Numerical Study on Mixed Convection Flow and Energy Transfer in an Inclined Channel Cavity: Effect of Baffle Size

Abstract

:1. Introduction

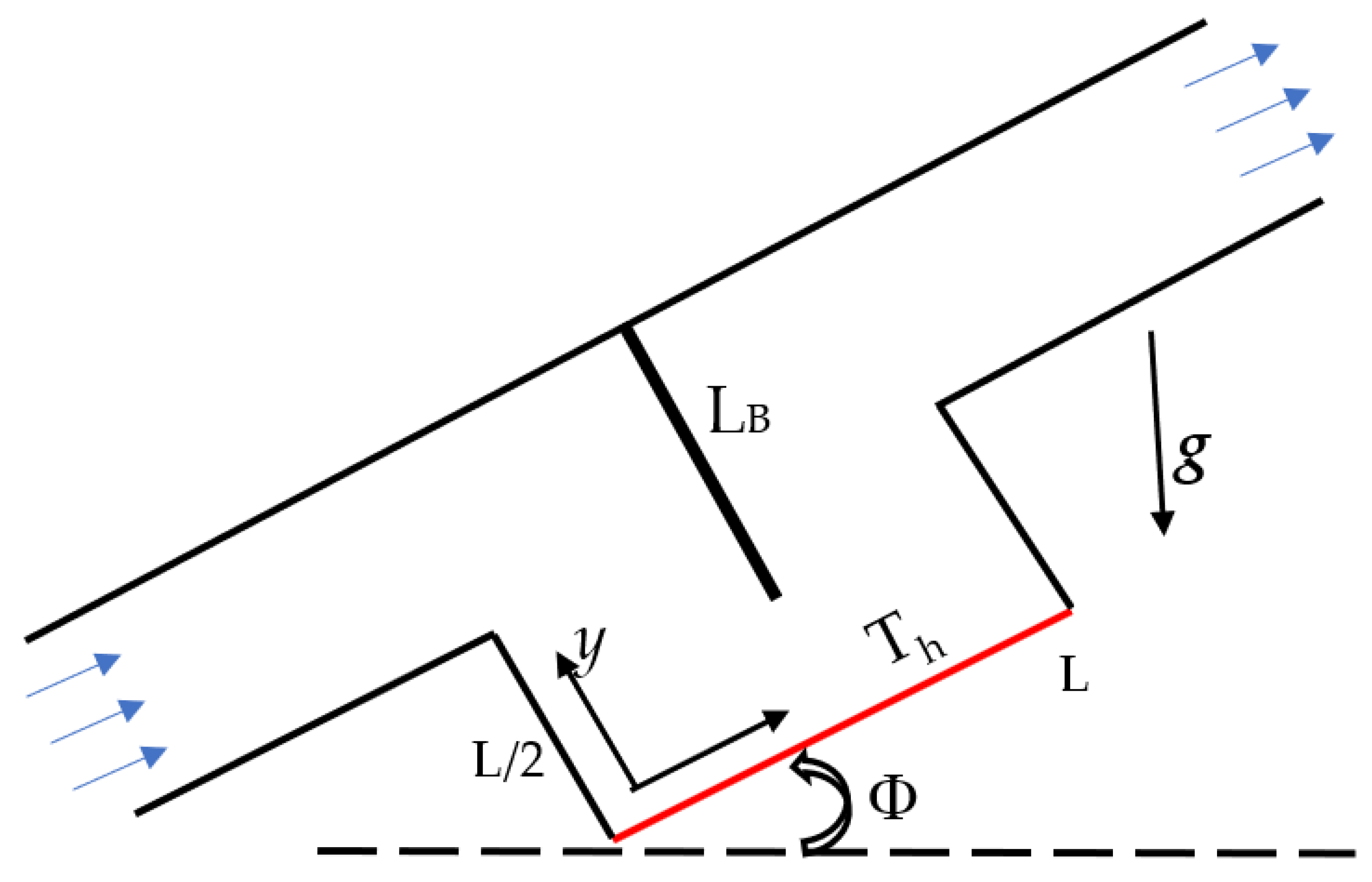

