High-Pressure Pasteurization of Soy Okara

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Experimental Design of HPP-Process and Storage Study

2.3. Microbiological Growth

2.4. Proximate Composition

2.5. Water Activity

2.6. Differential Scanning Calorimetry

2.7. Viscosity

2.8. Water and Oil Holding Capacities

2.9. Scanning Electron Microscopy

2.10. Statistical Analysis

3. Results and Discussion

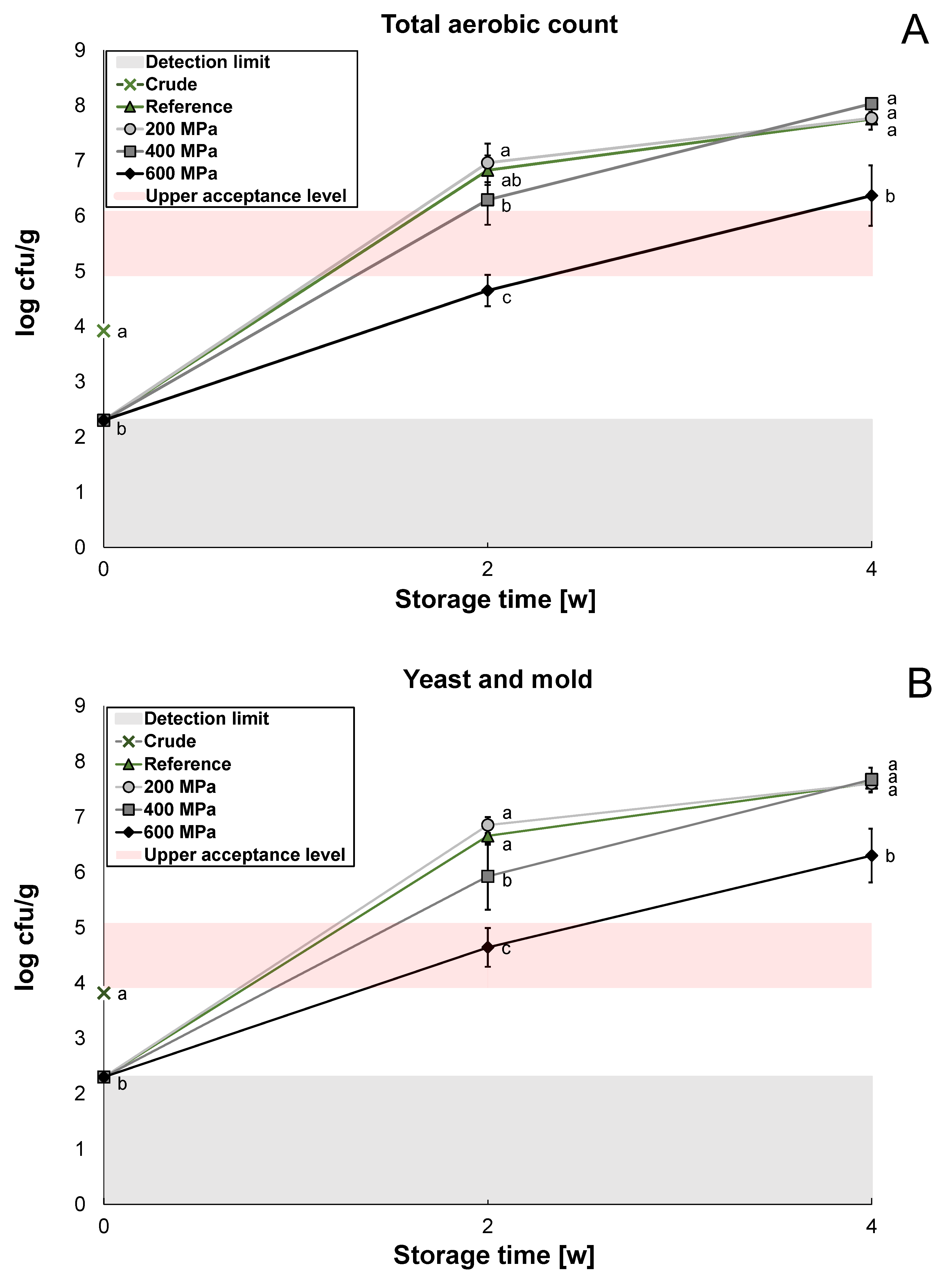

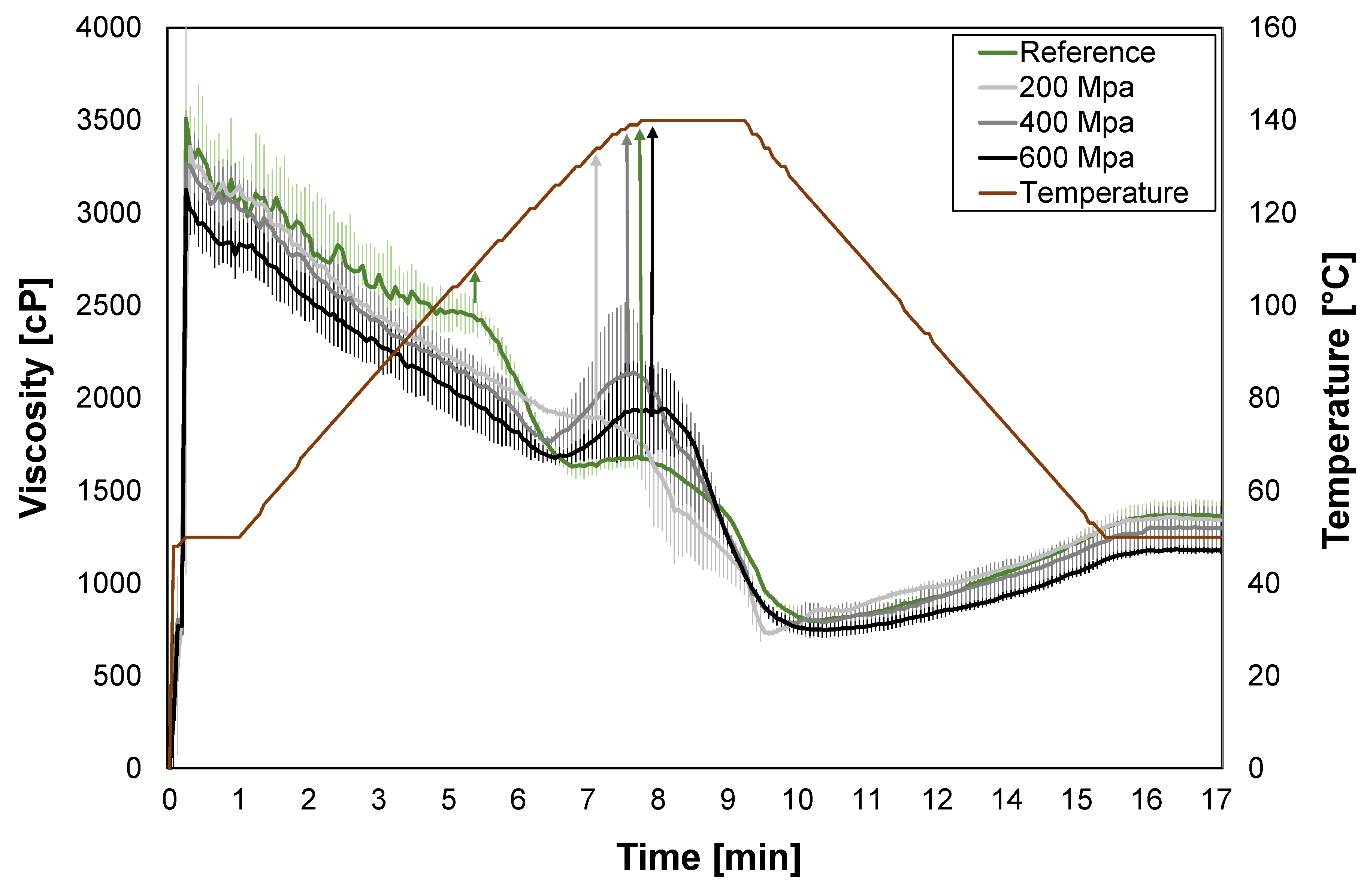

3.1. Microbiological Content

3.2. Proximate Composition and Water Activity

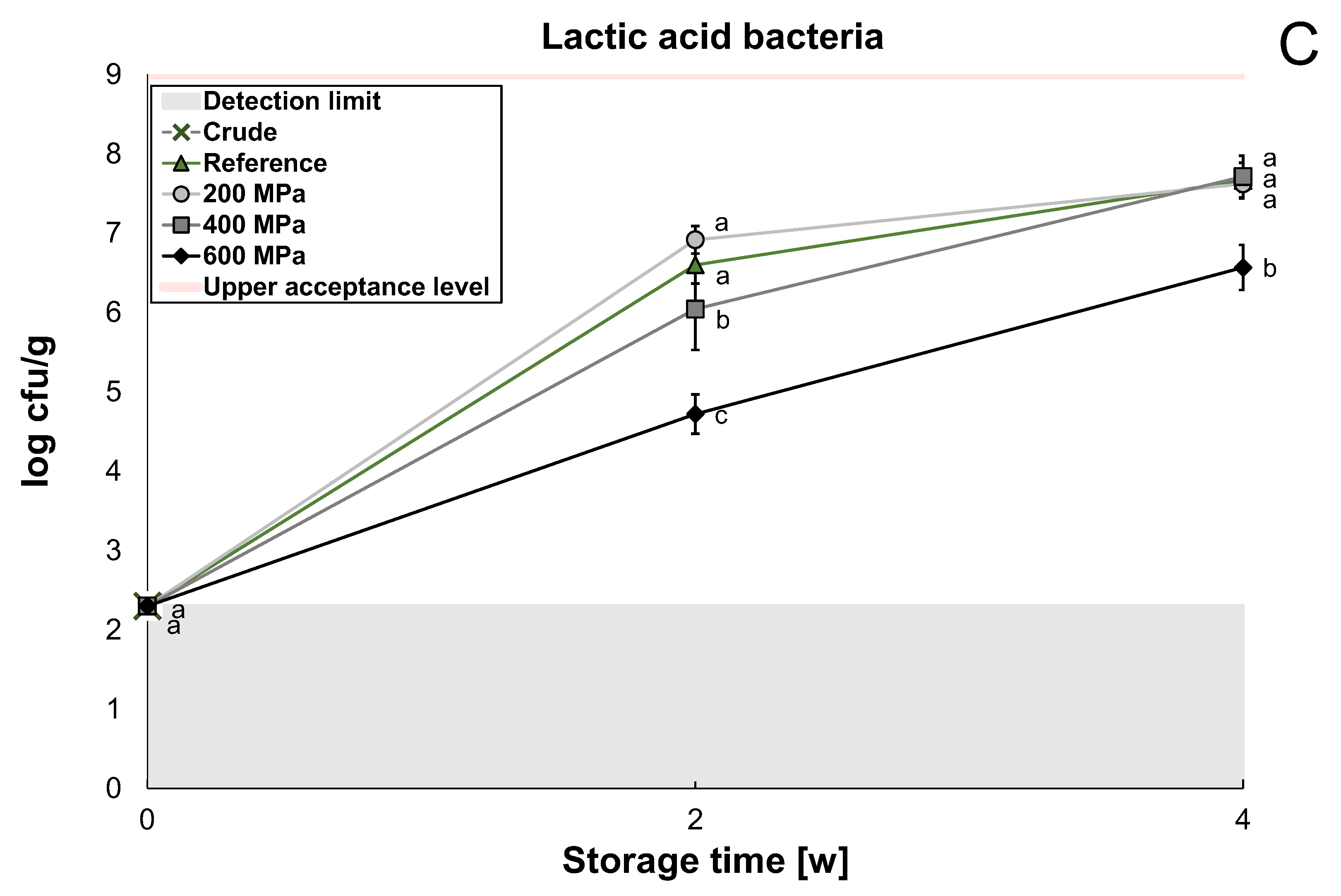

3.3. Thermal Properties

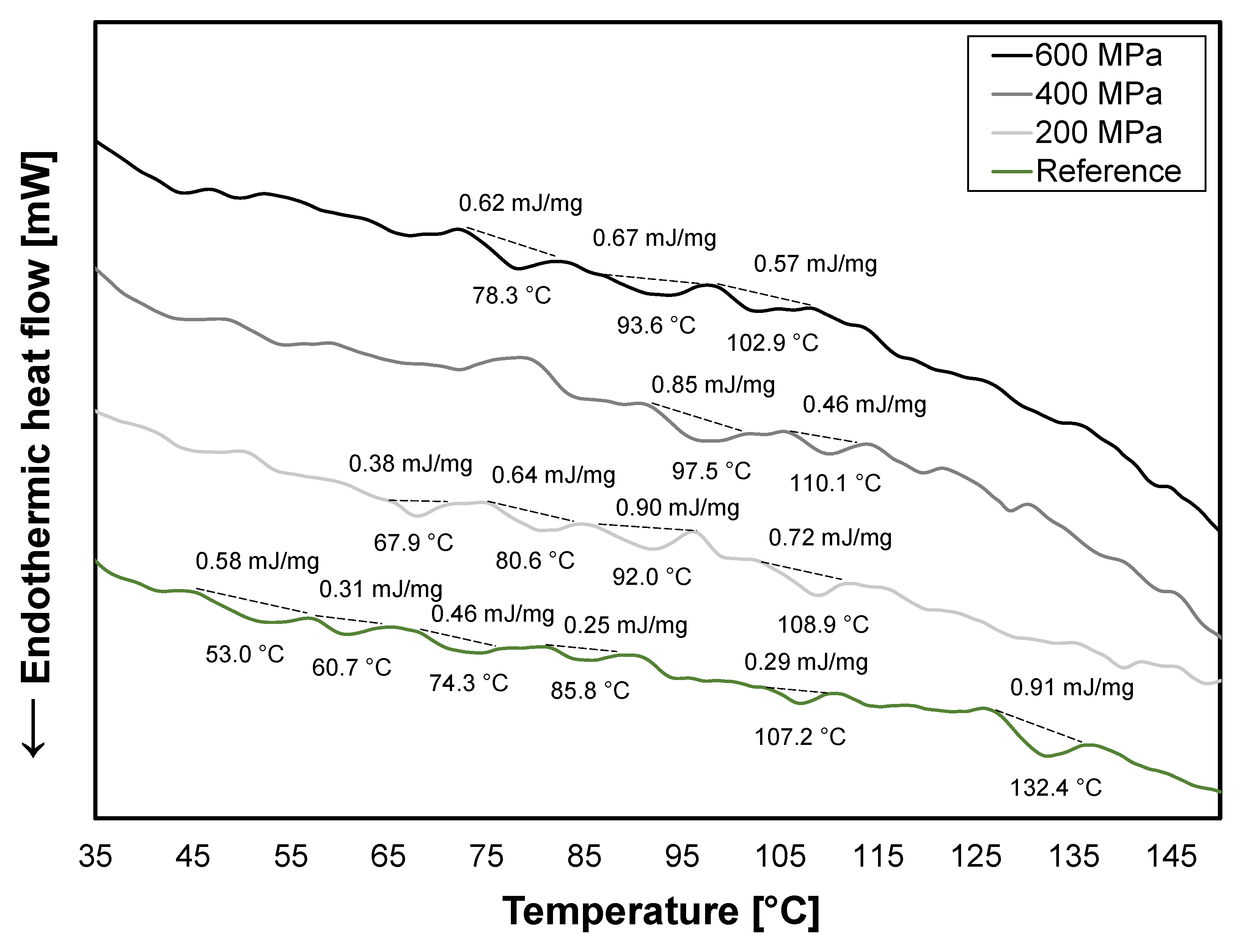

3.4. Viscosity

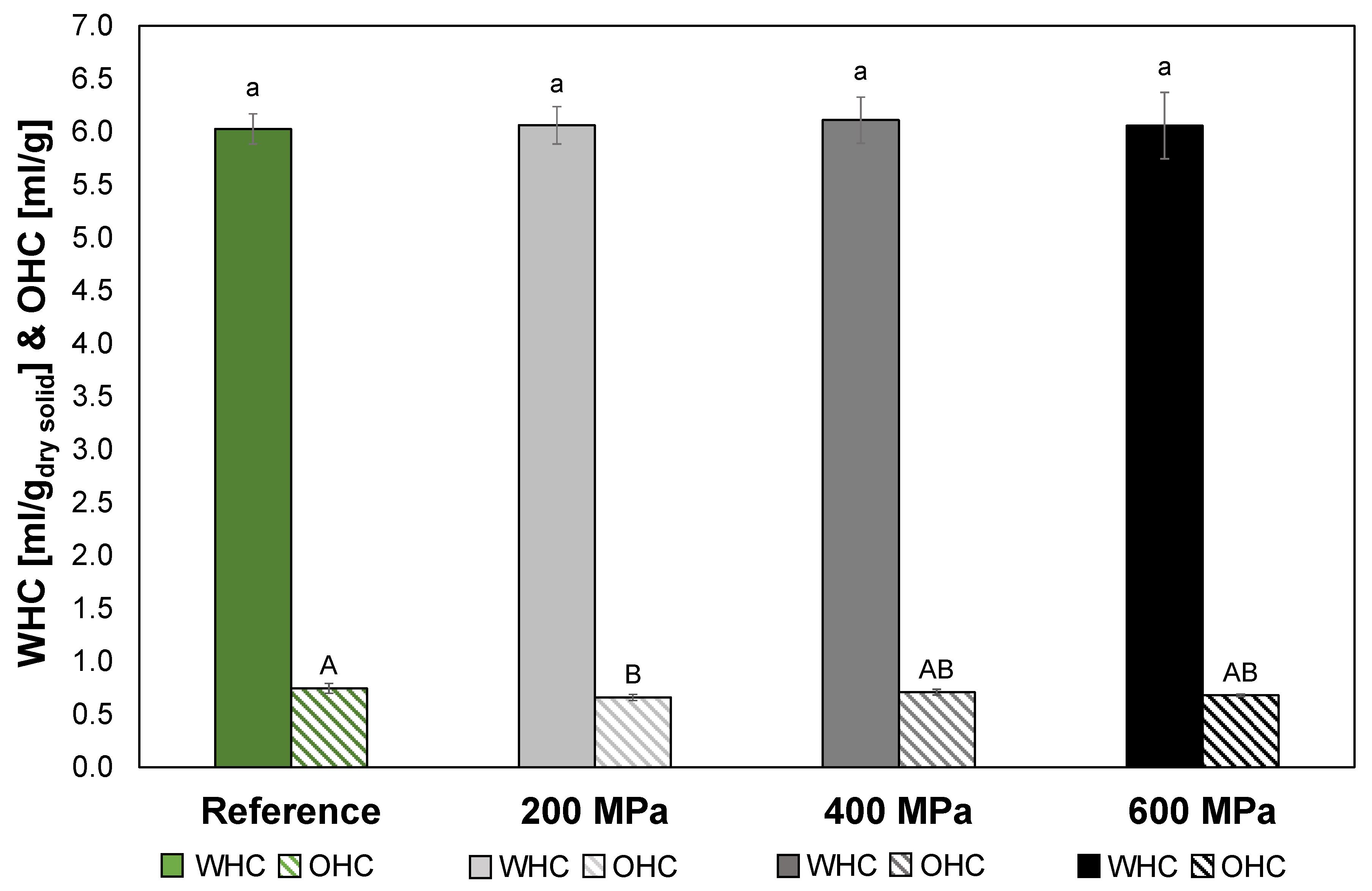

3.5. Water and Oil Holding Capacity

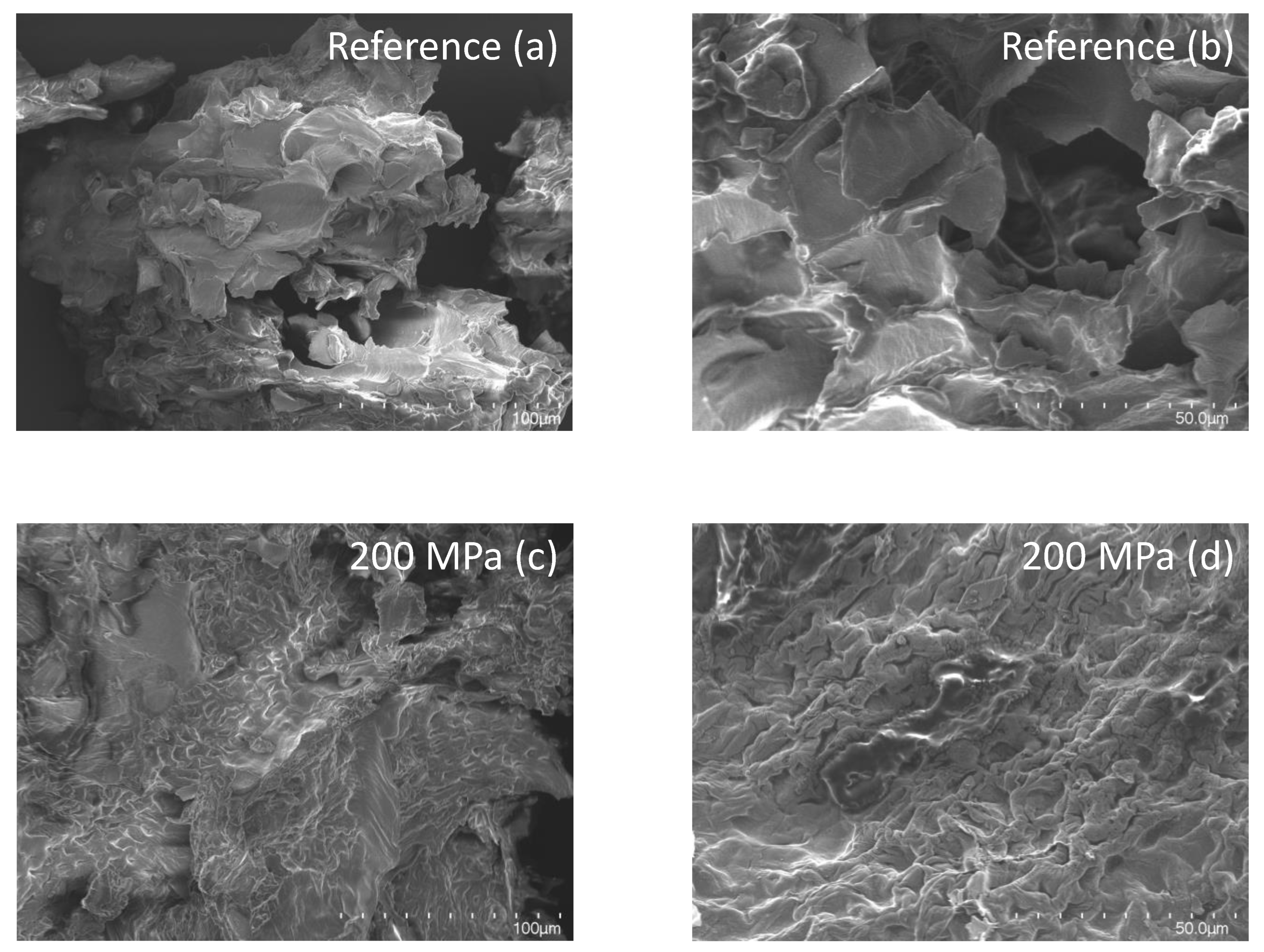

