Abstract

In this paper, a high energy 3.5 μm mid-infrared (MIR) burst-mode KTA optical parametric oscillator (OPO) was demonstrated. Utilizing a quasi-continuous wave (QCW) laser diode (LD) side-pump module and electro-optic (EO) Q-switching technique, a high beam quality 1064 nm burst-mode laser was achieved as the fundamental source, generating 30 mJ high-energy pulses at burst repetition rates of 100 Hz and 200 Hz with sub-burst repetition rates of 20 kHz, 40 kHz, and 50 kHz. The KTA-OPO produced a 3.5 μm MIR burst-mode laser output with 4 to 11 sub-pulses per pulse envelope. The output energies were 2.9 mJ, 2.81 mJ, and 2.79 mJ at 100 Hz, as well as 2.8 mJ, 2.75 mJ, and 2.72 mJ at 200 Hz, with corresponding conversion efficiencies of 9.6%, 9.3%, and 9.3% at 100 Hz, as well as 9.3%, 9.2%, and 9.1% at 200 Hz, respectively. Our results pave a new way for generating burst-mode MIR lasers.

1. Introduction

Mid-infrared (MIR) lasers play a pivotal role across diverse fields [1,2], including environmental monitoring [3], medical applications [4], and material processing [5,6]. Their ability to target the absorption peaks of various gasses and excel in atmospheric penetration makes them ideal for detecting trace gasses like methane and ethane [7,8], crucial for accurate environmental monitoring. In medicine, MIR lasers’ optimal penetration depth and absorption characteristics in biological tissues enable precise tissue imaging and non-invasive surgical procedures, significantly enhancing the accuracy of treatments such as laser ablation and photothermal therapy [9,10]. Furthermore, in material processing, MIR lasers efficiently cut and weld specific materials like polymers and composites [11,12], offering improved efficiency and precision. Notably, burst-mode lasers deliver a rapid succession of high-energy pulses within a single burst, allowing for precise control over both energy and temporal distribution, which is essential for applications requiring high repetition rate accumulation effects [13]. Therefore, the development of high-energy MIR burst-mode lasers is crucial for advancing these technologies, providing unique performance capabilities that continuous-wave or single-pulse lasers cannot achieve.

There are several methods to generate MIR burst-mode lasers, such as acousto-optic modulation, extracavity modulation, and fiber lasers. Fu et al. employed an optical chopper in front of the OPO, which was synchronously pumped by a thulium-doped fiber master oscillator power amplifier with orientation-patterned gallium arsenide, achieving a wide wavelength tuning range of 2895–3342 nm (signal) and 4935–6389 nm (idler) [14]. However, extracavity modulation with a chopper can result in energy losses, thereby reducing the output energy. Cai et al. employed a linearly polarized fiber laser as the pump source, consisting of a seed laser and three amplifier stages. The seed laser was a gain-switched distributed Bragg reflector laser diode (LD), directly modulated for burst-mode operation, achieving laser emission at 3.8 µm with an average output power of 7.9 W at a pump power of 45.3 W, but the amplified energy was only at the μJ level [15]. Okabayashi et al. utilized an acousto-optic Q-switched burst-pulse laser to pump Cr:ZnSe, achieving a maximum output energy of 0.42 mJ at a pump energy of 3.1 mJ, with the output wavelength tuned to 2.44 μm [16]. Recently, Wu et al. proposed a novel approach to generate high-energy burst-mode lasers, achieving a single pulse energy of 13.4 mJ and a peak power of 1.3 MW at 355 nm. This was accomplished using a pulse pump frequency of 10 Hz and a Q-switched repetition rate of 10 kHz, through a pulse side-pump module and intracavity electro-optical (EO) Q-switching after amplification [17]. However, to the best of our knowledge, this method has not yet been applied to generate burst-mode MIR lasers.