2. Mathematical Methods

3. Numerical Method

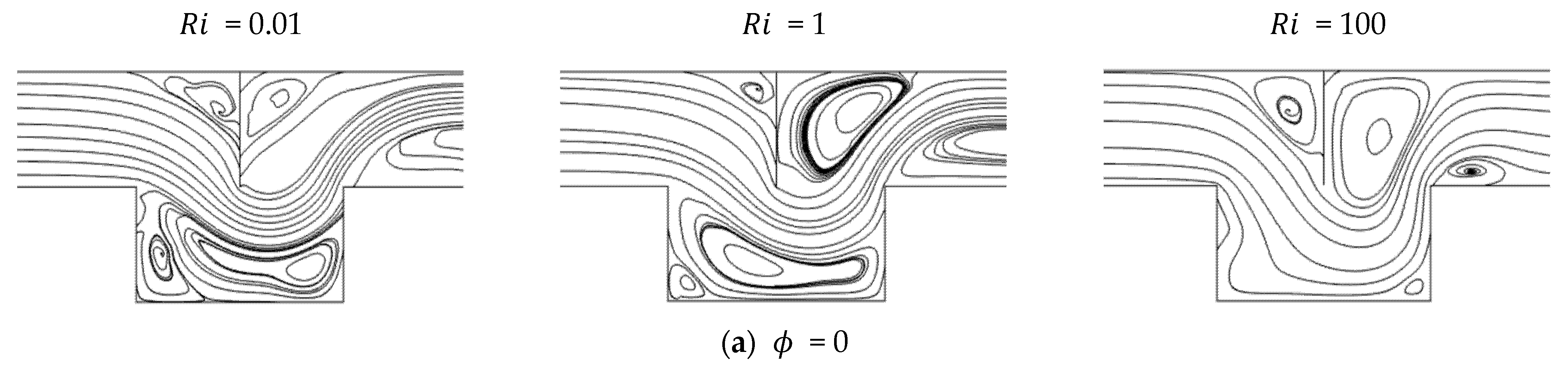

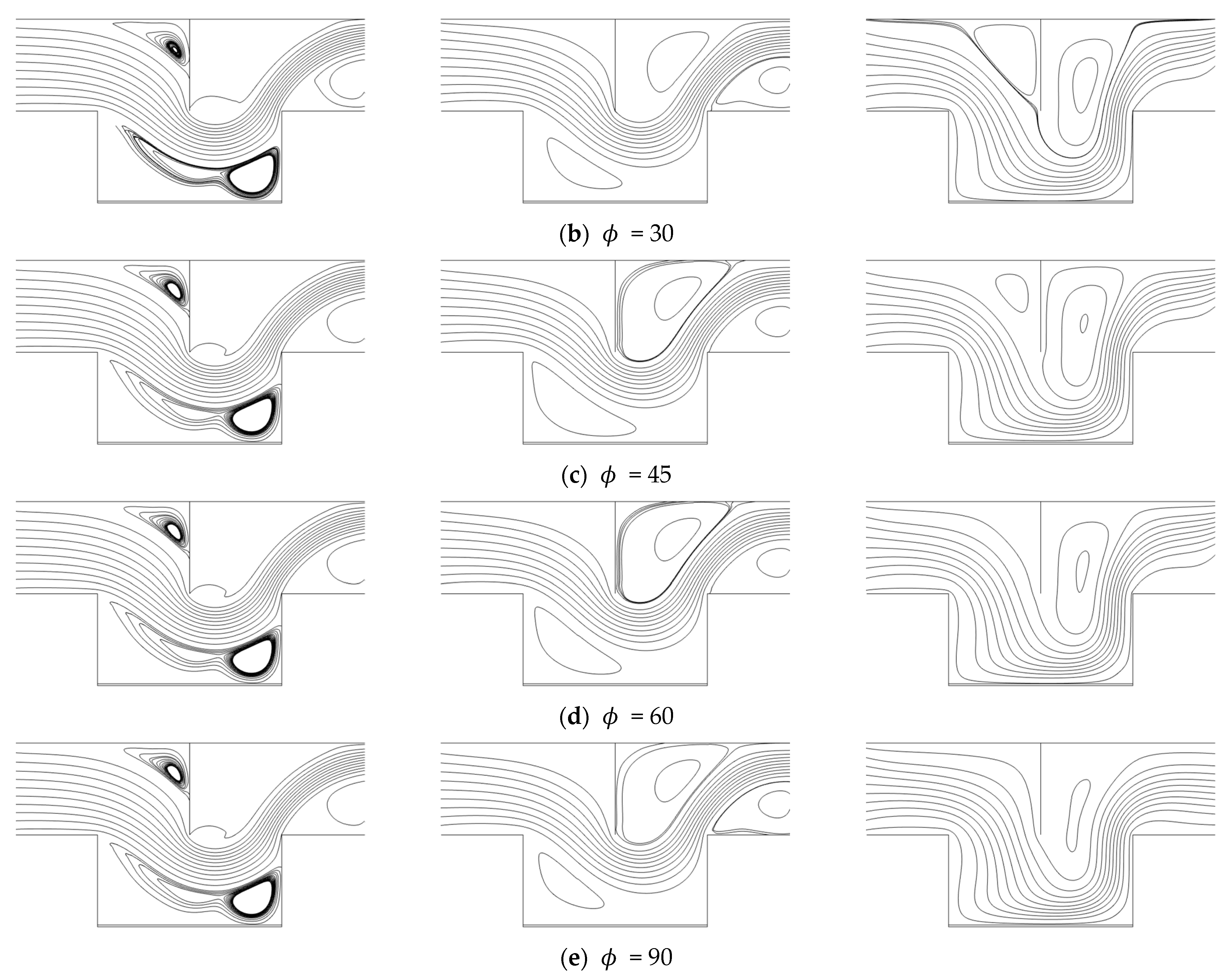

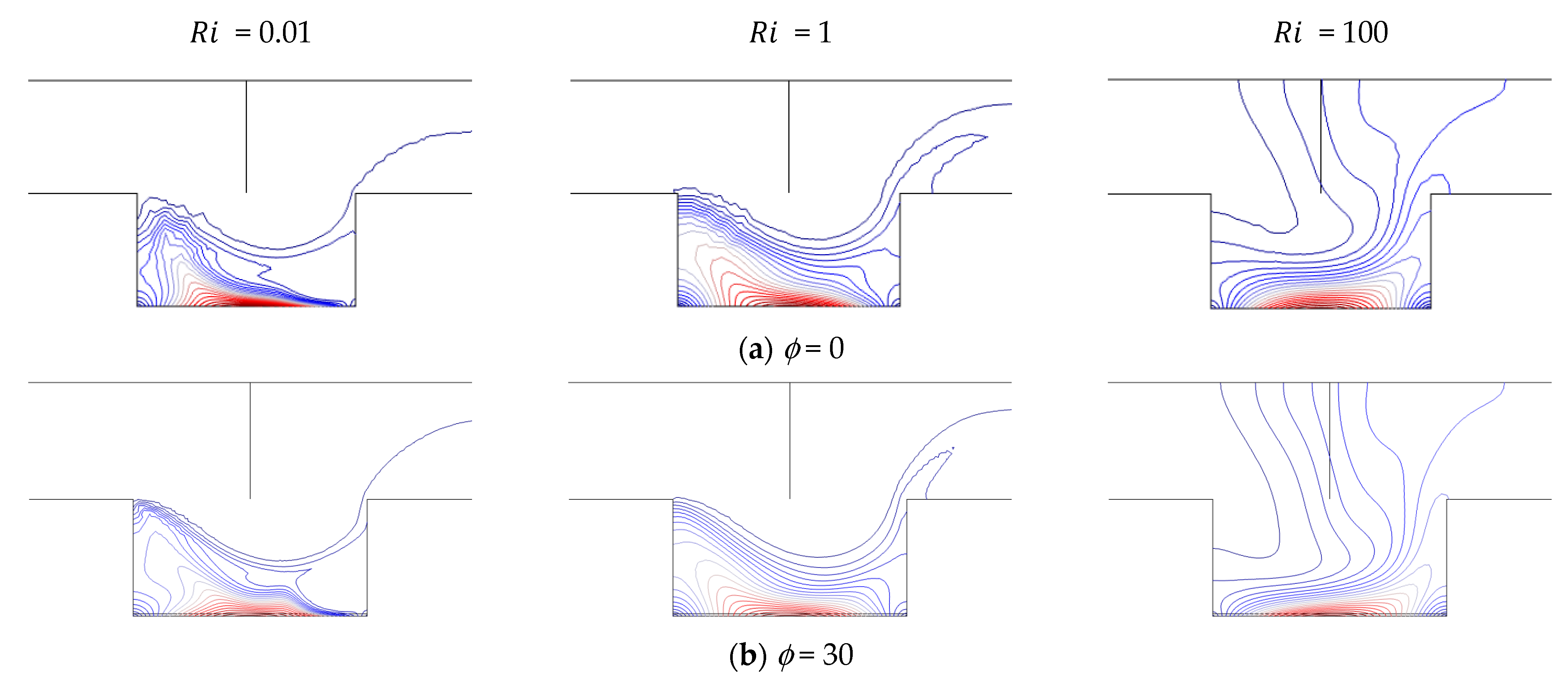

