Advances in the Mechanism and Application of Nanoparticles in Concrete Property Modification

Abstract

1. Introduction

2. Types and Properties of Nanoparticles

2.1. Silicon Dioxide Nanoparticles

2.2. Aluminum Oxide Nanoparticles

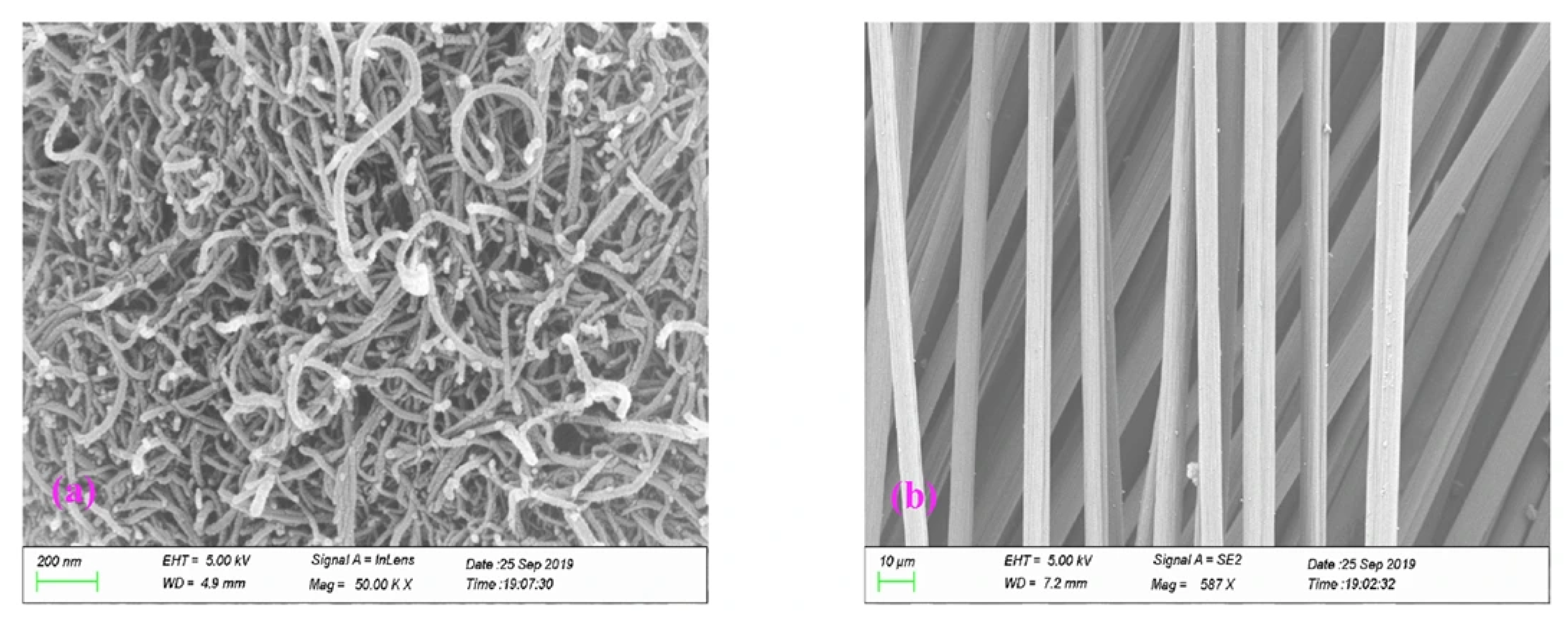

2.3. Carbon Nanotubes

2.4. Nanoclay

2.5. Other Nanoparticles

2.6. Cross-Material Comparison of Modification Efficacy for Mainstream Nanoparticles and Selection Recommendations

3. Mechanism of Nanoparticles in Concrete

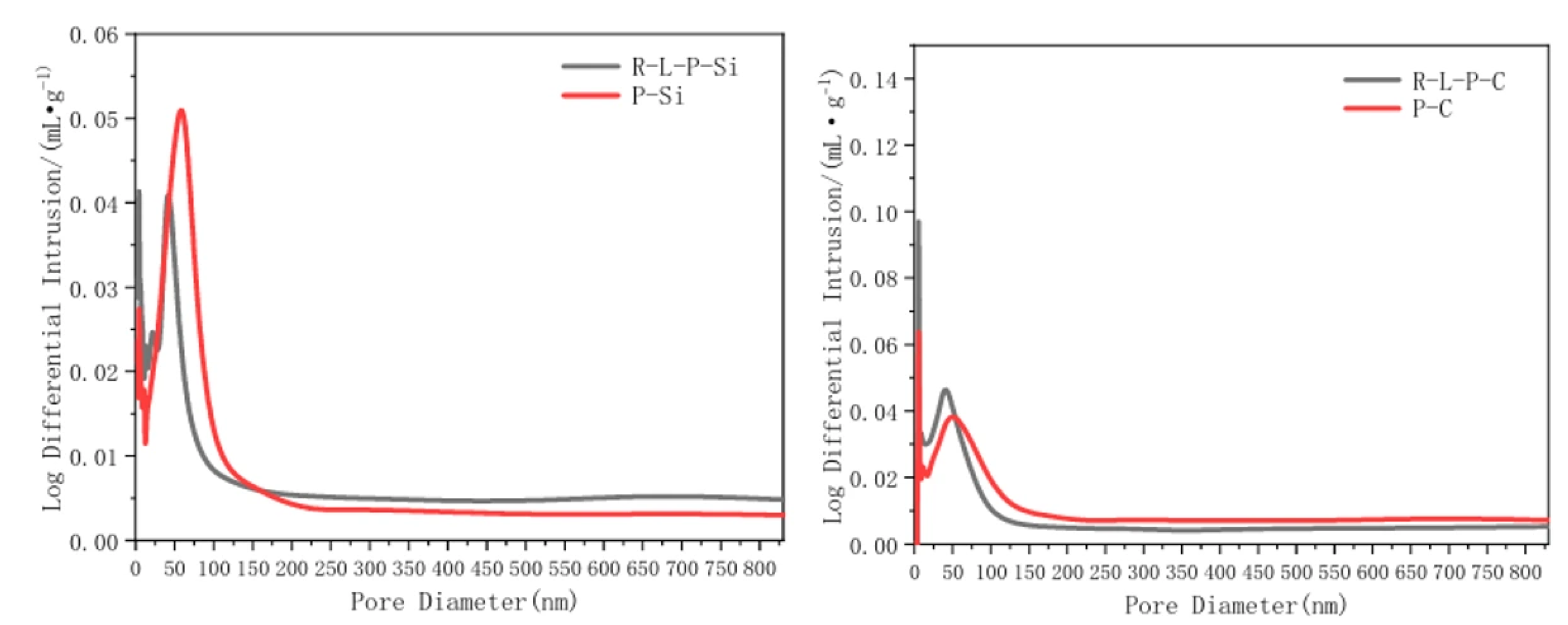

3.1. Microfilling Effects

3.2. Nucleation

3.3. Chemical Effects

3.4. Interface Transition Zone Improvement

3.5. Synergistic Tradeoff Relationships Among Mechanisms and Engineering Application Constraints

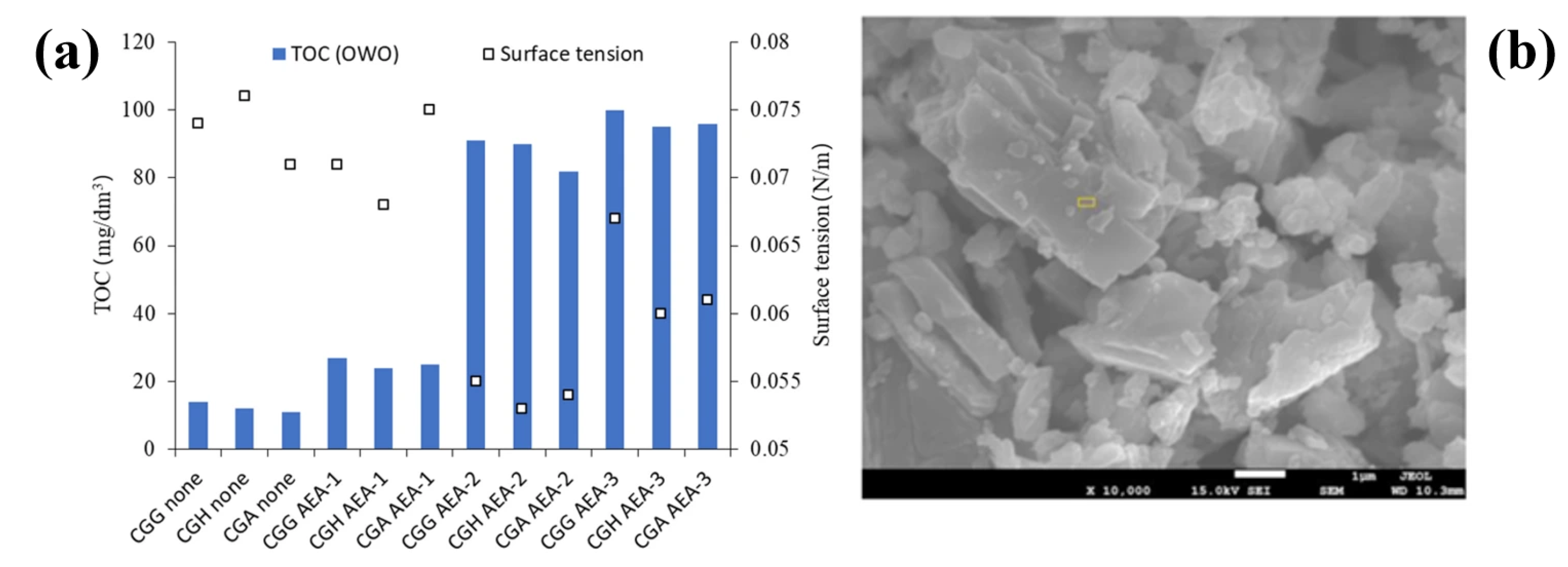

3.6. Mechanism of Interaction with Chemical Admixtures

4. Modification Effect of Nanoparticles on Concrete Properties

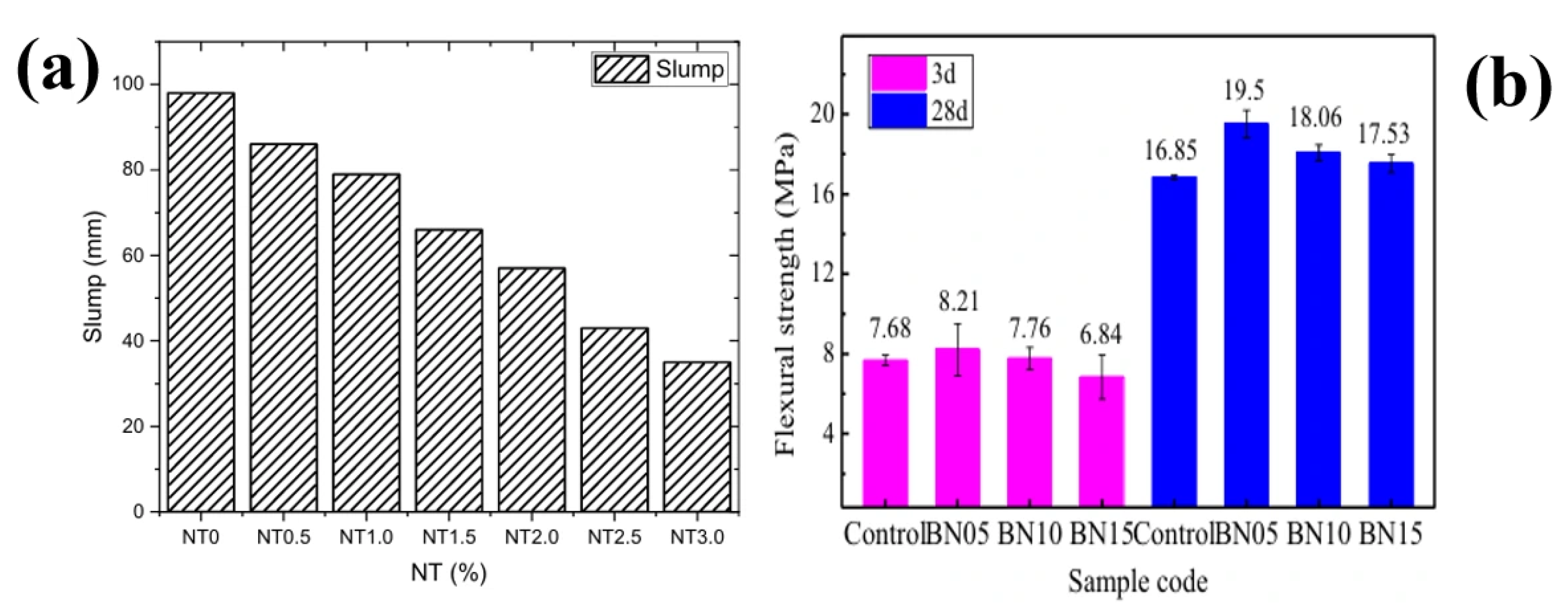

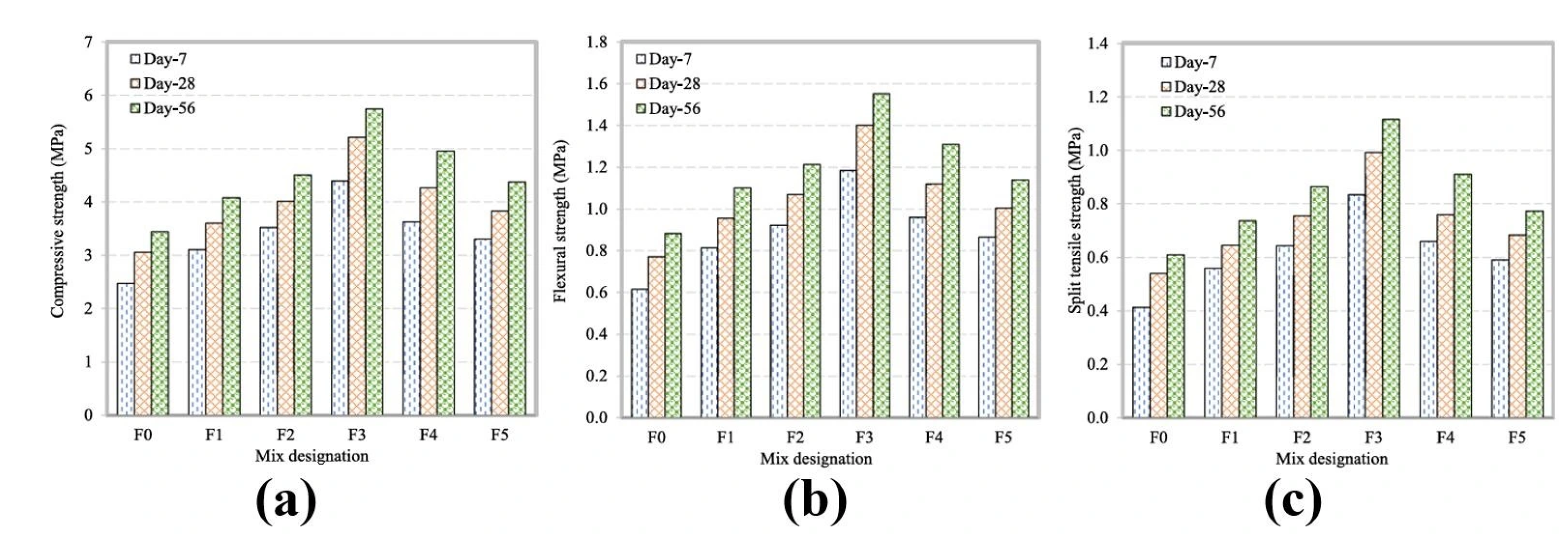

4.1. Mechanical Properties

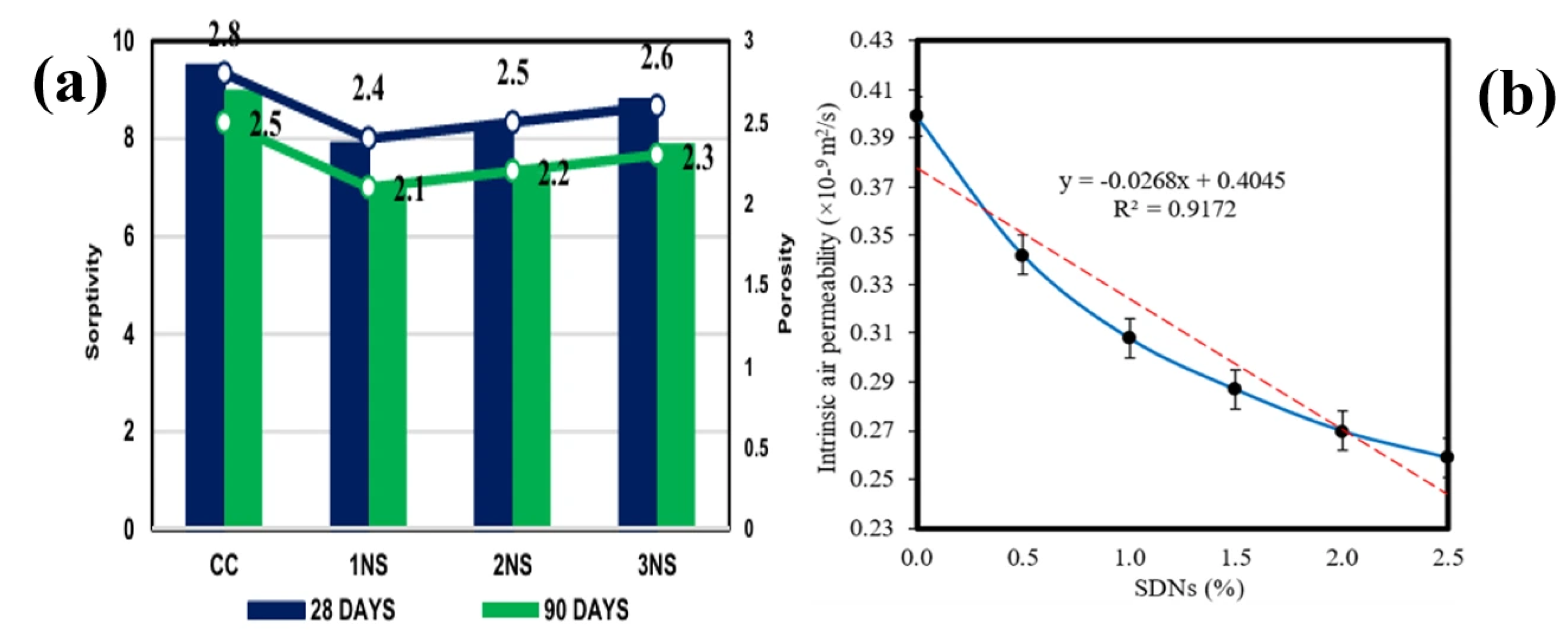

4.2. Durability

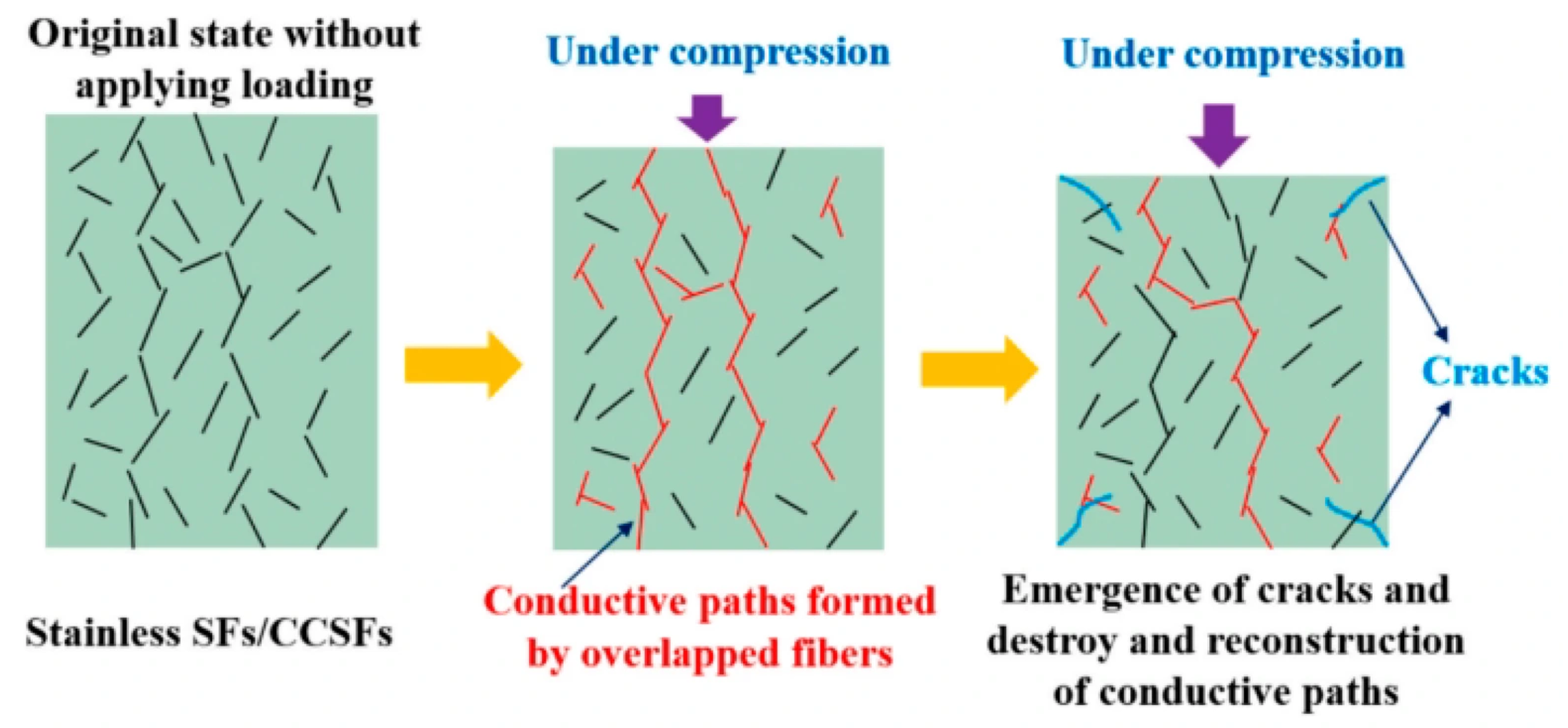

4.3. Functional Characteristics

5. Current Status of Nanoparticles in Concrete Applications

5.1. Construction Engineering

5.2. Infrastructure

5.3. Special Engineering

