Additive Manufacturing of Zirconia Ceramic and Its Application in Clinical Dentistry: A Review

Abstract

:1. Introduction

2. Additive Manufacturing Techniques for Zirconia Ceramic

2.1. Vat Photopolymerization

2.1.1. Stereolithography (SLA)

2.1.2. Direct Light Processing (DLP)

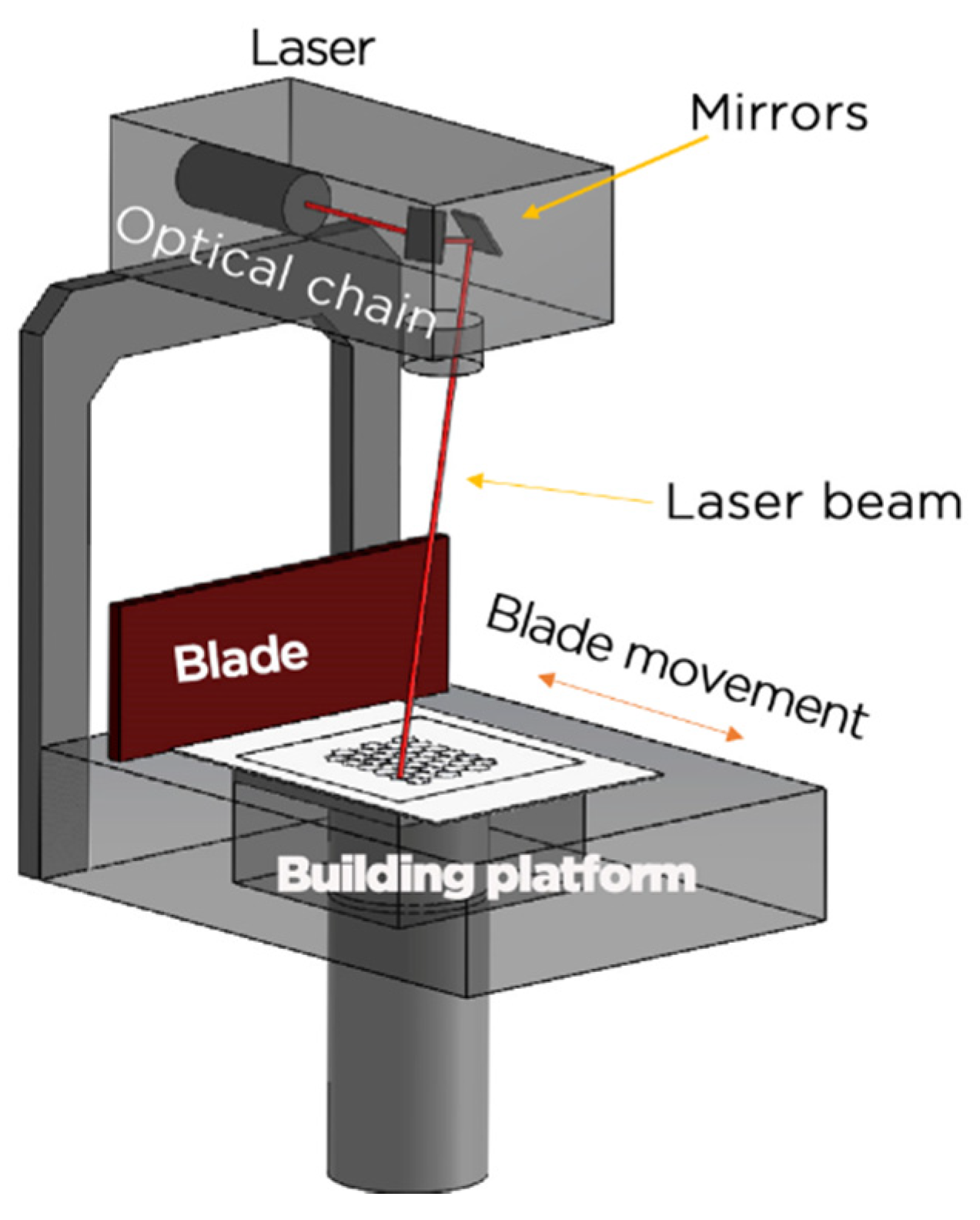

2.2. Selective Laser Sintering (SLS)

2.3. Selective Laser Melting (SLM)

2.4. Direct Inkjet Printing (DIP)

2.5. Binder Jetting

2.6. Fused Deposition Modeling (FDM)

2.7. Direct Ink Writing (DIW)

3. Dental Applications of AM Zirconia Ceramics

3.1. AM Zirconia Restorative Applications

3.2. AM Zirconia in Implant Dentistry

3.3. AM Bone Regeneration Zirconia Applications

4. Challenges and Future Perspectives

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef]