In our work, we utilized a pulsed side-pump module and intracavity EO Q-switching technology to produce 1064 nm burst-mode lasers with adjustable burst and sub-burst repetition rates. By using the as-generated 1064 nm burst-mode laser to pump the KTA optical parametric oscillator (OPO), a burst-mode 3.5 μm MIR laser was generated. The output energies of the 3.5 μm MIR burst-mode lasers were measured at 2.9 mJ, 2.81 mJ, and 2.79 mJ at a repetition rate of 100 Hz, as well as 2.8 mJ, 2.75 mJ, and 2.72 mJ at 200 Hz.

2. Experimental Section

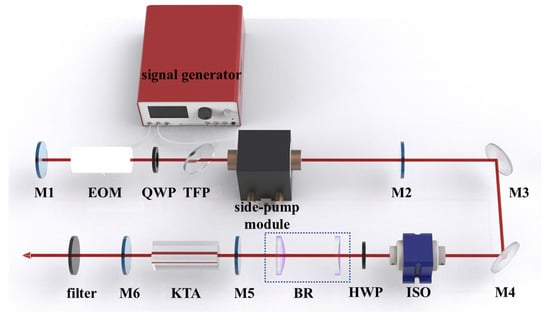

Figure 1 shows the experimental setup of the 3.5 μm burst-mode laser. The core components consisted of a 1064 nm burst-mode laser oscillator and a KTA-OPO module. The 1064 nm fundamental laser is composed of a side pump module, a thin-film polarizer (TFP), an electro-optic modulator (EOM), a quarter-wave plate (QWP), and two reflectors (M1 and M2). A quasi-continuous wave (QCW) 808 nm LD served as the pump source, delivering a peak pump power of 1200 W. The Nd:YAG crystal rod with the dimensions of Φ3 mm × 75 mm was used as the gain medium. The concentration of Nd3+ dopant was 0.6 at. %, and the two end surfaces were anti-reflection (AR) coated at 1064 nm. The side pump module offered adjustable pulse repetition rates between 100 and 200 Hz via power supply regulation, with a fixed pulse width of 250 μs. M1 was a plano-concave mirror with high reflectance at 1064 nm and a radius of curvature of R = −1500 mm, while M2 was a Gaussian output coupler with 60% transmittance at 1064 nm and R = 500 mm, 2a = 4 mm 2b = 0, designed to compensate for thermal lensing in the crystal and improve beam quality. The Gaussian output mirror ensured superior mode matching and promoted high-quality fundamental beam output, offering significant advantages in beam quality and power stability. Additionally, the TFP’s incident angle was optimized at 56° for beam transmission. The EOM utilized a BBO crystal controlled by a high-voltage driver, with a quarter-wave voltage of approximately 2900 V, a pulse duration of 1 μs, and a maximum repetition rate of 50 kHz.

Figure 1.

Schematic diagram of the experimental setup for the 3.5 μm burst-mode laser system. QWP: quarter wave plate; EOM: electro-optic modulator; TFP: thin film polarizer; BR: beam reducer; ISO: isolator; HWP: half-wave plate.

Before entering the nonlinear frequency conversion unit, the 1064 nm burst-mode output beam was collimated using a beam reducer (BR), consisting of lens groups L1 and L2 with focal lengths of 200 mm and −200 mm, respectively. The spot sizes at the Q-switching repetition rates of 20 kHz, 40 kHz, and 50 kHz were determined to be 1400 μm, 930 μm, and 850 μm, respectively. To prevent the 1064 nm reflected laser from damaging components within the resonant cavity, an isolator (ISO) was positioned behind two 45° plane mirrors (M3 and M4) coated with high reflection (HR) films at 1.06 μm. The nonlinear frequency conversion unit featured a KTA crystal, cut at angles of θ = 90° and ϕ = 0°, with dimensions of 4 mm × 4 mm × 23 mm, placed in a water-cooled heat sink maintained at 20 °C. For optimal phase matching, a half-wave plate (HWP) was used. To enhance optical-to-optical conversion efficiency, a plano–plano cavity structure was employed. The input mirror M5 was HR coated at 1.4–1.6 μm and 3.3–4.0 μm, and HT coated at 1.05–1.1 μm, while the flat output mirror M6 was HR coated at 1.05–1.1 μm and 1.35–2.0 μm, and HT coated at 2.5–4.2 μm. To measure the output energy and conversion efficiency of the nonlinear frequency conversion laser, a germanium plate was utilized for filtering, exhibiting strong absorption at 1.064 μm and high transmittance at 3.5 μm. A signal generator (922pro, Rigol, Suzhou, China) was used to set the pump repetition rates to 100 Hz and 200 Hz, with a pump duration of 250 μs. The electro-optical module (EOM) repetition rates were set to 20 kHz, 40 kHz, and 50 kHz, with a duration of 1 μs. The laser output power was measured using a power meter (PM100D, Thorlabs, Newton, NJ, USA).

