Plant-Based Meat Proteins: Processing, Nutrition Composition, and Future Prospects

Abstract

:1. Introduction

2. Processing Method

2.1. Preparation of Plant-Based Alternative Protein

2.1.1. Chemical Method

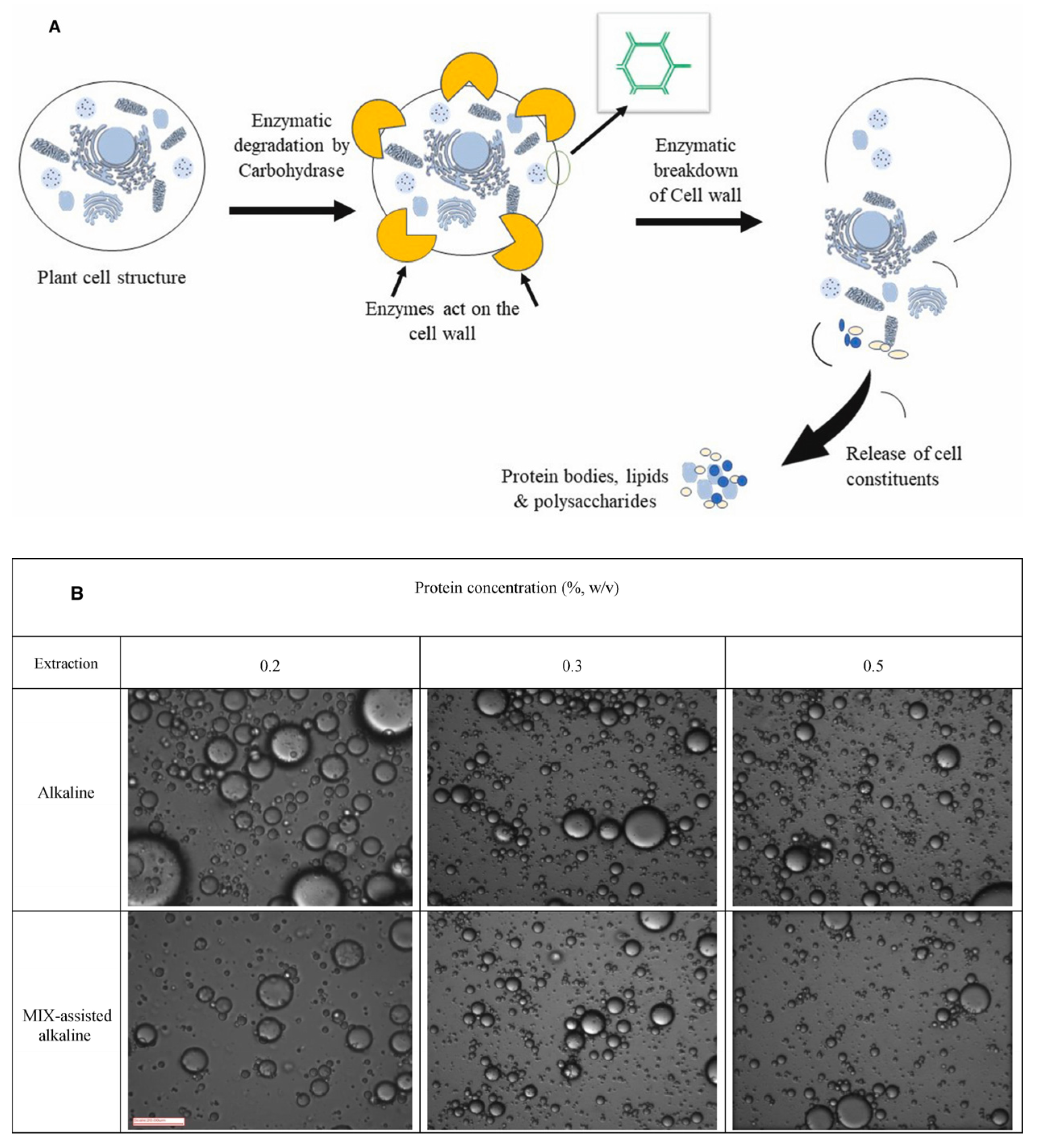

2.1.2. Enzyme-Assisted Method

2.1.3. Physical Assisted Method

| Target | Extraction Method | Extraction Reagents | Extraction Efficiency | Refs. |

|---|---|---|---|---|

| Moringa oleifera | Organic solvent extraction | PE-ethanol/water | recovery rate: 33% | [23] |

| Mung bean protein | Alkaline extraction | KOH solution | 77.32% protein | [24] |

| Rapeseed | Enzyme-assisted method | Protease A-01 | 80.7% (cold-pressed rapeseed meal), 78.3% (pre-pressed rapeseed meal) | [25] |