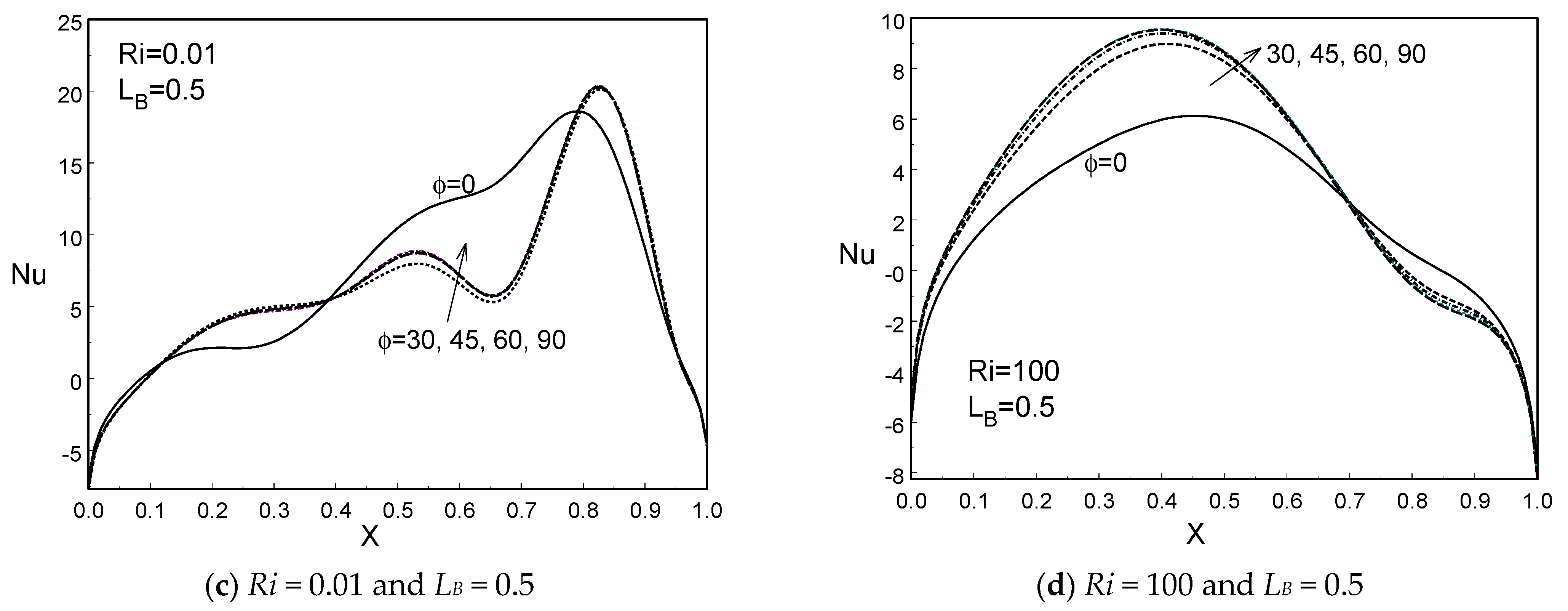

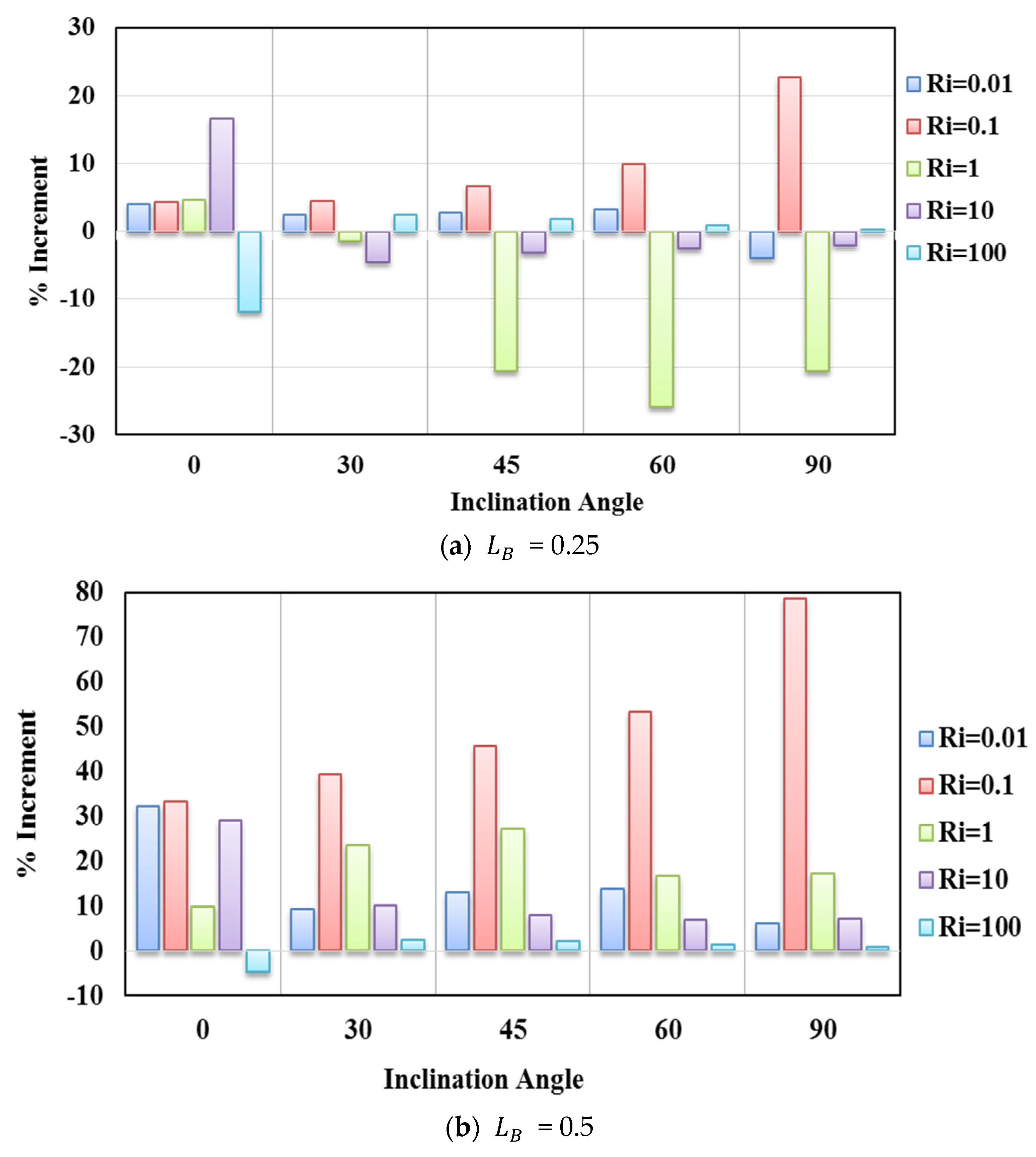

4. Results and Discussion

5. Conclusions

- ○

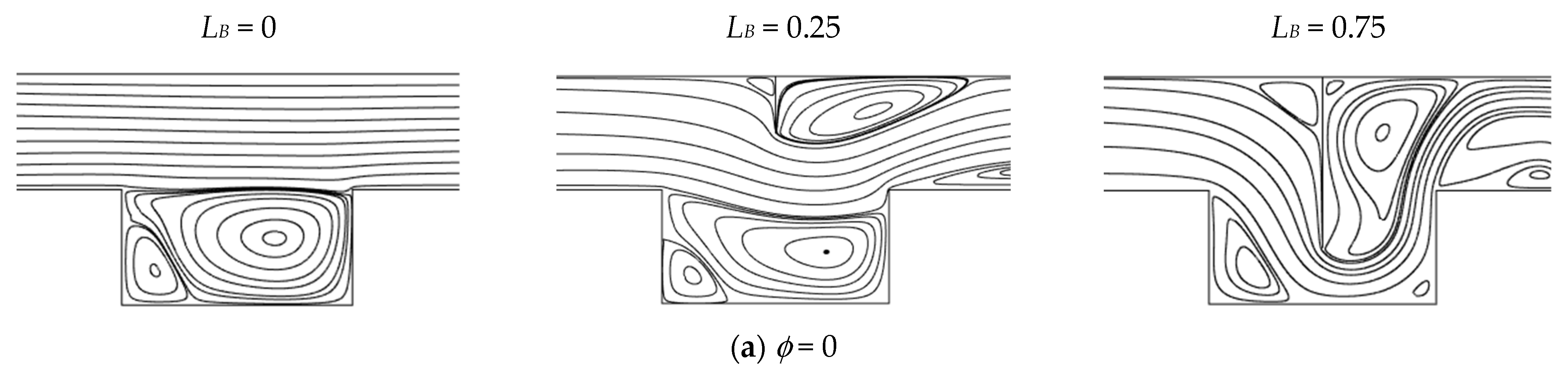

- The recirculating eddies beside