3. Results and Discussions

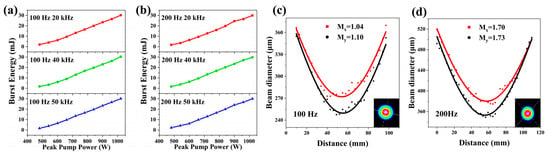

Figure 2a depicts the correlation between burst energy and peak pump power at varying pump and Q-switched repetition rates. As peak pump power increased, the output laser energy progressively grew, achieving 30 mJ across all repetition rates when the peak pump power reached 1020 W. Specifically, the output energy was 30.2 mJ at 100 Hz, slightly decreasing to 30.0 mJ at 200 Hz. This slight reduction, likely attributed to thermal effects intensified at higher pump repetition rates, indicates that while the pump repetition rate influences burst output energy, the overall difference remains minor.

Figure 2.

The output 1064 nm burst-mode laser energy versus the peak pump power for various burst repetition rates of (a) 100 Hz and (b) 200 Hz; the beam quality factors of the 1064 nm burst-mode laser at (c) 100 Hz and (d) 200 Hz.

The beam quality of the 1064 nm laser at its highest output energy was evaluated using a beam quality analyzer. The beam quality factors at pump repetition rates of 100 Hz and 200 Hz were measured to be Mx2 = 1.04, My2 = 1.10 and Mx2 = 1.70, My2 = 1.73, respectively, as shown in Figure 2c,d. The corresponding two-dimensional spatial intensity distributions of the laser are inserted in the figure, indicating that the 1064 nm laser consistently maintained a Gaussian TEM00 mode with good beam quality under burst-mode operation, providing a solid foundation for the subsequent OPO MIR burst-mode laser experiment.

