The Effects of Toothbrush Wear on the Surface Roughness and Gloss of Resin Composites with Various Types of Matrices

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used in This Study

- Tetric EvoCeram (TEC) (Ivoclar Vivadent, Schaan, Liechtenstein, shade A2, batch no W10431): based on dimethacrylate and Bis-GMA.

- Admira Fusion (AD) (Voco, Cuxhaven, Germany, shade A2, batch no 1905236): based on ormocer as an example of a non-DMA group.

- Venus Diamond (VD) (Kulzer, Hanau, Germany, shade A2, batch no K010072): as an example of a Bis-GMA-free group.

2.2. Methods

Specimen Preparations

2.3. Finishing and Polishing

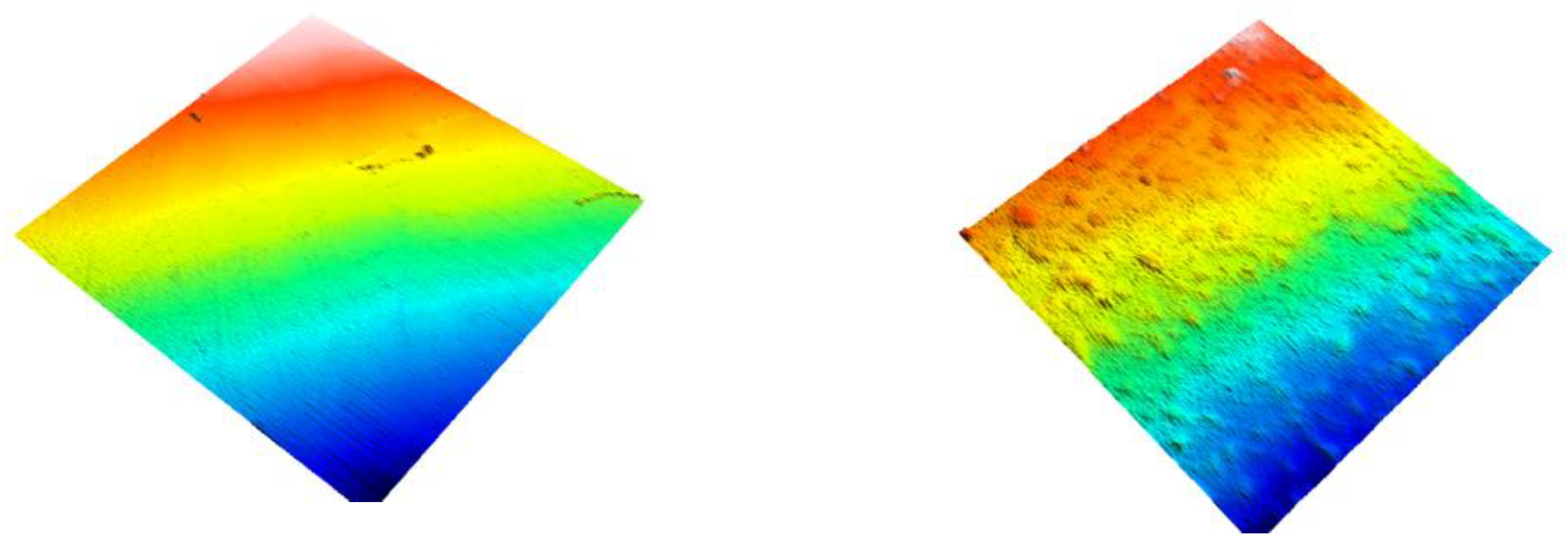

2.4. Surface Roughness Measurement (Ra)

2.5. Surface Gloss Measurement

2.6. Toothbrushing Simulation

2.7. Statistical Analyses

3. Results

3.1. Surface Roughness Measurement (Ra)

3.2. Surface Gloss Measurement

3.3. The Association between Surface Gloss and Roughness

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sources of Support

Clinical Significance

References

- Brunton, P.A.; Ratnayake, J.; Loch, C.; Veerasamy, A.; Cathro, P.; Lee, R. Indirect restorations and fixed prosthodontics: Ma-terials and techniques used by general dentists of New Zealand. Int. J. Dent. 2019, 2, 5210162. [Google Scholar] [CrossRef]

- Watanabe, T.; Miyazaki, M.; Takamizawa, T.; Kurokawa, H.; Rikuta, A.; Ando, S. Influence of polishing duration on surface roughness of resin composites. J. Oral Sci. 2005, 47, 21–25. [Google Scholar] [CrossRef]

