Watt-Level Tunable Mid-Infrared Laser Emission at 2.8 μm Generated by Stimulated Raman Scattering of Methane Molecules in Hollow-Core Fibers

Abstract

1. Introduction

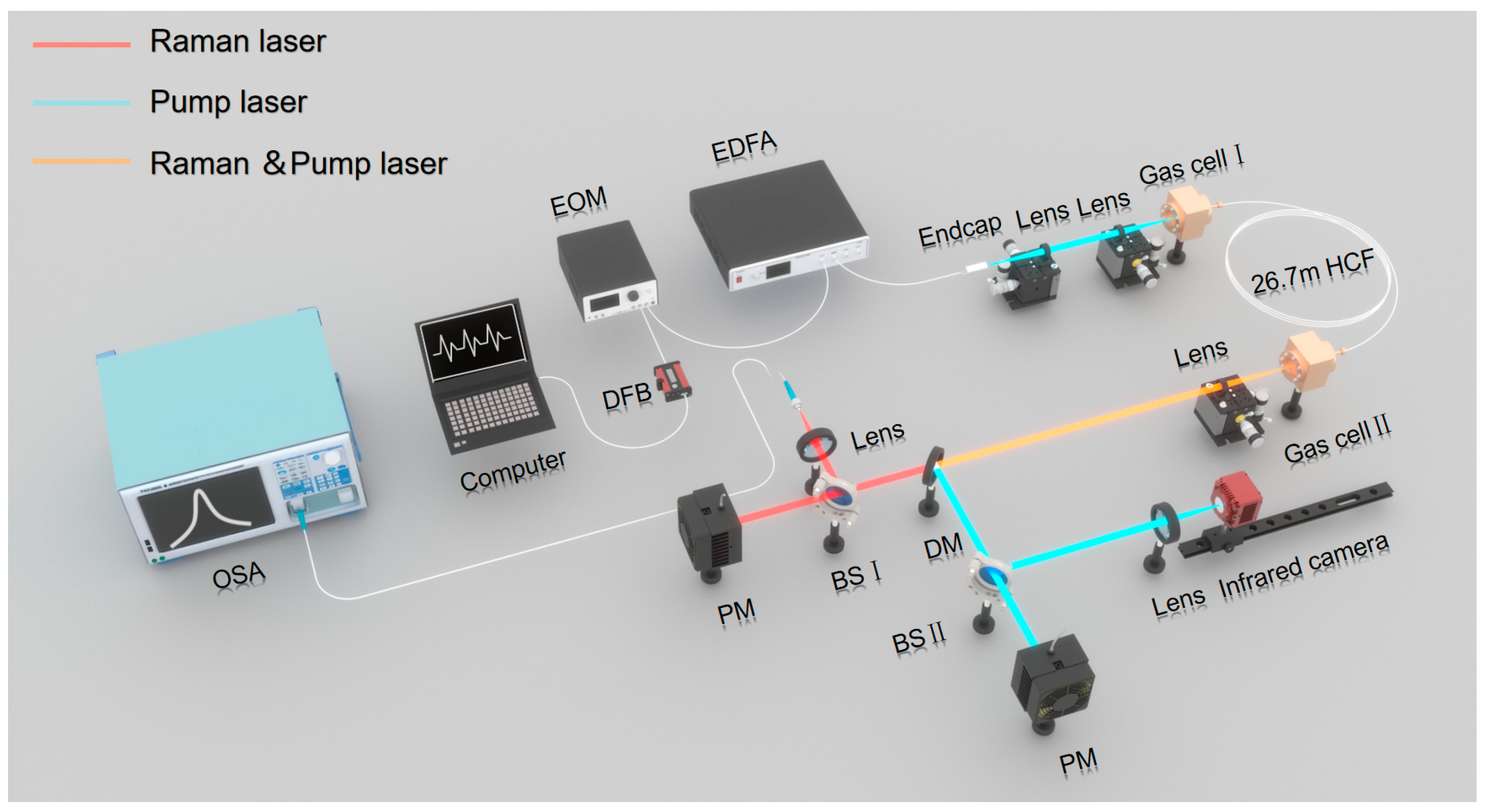

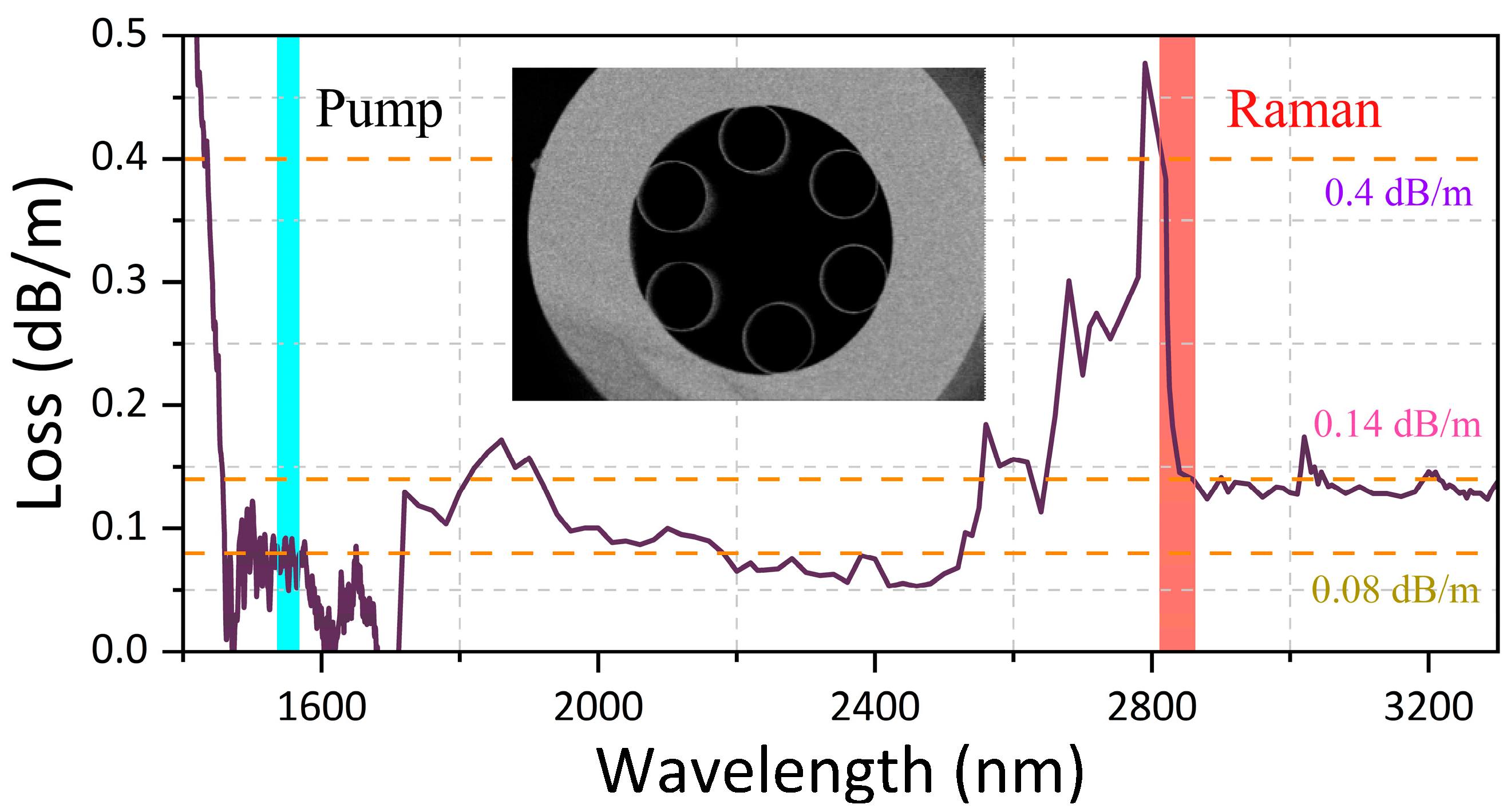

2. Experimental Setup

3. Results and Discussion

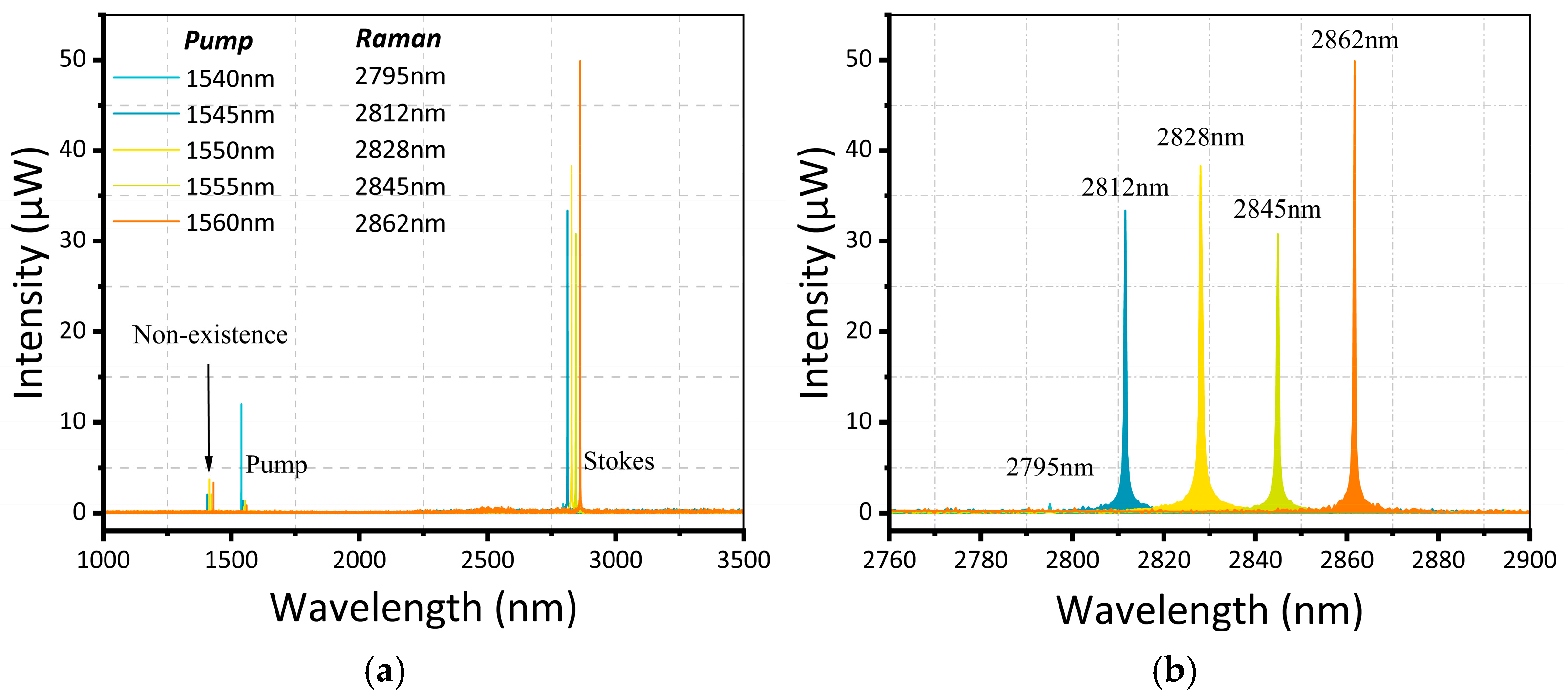

3.1. Spectral Characteristics

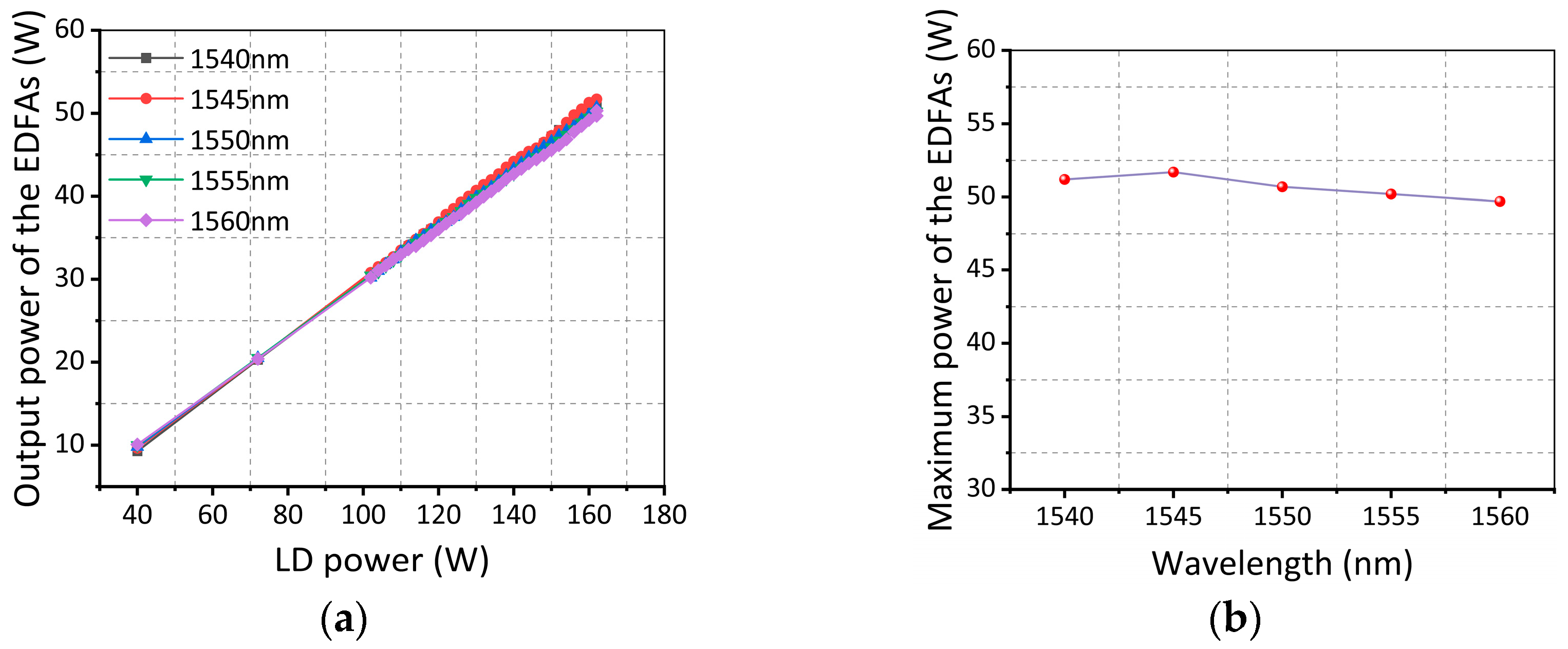

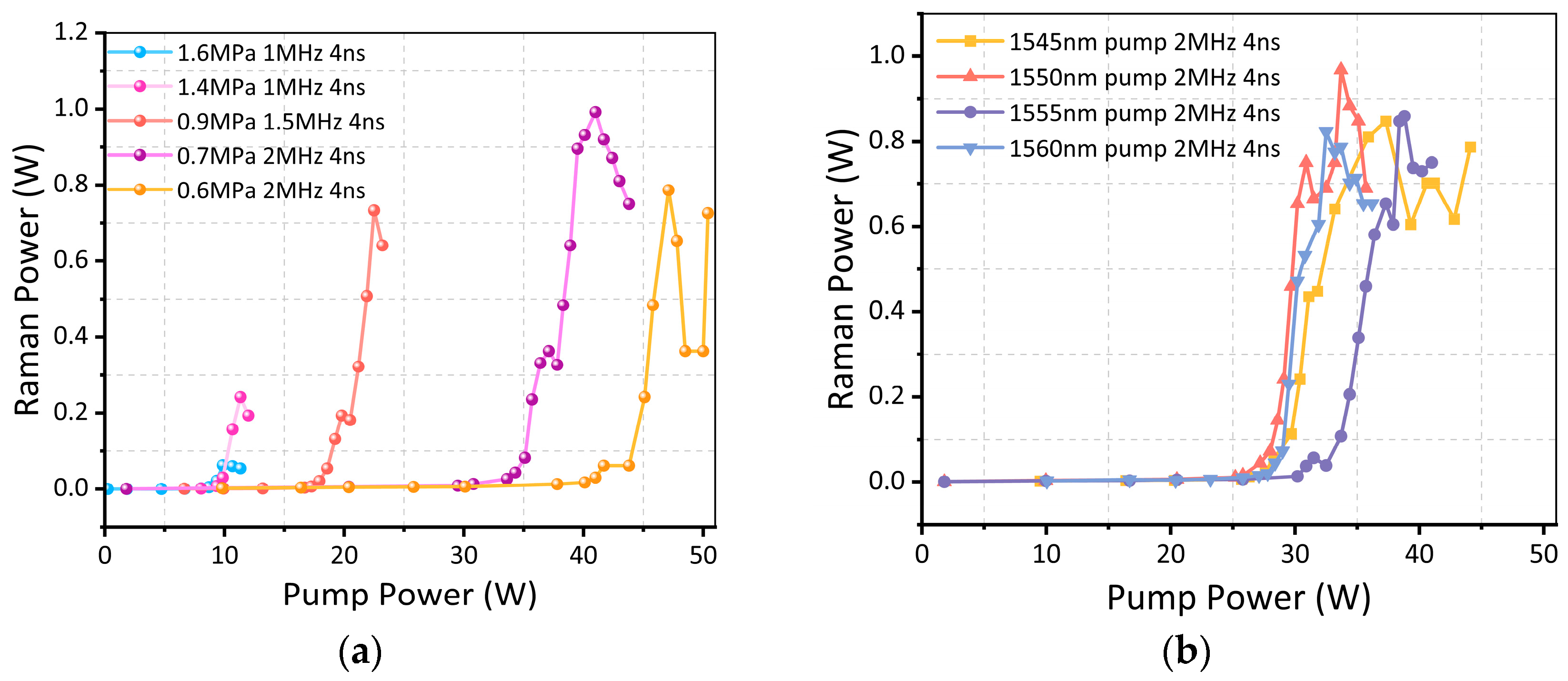

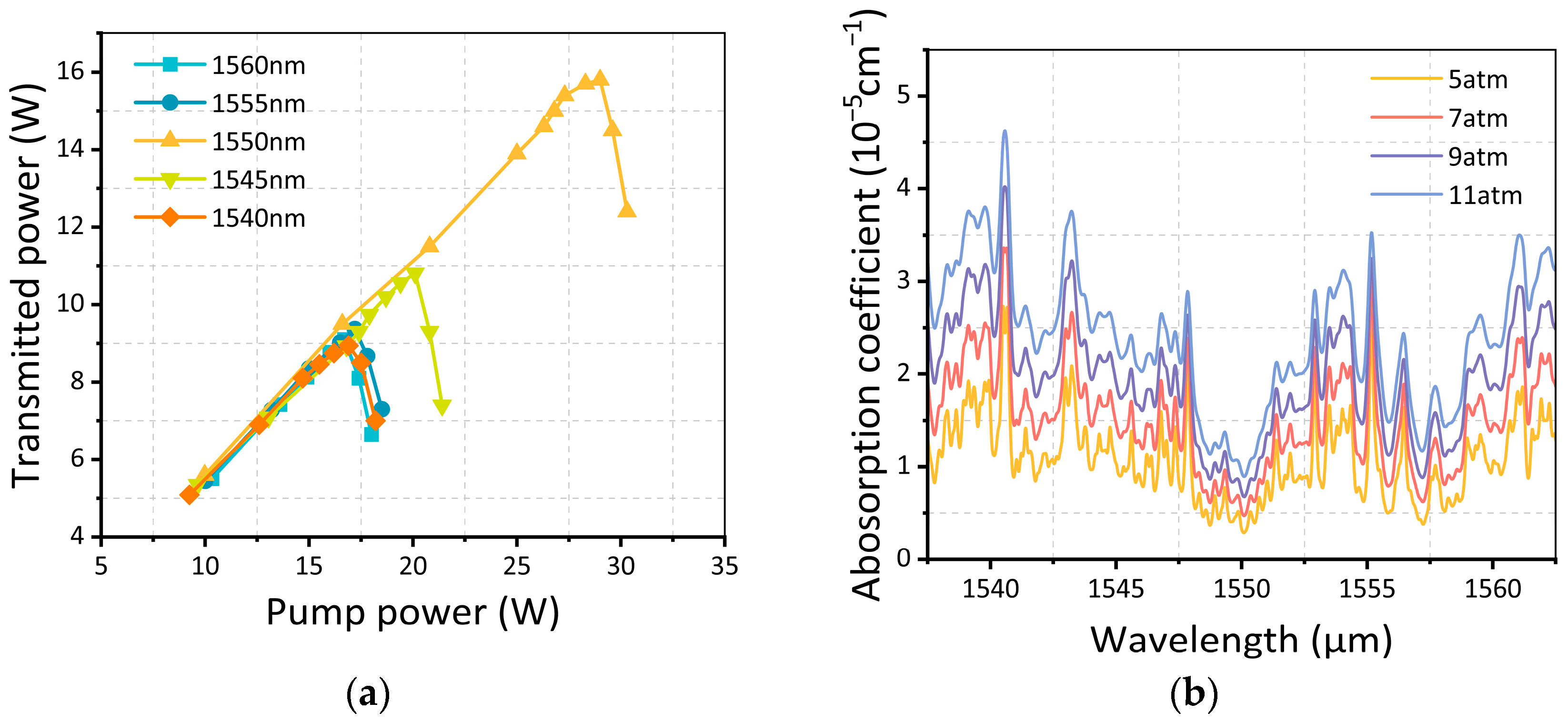

3.2. Power Characteristics

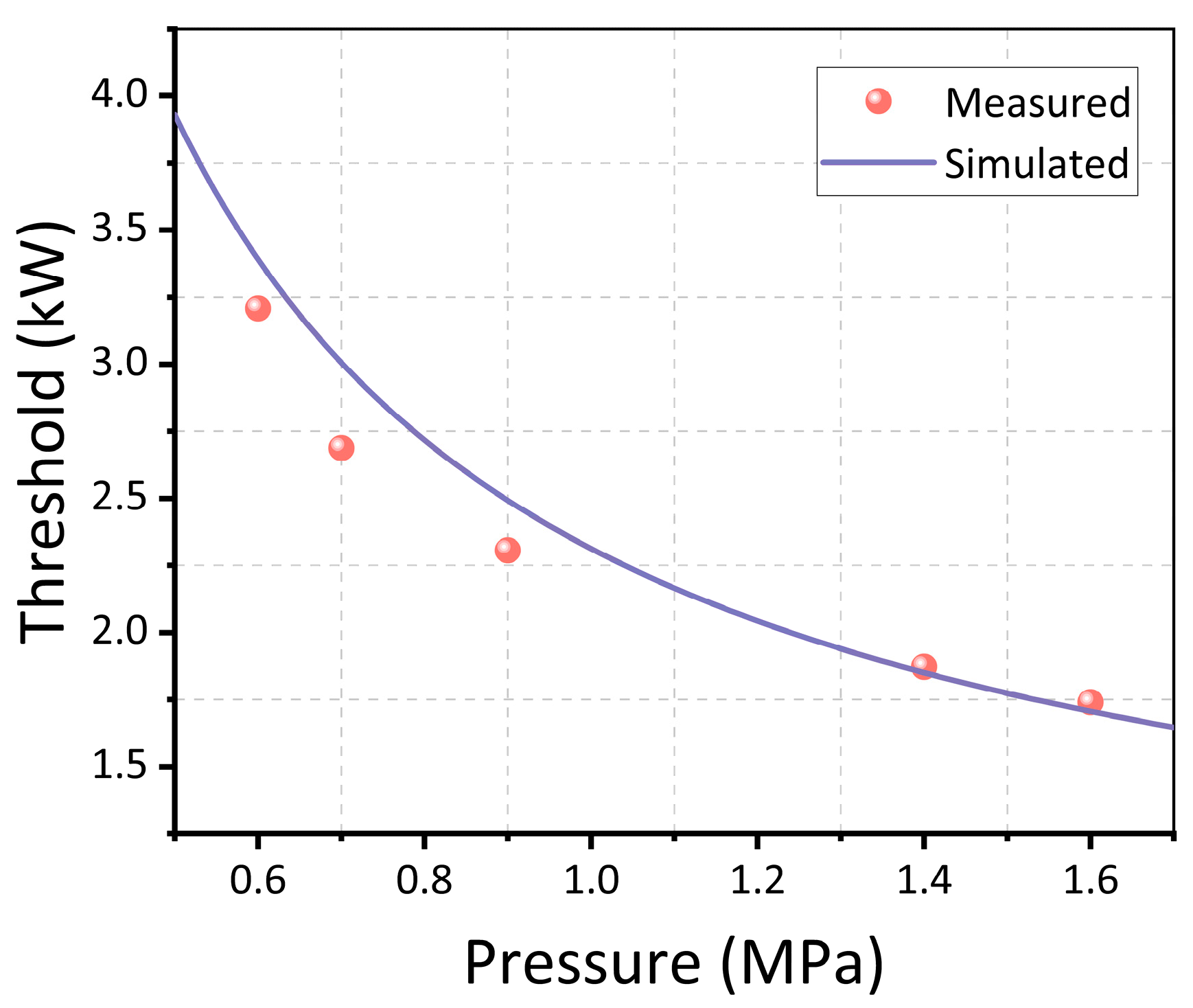

