Integrated Bragg Grating Spectra

Abstract

1. Introduction

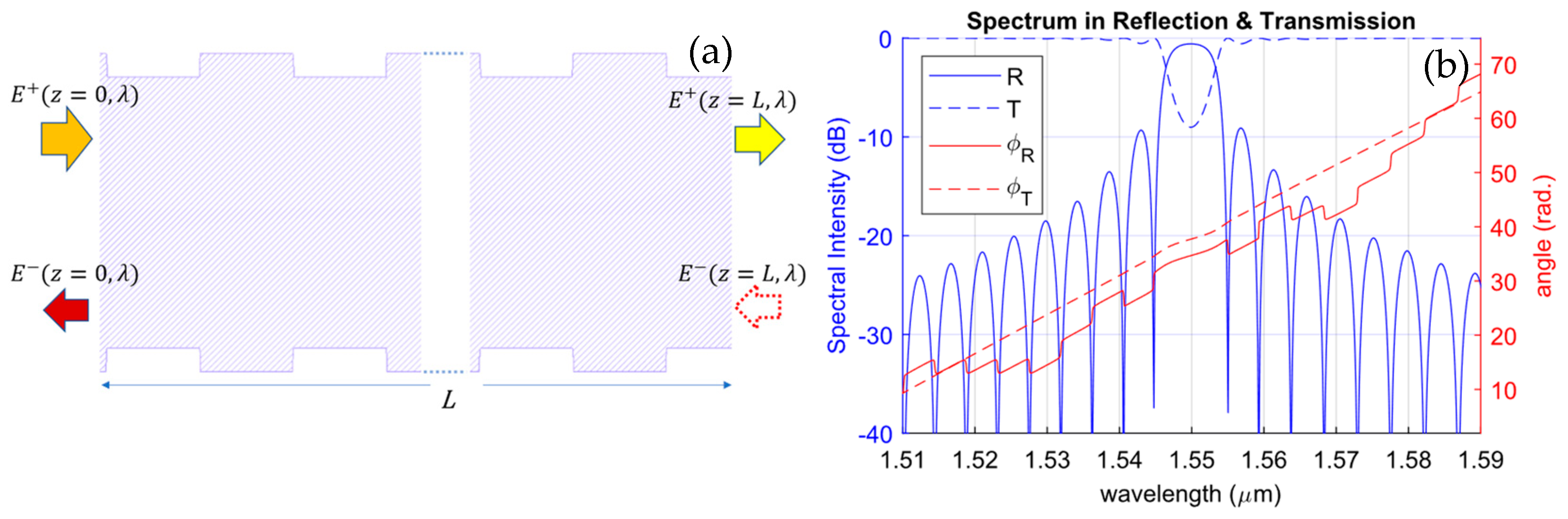

2. Design of Integrated Bragg Grating

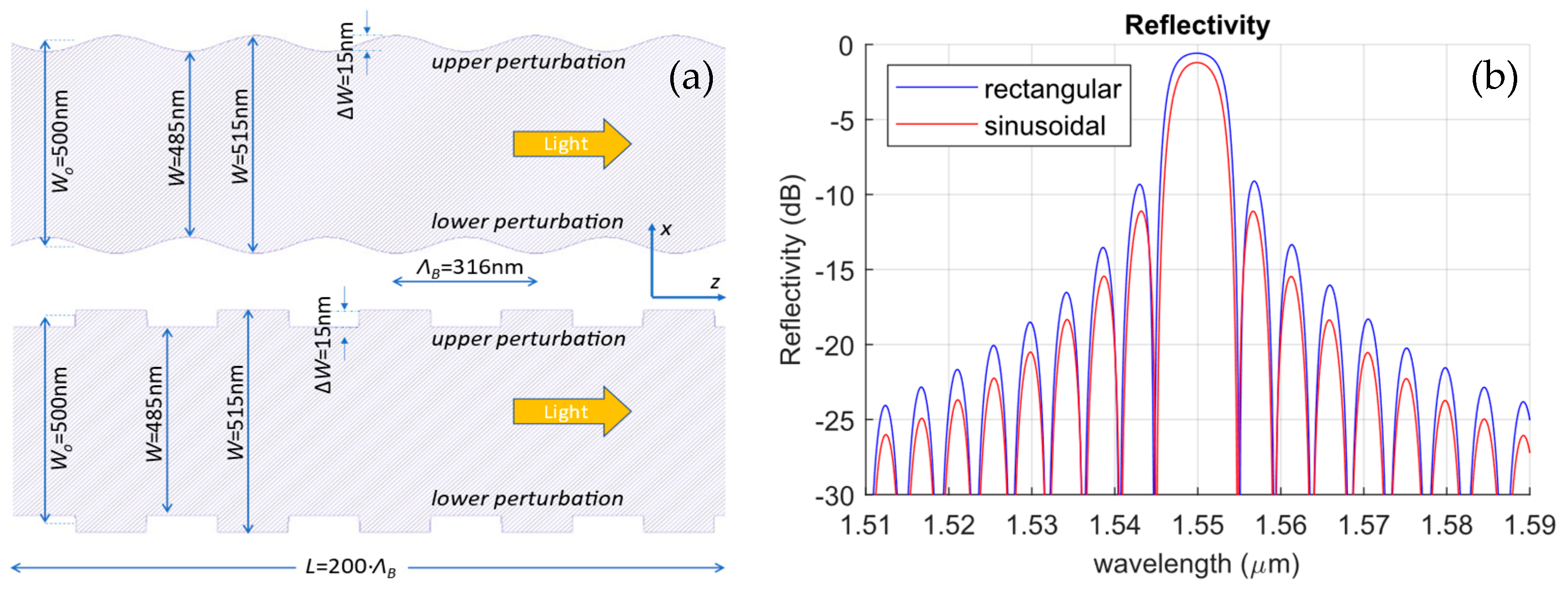

2.1. Corrugation Shape

2.2. Waveguide Width, W0(z)

2.3. IBG Corrugation Width, ΔW(z)

2.4. Bragg Period, ΛB(z)

2.5. Apodization Function, A(z)

2.6. Grating Phase, φ(z)

2.7. Grating Length, L

3. Methodology: Modeling and Simulation

