Applications of Gas Sensing in Food Quality Detection: A Review

Abstract

:1. Introduction

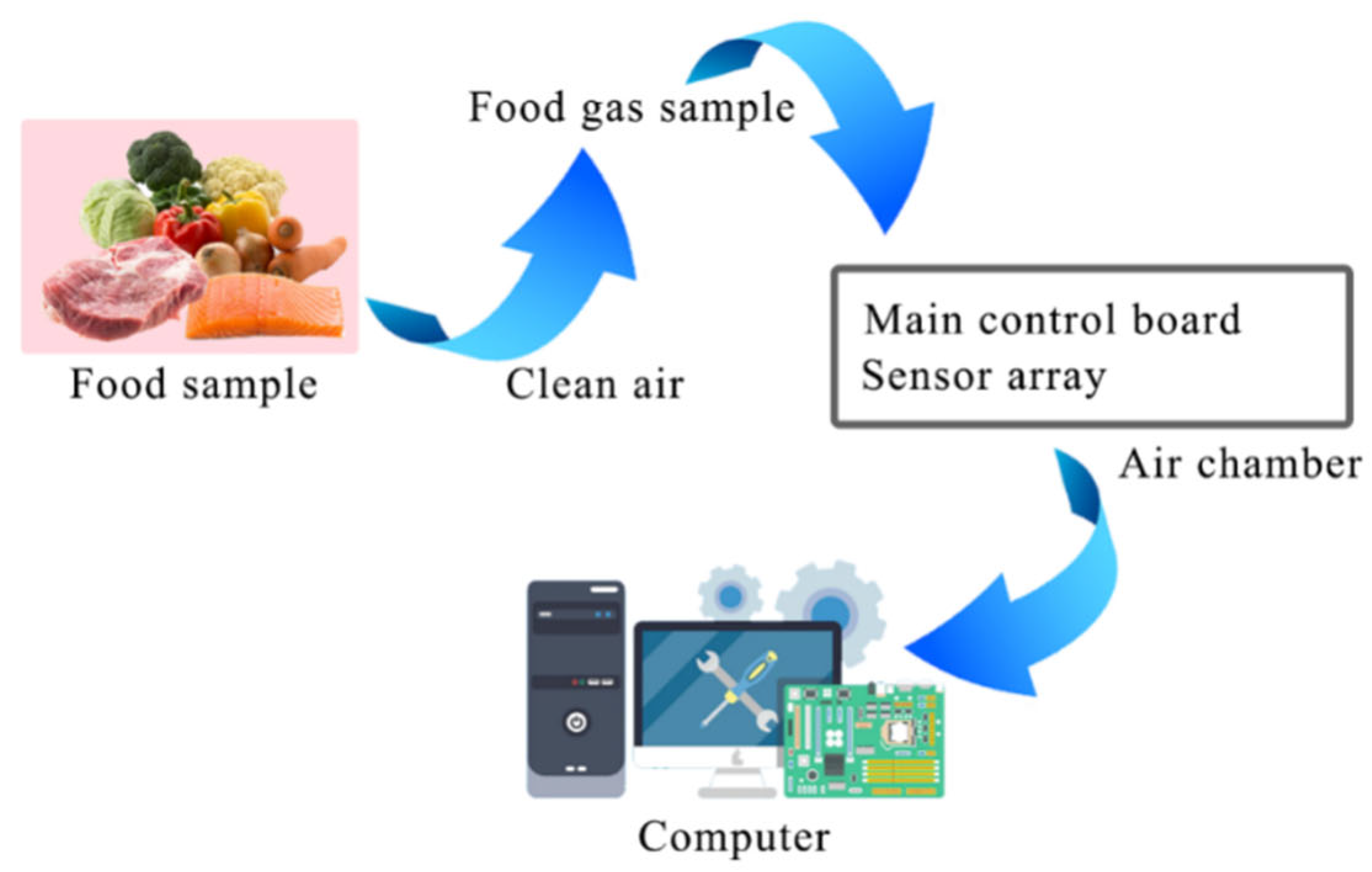

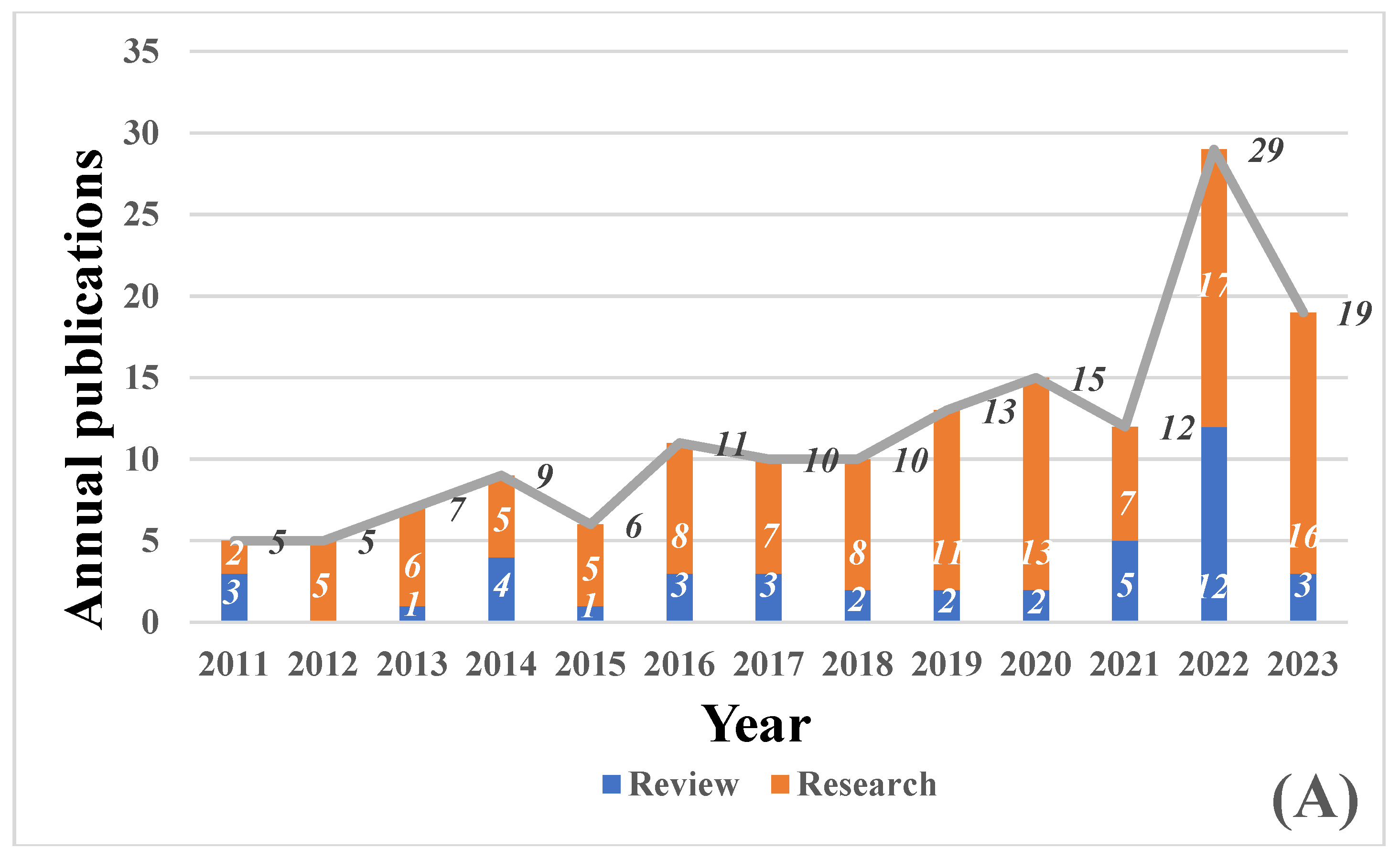

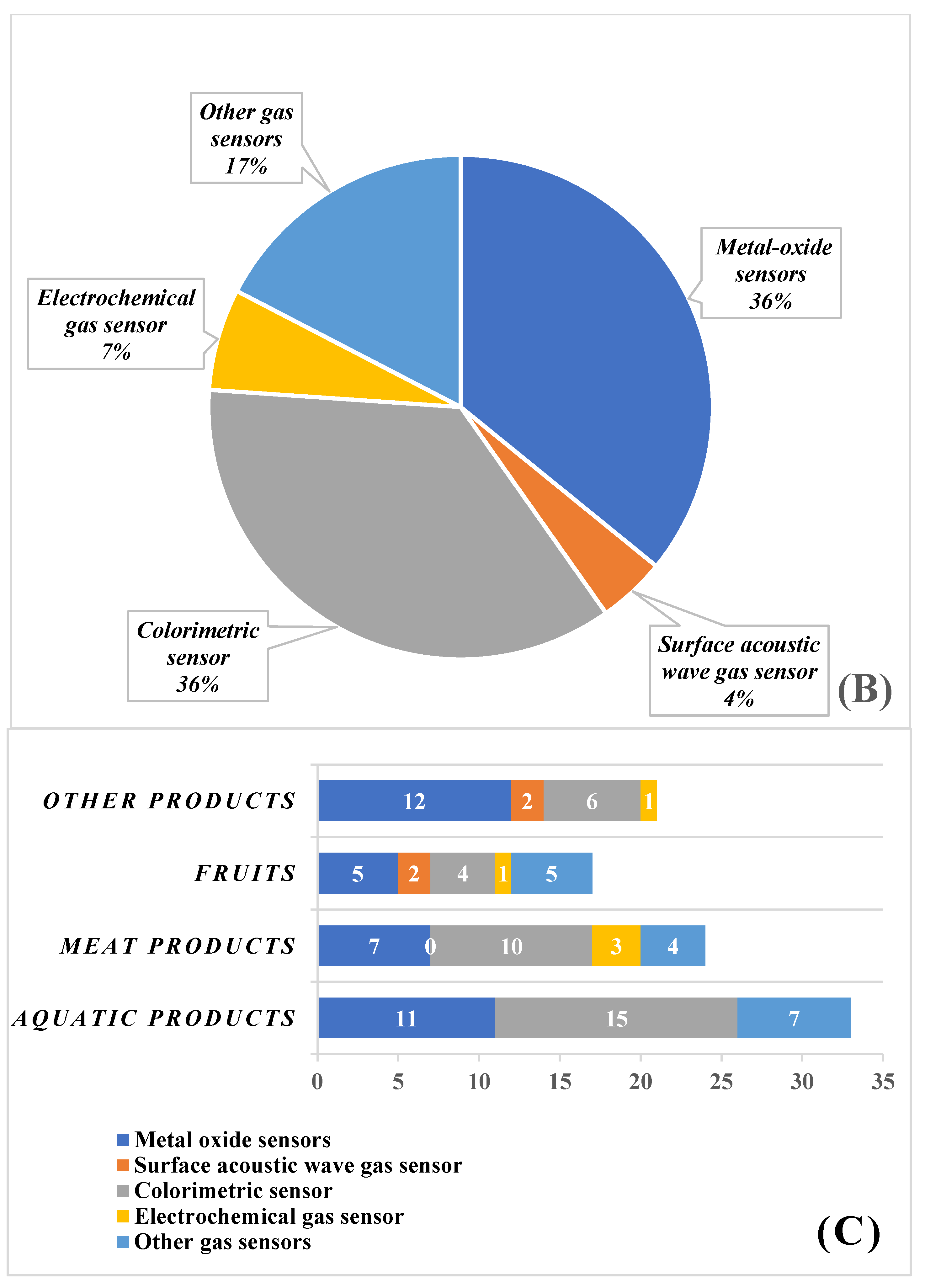

2. Overview of Gas Sensor Technology on Food Quality Monitoring

3. Gas sensors for Food Quality Monitoring

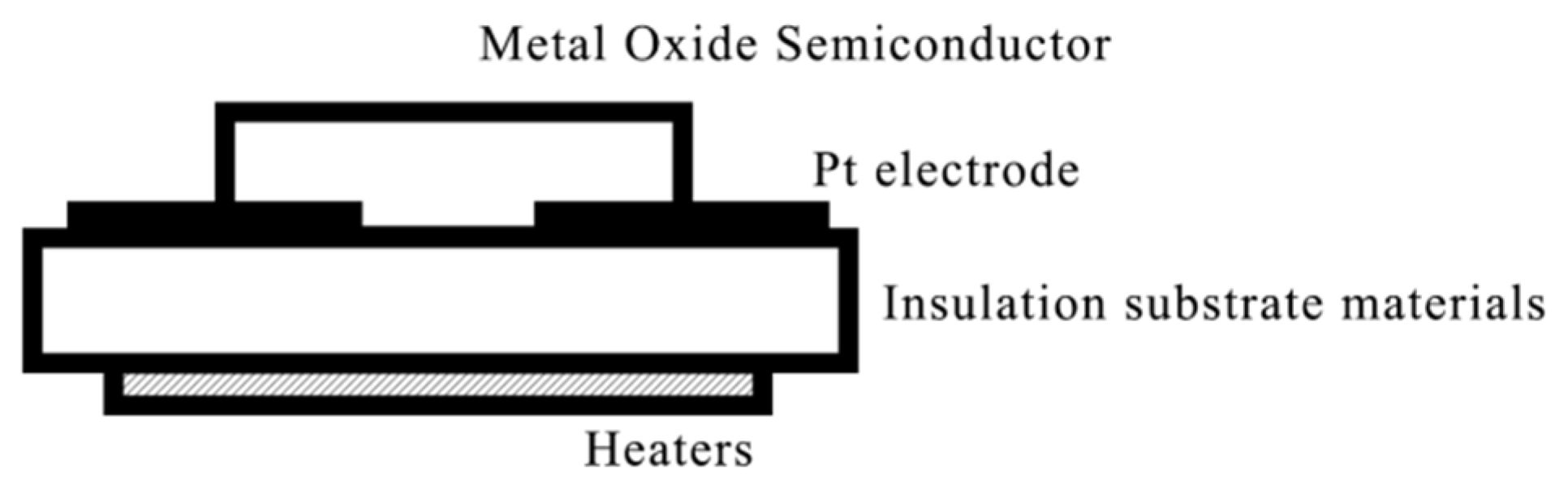

3.1. Metal Oxide Sensors

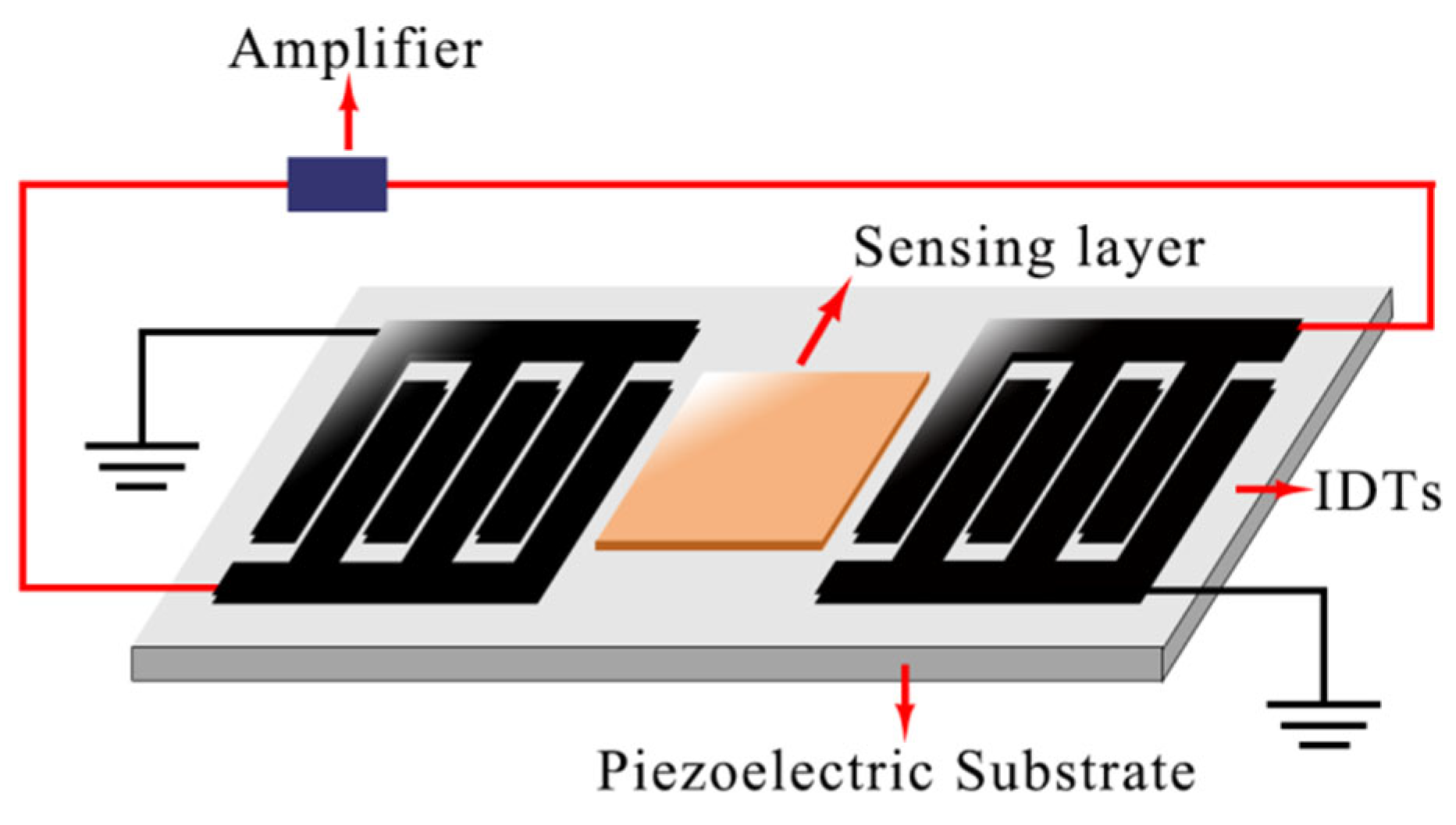

3.2. Surface Acoustic Wave Gas Sensors

3.3. Colorimetric Sensors

3.4. Electrochemical Gas Sensors

3.5. Sensor Arrays

4. The Application of Gas Sensors in Food Quality Monitoring

4.1. Aquatic Products

4.2. Meat Products

4.3. Fruit Products

4.4. Dairy Products

4.5. Grain and Oil Products

4.6. Alcohol Products

5. Future Outlook

- (a)

- Enhancing the immunity and stability of gas sensors holds paramount importance in the realm of food quality monitoring. The complexity of real-world food storage and transportation environments can introduce various challenges, potentially leading to inaccuracies in the data collected during freshness monitoring. Factors like sensor aging, reduced catalytic activity, and fluctuations in temperature and humidity can result in errors in sensor readings, adversely affecting the accuracy of detection. Therefore, focusing on enhancing the sensor array and the system’s resistance to interference becomes a crucial avenue for optimizing the identification accuracy of the system.

