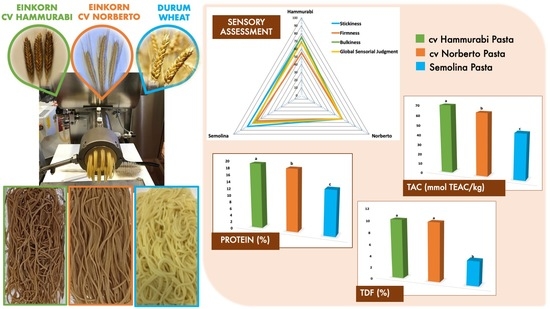

Cooking Quality and Chemical and Technological Characteristics of Wholegrain Einkorn Pasta Obtained from Micronized Flour

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Material and Milling Process

2.2. Rheological and Technological Analyses

2.3. Pasta-Making Process

2.4. Chemical Characterization and Total Antioxidant Capacity of Cooked Pasta

2.5. Cooking Quality and Pasta Colour

2.6. Sensory Test

2.7. Statistical Analysis

3. Results and Discussion

3.1. Chemical Characterization of Cooked Pasta

3.2. Rheological and Technological Parameters

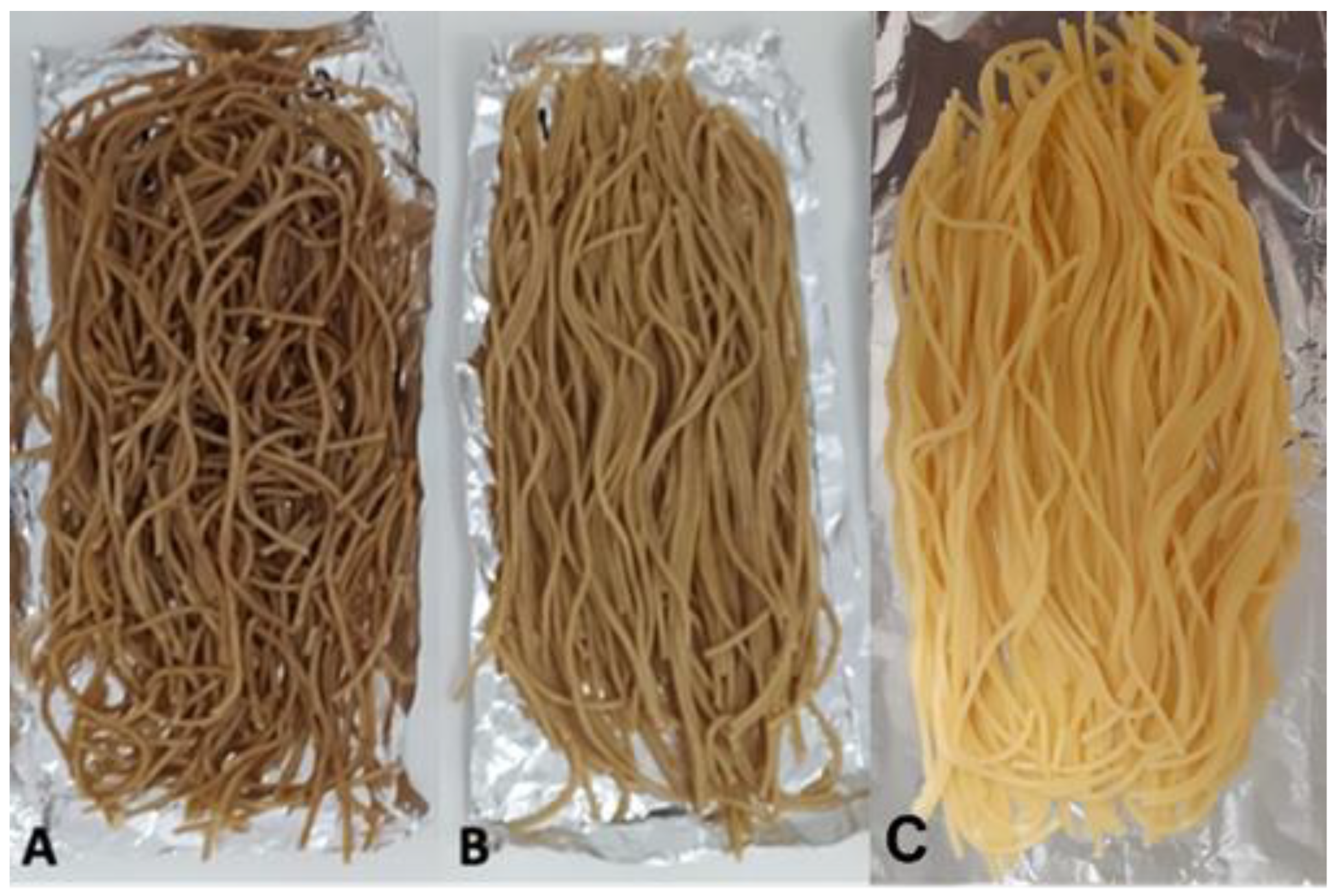

3.3. Cooking Quality Parameters and Pasta Colour

3.4. Sensory Evaluation of Cooked Pasta

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Romano, A.; Ferranti, P.; Gallo, V.; Masi, P. New ingredients and alternatives to durum wheat semolina for a high quality dried pasta. Curr. Opin. Food Sci. 2021, 41, 249–259. [Google Scholar] [CrossRef]

- Dziki, D. Current trends in enrichment of wheat pasta: Quality, nutritional value and antioxidant properties. Processes 2021, 9, 1280. [Google Scholar] [CrossRef]

- Longin, C.F.H.; Würschum, T. Back to the future–tapping into ancient grains for food diversity. Trends Plant Sci. 2016, 21, 731–737. [Google Scholar] [CrossRef] [PubMed]

- Geisslitz, S.; Scherf, K.A. Rediscovering ancient wheats. Cereal Foods World 2020, 65, 2. [Google Scholar] [CrossRef]

- Shewry, P.R. Do ancient types of wheat have health benefits compared with modern bread wheat? J. Cereal Sci. 2018, 79, 469–476. [Google Scholar] [CrossRef]