| Potato Proteins | Enzyme-assisted method | α-amylase, galactanase | 86.5% (protein content) | [26] |

| Flaxseed | Enzyme-assisted method | Cellulase | 86.80 ± 0.91% (enzymatic-solvent flaxseed protein concentrates, ES-FPC) | [15] |

| Soybean | Reverse micelles extraction | 25 min, pH 3.0, 45 °C | 48.66% | [27] |

| Mango peel pectin | Microwave-assisted extraction | 700 W, 3 min | / | [28] |

| Sesame Bran | Ultrasound-assisted extraction | Water, 35 kHz, 18 time | 59.8% | [29] |

| Chlorella vulgaris (SAG 211-12) | Pulsed electric field (PEF) treatment | 1.94 kJ kg sus −1 | 96.6 ± 4.8% (available free protein) | [30] |

| Wet biomass of Arthrospira platensis (spirulina) | High-pressure assisted extraction | 300 MPa, 20 °C, 10 min | 90% (C-phycocyanin), 60% (total soluble proteins) | [31] |

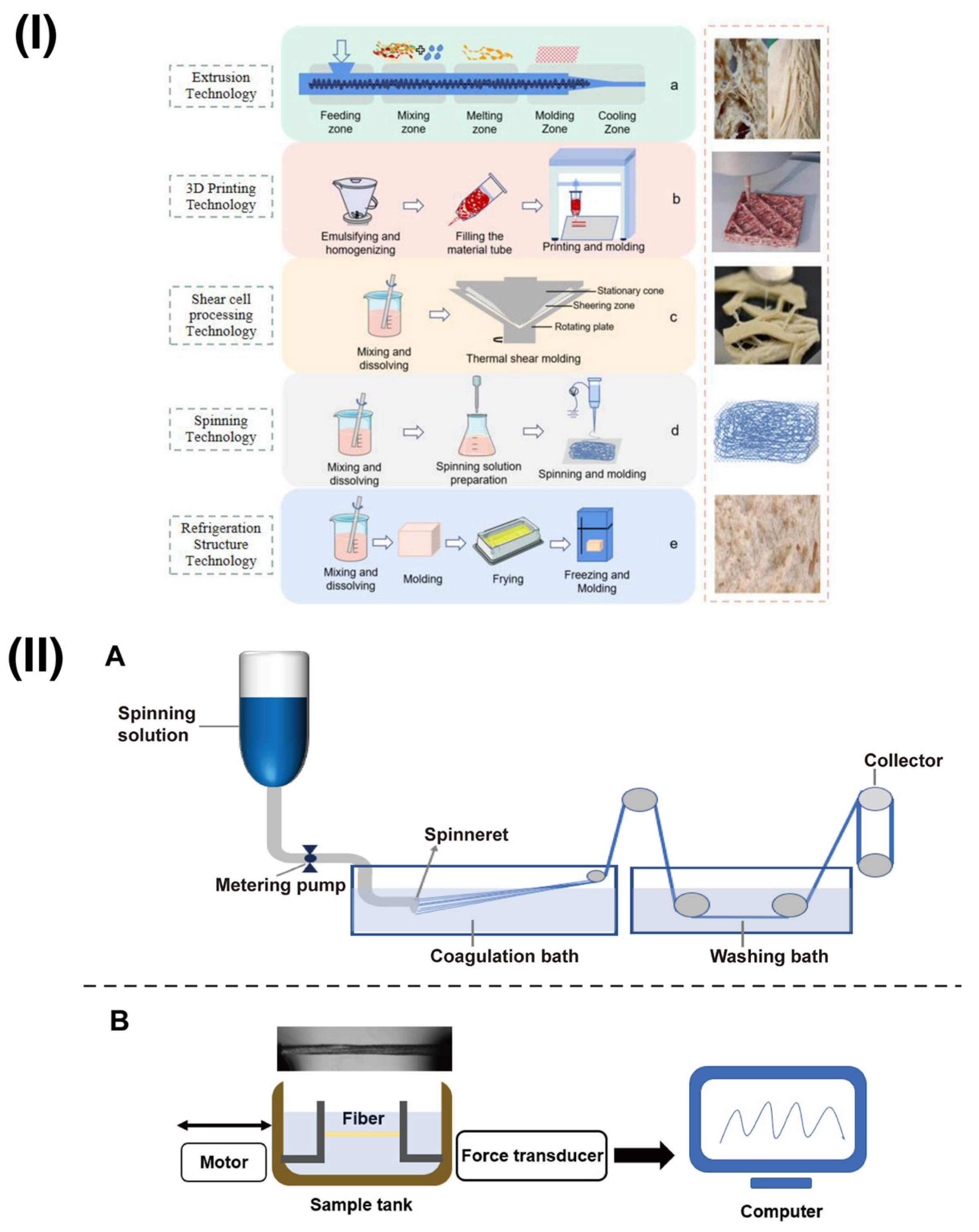

2.2. Processing Technology of Plant-Based Alternative Protein Products

2.2.1. Extrusion Technology

2.2.2. Three-Dimensional Printing

2.2.3. Emerging Processing Methods

2.2.4. Technology for Improved Functional Properties of Plant Proteins

| Processing Methodology | Advantages | Disadvantages | Refs. |

|---|---|---|---|

| Extrusion technology |

|

| [2,23,50,51] |

| 3D printing |

|

| [34,52,53] |

| Electrospinning |

|

| [39,54] |

| Shear cell | Requires lower mechanical energy than the extrusion technique. |

| [41,55] |

3. Nutrition in Processing

3.1. Protein

3.2. Carbohydrates and Dietary Fiber

3.3. Lipids

3.4. Vitamin and Mineral Salt

3.5. Moisture

3.6. Additives

4. Challenges and Prospectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tim, W.; Nathan, P. Global trends in meat consumption. Agr. Commod. 2019, 9, 96. [Google Scholar]

- Vatansever, S.; Tulbek, M.C.; Riaz, M.N. Low- and high-moisture extrusion of pulse proteins as plant-based meat ingredients: A review. Cereal Foods World 2020, 65, 12–14. [Google Scholar] [CrossRef]

- Alexandratos, N.; Bruinsma, J. World Agriculture towards 2030/2050: The 2012 Revision; Agricultural Development Economics Division, Food and Agriculture Organization of the United Nations: Rome, Italy, 2012. [Google Scholar]