6. Challenges Faced and Research Prospects

6.1. Technical Challenges

6.2. Economic Costs

6.3. Environmental and Health Risks

6.4. Directions for Future Research

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bekturganova, N.Y.; Kolesnikova, I.V. Effect of Polymer Additives on Improvement of Concrete Properties. Adv. Polym. Technol. 2025, 2025, 6235216. [Google Scholar] [CrossRef]

- Dai, Z.; Guo, H.; Wang, Y.; Wang, M.; Zhang, Y.; Qian, K. Mechanically Strength with Water Repellency: Recently Advances in Superhydrophobic Concrete. J. Clean. Prod. 2025, 491, 144839. [Google Scholar] [CrossRef]

- Mohaisen, K.O.; Zahir, M.H.; Al-Dulaijan, S.U.; Ahmad, S.; Al-Zahrani, M.M.; Maslehuddin, M. An innovative lightweight aggregate composite phase change material for thermal energy storage enhancement of concrete under hot weather conditions. J. Build. Eng. 2025, 99, 111575. [Google Scholar] [CrossRef]

- Huang, D.; Wang, X.; Li, X.; Su, L.; Tian, J. Advanced nuclear magnetic resonance technology analysis of hybrid fiber reinforced concrete for optimized pore structure and strength. Constr. Build. Mater. 2025, 467, 140383. [Google Scholar] [CrossRef]

- Wang, C.; Yuan, J.; Lu, B.; Zhang, Y.; Ma, Z. Mesoscopic 3D simulation and in-situ 4D CT investigation on the mechanical behaviors of high-toughness recycled aggregate concrete. Constr. Build. Mater. 2024, 442, 137560. [Google Scholar] [CrossRef]

