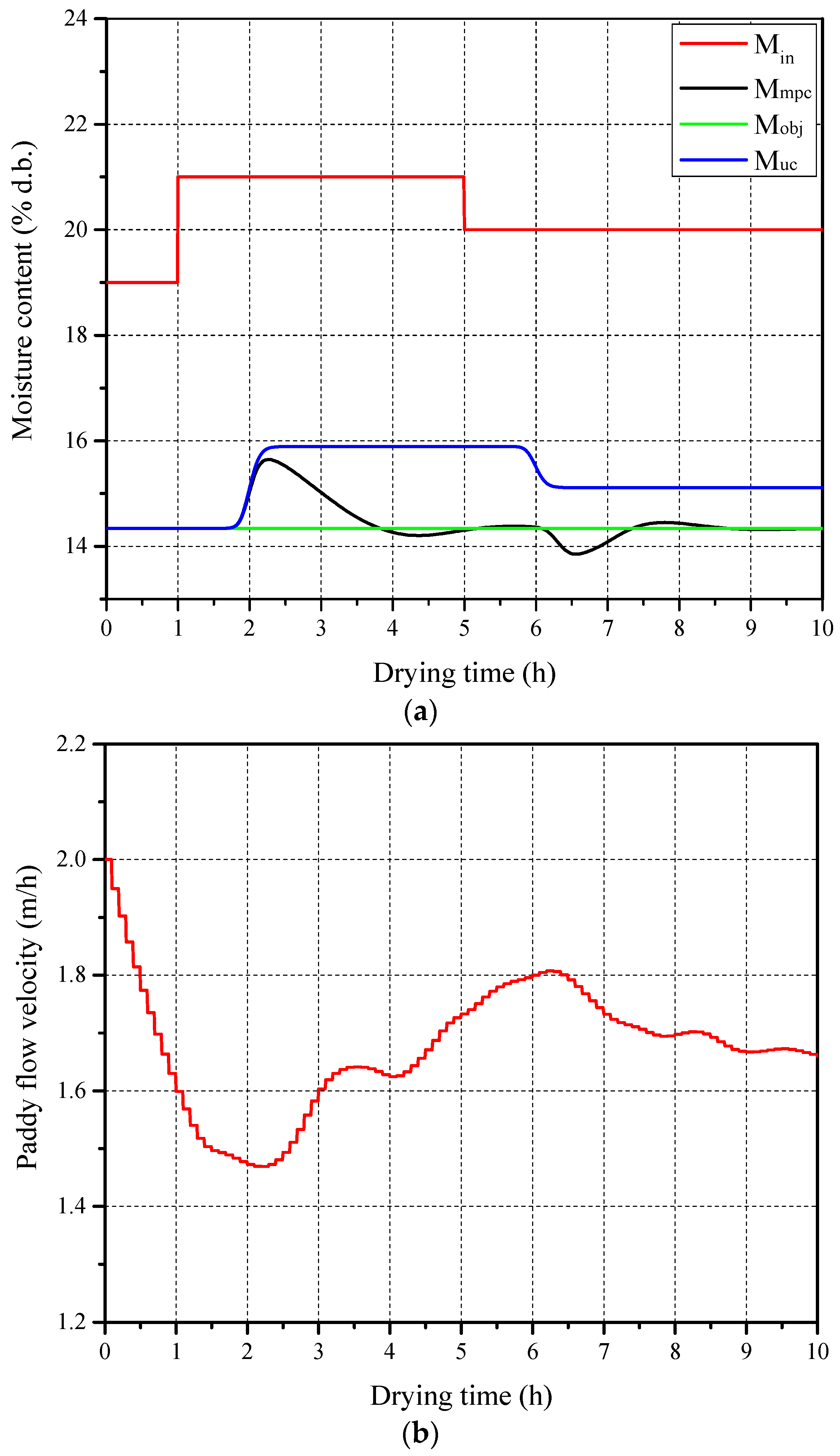

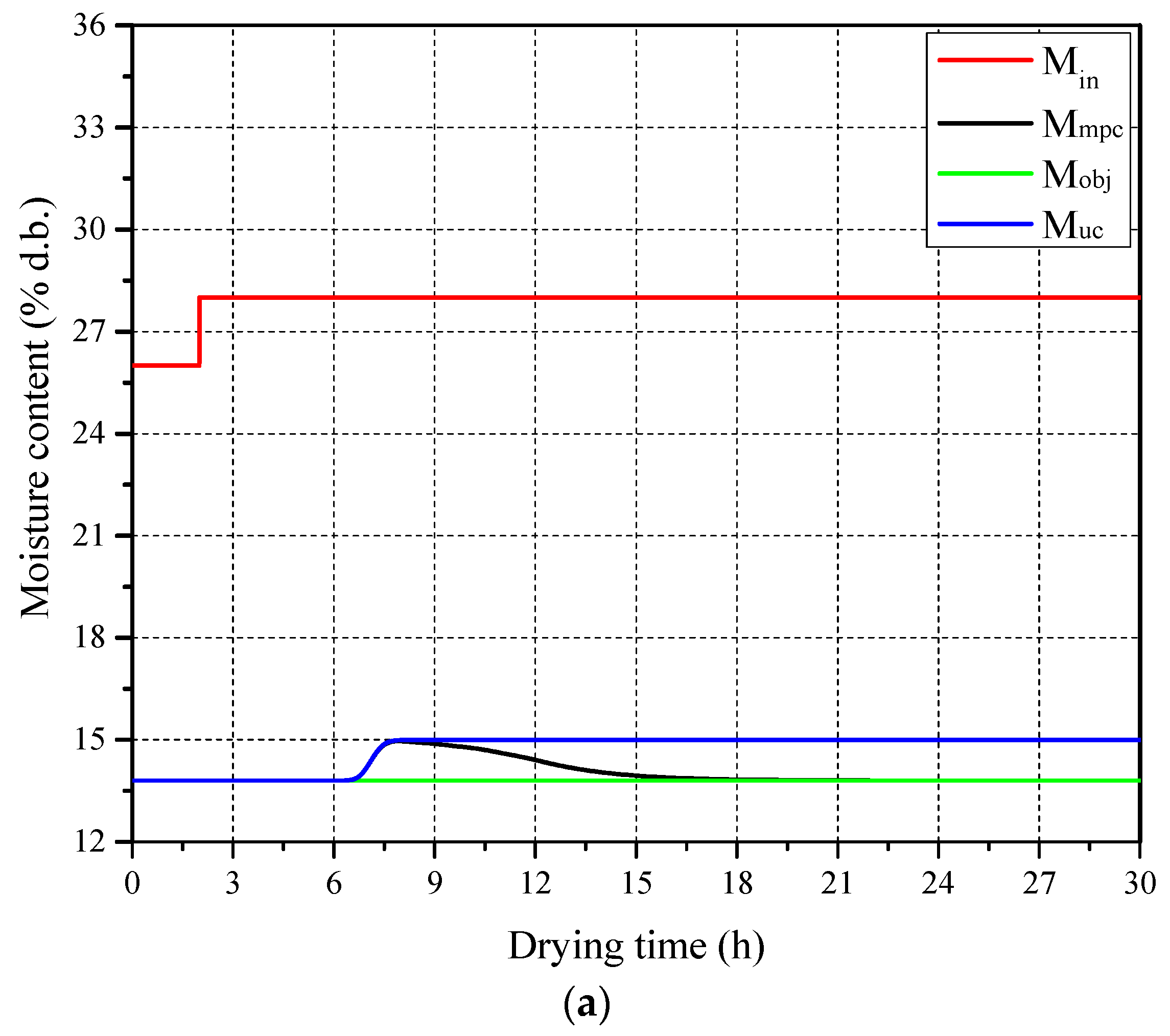

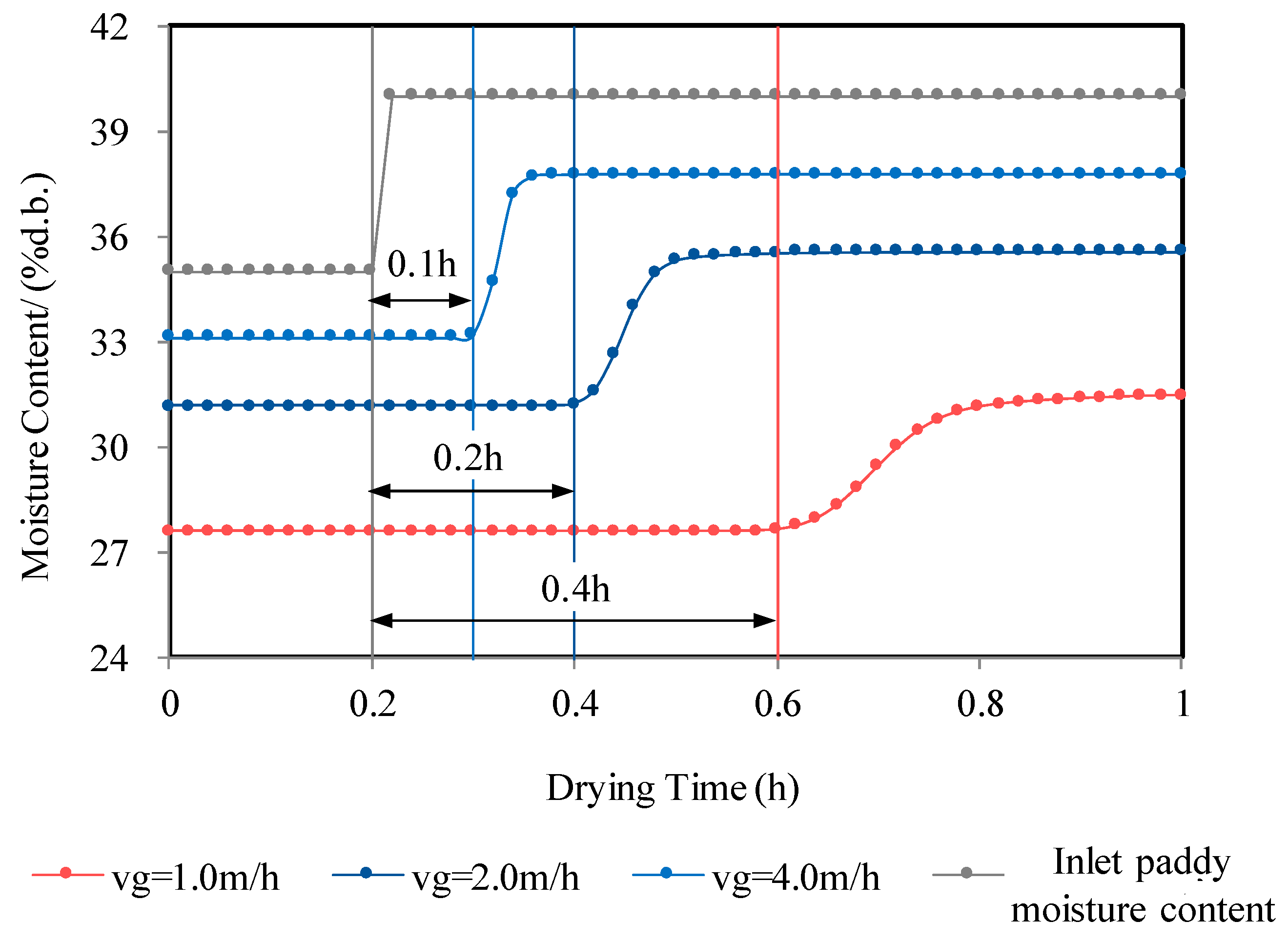

4.1. Simulation of Single-Drying Stage

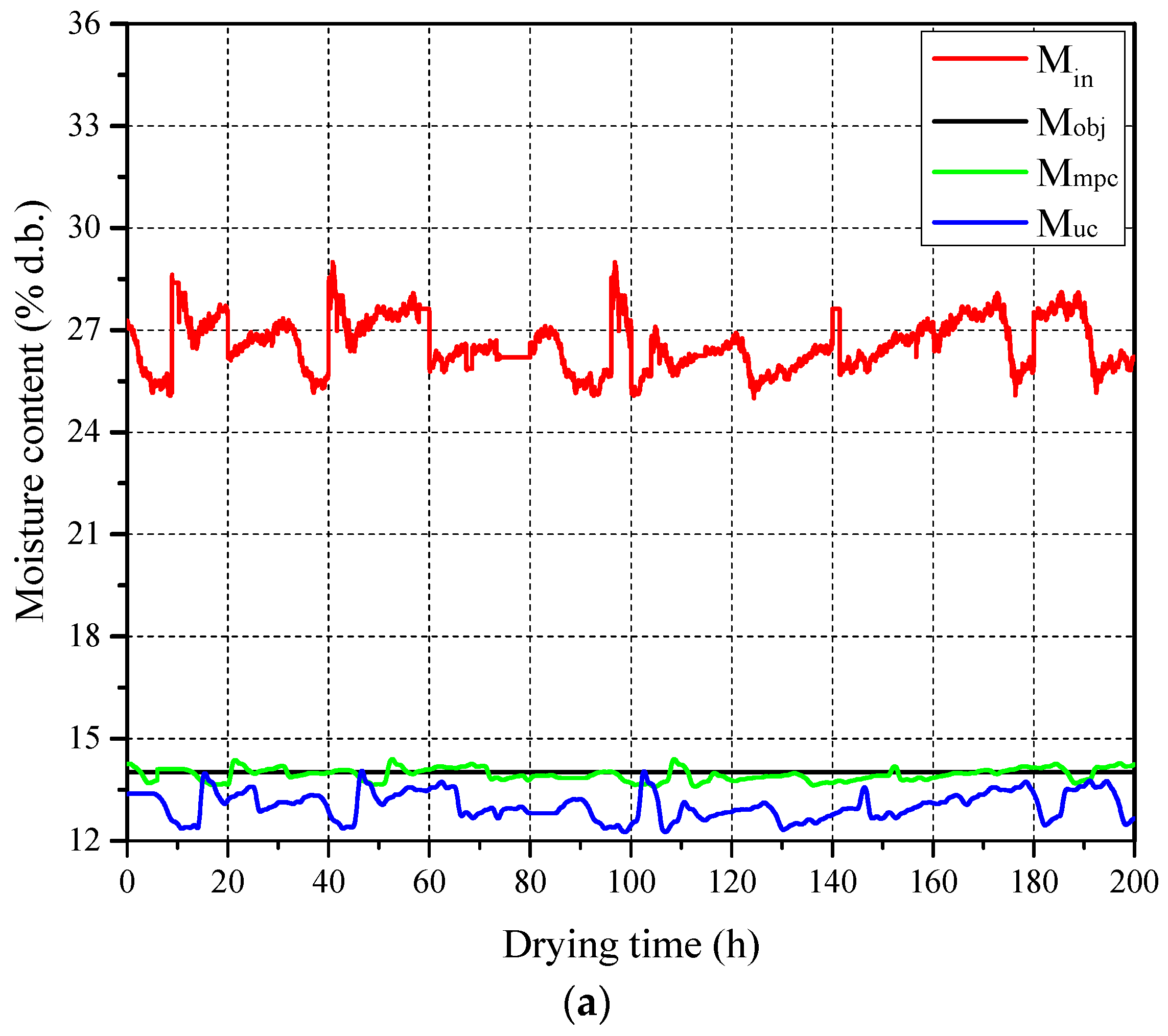

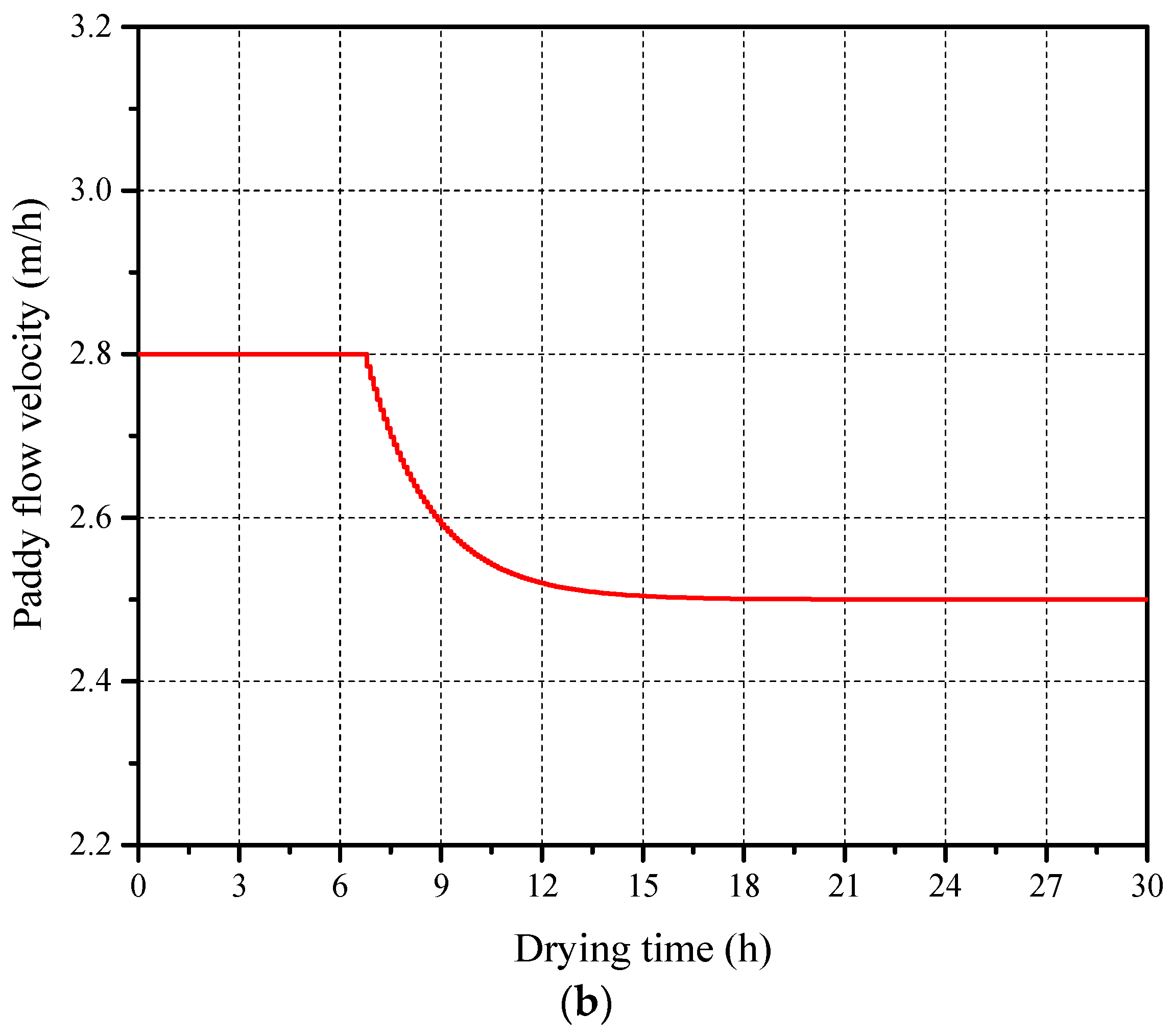

4.2. Simulation of Multiple-Drying Stage

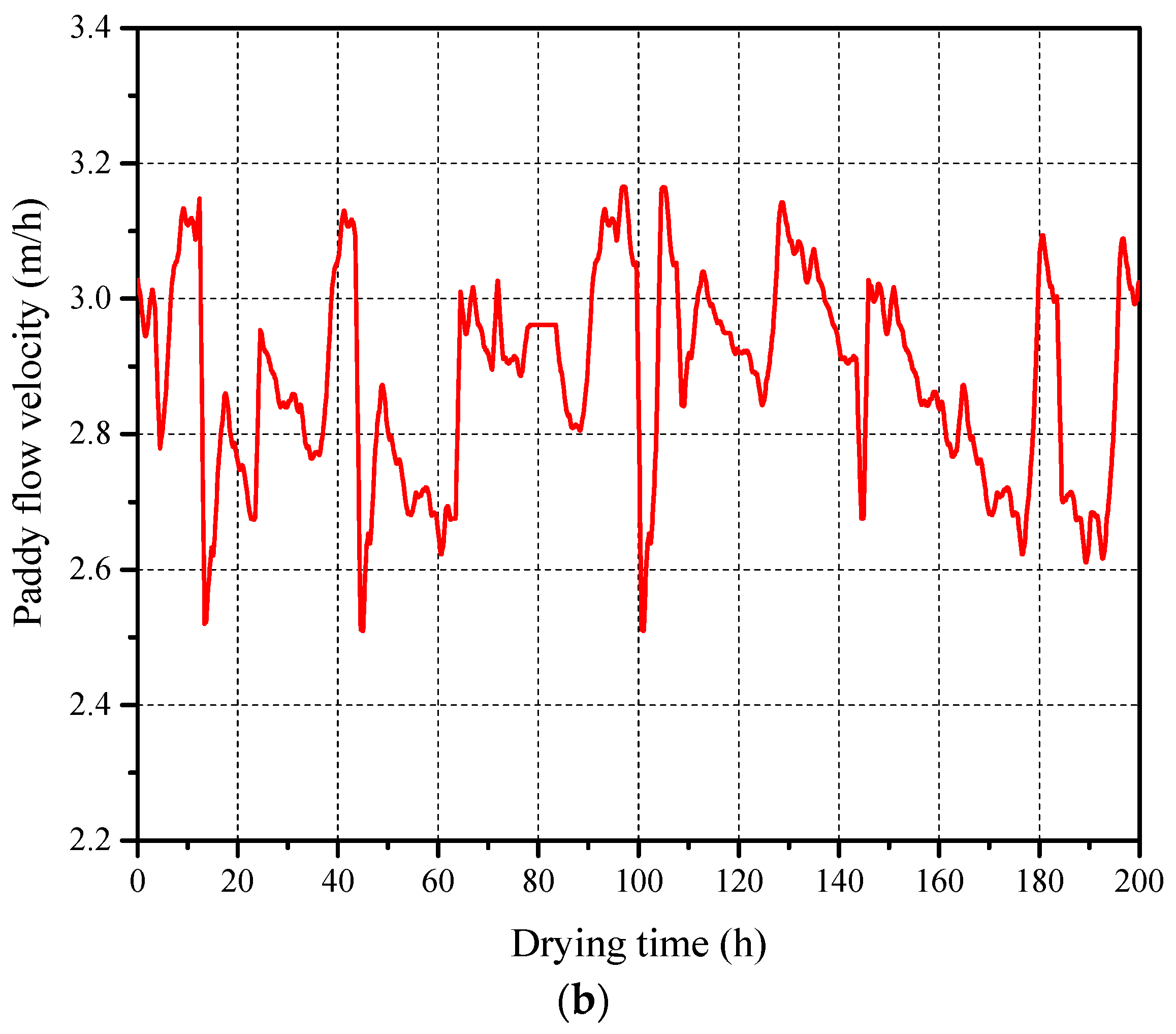

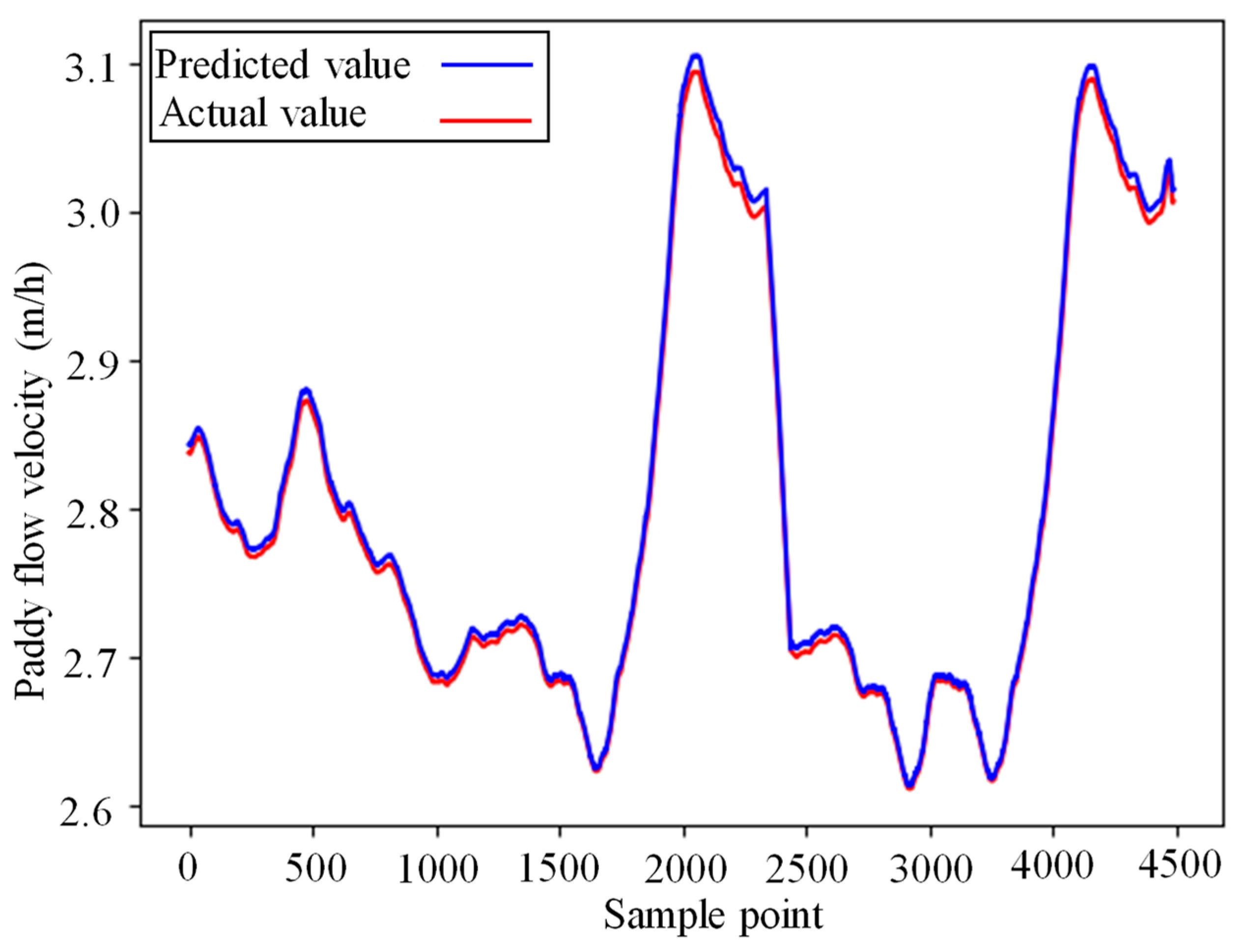

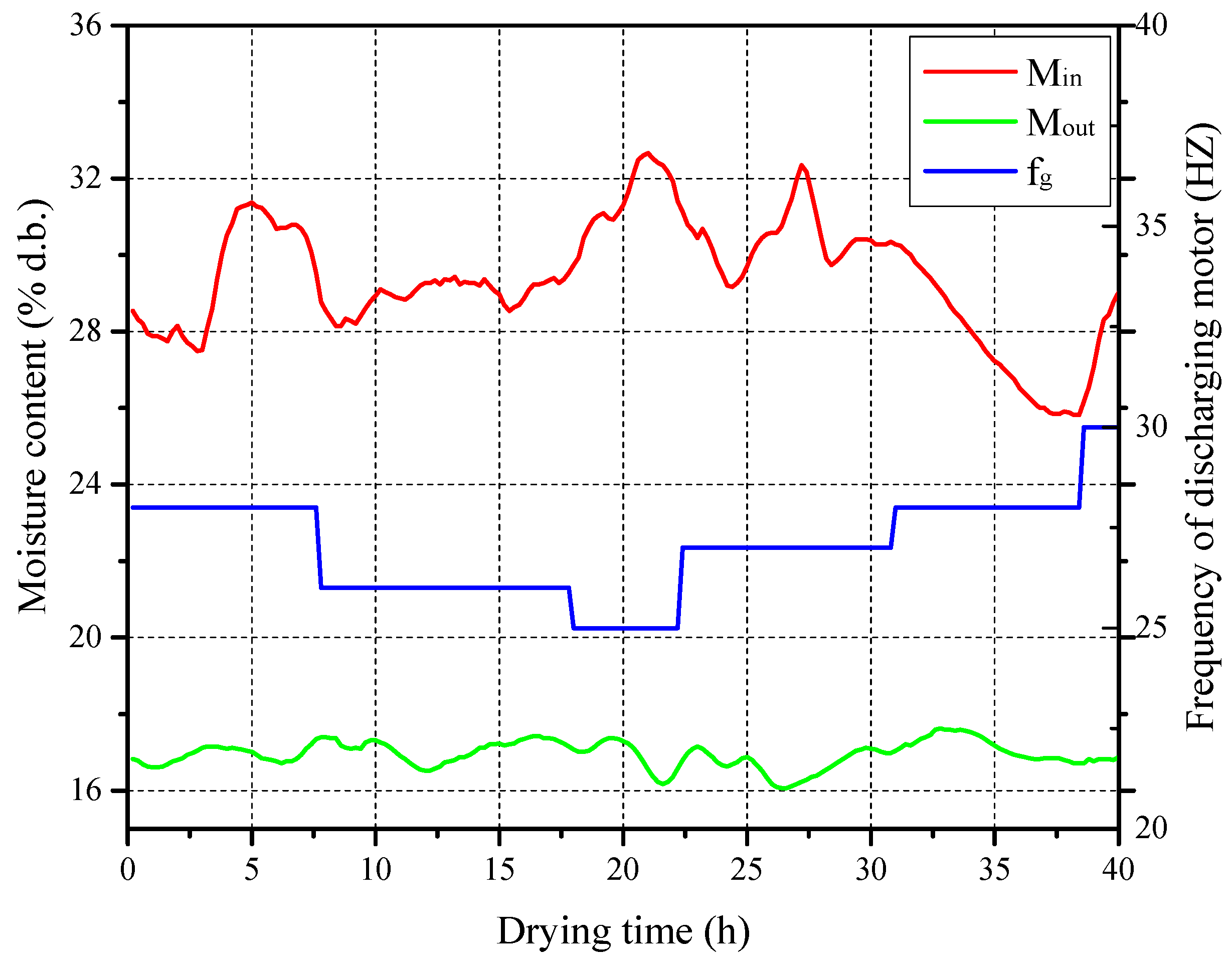

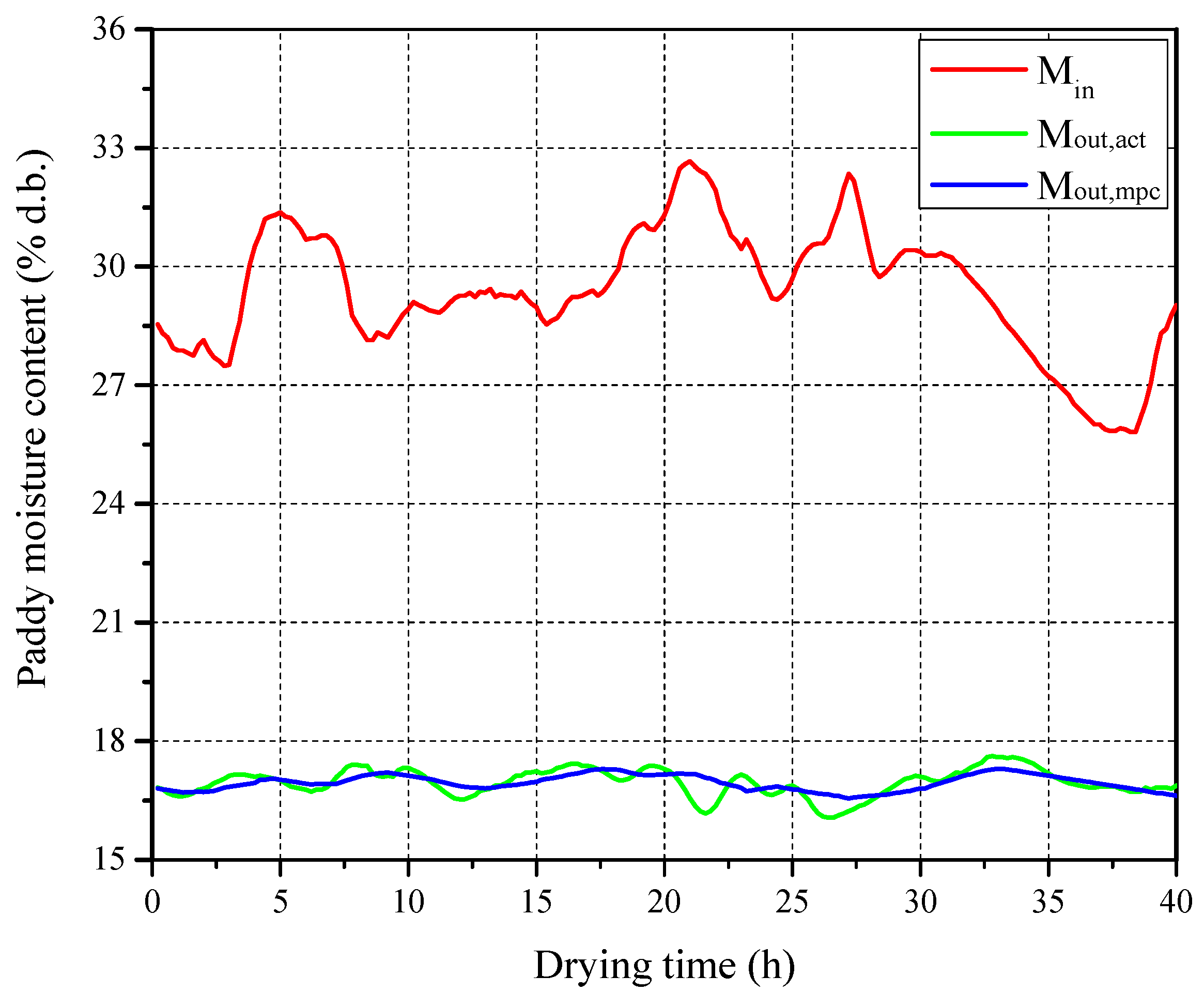

5. Experiment

6. Discussions

7. Conclusions

- (1)

- For a single-drying stage, the DL-MPC system achieves a simulation time of 7.245 s, significantly improving computational speed compared to classical MPC (144.889 s). This makes DL-MPC more suitable for online processes while ensuring effective control.