3.1. Characterization of the Effective Refractive Index of an Optical Waveguide

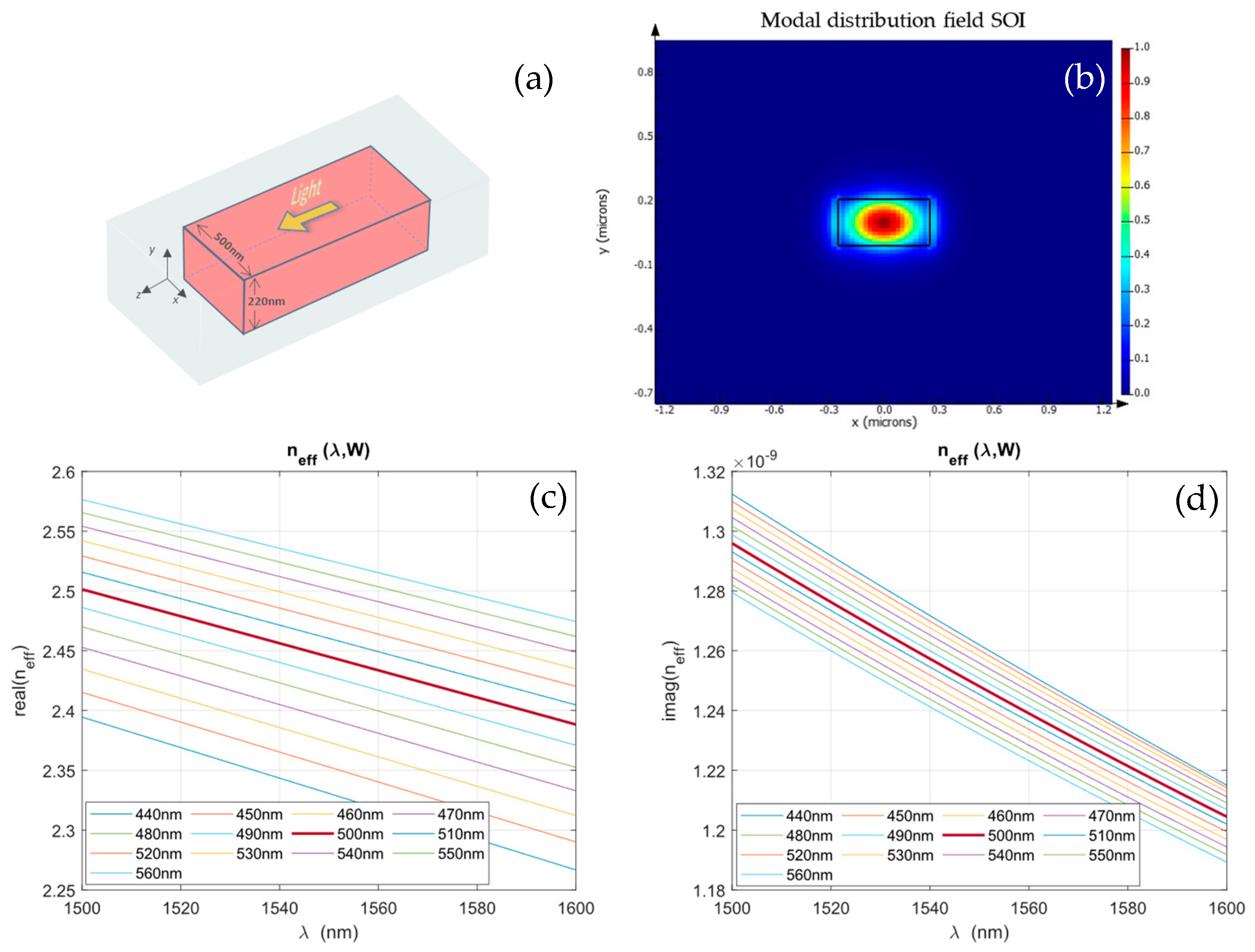

3.1.1. The SOI Optical Waveguide

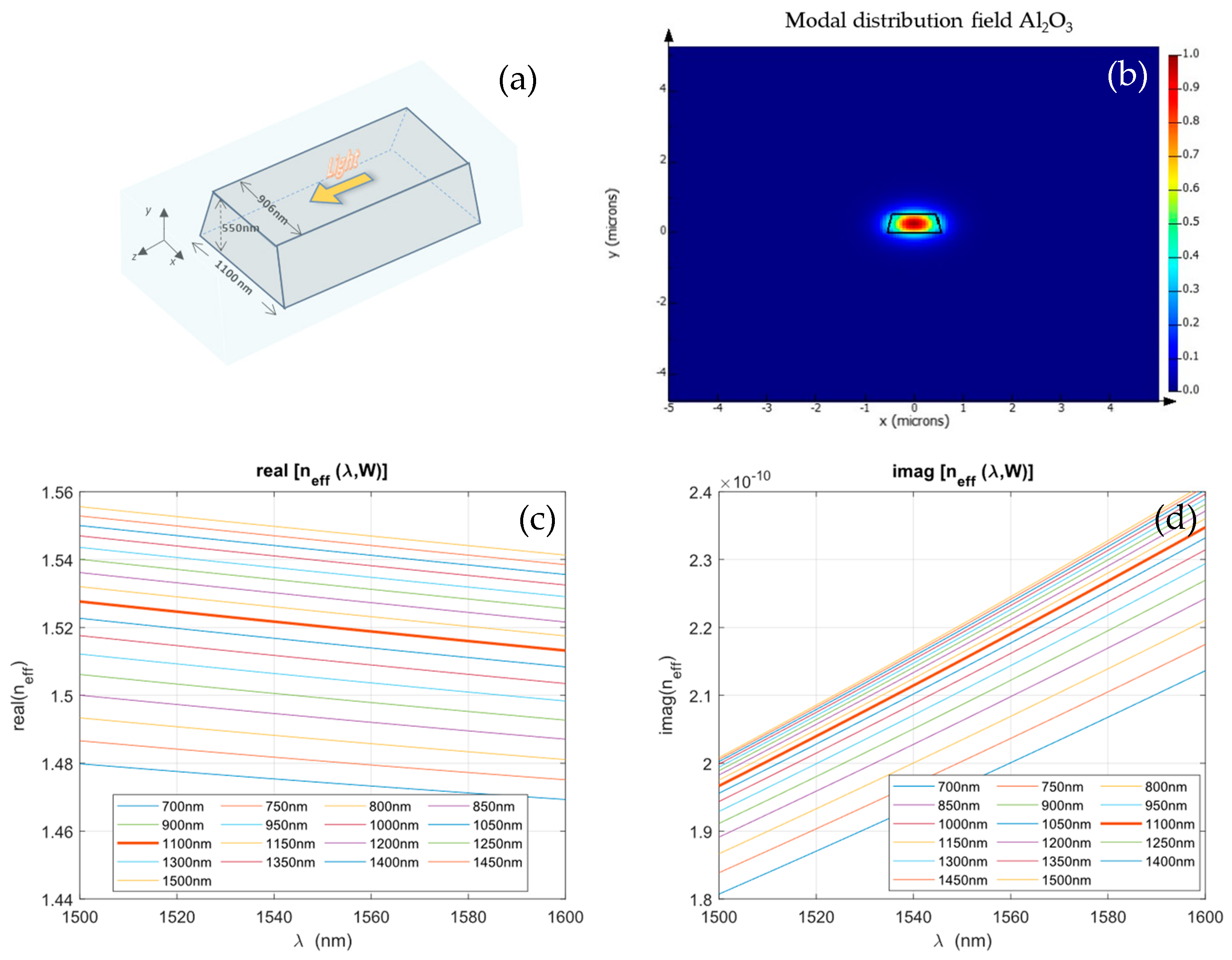

3.1.2. The Al2O3 Optical Waveguide

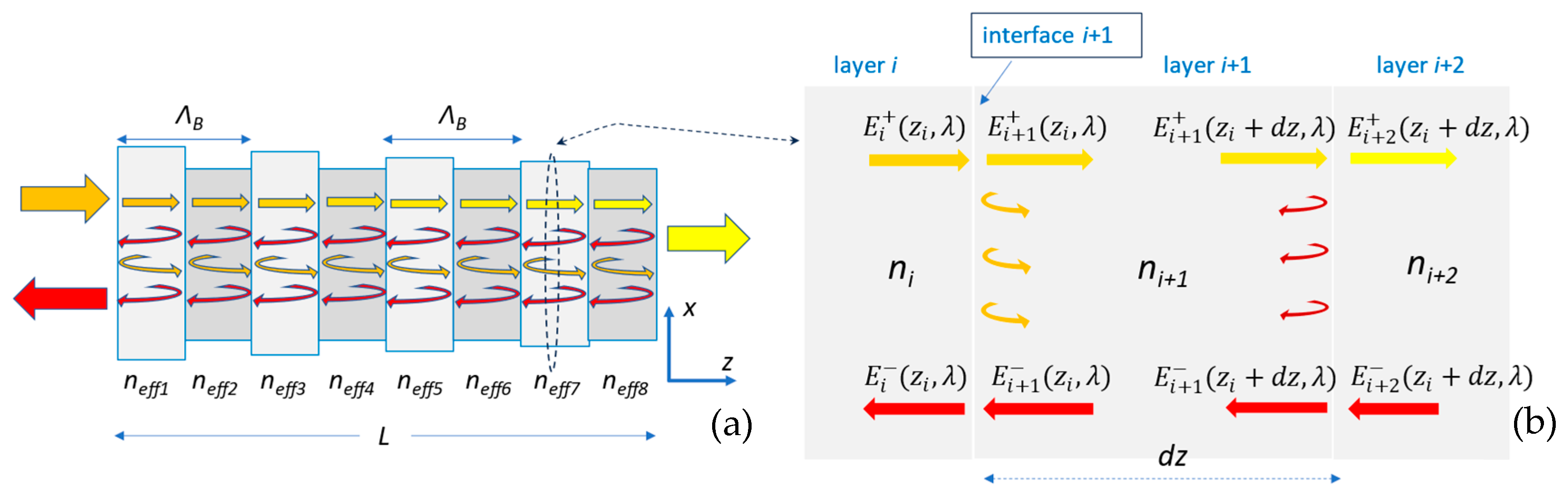

3.2. Sampling and Modeling of the IBG

3.3. Calculating the Transfer Matrix of the IBG, MT

3.4. Obtaining the Transfer Functions of the IBG