- Sha, L.; Xiong, Y.L. Plant protein-based alternatives of reconstructed meat: Science, technology, and challenges. Trends Food Sci. Technol. 2020, 102, 51–61. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Keppler, J.K.; van der Goot, A.J. Functionality of ingredients and additives in plant-based meat analogues. Foods 2021, 10, 600. [Google Scholar] [CrossRef]

- Szenderák, J.; Fróna, D.; Rákos, M. Consumer acceptance of plant-based meat substitutes: A narrative review. Foods 2022, 11, 1274. [Google Scholar] [CrossRef] [PubMed]

- Rubio, N.R.; Xiang, N.; Kaplan, D.L. Plant-based and cell-based approaches to meat production. Nat. Commun. 2020, 11, 6276. [Google Scholar] [CrossRef]

- Xia, Y.; Qian, J.; Zhao, Y.; Zheng, B.; Wei, K.; Peng, B.; Yuan, J.; Xing, C.; Yan, W. Effects of food components and processing parameters on plant-based meat texture formation and evaluation methods. J. Texture Stud. 2023, 54, 394–409. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, W.; Li, L.; Gao, Y.; Lai, K.-H. Recent advances in the processing and manufacturing of plant-based meat. J. Agric. Food Chem. 2023, 71, 1276–1290. [Google Scholar] [CrossRef]

- Wang, Y.; Tuccillo, F.; Lampi, A.; Knaapila, A.; Pulkkinen, M.; Kariluoto, S.; Coda, R.; Edelmann, M.; Jouppila, K.; Sandell, M.; et al. Flavor challenges in extruded plant-based meat alternatives: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2898–2929. [Google Scholar] [CrossRef]

- Boye, J.; Aksay, S.; Roufik, S.; Ribéreau, S.; Mondor, M.; Farnworth, E.; Rajamohamed, S. Comparison of the functional properties of pea, chickpea and lentil protein concentrates processed using ultrafiltration and isoelectric precipitation techniques. Food Res. Int. 2010, 43, 537–546. [Google Scholar] [CrossRef]

- Kumar, M.; Tomar, M.; Potkule, J.; Verma, R.; Punia, S.; Mahapatra, A.; Belwal, T.; Dahuja, A.; Joshi, S.; Berwal, M.K.; et al. Advances in the plant protein extraction: Mechanism and recommendations. Food Hydrocoll. 2021, 115, 106595. [Google Scholar] [CrossRef]

- Cui, Q.; NI, X.; Zeng, L.; Tu, Z.; Li, J.; Sun, K.; Chen, X.; Li, X. Optimization of protein extraction and decoloration conditions for tea residues. Hortic. Plant J. 2017, 3, 172–176. [Google Scholar] [CrossRef]

- Hewage, A.; Olatunde, O.O.; Nimalaratne, C.; Malalgoda, M.; Aluko, R.E.; Bandara, N. Novel extraction technologies for developing plant protein ingredients with improved functionality. Trends Food Sci. Technol. 2022, 129, 492–511. [Google Scholar] [CrossRef]