- Dinu, M.; Whittaker, A.; Pagliai, G.; Benedettelli, S.; Sofi, F. Ancient wheat species and human health: Biochemical and clinical implications. J. Nutr. Biochem. 2017, 52, 1–9. [Google Scholar] [CrossRef]

- Picascia, S.; Camarca, A.; Malamisura, M.; Mandile, R.; Galatola, M.; Cielo, D.; Gazza, L.; Mamone, G.; Auricchio, S.; Troncone, R.; et al. In celiac disease patients the in vivo challenge with the diploid Triticum monococcum elicits a reduced immune response compared to hexaploid wheat. Mol. Nutr. Food Res. 2020, 64, 1901032. [Google Scholar] [CrossRef]

- Zaharieva, M.; Monneveux, P. Cultivated einkorn wheat (Triticum monococcum L. subsp. monococcum): The long life of a founder crop of agriculture. Genet. Resour. Crop Ev. 2014, 61, 677–706. [Google Scholar]

- Hidalgo, A.; Brandolini, A. Nutritional properties of einkorn wheat (Triticum monococcum L.). J. Sci. Food Agr. 2014, 94, 601–612. [Google Scholar] [CrossRef]

- Ciccoritti, R.; Taddei, F.; Gazza, L.; Nocente, F. Influence of kernel thermal pre-treatments on 5-n-alkylresorcinols, polyphenols and antioxidant activity of durum and einkorn wheat. Eur. Food Res. Technol. 2020, 247, 353–362. [Google Scholar] [CrossRef]

- Suchowilska, E.; Wiwart, M.; Kandler, W.; Krska, R. A comparison of macro- and microelement concentrations in the whole grain of four Triticum species. Plant Soil Environ. 2012, 58, 141–147. [Google Scholar] [CrossRef]

- Hidalgo, A.; Brandolini, A. Kinetics of carotenoids degradation during the storage of einkorn (Triticum monococcum L. ssp. monococcum) and bread wheat (Triticum aestivum L. ssp. aestivum) flours. J. Agric. Food Chem. 2008, 56, 11300–11305. [Google Scholar] [PubMed]

