Fit Accuracy of Plate-Type Retainers Fabricated Using Dental CAD/CAM Systems: A Controlled In Vitro Comparison Using Typodont-Derived Models

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of Working Models

2.2. Fabrication of Conventional Retainers

2.3. Fabrication of CAD/CAM Retainers

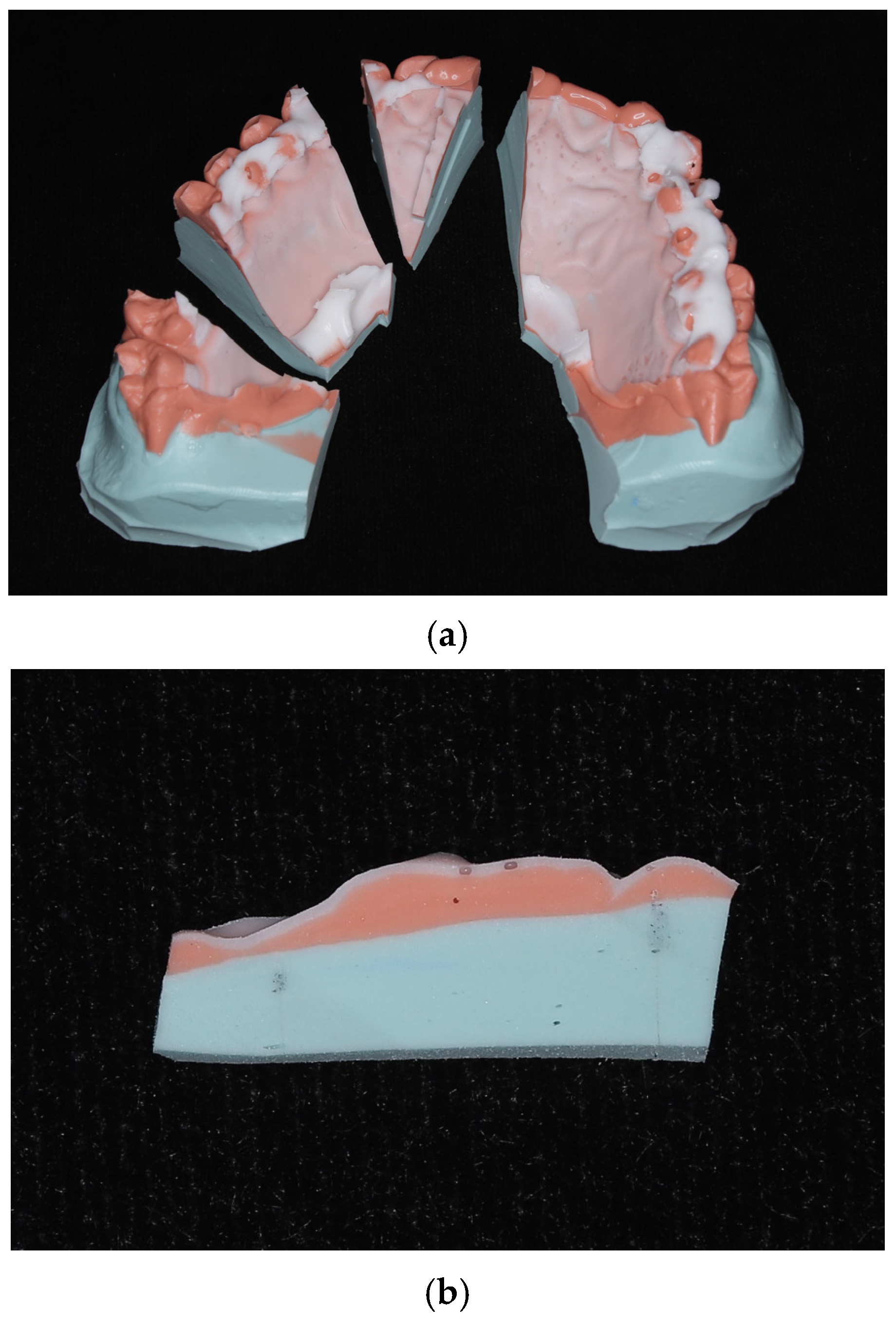

2.4. Evaluation Using the Impression Replica Technique

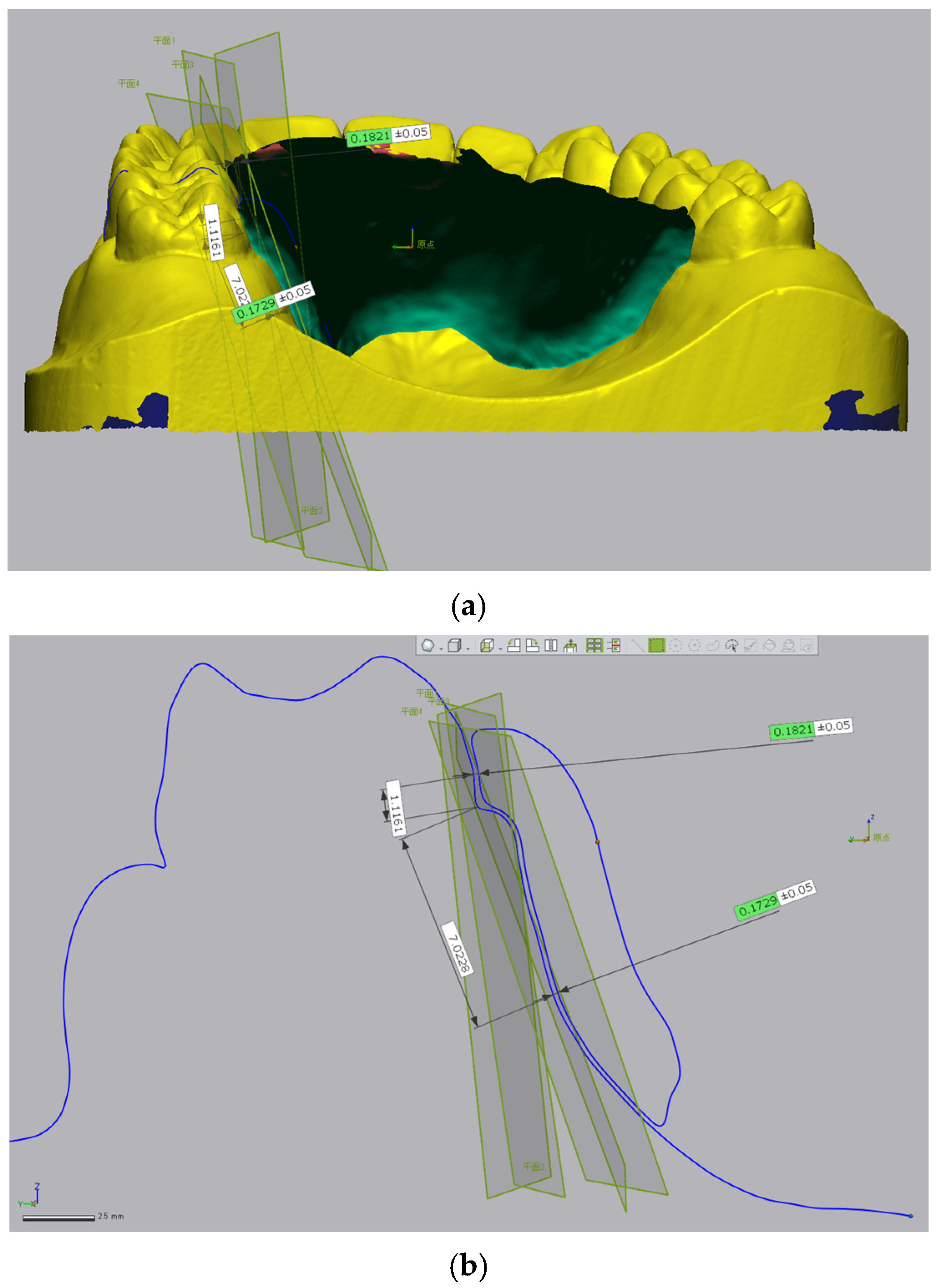

2.5. Evaluation Using a 3D Triple-Scan Protocol

2.6. Classification and Integration of Measurement Sites

2.7. Statistical Analysis