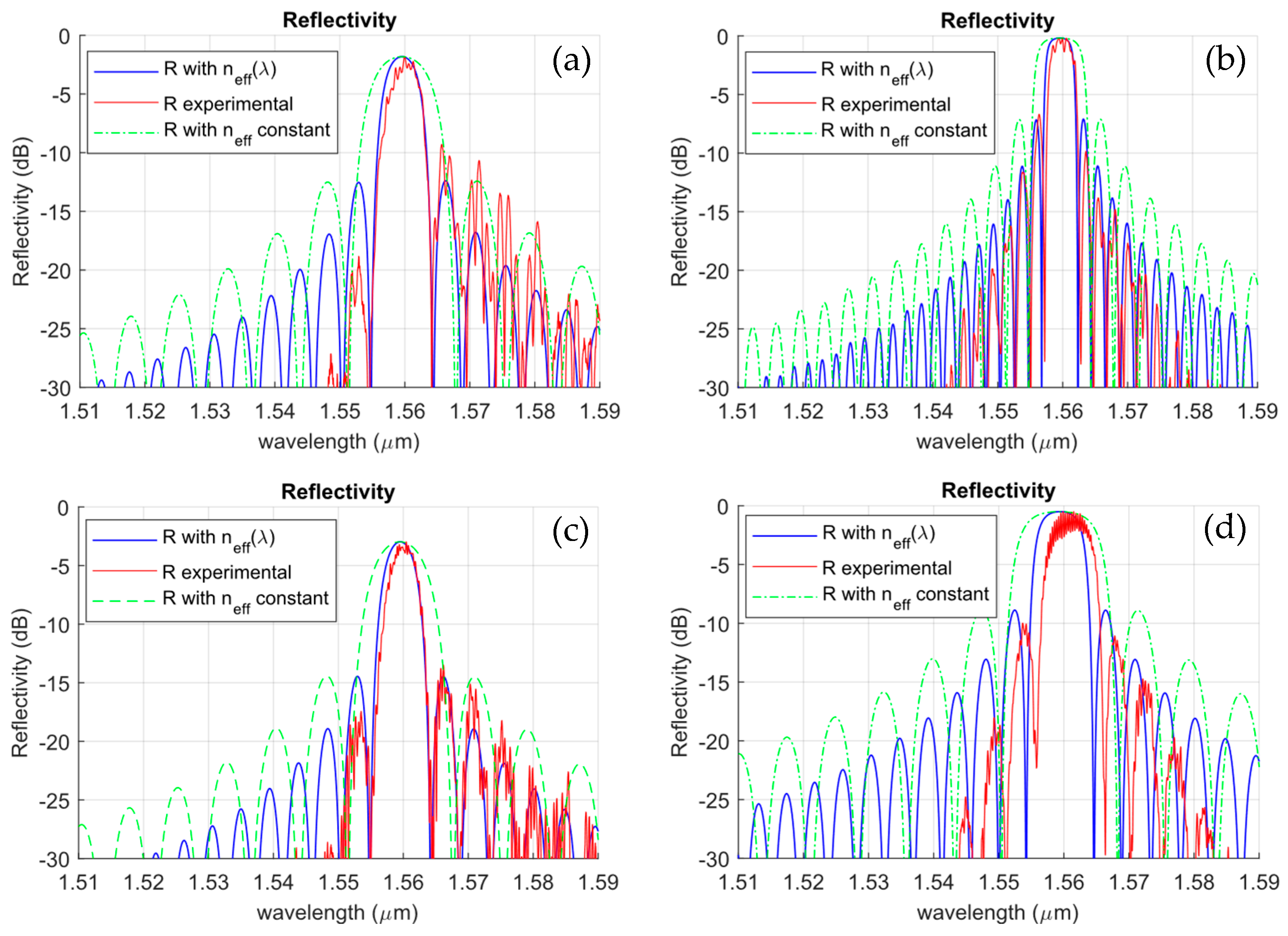

4. Experimental Results: Uniform IBGs

5. Advanced Simulation Results I: Apodization Techniques for an IBG

5.1. Apodization Through Corrugation Width Modulation

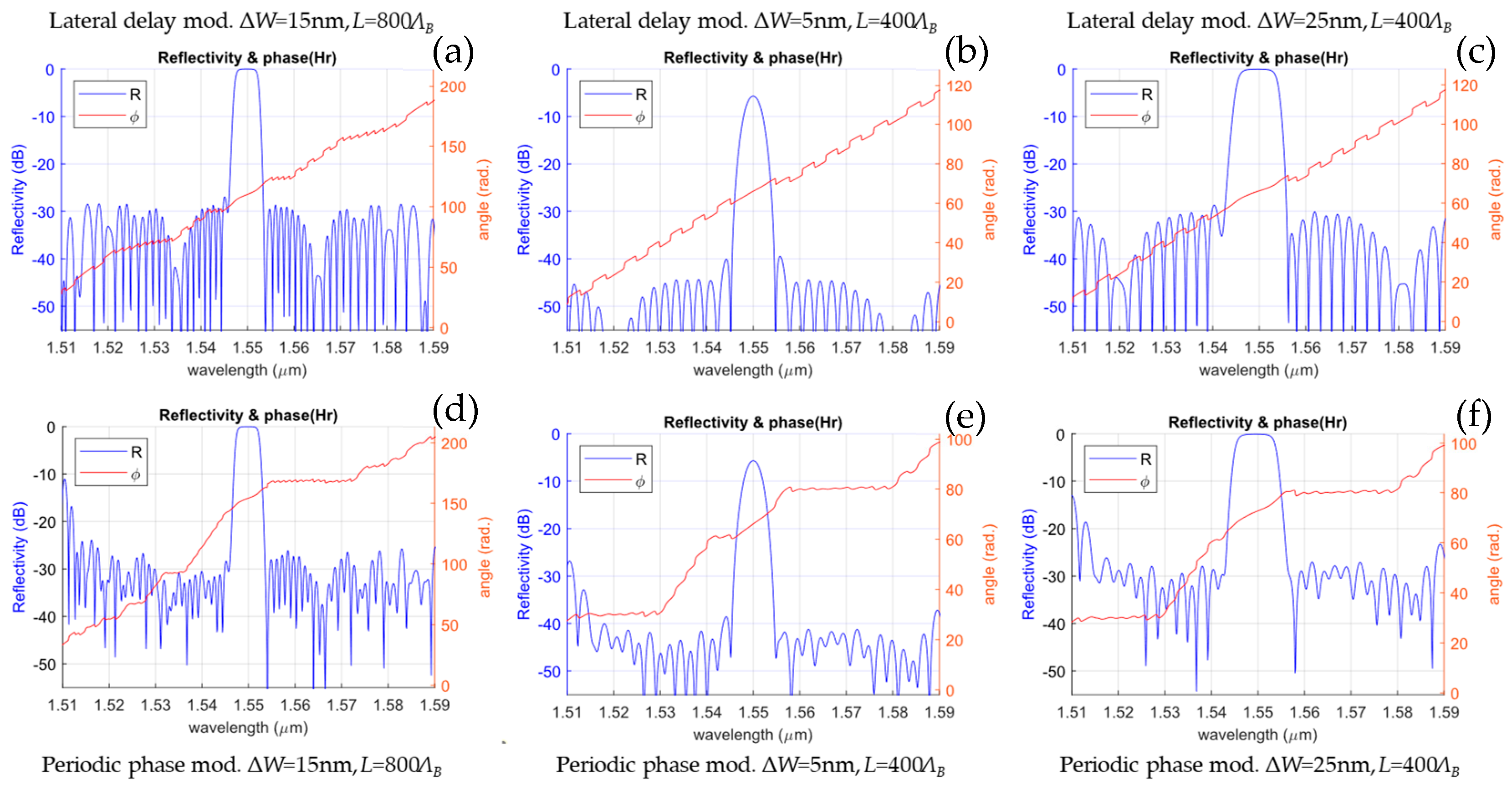

5.2. Apodization Through Lateral Delay Modulation

5.3. Apodization Through Duty Cycle Modulation

5.4. Apodization Through Periodic Phase Modulation

5.5. Comparison of Apodization Techniques Through ERI-TMM

- Reflectivity increases as predicted by theory for both longer lengths and greater corrugation widths [40].

- The designed Bragg wavelength is maintained at 1550 nm, except for the duty-cycle technique due to the alterations introduced in the ΛB by this method [49].

- The length of the IBG does not affect λB.

- The bandwidth increases as the corrugation width increases and decreases as the IBG length increases [27].