- Makhija, S.K.; Lawson, N.C.; Gilbert, G.H.; Litaker, M.S.; McClelland, J.A.; Louis, D.R.; Gordan, V.V.; Pihlstrom, D.J.; Meyerowitz, C.; Mungia, R.; et al. Dentist material selection for single-unit crowns: Findings from the national dental Ppractice-based research network. J. Dent. 2016, 55, 40–47. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pereira, G.K.R.; Guilardi, L.F.; Dapieve, K.S.; Kleverlaan, C.J.; Rippe, M.P.; Valandro, L.F. Mechanical reliability, fatigue strength and survival analysis of new polycrystalline translucent zirconia ceramics for monolithic restorations. J. Mech. Behav. Biomed. Mater. 2018, 85, 57–65. [Google Scholar] [CrossRef] [PubMed]

- Van Noort, R. The future of dental devices is digital. Dent. Mater. 2012, 28, 3–12. [Google Scholar] [CrossRef]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef]

- Zarone, F.; Russo, S.; Sorrentino, R. From porcelain-fused-to-metal to zirconia: Clinical and experimental considerations. Dent. Mater. 2011, 27, 83–96. [Google Scholar] [CrossRef] [PubMed]

- Guazzato, M.; Albakry, M.; Ringer, S.P.; Swain, M.V. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent. Mater. 2004, 20, 449–456. [Google Scholar] [CrossRef] [PubMed]

- Pereira, G.K.R.; Venturini, A.B.; Silvestri, T.; Dapieve, K.S.; Montagner, A.F.; Soares, F.Z.M.; Valandro, L.F. Low-temperature degradation of Y-TZP ceramics: A systematic review and meta-analysis. J. Mech. Behav. Biomed. Mater. 2016, 55, 151–163. [Google Scholar] [CrossRef] [PubMed]

- Lughi, V.; Sergo, V. Low temperature degradation-aging-of zirconia: A critical review of the relevant aspects in dentistry. Dent. Mater. 2010, 26, 807–820. [Google Scholar] [CrossRef]

- Lebon, N.; Tapie, L.; Duret, F.; Attal, J.P. Understanding dental CAD/CAM for restorations—Dental milling machines from a mechanical engineering viewpoint. Part A: Chairside milling machines. Int. J. Comput. Dent. 2016, 19, 45–62. [Google Scholar]

- Lebon, N.; Tapie, L.; Duret, F.; Attal, J.P. Understanding dental CAD/CAM for restorations—Dental milling machines from a mechanical engineering viewpoint. Part B: Labside milling machines. Int. J. Comput. Dent. 2016, 19, 115–134. [Google Scholar]

- Dawood, A.; Marti, B.M.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef]

- Abduo, J.; Lyons, K.; Bennamoun, M. Trends in computer-aided manufacturing in prosthodontics: A Review of the Available Streams. Int. J. Dent. 2014, 2014, 783948. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Galante, R.; Figueiredo-Pina, C.G.; Serro, A.P. Additive manufacturing of ceramics for dental applications: A review. Dent. Mater. 2019, 35, 825–846. [Google Scholar] [CrossRef]

- Kessler, A.; Hickel, R.; Reymus, M. 3D Printing in Dentistry—State of the Art. Oper. Dent. 2020, 45, 30–40. [Google Scholar] [CrossRef]

- Methani, M.M.; Revilla-León, M.; Zandinejad, A. The potential of additive manufacturing technologies and their processing parameters for the fabrication of all-ceramic crowns: A review. J. Esthet. Restor. Dent. 2020, 32, 182–192. [Google Scholar] [CrossRef] [PubMed]

- Zandinejad, A.; Methani, M.M.; Schneiderman, E.D.; Revilla-León, M.; Morton, D. Fracture resistance of additively manufactured zirconia crowns when cemented to implant supported zirconia abutments: An in vitro Study. J. Prosthodont. 2019, 28, 893–897. [Google Scholar] [CrossRef]

- Deckers, J.; Vleugels, J.; Kruth, J.P. Additive manufacturing of ceramics: A review. J. Ceram. Sci. Technol. 2014, 5, 245–260. [Google Scholar] [CrossRef]

- Kim, G.B.; Lee, S.; Kim, H.; Yang, D.H.; Kim, Y.H.; Kyung, Y.S.; Kim, C.S.; Choi, S.H.; Kim, B.J.; Ha, H.; et al. Three-dimensional printing: Basic principles and applications in medicine and radiology. Korean J. Radiol. 2016, 17, 182–197. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, H.; Cheng, Y.; Liu, W.; He, R.; Zhou, M.; Wu, S.; Song, X.; Chen, Y. Effect of the particle size and the debinding process on the density of alumina ceramics fabricated by 3D printing based on stereolithography. Ceram. Int. 2016, 42, 17290–17294. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive manufacturing of ceramics: Issues, potentialities, and opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Lian, Q.; Sui, W.; Wu, X.; Yang, F.; Yang, S. Additive manufacturing of ZrO2 ceramic dental bridges by stereolithography. Rapid Prototyp. J. 2018, 24, 114–119. [Google Scholar] [CrossRef]