- Tirgar, M.; Silcock, P.; Carne, A.; Birch, E.J. Effect of extraction method on functional properties of flaxseed protein concentrates. Food Chem. 2017, 215, 417–424. [Google Scholar] [CrossRef]

- Jung, S.; Lamsal, B.P.; Stepien, V.; Johnson, L.A.; Murphy, P.A. Functionality of soy protein produced by enzyme-assisted extraction. J. Am. Oil Chem. Soc. 2006, 83, 71–78. [Google Scholar] [CrossRef]

- Perović, M.N.; Jugović, Z.D.K.; Antov, M.G. Improved recovery of protein from soy grit by enzyme-assisted alkaline extraction. J. Food Eng. 2020, 276, 109894. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhou, X.; Zheng, Y.; Wang, D.; Deng, Y.; Zhao, Y. Impact of ultrasonication/shear emulsifying/microwave-assisted enzymatic extraction on rheological, structural, and functional properties of Akebia trifoliata (Thunb.) Koidz. seed protein isolates. Food Hydrocoll. 2021, 112, 106355. [Google Scholar] [CrossRef]

- Pojić, M.; Mišan, A.; Tiwari, B. Eco-innovative technologies for extraction of proteins for human consumption from renewable protein sources of plant origin. Trends Food Sci. Technol. 2018, 75, 93–104. [Google Scholar] [CrossRef]

- Rahman, M.; Dutta, S.; Lamsal, B.P. High-power sonication-assisted extraction of soy protein from defatted soy meals: Influence of important process parameters. J. Food Process. Eng. 2021, 44, e13720. [Google Scholar] [CrossRef]

- Dong, X.-Y.; Guo, L.-L.; Wei, F.; Li, J.-F.; Jiang, M.-L.; Li, G.-M.; Zhao, Y.-D.; Chen, H. Some characteristics and functional properties of rapeseed protein prepared by ultrasonication, ultrafiltration and isoelectric precipitation. J. Sci. Food Agric. 2011, 91, 1488–1498. [Google Scholar] [CrossRef]

- Lafarga, T.; Álvarez, C.; Bobo, G.; Aguiló-Aguayo, I. Characterization of functional properties of proteins from Ganxet beans (Phaseolus vulgaris L. var. Ganxet) isolated using an ultrasound-assisted methodology. LWT 2018, 98, 106–112. [Google Scholar] [CrossRef]

- Xia, S.; Shen, S.; Song, J.; Li, K.; Qin, X.; Jiang, X.; Xue, C.; Xue, Y. Physicochemical and structural properties of meat analogues from yeast and soy protein prepared via high-moisture extrusion. Food Chem. 2023, 402, 134265. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhang, M.; Sun, X.; Chen, F.; Wu, Q. Effects of AOT reverse micelle extraction on structure and emulsifying properties of soybean protein. J. Am. Oil Chem. Soc. 2021, 98, 923–932. [Google Scholar] [CrossRef]

- Samard, S.; Gu, B.; Ryu, G.-H. Effects of extrusion types, screw speed and addition of wheat gluten on physicochemical characteristics and cooking stability of meat analogues. J. Sci. Food Agric. 2019, 99, 4922–4931. [Google Scholar] [CrossRef]

- Bingol, E.B.; Akkaya, E.; Hampikyan, H.; Cetin, O.; Colak, H. Effect of nisin-EDTA combinations and modified atmosphere packaging on the survival of Salmonella enteritidis in Turkish type meatballs. CyTA—J. Food 2018, 16, 1030–1036. [Google Scholar] [CrossRef]

- Pietsch, V.L.; Werner, R.; Karbstein, H.P.; Emin, M.A. High moisture extrusion of wheat gluten: Relationship between process parameters, protein polymerization, and final product characteristics. J. Food Eng. 2019, 259, 3–11. [Google Scholar] [CrossRef]

- Riazi, F.; Tehrani, M.M.; Lammers, V.; Heinz, V.; Savadkoohi, S. Unexpected morphological modifications in high moisture extruded pea-flaxseed proteins: Part I, topological and conformational characteristics, textural attributes, and viscoelastic phenomena. Food Hydrocoll. 2023, 136, 108304. [Google Scholar] [CrossRef]

- Cho, S.Y.; Ryu, G.H. Effects of oyster mushroom addition on quality characteristics of full fat soy-based analog burger patty by extrusion process. J. Food Process. Eng. 2022, 46, e14128. [Google Scholar] [CrossRef]