3.6. Scanning Electron Micrographs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Markets and Markets. Dairy Alternatives Market by Source (Soy, Almond, Coconut, Oats, Rice, Hemp), Application (Milk, Yogurt, Ice Creams, Cheese, Creamers), Distribution Channel (Supermarkets, Health Food Stores, Pharmacies), Formulation, and Region—Forecast to 2027. Available online: https://www.marketsandmarkets.com/Market-Reports/dairy-alternative-plant-milk-beverages-market-677.html (accessed on 19 April 2023).

- Sethi, S.; Tyagi, S.K.; Anurag, R.K. Plant-based milk alternatives an emerging segment of functional beverages: A review. J. Food Sci. Technol. 2016, 53, 3408–3423. [Google Scholar] [CrossRef]

- Paul, A.A.; Kumar, S.; Kumar, V.; Sharma, R. Milk Analog: Plant based alternatives to conventional milk, production, potential and health concerns. Crit. Rev. Food Sci. Nutr. 2019, 60, 3005–3023. [Google Scholar] [CrossRef] [PubMed]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. Forests and Deforestation. Available online: https://ourworldindata.org/forests-and-deforestation (accessed on 11 September 2023).

- FAO. UN Food and Agriculture Organization. Available online: https://www.fao.org/faostat/en/#data (accessed on 11 September 2023).

