Computer Science Integrations with Laser Processing for Advanced Solutions

Abstract

1. Introduction

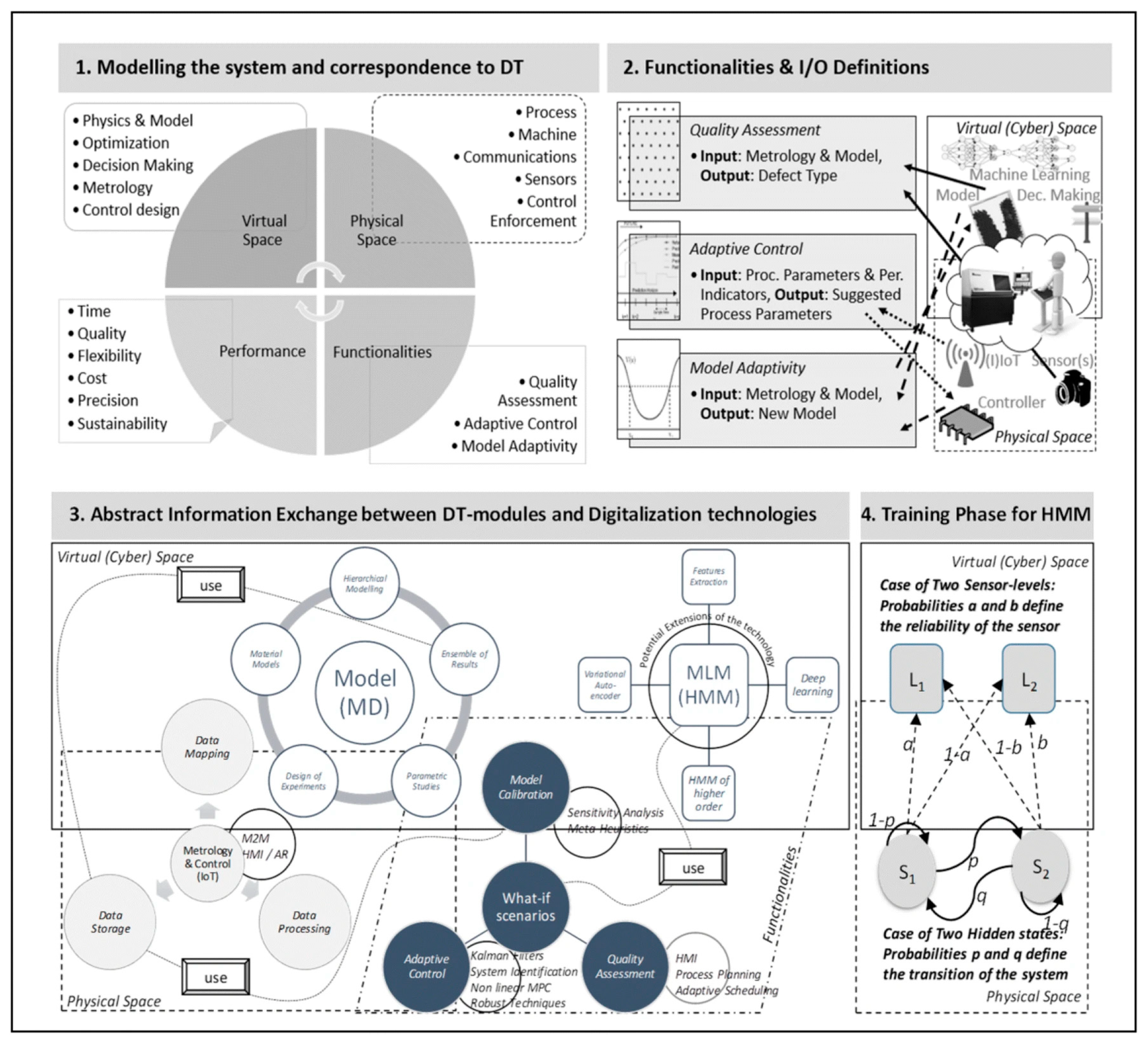

2. Modeling and Simulation in Laser Processing

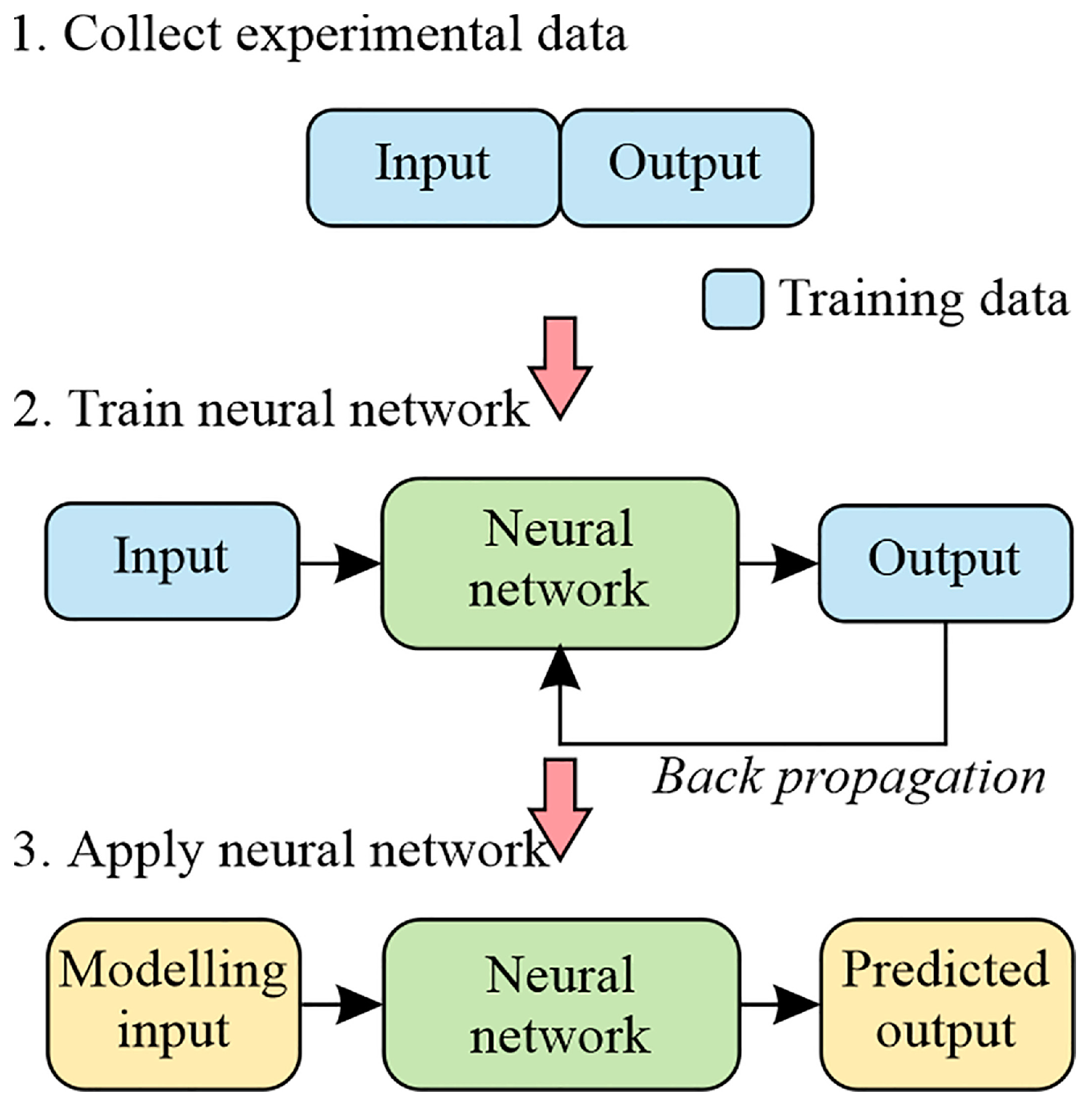

3. Intelligent Control Systems in Laser Material Processing

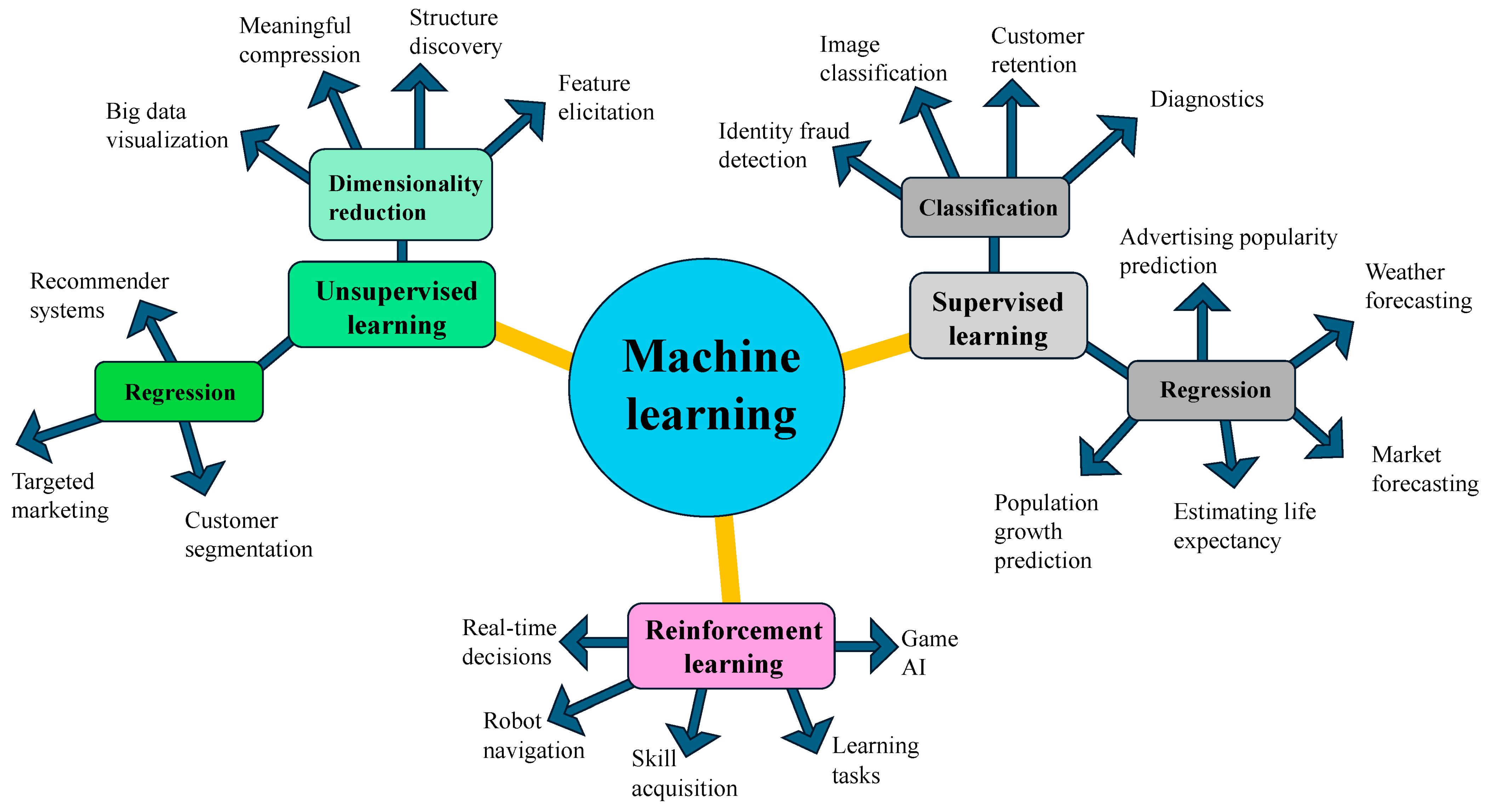

4. Computer-Generated DOEs and SLMs

4.1. SLMs in Laser Processing