- Kim, K.H.; Ong, J.L.; Okuno, O. The effect of filler loading and morphology on the mechanical properties of contemporary composites. J. Prosthet. Dent. 2002, 87, 642–649. [Google Scholar] [CrossRef]

- Morgan, M. Finishing and polishing of direct posterior resin restorations. Pract. Proced. Aesthetic Dent. 2004, 16, 211–234. [Google Scholar]

- Jones, C.S.; Billington, R.W.; Pearson, G.J. The in vivo perception of roughness of restorations. Br. Dent. J. 2004, 196, 42–45. [Google Scholar] [CrossRef]

- Combe, E.; Burke, F. Contemporary Resin-based Composite Materials for Direct Placement Restorations: Packables, Flowables and Others. Dent. Update 2000, 27, 326–336. [Google Scholar] [CrossRef]

- Cramer, N.B.; Stansbury, J.W.; Bowman, C.N. Recent advances and developments in composite dental restorative materials. J. Dent. Res. 2011, 90, 402–416. [Google Scholar] [CrossRef]

- Cunha, L.G.; Alonso, R.C.B.; Dos Santos, P.H.; Sinhoreti, M.A.C. Comparative study of the surface roughness of Ormocer-based and conventional composites. J. Appl. Oral Sci. 2003, 11, 348–353. [Google Scholar] [CrossRef]

- O’Neill, C.; Kreplak, L.; Rueggeberg, F.A.; Labrie, D.; Shimokawa, C.A.K.; Price, R.B. Effect of tooth brushing on gloss retention and surface roughness of five bulk-fill resin composites. J. Esthet. Restor. Dent. 2018, 30, 59–69. [Google Scholar] [CrossRef]

- Monteiro, B.; Spohr, A.M. Surface roughness of composite resins after simulated toothbrushing with different dentifrices. J. Int. Oral Health 2015, 7, 1–5. [Google Scholar]

- Barbieri, G.M.; Mota, E.G.; Rodrigues, L.H.B., Jr.; Rodrigues-Junior, S.A. Effect of Whitening Dentifrices on the Surface Roughness of Commercial Composites. J. Esthet. Restor. Dent. 2011, 23, 338–345. [Google Scholar] [CrossRef]

- Taylor Hobson Precision. Talysurf CLI 1000/2000 Operator’s Handbook; Taylor Hobson: Leicester, UK, 2009. [Google Scholar]

- Elbishari, H.; Silikas, N.; Satterthwaite, J.D. Is Deterioration of Surface Properties of Resin Composites Affected by Filler Size? Int. J. Dent. 2020, 2020, 1–6. [Google Scholar] [CrossRef]

- Jefferies, S.R. The art and science of abrasive finishing and polishing in restorative dentistry. Dent. Clin. N. Am. 1998, 42, 613–627. [Google Scholar]

- Lefever, D.; Perakis, N.; Roig, M.; Krejci, I.; Ardu, S. The effect of toothbrushing on surface gloss of resin composites. Am. J. Dent. 2012, 25, 54–58. [Google Scholar]

- Da Costa, J.; Adams-Belusko, A.; Riley, K.; Ferracane, J.L. The effect of various dentifrices on surface roughness and gloss of resin composites. J. Dent. 2010, 38, e123–e128. [Google Scholar] [CrossRef]

- Turssi, C.P.; Saad, J.R.; Duarte, J.S.; Rodrigues, J.A. Composite surfaces after finishing and polishing techniques. Am. J. Dent. 2000, 13, 136–138. [Google Scholar]

- Ilie, N.; Hickel, R. Resin composite restorative materials. Aust. Dent. J. 2011, 56, 59–66. [Google Scholar] [CrossRef]

- Cerutti, F.; Acquaviva, P.A.; Gagliani, M.; Madini, L.; Mangani, F.; Depero, L.E.; Cerutti, A. Relevance of different polymer-isation methods on light-curing composites conversion degree. In Proceedings of the 87th General Session & Exhibition of the IADR, Washington, DC, USA, 1–4 April 2009. [Google Scholar]

- Garcia, L.D.F.R.; Roselino, L.D.M.R.; Pires-De-Souza, F.D.C.P.; Consani, S. Evaluation of the conversion degree, microhardness, and surface roughness of composite resins used after their expiration date. Gen. Dent. 2010, 58, e262-7. [Google Scholar]