the baffle become weak or disappear when increasing the inclination angle of the channel cavity.

- ○

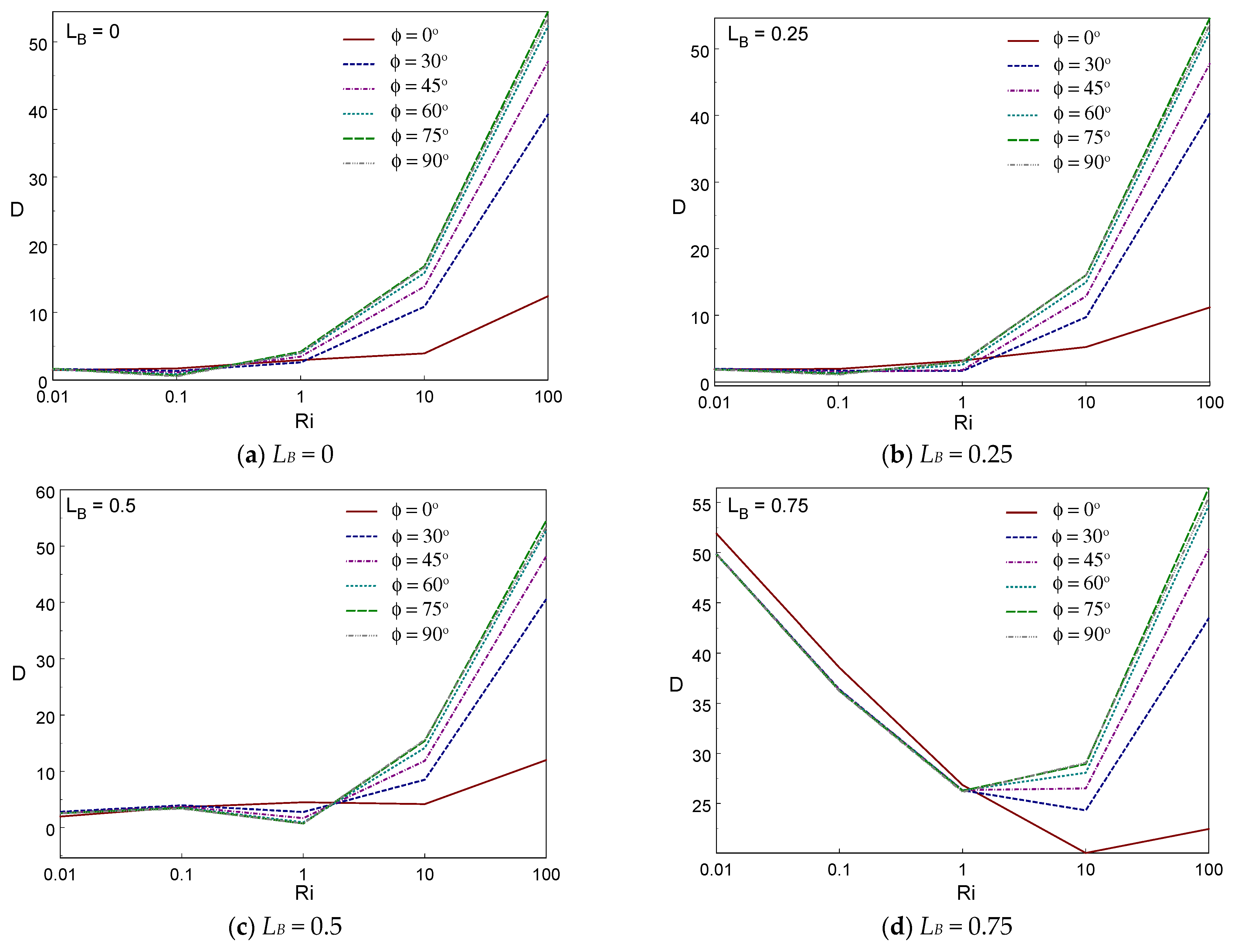

- The energy transfer enriches when enhancing the baffle size since the stream further induces the inner part of the cavity with the existence of the partition, resulting in an enormous energy transference within the cavity.