- Ma, X.; Ryu, G. Effects of green tea contents on the quality and antioxidant properties of textured vegetable protein by extrusion-cooking. Food Sci. Biotechnol. 2019, 28, 67–74. [Google Scholar] [CrossRef]

- Wild, F.; Czerny, M.; Janssen, A.M.; Kole, A.P.W.; Zunabovic, M.; Domig, K.J. The evolution of a plant-based alternative to meat from niche markets to widely accepted meat alternatives. Argo Food. Ind. Hi Tech 2014, 25, 45–49. [Google Scholar]

- Dankar, I.; Haddarah, A.; Omar, F.E.; Sepulcre, F.; Pujolà, M. 3D printing technology: The new era for food customization and elaboration. Trends Food Sci. Technol. 2018, 75, 231–242. [Google Scholar] [CrossRef]

- Portanguen, S.; Tournayre, P.; Sicard, J.; Astruc, T.; Mirade, P.-S. Toward the design of functional foods and biobased products by 3D printing: A review. Trends Food Sci. Technol. 2019, 86, 188–198. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, M.; Bhandari, B. 3D Printing of steak-like foods based on textured soybean protein. Foods 2021, 10, 2011. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Tan, B.; Liu, M.; Tian, X.; Zheng, X.; Wang, L.; Wu, N.; Gao, K.; Zhai, X.; Liu, J.; et al. Effects of food additives on physicochemical properties of high moisture extrusion textured composite protein. Trans. Chin. Soc. Agric. Eng. 2019, 35, 294–302. [Google Scholar]

- Shi, Z.; Blecker, C.; Richel, A.; Wei, Z.; Chen, J.; Ren, G.; Guo, D.; Yao, Y.; Haubruge, E. Three-dimensional (3D) printability assessment of food-ink systems with superfine ground white common bean (Phaseolus vulgaris L.) protein based on different 3D food printers. LWT 2022, 155, 112906. [Google Scholar] [CrossRef]

- Shahbazi, M.; Jäger, H.; Chen, J.; Ettelaie, R. Construction of 3D printed reduced-fat meat analogue by emulsion gels. Part I: Flow behavior, thixotropic feature, and network structure of soy protein-based inks. Food. Hydrocolloid. 2021, 120, 106967. [Google Scholar] [CrossRef]

- Dutta, S.D.; Ganguly, K.; Jeong, M.-S.; Patel, D.K.; Patil, T.V.; Cho, S.-J.; Lim, K.-T. Bioengineered lab-grown meat-like constructs through 3D bioprinting of antioxidative protein hydrolysates. ACS Appl. Mater. Interfaces 2022, 14, 34513–34526. [Google Scholar] [CrossRef]

- Cui, B.; Liang, H.; Li, J.; Zhou, B.; Chen, W.; Liu, J.; Li, B. Development and characterization of edible plant-based fibers using a wet-spinning technique. Food Hydrocoll. 2022, 133, 107965. [Google Scholar] [CrossRef]

- Chen, D.; Jones, O.G.; Campanella, O.H. Plant protein-based fibers: Fabrication, characterization, and potential food applications. Crit. Rev. Food Sci. Nutr. 2021, 63, 4554–4578. [Google Scholar] [CrossRef]

- Krintiras, G.A.; Göbel, J.; van der Goot, A.J.; Stefanidis, G.D. Production of structured soy-based meat analogues using simple shear and heat in a couette cell. J. Food Eng. 2015, 160, 34–41. [Google Scholar] [CrossRef]

- Ebert, S.; Gibis, M.; Terjung, N.; Weiss, J. Survey of aqueous solubility, appearance, and pH of plant protein powders from carbohydrate and vegetable oil production. LWT 2020, 133, 110078. [Google Scholar] [CrossRef]

- Qi, X.; Li, Y.; Li, J.; Rong, L.; Pan, W.; Shen, M.; Xie, J. Fibrillation modification to improve the viscosity, emulsifying, and foaming properties of rice protein. Food Res. Int. 2023, 166, 112609. [Google Scholar] [CrossRef] [PubMed]

- Schlegel, K.; Sontheimer, K.; Hickisch, A.; Wani, A.A.; Eisner, P.; Schweiggert-Weisz, U. Enzymatic hydrolysis of lupin protein isolates—Changes in the molecular weight distribution, technofunctional characteristics, and sensory attributes. Food Sci. Nutr. 2019, 7, 2747–2759. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Xu, J.; Zhang, X.; Xie, F.; Zhang, S.; Jiang, L.; Qi, B.; Li, Y. Effect of pH-shifting treatment on the structural and functional properties of soybean protein isolate and its interactions with (–)-epigallocatechin-3-gallate. Process. Biochem. 2021, 101, 190–198. [Google Scholar] [CrossRef]