- (2)

- In multistage combined continuous drying, DL-MPC reduces the control time from 15,120 s to 22.499 s. However, due to the tall height of the control object, the adjustment time is longer compared to a single-drying stage, indicating the pure lag characteristics of the paddy deep-bed drying system.

- (3)

- Field validation experiments demonstrate that the predicted paddy flow velocity follows the discharge motor frequency trend and exhibits a smoother variation. This indicates that the designed DL-MPC controller offers a higher adjustment frequency and more precise control compared to manual adjustments. The MAE between the predicted and actual outlet paddy moisture content is 0.19% d.b., confirming the effectiveness of the DL-MPC controller.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, S.; Zhao, X.; Pittelkow, C.M.; Fan, M.; Zhang, X.; Yan, X. Optimal nitrogen rate strategy for sustainable rice production in China. Nature 2023, 615, 73–79. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Chen, S.; Xiao, S.; Ma, L.; Zhang, Y.; Chen, S. Process research and performance verification of variable temperature homogeneous drying device for paddy. Trans. Chin. Soc. Agric. Mach. 2023. Available online: https://link.cnki.net/urlid/11.1964.S.20230925.0912.012 (accessed on 25 September 2023).

- Mesterházy, Á.; Oláh, J.; Popp, J. Losses in the grain supply chain: Causes and solutions. Sustainability 2020, 12, 2342. [Google Scholar] [CrossRef]

- Du, Y.; Yan, J.; Wei, H.; Xie, H.; Wu, Y.; Zhou, J. Drying kinetics of paddy drying with graphene far-infrared drying equipment at different IR temperatures, radiations-distances, grain-flow, and dehumidifying-velocities. Case Stud. Therm. Eng. 2023, 43, 102780. [Google Scholar] [CrossRef]

- Mujumdar, A.S.; Menon, A.S. Drying of solids: Principles, classification, and selection of dryers. In Handbook of Industrial Drying; CRC Press: Boca Raton, FL, USA, 2020; pp. 1–39. [Google Scholar]