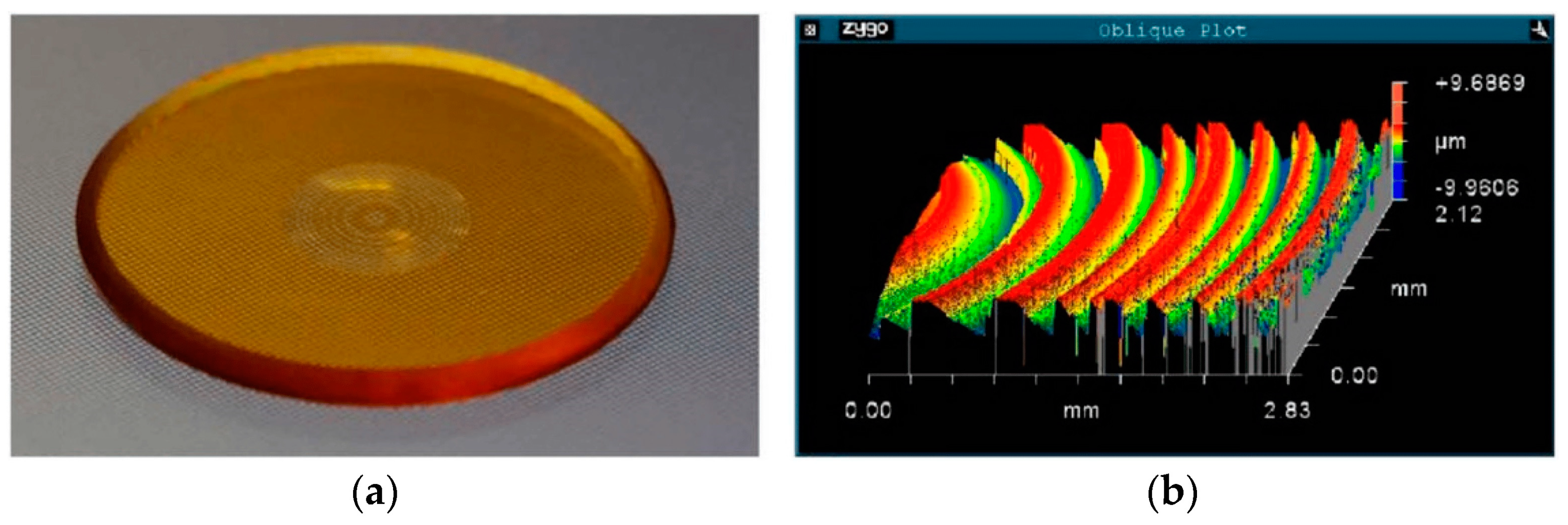

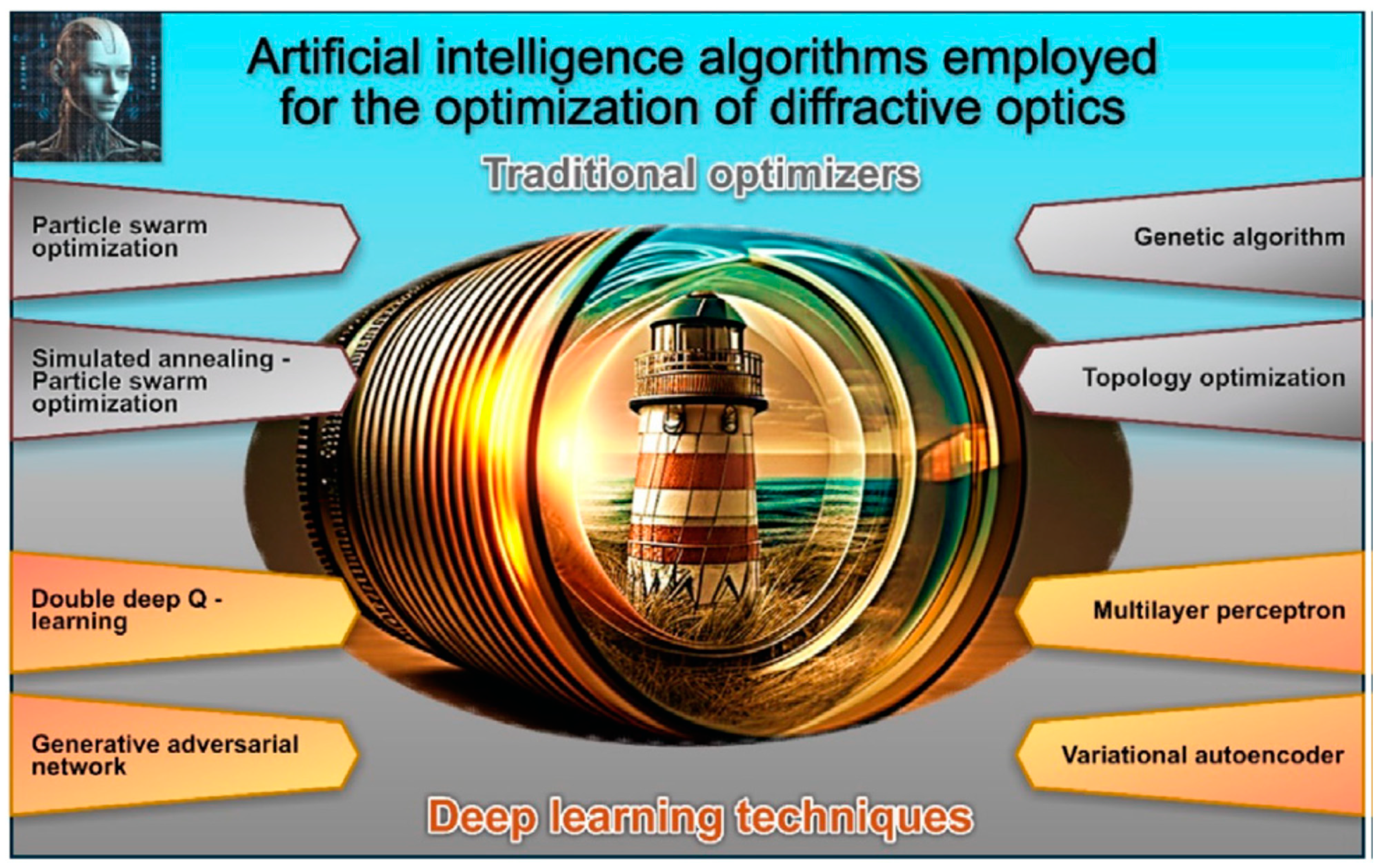

4.2. Computer-Generated DOEs

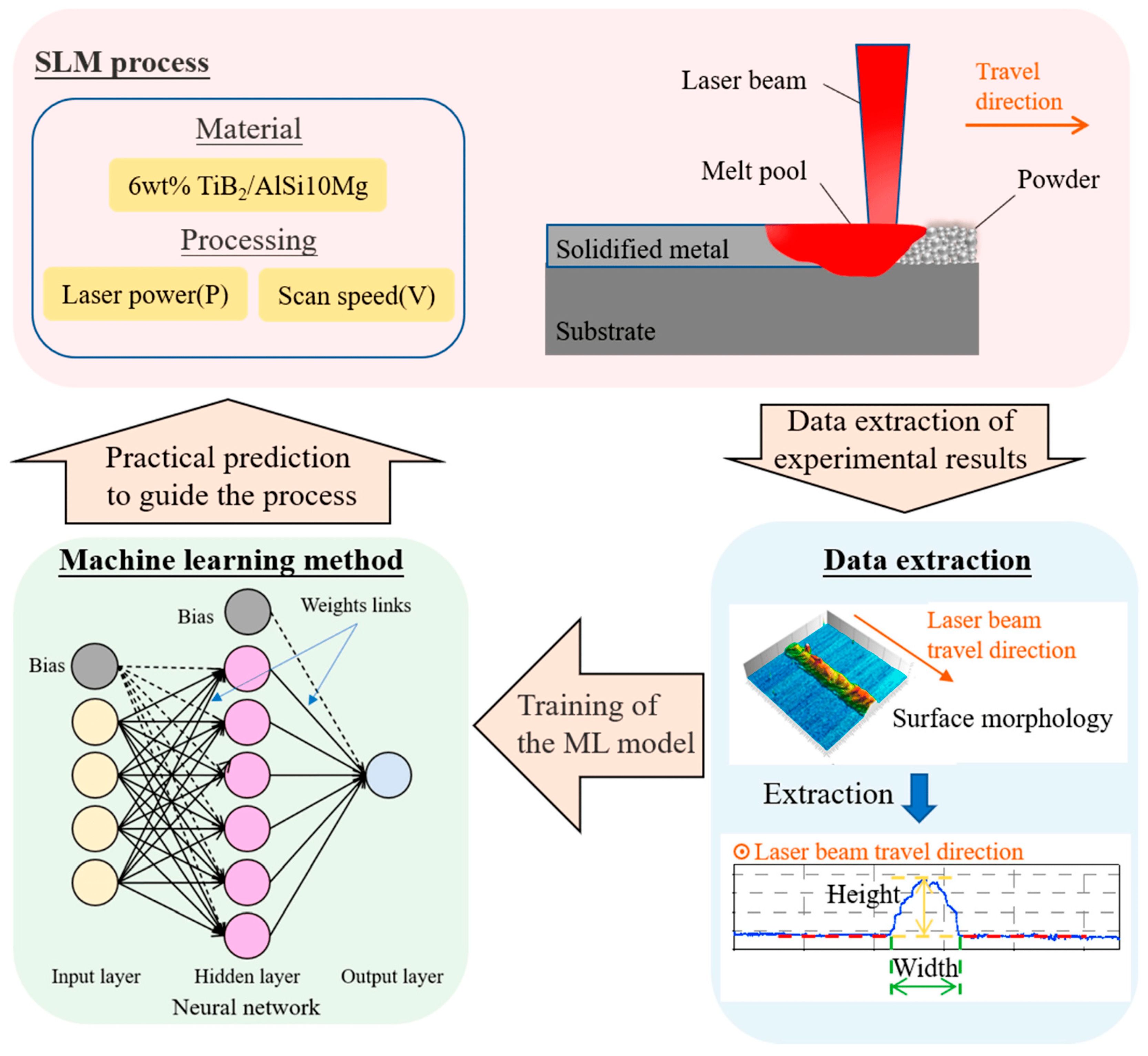

5. Prediction and Data Analysis

6. Discussion

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lawrence, J.R. (Ed.) Advances in Laser Materials Processing: Technology, Research and Applications, 2nd ed.; Woodhead Publishing: Oxford, UK, 2017; 802p. [Google Scholar]

- Ossi, P.M. Advances in the Application of Lasers in Materials Science, 1st ed.; Springer International Publishing: Cham, Switzerland, 2018; 395p. [Google Scholar]

- Nof, S.Y.; Weiner, A.M.; Cheng, G.J. (Eds.) Laser and Photonic Systems: Design and Integration, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017; 427p. [Google Scholar]