3.3. Threshold Characteristics

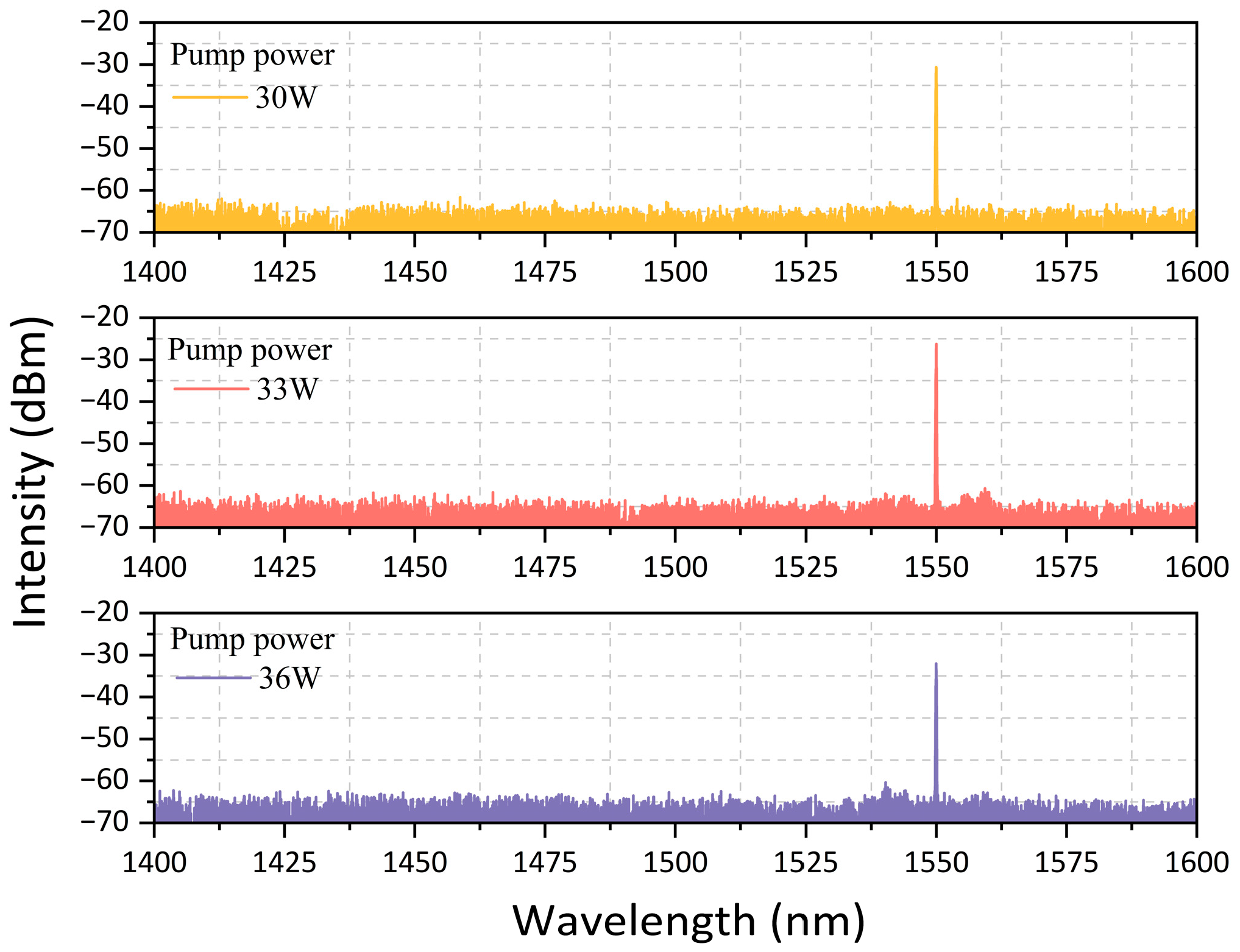

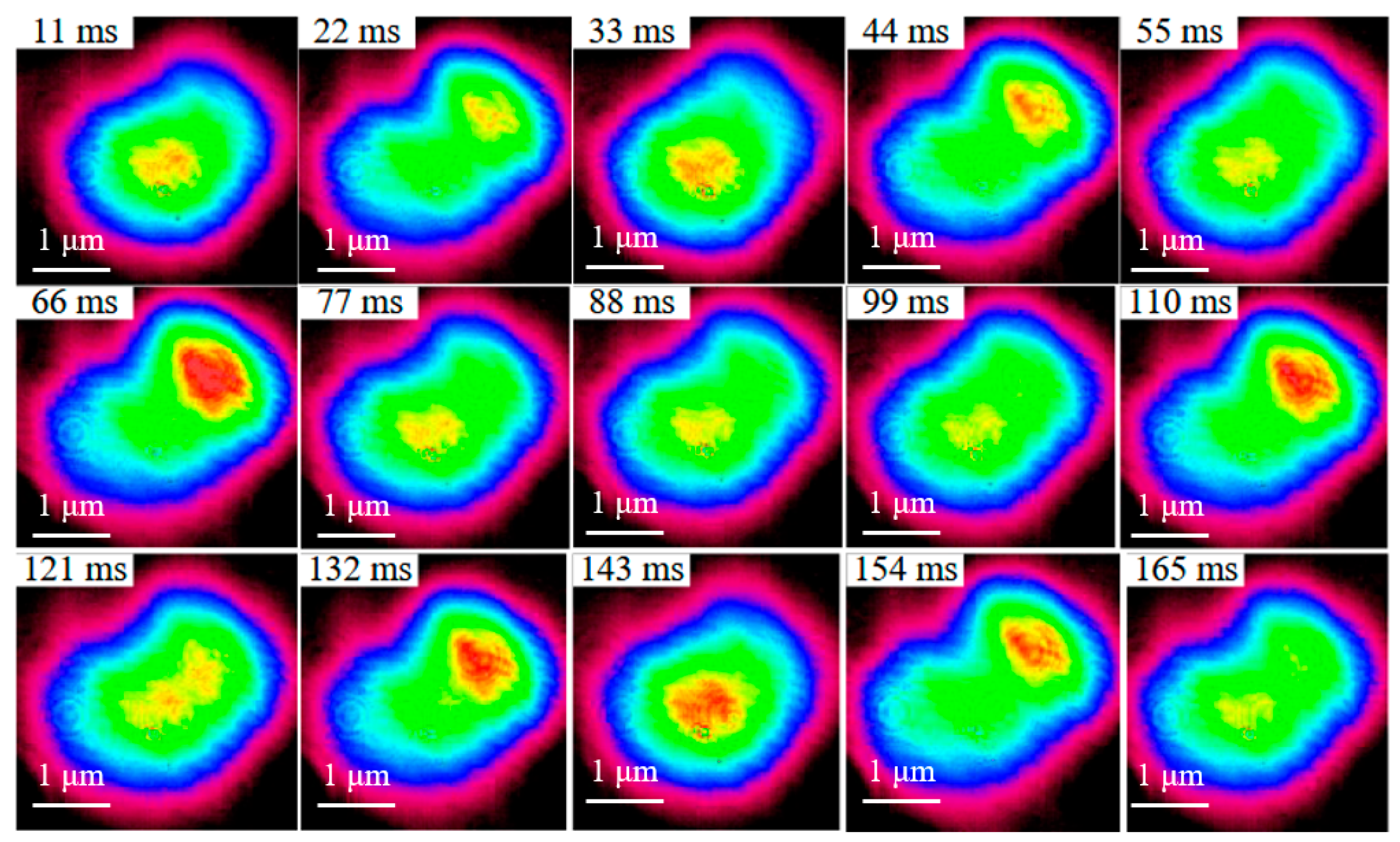

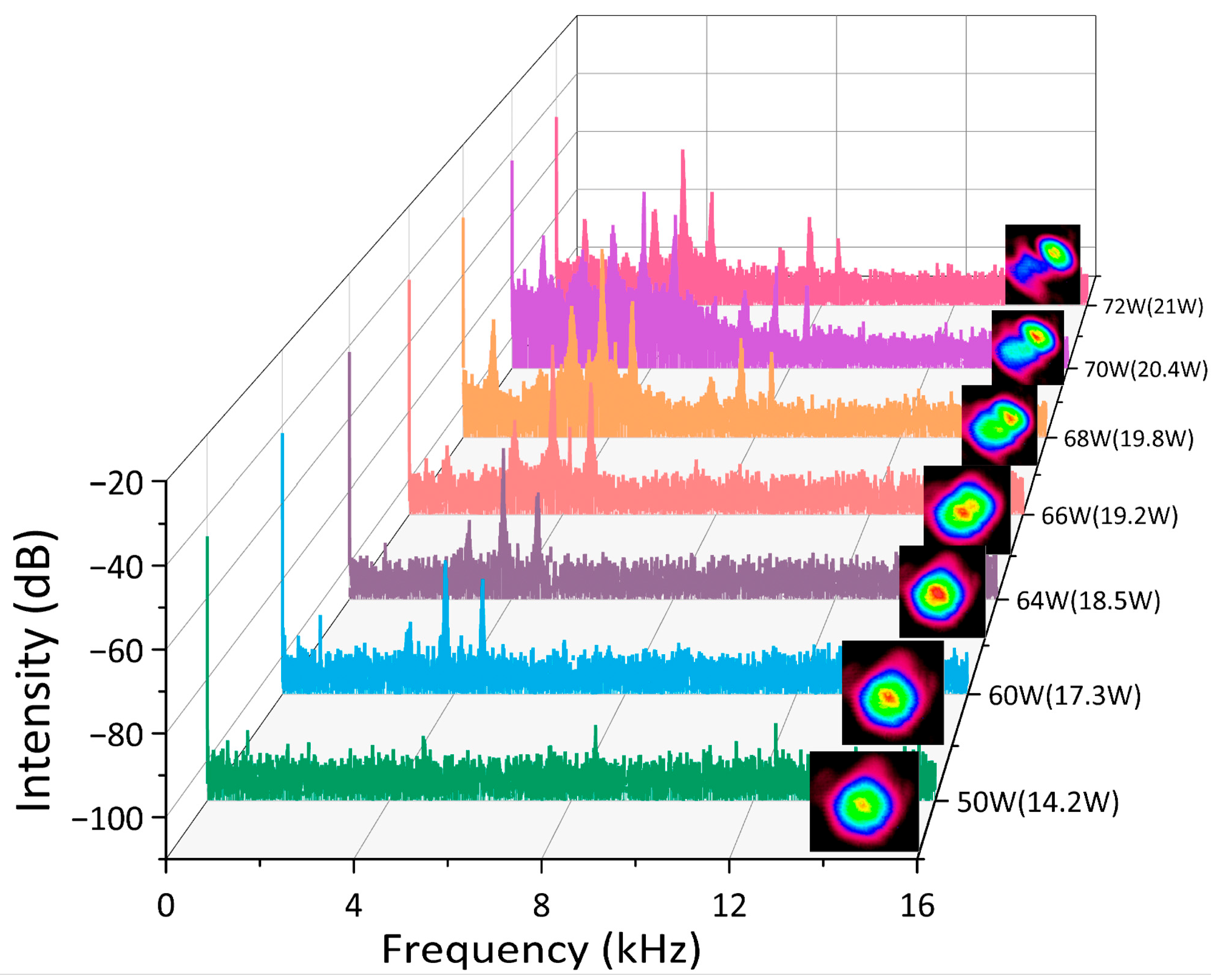

3.4. Transverse Mode Instability in Hollow-Core Fibers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jackson, S.D. Towards High-Power Mid-Infrared Emission from a Fibre Laser. Nat. Photonics 2012, 6, 423–431. [Google Scholar] [CrossRef]

- Jackson, S.D.; Jain, R.K. Fiber-Based Sources of Coherent MIR Radiation: Key Advances and Future Prospects (Invited). Opt. Express 2020, 28, 30964. [Google Scholar] [CrossRef]