- Ikya, J.K.; Gernah, I.; Ojobo, E.; Oni, K. Effect of cooking temperature on some quality characteristics of soy milk. Adv. J. Food Sci. Technol. 2013, 5, 543–546. [Google Scholar] [CrossRef]

- Shurtleff, W.; Aoyagi, A. Tofu & Soymilk Production: A Craft and Technical Manual; Soyinfo Center: Lafayette, CA, USA, 2000; Volume 2. [Google Scholar]

- Khare, S.; Jha, K.; Gandhi, A. Citric acid production from okara (soy-residue) by solid-state fermentation. Bioresour. Technol. 1995, 54, 323–325. [Google Scholar] [CrossRef]

- Li, B.; Qiao, M.; Lu, F. Composition, nutrition, and utilization of okara (soybean residue). Food Rev. Int. 2012, 28, 231–252. [Google Scholar] [CrossRef]

- Schved, F.; Hassidov, B. Okara, a natural food ingredient for new product development of foodstuffs. Agro Food Ind. Hi-Tech 2010, 21, 46. [Google Scholar]

- Shi, C.; Wang, L.-j.; Wu, M.; Adhikari, B. Optimization of twin-screw extrusion process to produce okara-maize snack foods using response surface methodology. Int. J. Food Eng. 2011, 7, 1–24. [Google Scholar] [CrossRef]

- Rinaldi, V.; Ng, P.; Bennink, M. Effects of extrusion on dietary fiber and isoflavone contents of wheat extrudates enriched with wet okara. Cereal Chem. 2000, 77, 237–240. [Google Scholar] [CrossRef]

- Matsuo, M. Application of okara koji, okara fermented by Aspergillus oryzae, for cookies and cupcakes. J. Home Econ. Jpn. 1999, 50, 1029–1034. [Google Scholar]

- Zhu, Y.; Fan, J.; Cheng, Y.; Li, L. Improvement of the antioxidant activity of Chinese traditional fermented okara (Meitauza) using Bacillus subtilis B2. Food Control. 2008, 19, 654–661. [Google Scholar] [CrossRef]

- Vong, W.C.; Liu, S.-Q. Biovalorisation of okara (soybean residue) for food and nutrition. Trends Food Sci. Technol. 2016, 52, 139–147. [Google Scholar] [CrossRef]

- Azanza, M.P.V.; Gascon, F.S. Shelf-stable Dried Okara from the Wet By-product of Philippine Soybean Curd Processing. Philipp. J. Sci. 2015, 144, 171–185. [Google Scholar]

- Voss, G.; Rodríguez-Alcalá, L.; Valente, L.; Pintado, M. Impact of different thermal treatments and storage conditions on the stability of soybean byproduct (okara). J. Food Meas. Charact. 2018, 12, 1981–1996. [Google Scholar] [CrossRef]

- Badarinath, V.; Raghavendra, P.; Halami, P.M. Characterization of Lactic Acid Bacteria isolated from okara for probiotic properties. Int. J. Probiotics Prebiotics 2010, 5, 149. [Google Scholar]

- Redondo-Cuenca, A.; Villanueva-Suárez, M.J.; Mateos-Aparicio, I. Soybean seeds and its by-product okara as sources of dietary fibre. Measurement by AOAC and Englyst methods. Food Chem. 2008, 108, 1099–1105. [Google Scholar] [CrossRef]

- Choi, I.S.; Kim, Y.G.; Jung, J.K.; Bae, H.-J. Soybean waste (okara) as a valorization biomass for the bioethanol production. Energy 2015, 93, 1742–1747. [Google Scholar] [CrossRef]

- Mejia, A.; Harwatt, H.; Jaceldo-Siegl, K.; Sranacharoenpong, K.; Soret, S.; Sabaté, J. Greenhouse gas emissions generated by tofu production: A case study. J. Hunger. Environ. Nutr. 2018, 13, 131–142. [Google Scholar] [CrossRef]

- Wachiraphansakul, S.; Devahastin, S. Drying kinetics and quality of okara dried in a jet spouted bed of sorbent particles. LWT-Food Sci. Technol. 2007, 40, 207–219. [Google Scholar] [CrossRef]

- Taruna, I.; Jindal, V.K. Drying of soy pulp (okara) in a bed of inert particles. Dry. Technol. 2002, 20, 1035–1051. [Google Scholar] [CrossRef]

- Lee, L.; Lin, Y.; Wang, C. Study of the supercritical drying of wet Okara. In Proceedings of the 15th International Conference on Sustainable Energy Technologies (SET2016), Singapore, 19–22 July 2016. [Google Scholar]

- Guimarães, R.M.; Ida, E.I.; Falcão, H.G.; de Rezende, T.A.M.; de Santana Silva, J.; Alves, C.C.F.; da Silva, M.A.P.; Egea, M.B. Evaluating technological quality of okara flours obtained by different drying processes. LWT 2020, 123, 109062. [Google Scholar] [CrossRef]

- Ezaki, M.; Mitsuyoshi, K.; Kanada, Y.; Inaba, M.; Yamaguchi, M. Process for Producing Wet Okara. U.S. Patent 6,541,058B1, 1 April 2003. [Google Scholar]

- Rotem, I.; Almog, N. Method for Processing Okara. Available online: https://patents.google.com/patent/US20060034977A1/en?q=(Method+for+processing+okara+rotem)&inventor=almog&oq=Method+for+processing+okara+rotem+almog (accessed on 9 October 2023).