- Lendenmann, U.; EvoCeram, W.M.T.; EvoFlow, T. Scientific documentation for Tetric EvoCeram and Ivoclar Vivadent. In Scientific Documentation; Ivoclar Vivadent: Schaan, Liechtenstein, 2011. [Google Scholar]

- Kalra, S.; Singh, A.; Gupta, M.; Chadha, V. Ormocer: An aesthetic direct restorative material; An in vitro study comparing the marginal sealing ability of organically modified ceramics and a hybrid composite using an ormocer-based bonding agent and a conventional fifth-generation bonding agent. Contemp. Clin. Dent. 2012, 3, 48–53. [Google Scholar] [CrossRef]

- Baseren, M. Surface Roughness of Nanofill and Nanohybrid Composite Resin and Ormocer-based Tooth-colored Restorative Materials after Several Finishing and Polishing Procedures. J. Biomater. Appl. 2004, 19, 121–134. [Google Scholar] [CrossRef]

- Tanoue, N.; Matsumura, H.; Atsuta, M. Wear and surface roughness of current prosthetic composites after tooth-brush/dentifrice abrasion. J. Prosthet. Dent. 2000, 84, 93–97. [Google Scholar] [CrossRef] [PubMed]

- Kaizer, M.R.; De Oliveira-Ogliari, A.; Cenci, M.S.; Opdam, N.J.; Moraes, R.R. Do nanofill or submicron composites show improved smoothness and gloss? A systematic review of in vitro studies. Dent. Mater. 2014, 30, e41–e78. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.-K.; Lu, H.; Oguri, M.; Powers, J.M. Changes in gloss after simulated generalized wear of composite resins. J. Prosthet. Dent. 2005, 94, 370–376. [Google Scholar] [CrossRef] [PubMed]

- Ferracane, J.L. Resin composite—State of the art. Dent. Mater. 2011, 27, 29–38. [Google Scholar] [CrossRef] [PubMed]

- Ardu, S.; Braut, V.; Uhac, I.; Benbachir, N.; Feilzer, A.J.; Krejci, I. Influence of mechanical and chemical degradation on surface gloss of resin composite materials. Am. J. Dent. 2009, 22, 264. [Google Scholar]

- Schubert, A.; Wassmann, T.; Holtappels, M.; Kurbad, O.; Krohn, S.; Buergers, R. Predictability of Microbial Adhesion to Dental Materials by Roughness Parameters. Coatings 2019, 9, 456. [Google Scholar] [CrossRef]

- Matsumura, K.; Sato, Y.; Kitagawa, N.; Shichita, T.; Kawata, D.; Ishikawa, M. Influence of denture surface roughness and host factors on dental calculi formation on dentures: A cross-sectional study. BMC Oral Health 2018, 18, 78. [Google Scholar] [CrossRef]

- Rajan, V.V.; Ganapathy, D.; Sheeba, P.S.; Kanniappan, N. Effects of tooth brushing on wear, surface roughness, and color stability of composite resins-A review. J. Pharm. Res. 2018, 12, 95–102. [Google Scholar]

- Kontonasaki, E.; Valdés, O.; Ilia, C.; Istantsos, T. Monolithic Zirconia: An Update to Current Knowledge. Optical Properties, Wear, and Clinical Performance. Dent. J. 2019, 7, 90. [Google Scholar] [CrossRef]

- Pieniak, D.; Walczak, A.; Walczak, M.; Przystupa, K.; Niewczas, A. Hardness and Wear Resistance of Dental Biomedical Nanomaterials in a Humid Environment with Non-Stationary Temperatures. Materials 2020, 13, 1255. [Google Scholar] [CrossRef]

- Ghazal, M.; Kern, M. The influence of antagonistic surface roughness on the wear of human enamel and nanofilled composite resin artificial teeth. J. Prosthet. Dent. 2009, 101, 342–349. [Google Scholar] [CrossRef]

- Vasudeva, G. Monomer systems for dental composites and their future: A review. J. Calif. Dent. Assoc. 2009, 37, 389–398. [Google Scholar] [PubMed]

- Heintze, S.D. How to qualify and validate wear simulation devices and methods. Dent. Mater. 2006, 22, 712–734. [Google Scholar] [CrossRef] [PubMed]