- Rathnakumar, K.; Balakrishnan, G.; Ramesh, B.; Sujayasree, O.J.; Pasupuleti, S.K.; Pandiselvam, R. Impact of emerging food processing technologies on structural and functional modification of proteins in plant-based meat alternatives: An updated review. J. Texture Stud. 2023, 54, 599–612. [Google Scholar] [CrossRef]

- Li, X.; Li, J. The Flavor of Plant-Based Meat Analogues. Cereal Foods World 2020, 65, 0040. [Google Scholar] [CrossRef]

- Ismail, I.; Hwang, Y.-H.; Joo, S.-T. Meat analog as future food: A review. J. Anim. Sci. Technol. 2020, 62, 111–120. [Google Scholar] [CrossRef]

- Zhao, D.; Huang, L.; Li, H.; Ren, Y.; Cao, J.; Zhang, T.; Liu, X. Ingredients and process affect the structural quality of recombinant plant-based meat alternatives and their components. Foods 2022, 11, 2202. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Jiang, Y.; Shah, F.; Xu, Y.; Wang, Q. High-moisture extrusion of peanut protein-/carrageenan/sodium alginate/wheat starch mixtures: Effect of different exogenous polysaccharides on the process forming a fibrous structure. Food Hydrocoll. 2020, 99, 105311. [Google Scholar] [CrossRef]

- Singh, M.; Trivedi, N.; Enamala, M.K.; Kuppam, C.; Parikh, P.; Nikolova, M.P.; Chavali, M. Plant-based meat analogue (PBMA) as a sustainable food: A concise review. Eur. Food Res. Technol. 2021, 247, 2499–2526. [Google Scholar] [CrossRef]

- Ko, H.J.; Wen, Y.; Choi, J.H.; Park, B.R.; Kim, H.W.; Park, H.J. Meat analog production through artificial muscle fiber insertion using coaxial nozzle-assisted three-dimensional food printing. Food Hydrocoll. 2021, 120, 106898. [Google Scholar] [CrossRef]

- Wen, Y.; Che, Q.T.; Kim, H.W.; Park, H.J. Potato starch altered the rheological, printing, and melting properties of 3D-printable fat analogs based on inulin emulsion-filled gels. Carbohydr. Polym. 2021, 269, 118285. [Google Scholar] [CrossRef] [PubMed]

- MacQueen, L.A.; Alver, C.G.; Chantre, C.O.; Ahn, S.; Cera, L.; Gonzalez, G.M.; O’connor, B.B.; Drennan, D.J.; Peters, M.M.; Motta, S.E.; et al. Muscle tissue engineering in fibrous gelatin: Implications for meat analogs. NPJ Sci. Food 2019, 3, 56. [Google Scholar] [CrossRef] [PubMed]

- Schreuders, F.K.; Dekkers, B.L.; Bodnár, I.; Erni, P.; Boom, R.M.; van der Goot, A.J. Comparing structuring potential of pea and soy protein with gluten for meat analogue preparation. J. Food Eng. 2019, 261, 32–39. [Google Scholar] [CrossRef]

- Mistry, K.; Sardar, S.D.; Alim, H.; Patel, N.; Thakur, M.; Jabbarova, D.; Ali, A. Plant Based Proteins: Sustainable Alternatives. Plant Sci. Today 2022, 9, 820–828. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Zhao, X.; Sun, P.; Zhao, D.; Jiang, L.; Sui, X. The texture of plant protein-based meat analogs by high moisture extrusion: A review. J. Texture Stud. 2023, 54, 351–364. [Google Scholar] [CrossRef]

- Sun, X.D.; Arntfield, S.D. Gelation properties of salt-extracted pea protein isolate induced by heat treatment: Effect of heating and cooling rate. Food Chem. 2011, 124, 1011–1016. [Google Scholar] [CrossRef]

- Akharume, F.U.; Aluko, R.E.; Adedeji, A.A. Modification of plant proteins for improved functionality: A review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 198–224. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Wang, J.; Zhang, Y.; Dong, L.; Wang, J.; Zhang, Y.; Dong, L. Latest research on glycation of plant-based protein during heat processing. J. Food. Sci. Tech. 2020, 38, 1–9. [Google Scholar]

- McClements, D.J.; Newman, E.; McClements, I.F. Plant-based milks: A review of the science underpinning their design, fabrication, and performance. Compr. Rev. Food Sci. Food Saf. 2019, 18, 2047–2067. [Google Scholar] [CrossRef]

- Tangyu, M.; Muller, J.; Bolten, C.J.; Wittmann, C. Fermentation of plant-based milk alternatives for improved flavour and nutritional value. Appl. Microbiol. Biotechnol. 2019, 103, 9263–9275. [Google Scholar] [CrossRef]