- Masciandaro, S.; Torrell, M.; Leone, P.; Tarancón, A. Three-dimensional printed yttria-stabilized zirconia self-supported electrolytes for solid oxide fuel cell applications. J. Eur. Ceram. Soc. 2019, 39, 9–16. [Google Scholar] [CrossRef] [Green Version]

- Griffith, M.L.; Halloran, J.W. Freeform fabrication of ceramics via stereolithography. J. Am. Ceram. Soc. 1996, 79, 2601–2608. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Li, D.; Zhou, W.; Wang, L. Curing characteristics of ceramic stereolithography for an aqueous-based silica suspension. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 641–651. [Google Scholar] [CrossRef]

- Bertsch, A.; Jiguet, S.; Renaud, P. Microfabrication of ceramic components by microstereolithography. J. Micromech. Microeng. 2004, 14, 197–203. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, K.; Bourell, D.L.; Chen, F.; Sun, H.; Shi, Y.; Wang, J.; He, M.; Chen, J. Gelcasting of zirconia-based all-ceramic teeth combined with stereolithography. Ceram. Int. 2018, 44, 21556–21563. [Google Scholar] [CrossRef]

- Zhang, K.; He, R.; Xie, C.; Wang, G.; Ding, G.; Wang, M.; Song, W.; Fang, D. Photosensitive ZrO2 suspensions for stereolithography. Ceram. Int. 2019, 45, 12189–12195. [Google Scholar] [CrossRef]

- Gentry, S.P.; Halloran, J.W. Depth and width of cured lines in photopolymerizable ceramic suspensions. J. Eur. Ceram. Soc. 2013, 33, 1981–1988. [Google Scholar] [CrossRef]

- Badev, A.; Abouliatim, Y.; Chartier, T.; Lecamp, L.; Lebaudy, P.; Chaput, C.; Delage, C. Photopolymerization kinetics of a polyether acrylate in the presence of ceramic fillers used in stereolithography. J. Photochem. Photobiol. A Chem. 2011, 222, 117–122. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, X.; Shi, J. Additive manufacturing of zirconia ceramics: A state-of-the-art review. J. Mater. Res. Technol. 2020, 9, 9029–9048. [Google Scholar] [CrossRef]

- Johansson, E.; Lidström, O.; Johansson, J.; Lyckfeldt, O.; Adolfsson, E. Influence of resin composition on the defect formation in alumina manufactured by stereolithography. Materials 2017, 10, 138. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, J.C.; Dommati, H. Fabrication of zirconia ceramic parts by using solvent-based slurry stereolithography and sintering. Int. J. Adv. Manuf. Technol. 2018, 98, 1537–1546. [Google Scholar] [CrossRef]

- Della Bona, A.; Cantelli, V.; Britto, V.T.; Collares, K.F.; Stansbury, J.W. 3D printing restorative materials using a stereolithographic technique: A systematic review. Dent. Mater. 2021, 37, 336–350. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Husain, N.A.; Ceballos, L.; Özcan, M. Flexural strength and Weibull characteristics of stereolithography additive manufactured versus milled zirconia. J. Prosthet. Dent. 2021, 125, 685–690. [Google Scholar] [CrossRef]

- Revilla-León, M.; Mostafavi, D.; Methani, M.M.; Zandinejad, A. Manufacturing accuracy and volumetric changes of stereolithography additively manufactured zirconia with different porosities. J. Prosthet. Dent. 2021, 8. [Google Scholar] [CrossRef]

- Nakai, H.; Inokoshi, M.; Nozaki, K.; Komatsu, K.; Kamijo, S.; Liu, H.; Shimizubata, M.; Minakuchi, S.; Van Meerbeek, B.; Vleugels, J.; et al. Additively manufactured zirconia for dental applications. Materials 2021, 14, 3694. [Google Scholar] [CrossRef]

- ASTM, Committee. F42 on Additive Manufacturing Technologies, West Conshohocken, Pennsylvania, US 2009; Standard Terminology for Additive Manufacturing e General Principles and Terminology; ISO/ASTM52900-15. Available online: https://www.astm.org/Standards/ISOASTM52900.htm (accessed on 5 August 2021).

- Groth, C.; Kravitz, N.D.; Jones, P.E.; Graham, J.W.; Redmond, W.R. Three-dimensional printing technology. J. Clin. Orthod. 2014, 48, 475–485. [Google Scholar] [PubMed]

- Mitteramskogler, G.; Gmeiner, R.; Felzmann, R.; Gruber, S.; Hofstetter, C.; Stampfl, J.; Ebert, J.; Wachter, W.; Laubersheimer, J. Light curing strategies for lithography-based additive manufacturing of customized ceramics. Addit. Manuf. 2014, 1, 110–118. [Google Scholar] [CrossRef]

- Lee, M.P.; Cooper, G.J.; Hinkley, T.; Gibson, G.M.; Padgett, M.J.; Cronin, L. Development of a 3D printer using scanning projection stereolithography. Sci. Rep. 2015, 5, 9875. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, A.P.; Qu, X.; Soman, P.; Hribar, K.C.; Lee, J.W.; Chen, S.; He, S. Rapid fabrication of complex 3D extracellular microenvironments by dynamic optical projection stereolithography. Adv. Mater. 2012, 24, 4266–4270. [Google Scholar] [CrossRef] [Green Version]