- Grebnev, K.; Perminov, B.; Fernandez, T.T.; Fuerbach, A.; Chernysheva, M. Fluoride and Chalcogenide Glass Fiber Components for Mid-Infrared Lasers and Amplifiers: Breakthroughs, Challenges, and Future Perspective. APL Photonics 2024, 9, 110901–110921. [Google Scholar] [CrossRef]

- Boilard, T.; Fortin, V.; Lemieux-Tanguay, M.; Paradis, P.; Du Teilleul, P.; Carrée, J.-Y.; Vallée, R.; Bernier, M. 1.7 W Holmium-Doped Fluoroindate Fiber Laser at 3920 nm. Opt. Lett. 2024, 49, 2677. [Google Scholar] [CrossRef] [PubMed]

- Kotereva, T.V.; Sukhanov, M.V.; Lashmanov, E.N.; Velmuzhov, A.P.; Shiryaev, V.S. Continuous Pr3+-Doped Chalcogenide Glass Fiber Laser Emitting in the 5.60–5.83 μm Range. Opt. Mater. 2025, 168, 117528. [Google Scholar] [CrossRef]

- Nampoothiri, A.V.V.; Jones, A.M.; Fourcade-Dutin, C.; Mao, C.; Dadashzadeh, N.; Baumgart, B.; Wang, Y.Y.; Alharbi, M.; Bradley, T.; Campbell, N.; et al. Hollow-Core Optical Fiber Gas Lasers (HOFGLAS): A Review [Invited]. Opt. Mater. Express 2012, 2, 948. [Google Scholar] [CrossRef]

- Benabid, F.; Knight, J.C.; Antonopoulos, G.; Russell, P.S.J. Stimulated Raman Scattering in Hydrogen-Filled Hollow-Core Photonic Crystal Fiber. Science 2002, 298, 399–402. [Google Scholar] [CrossRef]