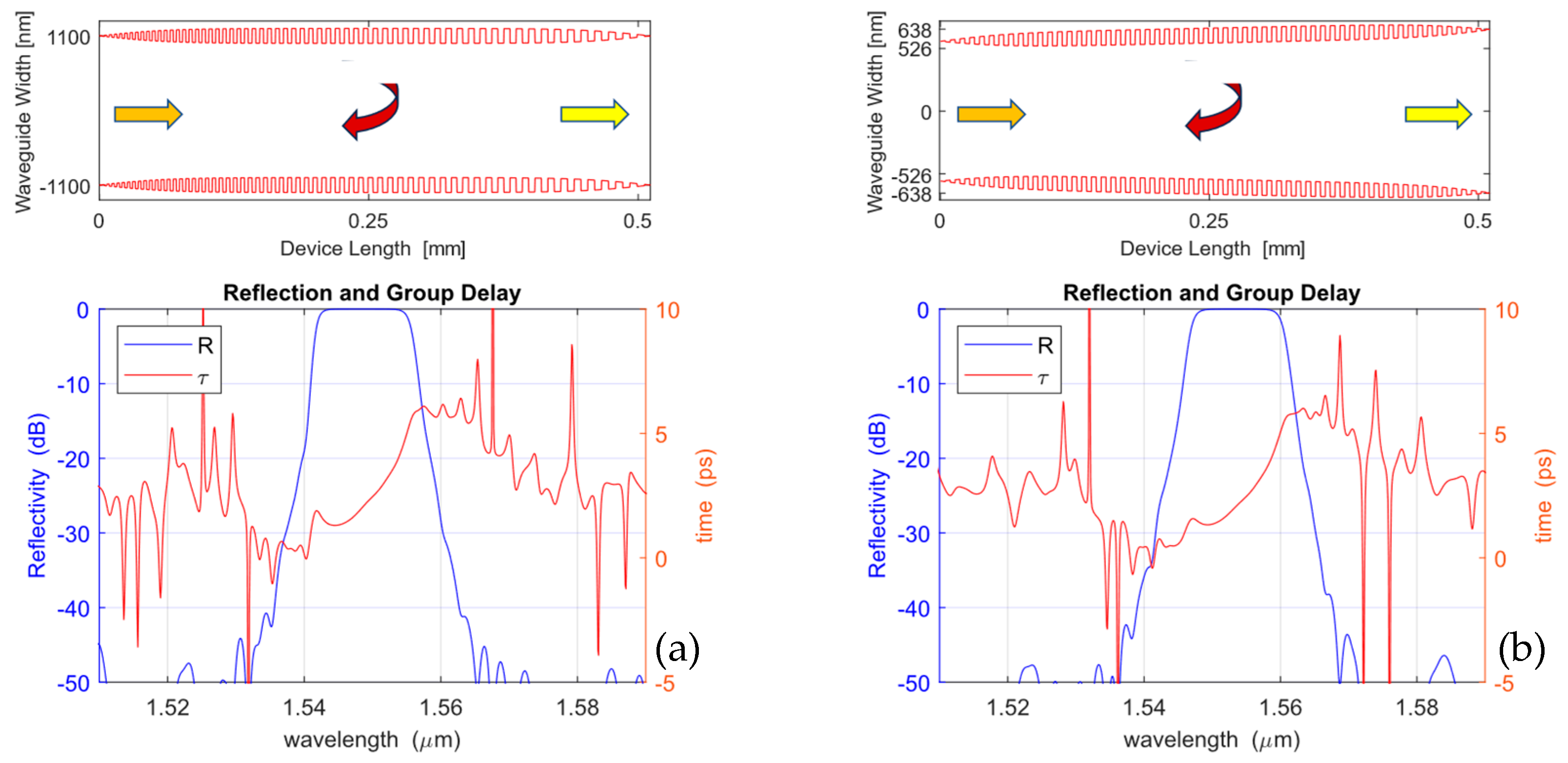

6. Advanced Simulation Results II: Chirp Techniques for an IBG

- Chirp via Bragg period variation. This method involves linearly changing the Bragg grating period along its length, causing a variation in λB and hence the bandwidth, which can be deduced from expression (3). The method keeps the waveguide width constant at W0. This variation can be mathematically expressed as follows:

- Chirp via IBG waveguide width variation. In this case, the method consists of linearly varying (increasing or decreasing) the average IBG width, W0(z), along the grating, to modify the neff, based on (7), and hence the λB. According to expression (3), this modification can be expressed as follows:

- Calculating the Bragg grating period for the wavelengths of the spectral interval for the desired bandwidth using expression (3);

- Using graphical representations or polynomial fits to determine the necessary waveguide width for a proposed effective refractive index at the wavelengths of interest;

- Estimating the length of the IBG by evaluating the time it takes for the pulse to be reflected by the grating using the group index concept;

- Applying the ERI-TMM method to obtain simulation results for reflectivity and group delay;

- Fine-tuning the initial parameters to achieve a better transfer function if necessary, based on the obtained results.