- (b)

- Advancements in gas sensors with cross-sensitivity to volatile compounds in food are crucial for effective food quality monitoring. To optimize the sensitivity, response time, cross-sensitivity, and doping process of these sensors, adjustments to their materials or structures become necessary. By incorporating such improvements, gas sensors can provide signals carrying more comprehensive information, necessitating the exploration of efficient data processing techniques. Techniques such as feature extraction and selection, pattern recognition, and regression modeling enable effective analysis and utilization of sensor signals, ultimately enhancing the accuracy and efficiency of food quality monitoring.

- (c)

- Developing highly sensitive gas sensors with improved detection limits remains a key focus in the field of sensor technology. Researchers are actively investigating materials with suitable surface and structural properties, exploring both rigid and flexible options to enhance sensor performance. By optimizing parameters such as sensitivity, response time, and cross-sensitivity, and refining doping processes and fabrication techniques, it is possible to achieve flexible gas sensors that offer remarkable sensitivity and stability. These sensors find significant applications in wearable electronic devices and electronic skin, presenting exciting possibilities for diverse industries. Despite these advancements, the selection of appropriate flexible substrates and sensing materials poses a primary challenge in the development of flexible gas sensors.

- (d)

- The miniaturization of sensors and real-time monitoring of smart data represent crucial directions in advancing gas sensors for food freshness monitoring. To effectively address the complexities of food storage and transportation, the expansion of test samples and the establishment of a comprehensive database characterizing the freshness of mixed food products are essential steps. Achieving more accurate food freshness monitoring requires not only expanding test samples but also optimizing model parameters and enhancing immunity to interference. As big data, the Internet of Things (IoT), 5G communication technology, and artificial intelligence continue to progress, future research should focus on achieving the portability of algorithmic models. This will enable faster and simpler food freshness recognition, promoting practical applications in various scenarios. Currently, freshness detection and recognition predominantly rely on odor information, offering relatively limited insights into food freshness using gas sensors. Therefore, future investigations could explore the integration of other detection methods, such as image recognition and colony detection, to achieve multi-sensory fusion detection and evaluation. This approach would lead to more accurate, intelligent, and rapid discrimination and monitoring of food freshness.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Persaud, K.; Dodd, G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 1982, 299, 355. [Google Scholar] [CrossRef]

- Gutierrez, J.; Horrillo, M.C. Advances in artificial olfaction: Sensors and applications. Talanta 2014, 124, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Fu, C.; Gao, Z.; Wei, F.; Ying, Y.; Xu, C.; Fu, G. Nanomaterial-based gas sensors: A review. Instrum. Sci. Technol. 2017, 46, 115–145. [Google Scholar] [CrossRef]

- Chiu, S.W.; Tang, K.T. Towards a chemiresistive sensor-integrated electronic nose: A review. Sensors 2013, 13, 14214–14247. [Google Scholar] [CrossRef]

- Wang, X.; Feng, H.; Chen, T.; Zhao, S.; Zhang, J.; Zhang, X. Gas sensor technologies and mathematical modelling for quality sensing in fruit and vegetable cold chains: A review. Trends Food Sci. Technol. 2021, 110, 483–492. [Google Scholar] [CrossRef]

- Mirzaei, M.S.; Taherpour, A.A. Tautomeric preferences of the cis and trans isomers of axitinib. Chem. Phys. 2018, 507, 10–18. [Google Scholar] [CrossRef]

- Ponzoni, A.; Comini, E.; Concina, I.; Ferroni, M.; Falasconi, M.; Gobbi, E.; Sberveglieri, V.; Sberveglieri, G. Nanostructured metal oxide gas sensors, a survey of applications carried out at sensor lab, Brescia (Italy) in the security and food quality fields. Sensors 2012, 12, 17023–17045. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, S.; Wang, X.; Huang, J.; Pan, W.; Zhang, J.; Meteku, B.E.; Zeng, J. UV illumination-enhanced ultrasensitive ammonia gas sensor based on (001)TiO2/MXene heterostructure for food spoilage detection. J. Hazard. Mater. 2022, 423, 127160. [Google Scholar] [CrossRef]

- Shalini Devi, K.S.; Anantharamakrishnan, A.; Maheswari Krishnan, U. Expanding horizons of metal oxide-based chemical and electrochemical sensors. Electroanalysis 2021, 33, 1979–1996. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, J.-H. Highly sensitive and selective gas sensors using p-type oxide semiconductors: Overview. Sens. Actuators B Chem. 2014, 192, 607–627. [Google Scholar]

- Lin, T.; Lv, X.; Hu, Z.; Xu, A.; Feng, C. Semiconductor metal oxides as chemoresistive sensors for detecting volatile organic compounds. Sensors 2019, 19, 233. [Google Scholar] [CrossRef]

- Ren, Q.; Cao, Y.-Q.; Arulraj, D.; Liu, C.; Wu, D.; Li, W.-M.; Li, A.-D. Review—Resistive-type hydrogen sensors based on zinc oxide nanostructures. J. Electrochem. Soc. 2020, 167, 067528. [Google Scholar] [CrossRef]

- Tiwale, N. Zinc oxide nanowire gas sensors: Fabrication, functionalisation and devices. Mater. Sci. Technol. 2015, 31, 1681–1697. [Google Scholar]

- Weston, M.; Geng, S.; Chandrawati, R. Food sensors: Challenges and opportunities. Adv. Mater. Technol. 2021, 6, 2001242. [Google Scholar] [CrossRef]

- Pereira, P.F.M.; de Sousa Picciani, P.H.; Calado, V.; Tonon, R.V. Electrical gas sensors for meat freshness assessment and quality monitoring: A review. Trends Food Sci. Technol. 2021, 118, 36–44. [Google Scholar] [CrossRef]

- Galstyan, V.; Bhandari, M.; Sberveglieri, V.; Sberveglieri, G.; Comini, E. Metal oxide nanostructures in food applications: Quality control and packaging. Chemosensors 2018, 6, 16. [Google Scholar] [CrossRef]

- Comini, E. Metal oxides nanowires chemical/gas sensors: Recent advances. Mater. Today Adv. 2020, 7, 100099. [Google Scholar] [CrossRef]

- Abbatangelo, M.; Nunez-Carmona, E.; Sberveglieri, V.; Zappa, D.; Comini, E.; Sberveglieri, G. An array of MOX sensors and ANNs to assess grated Parmigiano Reggiano cheese packs’ compliance with CFPR guidelines. BioSensors 2020, 10, 47. [Google Scholar] [CrossRef]

- Li, P.; Geng, J.; Li, H.; Niu, Z. Fish meal freshness detection by GBDT based on a portable electronic nose system and HS-SPME–GC–MS. Eur. Food Res. Technol. 2020, 246, 1129–1140. [Google Scholar] [CrossRef]