- Litchinitser, N.M.; Abeeluck, A.K.; Headley, C.; Eggleton, B.J. Antiresonant Reflecting Photonic Crystal Optical Waveguides. Opt. Lett. 2002, 27, 1592. [Google Scholar] [CrossRef]

- Astapovich, M.S.; Gladyshev, A.V.; Khudyakov, M.M.; Kosolapov, A.F.; Likhachev, M.E.; Bufetov, I.A. Watt-Level Nanosecond 4.42- μm Raman Laser Based on Silica Fiber. IEEE Photonics Technol. Lett. 2019, 31, 78–81. [Google Scholar] [CrossRef]

- Cao, L.; Gao, S.; Peng, Z.; Wang, X.; Wang, Y.; Wang, P. High Peak Power 2.8 μm Raman Laser in a Methane-Filled Negative-Curvature Fiber. Opt. Express 2018, 26, 5609. [Google Scholar] [CrossRef]

- Huang, W.; Wang, Z.; Zhou, Z.; Pei, W.; Cui, Y.; Li, X.; Li, Z.; Chen, J. Tunable Fiber Gas Raman Laser of 6 W at 2.9 μm by Deuterium-Filled Hollow-Core Fiber. IEEE J. Sel. Top. Quantum Electron. 2024, 30, 3292594. [Google Scholar] [CrossRef]

- Stübinger, S. Advances in Bone Surgery: The Er:YAG Laser in Oral Surgery and Implant Dentistry. Clin. Cosmet. Investig. Dent. 2010, 2, 47–62. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, B.; Liu, J.; Song, Y.; Zhang, H. Recent Developments in Mid-Infrared Fiber Lasers: Status and Challenges. Opt. Laser Technol. 2020, 132, 106497. [Google Scholar] [CrossRef]

- Li, Z.; Huang, W.; Cui, Y.; Wang, Z. Efficient Mid-Infrared Cascade Raman Source in Methane-Filled Hollow-Core Fibers Operating at 2.8 μm. Opt. Lett. 2018, 43, 4671. [Google Scholar] [CrossRef]

- Huang, W.; Cui, Y.; Li, Z.; Zhou, Z.; Chen, Y.; Wang, Z. Diode-Pumped Single-Pass Tunable Mid-Infrared Gas Raman Source by Methane-Filled Hollow-Core Fiber. Laser Phys. Lett. 2019, 16, 085107. [Google Scholar] [CrossRef]