- Unkovskiy, A.; Schmidt, F.; Beuer, F.; Li, P.; Spintzyk, S.; Kraemer Fernandez, P. Stereolithography vs. direct light processing for rapid manufacturing of complete denture bases: An in vitro accuracy analysis. J. Clin. Med. 2021, 10, 1070. [Google Scholar] [CrossRef] [PubMed]

- Komissarenko, D.; Sokolov, P.; Evstigneeva, A.; Shmeleva, I.; Dosovitsky, A. Rheological and curing behavior of acrylate-based suspensions for the DLP 3D printing of complex zirconia parts. Materials 2018, 11, 2350. [Google Scholar] [CrossRef] [Green Version]

- Deckard, C.R. Method and Apparatus for Producing Parts by Selective Sintering. U.S. Patent No. 4,863,538-A, 5 September 1986. [Google Scholar]

- Mazzoli, A. Selective laser sintering in biomedical engineering. Med. Biol. Eng. Comput. 2013, 51, 245–256. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Zhang, Z.; Kruth, J.P.; Vleugels, J. Additive manufacturing of zirconia parts by indirect selective laser sintering. J. Eur. Ceram. Soc. 2014, 34, 81–89. [Google Scholar] [CrossRef]

- Deckers, J.; Meyers, S.; Kruth, J.P.; Vleugels, J. Direct selective laser sintering/melting of high density alumina powder layers at elevated temperatures. Phys. Procedia 2014, 56, 117–124. [Google Scholar] [CrossRef] [Green Version]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Klocke, F.; Derichs, C.; Ader, C.; Demmer, A. Investigations on laser sintering of ceramic slurries. Prod. Eng. 2007, 1, 279–284. [Google Scholar] [CrossRef]

- Wu, Y.; Du, J.; Choy, K.L.; Hench, L.L. Laser densification of alumina powder beds generated using aerosol assisted spray deposition. J. Eur. Ceram. Soc. 2007, 27, 4727–4735. [Google Scholar] [CrossRef]

- Deckers, J.; Kruth, J.P.; Shahzad, K.; Vleugels, J. Density improvement of alumina parts produced through selective laser sintering of alumina-polyamide composite powder. CIRP Ann. 2012, 61, 211–214. [Google Scholar] [CrossRef]

- Yan, S.; Wu, D.; Niu, F.; Ma, G.; Kang, R. Al2O3-ZrO2 eutectic ceramic via ultrasonic-assisted laser engineered net shaping. Ceram. Int. 2017, 43, 15905–15910. [Google Scholar] [CrossRef]

- Meiners, W.; Wissenbach, K.; Gasser, A. Selective Laser Sintering at Melting Temperature. U.S. Patent No. 6,215,093, 10 April 2001. [Google Scholar]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Bertrand, P.; Bayle, F.; Combe, C.; Goeuriot, P.; Smurov, I. Ceramic components manufacturing by selective laser sintering. Appl. Surf. Sci. 2007, 254, 989–992. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Yadroitsev, I.; Bertrand, P.; Smurov, I. Alumina–zirconium ceramics synthesis by selective laser sintering/melting. Appl. Surf. Sci. 2007, 254, 966–970. [Google Scholar] [CrossRef]

- Liu, Q.; Danlos, Y.; Song, B.; Zhang, B.; Yin, S.; Liao, H. Effect of high-temperature preheating on the selective laser melting of yttria-stabilized zirconia ceramic. J. Mater. Process. Technol. 2015, 222, 61–74. [Google Scholar] [CrossRef]

- Liu, Z.; Song, K.; Gao, B.; Tian, T.; Yang, H.; Lin, X.; Huang, W. Microstructure and mechanical properties of Al2O3/ZrO2 directionally solidified eutectic ceramic prepared by laser 3D printing. J. Mater. Sci. Technol. 2016, 32, 320–325. [Google Scholar] [CrossRef]

- Liu, H.; Su, H.; Shen, Z.; Wang, E.; Zhao, D.; Guo, M.; Zhang, J.; Liu, L.; Fu, H. Direct formation of Al2O3/GdAlO3/ZrO2 ternary eutectic ceramics by selective laser melting: Microstructure evolutions. J. Eur. Ceram. Soc. 2018, 38, 5144–5152. [Google Scholar] [CrossRef]

- Hagedorn, Y.-C.; Wilkes, J.; Meiners, W.; Wissembach, K.; Poprawe, R. Net shaped high performance oxide ceramic parts by selective laser melting. Phys. Procedia 2010, 5, 587–594. [Google Scholar] [CrossRef]

- Özkol, E.; Ebert, J.; Uibel, K.; Wätjen, A.M.; Telle, R. Development of high solid content aqueous 3Y-TZP suspensions for direct inkjet printing using a thermal inkjet printer. J. Eur. Ceram. Soc. 2009, 29, 403–409. [Google Scholar] [CrossRef]