- Balasubramaniam, V.; Barbosa-Cánovas, G.V.; Lelieveld, H. High Pressure Processing of Food: Principles, Technology and Applications; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Hiperbaric. HPP Technology. Available online: https://www.hiperbaric.com/en/hpp-technology/equipment/hpp-in-pack/hiperbaric-525/ (accessed on 21 September 2023).

- Ambawat, S.; Khetarpaul, N. Comparative assessment of antioxidant, nutritional and functional properties of soybean and its by-product okara. Ann. Phytomed. 2018, 7, 112–118. [Google Scholar] [CrossRef]

- Deplace, G. Design of high pressure isostatic units for treatment of food product. In High Pressure Processing of Foods; Ledward, D.A., Johnston, D.E., Earnshaw, R.G., Hastings, A.P.M., Eds.; Nottingham University Press: Loughborough, UK, 1995; pp. 137–154. [Google Scholar]

- Cacace, F.; Bottani, E.; Rizzi, A.; Vignali, G. Evaluation of the economic and environmental sustainability of high pressure processing of foods. Innov. Food Sci. Emerg. Technol. 2020, 60, 102281. [Google Scholar] [CrossRef]

- Mateos-Aparicio, I.; Mateos-Peinado, C.; Rupérez, P. High hydrostatic pressure improves the functionality of dietary fibre in okara by-product from soybean. Innov. Food Sci. Emerg. Technol. 2010, 11, 445–450. [Google Scholar] [CrossRef]

- Fayaz, G.; Plazzotta, S.; Calligaris, S.; Manzocco, L.; Nicoli, M.C. Impact of high pressure homogenization on physical properties, extraction yield and biopolymer structure of soybean okara. LWT 2019, 113, 108324. [Google Scholar] [CrossRef]

- Thyssenkrupp. What Is HPP? All the Relevant Information about High Pressure Processing. Available online: https://www.thyssenkrupp-industrial-solutions.com/high-pressure-processing/en/what-is-hpp (accessed on 13 September 2023).

- Alveteg, M. KETF10 & KETF40 Introduction to Transport Phenomena and Separation Processes; MediaTryck: Lund, Sweden, 2022. [Google Scholar]

- Aziah, A.N.; Ho, L.; Shazliana, A.N.; Bhat, R. Quality evaluation of steamed wheat bread substituted with green banana flour. Int. Food Res. J. 2012, 19, 869. [Google Scholar]

- Minitab. What Is Tukey’s Method for Multiple Comparisons? Available online: https://support.minitab.com/en-us/minitab/21/help-and-how-to/statistical-modeling/anova/supporting-topics/multiple-comparisons/what-is-tukey-s-method/ (accessed on 12 September 2023).

- Minitab. Using Multiple Comparisons to Assess Differences in Group Means. Available online: https://support.minitab.com/en-us/minitab/21/help-and-how-to/statistical-modeling/anova/supporting-topics/multiple-comparisons/using-multiple-comparisons-to-assess-differences-in-means/ (accessed on 12 September 2023).

- Gao, J.; Yang, H.; Rong, A.; Bao, X.; Zhang, M. Effects of HHP on microorganisms, enzyme inactivation and physicochemical properties of instant oats and rice. J. Food Process Eng. 2014, 37, 191–198. [Google Scholar] [CrossRef]

- Centre for Food Safety. Microbiological Guidelines for Food (For Ready-to-Eat Food in General and Specific Food Items); Food and Environmental Hygiene Department: Hong Kong, China, 2014. [Google Scholar]

- FSANZ. Compendium of Microbiological Criteria for Food. Available online: https://www.foodstandards.gov.au/publications/Documents/Compedium%20of%20Microbiological%20Criteria/Compendium_revised-jan-2018.pdf (accessed on 11 September 2023).

- Black, E.P.; Setlow, P.; Hocking, A.D.; Stewart, C.M.; Kelly, A.L.; Hoover, D.G. Response of spores to high-pressure processing. Compr. Rev. Food Sci. Food Saf. 2007, 6, 103–119. [Google Scholar] [CrossRef]

- Ananta, E.; Heinz, V.; Schlüter, O.; Knorr, D. Kinetic studies on high-pressure inactivation of Bacillus stearothermophilus spores suspended in food matrices. Innov. Food Sci. Emerg. Technol. 2001, 2, 261–272. [Google Scholar] [CrossRef]

- Yang, P.; Rao, L.; Zhao, L.; Wu, X.; Wang, Y.; Liao, X. High pressure processing combined with selected hurdles: Enhancement in the inactivation of vegetative microorganisms. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1800–1828. [Google Scholar] [CrossRef]

- Mateos-Aparicio, I.; Redondo-Cuenca, A.; Villanueva-Suárez, M.-J.; Zapata-Revilla, M.-A.; Tenorio-Sanz, M.-D. Pea pod, broad bean pod and okara, potential sources of functional compounds. LWT-Food Sci. Technol. 2010, 43, 1467–1470. [Google Scholar] [CrossRef]

