Effect of TiC Particles on the Properties of Copper Matrix Composites

Abstract

1. Introduction

2. Results and Analysis

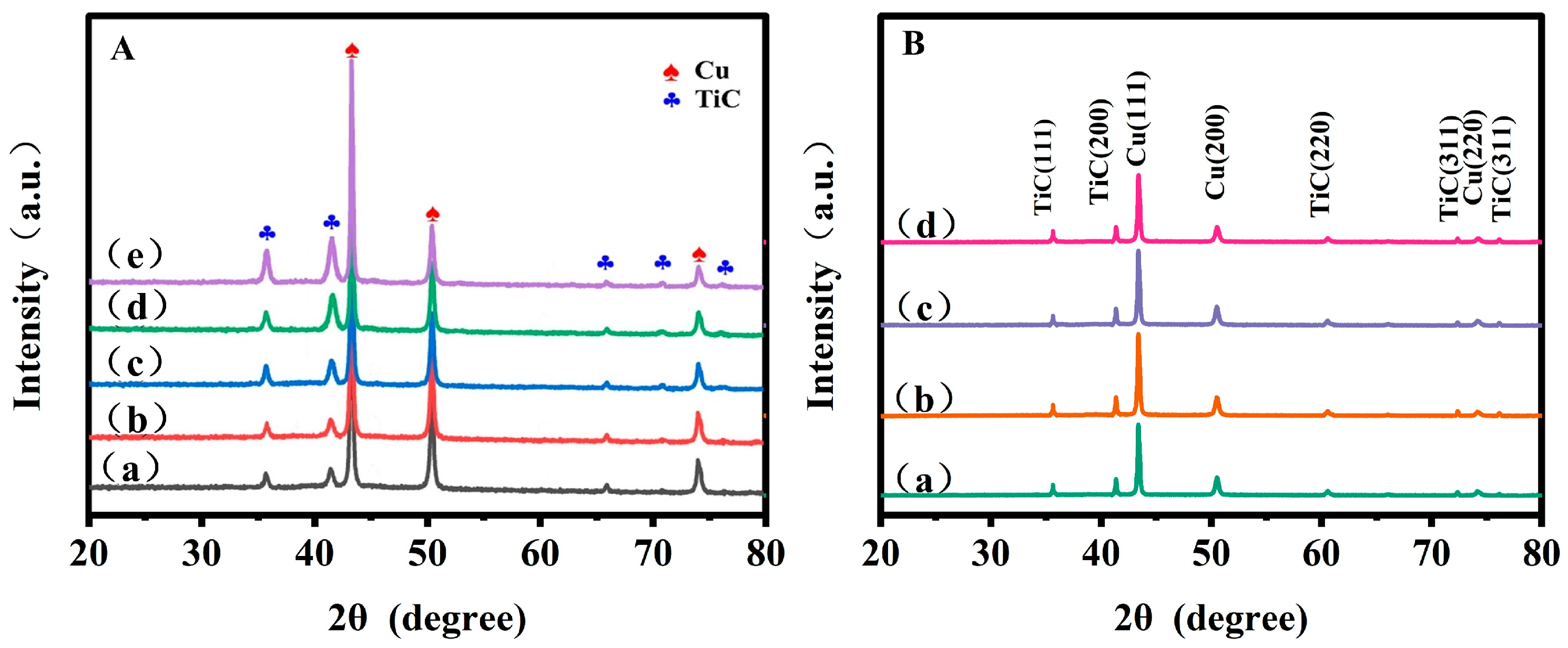

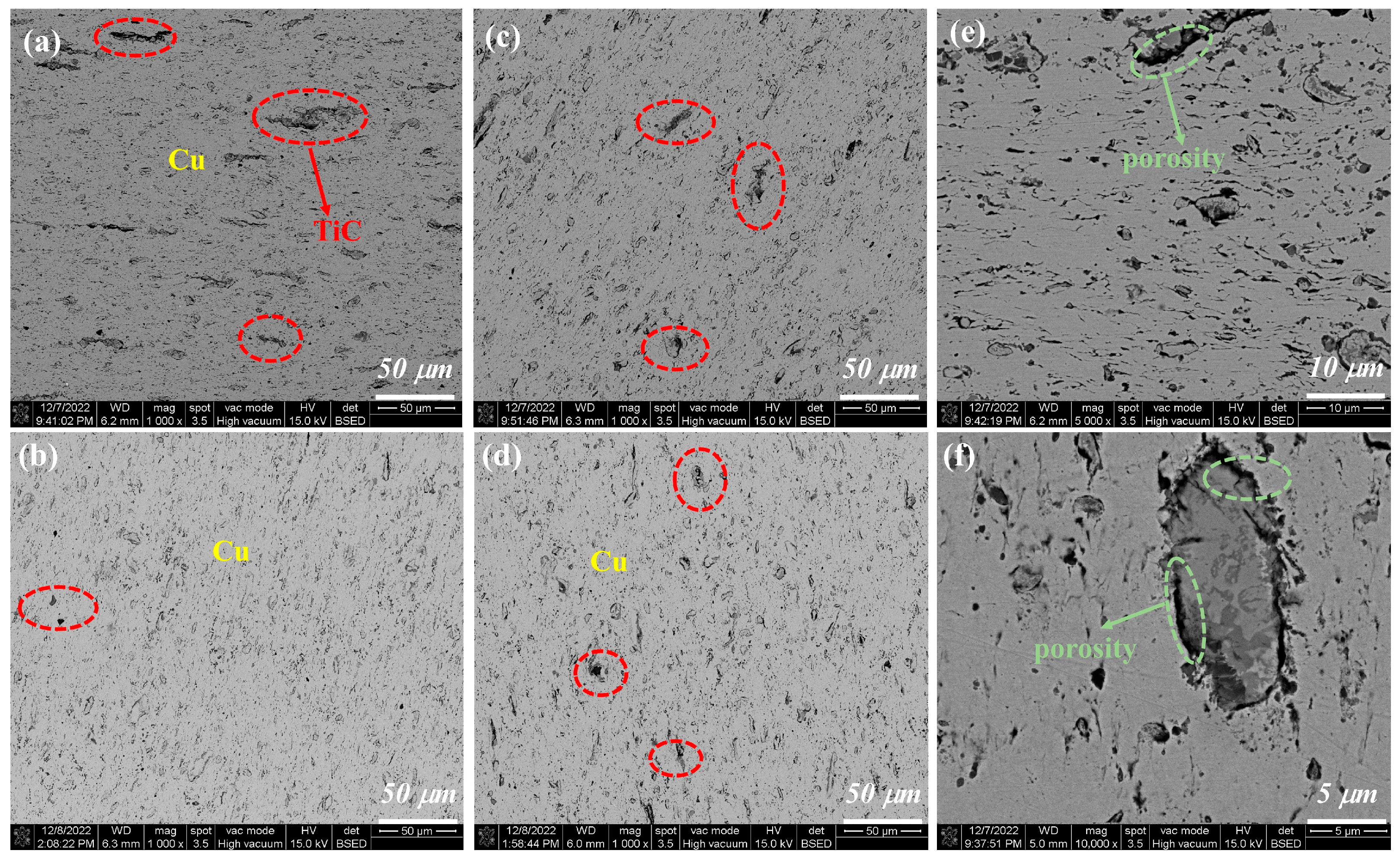

2.1. Physical Phase Composition and Microscopic Morphology of TiC/Cu with Different Sintering Temperatures

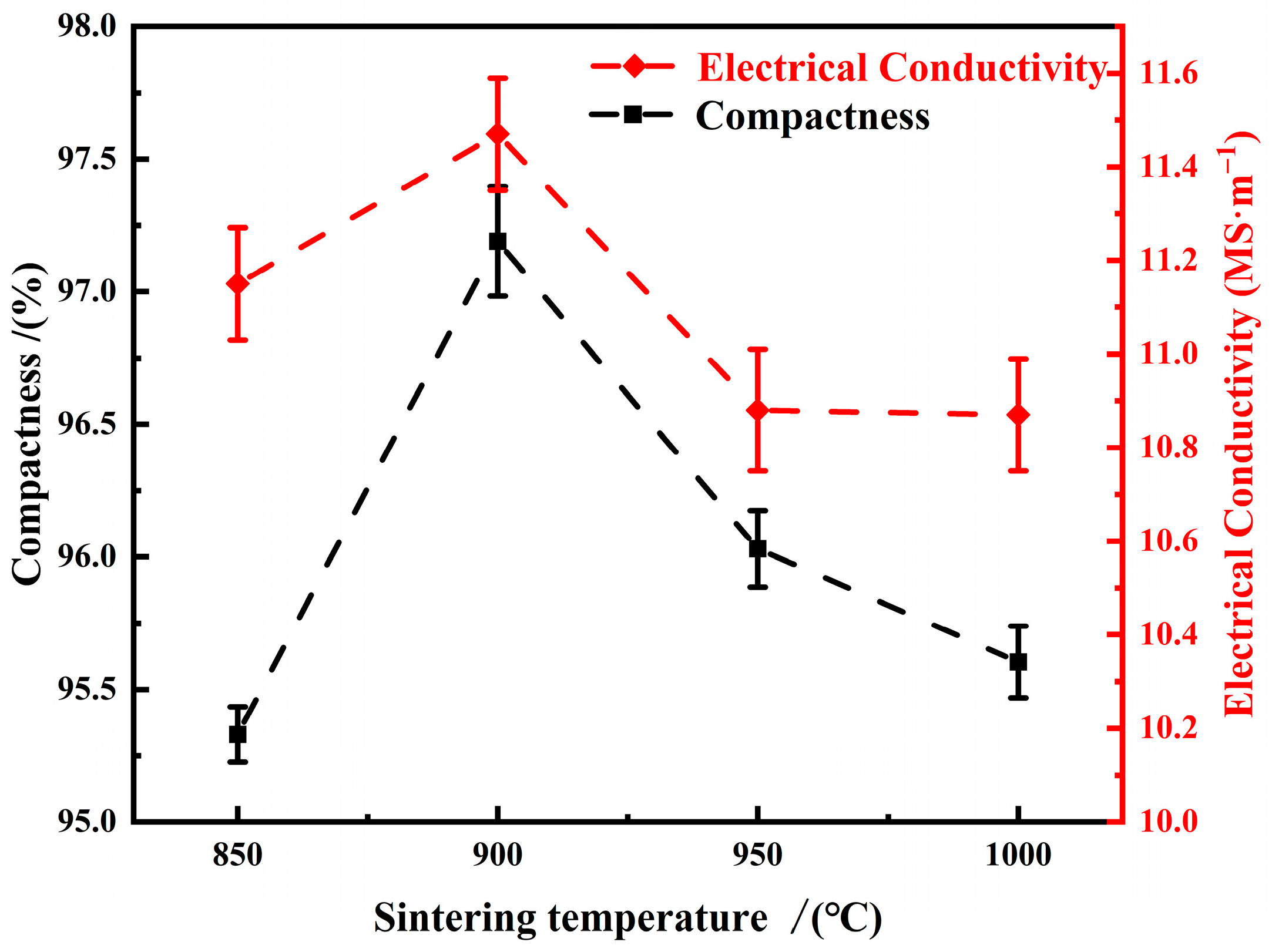

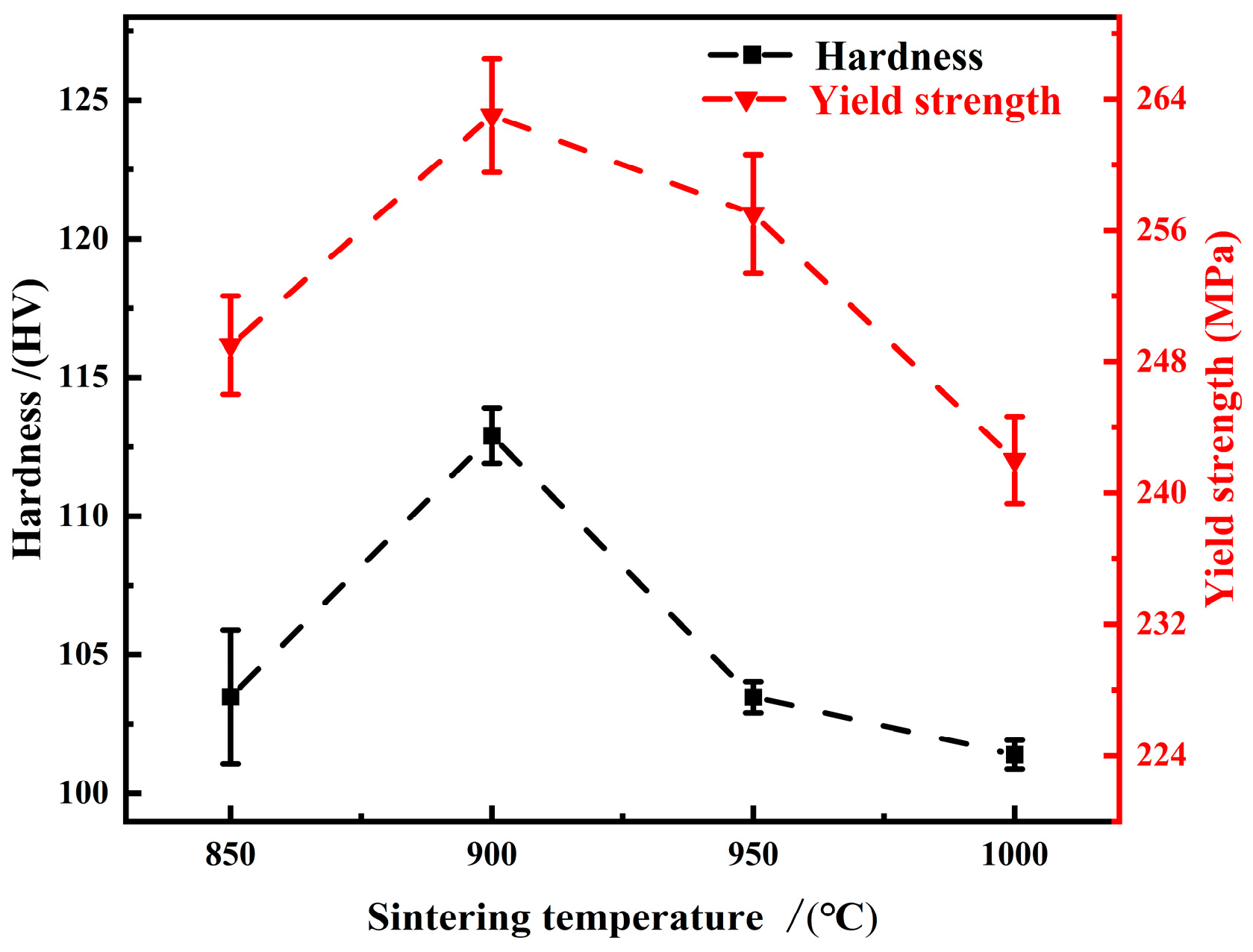

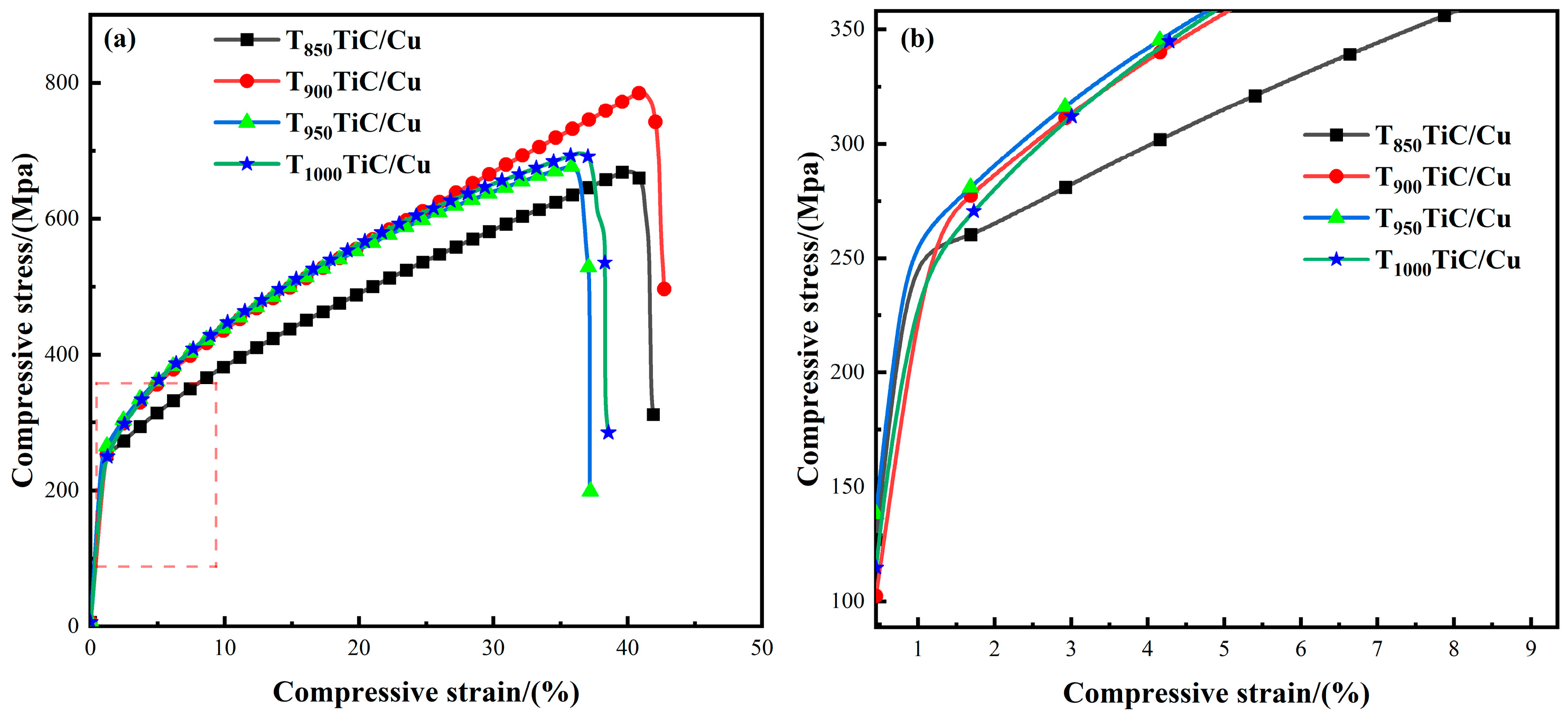

2.2. Effect of Sintering Temperature on Electrical and Mechanical Properties of TiC/Cu Composites

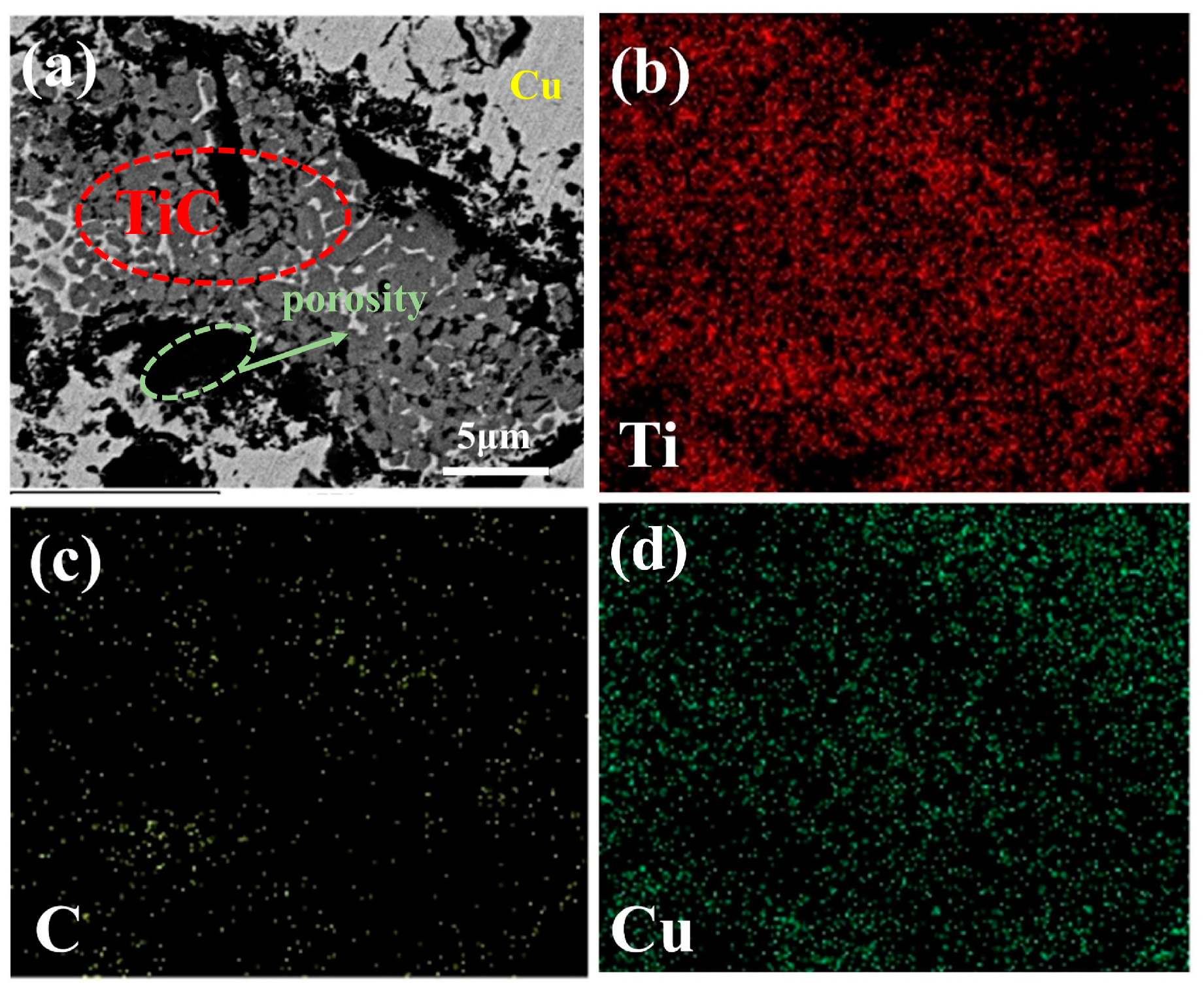

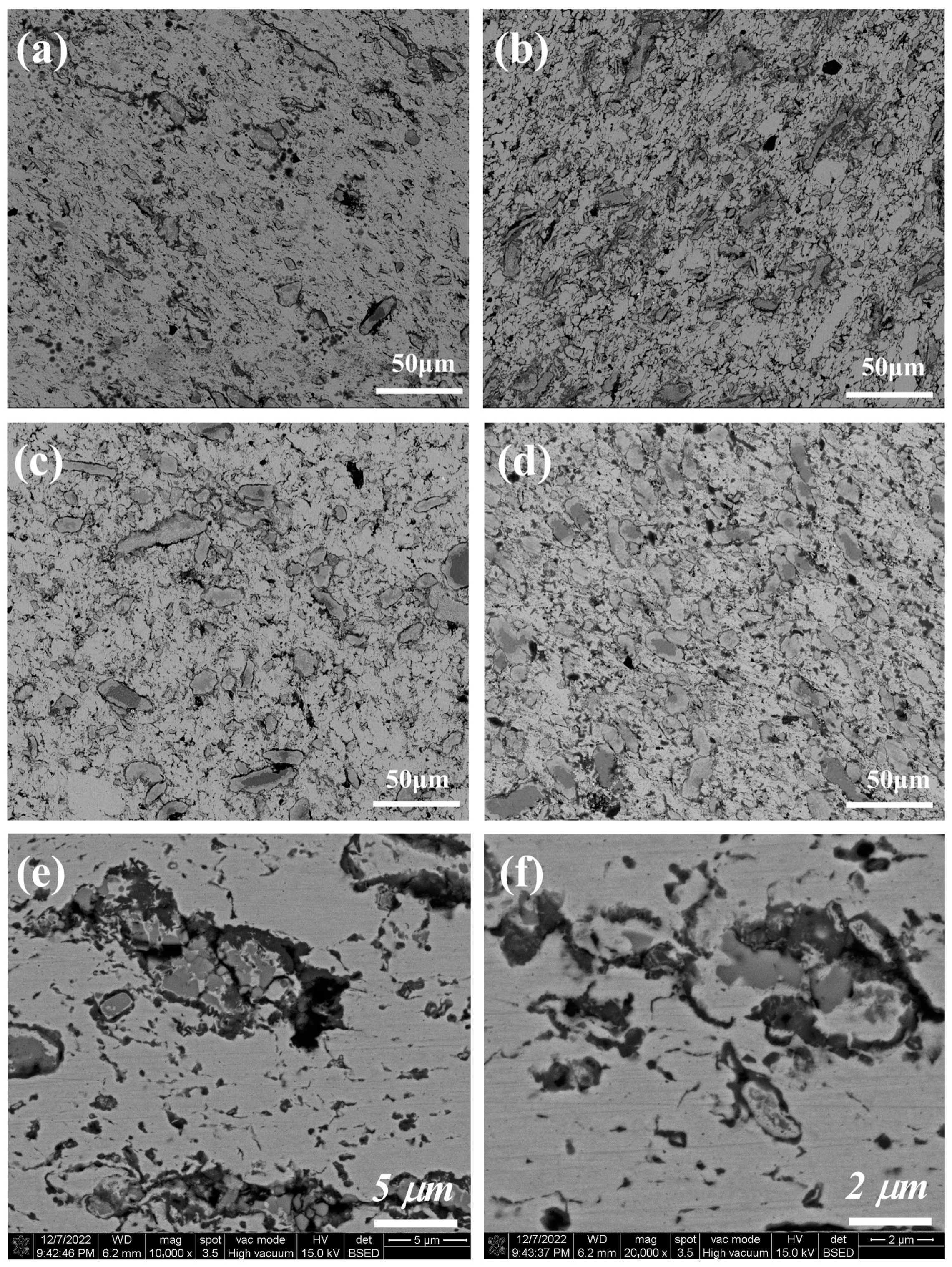

2.3. Microscopic Morphology of TiC/Cu Composites with Different TiC Contents

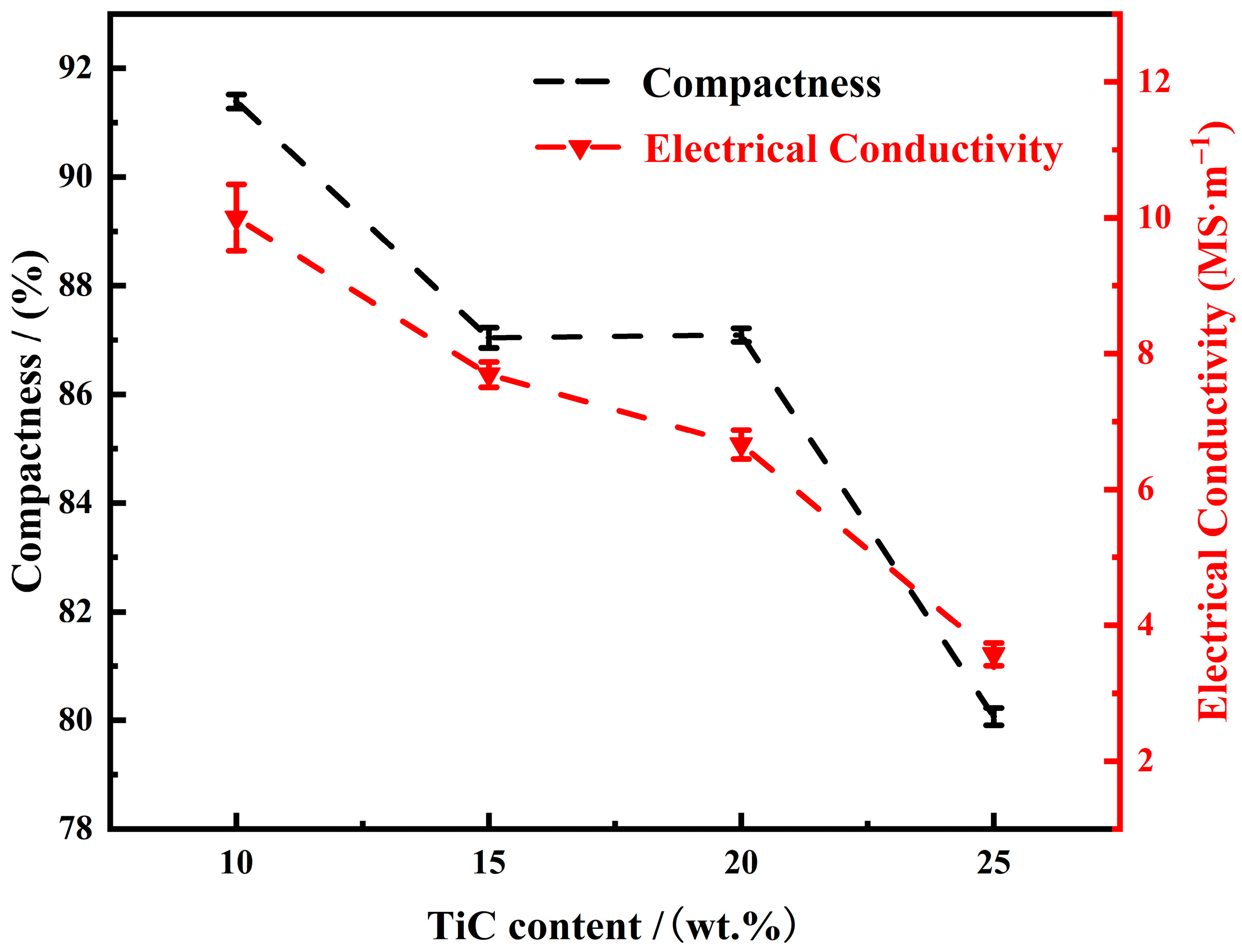