- Parandoush, P.; Hossain, A. A review of modeling and simulation of laser beam machining. Int. J. Mach. Tools Manuf. 2014, 85, 135–145. [Google Scholar] [CrossRef]

- Dutta, J.; Kundu, B.; Soni, H.; Mashinini, P.M. Analytical modelling for laser heating for materials processing and surface engineering. In Surface Engineering of Modern Materials: Engineering Materials; Gupta, K., Ed.; Springer: Cham, Switzerland, 2020; pp. 103–123. [Google Scholar]

- Wojtanowski, J.; Drozd, T. Simplified geometric approach to freeform beam shaper design. Int. J. Opt. 2020, 2020, 2896593. [Google Scholar] [CrossRef]

- Kumar, S.; Tong, Z.; Jiang, X. Advances in the design and manufacturing of novel freeform optics. Int. J. Extreme Manuf. 2022, 4, 32004. [Google Scholar] [CrossRef]

- Ayoub, A.B.; Psaltis, D. High speed, complex wavefront shaping using the digital micro-mirror device. Sci. Rep. 2021, 11, 18837. [Google Scholar] [CrossRef]

- Schmidt, M.; Cvecek, K.; Duflou, J.; Vollertsen, F.; Arnold, C.B.; Matthews, M.J. Dynamic beam shaping—Improving laser materials processing via feature synchronous energy coupling. CIRP Ann. 2024, 73, 533–559. [Google Scholar] [CrossRef]

- Soifer, V.A. (Ed.) Computer Design of Diffractive Optics, 1st ed.; Woodhead Publishing: Cambridge, UK, 2012; 896p. [Google Scholar]

- Hsu, K.H.; Lin, H.Y. Tradeoff between diffraction efficiency and uniformity for design of binary diffractive laser beam shaper. Opt. Rev. 2013, 20, 296–302. [Google Scholar] [CrossRef]

- Liu, X.; Xue, C. Design of diffractive optical elements based on axicon and its light analysis. Laser Optoelectron. Prog. 2018, 55, 40501. [Google Scholar]

- Doskolovich, L.L.; Mingazov, A.A.; Byzov, E.V.; Skidanov, R.; Ganchevskaya, S.; Bykov, D.A.; Bezus, E.A.; Podlipnov, V.V.; Porfirev, A.P.; Kazanskiy, N.L. Hybrid design of diffractive optical elements for optical beam shaping. Opt. Express 2021, 29, 31875–31890. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Skidanov, R.V. Binary beam splitter. Appl. Opt. 2012, 51, 2672–2677. [Google Scholar] [CrossRef]

- Doskolovich, L.L.; Bykov, D.A.; Andreev, E.S.; Bezus, E.A.; Oliker, V. Designing double freeform surfaces for collimated beam shaping with optimal mass transportation and linear assignment problems. Opt. Express 2018, 26, 24602–24613. [Google Scholar] [CrossRef]

- Freire, P.; Manuylovich, E.; Prilepsky, J.E.; Turitsyn, S.K. Artificial neural networks for photonic applications—from algorithms to implementation: Tutorial. Adv. Opt. Photonics 2023, 15, 739–834. [Google Scholar] [CrossRef]

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, É.; Egan, D.S.; Vijayaraghavan, R.K.; Joshi, A.M.; Acinas Garzon, V.; Dowling, D.P.; McNally, P.J.; et al. In-situ sensing, process monitoring and machine control in laser powder bed fusion: A review. Addit. Manuf. 2021, 45, 102058. [Google Scholar] [CrossRef]

- Herzog, T.; Brandt, M.; Trinchi, A.; Sola, A.; Molotnikov, A. Process monitoring and machine learning for defect detection in laser-based metal additive manufacturing. J. Intell. Manuf. 2024, 35, 1407–1437. [Google Scholar] [CrossRef]

- Chen, L.; Yao, X.; Chew, Y.; Weng, F.; Moon, S.K.; Bi, G. Data-driven adaptive control for laser-based additive manufacturing with automatic controller tuning. Appl. Sci. 2020, 10, 7967. [Google Scholar] [CrossRef]

- Ukwaththa, J.; Herath, S.; Meddage, D.P.P. A review of machine learning (ML) and explainable artificial intelligence (XAI) methods in additive manufacturing (3D printing). Mater. Today Commun. 2024, 41, 110294. [Google Scholar] [CrossRef]

- Jyeniskhan, N.; Shomenov, K.; Ali, M.H.; Shehab, E. Exploring the integration of digital twin and additive manufacturing technologies. Int. J. Lightweight Mater. Manuf. 2024, 7, 860–881. [Google Scholar] [CrossRef]

- Genty, G.; Salmela, L.; Dudley, J.M.; Brunner, D.; Kokhanovskiy, A.; Kobtsev, S.; Turitsyn, S.K. Machine learning and applications in ultrafast photonics. Nat. Photonics 2021, 15, 91–101. [Google Scholar] [CrossRef]

- Sarkar, D.; Kapil, A.; Sharma, A. Advances in computational modeling for laser powder bed fusion additive manufacturing: A comprehensive review of finite element techniques and strategies. Addit. Manuf. 2024, 85, 104157. [Google Scholar] [CrossRef]

- Karamimoghadam, M.; Rezayat, M.; Moradi, M.; Mateo, A.; Casalino, G. Laser surface transformation hardening for automotive metals: Recent progress. Metals 2024, 14, 339. [Google Scholar] [CrossRef]

- Orazi, L.; Rota, A.; Reggiani, B. Experimental investigation on a novel approach for laser surface hardening modelling. Int. J. Mech. Mater. Eng. 2021, 16, 2. [Google Scholar] [CrossRef]

- Łach, Ł. Recent advances in laser surface hardening: Techniques, modeling approaches, and industrial applications. Crystals 2024, 14, 726. [Google Scholar] [CrossRef]

- Sun, S.-Y.; Zhang, Y.-L.; Liu, G.-S.; Yang, R. Multiphysics modelling and verification of pulse laser surface treatment of an Al alloy. Lasers Eng. 2023, 55, 371–388. [Google Scholar]

- Mosavi, A.; Salehi, F.; Nadai, L.; Karoly, S.; Gorji, N.E. Modeling the temperature distribution during laser hardening process. Results Phys. 2020, 16, 102883. [Google Scholar] [CrossRef]

- Farshidianfar, A.; Nabavi, S.F.; Farshidianfar, M.H. The Laser Manufacturing Process: Fundamentals of Process and Applications; CRC Press: Boca Raton, FL, USA, 2024; 218p. [Google Scholar]

- Stavropoulos, P.; Papacharalampopoulos, A.; Athanasopoulou, L. A molecular dynamics based digital twin for ultrafast laser material removal processes. Int. J. Adv. Manuf. Technol. 2020, 108, 413–426. [Google Scholar] [CrossRef]

- Nabavi, S.F.; Farshidianfar, A.; Dalir, H. A comprehensive review on recent laser beam welding process: Geometrical, metallurgical, and mechanical characteristic modeling. Int. J. Adv. Manuf. Technol. 2023, 129, 4781–4828. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, M. Numerical simulations of oscillating laser welding: A review. J. Manuf. Process. 2024, 119, 744–757. [Google Scholar] [CrossRef]

- Liang, Z.; Shi, Y.; Xu, T.; Wang, Z.; Zhan, J. A complementary approach to experimental modeling and analysis of welding processes: Dimensional analysis. Int. J. Adv. Manuf. Technol. 2023, 127, 3077–3095. [Google Scholar] [CrossRef]