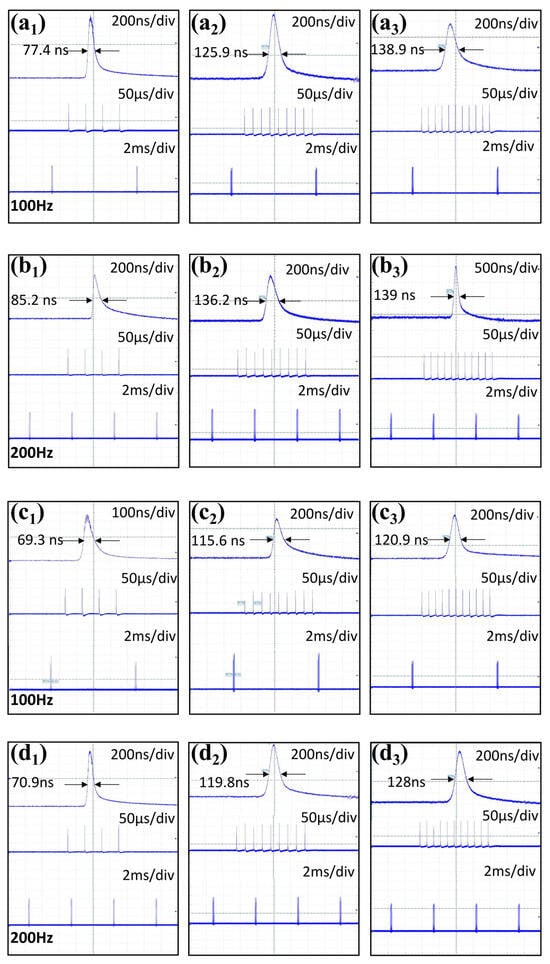

Figure 3a,b show the single pulse profiles and pulse trains of the 1064 nm fundamental frequency laser with the highest output burst energy of 30 mJ, measured at different Q-switching repetition rates with pump frequencies of 100 Hz and 200 Hz, respectively. The laser pulse width and pulse number increased as the Q-switching repetition rate rose. At the Q-switching repetition rates of 20 kHz, 40 kHz, and 50 kHz, the number of sub-pulses within each pulse envelope was 4, 9, and 11, respectively. The burst-mode 1064 nm laser with a burst energy of 30 mJ was then collimated and injected into the OPO unit. Figure 3c,d present the output pulse characteristics of the OPO-MIR laser. The pulse width after OPO was narrower compared to the fundamental laser. At a pump repetition rate of 100 Hz, with different Q-switch repetition rates of 20 kHz, 40 kHz, and 50 kHz, the pulse width decreased from 77 ns, 126 ns, and 139 ns to 69 ns, 116 ns, and 121 ns, respectively. Similarly, at the pump repetition rate of 200 Hz, the pulse width reduced from 85 ns, 136 ns, and 139 ns to 71 ns, 120 ns, and 128 ns, respectively.

Figure 3.

The output 1064 nm fundamental frequency laser at a pump repetition rate of 100 Hz for a sub-pulse repetition rate of 20 kHz (a1), 40 kHz (a2), and 50 kHz (a3); 200 Hz for 20 kHz (b1), 40 kHz (b2), and 50 kHz (b3); 3.5 μm MIR laser of 100 Hz for a sub-pulse repetition rate of 20 kHz (c1), 40 kHz (c2), and 50 kHz (c3); 200 Hz for 20 kHz (d1), 40 kHz (d2), and 50 kHz (d3).

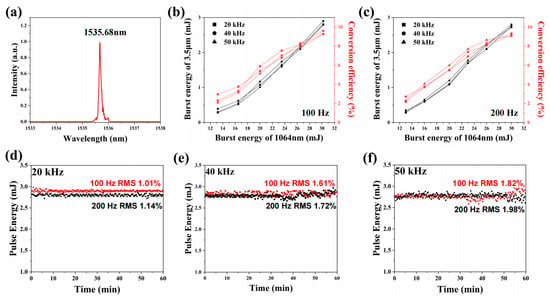

Due to the limitations of available instruments, a suitable pulse spectrometer covering the 3.5 μm range was not accessible to directly measure the output wavelength of the KTA-OPO. Therefore, the idler wavelength was calculated by measuring the signal wavelength in the cavity after the OPO process. As shown in Figure 4a, the central wavelength of the signal light was measured to be 1535.68 nm, and the corresponding idler wavelength was calculated to be 3.47 μm. Figure 4b,c illustrate the relationship between output energy, conversion efficiency, and 1064 nm pump energy of the mid-infrared 3.5 μm burst-mode laser at varying pump and Q-switching repetition rates. As the pump energy of the burst-mode 1064 nm fundamental frequency laser increased, the average output energy of the MIR 3.5 μm laser also increased gradually. It can be observed that since the single-pulse energy density of the 1064 nm fundamental frequency laser incident on the KTA crystal remained constant, the conversion efficiency of the generated 3.5 μm laser was comparable under different conditions. When the 1064 nm pump energy reached 30 mJ, the highest output burst energy of the 3.5 μm laser was 2.9 mJ, 2.81 mJ, and 2.79 mJ at a pump repetition rate of 100 Hz, as well as 2.8 mJ, 2.75 mJ, and 2.72 mJ at 200 Hz. Due to increased thermal effects at 200 Hz, the beam quality of the 1064 nm burst-mode laser degraded compared to that at 100 Hz, resulting in a slight reduction in output energy. At this point, the optical-to-optical conversion efficiency of the OPO was 9.6%, 9.3%, and 9.3% at 100 Hz, as well as 9.3%, 9.2%, and 9.1% at 200 Hz, respectively. As shown in Figure 4c–e, the pulse energy stability of the 3.5 μm MIR laser was measured over 60 min, with results of 1.01% and 1.14% at 20 kHz, 1.61% and 1.72% at 40 kHz, as well as 1.82% and 1.98% at 50 kHz.