- Geisslitz, S.; Longin, C.F.H.; Scherf, K.A.; Koehler, P. Comparative study on gluten protein composition of ancient (einkorn, emmer and spelt) and modern wheat species (durum and common wheat). Foods 2019, 8, 409. [Google Scholar] [CrossRef]

- Iacomino, G.; Di Stasio, L.; Fierro, O.; Picariello, G.; Venezia, A.; Gazza, L.; Ferranti, P.; Mamone, G. Protective effects of ID331 Triticum monococcum gliadin on in vitro models of the intestinal epithelium. Food Chem. 2016, 212, 537–542. [Google Scholar] [CrossRef] [PubMed]

- Di Stasio, L.; Picascia, S.; Auricchio, R.; Vitale, S.; Gazza, L.; Picariello, G.; Gianfrani, C.; Mamone, G. Comparative analysis of in vitro digestibility and immunogenicity of gliadins proteins from durum and einkorn wheat. Front. Nutr. 2020, 7, 56. [Google Scholar] [CrossRef]

- Saponaro, C.; Pogna, N.E.; Castagna, R.; Pasquini, M.; Cacciatori, P.; Redaelli, R. Allelic variation at the Gli-Am1, Gli-Am2 and Glu-Am1 loci and bread-making quality in diploid wheat Triticum monococcum. Genet. Res. Camb. 1995, 66, 127–137. [Google Scholar] [CrossRef]

- Borghi, B.; Castagna, R.; Corbellini, M.; Heun, M.; Salamini, F. Breadmaking quality of einkorn wheat (Triticum monococcum ssp. monococcum). Cereal Chem. 1996, 73, 208–214. [Google Scholar]

- Brandolini, A.; Hidalgo, A. Einkorn (Triticum monococcum) flour and bread. In Flour and Breads and Their Fortification in Health and Disease Prevention; Preedy, V.R., Watson, R.R., Patel, V.B., Eds.; Academic Press: London, UK, 2011; pp. 79–88. [Google Scholar]

- Geisslitz, S.; Wieser, H.; Scherf, K.A.; Koehler, P. Gluten protein composition and aggregation properties as predictors for bread volume of common wheat, spelt, durum wheat, emmer and einkorn. J. Cereal Sci. 2018, 83, 204–212. [Google Scholar] [CrossRef]

- Corbellini, M.; Empilli, S.; Vaccino, P.; Brandolini, A.; Borghi, B.; Heun, M.; Salamini, F. Einkorn characterization for bread and cookie production in relation to protein subunit composition. Cereal Chem. 1999, 76, 727–733. [Google Scholar] [CrossRef]

- Brandolini, A.; Lucisano, M.; Mariotti, M.; Hidalgo, A. A study on the quality of einkorn (Triticum monococcum L. ssp. monococcum) pasta. J. Cereal Sci. 2018, 82, 57–64. [Google Scholar] [CrossRef]

- Hidalgo, A.; Alamprese, C.; Marti, A.; Galli, S.; Terno, A.B.; Brandolini, A. Nutritional and technological properties of non-traditional einkorn (Triticum monococcum) wheat pasta. LWT 2020, 133, 109932. [Google Scholar] [CrossRef]

- Pasini, G.; Greco, F.; Cremonini, M.; Brandolini, A.; Consonni, R.; Gussoni, M. Structural and nutritional properties of pasta from Triticum monococcum and Triticum durum species. A combined 1H NMR, MRI and digestibility study. J. Agr. Food Chem. 2015, 63, 5072–5082. [Google Scholar] [CrossRef] [PubMed]