- Ebert, J.; Özkol, E.; Zeichner, A.; Uibel, K.; Weiss, Ö.; Koops, U.; Telle, R.; Fischer, H. Direct inkjet printing of dental prostheses made of zirconia. J. Dent. Res. 2009, 88, 673–676. [Google Scholar] [CrossRef]

- Mott, M.; Song, J.H.; Evans, J.R. Microengineering of ceramics by direct ink-jet printing. J. Am. Ceram. Soc. 1999, 82, 1653–1658. [Google Scholar] [CrossRef]

- Mott, M.; Evans, J.R. Zirconia/alumina functionally graded material made by ceramic ink jet printing. Mater. Sci. Eng. A 1999, 271, 344–352. [Google Scholar] [CrossRef]

- Song, J.H.; Edirisinghe, M.J.; Evans, J.R. Formulation and multilayer jet printing of ceramic inks. J. Am. Ceram. Soc. 1999, 82, 3374–3380. [Google Scholar] [CrossRef]

- Özkol, E. Rheological characterization of aqueous 3Y-TZP inks optimized for direct thermal ink-jet printing of ceramic components. J. Am. Ceram. Soc. 2013, 96, 1124–1130. [Google Scholar] [CrossRef]

- Özkol, E.; Zhang, W.; Ebert, J.; Telle, R. Potentials of the “direct inkjet printing” method for manufacturing 3Y-TZP based dental restorations. J. Eur. Ceram. Soc. 2012, 32, 2193–2201. [Google Scholar] [CrossRef]

- Deegan, R.D.; Bakajin, O.; Dupont, T.F.; Huber, G.; Nagel, S.R.; Witten, T.A. Capillary flow as the cause of ring stains from dried liquid drops. Nature 1997, 389, 827–829. [Google Scholar] [CrossRef]

- Majumder, M.; Rendall, C.S.; Eukel, J.A.; Wang, J.Y.; Behabtu, N.; Pint, C.L.; Liu, T.Y.; Orbeak, A.W.; Miri, F.; Nam, J.; et al. Overcoming the “coffee-stain” effect by compositional marangoni-flow-assisted drop-drying. J. Phys. Chem. B 2012, 116, 6536–6542. [Google Scholar] [CrossRef] [PubMed]

- Dou, R.; Wang, T.; Guo, Y.; Derby, B. Ink-jet printing of zirconia: Coffee staining and line stability. J. Am. Ceram. Soc. 2011, 94, 3787–3792. [Google Scholar] [CrossRef]

- Friederich, A.; Binder, J.R.; Bauer, W. Rheological control of the coffee stain effect for inkjet printing of ceramics. J. Am. Ceram. Soc. 2013, 96, 2093–2099. [Google Scholar] [CrossRef] [Green Version]

- Miyanaji, H.; Zhang, S.; Lassell, A.; Zandinejad, A.A.; Yang, L. Optimal process parameters for 3D printing of porcelain structures. Procedia Manuf. 2016, 5, 870–887. [Google Scholar] [CrossRef] [Green Version]

- Sachs, E.M.; Haggerty, J.S.; Cima, M.J.; Williams, P.A. Three-Dimensional Printing Techniques. U.S. Patent No. 5,204,055, 20 April 1993. [Google Scholar]

- Yang, L.; Miyanaji, H. Ceramic additive manufacturing: A review of current status and challenges. Solid Freeform Fabrication 2017. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017; pp. 652–679. [Google Scholar]

- Miyanaji, H.; Zhang, S.; Lassell, A.; Zandinejad, A.; Yang, L. Process development of porcelain cramic material with binder jetting process for dental applications. JOM 2016, 68, 831–841. [Google Scholar] [CrossRef]

- Danforth, S. Fused deposition of ceramics: A new technique for the rapid fabrication of ceramic components. Mater. Technol. 1995, 10, 144–146. [Google Scholar] [CrossRef]

- He, Q.; Jiang, J.; Yang, X.; Zhang, L.; Zhou, Z.; Zhong, Y.; Shen, Z. Additive manufacturing of dense zirconia ceramics by fused deposition modeling via screw extrusion. J. Eur. Ceram. Soc. 2021, 41, 1033–1040. [Google Scholar] [CrossRef]

- Li, Y.Y.; Li, L.T.; Li, B. Direct write printing of three-dimensional ZrO2 biological scaffolds. Mater. Des. 2015, 72, 16–20. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Lin, D.H.; Jiang, C.P.; Lin, Y.M. Dental implant customization using numerical optimization design and 3-dimensional printing fabrication of zirconia ceramic. Int. J. Numer. Method. Biomed. Eng. 2017, 33, e2820. [Google Scholar] [CrossRef]

- Anssari Moin, D.; Hassan, B.; Wismeijer, D. A novel approach for custom three-dimensional printing of a zirconia root analogue implant by digital light processing. Clin. Oral. Implant. Res. 2017, 28, 668–670. [Google Scholar] [CrossRef]