- Liedl, G.; Vázquez, R.G.; Murzin, S.P. Joining of aluminium alloy and steel by laser assisted reactive wetting. Lasers Manuf. Mater. Process. 2018, 5, 1–15. [Google Scholar] [CrossRef]

- Dowden, J.M. The Mathematics of Thermal Modeling: An Introduction to the Theory of Laser Material Processing, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2024; 274p. [Google Scholar]

- Liu, X.; Jiang, D.; Tao, B.; Xiang, F.; Jiang, G.; Sun, Y.; Kong, J.; Li, G. A systematic review of digital twin about physical entities, virtual models, twin data, and applications. Adv. Eng. Inform. 2023, 55, 101876. [Google Scholar] [CrossRef]

- Bevans, B.D.; Carrington, A.; Riensche, A.; Tenequer, A.; Barrett, C.; Halliday, H.S.; Srinivasan, R.; Cole, K.D.; Rao, P. Digital twins for rapid in-situ qualification of part quality in laser powder bed fusion additive manufacturing. Addit. Manuf. 2024, 93, 104415. [Google Scholar] [CrossRef]

- Teng, C.; Pal, D.; Gong, H.; Zeng, K.; Briggs, K.; Patil, N.; Stucker, B. A Review of Defect Modeling in Laser Material Processing. Additive Manuf. 2017, 14, 137–147. [Google Scholar] [CrossRef]

- Su, Y.; Xu, G.; Xu, X.; Zhang, H.; Luo, K.; Lu, J. Melt pool control-assisted additive manufacturing of thin-walled parts. Int. J. Mech. Sci. 2024, 280, 109519. [Google Scholar] [CrossRef]

- Sudmanns, M.; El-Awady, J.A. Connecting processing conditions to microstructure evolution in laser powder bed fusion via defect modeling. Scripta Mater. 2024, 245, 116035. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Bambach, M. Modelling and simulation of metal additive manufacturing processes with particle methods: A review. Virtual Phys. Prototyp. 2023, 18, e2274494. [Google Scholar] [CrossRef]

- Nabavi, S.F.; Farshidianfar, A.; Dalir, H. An applicable review on recent laser beam cutting process characteristics modeling: Geometrical, metallurgical, mechanical, and defect. Int. J. Adv. Manuf. Technol. 2024, 130, 2159–2217. [Google Scholar] [CrossRef]

- Ren, X.; Fan, J.; Pan, R.; Sun, K. Modeling and process parameter optimization of laser cutting based on artificial neural network and intelligent optimization algorithm. Int. J. Adv. Manuf. Technol. 2023, 127, 1177–1188. [Google Scholar] [CrossRef]

- Gong, J.; Shu, L.; Wang, J.; Li, J.; Qin, J. Research status and development trend of laser cladding process optimization method. Laser Optoelectron. Prog. 2023, 60, 1900003. [Google Scholar]

- Bakhtiyari, A.N.; Wang, Z.; Wang, L.; Zheng, H. A Review on applications of artificial intelligence in modeling and optimization of laser beam machining. Optics Laser Technol. 2021, 135, 106721. [Google Scholar] [CrossRef]

- Li, K.; Ma, R.; Qin, Y.; Gong, N.; Wu, J.; Wen, P.; Tan, S.; Zhang, D.Z.; Murr, L.E.; Luo, J. A review of the multi-dimensional application of machine learning to improve the integrated intelligence of laser powder bed fusion. J. Mater. Process. Technol. 2023, 318, 118032. [Google Scholar] [CrossRef]

- Murzin, S.P. Digital engineering in photonics: Optimizing laser processing. Photonics 2024, 11, 935. [Google Scholar] [CrossRef]

- Jin, L.; Zhai, X.; Wang, K.; Zhang, K.; Wu, D.; Nazir, A.; Jiang, J.; Liao, W.-H. Big data, machine learning, and digital twin assisted additive manufacturing: A review. Mater. Des. 2024, 244, 113086. [Google Scholar] [CrossRef]

- El Khediri, S.; Benfradj, A.; Thaljaoui, A.; Moulahi, T.; Khan, R.U.; Alabdulatif, A.; Lorenz, P. Integration of artificial intelligence (AI) with sensor networks: Trends, challenges, and future directions. J. King Saud Univ. Comput. Inf. Sci. 2024, 36, 101892. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Khonina, S.N.; Oseledets, I.V.; Nikonorov, A.V.; Butt, M.A. Revolutionary integration of artificial intelligence with meta-optics-focus on metalenses for imaging. Technologies 2024, 12, 143. [Google Scholar] [CrossRef]

- Tariq, U.; Joy, R.; Wu, S.-H.; Mahmood, M.A.; Malik, A.W.; Liou, F. A state-of-the-art digital factory integrating digital twin for laser additive and subtractive manufacturing processes. Rapid Prototyp. J. 2023, 29, 2061–2097. [Google Scholar] [CrossRef]

- Grant-Jacob, J.A.; Mills, B.; Zervas, M.N. Live imaging of laser machining via plasma deep learning. Opt. Express 2023, 31, 42581–42594. [Google Scholar] [CrossRef]

- Almakayeel, N.; Desai, S.; Alghamdi, S.; Qureshi, M.R.N.M. Smart agent system for cyber nano-manufacturing in Industry 4.0. Appl. Sci. 2022, 12, 6143. [Google Scholar] [CrossRef]

- Grant-Jacob, J.A.; Mills, B.; Zervas, M.N. Real-time control of laser materials processing using deep learning. Manuf. Lett. 2023, 38, 11–14. [Google Scholar] [CrossRef]

- Di Meglio, A.; Massarotti, N.; Nithiarasu, P. A physics-driven and machine learning-based digital twinning approach to transient thermal systems. Int. J. Numer. Methods Heat Fluid Flow 2024, 34, 2229–2256. [Google Scholar] [CrossRef]

- Yu, Y.; Bai, S.; Wang, S.; Hu, A. Ultra-short pulsed laser manufacturing and surface processing of microdevices. Engineering 2018, 4, 779–786. [Google Scholar] [CrossRef]

- Ritto, T.G.; Rochinha, F.A. Digital twin, physics-based model, and machine learning applied to damage detection in structures. Mech. Syst. Signal Process. 2021, 155, 107614. [Google Scholar] [CrossRef]

- Mills, B.; Heath, D.J.; Grant-Jacob, J.A.; Xie, Y.; Eason, R.W. Image-based monitoring of femtosecond laser machining via a neural network. J. Phys. Photonics 2018, 1, 15008. [Google Scholar] [CrossRef]

- Afazov, S.; Roberts, A.; Wright, L.; Jadhav, P.; Holloway, A.; Basoalto, H.; Milne, K.; Brierley, N. Metal powder bed fusion process chains: An overview of modelling techniques. Prog. Addit. Manuf. 2022, 7, 289–314. [Google Scholar] [CrossRef]

- Malik, A.W.; Mahmood, M.A.; Liou, F. Digital twin—driven optimization of laser powder bed fusion processes: A focus on lack-of-fusion defects. Rapid Prototyp. J. 2024, in press. [Google Scholar] [CrossRef]

- Barnowski, D.; Dahmen, M.; Farkas, T.; Petring, D.; Petschke, U.; Pootz, M.; Schal, R.; Stoyanov, S. Multifunctional laser processing with a digital twin. Procedia CIRP 2022, 111, 822–826. [Google Scholar] [CrossRef]

- Casalino, G. Computational intelligence for smart laser materials processing. Opt. Laser Technol. 2018, 100, 165–175. [Google Scholar] [CrossRef]

- Karkaria, V.; Goeckner, A.; Zha, R.; Chen, J.; Zhang, J.; Zhu, Q.; Cao, J.; Gao, R.X.; Chen, W. Towards a digital twin framework in additive manufacturing: Machine learning and Bayesian optimization for time series process optimization. J. Manuf. Syst. 2024, 75, 322–332. [Google Scholar] [CrossRef]