- Huang, C.; Yu, H.-Y.; Chen, G.; Liao, Y. “Reinforced concrete” design of robust mineralized cellulose composite with multilayered structure for efficient CO2 capture and passive radiative cooling ability. Compos. Sci. Technol. 2024, 258, 110886. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S.J.; Alnuaimi, N.A. Recent advancements in the nanomaterial application in concrete and its ecological impact. Materials 2021, 14, 6387. [Google Scholar] [CrossRef]

- Kishore, K.; Pandey, A.; Wagri, N.K.; Saxena, A.; Patel, J.; Al-Fakih, A. Technological challenges in nanoparticle-modified geopolymer concrete: A comprehensive review on nanomaterial dispersion, characterization techniques and its mechanical properties. Case Stud. Constr. Mater. 2023, 19, e02265. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Kabeer, K.S.A. Influence of nanomaterials on the water absorption and chloride penetration of cement-based concrete. Mater. Today Proc. 2022, 65, 2066–2069. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, C.; Diao, G. Application and microstructure properties of nanomaterials in new concrete materials. J. Nanomater. 2022, 2022, 7396295. [Google Scholar] [CrossRef]

- Wang, X.; Ding, S.; Qiu, L.; Ashour, A.; Wang, Y.; Han, B.; Ou, J. Improving bond of fiber-reinforced polymer bars with concrete through incorporating nanomaterials. Compos. Part B Eng. 2022, 239, 109960. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, Z.; Liu, C.; Deng, H.; Deng, X.; Hui, D.; Zhang, X.; Bai, Z. Research progress on key problems of nanomaterials-modified geopolymer concrete. Nanotechnol. Rev. 2021, 10, 779–792. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Kabeer, K.S.A. Influence of nanomaterials on the workability and compressive strength of cement-based concrete. Mater. Today Proc. 2022, 65, 2073–2076. [Google Scholar] [CrossRef]

- Mohtasham Moein, M.; Rahmati, K.; Saradar, A.; Moon, J.; Karakouzian, M. A critical review examining the characteristics of modified concretes with different nanomaterials. Materials 2024, 17, 409. [Google Scholar] [CrossRef]

- Jayasooriya, D.; Rajeev, P.; Sanjayan, J. Application of graphene-based nanomaterials as a reinforcement to concrete pavements. Sustainability 2022, 14, 11282. [Google Scholar] [CrossRef]

- Ting, W.; Qingshan, W.; Shenao, C.; Haihe, Y.; Tian, S.; Zhenyu, T. Effects of nanomaterials reinforced aggregate on mechanical properties and microstructure of recycled brick aggregate concrete. Mater. Sci. 2023, 29, 347–355. [Google Scholar] [CrossRef]