- ○

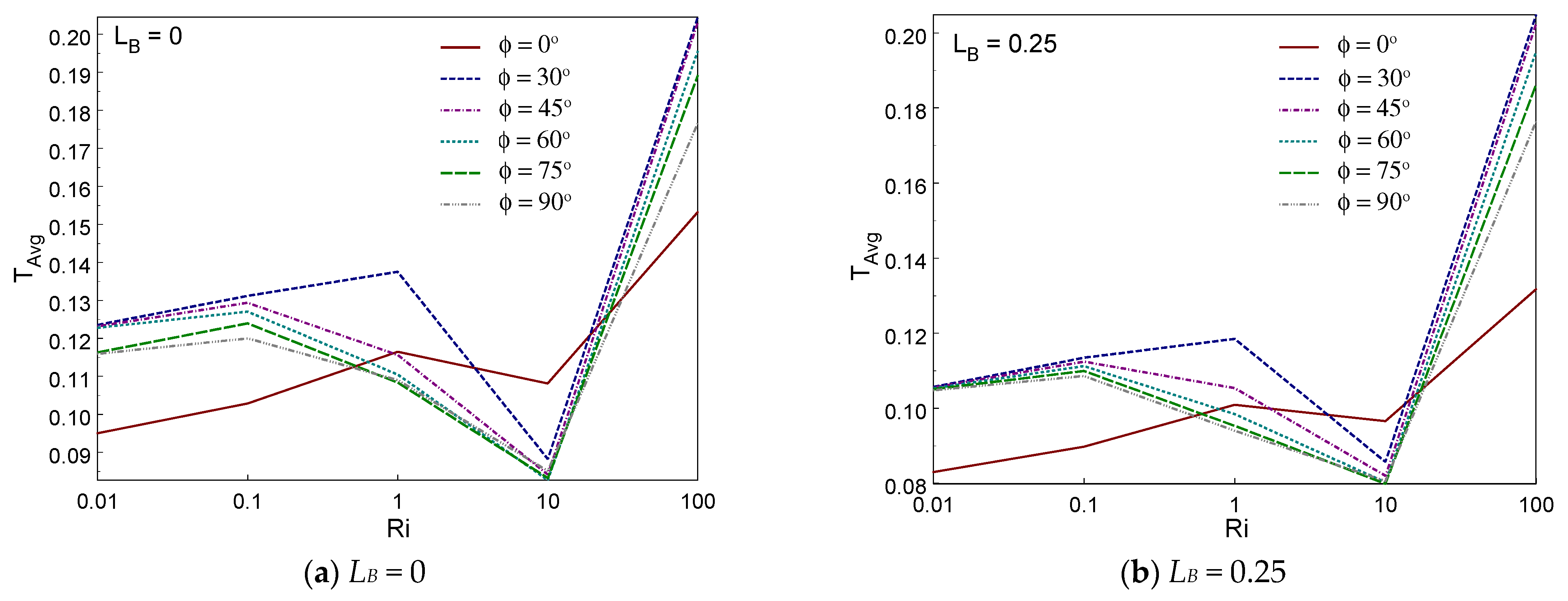

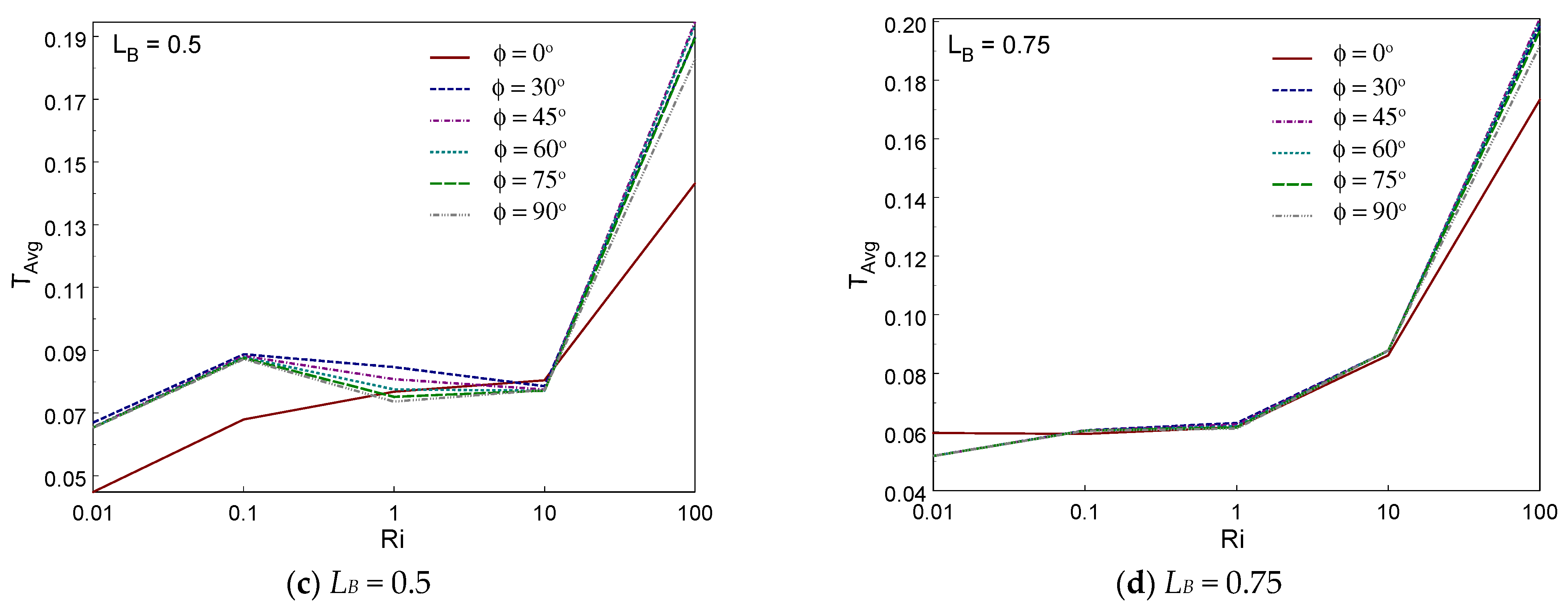

- The average thermal energy transportation reduces steadily until the Ri = 1 and then it rises for all inclination angles and lengths of the baffle. When comparing the inclination angles, no constant angle provides a higher heat transport inside the channel cavity.

- ○

- The increment of energy transference enhances when increasing the size of the baffle. The highest quantity of heat transport is found to be about 450% with the occurrence of a baffle.

Author Contributions

Funding

Conflicts of Interest

References

- You, X.; Li, S. Fully Developed Opposing Mixed Convection Flow in the Inclined Channel Filled with a Hybrid Nanofluid. Nanomaterials 2021, 11, 1107. [Google Scholar] [CrossRef] [PubMed]

- Borrelli, A.; Giantesio, G.; Patria, M.C. Magnetohydrodynamic Flow of a Bingham Fluid in a Vertical Channel: Mixed Convection. Fluids 2021, 6, 154. [Google Scholar] [CrossRef]

- Khan, S.I.U.; Alzahrani, E.; Khan, U.; Zeb, N.; Zeb, A. On Mixed Convection Squeezing Flow of Nanofluids. Energies 2020, 13, 3138. [Google Scholar] [CrossRef]

- Mohamed, A.B.; Hdidi, W.; Tlili, I. Evaporation of Water/Alumina Nanofluid Film by Mixed Convection Inside Heated Vertical Channel. Appl. Sci. 2020, 10, 2380. [Google Scholar] [CrossRef] [Green Version]

- Armaghani, T.; Ismael, M.A.; Chamkha, A.J.; Pop, I. Mixed Convection and Entropy Generation of an Ag-Water Nanofluid in an Inclined L-Shaped Channel. Energies 2019, 12, 1150. [Google Scholar] [CrossRef] [Green Version]

- Ozgen, F.; Varol, Y. Numerical Study of Mixed Convection in a Channel Filled with a Porous Medium. Appl. Sci. 2019, 9, 211. [Google Scholar] [CrossRef] [Green Version]

- Carozza, A. Numerical Study on Mixed Convection in Ventilated Cavities with Different Aspect Ratios. Fluids 2018, 3, 11. [Google Scholar] [CrossRef] [Green Version]