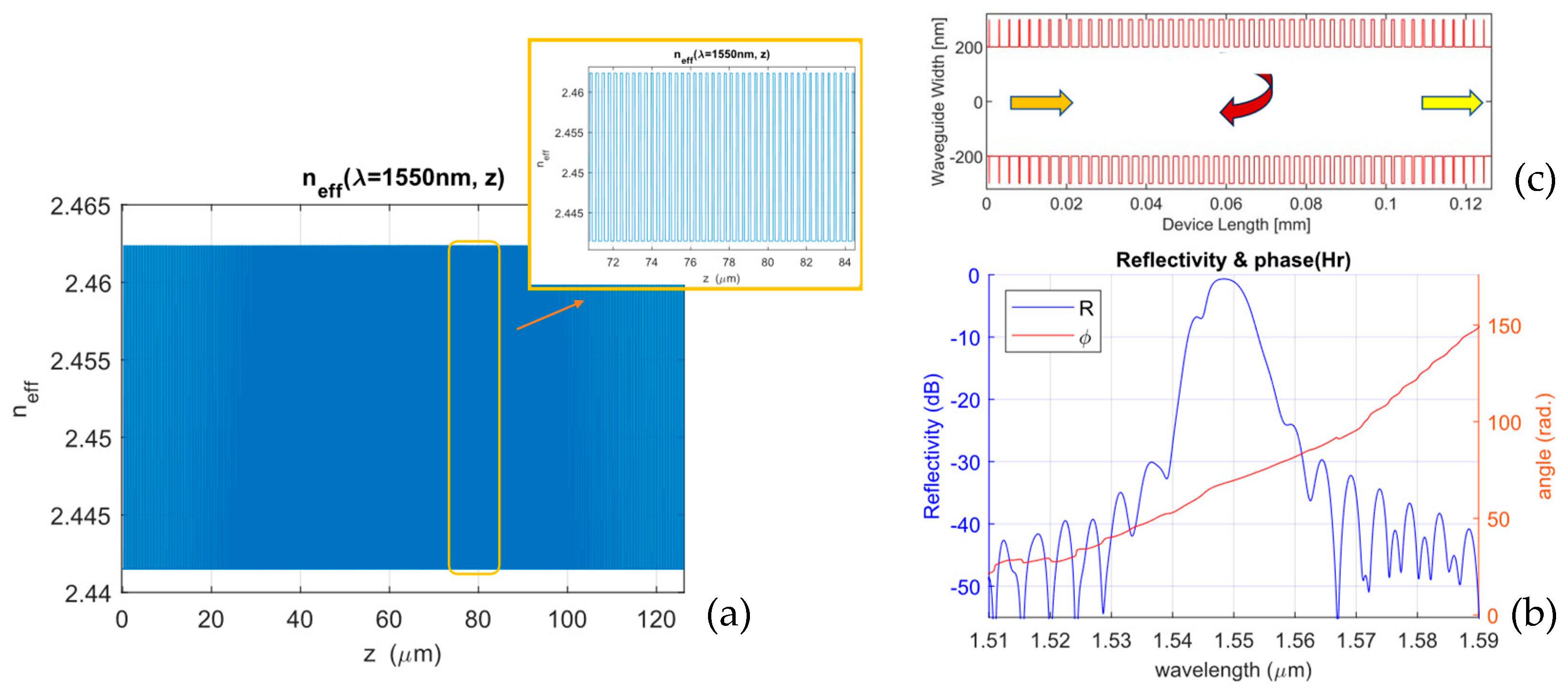

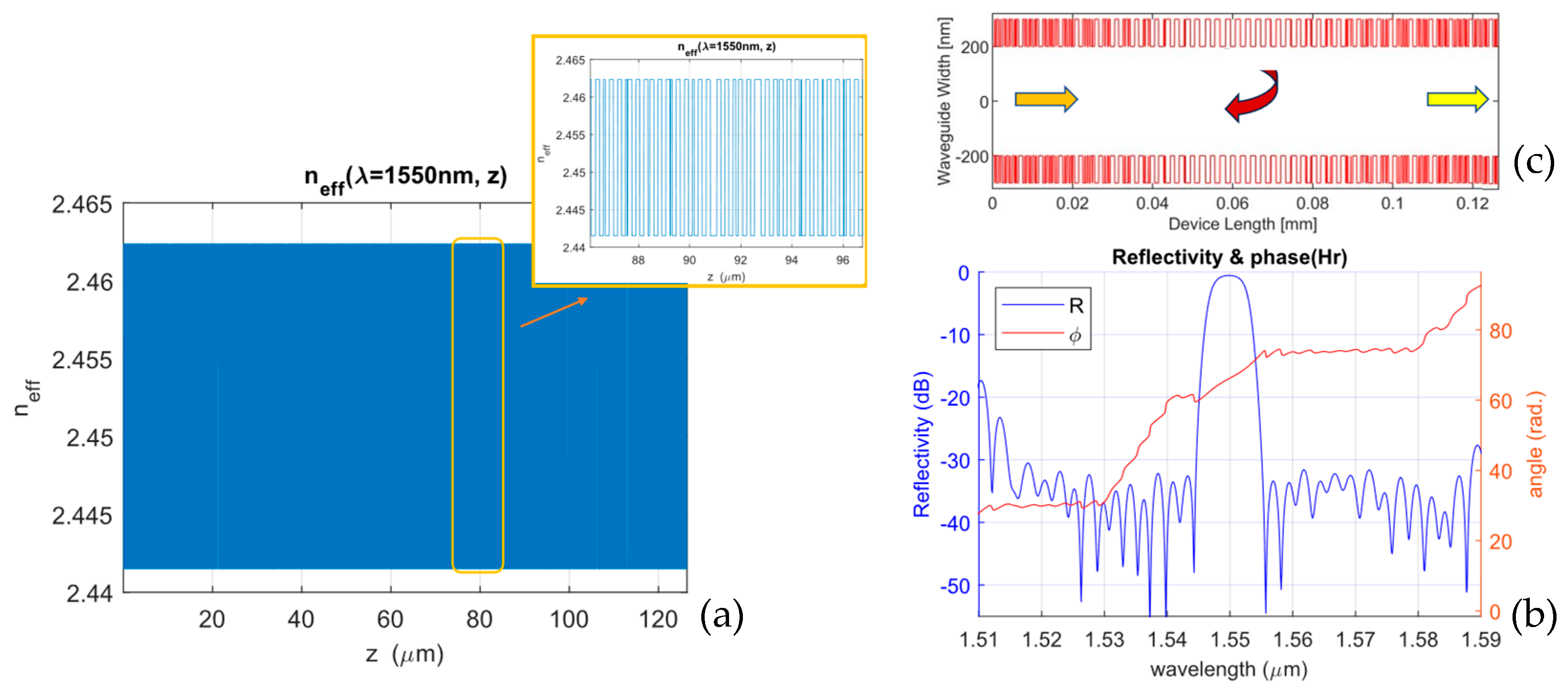

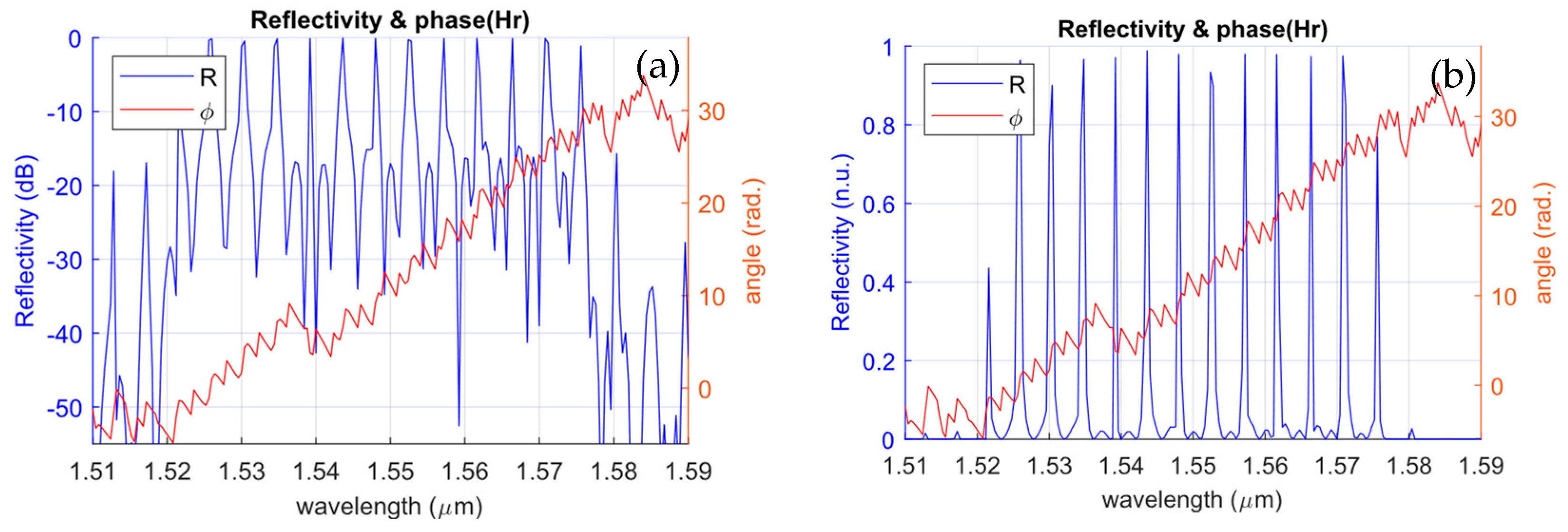

7. Advanced Simulation Results III: Complex IBG Profiles

7.1. Phase Shifted IBG

7.2. Sampled Diffraction Networks

7.3. Hilbert Transformer

8. Conclusions

- The validity of the method has been tested with experimental data for uniform IBG.

- The bandwidth and intensity of the reflectivity respond to theoretical prediction and to experimental results.

- Minimal differences in apodization can generate modifications in the spectral response, such as a single π-phase shift or several of them (Figure 15).

- Increases in IBG length lead to a reduction in reflectivity bandwidth.

- ERI-TMM can account for any physical variation in the geometry of the IBG and can translate it to the spectral response, to the order of 1 nm in the Bragg period. This can be verified by observing Figure 7, where the Bragg period is 317 nm to match the fabricated IBG. As can be seen, the Bragg wavelength of the simulated spectra is shifted to 1560 nm compared to the rest of the spectra in this paper, which are centered around 1550 nm due to a Bragg period of 316 nm, as stated by Equation (3).

- This fine resolution ensures accurate representation of the grating features, providing reliable simulation results. The methodology has been demonstrated to be robust and versatile, making it suitable for a wide range of photonic applications.