- Heintze, S.D.; Forjanic, M.; Ohmiti, K.; Rousson, V. Surface deterioration of dental materials after simulated toothbrushing in relation to brushing time and load. Dent. Mater. 2010, 26, 306–319. [Google Scholar] [CrossRef] [PubMed]

| Material | Manufacturer | Type | Code | Shade | Monomer | Composition Filler | wt.%/vol% | Batch No. |

|---|---|---|---|---|---|---|---|---|

| Tetric EvoCeram | Ivoclar Vivadent (Schaan, Liechtenstein) | Nano-hybrid composite | TEC | A2 | Dimethacrylates Bis-GMA | Barium glass, ytterbium trifluoride, mixed oxide and copolymers (40 nm and 3 μm) (0.6 μm average) | 78/55 | W10431 |

| Admira Fusion | Voco (Cuxhaven, Germany) | Nano-hybrid ormocer-based Composite | AD | A2 | 3-dimensionally linked inorganic organic copolymers (Ormocers) | Silicon oxide, glass-ceramic filler (<1 μm) (0.04–1.2 μm, average 0.7 μm) | 84/60 | 1905236 |

| Venus Diamond | Kulzer (Hanau, Germany) | Nano-hybrid Composite | VED | A2 | TCD-urethane cross linker (TCD-DI-HEA and UDMA) | Barium aluminium fluoride Glass Highly discrete nanoparticles (5 nm–20 μm) | 80/65 | K010072 |

| Colgate Cavity Protection | Colgate-Palmolive (Guildford, UK) | Toothpaste | Sodium fluoride (450 ppm F), sodium monofluorophosphate (1000 ppm F), natrium fluoride (450 ppm F), natrium monofluorphosphate (100 ppm F) | T8014003 | ||||

| Material | 0 Cycle | 5000 Cycles | 10,000 Cycles | 15,000 Cycles | 20,000 Cycles | Mean |

|---|---|---|---|---|---|---|

| Admira Fusion | 0.22 ± 0.01 | 0.39 ± 0.06 | 0.49 ± 0.1 | 0.49 ± 0.10 | 0.49 ± 0.09 | 0.42 ± 0.14 a |

| Tetric EvoCeram | 0.17 ± 0.02 | 0.37 ± 0.04 | 0.32 ± 0.09 | 0.39 ± 0.05 | 0.44 ± 0.07 | 0.34± 0.10 a,b |

| Venus Diamond | 0.14 ± 0.02 | 0.34 ±0.01 | 0.37 ± 0.05 | 0.39 ± 0.14 | 0.41 ± 0.07 | 0.33 ± 0.12 b |

| Mean | 0.18 ± 0.04 | 0.37 ± 0.05 a | 0.40 ± 0.11 a,b | 0.42 ± 0.11 a,c | 0.45 ± 0.08 b,c |

| Material | 0 Cycles | 5000 Cycles | 10,000 Cycles | 15,000 Cycles | 20,000 Cycles |

|---|---|---|---|---|---|

| Admira Fusion | 31.9 ± 1.4 | 7.0 ± 0.2 a | 6.3 ± 0.1 a | 6.1 ± 0.2 a | 5.1 ± 0.4 a |

| Tetric EvoCeram | 50.6 ± 0.36 | 44.4 ± 6.3 | 31.9 ± 4.5 | 27.5 ± 3.3 | 19.5 ± 3.3 |

| Venus Diamond | 46.2 ± 1.9 | 16.7 ± 6.1 b | 15.5 ± 5.2 b | 13.4 ± 3.5 c | 13.9 ± 1.6 b,c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

AlAli, M.; Silikas, N.; Satterthwaite, J. The Effects of Toothbrush Wear on the Surface Roughness and Gloss of Resin Composites with Various Types of Matrices. Dent. J. 2021, 9, 8. https://doi.org/10.3390/dj9010008

AlAli M, Silikas N, Satterthwaite J. The Effects of Toothbrush Wear on the Surface Roughness and Gloss of Resin Composites with Various Types of Matrices. Dentistry Journal. 2021; 9(1):8. https://doi.org/10.3390/dj9010008

Chicago/Turabian StyleAlAli, Murtadha, Nikolaos Silikas, and Julian Satterthwaite. 2021. "The Effects of Toothbrush Wear on the Surface Roughness and Gloss of Resin Composites with Various Types of Matrices" Dentistry Journal 9, no. 1: 8. https://doi.org/10.3390/dj9010008

APA StyleAlAli, M., Silikas, N., & Satterthwaite, J. (2021). The Effects of Toothbrush Wear on the Surface Roughness and Gloss of Resin Composites with Various Types of Matrices. Dentistry Journal, 9(1), 8. https://doi.org/10.3390/dj9010008