- Li, C.; Fang, Z.; Zhong, J.; Li, B.; Li, C. Evaluating the dynamic characteristics and energetic performance of a paddy multistage counter-flow dryer. Biosyst. Eng. 2022, 221, 208–223. [Google Scholar] [CrossRef]

- EL-Mesery, H.S.; EL-Seesy, A.I.; Hu, Z.; Li, Y. Recent developments in solar drying technology of food and agricultural products: A review. Renew. Sustain. Energy Rev. 2022, 157, 112070. [Google Scholar] [CrossRef]

- Flor, O.; Palacios, H.; Suárez, F.; Salazar, K.; Reyes, L.; González, M.; Jiménez, K. New Sensing Technologies for Grain Moisture. Agriculture 2022, 12, 386. [Google Scholar] [CrossRef]

- Khan, M.I.H.; Sablani, S.S.; Joardder, M.U.H.; Karim, M.A. Application of machine learning-based approach in food drying: Opportunities and challenges. Dry. Technol. 2022, 40, 1051–1067. [Google Scholar] [CrossRef]

- Khan, M.I.H.; Sablani, S.S.; Nayak, R.; Gu, Y. Machine learning-based modeling in food processing applications: State of the art. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1409–1438. [Google Scholar] [CrossRef]

- Noé, F.; Olsson, S.; Köhler, J.; Wu, H. Boltzmann generators: Sampling equilibrium states of many-body systems with deep learning. Science 2019, 365, eaaw1147. [Google Scholar] [CrossRef]

- Dibak, M.; Klein, L.; Krämer, A.; Noé, F. Temperature steerable flows and Boltzmann generators. Phys. Rev. Res. 2022, 4, L042005. [Google Scholar] [CrossRef]