- Vajdi, M.; Varidi, M.J.; Varidi, M.; Mohebbi, M. Using electronic nose to recognize fish spoilage with an optimum classifier. J. Food Meas. Charact. 2019, 13, 1205–1217. [Google Scholar] [CrossRef]

- Edita, R.; Darius, G.; Vinauskienė, R.; Eisinaitė, V.; Balčiūnas, G.; Dobilienė, J.; Tamkutė, L. Rapid evaluation of fresh chicken meat quality by electronic nose. Czech J. Food Sci. 2018, 36, 420–426. [Google Scholar]

- Lam, M.B.; Nguyen, T.-H.; Chung, W.-Y. Deep learning-based food quality estimation using radio frequency-powered sensor mote. IEEE Access 2020, 8, 88360–88371. [Google Scholar] [CrossRef]

- McGinn, C.K.; Lamport, Z.A.; Kymissis, I. Review of gravimetric sensing of volatile organic compounds. ACS Sens. 2020, 5, 1514–1534. [Google Scholar] [CrossRef]

- Mujahid, A.; Afzal, A.; Dickert, F.L. An overview of high frequency acoustic sensors-QCMs, SAWs and FBARs-chemical and biochemical applications. Sensors 2019, 19, 4395. [Google Scholar] [CrossRef] [PubMed]

- Lange, K. Bulk and surface acoustic wave sensor arrays for multi-analyte detection: A review. Sensors 2019, 19, 5382. [Google Scholar] [CrossRef] [PubMed]

- Panneerselvam, G.; Thirumal, V.; Pandya, H.M. Review of surface acoustic wave sensors for the detection and identification of toxic environmental gases/vapours. Arch. Acoust. 2018, 43, 357–367. [Google Scholar]

- Vallone, S.; Sivertsen, H.; Anthon, G.E.; Barrett, D.M.; Mitcham, E.J.; Ebeler, S.E.; Zakharov, F. An integrated approach for flavour quality evaluation in muskmelon (Cucumis melo L. Reticulatus group) during ripening. Food Chem. 2013, 139, 171–183. [Google Scholar] [CrossRef]

- Di Pietrantonio, F.; Benetti, M.; Cannata, D.; Verona, E.; Palla-Papavlu, A.; Fernandez-Pradas, J.M.; Serra, P.; Staiano, M.; Varriale, A.; D’Auria, S. A surface acoustic wave bio-electronic nose for detection of volatile odorant molecules. Biosens. Bioelectron. 2015, 67, 516–523. [Google Scholar] [CrossRef]

- Zheng, L.; Gao, Y.; Zhang, J.; Li, J.; Yu, Y.; Hui, G. Chinese quince (Cydonia oblonga Miller) freshness rapid determination method using surface acoustic wave resonator combined with electronic nose. Int. J. Food Prop. 2016, 19, 2623–2634. [Google Scholar] [CrossRef]

- Cali, K.; Tuccori, E.; Persaud, K.C. Gravimetric biosensors. Methods Enzym. 2020, 642, 435–468. [Google Scholar]

- Ma, Y.; Li, Y.; Ma, K.; Wang, Z. Optical colorimetric sensor arrays for chemical and biological analysis. Sci. China Chem. 2018, 61, 643–655. [Google Scholar] [CrossRef]

- Mallov, I.; Jeeva, F.; Caputo, C.B. An edible genipin-based sensor for biogenic amine detection. J. Chem. Technol. Biotechnol. 2020, 97, 830–836. [Google Scholar] [CrossRef]

- Xiao-Wei, H.; Xiao-Bo, Z.; Ji-Yong, S.; Zhi-Hua, L.; Jie-Wen, Z. Colorimetric sensor arrays based on chemo-responsive dyes for food odor visualization. Trends Food Sci. Technol. 2018, 81, 90–107. [Google Scholar] [CrossRef]

- Piriya, V.S.A.; Joseph, P.; Daniel, S.C.G.K.; Lakshmanan, S.; Kinoshita, T.; Muthusamy, S. Colorimetric sensors for rapid detection of various analytes. Mater. Sci. Eng. C 2017, 78, 1231–1245. [Google Scholar] [CrossRef] [PubMed]

- Xiao-Wei, H.; Zhi-Hua, L.; Xiao-Bo, Z.; Ji-Yong, S.; Han-Ping, M.; Jie-Wen, Z.; Li-Min, H.; Mel, H. Detection of meat-borne trimethylamine based on nanoporous colorimetric sensor arrays. Food Chem. 2016, 197, 930–936. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Nizamidin, P.; Zhang, Y.; Kari, N.; Yimit, A. Detection of trimethylamine based on a managnese tetraphenylporphyrin optical waveguide sensing element. Anal. Sci. 2018, 34, 559–565. [Google Scholar] [CrossRef]

- Alberti, G.; Zanoni, C.; Magnaghi, L.R.; Biesuz, R. Gold and silver nanoparticle-based colorimetric sensors: New trends and applications. Chemosensors 2021, 9, 305. [Google Scholar] [CrossRef]

- Sun, J.; Lu, Y.; He, L.; Pang, J.; Yang, F.; Liu, Y. Colorimetric sensor array based on gold nanoparticles: Design principles and recent advances. TrAC Trends Anal. Chem. 2020, 122, 115754. [Google Scholar] [CrossRef]

- Guth, U.; Vonau, W.; Zosel, J. Recent developments in electrochemical sensor application and technology—A review. Meas. Sci. Technol. 2009, 20, 042002. [Google Scholar] [CrossRef]

- Manjakkal, L.; Szwagierczak, D.; Dahiya, R. Metal oxides based electrochemical pH sensors: Current progress and future perspectives. Prog. Mater. Sci. 2020, 109, 100635. [Google Scholar] [CrossRef]

- Saeed, R.; Feng, H.; Wang, X.; Zhang, X.; Fu, Z. Fish quality evaluation by sensor and machine learning: A mechanistic review. Food Control 2022, 137, 108902. [Google Scholar] [CrossRef]

- Baranwal, J.; Barse, B.; Gatto, G.; Broncova, G.; Kumar, A. Electrochemical sensors and their applications: A review. Chemosensors 2022, 10, 363. [Google Scholar] [CrossRef]

- Ma, L.; Wang, L.; Chen, R.; Chang, K.; Wang, S.; Hu, X.; Sun, X.; Lu, Z.; Sun, H.; Guo, Q.; et al. A low cost compact measurement system constructed using a smart electrochemical sensor for the real-time discrimination of fruit ripening. Sensors 2016, 16, 501. [Google Scholar] [CrossRef]