Figure 4.

(a) The spectrum of the 1.5 μm signal light; the output burst energy (black lines) and efficiency (red lines) of 3.5 μm versus 1064 nm burst energy across varying sub-burst repetition rates with a burst repetition rate of (b) 100 Hz and (c) 200 Hz; energy stability of 3.5 μm MIR laser pulse for a sub-burst repetition rate of (d) 20 kHz, (e) 40 kHz and (f) 50 kHz.

4. Conclusions

In this work, a 3.5 μm MIR burst-mode laser based on a side-pump module and EO Q-switching techniques and KTA-OPO was demonstrated for the first time. A high-energy pulse of 30 mJ at a fundamental wavelength of 1064 nm, with burst repetition rates of 100 Hz and 200 Hz, and sub-burst repetition rates ranging from 20 kHz to 50 kHz, was used as the pump laser. In the subsequent KTA-OPO experiment, a 3.5 μm MIR burst-mode laser with 4, 9, and 11 sub-pulses per burst was realized. At 100 Hz, the output energies were 2.9 mJ, 2.81 mJ, and 2.79 mJ, respectively, with corresponding conversion efficiencies of 9.6%, 9.3%, and 9.3%. At 200 Hz, the output energies slightly decreased to 2.8 mJ, 2.75 mJ, and 2.72 mJ, with corresponding efficiencies of 9.3%, 9.2%, and 9.1%. Our findings demonstrate that the combination of pulse pumping and EO Q-switching enables a 1064 nm KTA-OPO to generate a 3.5 μm MIR burst-mode laser, paving a new technical pathway for MIR pulse train lasers and providing both theoretical and technical support for their further advancement.

Author Contributions

Conceptualization, H.G. and B.Z.; methodology, H.N. and S.Y.; software, H.G.; validation, Y.Y.; formal analysis, M.B.; investigation, H.G.; resources, C.J.; data curation, T.M.; writing—original draft preparation, H.G. and J.Z.; writing—review and editing, C.J.; visualization, B.Z.; supervision, J.H., J.X. and B.Y.; project administration, B.Z.; funding acquisition, H.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Research Foundation of China, grant numbers 62275144, 62105182, and 62322509; National Research Foundation of Shandong Province, grant number ZR2021QF082; the Youth Cross Innovation Group of Shandong University, grant number 2020QNQT; Distinguished Young Scholars from Shandong University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data in this study are available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, X.; Huang, X.; Hu, X.; Guo, X.; Han, Y. Recent progress on mid-infrared pulsed fiber lasers and the applications. Opt. Laser Technol. 2023, 158, 108898. [Google Scholar] [CrossRef]

- Sun, J.; Chang, J.; Zhang, Y.; Wei, Y.; Zhang, Q.; Wang, F.; Lin, S.; Wang, Z.; Mao, M. CH4/C2H6 dual gas sensing system using a single mid-infrared laser. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2023, 291, 122368. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Feng, Y.; Adamu, A.I.; Dasa, M.K.; Antonio-Lopez, J.E.; Amezcua-Correa, R.; Markos, C. Mid-infrared photoacoustic gas monitoring driven by a gas-filled hollow-core fiber laser. Sci. Rep. 2021, 11, 3512. [Google Scholar] [CrossRef] [PubMed]

- Tian, K.; Xiang, M.; Wen, X.; Guo, J.; He, L.; Yu, P.; Han, J.; Peng, X.; Wang, F.; Zhang, L.; et al. Tissue Ablation with Multi-Millimeter Depth and Cellular-Scale Collateral Damage by a Femtosecond Mid-Infrared Laser Tuned to the Amide-I Vibration. Laser Photonics Rev. 2023, 18, 2300421. [Google Scholar] [CrossRef]

- Li, Q.; Yuan, X.; Jiang, X.; Ju, Y.; Zhang, L. Femtosecond laser-induced damage characteristics of mid-infrared oxyfluorogallate glass. Opt. Laser Technol. 2019, 109, 659–665. [Google Scholar] [CrossRef]