- Arroyo, J.; Manna, C.; Spiessens, F.; Helsen, L. Reinforced model predictive control (RL-MPC) for building energy management. Appl. Energy 2022, 309, 118346. [Google Scholar] [CrossRef]

- Li, H.; Chen, S. A neural-network-based model predictive control scheme for grain dryers. Dry. Technol. 2019, 38, 1079–1091. [Google Scholar] [CrossRef]

- Wu, W.; Liu, Z.; Han, F.; Zhang, Y.; Chen, J. Dual Drive Mutual Window Control Method for Continuous Grain Drying Based on Equivalent Water Potential Product. Patent No. CN113778153A, 29 September 2021. [Google Scholar]

- Jin, Y.; Wong, K.W.; Yang, D.; Zhang, Z.; Wu, W.; Yin, J. A neural network model used in continuous grain dryer control system. Dry. Technol. 2022, 40, 1901–1922. [Google Scholar] [CrossRef]

- Bai, H.; Chu, Z.; Wang, D.; Bao, Y.; Qin, L.; Zheng, Y.; Li, F. Predictive control of microwave hot-air coupled drying model based on GWO-BP neural network. Dry. Technol. 2023, 41, 1148–1158. [Google Scholar] [CrossRef]

- Salehi, F. Recent applications of heat pump dryer for drying of fruit crops: A review. Int. J. Fruit Sci. 2021, 21, 546–555. [Google Scholar] [CrossRef]

- Reis, F.R.; Marques, C.; de Moraes, A.C.S.; Masson, M.L. Trends in quality assessment and drying methods used for fruits and vegetables. Food Control 2022, 142, 109254. [Google Scholar] [CrossRef]

- Karamanakos, P.; Liegmann, E.; Geyer, T.; Kennel, R. Model predictive control of power electronic systems: Methods, results, and challenges. IEEE Open J. Ind. Appl. 2020, 1, 95–114. [Google Scholar] [CrossRef]

- Karamanakos, P.; Geyer, T. Guidelines for the design of finite control set model predictive controllers. IEEE Trans. Power Electron. 2019, 35, 7434–7450. [Google Scholar] [CrossRef]

- Drgoňa, J.; Arroyo, J.; Figueroa, I.C.; Blum, D.; Arendt, K.; Kim, D.; Ollé, E.; Oravec, J.; Wetter, M.; Vrabie, D.L.; et al. All you need to know about model predictive control for buildings. Annu. Rev. Control 2020, 50, 190–232. [Google Scholar] [CrossRef]

- Kamilaris, A.; Prenafeta-Boldú, F.X. Deep learning in agriculture: A survey. Comput. Electron. Agric. 2018, 147, 70–90. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Chen, Y.; Lu, Y.; Hua, K.; Ren, J.; Mozafari, G.; Lu, Q.; Cao, Y. Deep-Learning-Based Predictive Control of Battery Management for Frequency Regulation. Ind. Eng. Chem. Res. 2022, 61, 8432–8442. [Google Scholar] [CrossRef]

- Zhang, X.; Bujarbaruah, M.; Borrelli, F. Near-optimal rapid MPC using neural networks: A primal-dual policy learning framework. IEEE Trans. Control Syst. Technol. 2021, 29, 2102–2114. [Google Scholar] [CrossRef]

- Vaupel, Y.; Hamacher, N.C.; Caspari, A.; Mhamdi, A.; Kevrekidis, I.G.; Mitsos, A. Accelerating nonlinear model predictive control through machine learning. J. Process Contr. 2020, 92, 261–270. [Google Scholar] [CrossRef]

- Li, T.; Li, C.; Li, B.; Li, C.; Fang, Z.; Zeng, Z.; Ou, W.; Huang, J. Characteristic analysis of heat loss in multistage counter-flow paddy drying process. Energy Rep. 2020, 6, 2153–2166. [Google Scholar] [CrossRef]

- Kamali, S.; Ward, V.C.; Ricardez-Sandoval, L. Closed-loop operation of a simulated recirculating aquaculture system with an integrated application of nonlinear model predictive control and moving horizon estimation. Comput. Electron. Agric. 2023, 209, 107820. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, Y.; Zhang, Z.; Wang, Z.; Liu, B.; Liu, C.; Huang, C.; Dong, S.; Pu, X.; Wan, F.; et al. Plant image recognition with deep learning: A review. Comput. Electron. Agric. 2023, 212, 108072. [Google Scholar] [CrossRef]

- Yu, Y.; Si, X.; Hu, C.; Zhang, J. A review of recurrent neural networks: LSTM cells and network architectures. Neural. Comput. 2019, 31, 1235–1270. [Google Scholar] [CrossRef]

- Sherstinsky, A. Fundamentals of recurrent neural network (RNN) and long short-term memory (LSTM) network. Phys. D 2020, 404, 132306. [Google Scholar] [CrossRef]

- Fang, Z.; Li, C.; Zhao, Y. Transient mathematical modeling of circulation counter-flow rice drying system. Trans. Chin. Soc. Agric. Eng. 2019, 35, 286–295. [Google Scholar] [CrossRef]

- Motohashi, K.; Hosokawa, A. An application of forced air drying theory to the deep bed drying of rough rice (I). J. Jpn. Soc. Agric. Mach. 1979, 40, 557–564. [Google Scholar] [CrossRef]

- Song, Q.; Wei, X.; Sun, W.; Li, D. Model predictive control strategy of head rice yield in paddy rice intermittent drying. Dry. Technol. 2022, 40, 2941–2951. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, T.; Ma, J.; Song, Q.; Wei, Q.; Sun, W. Application of Two-Stage Variable Temperature Drying in Hot Air-Drying of Paddy Rice. Foods 2022, 11, 888. [Google Scholar] [CrossRef] [PubMed]

- Chokphoemphun, S.; Chokphoemphun, S. Moisture content prediction of paddy drying in a fluidized-bed drier with a vortex flow generator using an artificial neural network. Appl. Therm. Eng. 2018, 145, 630–636. [Google Scholar] [CrossRef]

- Jha, A.; Tripathy, P.P. Optimization of process parameters and numerical modeling of heat and mass transfer during simulated solar drying of paddy. Comput. Electron. Agric. 2021, 187, 106215. [Google Scholar] [CrossRef]

- Jin, Y.; Xie, H.; Yin, J.; Zhang, Z. Research on intelligent control method of grain drying based on LSTM-MPC. Sci. Technol. Cereals Oils Foods 2023, 31, 25–34. [Google Scholar] [CrossRef]