- Pérez-Esteve, E.; Fuentes, A.; Grau, R.; Fernández-Segovia, I.; Masot, R.; Alcañiz, M.; Barat, J.M. Use of impedance spectroscopy for predicting freshness of sea bream (Sparus aurata). Food Control 2014, 35, 360–365. [Google Scholar] [CrossRef]

- Goldschmidt, M.C. Biosensors–scope in microbiological analysis. In Encyclopedia of Food Microbiology; Academic Press: Cambridge, MA, USA, 2014; pp. 274–287. [Google Scholar]

- Murtada, K.; Moreno, V. Nanomaterials-based electrochemical sensors for the detection of aroma compounds-towards analytical approach. J. Electroanal. Chem. 2020, 861, 113988. [Google Scholar] [CrossRef]

- Costello, B.P.J.d.L.; Ewen, R.J.; Gunson, H.E.; Ratcliffe, N.M.; Spencer-Phillips, P.T.N. The development of a sensor system for the early detection of soft rot in stored potato tubers. Meas. Sci. Technol. 2000, 11, 1685–1691. [Google Scholar] [CrossRef]

- Lotfivand, N.; Abdolzadeh, V.; Hamidon, M.N. Artificial olfactory system with fault-tolerant sensor array. ISA Trans. 2016, 63, 425–435. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Gao, F.; Wu, Q.; Zhang, J.; Xue, Y.; Wan, H.; Wang, P. Real-time assessment of food freshness in refrigerators based on a miniaturized electronic nose. Anal. Methods 2018, 10, 4741–4749. [Google Scholar] [CrossRef]

- Yuan, Z.; Bariya, M.; Fahad, H.M.; Wu, J.; Han, R.; Gupta, N.; Javey, A. Trace-level, multi-gas detection for food quality assessment based on decorated silicon transistor arrays. Adv. Mater. 2020, 32, e1908385. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Pu, H.; Sun, D.-W. Novel techniques for evaluating freshness quality attributes of fish: A review of recent developments. Trends Food Sci. Technol. 2019, 83, 259–273. [Google Scholar] [CrossRef]

- Han, F.; Huang, X.; Teye, E.; Gu, F.; Gu, H. Nondestructive detection of fish freshness during its preservation by combining electronic nose and electronic tongue techniques in conjunction with chemometric analysis. Anal. Methods 2014, 6, 529–536. [Google Scholar] [CrossRef]

- Li, J.; Feng, H.; Liu, W.; Gao, Y.; Hui, G. Design of a portable electronic nose system and application in k value prediction for large yellow croaker (Pseudosciaena crocea). Food Anal. Methods 2016, 9, 2943–2951. [Google Scholar] [CrossRef]

- Semeano, A.T.S.; Maffei, D.F.; Palma, S.; Li, R.W.C.; Franco, B.; Roque, A.C.A.; Gruber, J. Tilapia fish microbial spoilage monitored by a single optical gas sensor. Food Control 2018, 89, 72–76. [Google Scholar] [CrossRef] [PubMed]

- González-Ceballos, L.; Melero, B.; Trigo-López, M.; Vallejos, S.; Muñoz, A.; García, F.C.; Fernandez-Muiño, M.A.; Sancho, M.T.; García, J.M. Functional aromatic polyamides for the preparation of coated fibres as smart labels for the visual detection of biogenic amine vapours and fish spoilage. Sens. Actuators B Chem. 2020, 304, 127249. [Google Scholar] [CrossRef]

- Chen, W.; Wang, Z.; Gu, S.; Wang, J.; Wang, Y.; Wei, Z. Hydrophobic amino-functionalized graphene oxide nanocomposite for aldehydes detection in fish fillets. Sens. Actuators B Chem. 2020, 306, 127579. [Google Scholar] [CrossRef]

- Langkvist, M.; Coradeschi, S.; Loutfi, A.; Rayappan, J.B. Fast classification of meat spoilage markers using nanostructured ZnO thin films and unsupervised feature learning. Sensors 2013, 13, 1578–1592. [Google Scholar] [CrossRef]

- Perez de Vargas-Sansalvador, I.M.; Erenas, M.M.; Martinez-Olmos, A.; Mirza-Montoro, F.; Diamond, D.; Capitan-Vallvey, L.F. Smartphone based meat freshness detection. Talanta 2020, 216, 120985. [Google Scholar] [CrossRef] [PubMed]

- Senapati, M.; Sahu, P.P. Meat quality assessment using au patch electrode Ag-SnO2/SiO2/Si MIS capacitive gas sensor at room temperature. Food Chem. 2020, 324, 126893. [Google Scholar] [CrossRef] [PubMed]

- Sanaeifar, A.; Mohtasebi, S.S.; Ghasemi-Varnamkhasti, M.; Ahmadi, H. Application of MOS based electronic nose for the prediction of banana quality properties. Measurement 2016, 82, 105–114. [Google Scholar] [CrossRef]

- Beniwal, A. Sunny Apple fruit quality monitoring at room temperature using sol–gel spin coated Ni–SnO2 thin film sensor. J. Food Meas. Charact. 2018, 13, 857–863. [Google Scholar] [CrossRef]

- Rusinek, R.; Gancarz, M.; Krekora, M.; Nawrocka, A. A novel method for generation of a fingerprint using electronic nose on the example of rapeseed spoilage. J. Food Sci. 2019, 84, 51–58. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Zhang, C. Volatile organic compounds gas sensor based on quartz crystal microbalance for fruit freshness detection: A review. Food Chem. 2021, 334, 127615. [Google Scholar] [PubMed]

- Rutolo, M.F.; Clarkson, J.P.; Covington, J.A. The use of an electronic nose to detect early signs of soft-rot infection in potatoes. Biosyst. Eng. 2018, 167, 137–143. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, J.; Hu, X.; Huang, X.; Zhang, X.; Zou, X.; Shi, J. A visible colorimetric sensor array based on chemo-responsive dyes and chemometric algorithms for real-time potato quality monitoring systems. Food Chem. 2023, 405, 134717. [Google Scholar] [CrossRef] [PubMed]

- Rayappan, D.S.J.B.B. Development of e-nose prototype for raw milk quality discrimination. Milchwissenschaft 2012, 67, 381–385. [Google Scholar]

- Sberveglieri, V. Validation of Parmigiano Reggiano cheese aroma authenticity, categorized through the use of an array of semiconductors nanowire device (S3). Materials 2016, 9, 81. [Google Scholar] [CrossRef]