- Sivasankaran, S.; Sivakumar, V.; Hussein, A.K. Numerical study on mixed convection in a lid-driven cavity with discrete heating. Int. Comm. Heat Mass Transf. 2013, 46, 112–125. [Google Scholar] [CrossRef]

- Roy, M.; Roy, S.; Basak, T. Role of various moving walls on energy transfer rates via heat flow visualization during mixed convection in square cavities. Energy 2015, 82, 1–22. [Google Scholar] [CrossRef]

- Sivasankaran, S.; Niranjan, H.; Bhuvaneswari, M. Chemical reaction, radiation and slip effects on MHD mixed convection stagnation-point flow in a porous medium with convective boundary condition. Int. J. Numer. Methods Heat Fluid Flow 2017, 27, 454–470. [Google Scholar] [CrossRef]

- Manca, O.; Nardini, S.; Khanafer, K.; Vafai, K. Effect of heated wall position on mixed convection in a channel with an open cavity. Numer. Heat Transfer A 2003, 43, 259–282. [Google Scholar] [CrossRef]

- Leong, J.C.; Brown, N.M.; Lai, F.C. Mixed convection from an open cavity in a horizontal channel. Int. Comm. Heat Mass Transf. 2005, 32, 583–592. [Google Scholar] [CrossRef]

- Rahman, M.M.; Öztop, H.F.; Saidur, R.; Mekhilef, S.; Al-Salem, K. Finite element solution of MHD mixed convection in a channel with a fully or partially heated cavity. Comput. Fluids 2013, 79, 53–64. [Google Scholar] [CrossRef]

- Rahman, M.M.; Parvin, S.; Saidur, R.; Rahim, N.A. Magneto-hydrodynamic mixed convection in a horizontal channel with an open cavity. Int. Comm. Heat Mass Transf. 2011, 38, 184–193. [Google Scholar] [CrossRef]

- Sharma, A.K.; Mahapatra, P.S.; Manna, N.K.; Ghosh, K. Mixed convection heat transfer in a grooved channel in the presence of a baffle. Numer. Heat Transf. Part A 2015, 67, 1097–1118. [Google Scholar] [CrossRef]

- Janagi, K.; Sivasankaran, S.; Bhuvaneswari, M.; Eswaramurthi, M. Numerical study on free convection of cold water in a square porous cavity with sinusoidal wall temperature. Int. J. Numer. Methods Heat Fluid Flow 2017, 27, 1000–1014. [Google Scholar] [CrossRef]