- La Gatta, B.; Rutigliano, M.; Rusco, G.; Petrella, G.; Di Luccia, A. Evidence for different supramolecular arrangements in pasta from durum wheat (Triticum durum) and einkorn (Triticum monococcum) flours. J. Cereal Sci. 2017, 73, 76–83. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists. 54-30.02 Alveograph method for soft and hard wheat flour. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- American Association of Cereal Chemists. 56-70.01 Sodium Dodecyl Sulfate Sedimentation Test for Durum Wheat. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- American Association of Cereal Chemists. 56-81B Determination of falling number. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- American Association of Cereal Chemists. 38-12, Wet Gluten, Dry Gluten, Water-Binding Capacity, and Gluten Index. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Nocente, F.; Taddei, F.; Galassi, E.; Gazza, L. Upcycling of brewers’ spent grain by production of dry pasta with higher nutritional potential. LWT 2019, 114, 108421. [Google Scholar] [CrossRef]

- International Association for Cereal Science and Technology. ICC Standard Methods (Methods No. 105/2); ICC: Vienna, Austria, 1994. [Google Scholar]

- Association of Official Analytical Chemists. Official Methods of Analysis 2002.02, Resistant Starch in Starch and Plant Materials; AOAC: Gaithersburg, MD, USA, 2002. [Google Scholar]

- Association of Official Analytical Chemists. Official Methods of Analysis 991.43, 16th ed.; Cunniff, P., Ed.; AOAC: Gaithersburg, MD, USA, 1995. [Google Scholar]

- American Association of Cereal Chemists. 08-01.01 Ash. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- American Association of Cereal Chemists. 32.32.01 Measurement of total fructans in foods by an enzymatic/spectrophotometric method. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Martini, D.; Taddei, F.; Nicoletti, I.; Ciccoritti, R.; Corradini, D.; D’Egidio, M.G. Effects of genotype and environment on phenolic acids content and total antioxidant capacity in durum wheat. Cereal Chem. 2014, 91, 310–317. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists. 66-50.01 Pasta and noodle cooking quality-firmness. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Nocente, F.; Natale, C.; Galassi, E.; Taddei, F.; Gazza, L. Using einkorn and tritordeum brewers’ spent grain to increase the nutritional potential of durum wheat pasta. Foods 2021, 10, 502. [Google Scholar] [CrossRef]

- D’Egidio, M.G.; Mariani, B.M.; Nardi, S.; Novaro, P.; Cubadda, R. Chemical and technological variables and their relationships: A predictive equation for pasta cooking quality. Cereal Chem. 1990, 67, 275–281. [Google Scholar]

- Bencze, S.; Makádi, M.; Aranyos, T.J.; Földi, M.; Hertelendy, P.; Mikó, P.; Bosi, S.; Negri, L.; Drexler, D. Re-introduction of ancient wheat cultivars into organic agriculture—Emmer and einkorn cultivation experiences under marginal conditions. Sustainability 2020, 12, 1584. [Google Scholar] [CrossRef]

- Rotondi Aufiero, V.; Di Stasio, L.; Maurano, F.; Accardo, F.; Ferranti, P.; Mamone, G.; Rossi, M.; Mazzarella, G. Beneficial effects of a T. monococcum wheat cultivar on diabetes incidence evaluated in non-obese diabetic mice and after in vitro simulated gastroduodenal digestion. Int. J. Food Sci. Nutr. 2022, 73, 327–335. [Google Scholar] [CrossRef]

- Kolaric, L.; Minarovicova, L.; Laukova, M.; Karovicova, J.; Kohajdova, Z. Pasta noodles enriched with sweet potato starch: Impact on quality parameters and resistant starch content. J Texture Stud. 2020, 51, 464–474. [Google Scholar] [CrossRef]

- Official Journal of the European Union. REGULATION (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods; Official Journal of the European Union: Brussels, Belgium, 2006. [Google Scholar]

- Regulation (UE). N. 1047/2012 UE Commission. 8 November 2012. Available online: https://eur-lex.europa.eu/legal-content/IT/TXT/PDF/?uri=CELEX:32012R1047&from=BG (accessed on 28 June 2022).

- Italian Presidential Decree n.187. Regulation for the Revision of the Legislation on the Production and Marketing of Flour and Pasta Dishes, Pursuant to Article 50 of the Law of February 22, 1994, n. 146. 9 February 2001. Available online: https://www.politicheagricole.it/flex/cm/pages/ServeAttachment.php/L/IT/D/e%252Fe%252F2%252FD.42f2f8869ef2c1b3a2e1/P/BLOB%3AID%3D2772/E/pdf?mode=download (accessed on 24 June 2022).