- Finally, the method also has proved to be capable of modeling both SOI and Al2O3 technologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chrostowski, L.; Hochberg, M.E. Silicon Photonics Design; Cambridge University Press: Cambridge, UK, 2015; ISBN 978-1-107-08545-9. [Google Scholar]

- Reed, G.T.; Knights, A.P. Silicon Photonics: An Introduction; Wiley: Chichester, UK, 2005; ISBN 978-0-470-87034-1. [Google Scholar]

- Zhang, W.; Yang, S.; Zheng, S.; Wang, B. Low-Loss Ultra-Compact Silicon Photonic Integrated Micro-Disk Modulator for Large-Scale WDM Optical Interconnection. J. Light. Technol. 2024, 42, 3306–3313. [Google Scholar] [CrossRef]

- Sajan, S.C.; Singh, A.; Sharma, P.K.; Kumar, S. Silicon Photonics Biosensors for Cancer Cells Detection—A Review. IEEE Sens. J. 2023, 23, 3366–3377. [Google Scholar] [CrossRef]

- Dhote, C.; Singh, A.; Kumar, S. Silicon Photonics Sensors for Biophotonic Applications—A Review. IEEE Sens. J. 2022, 22, 18228–18239. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, H.; Hu, J.; Li, M. Heterogeneously Integrated Silicon Photonics for the Mid-Infrared and Spectroscopic Sensing. ACS Nano 2014, 8, 6955–6961. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Li, M.; Guzzon, R.S.; Norberg, E.J.; Parker, J.S.; Lu, M.; Coldren, L.A.; Yao, J. A Fully Reconfigurable Photonic Integrated Signal Processor. Nat. Photonics 2016, 10, 190–195. [Google Scholar] [CrossRef]

- Rivas, L.M.; Strain, M.J.; Duchesne, D.; Carballar, A.; Sorel, M.; Morandotti, R.; Azaña, J. Picosecond Linear Optical Pulse Shapers Based on Integrated Waveguide Bragg Gratings. Opt. Lett. 2008, 33, 2425. [Google Scholar] [CrossRef] [PubMed]

- Marpaung, D.; Yao, J.; Capmany, J. Integrated Microwave Photonics. Nat. Photonics 2019, 13, 80–90. [Google Scholar] [CrossRef]

- Iezekiel, S.; Burla, M.; Klamkin, J.; Marpaung, D.; Capmany, J. RF Engineering Meets Optoelectronics: Progress in Integrated Microwave Photonics. IEEE Microw. 2015, 16, 28–45. [Google Scholar] [CrossRef]

- Cheng, R. Spectral Tailoring of Silicon Integrated Bragg Gratings. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2020. [Google Scholar] [CrossRef]

- Wang, X. Silicon Photonic Waveguide Bragg Gratings. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2014. [Google Scholar] [CrossRef]

- Bazargani, H.P.; Burla, M.; Chrostowski, L.; Azaña, J. Photonic Hilbert Transformers Based on Laterally Apodized Integrated Waveguide Bragg Gratings on a SOI Wafer. Opt. Lett. 2016, 41, 5039. [Google Scholar] [CrossRef]

- Kulishov, M.; Azaña, J. Design of High-Order All-Optical Temporal Differentiators Based on Multiple-Phase-Shifted Fiber Bragg Gratings. Opt. Express 2007, 15, 6152. [Google Scholar] [CrossRef]

- Golovastikov, N.V.; Bykov, D.A.; Doskolovich, L.L.; Bezus, E.A. Spatial Optical Integrator Based on Phase-Shifted Bragg Gratings. Opt. Commun. 2015, 338, 457–460. [Google Scholar] [CrossRef]

- Sinobad, M.; Lorenzen, J.; Wang, K.; Dijkstra, M.; Gaafar, M.A.; Herr, T.; Garcia-Blanco, S.M.; Singh, N.; Kärtner, F.X. C-Band Apodized Chirped Gratings in Aluminum Oxide Strip Waveguides. In Proceedings of the European Conference on Integrated Optics, Enschede, The Netherlands, 19–21 April 2023. [Google Scholar]

- Simard, A.D.; Strain, M.J.; Meriggi, L.; Sorel, M.; LaRochelle, S. Bandpass Integrated Bragg Gratings in Silicon-on-Insulator with Well-Controlled Amplitude and Phase Responses. Opt. Lett. 2015, 40, 736. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.; Wang, D.; Huang, Q.; Zhang, C.; Zhang, X. Large Group Delay and Low Loss Optical Delay Line Based on Chirped Waveguide Bragg Gratings. Opt. Express 2023, 31, 4630. [Google Scholar] [CrossRef]

- Du, Z.; Xiang, C.; Fu, T.; Chen, M.; Yang, S.; Bowers, J.E.; Chen, H. Silicon Nitride Chirped Spiral Bragg Grating with Large Group Delay. APL Photonics 2020, 5, 101302. [Google Scholar] [CrossRef]

- Cheng, R.; Chrostowski, L. Spectral Design of Silicon Integrated Bragg Gratings: A Tutorial. J. Light. Technol. 2021, 39, 712–729. [Google Scholar] [CrossRef]

- Huang, W.-P. Coupled-Mode Theory for Optical Waveguides: An Overview. J. Opt. Soc. Am. A 1994, 11, 963. [Google Scholar] [CrossRef]

- Yariv, A. Coupled-Mode Theory for Guided-Wave Optics. IEEE J. Quantum Electron. 1973, 9, 919–933. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings, 2nd ed.; Academic Press: Burlington, MA, USA, 2010; ISBN 978-0-12-372579-0. [Google Scholar]

- Othonos, A.; Kalli, K. Fiber Bragg Gratings: Fundamentals and Applications in Telecommunications and Sensing; Artech House optoelectronics library; Artech House: Boston, MA, USA, 1999; ISBN 978-0-89006-344-6. [Google Scholar]

- Skorobogatiy, M.; Johnson, S.G.; Jacobs, S.A.; Fink, Y. Dielectric Profile Variations in High-Index-Contrast Waveguides, Coupled Mode Theory, and Perturbation Expansions. Phys. Rev. E 2003, 67, 046613. [Google Scholar] [CrossRef]

- Sipe, J.E.; Poladian, L.; De Sterke, C.M. Propagation through Nonuniform Grating Structures. J. Opt. Soc. Am. A 1994, 11, 1307. [Google Scholar] [CrossRef]

- Carballar Rincón, A. Estudio de Redes de Difracción en Fibra Para su Aplicación en Comunicaciones Ópticas. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 1999. [Google Scholar]

- Fernández-Ruiz, M.R.; Carballar, A. Fiber Bragg Grating-Based Optical Signal Processing: Review and Survey. Appl. Sci. 2021, 11, 8189. [Google Scholar] [CrossRef]

- Macleod, H.A. Thin-Film Optical Filters, 5th ed.; Series in Optics and Optoelectronics; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2018; ISBN 978-1-138-19824-1. [Google Scholar]

- Kaushal, S.; Cheng, R.; Ma, M.; Mistry, A.; Burla, M.; Chrostowski, L.; Azaña, J. Optical Signal Processing Based on Silicon Photonics Waveguide Bragg Gratings: Review. Front. Optoelectron. 2018, 11, 163–188. [Google Scholar] [CrossRef]

- Reed, G.T. Silicon Photonics: The State of the Art; Wiley: Chichester, UK, 2008; ISBN 978-0-470-02579-6. [Google Scholar]