- Osman, R.B.; van der Veen, A.J.; Huiberts, D.; Wismeijer, D.; Alharbi, N. 3D-printing zirconia implants; a dream or a reality? An in-vitro study evaluating the dimensional accuracy, surface topography and mechanical properties of printed zirconia implant and discs. J. Mech. Behav. Biomed. Mater. 2017, 75, 521–528. [Google Scholar] [CrossRef]

- Wang, W.; Yu, H.; Liu, Y.; Jiang, X.; Gao, B. Trueness analysis of zirconia crowns fabricated with 3-dimensional printing. J. Prosthet. Dent. 2019, 121, 285–291. [Google Scholar] [CrossRef]

- Li, R.; Wang, Y.Y.; Hu, M.; Wang, Y.Y.; Xv, Y.; Liu, Y.; Sun, Y. Strength and adaptation of stereolithography-fabricated zirconia dental crowns: An in vitro study. Int. J. Prosthodont. 2019, 32, 439–443. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Methani, M.M.; Morton, D.; Zandinejad, A. Internal and marginal discrepancies associated with stereo-lithography (SLA) additively manufactured zirconia crowns. J. Prosthet. Dent. 2020, 124, 730–737. [Google Scholar] [CrossRef] [PubMed]

- Ioannidis, A.; Bomze, D.; Hämmerle, C.H.F.; Hüsler, J.; Birrer, O.; Mühlemann, S. Load-bearing capacity of CAD/CAM 3D-printed zirconia, CAD/CAM milled zirconia, and heat-pressed lithium disilicate ultra-thin occlusal veneers on molars. Dent. Mater. 2020, 36, e109–e116. [Google Scholar] [CrossRef]

- Wang, W.; Sun, J. Dimensional accuracy and clinical adaptation of ceramic crowns fabricated with the stereolithography technique. J. Prosthet. Dent. 2021, 125, 657–663. [Google Scholar] [CrossRef]

- Li, R.; Chen, H.; Wang, Y.; Sun, Y. Performance of stereolithography and milling in fabricating monolithic zirconia crowns with different finish line designs. J. Mech. Behav. Biomed. Mater. 2021, 115, 104255. [Google Scholar] [CrossRef] [PubMed]

- Zandinejad, A.; Lin, W.S.; Morton, D. Method for Fabricating Dental Restorations. U.S. Patent No. 10,716,648 B2, 21 July 2020. [Google Scholar]

- Sakthiabirami, K.; Soundharrajan, V.; Kang, J.; Yang, Y.P.; Park, S. Three-dimensional zirconia-based scaffolds for load-bearing bone-regeneration applications: Prospects and challenges. Materials 2021, 14, 3207. [Google Scholar] [CrossRef]

- Schmidt, J.; Colombo, P. Digital light processing of ceramic components from polysiloxanes. J. Eur. Ceram Soc. 2018, 38, 57–66. [Google Scholar] [CrossRef]

- Bienia, M.; Lejeune, M.; Chambon, M.; Baco Carles, V.; Dossou Yovo, C.; Noguera, R.; Noguera, R.; Rossignol, F. Inkjet printing of ceramic colloidal suspensions: Filament growth and breakup. Chem. Eng. Sci. 2016, 149, 1–13. [Google Scholar] [CrossRef] [Green Version]

| Author/Year | AM Technology | Application | Composition | Evaluated Parameters | Main Findings |

| Ebert et al., 2009 [65] | Direct Inkjet printing (DIP) (From Hewlett Packard) | Dental crown | Suspension consisted of 27 vol% zirconia powder, 55% distilled water, dispersants, and 3 mol% yttria partially stabilized zirconia powder | -Density -Sintering shrinkage -Microstructure -Mechanical properties | -Relative density: 96.9% -Isotropic shrinkage: 20 vol% -Homogeneous microstructure with some submicron-sized pores -Single bigger defects owing to clogging printing nozzles -Characteristic strength: 763 MPa -Weibull modulus: 3.5 -Fracture toughness: 6.7 ± 1.6 MPa.m1/2. -Crack-free components |

| Özkol et al., 2012 [70] | Direct Inkjet printing (DIP) (From HP Deskjet) | Dental bridge framework | -Ceramic ink consisted of an aqueous dispersion of 40 vol% 3Y-TZP particles (particle size 0.63 µm), Carboxylic acid-based dispersant, water, dispersants, and humectants -Supportive ink contained aqueous dispersion of sub-micron-sized thermal black type carbon black particles, alkali free carboxylic acid ester-based dispersant | -Density -Stress distributions -Maximum tensile stress -Flexural strength | -No clogging printing nozzles -Printed components had a smooth surface without any stair steps and drying or sintering cracks -Relative density: >96% -Maximum tensile stress under realistic clenching conditions: ∼340 MPa -Flexural strength (characteristic strength): ∼843 MPa -Weibull modulus: 3.6 -The defect on the supportive base was transferred to the framework structure leading a void on the top surface |