- Singh, L.; Karade, S.; Bhattacharyya, S.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Swathi, B.; Vidjeapriya, R. Synergistic use of nano-silica to enhance the characterization of ambient-cured geopolymer concrete. Arch. Civ. Mech. Eng. 2023, 24, 4. [Google Scholar] [CrossRef]

- Majeed, S.S.; Mydin, M.A.O.; Bahrami, A.; Dulaimi, A.; Özkılıç, Y.O.; Omar, R.; Jagadesh, P. Development of ultra-lightweight foamed concrete modified with silicon dioxide (SiO2) nanoparticles: Appraisal of transport, mechanical, thermal, and microstructural properties. J. Mater. Res. Technol. 2024, 30, 3308–3327. [Google Scholar] [CrossRef]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.A.; Mohammed, A.S. Effectiveness of silicon dioxide nanoparticles (Nano SiO2) on the internal structures, electrical conductivity, and elevated temperature behaviors of geopolymer concrete composites. J. Inorg. Organomet. Polym. Mater. 2023, 33, 3894–3914. [Google Scholar] [CrossRef]

- Rawat, G.; Gandhi, S.; Murthy, Y.I. Strength and rheological aspects of concrete containing nano-titanium dioxide. Asian J. Civ. Eng. 2022, 23, 1197–1208. [Google Scholar] [CrossRef]

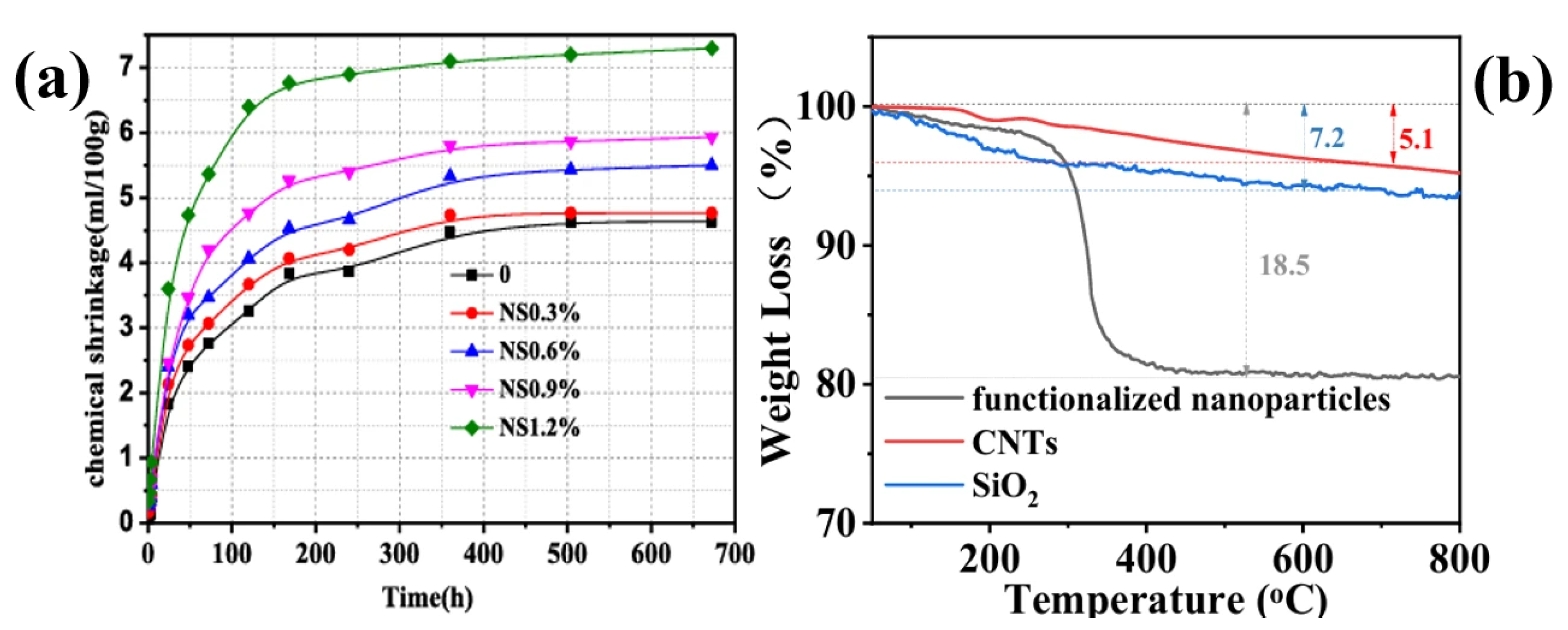

- Wang, J.; Cheng, Y.; Yuan, L.; Xu, D.; Du, P.; Hou, P.; Zhou, Z.; Cheng, X.; Liu, S.; Wang, Y. Effect of nano-silica on chemical and volume shrinkage of cement-based composites. Constr. Build. Mater. 2020, 247, 118529. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhu, Y.; Chen, C.; Zhang, Y. Effect of nano-alumina modified foaming agents on properties of foamed concrete. Constr. Build. Mater. 2021, 267, 121045. [Google Scholar] [CrossRef]

- Jia, Y.; Ding, M.; Lin, Y.; Wang, L.; Wei, Y.; Han, S. Effect of pozzolanic slurry coating containing nano-alumina on macro-micro properties of recycled brick aggregate. Constr. Build. Mater. 2025, 459, 139752. [Google Scholar] [CrossRef]

- Jaishankar, P.; Karthikeyan, C. In Characteristics of cement concrete with nano alumina particles. IOP Conf. Ser. Earth Environ. Sci. 2017, 80, 012005. [Google Scholar] [CrossRef]

- Ahmed, N.Y.; Alkhafaji, F.F. In Enhancements and mechanisms of nano alumina (Al2O3) on wear resistance and microstructure characteristics of concrete pavement. IOP Conf. Ser. Mater. Sci. Eng. 2020, 871, 012001. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Sadeghi, A.M.; Esmaeili, J. Hybrid-fibre-reinforced concrete containing multi-wall carbon nanotubes. Proc. Inst. Civ. Eng.-Struct. Build. 2020, 173, 646–654. [Google Scholar] [CrossRef]

- Fu, Q.; Zhou, Z.; Wang, Z.; Huang, J.; Niu, D. Insight into dynamic compressive response of carbon nanotube/carbon fiber-reinforced concrete. Cem. Concr. Compos. 2022, 129, 104471. [Google Scholar] [CrossRef]

- Taha, A.; Alnahhal, W.; Irshidat, M. Effect of carbon nanotubes on the bonding mechanism of non-corrosive reinforcements to concrete. Structures 2024, 60, 105952. [Google Scholar] [CrossRef]

- Chang, T.-P.; Shih, J.-Y.; Yang, K.-M.; Hsiao, T.-C. Material properties of Portland cement paste with nano-montmorillonite. J. Mater. Sci. 2007, 42, 7478–7487. [Google Scholar] [CrossRef]