- Ziyaina, M.; Rasco, B.; Coffey, T.; Ünlü, G.; Sablani, S.S. Colorimetric detection of volatile organic compounds for shelf-life monitoring of milk. Food Control 2019, 100, 220–226. [Google Scholar] [CrossRef]

- Wang, M.; Du, J.; Zhao, M.; Huang, J.; Chen, D.; Hui, G. Paddy and maize moldy status characterization using electronic nose. J. Food Meas. Charact. 2013, 8, 54–60. [Google Scholar] [CrossRef]

- Rahimzadeh, H.; Sadeghi, M.; Ghasemi-Varnamkhasti, M.; Mireei, S.A.; Tohidi, M. On the feasibility of metal oxide gas sensor based electronic nose software modification to characterize rice ageing during storage. J. Food Eng. 2019, 245, 1–10. [Google Scholar] [CrossRef]

- Liu, T.; Jiang, H.; Chen, Q. Qualitative identification of rice actual storage period using olfactory visualization technique combined with chemometrics analysis. Microchem. J. 2020, 159, 105339. [Google Scholar] [CrossRef]

- Guan, B.; Zhao, J.; Jin, H.; Lin, H. Determination of rice storage time with colorimetric sensor array. Food Anal. Methods 2016, 10, 1054–1062. [Google Scholar] [CrossRef]

- Escuderos, M.E.; Sánchez, S.; Jiménez, A. Quartz crystal microbalance (QCM) sensor arrays selection for olive oil sensory evaluation. Food Chem. 2011, 124, 857–862. [Google Scholar] [CrossRef]

- Yimenu, S.M.; Kim, J.Y.; Kim, B.S. Prediction of egg freshness during storage using electronic nose. Poult. Sci. 2017, 96, 3733–3746. [Google Scholar] [CrossRef]

- Gonzalez Viejo, C.; Fuentes, S.; Godbole, A.; Widdicombe, B.; Unnithan, R.R. Development of a low-cost e-nose to assess aroma profiles: An artificial intelligence application to assess beer quality. Sens. Actuators B Chem. 2020, 308, 127688. [Google Scholar] [CrossRef]

- Li, P.; Niu, Z.; Shao, K.; Wu, Z. Quantitative analysis of fish meal freshness using an electronic nose combined with chemometric methods. Measurement 2021, 179, 109484. [Google Scholar] [CrossRef]

- Kawabe, S.; Murakami, H.; Usui, M.; Miyasaki, T. Changes in volatile compounds of living pacific oyster Crassostrea gigas during air-exposed storage. Fish. Sci. 2019, 85, 747–755. [Google Scholar] [CrossRef]

- Lv, R.; Huang, X.; Ye, W.; Aheto, J.H.; Xu, H.; Dai, C.; Tian, X. Research on the reaction mechanism of colorimetric sensor array with characteristic volatile gases-TMA during fish storage. J. Food Process Eng. 2019, 42, e12952. [Google Scholar] [CrossRef]

- Zhai, X.; Sun, Y.; Cen, S.; Wang, X.; Zhang, J.; Yang, Z.; Li, Y.; Wang, X.; Zhou, C.; Arslan, M.; et al. Anthocyanins-encapsulated 3d-printable bigels: A colorimetric and leaching-resistant volatile amines sensor for intelligent food packaging. Food Hydrocoll. 2022, 133, 107989. [Google Scholar] [CrossRef]

- Tavassoli, M.; Alizadeh Sani, M.; Khezerlou, A.; Ehsani, A.; Jahed-Khaniki, G.; McClements, D.J. Smart biopolymer-based nanocomposite materials containing pH-sensing colorimetric indicators for food freshness monitoring. Molecules 2022, 27, 3168. [Google Scholar] [CrossRef]

- Tavassoli, M.; Khezerlou, A.; Firoozy, S.; Ehsani, A.; Punia Bangar, S. Chitosan-based film incorporated with anthocyanins of red poppy (Papaver rhoeas L.) as a colorimetric sensor for the detection of shrimp freshness. Int. J. Food Sci. Technol. 2023, 58, 3050–3057. [Google Scholar] [CrossRef]

- Kamer, D.D.A.; Kaynarca, G.B.; Yucel, E.; Gumus, T. Development of gelatin/PVA based colorimetric films with a wide pH sensing range winery solid by-product (vinasse) for monitor shrimp freshness. Int. J. Biol. Macromol. 2022, 220, 627–637. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, L.; Yu, J.; Farag, M.A.; Shao, P. Intelligent starch/chitosan-based film incorporated by anthocyanin-encapsulated amylopectin nanoparticles with high stability for food freshness monitoring. Food Control 2023, 151, 109798. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, D.W.; Ma, J.; Cheng, J.; Wang, Z.; Tang, B.Z. A volatile basic nitrogens-responsive tag based on aggregation-induced emission luminogen for real-time monitoring and in situ visualization of salmon freshness. Anal. Chim. Acta 2022, 1221, 340122. [Google Scholar] [CrossRef] [PubMed]

- Guohua, H.; Lvye, W.; Yanhong, M.; Lingxia, Z. Study of grass carp (Ctenopharyngodon idellus) quality predictive model based on electronic nose. Sens. Actuators B Chem. 2012, 166–167, 301–308. [Google Scholar] [CrossRef]

- Lv, R.; Huang, X.; Aheto, J.H.; Mu, L.; Tian, X. Analysis of fish spoilage by gas chromatography–mass spectrometry and electronic olfaction bionic system. J. Food Saf. 2018, 38, e12557. [Google Scholar] [CrossRef]

- Górska-Horczyczak, E.; Guzek, D.; Molęda, Z.; Wojtasik-Kalinowska, I.; Brodowska, M.; Wierzbicka, A. Applications of electronic noses in meat analysis. Food Sci. Technol. 2016, 36, 389–395. [Google Scholar] [CrossRef]

- Jiang, S.; Liu, Y. Gas sensors for volatile compounds analysis in muscle foods: A review. TrAC Trends Anal. Chem. 2020, 126, 115877. [Google Scholar] [CrossRef]

- Tang, X.; Yu, Z. Rapid evaluation of chicken meat freshness using gas sensor array and signal analysis considering total volatile basic nitrogen. Int. J. Food Prop. 2020, 23, 297–305. [Google Scholar] [CrossRef]