| Cheng et al., 2017 [82] | Stereolithography (SLA) | Dental implant | -Slurry contained zirconia-yttrium ceramic powder (EZU3YA-1) with particle size 1 µm mixed with photocurable resin at a weight ratio 13:5 -Resin binder: triethylene glycol dimethacrylate and urethane dimethacrylate, 1:3 ratio -Photoinitiator: camphorquinone Wavelength: 470 nm | -Microstructure -Hardness -Flexural strength | -Flexural strength: Green body: 20.41 ± 3.8 MPa Sintered specimens: 632.1 ± 72.5 MPa -Vickers hardness Green body: 0.12 GPa Sintered body: 14.72 GPa -Stable microstructure with no microcracks |

| Anssari Moin et al., 2017 [83] | Direct light processing (DLP) (from Admatec) | Root analogue implants (RAI) | -The photopolymer used was a dispersion of a commercial ceramic powder into a liquid solution of polyacrylate -Due to the patenting process, the authors could not release further details | -Dimensional accuracy | -Printed RAI had a 6.67% larger surface area and 46.38% of the printed RAI has a greater distance than 0.1 mm from the original tooth representing a volumetrically larger copy -Compared to CAD model, the printed customized implant had greater divergence for surface area change (7.14%), percentage threshold exceeding for 0.1 mm (59.33%) and 0.5 mm (4.86%). |

| Osman et al., 2017 [84] | Direct light processing (DLP) (From Admatec) | Dental implant | -Slurry contained commercial zirconia-yttrium ceramic powder (TZ-3YS-E) mixed with photocurable resin -3 mol% yttria -particle size 0.09 µm | -Dimensional accuracy -Density -Flexural strength -Morphology -Surface roughness --Crystallographic phase | -Dimensional accuracy: high (average deviation: 0.089 and −0.129 mm (±0.068). -Presence of several microcracks, porosities and interconnected pores. -Surface roughness Ra value: 1.59 ± 0.41 µm Rq value: 1.94 ± 0.47 µm -Flexural strength: 943 MPa |

| Lian et al., 2018 [23] | Stereolithography (SLA) (From Shaanxi Hengtong Intelligent Machine) | Dental bridges | Ceramic suspension: -An aqueous dispersion of 40 vol% submicron sized 3Y-TZP particles (particle size 0.2 µm) -Stir of acrylamide and methylenebisacrylamide, deionized water, and glycerol -photoinitiator liquid (PI-1173) | -Shrinkage -Density -Hardness -Surface roughness -Microstructure | -Relative density: 98.58% -Vickers hardness: 1398 HV -Isotropic shrinkage: 20 to 30 vol% -Superficial roughness: 2.06 µm -Flexural strength: 200.14 MPs -Internal defects (pores)detected |

| Wang et al., 2019 [85] | Stereolithography (SLA) (From 3DCeram) | Dental crown | -Photosensitive resin mixed with zirconia paste (3DMixZrO2L) | -3D trueness (In the 4 locations of the crown) | -3D printed zirconia crowns met the trueness standards. |

| Li et al., 2019 [86] | Stereolithography (SLA) (From Porimy) | Dental crown | Slurry of custom-made resin-based zirconia (45 vol%) | -Density, -Shrinkage, -Flexural strength -Internal and marginal adaptation | -Density: 5.83 g/cm³ Shrinkage rate was 18.1% in length (x axial), 20% in width (y axial), and 24.3% in height (z axial). -Flexural strength of 812 ± 128 MPa -Weibull modulus of 7.44 -Weibull characteristic strength: 866.7 MPa -Homogenous microstructure -Cement space of 63.40 ± 6.54 μm in the occlusal area, 135.08 ± 10.55 μm in the axial area, and 169.58 ± 18.13 μm in the marginal area which was not ideal. |

| Zandinejad et al., 2019 [18] | Stereolithography (SLA) (From 3DCeram) | Implant-supported AM crown | -Commercial slurry (3DMix ZrO2) -Zirconia paste mixed with liquid photosensitive resin -Particle size: 0.1–0.8 µm | -Fracture resistance -Mode of failure | -Fracture resistance of AM crown: 1243.5 ± 265.5 N -The fracture line was located near the interface of zirconia abutment and implant analog. -AM crowns showed comparable fracture resistance to milled restorations when cemented to zirconia abutments. |

| Revilla-León et al., 2020 [87] | Stereolithography (SLA) (From 3DCeram) | Dental crown | -Commercial slurry of zirconia paste (3DMix ZrO2 paste) mixed with liquid photosensitive resin -Particle size: 0.1–0.8 µm | -Marginal and internal discrepancies | -Higher marginal and internal discrepancies in AM groups |