3. Results

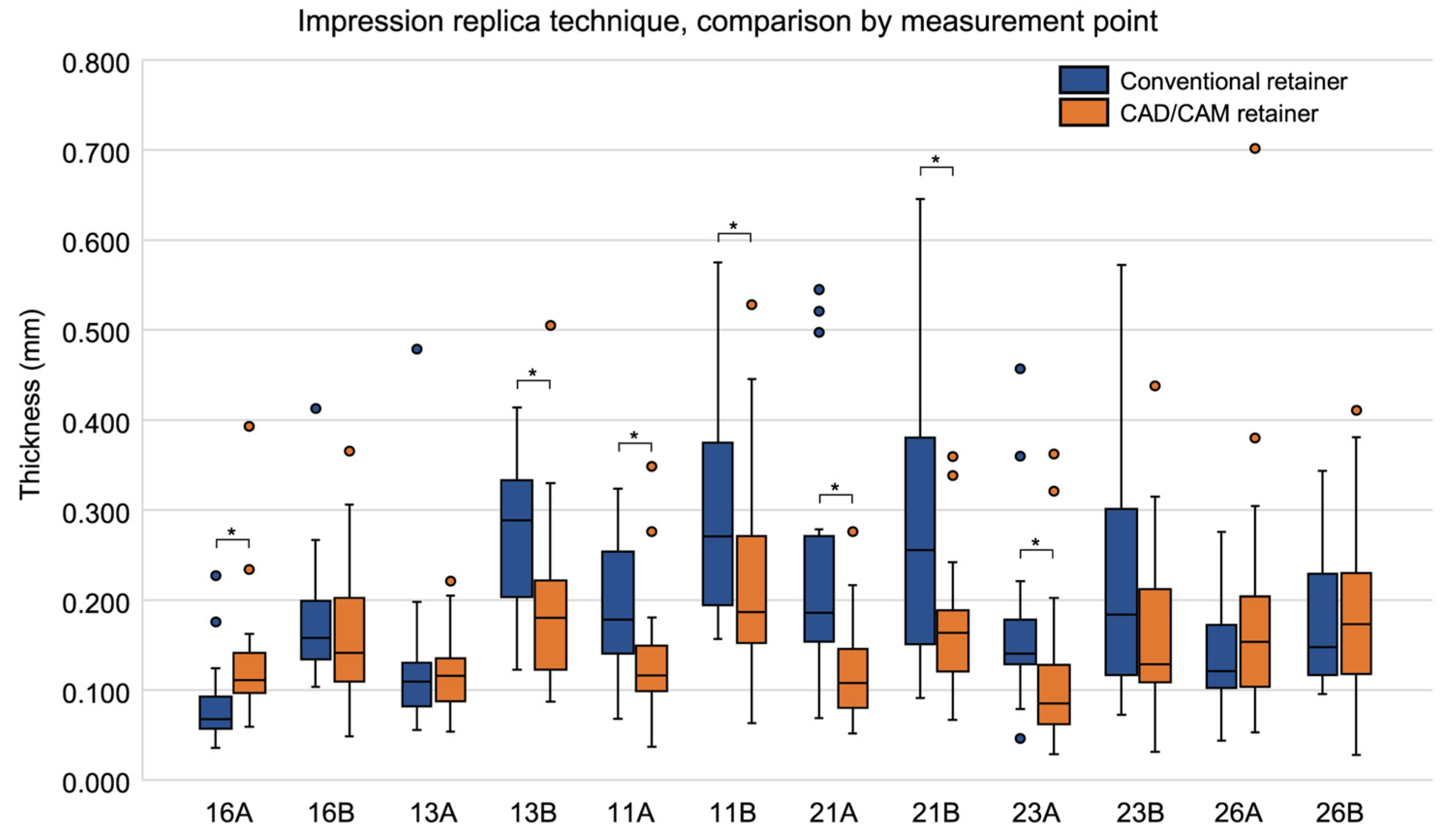

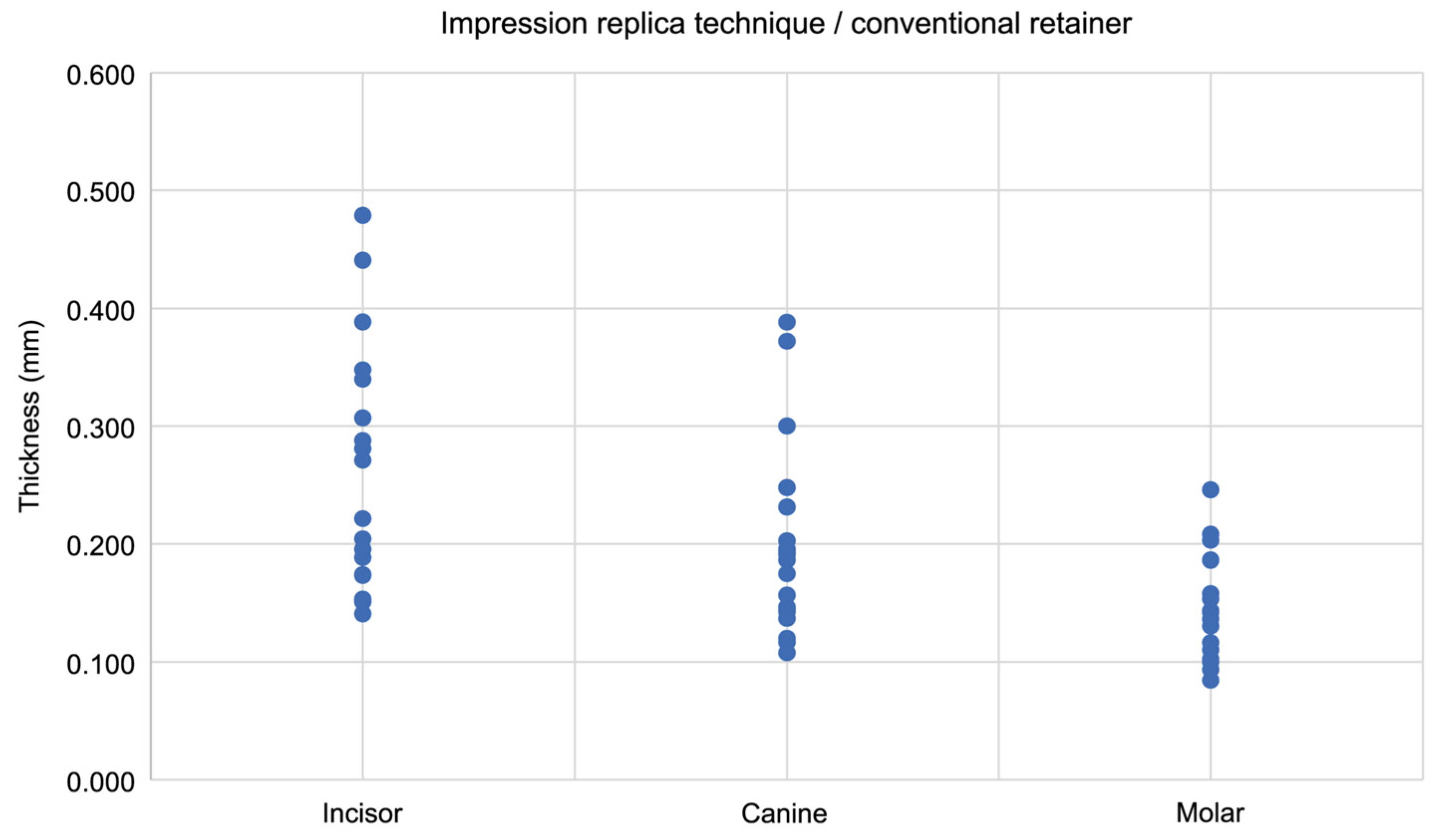

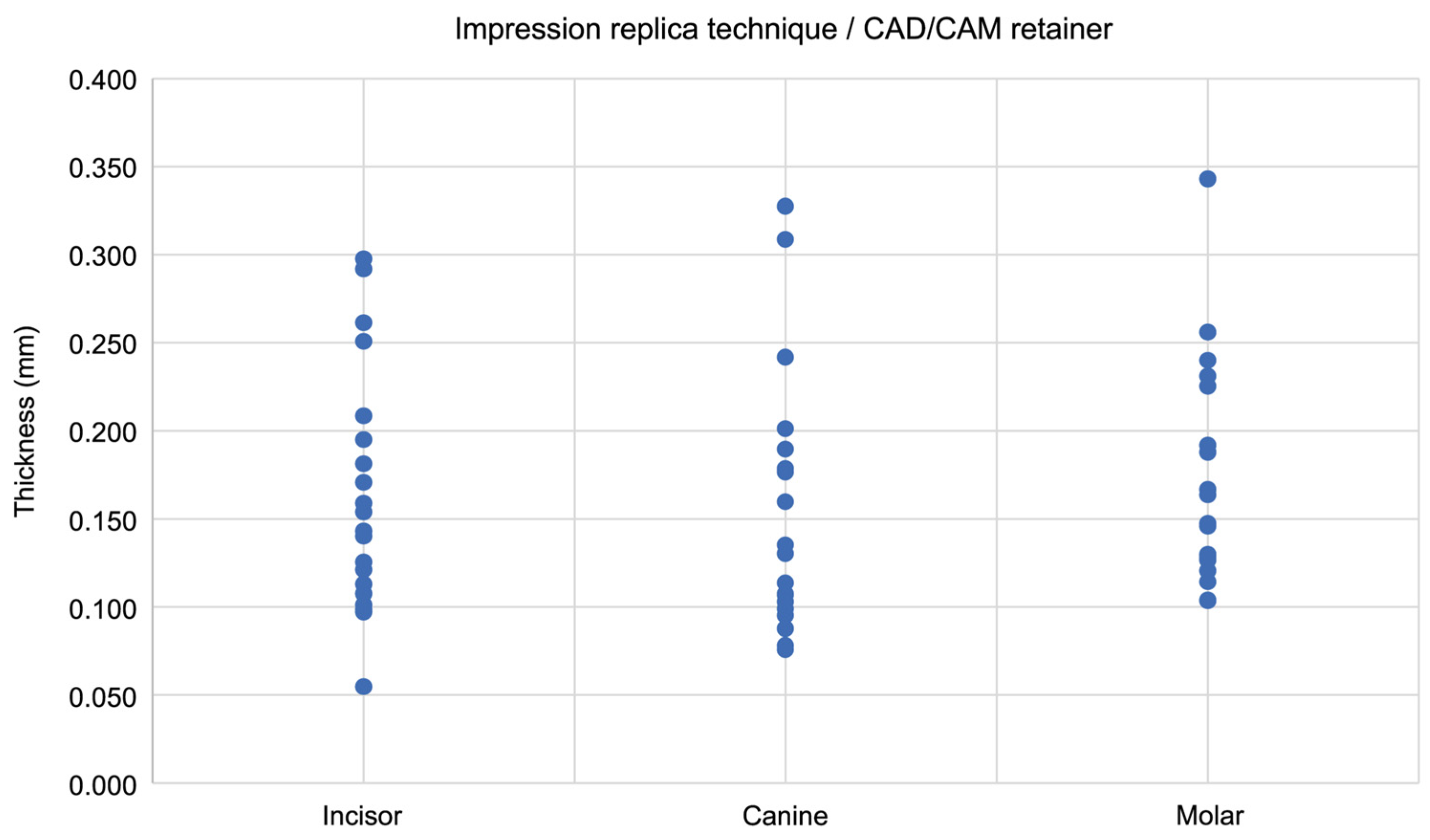

3.1. Results of the Impression Replica Technique

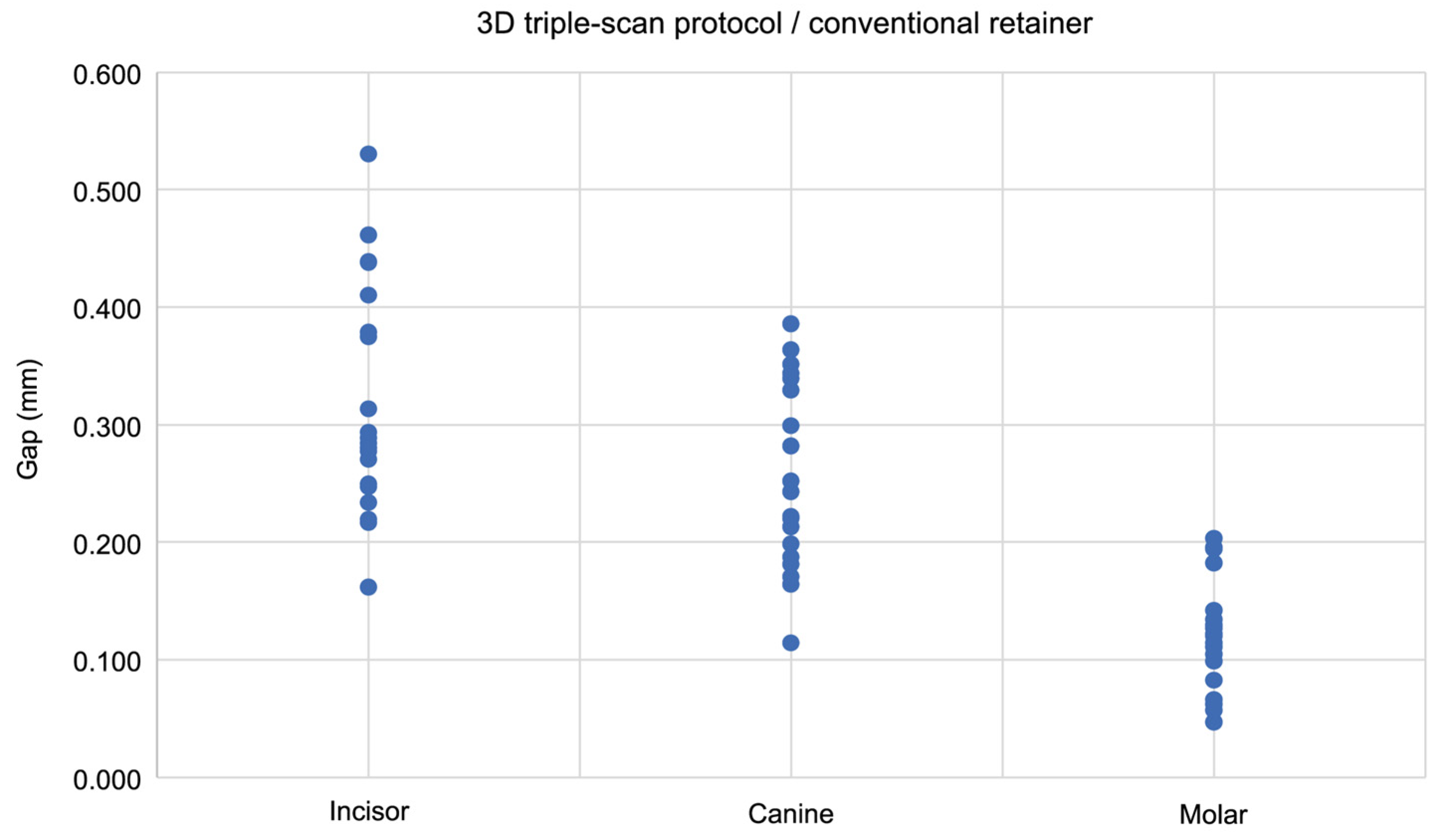

3.2. Results of the 3D Triple-Scan Protocol