- Mirgozar Langaroudi, M.A.; Mohammadi, Y. Effect of nano-clay on the freeze–thaw resistance of self-compacting concrete containing mineral admixtures. Eur. J. Environ. Civ. Eng. 2022, 26, 481–500. [Google Scholar] [CrossRef]

- Abuzeid, M.; Bassuoni, M.; Sakr, M. Effect of Polymer/Nano-Clay Coatings on the Performance of Concrete with High-Content Supplementary Cementitious Materials under Harsh Exposures. Materials 2024, 17, 1030. [Google Scholar] [CrossRef] [PubMed]

- Noori, A.; Yubin, L.; Saffari, P.; Zhang, Y.; Wang, M. The optimum percentage of nano clay (NC) in both direct-additive and sonicated modes to improve the mechanical properties of self-compacting concrete (SCC). Case Stud. Constr. Mater. 2022, 17, e01493. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. The effects of TiO2 nanoparticles on physical, thermal and mechanical properties of concrete using ground granulated blast furnace slag as binder. Mater. Sci. Eng. A 2011, 528, 2085–2092. [Google Scholar] [CrossRef]

- Mendoza, J.; Lee, D.; Kim, L.-H.; Kim, I.; Kang, J.-H. Photocatalytic performance of TiO2 and WO3/TiO2 nanoparticles coated on urban green infrastructure materials in removing nitrogen oxide. Int. J. Environ. Sci. Technol. 2018, 15, 581–592. [Google Scholar] [CrossRef]

- Zhang, W.; Han, B.; Yu, X.; Ruan, Y.; Ou, J. Nano boron nitride modified reactive powder concrete. Constr. Build. Mater. 2018, 179, 186–197. [Google Scholar] [CrossRef]

- Yang, B.; Hu, X.; Qiao, H. Enhancing durability of concrete in saline soil with nano-CaCO3 modification: Investigation and reliability analysis. KSCE J. Civ. Eng. 2024, 28, 3791–3804. [Google Scholar] [CrossRef]

- Noh, H.W.; Kim, D.J. Effects of combined nanoparticles on dynamic strength of ultra-high-performance fiber-reinforced concrete. J. Build. Eng. 2024, 96, 110508. [Google Scholar]

- Wang, Q.; Zhou, C.; Wang, X.; An, Z.; Luo, Y. Effect of graphene oxide on strength and interfacial transition zone of recycled aggregate concrete. Mater. Res. Express 2022, 9, 075008. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, L.; Chen, X.; Liu, F. Study on the mechanical properties and frost resistance of multiple modified concrete. Mater. Res. Express 2022, 9, 045013. [Google Scholar] [CrossRef]

- Alharthai, M.; Mydin, M.A.O.; Majeed, S.S.; Tayeh, B.A.; Tobbala, D.E. Synthesis and characterisation of ZnO nanoparticles and its influence on the engineering properties of lightweight foamed concrete. Arch. Civ. Mech. Eng. 2025, 25, 79. [Google Scholar] [CrossRef]

- Abiz, M.R.N.; Esfahani, M.R.; Tanhadoust, A.; Nehdi, M.L.; Banijamali, S.M. Magnesium nanoparticle modified cement-based composites: Performance and compatibility in repair applications. Constr. Build. Mater. 2023, 400, 132781. [Google Scholar] [CrossRef]

- Facin, F.; Staub de Melo, J.V.; Costa Puerari, R.; Matias, W.G. Toxicological Effects of Leachates Extracted from Photocatalytic Concrete Blocks with Nano-TiO2 on Daphnia magna. Nanomaterials 2024, 14, 1447. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, S.K.; Bhuiyan, M.; Robert, D.; Roychand, R.; Gao, L.; Pramanik, B.K. MIL-101 (Cr)/epoxy composite coating for enhanced corrosion resistance in concrete sewer infrastructure. Process Saf. Environ. Prot. 2025, 199, 107360. [Google Scholar] [CrossRef]

- Xiao, X.; Unluer, C.; Chu, S.; Yang, E.-H. Single bacteria spore encapsulation through layer-by-layer self-assembly of poly (dimethyldiallyl ammonium chloride) and silica nanoparticles for self-healing concrete. Cem. Concr. Compos. 2023, 140, 105105. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Tan, Y.; Li, J.; Wang, D.; Yuan, D.; Zhang, J. A sustainable superhydrophobic and photothermal coatings for anti-icing application on concrete with a simple method for CNTs/SiO2 modification. Sustainability 2023, 15, 15865. [Google Scholar] [CrossRef]

- Siddique, S.N. A review on mobility of engineered carbon-based nanoparticles in porous media. Environ. Geotech. 2020, 7, 382–392. [Google Scholar] [CrossRef]

- Huseien, G.F. A review on concrete composites modified with nanoparticles. J. Compos. Sci. 2023, 7, 67. [Google Scholar] [CrossRef]

- Kotop, M.A.; El-Feky, M.; Alharbi, Y.R.; Abadel, A.A.; Binyahya, A.S. Engineering properties of geopolymer concrete incorporating hybrid nano-materials. Ain Shams Eng. J. 2021, 12, 3641–3647. [Google Scholar] [CrossRef]

- Shah, S.P.; Hou, P.; Cheng, X. Durability of cement-based materials and nano-particles: A review. In Nanotechnology in Construction; Springer: Cham, Switzerland, 2015; pp. 15–24. [Google Scholar]

- Yuan, Q.; Wang, L.; Kong, D.; Han, Y.; Ren, C.; Tian, Y.; Zhu, G. Synergistic action and effect mechanism of coal gangue powder and red mud on the properties of concretes. J. Build. Eng. 2024, 98, 110999. [Google Scholar] [CrossRef]

- Bai, E.; Wang, Z.; Du, Y.; Ren, B.; Liu, C. Mechanical properties and strain rate effect of graphene oxide grafted carbon fiber modified concrete under dynamic impact load. Constr. Build. Mater. 2024, 445, 137978. [Google Scholar] [CrossRef]

- Sypek, M.; Latawiec, R.; Łaźniewska-Piekarczyk, B.; Pichór, W. Impact of surfactant and calcium sulfate type on air-entraining effectiveness in concrete. Materials 2022, 15, 985. [Google Scholar] [CrossRef] [PubMed]

- Belayachi, N.; Mallet, C.; El Marzak, M. Thermally-induced cracks and their effects on natural and industrial geomaterials. J. Build. Eng. 2019, 25, 100806. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, J.; Nie, Y.; He, W. Effect of seashell powder as binder material on the performance and microstructure of low-carbon sustainable alkali-activated concrete. J. Build. Eng. 2024, 90, 109442. [Google Scholar] [CrossRef]

- Lin, D.; Lin, K.; Chang, W.; Luo, H.; Cai, M. Improvements of nano-SiO2 on sludge/fly ash mortar. Waste Manag. 2008, 28, 1081–1087. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, Z.; Zhang, J.; Li, H.; Xu, M.; Pi, Z.; Wu, K.; Ma, G. Characterization of the interface transition zone in granulated blast furnace slag-calcium sulphoaluminate cement concrete. Constr. Build. Mater. 2025, 476, 141224. [Google Scholar] [CrossRef]