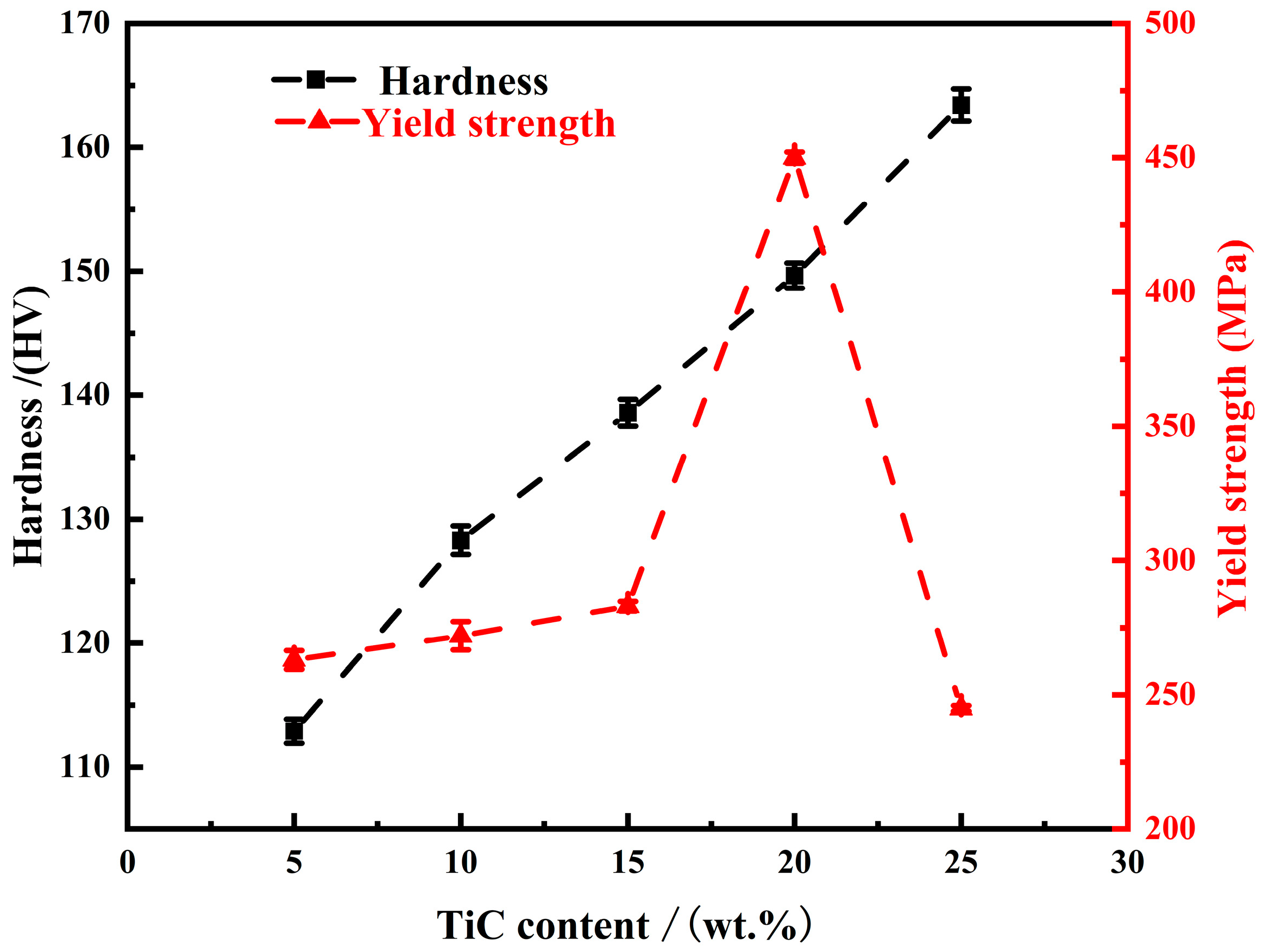

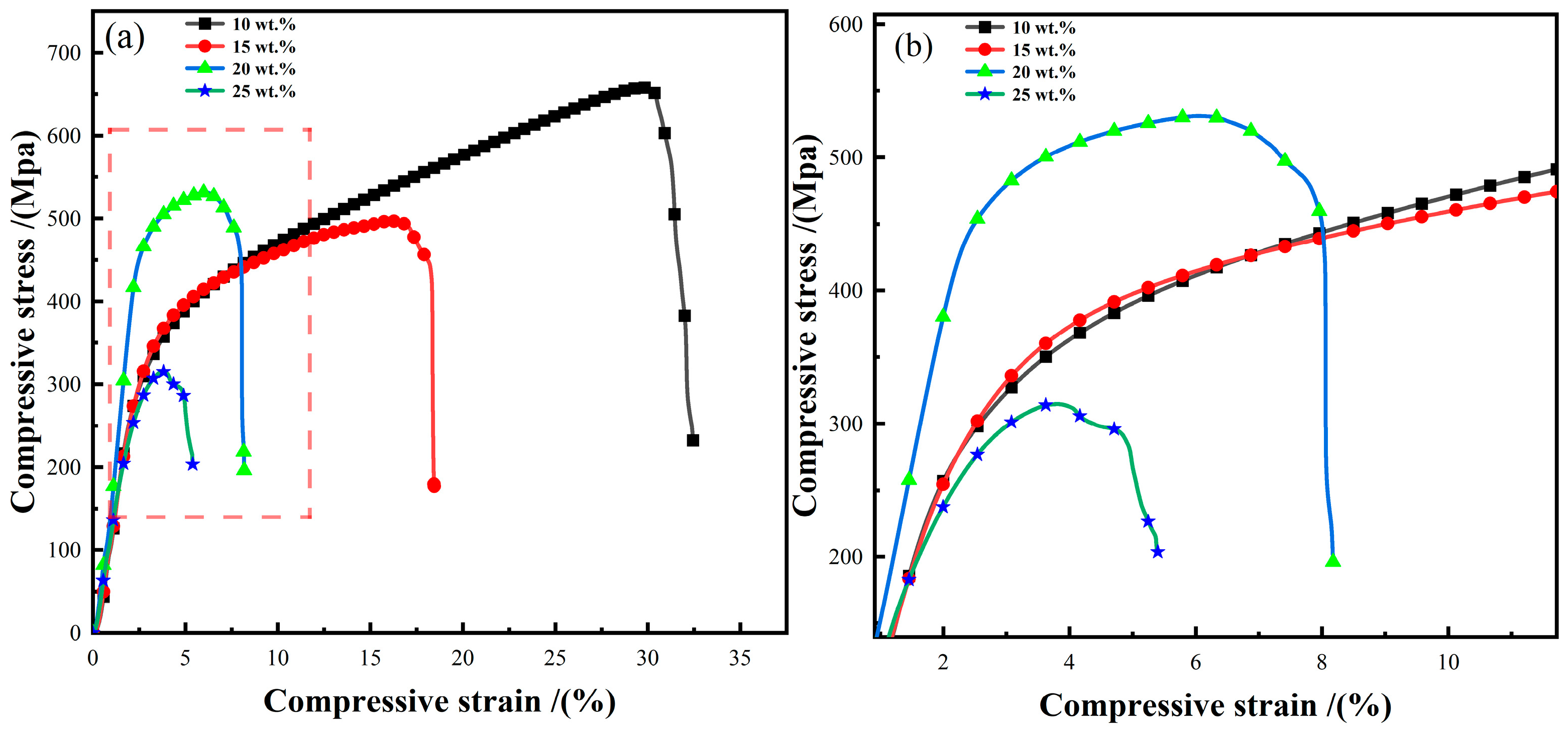

2.4. Effect of TiC Content on Electrical and Mechanical Properties of TiC/Cu Composites

3. Experimental Materials and Methods

3.1. Experimental Raw Materials

3.2. Experimental Methods

- (1)

- Preparation of composite powder

- (2)

- Preparation of TiC/Cu composites

3.3. Testing and Characterization

4. Conclusions

- (1)

- In this study, TiC/particle-reinforced Cu composites with uniform particle distribution were prepared by high-energy ball milling and SPS sintering using Ti, C and Cu powders as raw materials. The effects of different SPS sintering temperatures and TiC contents on the microstructure and morphology, mechanical and electrical properties of the composites were investigated.