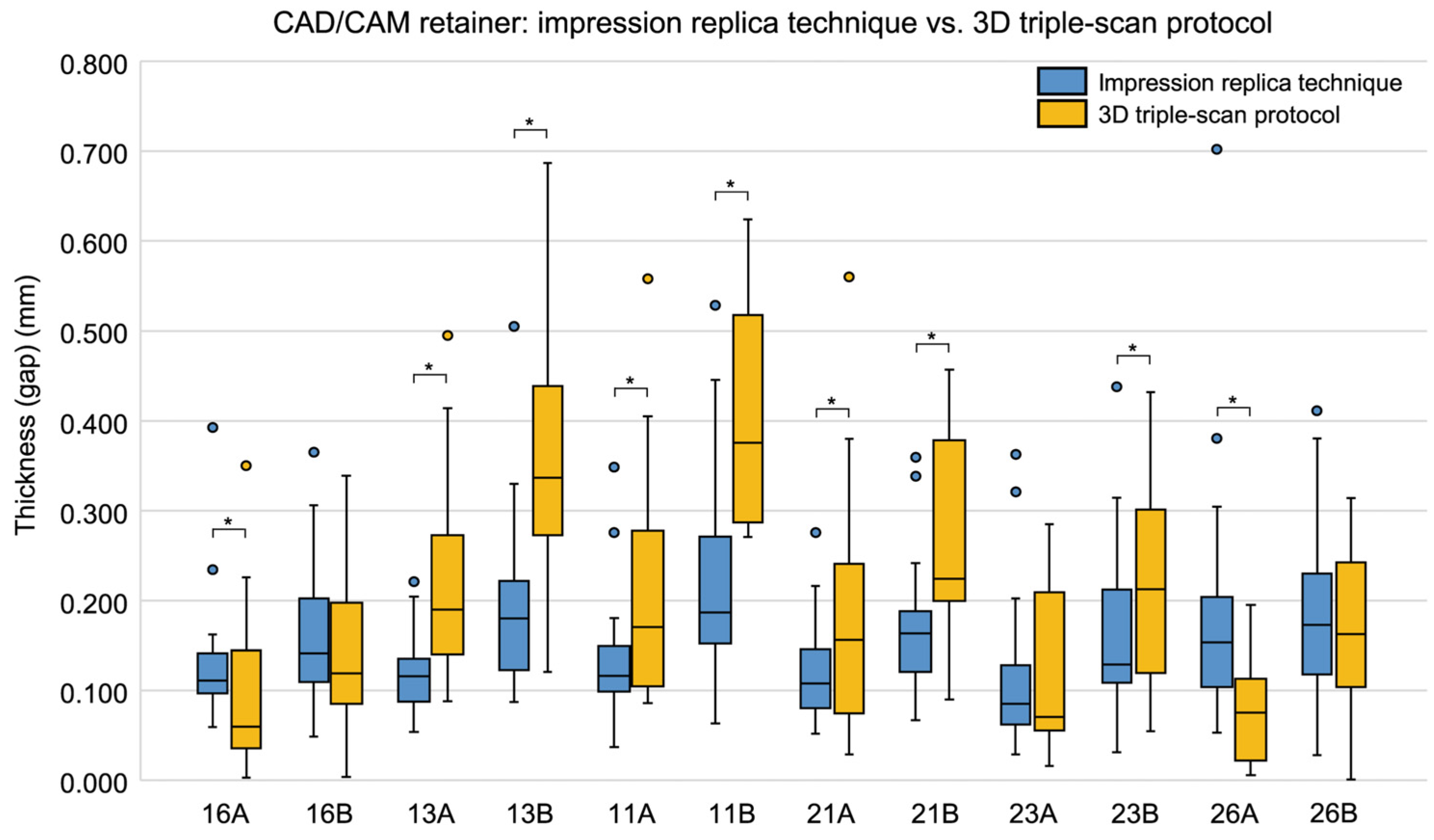

3.3. Comparison Between the Two Evaluation Methods

3.4. Correlation Between Thickness (Gap) and Measurement Region

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | three-dimensional |

| CAD/CAM | computer-aided design/computer-aided manufacturing |

References

- Schwärzler, A.; Ludwig, B.; Chitan, P.; Lettner, S.; Sagl, B.; Jonke, E. Transfer accuracy of 3D printed versus CAD/CAM milled surgical guides for temporary orthodontic implants: A preclinical micro CT study. J. Dent. 2024, 146, 105060. [Google Scholar] [CrossRef]