- Pranoto, Y.; Anggrahini, S.; Efendi, Z. Effect of natural and Lactobacillus plantarum fermentation on in-vitro protein and starch digestibilities of sorghum flour. Food Biosci. 2013, 2, 46–52. [Google Scholar] [CrossRef]

- Nkhata, S.G.; Ayua, E.; Kamau, E.H.; Shingiro, J. Fermentation and germination improve nutritional value of cereals and legumes through activation of endogenous enzymes. Food Sci. Nutr. 2018, 6, 2446–2458. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Jiang, Y.; Faisal, S.; Wei, L.; Cao, C.; Yan, W.; Wang, Q. Converting peanut protein biomass waste into “double green” meat substitutes using a high-moisture extrusion process: A multiscale method to explore a process for forming a meat-like fibrous structure. J. Agric. Food Chem. 2019, 67, 10713–10725. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.; Hu, X.; Luo, S.; Liu, W.; Chen, J.; Zeng, Z.; Liu, C. Properties of starch after extrusion: A review. Starch-Stärke 2018, 70, 1700110. [Google Scholar] [CrossRef]

- Huang, X.; Liu, H.; Ma, Y.; Mai, S.; Li, C. Effects of extrusion on starch molecular degradation, order–disorder structural transition and digestibility—A review. Foods 2022, 11, 2538. [Google Scholar] [CrossRef]

- Rong, L.; Chen, X.; Shen, M.; Yang, J.; Qi, X.; Li, Y.; Xie, J. The application of 3D printing technology on starch-based product: A review. Trends Food Sci. Technol. 2023, 134, 149–161. [Google Scholar] [CrossRef]

- Bis-Souza, C.V.; Ozaki, M.M.; Vidal, V.A.S.; Pollonio, M.A.R.; Penna, A.L.B.; Barretto, A.C.S. Can dietary fiber improve the technological characteristics and sensory acceptance of low-fat Italian type salami? J. Food Sci. Technol. 2020, 57, 1003–1012. [Google Scholar] [CrossRef]

- Madeline Timm, J.S. Dietary fiber: Classification and physiological role. Encycl. Hum. Nutr. 2023, 1–4, 209–216. [Google Scholar]

- Twarogowska, A.; Van Droogenbroeck, B.; Fraeye, I. Application of Belgian endive (Cichorium intybus var. foliosum) dietary fiber concentrate to improve nutritional value and functional properties of plant-based burgers. Food Biosci. 2022, 48, 101825. [Google Scholar] [CrossRef]

- Zaini, H.B.M.; Mantihal, S.; Ng, F.W.Y.; Pindi, W. The incorporation of green peas as the source of dietary fiber in developing functional chicken nuggets. J. Food Process. Preserv. 2021, 45, e15412. [Google Scholar] [CrossRef]

- Ramos-Diaz, J.; Kantanen, K.; Edelmann, J.; Jouppila, K.; Sontag-Strohm, T.; Piironen, V. Functionality of oat fiber concentrate and faba bean protein concentrate in plant-based substitutes for minced meat. Curr. Res. Food Sci. 2022, 5, 858–867. [Google Scholar] [CrossRef]

- Ain, H.B.U.; Saeed, F.; Ahmed, A.; Khan, M.A.; Niaz, B.; Tufail, T. Improving the physicochemical properties of partially enhanced soluble dietary fiber through innovative techniques: A coherent review. J. Food Process. Preserv. 2019, 43, e13917. [Google Scholar] [CrossRef]

- Filannino, P.; Bai, Y.; Di Cagno, R.; Gobbetti, M.; Gänzle, M.G. Metabolism of phenolic compounds by Lactobacillus spp. during fermentation of cherry juice and broccoli puree. Food Microbiol. 2015, 46, 272–279. [Google Scholar] [CrossRef]

- Yashini, M.; Sunil, C.K.; Sahana, S.; Hemanth, S.D.; Chidanand, D.; Rawson, A. Protein-based fat replacers—A review of recent advances. Food Rev. Int. 2021, 37, 197–223. [Google Scholar] [CrossRef]

- Beniwal, A.S.; Singh, J.; Kaur, L.; Hardacre, A.; Singh, H. Meat analogs: Protein restructuring during thermomechanical processing. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1221–1249. [Google Scholar] [CrossRef]

- Wu, M.; Huang, X.; Gao, F.; Sun, Y.; Duan, H.; Li, D. Dynamic mechanical properties and fractal analysis of texturized soybean protein/wheat gluten composite produced by high moisture extrusion. Int. J. Food Sci. Technol. 2019, 54, 499–508. [Google Scholar] [CrossRef]