- (2)

- When the sintering temperature was 900 °C, the dispersion of TiC in the copper matrix was good. The pores were eliminated in time. The densification of 5 wt.% TiC/Cu composites reached 97.19%. The average values of conductivity, hardness and compressive yield strength reached 11.47 MS·m−1, 112.9 HV and 162 MPa, respectively, at which time the comprehensive performance of the composites were at their best. As the sintering temperature increased or decreased, the dispersion effect of TiC obviously deteriorated, and the comprehensive performance of the composites also deteriorated.

- (3)

- The yield strength of the composites increased with the increase in TiC content. However, the degree of agglomeration of TiC and the brittleness of the composites also increased. When the mass fraction of TuC reached 25%, the mechanical properties of the composites decreased significantly. The best overall performance of the composites was obtained when the TiC content was 10%. At that time, the yield strength was 272 MPa, the hardness was 128.3 HV, the conductivity was 9.98 MS·m−1, and the densification was 90.70%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ankit; Kumar, V.; Mishra, A.; Mohan, S.; Singh, K.; Mohan, A. The effect of titanium carbide particles on microstructure and mechanical properties of copper/graphite composites prepared by flake powder metallurgy route. Mater. Today Proc. 2020, 26, 1140–1144. [Google Scholar] [CrossRef]