- Hidalgo, A.; Brandolini, A.; Pompei, C.; Piscozzi, R. Carotenoids and tocols of einkorn wheat (Triticum monococcum ssp. monococcum L.). J. Cereal Sci. 2006, 44, 182–193. [Google Scholar] [CrossRef]

- Tomomatsu, H. Health effects of oligosaccharides. Food Tech. 1994, 48, 61–65. [Google Scholar]

- Paradiso, A.; Cecchini, C.; Greco, E.; D’Egidio, M.G.; De Gara, L. Variation in fructooligosaccharide contents during plant development and in different cultivars of durum wheat. Plant. Biosyst.-Int. J. Deal All Asp. Plant. Biol. 2008, 142, 656–660. [Google Scholar] [CrossRef]

- Brandolini, A.; Hidalgo, A.; Plizzari, L.; Erba, D. Impact of genetic and environmental factors on einkorn wheat (Triticum monococcum L. subsp. monococcum) polysaccharides. J. Cereal Sci. 2011, 53, 65–72. [Google Scholar] [CrossRef]

- Moshfegh, A.J.; Friday, J.E.; Goldman, J.P.; Chug Ahuja, J.K. Presence of inulin and oligofructose in the diets of the Americans. J. Nutr. 1999, 129, 1407–1411. [Google Scholar] [CrossRef]

- Cubadda, R.; Carcea, M.; Pasqui, L.A. Suitability of the gluten index method for assessing gluten strength in durum wheat and semolina. Cereal Foods World 1992, 37, 866–869. [Google Scholar]

- Sjoberg, S.M.; Carter, A.H.; Steber, C.M.; Garland-Campbell, K.A. Unraveling complex traits in wheat: Approaches for analyzing genotype × environment interactions in a multienvironment study of falling numbers. Crop Sci. 2020, 60, 3013–3026. [Google Scholar] [CrossRef]

- Brandolini, A.; Hidalgo, A.; Plizzari, L. Storage-induced changes in einkorn (Triticum monococcum L.) and breadwheat (Triticum aestivum L. ssp. aestivum) flours. J. Cereal Sci. 2010, 51, 205–212. [Google Scholar] [CrossRef]

- Brennan, M.A.; Merts, I.; Monro, J.; Woolnough, J.; Brennan, C.S. Impact of guar and wheat bran on the physical and nutritional quality of extruded breakfast cereals. Starch 2008, 60, 248–256. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C.M. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012, 130, 299–309. [Google Scholar] [CrossRef]

- D’Egidio, M.G.; De Stefanis, E.; Fortini, S.; Galterio, G.; Nardi, S.; Sgrulletta, D.; Bozzini, A. Standardization of cooking quality analysis in macaroni and pasta products. Cereal Foods World 1982, 27, 367–368. [Google Scholar]

- Foschia, M.; Peressini, D.; Sensidoni, A.; Brennan, M.A.; Brennan, C.S. How combinations of dietary fibres can affect physicochemical characteristics of pasta. LWT 2015, 61, 41–46. [Google Scholar] [CrossRef]

- Marti, A.; Seetharaman, K.; Pagani, M.A. Rice-based pasta: A comparison between conventional pasta-making and extrusion-cooking. J. Cereal Sci. 2010, 52, 404–409. [Google Scholar] [CrossRef]

- Taddei, F.; Galassi, E.; Nocente, F.; Gazza, L. Innovative milling processes to improve the technological and nutritional quality of parboiled brown rice pasta from contrasting amylose content cultivars. Foods 2021, 10, 1316. [Google Scholar] [CrossRef] [PubMed]

| Proteins | RS | TDF | FOS | TAC | Ash | |

|---|---|---|---|---|---|---|

| (g/100 g) | (g/100 g) | (g/100 g) | (g/100 g) | (mmol TEAC/kg) | (g/100 g) | |

| Hammurabi | 19.10 ± 0.07 a | 0.276 ± 0.002 c | 10.1 ± 0.3 a | 1.11 ± 0.03 a | 69.7 ± 0.5 a | 2.59 ± 0.01 a |