- Ran, X.; Lou, X.; Zheng, H.; Gu, Q.; Yang, H. Improving the texture and rheological qualities of a plant-based fishball analogue by using konjac glucomannan to enhance crosslinks with soy protein. Innov. Food Sci. Emerg. Technol. 2022, 75, 102910. [Google Scholar] [CrossRef]

- Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the physicochemical and structural properties and the sensory characteristics of meat analogues prepared with various non-animal based liquid additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef]

- Guo, Z.; Teng, F.; Huang, Z.; Lv, B.; Lv, X.; Babich, O.; Yu, W.; Li, Y.; Wang, Z.; Jiang, L. Effects of material characteristics on the structural characteristics and flavor substances retention of meat analogs. Food Hydrocoll. 2020, 105, 105752. [Google Scholar] [CrossRef]

- Lampi, A.-M.; Damerau, A.; Li, J.; Moisio, T.; Partanen, R.; Forssell, P.; Piironen, V. Changes in lipids and volatile compounds of oat flours and extrudates during processing and storage. J. Cereal Sci. 2015, 62, 102–109. [Google Scholar] [CrossRef]

- Fresán, U.; Mejia, M.A.; Craig, W.J.; Jaceldo-Siegl, K.; Sabaté, J. Meat analogs from different protein sources: A comparison of their sustainability and nutritional content. Sustainability 2019, 11, 3231. [Google Scholar] [CrossRef]

- Riaz, M.N.; Asif, M.; Ali, R. Stability of Vitamins during Extrusion. Crit. Rev. Food Sci. Nutr. 2009, 49, 361–368. [Google Scholar] [CrossRef]

- Brennan, C.; Brennan, M.; Derbyshire, E.; Tiwari, B.K. Effects of extrusion on the polyphenols, vitamins and antioxidant activity of foods. Trends Food Sci. Technol. 2011, 22, 570–575. [Google Scholar] [CrossRef]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and extruded products: Changes in quality attributes as affected by extrusion process parameters: A review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef]

- Schmid, E.; Farahnaky, A.; Adhikari, B.; Torley, P.J. High moisture extrusion cooking of meat analogs: A review of mechanisms of protein texturization. Compr. Rev. Food Sci. Food Saf. 2022, 21, 4573–4609. [Google Scholar] [CrossRef]

- Smetana, S.; Larki, N.A.; Pernutz, C.; Franke, K.; Bindrich, U.; Toepfl, S.; Heinz, V. Structure design of insect-based meat analogs with high-moisture extrusion. J. Food Eng. 2018, 229, 83–85. [Google Scholar] [CrossRef]

- McClements, D.J.; Grossmann, L. The science of plant-based foods: Constructing next-generation meat, fish, milk, and egg analogs. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4049–4100. [Google Scholar] [CrossRef]

- Sow, L.C.; Toh, N.Z.Y.; Wong, C.W.; Yang, H. Combination of sodium alginate with tilapia fish gelatin for improved texture properties and nanostructure modification. Food Hydrocoll. 2019, 94, 459–467. [Google Scholar] [CrossRef]

- Li, R.; Jia, X.; Wang, Y.; Li, Y.; Cheng, Y. The effects of extrusion processing on rheological and physicochemical properties of sesbania gum. Food Hydrocoll. 2019, 90, 35–40. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, X.; Zhang, X.; Liu, H. The effects of processing on bioactive compounds and biological activities of sorghum grains. Molecules 2022, 27, 3246. [Google Scholar] [CrossRef]

- Abdullah, F.A.A.; Dordevic, D.; Kabourkova, E.; Zemancová, J.; Dordevic, S. Antioxidant and sensorial properties: Meat analogues versus conventional meat products. Processes 2022, 10, 1864. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.; Wang, L.; Zhang, Z. Plant-Based Meat Proteins: Processing, Nutrition Composition, and Future Prospects. Foods 2023, 12, 4180. https://doi.org/10.3390/foods12224180

Yu J, Wang L, Zhang Z. Plant-Based Meat Proteins: Processing, Nutrition Composition, and Future Prospects. Foods. 2023; 12(22):4180. https://doi.org/10.3390/foods12224180

Chicago/Turabian StyleYu, Jialing, Liyuan Wang, and Zhaowei Zhang. 2023. "Plant-Based Meat Proteins: Processing, Nutrition Composition, and Future Prospects" Foods 12, no. 22: 4180. https://doi.org/10.3390/foods12224180

APA StyleYu, J., Wang, L., & Zhang, Z. (2023). Plant-Based Meat Proteins: Processing, Nutrition Composition, and Future Prospects. Foods, 12(22), 4180. https://doi.org/10.3390/foods12224180