- Dai, A.; Zhou, X.; Liu, X.; Liu, J.; Zhang, C. Intelligent control of a grain drying system using a GA-SVM-IMPC controller. Dry. Technol. 2018, 36, 1413–1435. [Google Scholar] [CrossRef]

- Dai, A.; Zhou, X.; Dang, H.; Sun, M.; Wu, Z. Intelligent modeling method for a combined radiation-convection grain dryer: A support vector regression algorithm based on an improved particle swarm optimization algorithm. IEEE Access 2018, 6, 14285–14297. [Google Scholar] [CrossRef]

- Eh, S.H.; Choi, Y.S.; Nam, Y.S.; Lee, C.G.; Lee, S.Y.; Oh, K.C.; Oh, J.H.; Kim, D.H. Development of a real-time drying control system for a pneumatic conveying dryer for sawdust in pellet production. Energy 2018, 161, 10–16. [Google Scholar] [CrossRef]

- Han, F.; Zuo, C.; Wu, W.; Li, J.; Liu, Z. Model predictive control of the grain drying process. Math. Probl. Eng. 2012, 2012, 584376. [Google Scholar] [CrossRef]

- Li, J.; Xiong, Q.; Wang, K.; Shi, X.; Liang, S. A recurrent self-evolving fuzzy neural network predictive control for microwave drying process. Dry. Technol. 2016, 34, 1434–1444. [Google Scholar] [CrossRef]

- Wang, D.; Wang, J.; Qiu, S.; Zhan, T.; Tao, D.; Zhang, B. Optimization and experimental study of tempering process parameters during hot air drying of paddy rice. Trans. Chin. Soc. Agric. Mach. 2021, 37, 285–292. [Google Scholar] [CrossRef]

- Shen, L.; Zhu, Y.; Liu, C.; Wang, L.; Liu, H.; Kamruzzaman, M.; Liu, C.; Zhang, Y.; Zheng, X. Modelling of moving drying process and analysis of drying characteristics for germinated brown rice under continuous microwave drying. Biosyst. Eng. 2020, 195, 64–88. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, M.; Xu, B.; Sun, J.; Mujumdar, A.S. Artificial intelligence assisted technologies for controlling the drying of fruits and vegetables using physical fields: A review. Trends Food Sci. Technol. 2020, 105, 251–260. [Google Scholar] [CrossRef]

- Abhigna, R.; Sharma, A.; Kavya, K.; Sharma, P.; Salkuti, S.R.; Rajesh Kumar, M.; Naidu, R.C.; Sreekeessoon, B. Genetically Optimized PID Controller for a Novel Corn Dryer. In Soft Computing for Problem Solving. Lecture Notes in Networks and Systems; Thakur, M., Agnihotri, S., Rajpurohit, B.S., Pant, M., Deep, K., Nagar, A.K., Eds.; Springer: Singapore, 2023; Volume 547. [Google Scholar] [CrossRef]

| Devices | Model | Precision | Manufacturer |

|---|---|---|---|

| Air convection oven | DHG070B | - | Shanghai Anting Scientific Instrument Factory, Shanghai, China |

| Infrared thermometer | 62 MAX+ | 1 °C | Fluke Testing Instruments (Shanghai) Co., Ltd., Shanghai, China |

| Temperature and humidity sensor | AM2305 | 0.3 °C and 2% | Guangzhou Aosong Electronics Co., Ltd., Guangzhou, China |

| Anemometer | AS8336 | ±0.01 m/s | Guangzhou Ximarui Electronics Co., Ltd., Guangzhou, China |

| Electronic scale | DY-718 | ±1 g | Jinhua Furuisi Electronics Co., Ltd., Jinhua, China |

| Meters | Equations/Values | Units |

|---|---|---|

| Ps | Pa | |

| d | kg/kg | |

| Me | g water/g dry matter | |

| ρa | 1.293 | kg/m3 |

| ca | 1.005 | kJ/(kg·°C) |

| ρg | kg/m3 | |

| cg | kJ/(kg·°C) | |

| λg | kJ/kg | |

| μγα | kg/(h·m3) | |

| r | 1/h | |

| hτα | kJ/(h·m3·°C) |

| Parameters | Values | Units |

|---|---|---|

| Thickness of drying stage | 0.5 | m |

| Thickness of tempering stage (air outlet) | 0.5 | m |

| Target moisture content | 14.61 | % d.b. |

| Paddy initial temperature | 20 | °C |

| Ambient temperature | 20 | °C |

| Ambient relative humidity | 50 | % |

| Drying air temperature | 60 | °C |

| Drying air flow velocity | 2300 | m/h |

| Controllable range of paddy flow velocity | 1–5 | m/h |

| Parameters | Values | Units |

|---|---|---|

| Thickness of drying stage | 0.5 | m |

| Thickness of tempering stage (air outlet) | 0.5 | m |

| Thickness of tempering stage | 1.58 | m |

| Target moisture content | 14.01 | % d.b. |

| Paddy initial temperature | 20 | °C |

| Ambient temperature | 20 | °C |

| Ambient relative humidity | 50 | % |

| Drying air temperature in high-temperature drying stage | 70 | °C |

| Drying air temperature in low-temperature drying stage | 50 | °C |

| Drying air flow velocity in high-temperature drying stage | 1924.5 | m/h |

| Drying air flow velocity in low-temperature drying stage | 1154.2 | m/h |

| Controllable range of paddy flow velocity | 1–5 | m/h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Fang, Z.; Li, C.; Li, C. Deep-Learning-Based Model Predictive Control of an Industrial-Scale Multistate Counter-Flow Paddy Drying Process. Foods 2024, 13, 43. https://doi.org/10.3390/foods13010043

Zhang Y, Fang Z, Li C, Li C. Deep-Learning-Based Model Predictive Control of an Industrial-Scale Multistate Counter-Flow Paddy Drying Process. Foods. 2024; 13(1):43. https://doi.org/10.3390/foods13010043

Chicago/Turabian StyleZhang, Ye, Zhuangdong Fang, Changyou Li, and Chengjie Li. 2024. "Deep-Learning-Based Model Predictive Control of an Industrial-Scale Multistate Counter-Flow Paddy Drying Process" Foods 13, no. 1: 43. https://doi.org/10.3390/foods13010043

APA StyleZhang, Y., Fang, Z., Li, C., & Li, C. (2024). Deep-Learning-Based Model Predictive Control of an Industrial-Scale Multistate Counter-Flow Paddy Drying Process. Foods, 13(1), 43. https://doi.org/10.3390/foods13010043