| Norberto | 18.3 ± 0.2 b | 0.80 ± 0.02 a | 10.03 ± 0.08 a | 1.3 ± 0.2 a | 64.2 ± 0.5 b | 2.26 ± 0.03 b |

| Semolina | 13.3 ± 0.2 c | 0.382 ± 0.005 b | 3.6 ± 0.3 b | 1.29 ± 0.02 a | 46.8 ± 0.5 c | 0.708 ± 0.001 c |

| GI | SDS | W | P/L | FN | |

|---|---|---|---|---|---|

| (%) | (mL) | (J × 10−4) | (sec″) | ||

| Hammurabi | 0 c | 24.7 ± 0.7 c | 44.0 ± 3.6 c | 2.5 ± 0.1 a | 463″ ± 10 b |

| Norberto | 52 ± 2 b | 58.5 ± 0.7 a | 84 ± 4 b | 1.6 ± 0.4 b | 417″ ± 11 c |

| Semolina | 84 ± 3 a | 37.5 ± 0.7 b | 227 ± 21 a | 1.8 ± 0.1 b | 483″ ± 2 a |

| Spaghetti Diameter | OCT | WA | TOM | CL | Firmness | Colour | |||

|---|---|---|---|---|---|---|---|---|---|

| (mm) | (min′ s″) | (g) | (g) | (g/100 g) | (kg) | (b*) | (100-L) | (a*) | |

| Hammurabi | 1.52–1.64 | 7′ 00″ ± 5″ c | 128.21 ± 0.08 c | 2.06 ± 0.01 a | 10.7 ± 0.3 a | 0.33 ± 0.02 b | 22.4 ± 0.8 c | 59.8 ± 0.5 a | 12.1 ± 0.3 a |

| Norberto | 1.56–1.66 | 7′ 30″ ± 5″ b | 137.99 ± 0.09 b | 1.7 ± 0.1 b | 7.9 ± 0.1 b | 0.48 ± 0.04 a | 28.0 ± 0.7 a | 56.3 ± 0.5 b | 10.8 ± 0.2 b |

| Semolina | 1.53–1.60 | 10′ 30″ ± 5″ a | 148.6 ± 0.2 a | 1.64 ± 0.04 b | 3.67 ± 0.02 c | 0.276 ± 0.005 b | 25.4 ± 0.2 b | 38.2 ± 0.1 c | 1.25 ± 0.08 c |

| Firmness | Stickiness | Bulkiness | Global Sensorial Judgment | |

|---|---|---|---|---|

| Hammurabi | 55 c | 75 b | 75 a | 68 b |

| Norberto | 60 b | 60 c | 60 c | 60 c |

| Semolina | 65 a | 80 a | 70 b | 72 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gazza, L.; Galassi, E.; Nocente, F.; Natale, C.; Taddei, F. Cooking Quality and Chemical and Technological Characteristics of Wholegrain Einkorn Pasta Obtained from Micronized Flour. Foods 2022, 11, 2905. https://doi.org/10.3390/foods11182905

Gazza L, Galassi E, Nocente F, Natale C, Taddei F. Cooking Quality and Chemical and Technological Characteristics of Wholegrain Einkorn Pasta Obtained from Micronized Flour. Foods. 2022; 11(18):2905. https://doi.org/10.3390/foods11182905

Chicago/Turabian StyleGazza, Laura, Elena Galassi, Francesca Nocente, Chiara Natale, and Federica Taddei. 2022. "Cooking Quality and Chemical and Technological Characteristics of Wholegrain Einkorn Pasta Obtained from Micronized Flour" Foods 11, no. 18: 2905. https://doi.org/10.3390/foods11182905

APA StyleGazza, L., Galassi, E., Nocente, F., Natale, C., & Taddei, F. (2022). Cooking Quality and Chemical and Technological Characteristics of Wholegrain Einkorn Pasta Obtained from Micronized Flour. Foods, 11(18), 2905. https://doi.org/10.3390/foods11182905