- Mills, B.; Grant-Jacob, J.A. Lasers that learn: The interface of laser machining and machine learning. IET Optoelectron. 2021, 15, 207–224. [Google Scholar] [CrossRef]

- Sefene, E.M. State-of-the-art of selective laser melting process: A comprehensive review. J. Manuf. Syst. 2022, 63, 250–274. [Google Scholar] [CrossRef]

- Gautam, G.D.; Pandey, A.K. Pulsed Nd:YAG laser beam drilling: A review. Opt. Laser Technol. 2018, 100, 183–215. [Google Scholar] [CrossRef]

- Bakhtiyari, A.N.; Wang, Z.; Zheng, H. Feasibility of artificial neural network on modeling laser-induced colors on stainless steel. J. Manuf. Process. 2021, 65, 471–477. [Google Scholar] [CrossRef]

- Stratakis, E.; Bonse, J.; Heitz, J.; Siegel, J.; Tsibidis, G.D.; Skoulas, E.; Papadopoulos, A.; Mimidis, A.; Joel, A.-C.; Comanns, P.; et al. Laser engineering of biomimetic surfaces. Mater. Sci. Eng. R Rep. 2020, 141, 100562. [Google Scholar] [CrossRef]

- Kannatey-Asibu, E., Jr. Principles of Laser Materials Processing: Developments and Applications, 2nd ed.; John Wiley & Sons: Ho-boken, NJ, USA, 2023; 608p. [Google Scholar]

- He, Z.; Lei, L.; Lin, S.; Tian, S.; Tian, W.; Yu, Z.; Li, F. Metal material processing using femtosecond lasers: Theories, principles, and applications. Materials 2024, 17, 3386. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Li, Y.; Du, X.; Fan, H.; Gao, F. Microstructure and tribological performance of boride layers on ductile cast iron under dry sliding conditions. Eng. Fail. Anal. 2022, 134, 106080. [Google Scholar] [CrossRef]

- Tang, Y.; Li, Q.; Fang, Z.; Allegre, O.J.; Tang, Y.; Perrie, W.; Zhu, G.; Whitehead, D.; Schille, J.; Loeschner, U.; et al. Extending the operational limit of a cooled spatial light modulator exposed to 200 W average power for holographic picosecond laser materials processing. Opt. Laser Technol. 2025, 181, 111589. [Google Scholar] [CrossRef]

- Fang, Z.; Zhou, T.; Perrie, W.; Bilton, M.; Schille, J.; Löschner, U.; Edwardson, S.; Dearden, G. Pulse burst generation and diffraction with spatial light modulators for dynamic ultrafast laser materials processing. Materials 2022, 15, 9059. [Google Scholar] [CrossRef]

- Dupuy, J.; Von Horsten, H.; Lamblin, M.; Hernandez, Y. Beam Shaping and Power Handling of a Spatial Light Modulator System for Laser Induced Periodic Surface Structuring Texturation. J. Laser Micro Nanoeng. 2020, 15, 228–231. [Google Scholar]

- Hasegawa, S.; Nozaki, K.; Tanabe, A.; Hashimoto, N.; Hayasaki, Y. Holographic Femtosecond Laser Processing Using 6.3 kHz Pulse-to-Pulse Spatial Light Modulation with Binary Phase Masks. Opt. Laser Technol. 2024, 176, 111014. [Google Scholar] [CrossRef]

- Harrison, J.; Naidoo, D.; Forbes, A.; Dudley, A. Progress in high-power and high-intensity structured light. Adv. Phys. X 2024, 9, 2327453. [Google Scholar] [CrossRef]

- Shirshneva-Vashchenko, E.; Mohammadian, N.; Divliansky, I.; Glebov, L. Modeling of laser beam shaping by volume holographic phase masks. Proc. SPIE 2023, 12402, 124020A. [Google Scholar]

- Han, Z.; Fan, W.; Song, Y.; Huang, D.; Cheng, H.; Pan, H.; Lin, C. Analysis of continuous laser-irradiation resistance of liquid-crystal optical switch based on sapphire-substrate GaN. Appl. Opt. 2024, 63, 4396–4404. [Google Scholar] [CrossRef]

- Du, T.; Huang, D.; Cheng, H.; Fan, W.; Xing, Z.; Zhu, J.; Liu, W. Research on high power laser damage resistant optically addressable spatial light modulator. Photonics 2022, 9, 811. [Google Scholar] [CrossRef]

- Shields, J.; De Galarreta, C.R.; Penketh, H.; Au, Y.-Y.; Bertolotti, J.; Wright, C.D. A Route to ultra-fast amplitude-only spatial light modulation using phase-change materials. Adv. Opt. Mater. 2023, 11, 2300765. [Google Scholar] [CrossRef]

- Hu, X.-B.; Ma, S.-Y.; Rosales-Guzman, C. High-speed generation of singular beams through random spatial multiplexing. J. Opt. 2021, 23, 44002. [Google Scholar] [CrossRef]

- Heath, D.J.; Mackay, B.S.; Grant-Jacob, J.A.; Xie, Y.; Oreffo, R.O.C.; Eason, R.W.; Mills, B. Closed-loop corrective beam shaping for laser processing of curved surfaces. J. Micromech. Microeng. 2018, 28, 127001. [Google Scholar] [CrossRef]

- Popoff, S.M.; Gutierrez-Cuevas, R.; Bromberg, Y.; Matthes, M.W. A practical guide to digital micro-mirror devices (DMDs) for wavefront shaping. J. Phys. Photonics 2024, 6, 43001. [Google Scholar] [CrossRef]

- Doskolovich, L.L.; Mingazov, A.A.; Bykov, D.A.; Bezus, E.A. Formulation of the inverse problem of calculating the optical surface for an illuminating beam with a plane wavefront as the Monge-Kantorovich problem. Comput. Opt. 2019, 43, 705–713. [Google Scholar] [CrossRef]

- Fang, F.Z.; Zhang, X.D.; Weckenmann, A.; Zhang, G.X.; Evans, C. Manufacturing and measurement of freeform optics. CIRP Ann.-Manuf. Technol. 2013, 62, 823–846. [Google Scholar] [CrossRef]

- Doskolovich, L.L.; Skidanov, R.V.; Bezus, E.A.; Ganchevskaya, S.V.; Bykov, D.A.; Kazanskiy, N.L. Design of diffractive lenses operating at several wavelengths. Opt. Express 2020, 28, 11705–11720. [Google Scholar] [CrossRef]

- Khonina, S.N.; Kazanskiy, N.L.; Khorin, P.A.; Butt, M.A. Modern types of axicons: New functions and applications. Sensors 2021, 21, 6690. [Google Scholar] [CrossRef]

- Nikonorov, A.V.; Petrov, M.V.; Bibikov, S.A.; Kutikova, V.V.; Morozov, A.A.; Kazanskiy, N.L. Image restoration in diffractive optical systems using deep learning and deconvolution. Comput. Opt. 2017, 41, 875–887. [Google Scholar] [CrossRef]

- Andreeva, K.V.; Moiseev, M.A.; Kravchenko, S.V.; Doskolovich, L.L. Design of optical elements with TIR freeform surface. Comput. Opt. 2016, 40, 467–474. [Google Scholar] [CrossRef]

- Doskolovich, L.L.; Bykov, D.A.; Andreev, E.S.; Byzov, E.V.; Moiseev, M.A.; Bezus, E.A.; Kazanskiy, N.L. Design and fabrication of freeform mirrors generating prescribed far-field irradiance distributions. Appl. Opt. 2020, 59, 5006–5012. [Google Scholar] [CrossRef] [PubMed]