- Van der Riet, W.; Wight, A.; Cilliers, J.; Datel, J. Food chemical investigation of tofu and its byproduct okara. Food Chem. 1989, 34, 193–202. [Google Scholar] [CrossRef]

- Renkema, J.M.; van Vliet, T. Heat-induced gel formation by soy proteins at neutral pH. J. Agric. Food Chem. 2002, 50, 1569–1573. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ye, R.; Yin, L.; Zhang, N. Novel blasting extrusion processing improved the physicochemical properties of soluble dietary fiber from soybean residue and in vivo evaluation. J. Food Eng. 2014, 120, 1–8. [Google Scholar] [CrossRef]

- Liu, Y.; Yi, S.; Ye, T.; Leng, Y.; Hossen, M.A.; Sameen, D.E.; Dai, J.; Li, S.; Qin, W. Effects of ultrasonic treatment and homogenization on physicochemical properties of okara dietary fibers for 3D printing cookies. Ultrason. Sonochem. 2021, 77, 105693. [Google Scholar] [CrossRef]

- Yuan, T.Z.; Liu, S.; Reimer, M.; Isaak, C.; Ai, Y. Evaluation of pasting and gelling properties of commercial flours under high heating temperatures using Rapid Visco Analyzer 4800. Food Chem. 2021, 344, 128616. [Google Scholar] [CrossRef]

- Mudgil, D. The interaction between insoluble and soluble fiber. In Dietary Fiber for the Prevention of Cardiovascular Disease; Elsevier: Amsterdam, The Netherlands, 2017; pp. 35–59. [Google Scholar]

- Grigelmo-Miguel, N.; Martıń-Belloso, O. Characterization of dietary fiber from orange juice extraction. Food Res. Int. 1998, 31, 355–361. [Google Scholar] [CrossRef]

- Woldemariam, H.W.; Emire, S.A. High pressure processing of foods for microbial and mycotoxins control: Current trends and future prospects. Cogent Food Agric. 2019, 5, 1622184. [Google Scholar] [CrossRef]

| Pressure (MPa) | Temperature Interval (°C) | Pressure Interval (MPa) |

|---|---|---|

| 200 | 15.3–17.8 | 200.6–203.9 |

| 400 | 18.3–20.4 | 399.8–405.2 |

| 600 | 21.4–22.5 | 600.4–605.0 |

| Start (°C) | Limit (°C) | Rate (°C/min) | Hold (min) | Sampling (s) | |

|---|---|---|---|---|---|

| 25 | 25 | 10 | 1 | 0.2 | |

| End step | 25 | 200 | 10 | 0 | 0.2 |

| Time | ||

|---|---|---|

| 00:00 | Temp | 50 °C |

| 00:00 | Speed | 960 rpm |

| 00:10 | Speed | 160 rpm |

| 01:00 | Temp | 50 °C |

| 06:50 | Temp | 140 °C |

| 09:20 | Temp | 140 °C |

| 15:10 | Temp | 50 °C |

| 17:10 | End |

| Reference | 200 MPa | 400 MPa | 600 MPa | |

|---|---|---|---|---|

| Water content (%) | 77.10 ± 0.06 | 76.79 ± 0.17 | 76.76 ± 0.31 | 76.73 ± 0.06 |

| Water activity | 0.993 ± 0.004 | 0.992 ± 0.001 | 0.992 ± 0.002 | 0.991 ± 0.003 |

| Reference | 200 MPa | 400 MPa | 600 MPa | |

|---|---|---|---|---|

| Total dietary fiber (%) | 26.9 ± 4.0 | 24.5 ± 3.7 | 24.4 ± 3.7 | 24.9 ± 3.7 |

| Insoluble fiber (%) | 29.4 ± 4.4 | 25.1 ± 3.8 | 24.5 ± 3.7 | 23.8 ± 3.6 |

| Soluble fiber (%) | n.d. | n.d. | n.d. | 1.1 ± 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Helstad, A.; Marefati, A.; Ahlström, C.; Rayner, M.; Purhagen, J.; Östbring, K. High-Pressure Pasteurization of Soy Okara. Foods 2023, 12, 3736. https://doi.org/10.3390/foods12203736

Helstad A, Marefati A, Ahlström C, Rayner M, Purhagen J, Östbring K. High-Pressure Pasteurization of Soy Okara. Foods. 2023; 12(20):3736. https://doi.org/10.3390/foods12203736

Chicago/Turabian StyleHelstad, Amanda, Ali Marefati, Cecilia Ahlström, Marilyn Rayner, Jeanette Purhagen, and Karolina Östbring. 2023. "High-Pressure Pasteurization of Soy Okara" Foods 12, no. 20: 3736. https://doi.org/10.3390/foods12203736

APA StyleHelstad, A., Marefati, A., Ahlström, C., Rayner, M., Purhagen, J., & Östbring, K. (2023). High-Pressure Pasteurization of Soy Okara. Foods, 12(20), 3736. https://doi.org/10.3390/foods12203736