- Zheng, J.X.; Liu, X.Q.; Tian, K.S.; Li, H.Y.; Zhang, X.; Tian, Z.N.; Qian, M.D.; Wang, L.; Chen, Q.D. Nanofabrication of Lithium Niobate Anti-Reflective Subwavelength Structures for High Power Mid-Infrared Lasers. Laser Photonics Rev. 2024, 18, 2400546. [Google Scholar] [CrossRef]

- Huang, Y.; Fu, W.; Yang, S.; Li, C.; Hu, X.; Zhang, M.; Chen, C.; Chang, S. Highly sensitive measurement of trace methane gas using mid-infrared tunable diode laser absorption spectroscopy method. Microw. Opt. Technol. Lett. 2023, 66, e33701. [Google Scholar] [CrossRef]

- Xia, J.; Feng, C.; Zhu, F.; Ye, S.; Zhang, S.; Kolomenskii, A.; Wang, Q.; Dong, J.; Wang, Z.; Jin, W.; et al. A sensitive methane sensor of a ppt detection level using a mid-infrared interband cascade laser and a long-path multipass cell. Sens. Actuators B Chem. 2021, 334, 129641. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, Y.; Han, Y. Methane, Ethylene, and Ethane Detection by Differential Helmholtz Resonance Spectroscopy Using a 3345 nm Mid-Infrared Tunable Diode Laser Source. Appl. Sci. 2023, 13, 3169. [Google Scholar] [CrossRef]

- Serebryakov, V.S.; Boĭko, É.V.; Kalintsev, A.G.; Kornev, A.F.; Narivonchik, A.S.; Pavlova, A.L. Mid-IR laser for high-precision surgery. J. Opt. Technol. 2016, 82, 781–788. [Google Scholar] [CrossRef]

- Berube, J.P.; Frayssinous, C.; Lapointe, J.; Duval, S.; Fortin, V.; Vallee, R. Direct Inscription of on-surface waveguides in polymers using a mid-ir fiber laser. Opt. Express 2019, 27, 31013–31022. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Zhou, L.; Cheng, H.; Li, P.; Liu, S.; Mao, S.; Jin, C.; Zhu, X.; Zhao, J. Mid-wave infrared planar optical device via femtosecond laser ablation on a sulfur-based polymeric glass surface. Opt. Mater. Express 2022, 12, 2541–2549. [Google Scholar] [CrossRef]

- Kerse, C.; Kalaycioglu, H.; Elahi, P.; Cetin, B.; Kesim, D.K.; Akcaalan, O.; Yavas, S.; Asik, M.D.; Oktem, B.; Hoogland, H.; et al. Ablation-cooled material removal with ultrafast bursts of pulses. Nature 2016, 537, 84–88. [Google Scholar] [CrossRef]

- Fu, Q.; Xu, L.; Liang, S.; Shardlow, P.C.; Shepherd, D.P.; Alam, S.U.; Richardson, D.J. High-average-power picosecond mid-infrared OP-GaAs OPO. Opt. Express 2020, 28, 5741–5748. [Google Scholar] [CrossRef] [PubMed]

- Cai, S.; Ruan, M.; Wu, B.; Shen, Y.; Jiang, P. High Conversion Efficiency, Mid-Infrared Pulses Generated via Burst-Mode Fiber Laser Pumped Optical Parametric Oscillator. IEEE Access 2020, 8, 64725–64729. [Google Scholar] [CrossRef]

- Okabayashi, Y.; Tomihari, Y.; Yumoto, M.; Imai, S. Burst pulse generation in Cr:ZnSe laser with mid-infrared tunability. Opt. Eng. 2022, 61, 36105. [Google Scholar] [CrossRef]

- Li, X.; Wu, W.; Yan, R.; Xu, G.; Liu, Z.; Wen, X.; Fan, R.; Chen, D. 10 kHz, 10 ns, 13.4 mJ Nd:YAG based frequency-tripled burst-mode MOPA source at 355 nm. Opt. Laser Technol. 2019, 114, 190–195. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).