- Su, Z.; Li, X. Study on preparation and interfacial transition zone microstructure of red mud-yellow phosphorus slag-cement concrete. Materials 2021, 14, 2768. [Google Scholar] [CrossRef]

- Karakuzu, K.; Kobya, V.; Mardani, A.; Felekoğlu, B.; Ramyar, K. Effect of PCE anionic charge density on fly ash cementitious system-PCE compatibility. J. Adhes. Sci. Technol. 2025, 39, 209–225. [Google Scholar] [CrossRef]

- Xiang, S.; Tan, Y.; Gao, Y.; Jiang, Z.; Liu, B.; Zeng, W. Bubble evolution under the action of polycarboxylate and air-entraining agent and its effects on concrete properties—A review. Materials 2022, 15, 7053. [Google Scholar] [CrossRef]

- Saladi, N.; Montanari, L.; Mohebbi, A.; Cooper, M.A.; Graybeal, B. Assessing the setting behavior of ultra-high performance concrete. Mater. Struct. 2024, 57, 143. [Google Scholar] [CrossRef]

- Lei, J.; Feng, F.; Xu, S.; Wen, W.; He, X. Study on mechanical properties of modified polyurethane concrete at different temperatures. Appl. Sci. 2022, 12, 3184. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.; Jin, R.; Chen, H. Mechanical properties of recycled aggregate concrete modified by nano-particles. Constr. Build. Mater. 2020, 241, 118030. [Google Scholar] [CrossRef]

- Hou, P.; Kawashima, S.; Kong, D.; Corr, D.J.; Qian, J.; Shah, S.P. Modification effects of colloidal nanoSiO2 on cement hydration and its gel property. Compos. Part B Eng. 2013, 45, 440–448. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, H.; Wang, Z. Mechanical property enhancement, durability improvement and micro mechanism of all-bamboo aggregate concrete by ACQ-polyacrylate modification. Ind. Crops Prod. 2025, 228, 120947. [Google Scholar] [CrossRef]

- Wang, T.; Xu, J.; Meng, B.; Peng, G. Experimental study on the effect of carbon nanofiber content on the durability of concrete. Constr. Build. Mater. 2020, 250, 118891. [Google Scholar] [CrossRef]

- Lv, S.; Liu, J.; Sun, T.; Ma, Y.; Zhou, Q. Effect of GO nanosheets on shapes of cement hydration crystals and their formation process. Constr. Build. Mater. 2014, 64, 231–239. [Google Scholar] [CrossRef]

- Krystek, M.; Pakulski, D.; Patroniak, V.; Górski, M.; Szojda, L.; Ciesielski, A.; Samorì, P. High-performance graphene-based cementitious composites. Adv. Sci. 2019, 6, 1801195. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Lin, Y.-C.; Chung, J.H.; Chiu, H.-Y.; Yeh, N.-L.; Chang, S.-J.; Chan, C.-H.; Shih, C.-C.; Chen, G.-Y. Enhancing cementitious composites with functionalized graphene oxide-based materials: Surface chemistry and mechanisms. Int. J. Mol. Sci. 2023, 24, 10461. [Google Scholar] [CrossRef]

- Qiao, W.; Shi, M.; Ban, T.; Hou, B.; Zhang, W.; Kong, X. Using graphene oxide to enhance the bonding properties between carbon fibers and cement matrix to improve the mechanical properties of cement-based composites. Constr. Build. Mater. 2024, 453, 138992. [Google Scholar] [CrossRef]

- Qiu, L.; Dong, S.; Yu, X.; Han, B. Self-sensing ultra-high performance concrete for in-situ monitoring. Sens. Actuators A Phys. 2021, 331, 113049. [Google Scholar] [CrossRef]

- Cho, S.-S.; Kim, J.-M.; Hong, I.-P. Electromagnetic Shielding Characteristics of Eco-Friendly Foamed Concrete Wall. Int. J. Antennas Propag. 2017, 2017, 9794053. [Google Scholar] [CrossRef]

- Li, S.; Liew, J.R.; Xiong, M.-X.; Lai, B.-L. Experimental investigation on fire resistance of high-strength concrete encased steel composite columns. Fire Saf. J. 2021, 121, 103273. [Google Scholar] [CrossRef]

- Li, X.; Sun, G. Optimal freeze-thaw resistance air-entrained concrete with designed nanoparticle stabilised bubble system. Constr. Build. Mater. 2024, 435, 136769. [Google Scholar] [CrossRef]

- Hossain, M.M.; Al-Deen, S.; Hassan, M.K.; Shill, S.K.; Kader, M.A.; Hutchison, W. Mechanical and thermal properties of hybrid fibre-reinforced concrete exposed to recurrent high temperature and aviation oil. Materials 2021, 14, 2725. [Google Scholar] [CrossRef]

- Yu, L.; Xu, F. Bilateral chloride diffusion model of nanocomposite concrete in marine engineering. Constr. Build. Mater. 2020, 263, 120634. [Google Scholar] [CrossRef]

- Li, W.; Huang, Z.; Cao, F.; Sun, Z.; Shah, S.P. Effects of nano-silica and nano-limestone on flowability and mechanical properties of ultra-high-performance concrete matrix. Constr. Build. Mater. 2015, 95, 366–374. [Google Scholar] [CrossRef]

- Qian, X.; Wang, J.; Wang, L.; Fang, Y.; Chen, P.; Li, M. A clean dispersant for nano-silica to enhance the performance of cement mortars. J. Clean. Prod. 2022, 371, 133647. [Google Scholar] [CrossRef]

- Wu, G.; Li, T.; Zhang, M.; Cui, J.; Li, J. Durability and thermal insulation properties of glazed hollow bead concrete with nanoparticles in marine atmospheric environment. J. Build. Eng. 2024, 94, 110071. [Google Scholar] [CrossRef]

- Khadanga, V.; Mishra, P.C. A review on toxicity mechanism and risk factors of nanoparticles in respiratory tract. Toxicology 2024, 504, 153781. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.T.; Thai, H.T.; Ngo, T. Effect of steel fibers on the performance of an economical ultra-high strength concrete. Struct. Concr. 2023, 24, 2327–2341. [Google Scholar] [CrossRef]

- Zhu, H.-L.; Cheng, Q.-Y.; Liao, M.-Y.; Zhang, Z.-L.; Cai, W.-G.; Ma, J.-J.; Sun, M.-Y.; Yu, M.-X.; Tian, Z.-Q.; Pang, D.-W. Economical synthesis of ultra-small Bi2S3 nanoparticles for high-sensitive CT imaging. Mater. Res. Express 2019, 6, 095005. [Google Scholar] [CrossRef]