- Dickey, F.M.; Lizotte, T.E. (Eds.) Laser Beam Shaping Applications, 2nd ed.; CRC Press Taylor & Francis: Boca Raton, FL, USA, 2017; 442p. [Google Scholar]

- Gan, Z.; Peng, X.; Hong, H. An evaluation model for analyzing the overlay error of computer-generated holograms. Curr. Opt. Photonics 2020, 4, 277–285. [Google Scholar]

- Murzin, S.P.; Kazanskiy, N.L. Study of the beam intensity redistribution in the focal plane of diffractive optical element. Proc. SPIE 2019, 11146, 111460V. [Google Scholar]

- Murzin, S.P.; Kazanskiy, N.L. Use of diffractive optical elements for beam intensity redistribution. Proc. SPIE 2020, 11516, 115160H. [Google Scholar]

- Werdehausen, D. Achromatic diffractive optical elements (DOEs) for broadband applications. In Nanocomposites as Next-Generation Optical Materials: Fundamentals, Design and Advanced Applications (Springer Series in Materials Science, 316), 1st ed.; Springer: Cham, Switzerland, 2021; pp. 65–105. [Google Scholar]

- Skidanov, R.V.; Ganchevskaya, S.V.; Vasil’ev, V.S.; Podlipnov, V.V. Experimental study of image-forming lens based on diffractive lenses, correcting aberrations. Opt. Spectrosc. 2021, 129, 581–585. [Google Scholar] [CrossRef]

- Ivliev, N.; Evdokimova, V.; Podlipnov, V.; Petrov, M.; Ganchevskaya, S.; Tkachenko, I.; Abrameshin, D.; Yuzifovich, Y.; Nikonorov, A.; Skidanov, R.; et al. First earth-imaging CubeSat with harmonic diffractive lens. Remote Sens. 2022, 14, 2230. [Google Scholar] [CrossRef]

- Skidanov, R.V.; Ganchevskaya, S.V.; Vasiliev, V.S.; Blank, V.A. Systems of generalized harmonic lenses for image formation. J. Opt. Technol. 2022, 89, 25–32. [Google Scholar] [CrossRef]

- Palmer, C. Diffraction Grating Handbook, 8th ed.; MKS Instruments, Inc.: Rochester, NY, USA, 2020; 251p. [Google Scholar]

- Savelyev, D.A. Peculiarities of focusing circularly and radially polarized super-Gaussian beams using ring gratings with varying relief height. Comput. Opt. 2022, 46, 537–546. [Google Scholar] [CrossRef]

- Kharitonov, S.I.; Doskolovich, L.L.; Kazanskiy, N.L. Solving the inverse problem of focusing laser radiation in a plane region using geometrical optics. Comput. Opt. 2016, 40, 439–450. [Google Scholar] [CrossRef]

- Murzin, S.P.; Kazanskiy, N.L.; Stiglbrunner, C. Analysis of the advantages of laser processing of aerospace materials using diffractive optics. Metals 2021, 11, 963. [Google Scholar] [CrossRef]

- Murzin, S.P.; Stiglbrunner, C. Fabrication of smart materials using laser processing: Analysis and prospects. Appl. Sci. 2024, 14, 85. [Google Scholar] [CrossRef]

- Khonina, S.N.; Kazanskiy, N.L.; Skidanov, R.V.; Butt, M.A. Advancements and applications of diffractive optical elements in contemporary optics: A comprehensive overview. Adv. Mater. Technol. 2024, in press. [Google Scholar] [CrossRef]

- Gao, J.; Guo, J.; Dai, A.; Situ, G. Optical system design: From iterative optimization to artificial intelligence. Zhongguo Jiguang/Chin. J. Lasers 2023, 50, 1101012. [Google Scholar]

- Murzin, S.P.; Bielak, R.; Liedl, G. Algorithm for calculating of the power density distribution of the laser beam to create a desired thermal effect on technological objects. Comput. Opt. 2016, 40, 679–684. [Google Scholar] [CrossRef]

- Wu, R.; Liu, P.; Zhang, Y.; Zheng, Z.; Li, H.; Liu, X. A mathematical model of the single freeform surface design for collimated beam shaping. Opt. Express 2013, 21, 20974–20989. [Google Scholar] [CrossRef]

- Porfirev, A.; Khonina, S.; Meshalkin, A.; Ivliev, N.; Achimova, E.; Abashkin, V.; Prisacar, A.; Podlipnov, V. Two-step maskless fabrication of compound fork-shaped gratings in nanomultilayer structures based on chalcogenide glasses. Opt. Lett. 2021, 46, 3037–3040. [Google Scholar] [CrossRef]

- Kononenko, T.V.; Sovyk, D.N.; Pivovarov, P.A.; Pavelyev, V.S.; Mezhenin, A.V.; Cherepanov, K.V.; Komlenok, M.S.; Sorochenko, V.R.; Khomich, A.A.; Pashinin, V.P.; et al. Fabrication of diamond diffractive optics for powerful CO2 lasers via replication of laser microstructures on silicon template. Diam. Relat. Mater. 2020, 101, 107656. [Google Scholar] [CrossRef]

- Volodkin, B.; Choporova, Y.; Knyazev, B.; Kulipanov, G.; Pavelyev, V.; Soifer, V.; Vinokurov, N. Fabrication and characterization of diffractive phase plates for forming high-power terahertz vortex beams using free electron laser radiation. Opt. Quantum Electron. 2016, 48, 223. [Google Scholar] [CrossRef]

- Kazanskiy, N.L. Modeling diffractive optics elements and devices. Proc. SPIE 2018, 10774, 107740. [Google Scholar]

- Khonina, S.; Kazanskiy, N.; Efimov, A.; Nikonorov, A.; Oseledets, I.; Skidanov, R.; Butt, M. A perspective on the artificial intelligence’s transformative role in advancing diffractive optics. iScience 2024, 27, 110270. [Google Scholar] [CrossRef] [PubMed]

- Velli, M.-C.; Tsibidis, G.D.; Mimidis, A.; Pantazis, Y.; Stratakis, E. Predictive modeling approaches in laser-based material processing. J. Appl. Phys. 2020, 128, 18235. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, P.; Yu, Z.; Gao, Y.; Zhang, H.; Chen, H.; Chen, S.; Tian, Y. Progress and perspectives of in-situ optical monitoring in laser beam welding: Sensing, characterization, and modeling. J. Manuf. Process. 2023, 75, 767–791. [Google Scholar] [CrossRef]

- Fang, Z.-C.; Wu, Z.-L.; Huang, C.-G.; Wu, C.-W. Review on residual stress in selective laser melting additive manufacturing of alloy parts. Optics Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- Wu, S.-H.; Tariq, U.; Joy, R.; Sparks, T.; Flood, A.; Liou, F. Experimental, computational, and machine learning methods for prediction of residual stresses in laser additive manufacturing: A critical review. Materials 2024, 17, 1498. [Google Scholar] [CrossRef]

- Li, Y.; Wang, K.; Fu, H.; Zhi, X.; Guo, X.; Lin, J. Prediction for dilution rate of AlCoCrFeNi coatings by laser cladding based on a BP Neural Network. Coatings 2021, 11, 1402. [Google Scholar] [CrossRef]

- Ma, Z.-X.; Cheng, P.-X.; Ning, J.; Zhang, L.-J.; Na, S.-J. Innovations in monitoring, control and design of laser and laser-arc hybrid welding processes. Metals 2021, 11, 1910. [Google Scholar] [CrossRef]