| Ioannidis et al., 2020 [88] | lithography-based (LCM) process (similar to DLP) (From Lithoz) | Occlusal veneers | -Slurry consisted of 40–60 vol% various types of ceramic powder (3 mol% yttria stabilized zirconia particles in a purity of 99.9%) mixed with a photopolymerizable monomer (dynamic viscosity at 20 °C is 43 Pa s) | -Load-bearing capacity | -load-bearing capacities were surpassed clinically expected average bite forces -Median F initial values 1′650 N -median Fmax values 2′026 N |

| Wang et al., 2021 [89] | Stereolithography (SLA) (From Porimy) | Dental crown | -Commercial slurry CSL150 (Zirconia, 1,6-Hexanediol diacrylate, Pentaerythritol tetraacrylate) | -Dimensional accuracy -Clinical adaptation | -Dimensional accuracy: 65 ± 6 µm -No significant difference was found between the AM and milling zirconia crowns. -AM crowns had high dimensional accuracy and marginal adaptation within clinically acceptable limits |

| Li et al., 2021 [90] | Stereolithography (SLA) (From Porimy) | Dental crown | -Commercial slurry CSL 100 (47 vol% 3 mol zirconia suspension.) | -Manufacturing accuracy -Margin quality | -AM crowns indicated comparable accuracy to milled crowns. -Knife- edged crowns were susceptible to large marginal chipping. -AM crowns had rounded line angle margins and were free of small faults |

| Revilla-León et al., 2021 [36] | Stereolithography (SLA) (From 3DCeram) | Bar-shaped | -Commercial slurry 3DMix ZrO2 paste (Zirconia paste mixed with liquid photosensitive resin) -Particle size: 0.1–0.8 µm | -Flexural strength -Fracture resistance | -Mean fracture resistance value of Am specimens: 640.64 ± 81.10 N -Flexural strength of AM specimens: 320.32 ± 40.55 MPa. -Lower flexural strength for AM zirconia than milling zirconia. |

| Revilla-León et al., 2021 [37] | Stereolithography (SLA) (From 3DCeram) | Bar-shaped | -Commercial slurry 3DMix ZrO2 paste (Zirconia paste mixed with liquid photosensitive resin) -Particle size: 0.1–0.8 µm | -Manufacturing accuracy -Volumetric changes | -The 40% porosity AM zirconia had the highest manufacturing accuracy and the lowest manufacturing volume change, followed by the 20%-porosity and the 0%-porosity groups. -All the groups tested were unable to perfectly mimic the virtual design of the specimens. |

| Nakai et al., 2021 [38] | Stereolithography (SLA) (From 3DCeram and Lithoz) | square-shaped | -Three different commercial slurry: 1. LithaCon 3Y 230 2. 3D Mix zirconia 3. 3D Mix ATZ | -Crystallography -Microstructure -Flexural strength | -Comparable phase composition, residual porosity, and flexural strength for AM zirconia specimens with milling zirconia. -ATZ had the highest flexural strength - Lithoz showed a significantly lower biaxial flexural strength than 3D Mix zirconia -The highest Weibull modulus: 3D Mix zirconia (16.3) -The highest scale: 3D Mix ATZ (1108.8 MPa) |

| Manufacturer | 3D Printer | Technology | Zirconia Grades | Composition |

|---|---|---|---|---|

| Lithoz | Cerafab 7500 Cerafab LabL30 Cerafab system S65 | Lithographic-based ceramic manufacturing (LCM) based on a DLP technology | Lithacon 3Y 210 Lithacon 3Y 230 | 3 mol% yttria stabilized zirconia |

| 3DCeram | Ceramaker 900 C3600 Ultimate | Stereolithography (SLA) | 3D Mix zirconia | 3 mol% yttria stabilized zirconia |

| 3D Mix ATZ | Alumina (20%) and Zirconia (80%) | |||

| Admatec | Admaflex 130 Admaflex 300 | Direct light processing (DLP) | AdmaPrint Z130 | 3 mol% yttria stabilized zirconia |

| Porimy | CSL 150 | Stereolithography (SLA) | NP | NP |

| Prodways | Promaker V6000 | Moving Light technology, based on DLP technology | NP | NP |

| Exone | X1 160Pro | binder jetting | NP | NP |

| Lynxter | Lynxter S600D | Extrusion | NP | NP |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanlar, L.N.; Salazar Rios, A.; Tahmaseb, A.; Zandinejad, A. Additive Manufacturing of Zirconia Ceramic and Its Application in Clinical Dentistry: A Review. Dent. J. 2021, 9, 104. https://doi.org/10.3390/dj9090104

Khanlar LN, Salazar Rios A, Tahmaseb A, Zandinejad A. Additive Manufacturing of Zirconia Ceramic and Its Application in Clinical Dentistry: A Review. Dentistry Journal. 2021; 9(9):104. https://doi.org/10.3390/dj9090104

Chicago/Turabian StyleKhanlar, Leila Nasiry, Alma Salazar Rios, Ali Tahmaseb, and Amirali Zandinejad. 2021. "Additive Manufacturing of Zirconia Ceramic and Its Application in Clinical Dentistry: A Review" Dentistry Journal 9, no. 9: 104. https://doi.org/10.3390/dj9090104