- Mohanavel, V.; Vinoth, T.; Iyankumar, R.; Vinoth, N. Mechanical and corrosion behaviour of copper matrix composites fabricated by powder metallurgy process. Mater. Today Proc. 2020, 33, 3394–3398. [Google Scholar] [CrossRef]

- Dong, L.; Fu, Y.; Liu, Y.; Lu, J.; Zhang, W.; Huo, W.; Jin, L.; Zhang, Y. Interface engineering of graphene/copper matrix composites decorated with tungsten carbide for enhanced physico-mechanical properties. Carbon 2021, 173, 41–53. [Google Scholar] [CrossRef]

- Hussain, Z.; Kit, L.C. Properties and spot welding behaviour of copper–alumina composites through ball milling and mechanical alloying. Mater. Des. 2008, 29, 1311–1315. [Google Scholar] [CrossRef]

- Sheibani, S.; Heshmati-Manesh, S.; Ataie, A. Structural investigation on nano-crystalline Cu–Cr supersaturated solid solution prepared by mechanical alloying. J. Alloys Compd. 2010, 495, 59–62. [Google Scholar] [CrossRef]

- Besterci, M.; Ivan, J.; Kováč, L.; Weissgaerber, T.; Sauer, C. Strain and fracture mechanism of Cu–TiC. Mater. Lett. 1999, 38, 270–274. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, Y.; Wang, J. Tribological behavior of Ti2SnC particulate reinforced copper matrix composites. Mater. Sci. Eng. A 2006, 422, 266–271. [Google Scholar] [CrossRef]

- Huang, K.; Marthinsen, K.; Zhao, Q.; Logé, R.E. The double-edge effect of second-phase particles on the recrystallization behaviour and associated mechanical properties of metallic materials. Prog. Mater. Sci. 2018, 92, 284–359. [Google Scholar] [CrossRef]

- Han, L.; Wang, J.; Chen, Y.; Huang, Y.; Liu, Y.; Wang, Z. Fabrication and mechanical properties of WC nanoparticle dispersion-strengthened copper. Mater. Sci. Eng. A 2021, 817, 141274. [Google Scholar] [CrossRef]

- Wang, Z.; Bian, Y.; Ni, J.; Li, X.; Xu, Y.; Shao, Y.; Zhen, J.; Cai, L.; Luo, L. Tribological and electrochemical corrosion behaviors of Cu-based powder metallurgy composites reinforced by in-situ WC with different morphology. J. Mater. Res. Technol. 2022, 21, 4067–4078. [Google Scholar] [CrossRef]

- Frage, N.; Froumin, N.; Rubinovich, L.; Dariel, M.P. Infiltrated TiC/Cu composites. In Powder Metallurgical High Performance Materials; Plansee Holding AG: Breitenwang, Austria, 2001; pp. 202–216. [Google Scholar]