- Cheong, H.T.; Sivasankaran, S.; Bhuvaneswari, M. Natural convection in a wavy porous cavity with sinusoidal heating and internal heat generation. Int. J. Numer. Methods Heat Fluid Flow 2017, 27, 287–309. [Google Scholar] [CrossRef]

- Sivasankaran, S.; Bhuvaneswari, M. Natural convection in a porous cavity with sinusoidal heating on both sidewalls. Numeri. Heat Transf. A 2013, 63, 14–30. [Google Scholar] [CrossRef]

- Bhuvaneswari, M.; Sivasankaran, S.; Kim, Y.J. Magneto-convection in an enclosure with sinusoidal temperature distributions on both sidewalls. Numer. Heat Transf. A 2011, 59, 167–184. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Wang, J.; Baleta, J.; Min, C.; Sundén, B. Effects of gravity and variable thermal properties on nanofluid convective heat transfer using connected and unconnected walls. Energy Convers. Manag. 2018, 171, 1440–1448. [Google Scholar] [CrossRef]

- Bhardwaj, S.; Dalal, A.; Pati, S. Influence of wavy wall and non-uniform heating on natural convection heat transfer and entropy generation inside porous complex enclosure. Energy 2015, 79, 467–481. [Google Scholar] [CrossRef]

- Sivasankaran, S.; Cheong, H.T.; Bhuvaneswari, M.; Ganesan, P. Effect of moving wall direction on mixed convection in an inclined lid-driven square cavity with sinusoidal heating. Numer. Heat Transf. A 2016, 69, 630–642. [Google Scholar] [CrossRef]

- Cheong, H.T.; Siri, Z.; Sivasankaran, S. Effect of aspect ratio on natural convection in an inclined rectangular enclosure with sinusoidal boundary condition. Int. Comm. Heat Mass Transf. 2013, 45, 75–85. [Google Scholar] [CrossRef]

- Sivakumar, V.; Sivasankaran, S. Mixed convection in an inclined lid-driven cavity with non-uniform heating on both sidewalls. J. Appl. Mech. Tech. Phy. 2014, 55, 634–649. [Google Scholar] [CrossRef]

- Hadidi, N.; Bennacer, R.; Ould-amer, Y. Two-dimensional thermosolutal natural convective heat and mass transfer in a bi-layered and inclined porous enclosure. Energy 2015, 93, 2582–2592. [Google Scholar] [CrossRef]

- Wang, H.; Chen, J.; Dai, P.; Zhang, F.; Li, Q. Simulation and Experimental Study of the Influence of the Baffles on Solar Chimney Power Plant System. Processes 2021, 9, 902. [Google Scholar] [CrossRef]

- Thao, P.B.; Truyen, D.C.; Phu, N.M. CFD Analysis and Taguchi-Based Optimization of the Thermohydraulic Performance of a Solar Air Heater Duct Baffled on a Back Plate. Appl. Sci. 2021, 11, 4645. [Google Scholar] [CrossRef]

- Alazwari, M.A.; Safaei, M.R. Combination Effect of Baffle Arrangement and Hybrid Nanofluid on Thermal Performance of a Shell and Tube Heat Exchanger Using 3-D Homogeneous Mixture Model. Mathematics 2021, 9, 881. [Google Scholar] [CrossRef]

- Yu, L.; Xue, M.; Zhu, A. Numerical Investigation of Sloshing in Rectangular Tank with Permeable Baffle. J. Mar. Sci. Eng. 2020, 8, 671. [Google Scholar] [CrossRef]

- Mahapatra, S.K.; Sarkar, A. Numerical simulation of opposing mixed convection in differentially heated square enclosure with partition. Int. J. Therm. Sci. 2007, 46, 970–979. [Google Scholar] [CrossRef]

- Ilis, G.G.; Mobedi, M.; Oztop, H.F. Heat transfer reduction due to a ceiling-mounted barrier in an enclosure with natural convection. Heat Transf. Eng. 2011, 32, 429–438. [Google Scholar] [CrossRef] [Green Version]

- Khatamifar, M.; Lin, W.; Armfield, S.W.; Holmes, D.; Kirkpatrick, M.P. Conjugate natural convection heat transfer in a partitioned differentially-heated square cavity. Int. Comm. Heat Mass Transf. 2017, 81, 92–103. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sivasankaran, S.; Janagi, K. Numerical Study on Mixed Convection Flow and Energy Transfer in an Inclined Channel Cavity: Effect of Baffle Size. Math. Comput. Appl. 2022, 27, 9. https://doi.org/10.3390/mca27010009

Sivasankaran S, Janagi K. Numerical Study on Mixed Convection Flow and Energy Transfer in an Inclined Channel Cavity: Effect of Baffle Size. Mathematical and Computational Applications. 2022; 27(1):9. https://doi.org/10.3390/mca27010009

Chicago/Turabian StyleSivasankaran, Sivanandam, and Kandasamy Janagi. 2022. "Numerical Study on Mixed Convection Flow and Energy Transfer in an Inclined Channel Cavity: Effect of Baffle Size" Mathematical and Computational Applications 27, no. 1: 9. https://doi.org/10.3390/mca27010009

APA StyleSivasankaran, S., & Janagi, K. (2022). Numerical Study on Mixed Convection Flow and Energy Transfer in an Inclined Channel Cavity: Effect of Baffle Size. Mathematical and Computational Applications, 27(1), 9. https://doi.org/10.3390/mca27010009