- Mörmann, W.H. Keramikinlay—Die Seitenzahnfüllung der Zukunft. In Proceedings of the 4th International Quintessenz-Symposium, 25 Jahre Akademie für Zahnärztliche Fortbildung, Karlsruhe, Germany, 28–30 March 1985; Quintessenz: Berlin, Germany, 1985. [Google Scholar]

- Graf, S.; Cornelis, M.A.; Hauber Gameiro, G.; Cattaneo, P.M. Computer-aided design and manufacture of hyrax devices: Can we really go digital? Am. J. Orthod. Dentofac. Orthop. 2017, 152, 870–874. [Google Scholar] [CrossRef]

- Czajkowska, M.; Walejewska, E.; Zadrożny, Ł.; Surowska, B.; Nowakowska, D. Comparison of dental stone models and their 3D printed acrylic replicas for the accuracy and mechanical properties. Materials 2020, 13, 4066. [Google Scholar] [CrossRef]

- Atwal, N.; Bhatnagar, D. Evaluating and comparing flexure strength of dental models printed using fused deposition modelling, digital light processing, and stereolithography apparatus printers. Cureus 2024, 16, e54312. [Google Scholar] [CrossRef]

- Lohfeld, S.; Belnap, B.; Retrouvey, J.M.; Walker, M.P. Effect of model body type and print angle on the accuracy of 3D-printed orthodontic models. Biomimetics 2024, 9, 217. [Google Scholar] [CrossRef] [PubMed]

- Brown, G.B.; Currier, G.F.; Kadioglu, O.; Kierl, J.P. Accuracy of 3-dimensional printed dental models reconstructed from digital intraoral impressions. Am. J. Orthod. Dentofac. Orthop. 2018, 154, 733–739. [Google Scholar] [CrossRef] [PubMed]

- Hazeveld, A.; Huddleston Slater, J.J.; Ren, Y. Accuracy and reproducibility of dental replica models reconstructed by different rapid prototyping techniques. Am. J. Orthod. Dentofac. Orthop. 2014, 145, 108–115. [Google Scholar] [CrossRef]

- Rebong, R.E.; Stewart, K.T.; Utreja, A.; Ghoneima, A. Accuracy of three-dimensional dental resin models created by fused deposition modeling, stereolithography, and Polyjet prototype technologies: A comparative study. Angle Orthod. 2018, 88, 363–369. [Google Scholar] [CrossRef]

- Cole, D.; Bencharit, S.; Carrico, C.K.; Arias, A.; Tüfekçi, E. Evaluation of fit for 3D-printed retainers compared with thermoform retainers. Am. J. Orthod. Dentofac. Orthop. 2019, 155, 592–599. [Google Scholar] [CrossRef]

- ElShebiny, T.; Menezes, L.M.; Matthaios, S.; Tsolakis, I.A.; Palomo, J.M. Effect of printing technology and orientation on the accuracy of three-dimensional printed retainers. Angle Orthod. 2024, 94, 657–663. [Google Scholar] [CrossRef] [PubMed]

- Tomášik, J.; Zsoldos, M.; Oravcová, Ľ.; Lifková, M.; Pavleová, G.; Strunga, M.; Thurzo, A. AI and face-driven orthodontics: A scoping review of digital advances in diagnosis and treatment planning. AI 2024, 5, 158–176. [Google Scholar] [CrossRef]

- Emera, R.M.K.; Shady, M.; Alnajih, M.A. Comparison of retention and denture base adaptation between conventional and 3D-printed complete dentures. J. Dent. Res. Dent. Clin. Dent. Prospect. 2022, 16, 179–185. [Google Scholar] [CrossRef]

- Lee, J.W.; Park, J.M.; Park, E.J.; Heo, S.J.; Koak, J.Y.; Kim, S.K.; Kim, J.H. Accuracy of a digital removable partial denture fabricated by casting a rapid prototyped pattern: A clinical study. J. Prosthet. Dent. 2017, 118, 468–474. [Google Scholar] [CrossRef]

- Alabdullah, S.A.; Hannam, A.G.; Wyatt, C.C.; McCullagh, A.P.G.; Aleksejuniene, J.; Mostafa, N.Z. Comparison of digital and conventional methods of fit evaluation of partial removable dental prosthesis frameworks fabricated by selective laser melting. J. Prosthet. Dent. 2022, 127, 478.e1–478.e10. [Google Scholar] [CrossRef]

- Ye, H.; Ning, J.; Li, M.; Niu, L.; Yang, J.; Sun, Y.; Zhou, Y. Preliminary clinical application of removable partial denture frameworks fabricated using computer-aided design and rapid prototyping techniques. Int. J. Prosthodont. 2017, 30, 348–353. [Google Scholar] [CrossRef] [PubMed]

- Bajunaid, S.O.; Altwaim, B.; Alhassan, M.; Alammari, M.R. The fit accuracy of removable partial denture metal frameworks using conventional and 3D printed techniques: An in vitro study. J. Contemp. Dent. Pract. 2019, 20, 476–481. [Google Scholar] [CrossRef]

- Holst, S.; Karl, M.; Wichmann, M.; Matta, R.E. A new triple-scan protocol for 3D fit assessment of dental restorations. Quintessence Int. 2011, 42, 651–657. [Google Scholar] [PubMed]

- Svanborg, P.; Andersson, M.; Reinedahl, T.; Alstad, T. Comparison of the 3D triple-scan protocol and the impression replica technique for 3-unit tooth-supported fixed dental prostheses. Biomater. Investig. Dent. 2019, 6, 32–34. [Google Scholar] [CrossRef]