- Nemati, N.; Khosroshahi, R.; Emamy, M.; Zolriasatein, A. Investigation of microstructure, hardness and wear properties of Al–4.5 wt.% Cu–TiC nanocomposites produced by mechanical milling. Mater. Des. 2011, 32, 3718–3729. [Google Scholar] [CrossRef]

- Dinaharan, I.; Albert, T. Effect of reinforcement type on microstructural evolution and wear performance of copper matrix composites via powder metallurgy. Mater. Today Commun. 2023, 34, 105250. [Google Scholar] [CrossRef]

- Bagheri, G. The effect of reinforcement percentages on properties of copper matrix composites reinforced with TiC particles. J. Alloys Compd. 2016, 676, 120–126. [Google Scholar] [CrossRef]

- Huang, X.; Bao, L.; Bao, R.; Liu, L.; Tao, J.; Wang, J.; Zhang, Z.; Ge, Z.; Tan, S.; Yi, J.; et al. Reinforced copper matrix composites with highly dispersed nano size TiC in-situ generated from the Carbon Polymer Dots. Adv. Powder Mater. 2023, 2, 00090. [Google Scholar] [CrossRef]

- Zhu, J.; Li, J.; Liu, T.; Chen, Z.; Fang, H.; Xiao, P.; Kong, F. Differences in mechanical behaviors and characteristics between natural graphite/copper composites and carbon-coated graphite/copper composites. Mater. Charact. 2020, 162, 110195. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S. Mechanical Alloying: For Fabrication of Advanced Engineering Materials; William Andrew: Norwich, NY, USA, 2001. [Google Scholar]

- Shehata, F.; Fathy, A.; Abdelhameed, M.; Moustafa, S. Fabrication of copper–alumina nanocomposites by mechano-chemical routes. J. Alloys Compd. 2009, 476, 300–305. [Google Scholar] [CrossRef]

- Duan, B.H.; Zhou, Y.; Wang, D.C. Effect of microwave sintering temperature on the structure and properties of CNTs/Cu composites. Powder Metall. Technol. 2018, 5, 323–330. [Google Scholar]

- Zhang, X.; Peng, K.; Cao, E.B.; Gao, Q.; Song, M. Effect of hot pressing temperature on the organization and properties of graphene copper matrix composites. Therm. Process. Technol. 2020, 49, 5. [Google Scholar]

- Yue, H.; Yao, L.; Gao, X.; Zhang, S.; Guo, E.; Zhang, H.; Lin, X.; Wang, B. Effect of ball-milling and graphene contents on the mechanical properties and fracture mechanisms of graphene nanosheets reinforced copper matrix composites. J. Alloys Compd. 2017, 691, 755–762. [Google Scholar] [CrossRef]

- Jingwei, L.I.; Ming, W.E.; Zengwu, Z.H. Effect of NbC particles on the properties of copper matrix composites. Nonferrous Met. Eng. 2023, 13, 30–36. [Google Scholar]

- Wang, H.S.; Chen, H.G.; Gu, J.W.; Hsu, C.E.; Wu, C.Y. Effects of heat treatment processes on the microstructures and properties of powder metallurgy produced Cu–Ni–Si–Cr alloy. Mater. Sci. Eng. A 2014, 619, 221–227. [Google Scholar] [CrossRef]

- Zhang, P.; Guo, B.; Zhou, S.; Zhang, Z.; Li, W. Study on Sliding Wear Characteristics of Tungsten Carbide Particle Reinforced Copper Matrix Composites Under Electrical Contact. Tribol. Trans. 2023, 66, 292–301. [Google Scholar] [CrossRef]

- Xiao, P.; Derby, B. Wetting of titanium nitride and titanium carbide by liquid metals. Acta Mater. 1996, 44, 307–314. [Google Scholar] [CrossRef]

- Froumin, N.; Frage, N.; Polak, M.; Dariel, M.P. Wetting phenomena in the TiC/(Cu–Al) system. Acta Mater. 2000, 48, 1435–1441. [Google Scholar] [CrossRef]

| Composite Material | Theoretical Density (g·cm−3) | Actual Density (g·cm–3) | Porosity (%) |

|---|---|---|---|

| T850TiC/Cu | 8.57 | 8.17 | 4.67 ± 0.12 |

| T900TiC/Cu | 8.57 | 8.33 | 2.81 ± 0.22 |

| T950TiC/Cu | 8.57 | 8.23 | 3.97 ± 0.12 |

| T1000TiC/Cu | 8.57 | 8.20 | 4.40 ± 0.14 |

| Composite Material | Theoretical Density (g·cm−3) | Actual Density (g·cm–3) | Porosity (%) |

|---|---|---|---|

| 5 wt.% TiC/Cu | 8.57 | 8.33 | 2.81 ± 0.22 |

| 10 wt.% TiC/Cu | 8.25 | 7.49 | 9.30 ± 0.13 |

| 15 wt.% TiC/Cu | 7.95 | 6.99 | 12.00 ± 0.22 |

| 20 wt.% TiC/Cu | 7.67 | 6.65 | 13.30 ± 0.13 |

| 25 wt.% TiC/Cu | 7.41 | 5.98 | 19.30 ± 0.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, Z.; Dong, H.; Li, D.; Wang, Z.; Sun, C.; Chen, C. Effect of TiC Particles on the Properties of Copper Matrix Composites. Inorganics 2024, 12, 120. https://doi.org/10.3390/inorganics12040120

Zhai Z, Dong H, Li D, Wang Z, Sun C, Chen C. Effect of TiC Particles on the Properties of Copper Matrix Composites. Inorganics. 2024; 12(4):120. https://doi.org/10.3390/inorganics12040120

Chicago/Turabian StyleZhai, Zhenjie, Haitao Dong, Denghui Li, Zhe Wang, Changfei Sun, and Cong Chen. 2024. "Effect of TiC Particles on the Properties of Copper Matrix Composites" Inorganics 12, no. 4: 120. https://doi.org/10.3390/inorganics12040120

APA StyleZhai, Z., Dong, H., Li, D., Wang, Z., Sun, C., & Chen, C. (2024). Effect of TiC Particles on the Properties of Copper Matrix Composites. Inorganics, 12(4), 120. https://doi.org/10.3390/inorganics12040120