- Kilic, B.; Dogan, V.; Kilic, V.; Kahyaoglu, L.N. Colorimetric food spoilage monitoring with carbon dot and uv light reinforced fish gelatin films using a smartphone application. Int. J. Biol. Macromol. 2022, 209, 1562–1572. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, X.; Huang, Y.; Li, H.; Chen, L.; Liu, X. Two colorimetric films based on chitin whiskers and sodium alginate/gelatin incorporated with anthocyanins for monitoring food freshness. Food Hydrocoll. 2022, 127, 107517. [Google Scholar] [CrossRef]

- Wojnowski, W.; Kalinowska, K.; Majchrzak, T.; Plotka-Wasylka, J.; Namiesnik, J. Prediction of the biogenic amines index of poultry meat using an electronic nose. Sensors 2019, 19, 1580. [Google Scholar] [CrossRef]

- Feng, T.; Zhuang, H.; Ye, R.; Jin, Z.; Xu, X.; Xie, Z. Analysis of volatile compounds of Mesona Blumes gum/rice extrudates via GC–MS and electronic nose. Sens. Actuators B Chem. 2011, 160, 964–973. [Google Scholar] [CrossRef]

- Guo, Z.; Guo, C.; Sun, L.; Zuo, M.; Chen, Q.; El-Seedi, H.R.; Zou, X. Identification of the apple spoilage causative fungi and prediction of the spoilage degree using electronic nose. J. Food Process Eng. 2021, 44, e13816. [Google Scholar] [CrossRef]

- Mirza Alizadeh, A.; Masoomian, M.; Shakooie, M.; Zabihzadeh Khajavi, M.; Farhoodi, M. Trends and applications of intelligent packaging in dairy products: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 383–397. [Google Scholar] [CrossRef]

- Hempel, A.; O’Sullivan, M.G.; Papkovsky, D.B.; Kerry, J.P. Use of optical oxygen sensors to monitor residual oxygen in pre- and post-pasteurised bottled beer and its effect on sensory attributes and product acceptability during simulated commercial storage. LWT-Food Sci. Technol. 2013, 50, 226–231. [Google Scholar] [CrossRef]

- Begum, P.; Yang, L.; Morozumi, T.; Sone, T.; Kawaguchi, T. Pani sensor for monitoring the oxidative degradation of wine using cyclic voltammetry. Food Chem. 2023, 414, 135740. [Google Scholar] [CrossRef]

| Type of Food | Class | Sensor Type | Gas | Reference |

|---|---|---|---|---|

| Aquatic Products | Pseudosciaena crocea | MOX sensor | Methane, ethane, dimethyl methane, ammonia, hydrogen sulphide, alcohol, toluene, xylene | [52] |

| Large yellow croaker | MOX sensor | Sulfide, flammable gases, ammonia gas, ethanol, aromatic hydrocarbons, hydrocarbon component gas, methane, propane, butane, nitrogen oxides | [53] | |

| Oncorhynchus mykiss | MOX sensor | TVB-N | [20] | |

| Fish meal | MOX sensor | TVB-N | [19] | |

| Tilapia fish | Optical gas sensor | Short-chain alcohols and carbonyls, amines, sulphur compounds, aromatic, N-cyclic, acid compounds | [54] | |

| Fresh fish | Colorimetric sensor | Amines | [55] | |

| Grass carp fish, hairtail | Quartz crystal microbalance | Aldehydes | [56] | |

| Meat products | Meat | MOX sensor | Ethanol, TMA | [57] |

| Meat | Colorimetric sensor arrays | TMA | [35] | |

| Pork | Colorimetric sensor | CO2 | [58] | |

| Chicken | MOX sensor | Volatile fatty acids | [21] | |

| Chicken | MOX sensor | NH3, TMA, ethanol, H2S | [59] | |

| Fruit | Muskmelon | SAW sensor | Ethylene, carbon dioxide | [27] |

| Apple, pear, kiwi fruit | Electrochemical sensor | Ethylene | [43] | |

| Banana | MOX sensor | Ethylene | [60] | |

| Apple | MOX sensor | Ethylene | [61] | |

| Rapeseed | MOX sensor | Volatile organic compounds | [62] | |

| Apple, banana, avocado, mango | Quartz crystal microbalance | Volatile organic compounds | [63] | |

| Vegetables | Potato | MOX sensor, Electrochemical sensors | Carbon monoxide, ethylene oxide, nitric oxide. | [64] |

| Potato | Colorimetric sensor | n-Hexadecanoic acid, pentadecanal, hexadecanoic acid, methyl ester, and methyl stearate | [65] | |

| Dairy products | Milk | MOX sensor | Volatile organic compounds | [66] |

| Cheese | MOX semiconductor gas sensor | Volatile organic compounds | [67] | |

| Cheese | MOX sensor | Volatile organic compounds | [18] | |

| Milk | Colorimetric sensor | Volatile organic compounds | [68] | |

| Grain and oil products | Paddy, maize | MOX sensor | Ethanol, propane, butane, nitrogen oxides, carbon monoxide, hydrogen, hydrogen sulfide, methane | [69] |

| Rice | MOX sensor | Aromatic compounds | [70] | |

| Rice | Colorimetric sensor | Volatile organic compounds | [71] | |

| Rice | Colorimetric sensor | Octaethylene glycol monododecyl ether, benzaldehyde | [72] | |

| Olive oil | Quartz crystal microbalance sensor array | Volatile organic compounds | [73] | |

| Egg products | Egg | MOX sensor | Volatile organic compounds | [74] |

| Alcohol products | Beer | Sensor array | Aromatic compounds | [75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, M.; Yang, X.; Ying, X.; Shi, C.; Jia, Z.; Jia, B. Applications of Gas Sensing in Food Quality Detection: A Review. Foods 2023, 12, 3966. https://doi.org/10.3390/foods12213966

Ma M, Yang X, Ying X, Shi C, Jia Z, Jia B. Applications of Gas Sensing in Food Quality Detection: A Review. Foods. 2023; 12(21):3966. https://doi.org/10.3390/foods12213966

Chicago/Turabian StyleMa, Minzhen, Xinting Yang, Xiaoguo Ying, Ce Shi, Zhixin Jia, and Boce Jia. 2023. "Applications of Gas Sensing in Food Quality Detection: A Review" Foods 12, no. 21: 3966. https://doi.org/10.3390/foods12213966

APA StyleMa, M., Yang, X., Ying, X., Shi, C., Jia, Z., & Jia, B. (2023). Applications of Gas Sensing in Food Quality Detection: A Review. Foods, 12(21), 3966. https://doi.org/10.3390/foods12213966