- Hasanzade, M.; Koulivand, S.; Moslemian, N.; Alikhasi, M. Comparison of three-dimensional digital technique with two-dimensional replica method for measuring marginal and internal fit of full coverage restorations. J. Adv. Prosthodont. 2020, 12, 173–180. [Google Scholar] [CrossRef]

- Springate, S.D. The effect of sample size and bias on the reliability of estimates of error: A comparative study of Dahlberg’s formula. Eur. J. Orthod. 2012, 34, 158–163. [Google Scholar] [CrossRef]

- Dunham, D.; Brudvik, J.S.; Morris, W.J.; Plummer, K.D.; Cameron, S.M. A clinical investigation of the fit of removable partial dental prosthesis clasp assemblies. J. Prosthet. Dent. 2006, 95, 323–326. [Google Scholar] [CrossRef]

- Zachrisson, B.U. Important aspects of long-term stability. J. Clin. Orthod. 1997, 31, 562–583. [Google Scholar]

- Hamran, T.; Čirgić, E.; Aiyar, A.; Vandevska-Radunovic, V. Survey on retention procedures and use of thermoplastic retainers among orthodontists in Norway, Sweden, and Denmark. J. World Fed. Orthod. 2022, 11, 114–119. [Google Scholar] [CrossRef]

- Al Yami, E.A.; Kuijpers-Jagtman, A.M.; van ’t Hof, M.A. Stability of orthodontic treatment outcome: Follow-up until 10 years postretention. Am. J. Orthod. Dentofac. Orthop. 1999, 115, 300–304. [Google Scholar] [CrossRef] [PubMed]

- de Bernabé, P.G.; Montiel-Company, J.M.; Paredes-Gallardo, V.; Gandía-Franco, J.L.; Bellot-Arcís, C. Orthodontic treatment stability predictors: A retrospective longitudinal study. Angle Orthod. 2017, 87, 223–229. [Google Scholar] [CrossRef]

- Sharma, P.; Kahlon, S.S.; Boparai, C.D.S. An in vivo study to compare the clinical effectiveness of clear retainer made on a conventional and a digitally fabricated model over a six-month period after debonding. Cureus 2024, 16, e54740. [Google Scholar] [CrossRef] [PubMed]

- Hawley, C.L. A removable retainer. Int. J. Orthod. Oral Surg. 1919, 5, 291–305. [Google Scholar] [CrossRef]

- Camardella, L.T.; de Vasconcellos Vilella, O.; Breuning, H. Accuracy of printed dental models made with 2 prototype technologies and different designs of model bases. Am. J. Orthod. Dentofac. Orthop. 2017, 151, 1178–1187. [Google Scholar] [CrossRef]

- Sherman, S.L.; Kadioglu, O.; Currier, G.F.; Kierl, J.P.; Li, J. Accuracy of digital light processing printing of 3-dimensional dental models. Am. J. Orthod. Dentofac. Orthop. 2020, 157, 422–428. [Google Scholar] [CrossRef]

- Johal, A.; Sharma, N.R.; McLaughlin, K.; Zou, L.F. The reliability of thermoform retainers: A laboratory-based comparative study. Eur. J. Orthod. 2015, 37, 503–507. [Google Scholar] [CrossRef] [PubMed]

- Boo, H.S.; Sivarajan, S.; Nor Zahidah Mohd Tahir, N.; Bahar, A.D. Accuracy of three-dimensionally printed retainers and aligners: A systematic review. J. Orofac. Orthop. 2025. online ahead of print. [Google Scholar] [CrossRef] [PubMed]

- ElShebiny, T.; Simon, Y.; Demko, C.A.; Palomo, J.M. The uses of 3-dimensional printing technology in orthodontic offices in North America. Am. J. Orthod. Dentofac. Orthop. 2024, 166, 76–80. [Google Scholar] [CrossRef] [PubMed]

- Miyasaka, H.; Endo, K.; Tamaoki, K.; Hattori, M. (Eds.) Kiso Shika Rikogaku [Basic Dental Materials Science]; Ishiyaku Publishers, Inc.: Tokyo, Japan, 2019. [Google Scholar]

- Schmutzler, C.; Bayerlein, F.; Janson, S.; Seidel, C.; Zaeh, M.F. Pre-compensation of warpage for additive manufacturing. J. Mech. Eng. Autom. 2016, 6, 392–399. [Google Scholar] [CrossRef]

| Evaluation Method | Group | Median (IQR), mm | p-Value |

|---|---|---|---|

| Impression replica technique | Conventional retainers | 0.169 (0.120–0.260) | ― |

| CAD/CAM retainers | 0.136 (0.096–0.198) | <0.001 * | |

| 3D triple-scan protocol | Conventional retainers | 0.206 (0.131–0.315) | ― |

| CAD/CAM retainers | 0.182 (0.091–0.289) | 0.013 * |

| Measurement Region | Conventional Retainers Median (IQR), mm | CAD/CAM Retainers Median (IQR), mm | p-Value |

|---|---|---|---|

| 16A | 0.068 (0.057–0.107) | 0.111 (0.095–0.144) | 0.003 * |

| 13B | 0.289 (0.201–0.337) | 0.180 (0.119–0.225) | 0.008 * |

| 11A | 0.178 (0.138–0.261) | 0.116 (0.094–0.150) | 0.009 * |

| 11B | 0.271 (0.189–0.399) | 0.187 (0.151–0.296) | 0.030 * |

| 21A | 0.186 (0.145–0.273) | 0.108 (0.076–0.146) | <0.001 * |

| 21B | 0.255 (0.151–0.384) | 0.164 (0.121–0.191) | 0.009 * |

| 23A | 0.141 (0.126–0.198) | 0.085 (0.057–0.135) | 0.007 * |

| Measurement Region | Conventional Retainers Median (IQR), mm | CAD/CAM Retainers Median (IQR), mm | p-Value |