- Vance, M.E.; Kuiken, T.; Vejerano, E.P.; McGinnis, S.P.; Hochella, M.F., Jr.; Rejeski, D.; Hull, M.S. Nanotechnology in the real world: Redeveloping the nanomaterial consumer products inventory. Beilstein J. Nanotechnol. 2015, 6, 1769–1780. [Google Scholar] [CrossRef]

- Saliani, M.; Honarbakhsh, A.; Zhiani, R.; Movahedifar, S.M.; Motavalizadehkakhky, A. Effects of GO/Al2O3 and Al2O3 nanoparticles on concrete durability against high temperature, freeze-thaw cycles, and acidic environments. Adv. Civ. Eng. 2021, 2021, 4555802. [Google Scholar] [CrossRef]

- Sutto, T.E. Magnetite fine particle and nanoparticle environmental contamination from industrial uses of coal. Environ. Pollut. 2018, 243, 528–533. [Google Scholar] [CrossRef]

- Gaharwar, U.S.; Meena, R.; Rajamani, P. Iron oxide nanoparticles induced cytotoxicity, oxidative stress and DNA damage in lymphocytes. J. Appl. Toxicol. 2017, 37, 1232–1244. [Google Scholar] [CrossRef]

- Park, Y.-W. Machine Learning-Based Prediction of Characteristics of Construction Materials. Master’s Thesis, Seoul National University, Seoul, Republic of Korea, 2023. [Google Scholar]

- Wang, X.; Zheng, Q.; Dong, S.; Ashour, A.; Han, B. Interfacial characteristics of nano-engineered concrete composites. Constr. Build. Mater. 2020, 259, 119803. [Google Scholar] [CrossRef]

- Sheikhnejad, O.; Nakamoto, T.; Kalteis, A.; Rajabtabar, A.; Major, Z. Molecular dynamic simulation of carbon nanotube reinforced nanocomposites: The effect of interface interaction on mechanical properties. MOJ Polym. Sci. 2018, 2, 6–10. [Google Scholar] [CrossRef]

| Nanoparticles | Main Function | Common Dosage | Ref. |

|---|---|---|---|

| Nano-CaCO3 | Accelerate hydration, refine pore size, enhance early strength and resistance to sulfate erosion | 1–2 wt% | [39] |

| Nano-Fe3O4 | Magneto-thermal conversion, self-induction, electromagnetic shielding | 0.5–1.5 wt% | [40] |

| Graphene Oxide | Strengthen the interface transition zone and enhance mechanical and electrical conductivity properties | 0.02–0.1 wt% | [41] |

| Reduced Graphene Oxide | Enhance resilience and endow with self-perception capabilities | 0.03–0.1 wt% | [42] |

| Nano-ZnO | Antibacterial, UV shielding, and enhanced strength | 0.5–1.0 wt% | [43] |

| Nano-CuO | Sterilization, promoting hydration, and enhancing durability | 0.5–1.0 wt% | [9] |

| Nano-MgO | Compensate for shrinkage, inhibit cracking and improve fire resistance | 1.0–2.0 wt% | [44] |

| Nano-TiO2 | Self-cleaning, photocatalysis, antibacterial | 1.0–2.0 wt% | [22] |

| Nano-BN | High thermal conductivity, insulation, and reduced dry shrinkage | 0.3–0.5 wt% | [38] |

| Nano-ZrO2 | Toughening, enhancing wear resistance and impermeability | 1.0–1.5 wt% | [14] |

| Nano-CeO2 | Anti-oxidation, improving fire resistance and corrosion resistance | 0.5–1.0 wt% | [7] |

| Nano-Ag | Broad-spectrum antibacterial, and anti-biological contamination | 0.01–0.05 wt% | [45] |

| Nano-Cu | Conductive, antimicrobial, and corrosion-resistant | 0.1–0.5 wt% | [46] |

| Nano-SiC | High hardness, wear resistance, and heat conductivity | 0.5–1.0 wt% | [5] |

| Nano-Ca (OH)2 | Repair agent, carbonization inhibitor, self-healing | 1.0–2.0 wt% | [47] |

| Layered Double Hydroxides (LDHs) | Ion exchange, chloride ion curing, rust inhibition | 1.0–3.0 wt% | [48] |

| Halloysite Nanotubes (HNTs) | Rust inhibitor, toughening | 1.0–2.0 wt% | [49] |

| Nano-Metakaolin | Volcanic ash reaction, filling, and enhanced durability | 5–10 wt% | [50] |

| Nano-Attapulgite | Thickening, water retention, and enhanced interfacial adhesion | 0.5–1.0 wt% | [51] |

| Nanomaterial | Typical Dosage (wt.% of Cement) | Primary Mechanism(s) | Key Performance Enhancement | Major Challenge(s) |

|---|---|---|---|---|

| Nano-SiO2 | 1.0–3.0 | Pozzolanic reaction; Nano-filling; Nucleation | Strength: +++ Durability (chloride/sulfate): +++ ITZ density: +++ | High shrinkage; Rapid setting; Dispersion |

| Nano-TiO2 | 1.0–5.0 | Photocatalysis; Nano-filling | Self-cleaning: +++ Air purification: +++ Antibacterial: +++ | High cost; Dispersion; UV dependency; Long-term activity |

| Carbon Nanotubes | 0.01–0.1 | Fiber bridging; Electrical conductivity; Nucleation | Tensile/Flexural strength: ++ Toughness: +++ Self-sensing: +++ | Severe agglomeration; Very high cost; Workability reduction |

| Nano-Clay | 1.0–5.0 | Barrier effect; Pore refinement; Nano-filling | Impermeability: +++ Fire resistance: ++ Freeze-thaw resistance: ++ | High water demand; Workability reduction; Dispersion |

| Nano-Al2O3 | 0.5–2.0 | Nano-filling; Nucleation; Hard phase | Abrasion resistance: +++ Early strength: ++ | Moderate cost; Potential agglomeration; Limited durability data |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhao, Y.; Zhao, Y.; Zhang, M.; Niu, Y.; Cao, X. Advances in the Mechanism and Application of Nanoparticles in Concrete Property Modification. Inorganics 2025, 13, 305. https://doi.org/10.3390/inorganics13090305

Li H, Zhao Y, Zhao Y, Zhang M, Niu Y, Cao X. Advances in the Mechanism and Application of Nanoparticles in Concrete Property Modification. Inorganics. 2025; 13(9):305. https://doi.org/10.3390/inorganics13090305

Chicago/Turabian StyleLi, Huaming, Yuhan Zhao, Yan Zhao, Min Zhang, Yanan Niu, and Xi Cao. 2025. "Advances in the Mechanism and Application of Nanoparticles in Concrete Property Modification" Inorganics 13, no. 9: 305. https://doi.org/10.3390/inorganics13090305

APA StyleLi, H., Zhao, Y., Zhao, Y., Zhang, M., Niu, Y., & Cao, X. (2025). Advances in the Mechanism and Application of Nanoparticles in Concrete Property Modification. Inorganics, 13(9), 305. https://doi.org/10.3390/inorganics13090305