- Wörhoff, K.; Bradley, J.D.B.; Ay, F.; Pollnau, M. Low-Loss Al2O3 Waveguides for Active Integrated Optics. In Proceedings of the Conference on Lasers and Electro-Optics/Quantum Electronics and Laser Science Conference and Photonic Applications Systems Technologies, Baltimore, MD, USA, 6–11 May 2007; Optica Publishing Group: Washington, DC, USA, 2007; p. CMW5. [Google Scholar]

- West, G.N.; Loh, W.; Kharas, D.; Sorace-Agaskar, C.; Mehta, K.K.; Sage, J.; Chiaverini, J.; Ram, R.J. Low-Loss Integrated Photonics for the Blue and Ultraviolet Regime. APL Photonics 2019, 4, 026101. [Google Scholar] [CrossRef]

- Hendriks, W.A.P.M.; Chang, L.; Van Emmerik, C.I.; Mu, J.; De Goede, M.; Dijkstra, M.; Garcia-Blanco, S.M. Rare-Earth Ion Doped Al2O3 for Active Integrated Photonics. Adv. Phys. X 2021, 6, 1833753. [Google Scholar] [CrossRef]

- Lu, Z.; Jhoja, J.; Klein, J.; Wang, X.; Liu, A.; Flueckiger, J.; Pond, J.; Chrostowski, L. Performance Prediction for Silicon Photonics Integrated Circuits with Layout-Dependent Correlated Manufacturing Variability. Opt. Express 2017, 25, 9712. [Google Scholar] [CrossRef] [PubMed]

- Saleh, B.E.A.; Teich, M.C. Fundamentals of Photonics, 3rd ed.; Wiley Series in Pure and Applied Optics; Wiley: Hoboken, NJ, USA, 2019; ISBN 978-1-119-50687-4. [Google Scholar]

- Carballar, A.; Muriel, M.A. Growth Modeling of Fiber Gratings: A Numerical Investigation. Fiber Integr. Opt. 2002, 21, 451–463. [Google Scholar] [CrossRef]

- Yeh, P. Optical Waves in Layered Media; Wiley Series in Pure and Applied Optics; Wiley-Interscience: Hoboken, NJ, USA, 2005; ISBN 978-0-471-73192-4. [Google Scholar]

- Wang, X.; Yin, C.; Cao, Z. Progress in Planar Optical Waveguides; Springer Tracts in Modern Physics; Springer: Berlin/Heidelberg, Germany, 2016; Volume 266, ISBN 978-3-662-48982-6. [Google Scholar]

- Strain, M.J.; Sorel, M. Design and Fabrication of Integrated Chirped Bragg Gratings for On-Chip Dispersion Control. IEEE J. Quantum Electron. 2010, 46, 774–782. [Google Scholar] [CrossRef]

- Skaar, J.; Wang, L.; Erdogan, T. On the Synthesis of Fiber Bragg Gratings by Layer Peeling. IEEE J. Quantum Electron. 2001, 37, 165–173. [Google Scholar] [CrossRef]

- Lumerical. Copyright 2024 Ansys Canada Ltd. Available online: https://www.lumerical.com/ (accessed on 22 January 2024).

- Bojko, R.J.; Li, J.; He, L.; Baehr-Jones, T.; Hochberg, M.; Aida, Y. Electron Beam Lithography Writing Strategies for Low Loss, High Confinement Silicon Optical Waveguides. J. Vac. Sci. Technol. B 2011, 29, 06F309. [Google Scholar] [CrossRef]

- Murphy, T.E. Design, Fabrication and Measurement of Integrated Bragg Grating Optical Filters. Ph.D. Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 2001. [Google Scholar]

- Cheng, R.; Yun, H.; Lin, S.; Han, Y.; Chrostowski, L. Apodization Profile Amplification of Silicon Integrated Bragg Gratings through Lateral Phase Delays. Opt. Lett. 2019, 44, 435. [Google Scholar] [CrossRef]

- Jiang, W.; Feng, J.; Yuan, S.; Liu, H.; Yu, Z.; Yang, C.; Ren, W.; Xia, X.; Wang, Z.; Huang, F. Sidewall Corrugation-Modulated Phase-Apodized Silicon Grating Filter. Micromachines 2024, 15, 666. [Google Scholar] [CrossRef]

- Lupu, A. Duty Cycle Variation Methods for Bragg Gratings: Comparative Study and Optimal Design. J. Opt. Soc. Am. B 2021, 38, C175. [Google Scholar] [CrossRef]

- Cheng, R.; Chrostowski, L. Apodization of Silicon Integrated Bragg Gratings Through Periodic Phase Modulation. IEEE J. Sel. Top. Quantum Electron. 2020, 26, 8300315. [Google Scholar] [CrossRef]

- Cheng, R.; Han, Y.; Chrostowski, L. Characterization and Compensation of Apodization Phase Noise in Silicon Integrated Bragg Gratings. Opt. Express 2019, 27, 9516. [Google Scholar] [CrossRef] [PubMed]

- Praena, J.Á.; Carballar, A. Chirped Integrated Bragg Grating Design. Photonics 2024, 11, 476. [Google Scholar] [CrossRef]

- Burla, M.; Li, M.; Cortés, L.R.; Wang, X.; Fernández-Ruiz, M.R.; Chrostowski, L.; Azaña, J. Terahertz-Bandwidth Photonic Fractional Hilbert Transformer Based on a Phase-Shifted Waveguide Bragg Grating on Silicon. Opt. Lett. 2014, 39, 6241. [Google Scholar] [CrossRef]

| Parameter | SOI | Al2O3 |

|---|---|---|

| W0 (x-dimension) | 500 nm | 1100 nm |

| H (y-dimension) | 220 nm | 400 nm |

| L (z-dimension) | By design | By design |

| ΔWmax | 5–25 nm | 100–200 nm |

| ΔWmin | ≈6 nm Lithography dependance | ≈75 nm Lithography dependance |

| ΛB | ~316 nm or ~317 nm | ~509 nm |

| λB | 1550 nm | 1550 nm |

| Type | Strip | Strip |

| Corrugation | Rectangular | Rectangular |

| Apodization Function | Math Expression |

|---|---|

| Square (rise) cosine | |

| Gaussian | |

| Sinc | |

| Hyperbolic tangent |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Praena, J.Á.; Carballar, A. Integrated Bragg Grating Spectra. Photonics 2025, 12, 351. https://doi.org/10.3390/photonics12040351

Praena JÁ, Carballar A. Integrated Bragg Grating Spectra. Photonics. 2025; 12(4):351. https://doi.org/10.3390/photonics12040351

Chicago/Turabian StylePraena, José Ángel, and Alejandro Carballar. 2025. "Integrated Bragg Grating Spectra" Photonics 12, no. 4: 351. https://doi.org/10.3390/photonics12040351

APA StylePraena, J. Á., & Carballar, A. (2025). Integrated Bragg Grating Spectra. Photonics, 12(4), 351. https://doi.org/10.3390/photonics12040351