- Gladyshev, A.V.; Astapovich, M.S.; Yatsenko, Y.P.; Kosolapov, A.F.; Bufetov, I.A. Nanosecond Raman Laser at 2840 nm Based on a Methane-Filled Revolver Fiber. In Proceedings of the 2020 International Conference Laser Optics (ICLO), St. Petersburg, Russia, 2–6 November 2020; p. 1. [Google Scholar]

- Zhang, X.; Peng, Z.; Dong, Z.; Yao, P.; Hou, Y.; Wang, P. High-Power Mid-Infrared 2.8-μm Ultrafast Raman Laser Based on Methane-Filled Anti-Resonant Fiber. IEEE Photonics Technol. Lett. 2022, 34, 1007–1010. [Google Scholar] [CrossRef]

- Song, W.; Sui, Q.; Zhang, Q.; Zhang, X.; Hong, D.; Qiao, S.; Wang, P. 10 Watt-Level High Energy CH4-Filled Hollow Core Fiber Picosecond Raman Laser at 2.8 μm. J. Light. Technol. 2025, 43, 9375–9381. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W.; Wang, C.; Cui, M.; Chen, Z.; Liu, W.; Xiao, H.; Ma, P.; Wang, Z. 1.4 kW 1030 nm All-Fiber Amplifier with ~3.5 GHz Linewidth Assisted by Confined Yb-Doped Active Fiber and Cascaded Phase Modulation Technique. Opt. Express 2025, 33, 32022. [Google Scholar] [CrossRef] [PubMed]

- Ma, P.; Yao, T.; Liu, W.; Pan, Z.; Chen, Y.; Yang, H.; Chen, Z.; Wang, Z.; Zhou, P.; Chen, J. A 7-kW Narrow-Linewidth Fiber Amplifier Assisted by Optimizing the Refractive Index of the Large-Mode-Area Active Fiber. High Power Laser Sci. Eng. 2024, 12, e67. [Google Scholar] [CrossRef]

- Yu, F.; Song, P.; Wu, D.; Birks, T.; Bird, D.; Knight, J. Attenuation Limit of Silica-Based Hollow-Core Fiber at Mid-IR Wavelengths. APL Photonics 2019, 4, 080803. [Google Scholar] [CrossRef]

- Benabid, F.; Bouwmans, G.; Knight, J.C.; Russell, P.S.J.; Couny, F. Ultrahigh Efficiency Laser Wavelength Conversion in a Gas-Filled Hollow Core Photonic Crystal Fiber by Pure Stimulated Rotational Raman Scattering in Molecular Hydrogen. Phys. Rev. Lett. 2004, 93, 123903. [Google Scholar] [CrossRef]

- Murray, J.; Goldhar, J.; Eimerl, D.; Szoke, A. Raman Pulse Compression of Excimer Lasers for Application to Laser Fusion. IEEE J. Quantum Electron. 1979, 15, 342–368. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, F.; Wadsworth, W.J.; Knight, J.C. Efficient 1.9 μm Emission in H2-Filled Hollow Core Fiber by Pure Stimulated Vibrational Raman Scattering. Laser Phys. Lett. 2014, 11, 105807. [Google Scholar] [CrossRef]

- Ottusch, J.J.; Rockwell, D.A. Measurement of Raman Gain Coefficients of Hydrogen, Deuterium, and Methane. IEEE J. Quantum Electron. 1988, 24, 2076–2080. [Google Scholar] [CrossRef]

- Eidam, T.; Wirth, C.; Jauregui, C.; Stutzki, F.; Jansen, F.; Otto, H.-J.; Schmidt, O.; Schreiber, T.; Limpert, J.; Tünnermann, A. Experimental Observations of the Threshold-like Onset of Mode Instabilities in High Power Fiber Amplifiers. Opt. Express 2011, 19, 13218. [Google Scholar] [CrossRef] [PubMed]

- Jauregui, C.; Eidam, T.; Limpert, J.; Tünnermann, A. Impact of Modal Interference on the Beam Quality of High-Power Fiber Amplifiers. Opt. Express 2011, 19, 3258–3271. [Google Scholar] [CrossRef]

- Smith, A.V.; Smith, J.J. Mode Instability in High Power Fiber Amplifiers. Opt. Express 2011, 19, 10180. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Pei, W.; Lei, L.; Li, T.; Lv, G.; Chen, Q.; Sun, G.; Wang, S.; Zhou, Z.; Wang, Z. Watt-Level Tunable Mid-Infrared Laser Emission at 2.8 μm Generated by Stimulated Raman Scattering of Methane Molecules in Hollow-Core Fibers. Photonics 2025, 12, 1137. https://doi.org/10.3390/photonics12111137

Liu P, Pei W, Lei L, Li T, Lv G, Chen Q, Sun G, Wang S, Zhou Z, Wang Z. Watt-Level Tunable Mid-Infrared Laser Emission at 2.8 μm Generated by Stimulated Raman Scattering of Methane Molecules in Hollow-Core Fibers. Photonics. 2025; 12(11):1137. https://doi.org/10.3390/photonics12111137

Chicago/Turabian StyleLiu, Peicong, Wenxi Pei, Luohao Lei, Tianyu Li, Guorui Lv, Qi Chen, Guangrong Sun, Shuyi Wang, Zhiyue Zhou, and Zefeng Wang. 2025. "Watt-Level Tunable Mid-Infrared Laser Emission at 2.8 μm Generated by Stimulated Raman Scattering of Methane Molecules in Hollow-Core Fibers" Photonics 12, no. 11: 1137. https://doi.org/10.3390/photonics12111137

APA StyleLiu, P., Pei, W., Lei, L., Li, T., Lv, G., Chen, Q., Sun, G., Wang, S., Zhou, Z., & Wang, Z. (2025). Watt-Level Tunable Mid-Infrared Laser Emission at 2.8 μm Generated by Stimulated Raman Scattering of Methane Molecules in Hollow-Core Fibers. Photonics, 12(11), 1137. https://doi.org/10.3390/photonics12111137