- Shu, L.; Ma, D.; Cao, S.; Wang, Y.; Jiang, P.; Geng, S. Optical coherence measurement-based penetration depth monitoring of stainless steel sheets in laser lap welding using long short-term memory network. Opt. Laser Technol. 2025, 181, 111811. [Google Scholar] [CrossRef]

- Lu, R.; Lou, M.; Xia, Y.; Huang, S.; Li, Z.; Lyu, T.; Wu, Y.; Li, Y. Machine learning-based in-process monitoring for laser deep penetration welding: A survey. Eng. Appl. Artif. Intell. 2024, 137, 109059. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.; Wu, Y.; Wang, H. Predicting the printability in selective laser melting with a supervised machine learning method. Materials 2020, 13, 5063. [Google Scholar] [CrossRef]

- Regassa Hunde, B.; Debebe Woldeyohannes, A. Future prospects of computer-aided design (CAD)—A review from the perspective of artificial intelligence (AI), extended reality, and 3D printing. Results Eng. 2022, 14, 100478. [Google Scholar] [CrossRef]

- Tsai, C.-C.; Yiu, T.-H. Investigation of laser ablation quality based on data science and machine learning XGBoost classifier. Appl. Sci. 2024, 14, 326. [Google Scholar] [CrossRef]

- Klimpel, A. Review and analysis of modern laser beam welding processes. Materials 2024, 17, 4657. [Google Scholar] [CrossRef] [PubMed]

- Piccininni, A.; Palumbo, G. Numerical modelling of the annealing determined by short-term laser treatment using a physical simulation-based approach. CIRP J. Manuf. Sci. Technol. 2023, 45, 210–224. [Google Scholar] [CrossRef]

- Castro Cerda, F.M.; Goulas, C.; Jones, D.; Méndez, P.; Wood, G. Modelling the laser surface hardening process in a steel with a spheroidized initial microstructure. J. Manuf. Process. 2024, 125, 364–373. [Google Scholar] [CrossRef]

- Wallerstein, D.; Salminen, A.; Lusquiños, F.; Badaoui, A.; Pou, J. Recent developments in laser welding of aluminum alloys to steel. Metals 2021, 11, 622. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Takahashi, T.; Nakazato, T.; Sakurai, H.; Tamaru, H.; Ishikawa, K.; Sakaue, K.; Tani, S. Fully automated data acquisition for laser production cyber-physical system. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 9411653. [Google Scholar] [CrossRef]

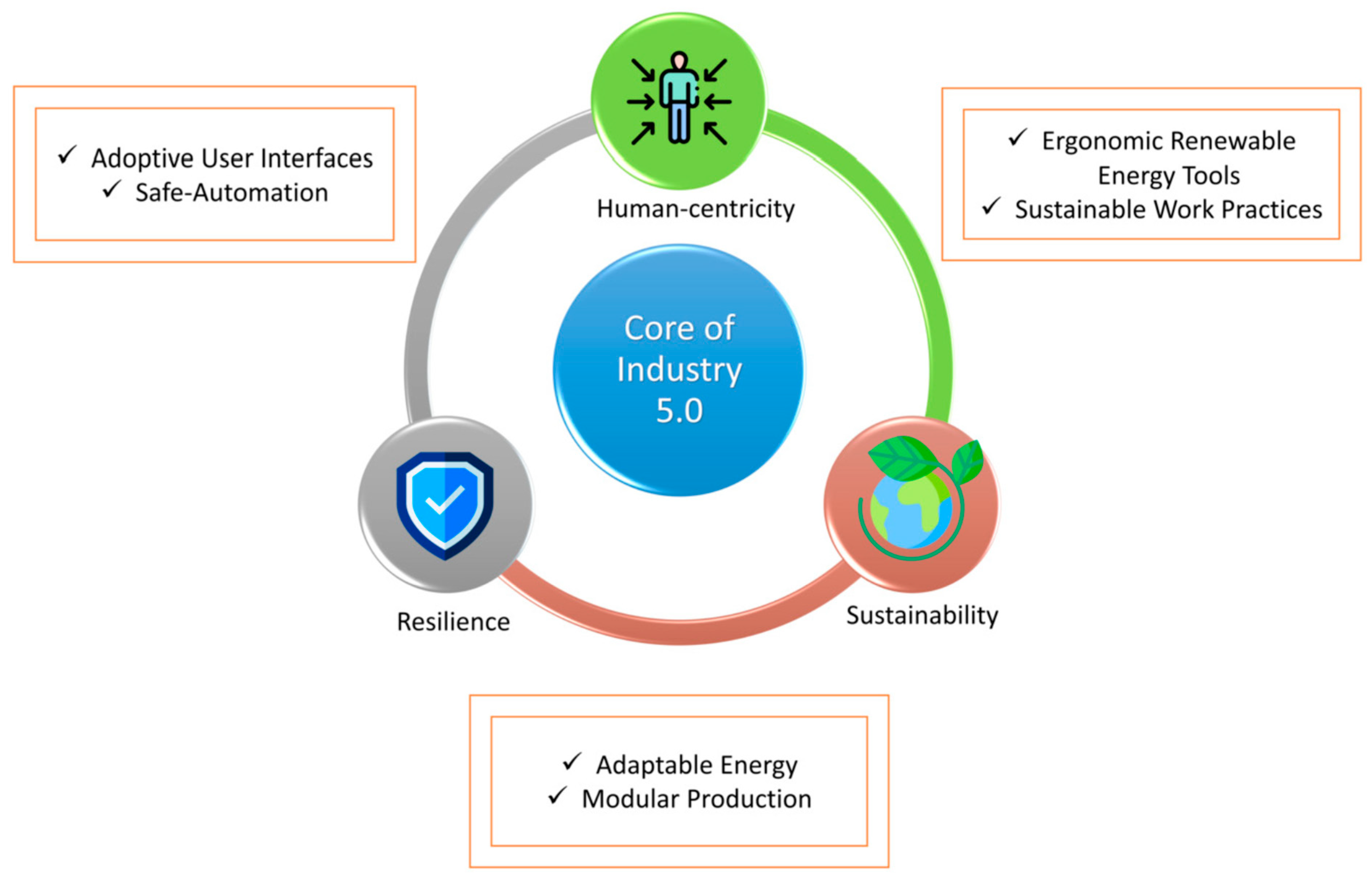

- Murtaza, A.A.; Saher, A.; Zafar, M.H.; Moosavi, S.K.R.; Aftab, M.F.; Sanfilippo, F. Paradigm shift for predictive maintenance and condition monitoring from Industry 4.0 to Industry 5.0: A systematic review, challenges and case study. Results Eng. 2024, 24, 102935. [Google Scholar] [CrossRef]

- Sahar, T.; Rauf, M.; Murtaza, A.; Khan, L.A.; Ayub, H.; Jameel, S.M.; Ahad, I.U. Anomaly detection in laser powder bed fusion using machine learning: A review. Results Eng. 2023, 17, 100803. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murzin, S.P. Computer Science Integrations with Laser Processing for Advanced Solutions. Photonics 2024, 11, 1082. https://doi.org/10.3390/photonics11111082

Murzin SP. Computer Science Integrations with Laser Processing for Advanced Solutions. Photonics. 2024; 11(11):1082. https://doi.org/10.3390/photonics11111082

Chicago/Turabian StyleMurzin, Serguei P. 2024. "Computer Science Integrations with Laser Processing for Advanced Solutions" Photonics 11, no. 11: 1082. https://doi.org/10.3390/photonics11111082

APA StyleMurzin, S. P. (2024). Computer Science Integrations with Laser Processing for Advanced Solutions. Photonics, 11(11), 1082. https://doi.org/10.3390/photonics11111082