|---|---|---|---|

| 21A | 0.279 (0.232–0.401) | 0.157 (0.066–0.273) | 0.002 * |

| 23A | 0.176 (0.120–0.241) | 0.071 (0.051–0.215) | 0.028 * |

| Evaluation Method | Median (IQR), mm | p-Value | |

|---|---|---|---|

| Conventional retainers | Impression replica technique | 0.169 (0.120–0.260) | ― |

| 3D triple-scan protocol | 0.206 (0.131–0.315) | <0.001 * | |

| CAD/CAM retainers | Impression replica technique | 0.136 (0.096–0.198) | ― |

| 3D triple-scan protocol | 0.182 (0.091–0.289) | <0.001 * | |

| Measurement Region | Impression Replica Technique Median (IQR), mm | 3D Triple-Scan Protocol Median (IQR), mm | p-Value |

|---|---|---|---|

| 16A | 0.068 (0.057–0.107) | 0.056 (0.035–0.075) | 0.079 |

| 16B | 0.158 (0.131–0.205) | 0.182 (0.148–0.251) | 0.167 |

| 13A | 0.109 (0.080–0.136) | 0.148 (0.138–0.222) | 0.002 * |

| 13B | 0.289 (0.201–0.337) | 0.386 (0.283–0.508) | <0.001 * |

| 11A | 0.178 (0.138–0.261) | 0.263 (0.205–0.316) | <0.001 * |

| 11B | 0.271 (0.189–0.399) | 0.372 (0.283–0.436) | 0.004 * |

| 21A | 0.186 (0.145–0.273) | 0.279 (0.232–0.401) | <0.001 * |

| 21B | 0.255 (0.151–0.384) | 0.267 (0.216–0.424) | 0.037 * |

| 23A | 0.141 (0.126–0.198) | 0.176 (0.120–0.241) | 0.455 |

| 23B | 0.184 (0.105–0.309) | 0.207 (0.150–0.344) | 0.005 * |

| 26A | 0.121 (0.101–0.179) | 0.062 (0.026–0.104) | <0.001 * |

| 26B | 0.148 (0.110–0.240) | 0.150 (0.102–0.182) | 0.015 * |

| Measurement Region | Impression Replica Technique Median (IQR), mm | 3D Triple-Scan Protocol Median (IQR), mm | p-Value |

|---|---|---|---|

| 16A | 0.111 (0.095–0.144) | 0.060 (0.027–0.158) | 0.002 * |

| 16B | 0.142 (0.104–0.210) | 0.119 (0.080–0.247) | 0.145 |

| 13A | 0.116 (0.087–0.140) | 0.190 (0.138–0.281) | <0.001 * |

| 13B | 0.180 (0.119–0.225) | 0.337 (0.268–0.455) | <0.001 * |

| 11A | 0.116 (0.094–0.150) | 0.171 (0.104–0.303) | 0.001 * |

| 11B | 0.187 (0.151–0.296) | 0.376 (0.284–0.521) | <0.001 * |

| 21A | 0.108 (0.076–0.146) | 0.157 (0.066–0.273) | 0.014 * |

| 21B | 0.164 (0.121–0.191) | 0.225 (0.197–0.386) | <0.001 * |

| 23A | 0.085 (0.057–0.135) | 0.071 (0.051–0.215) | 0.940 |

| 23B | 0.129 (0.106–0.214) | 0.213 (0.117–0.304) | 0.017 * |

| 26A | 0.154 (0.099–0.232) | 0.076 (0.019–0.114) | <0.001 * |

| 26B | 0.173 (0.116–0.236) | 0.163 (0.098–0.248) | 0.287 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nomi, K.; Koizumi, S.; Shimura, M.; Seimiya, K.; Nikaido, O.; Park, H.; Hatanaka, R.; Takahashi, M.; Fuchida, S.; Yamaguchi, T. Fit Accuracy of Plate-Type Retainers Fabricated Using Dental CAD/CAM Systems: A Controlled In Vitro Comparison Using Typodont-Derived Models. Dent. J. 2025, 13, 487. https://doi.org/10.3390/dj13110487

Nomi K, Koizumi S, Shimura M, Seimiya K, Nikaido O, Park H, Hatanaka R, Takahashi M, Fuchida S, Yamaguchi T. Fit Accuracy of Plate-Type Retainers Fabricated Using Dental CAD/CAM Systems: A Controlled In Vitro Comparison Using Typodont-Derived Models. Dentistry Journal. 2025; 13(11):487. https://doi.org/10.3390/dj13110487

Chicago/Turabian StyleNomi, Kosuke, So Koizumi, Masatoshi Shimura, Kazuhide Seimiya, Osamu Nikaido, Heetae Park, Reina Hatanaka, Masahiro Takahashi, Shinya Fuchida, and Tetsutaro Yamaguchi. 2025. "Fit Accuracy of Plate-Type Retainers Fabricated Using Dental CAD/CAM Systems: A Controlled In Vitro Comparison Using Typodont-Derived Models" Dentistry Journal 13, no. 11: 487. https://doi.org/10.3390/dj13110487

APA StyleNomi, K., Koizumi, S., Shimura, M., Seimiya, K., Nikaido, O., Park, H., Hatanaka, R., Takahashi, M., Fuchida, S., & Yamaguchi, T. (2025). Fit Accuracy of Plate-Type Retainers Fabricated Using Dental CAD/CAM Systems: A Controlled In Vitro Comparison Using Typodont-Derived Models. Dentistry Journal, 13(11), 487. https://doi.org/10.3390/dj13110487