Production of Extrudate Food with Mango By-Products (Mangifera indica): Analysis of Physical, Chemical, and Sensorial Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production of Mango Peel Flour and Kernel Mango Flour

Chemical Analysis

2.3. Extrusion Process

2.4. Physical Properties

2.4.1. Expansion Index (EI)

2.4.2. Hardness

2.4.3. Water Absorption Index (WAI) and Water Solubility Index (WSI)

2.5. Chemical Properties

2.5.1. Preparation of Sample Extracts

2.5.2. Total Polyphenol Determination

2.5.3. Determination of Antioxidant Activity

2.6. Sensory Evaluation of Extrudates

2.7. Experimental Design and Statistical Analysis

3. Results and Discussion

3.1. Production of Mango Peel and Kernel Flour

3.1.1. Characterization of Mango Fruit

3.1.2. Characterization of Flours

3.2. Physical Properties

3.2.1. Expansion Index (EI)

3.2.2. Hardness

3.2.3. The Water Absorption Index (WAI)

3.2.4. The Water Solubility Index (WSI)

3.3. Chemical Properties of Extrudates

3.3.1. Total Polyphenol

3.3.2. Antioxidant Activity

DPPH

ABTS

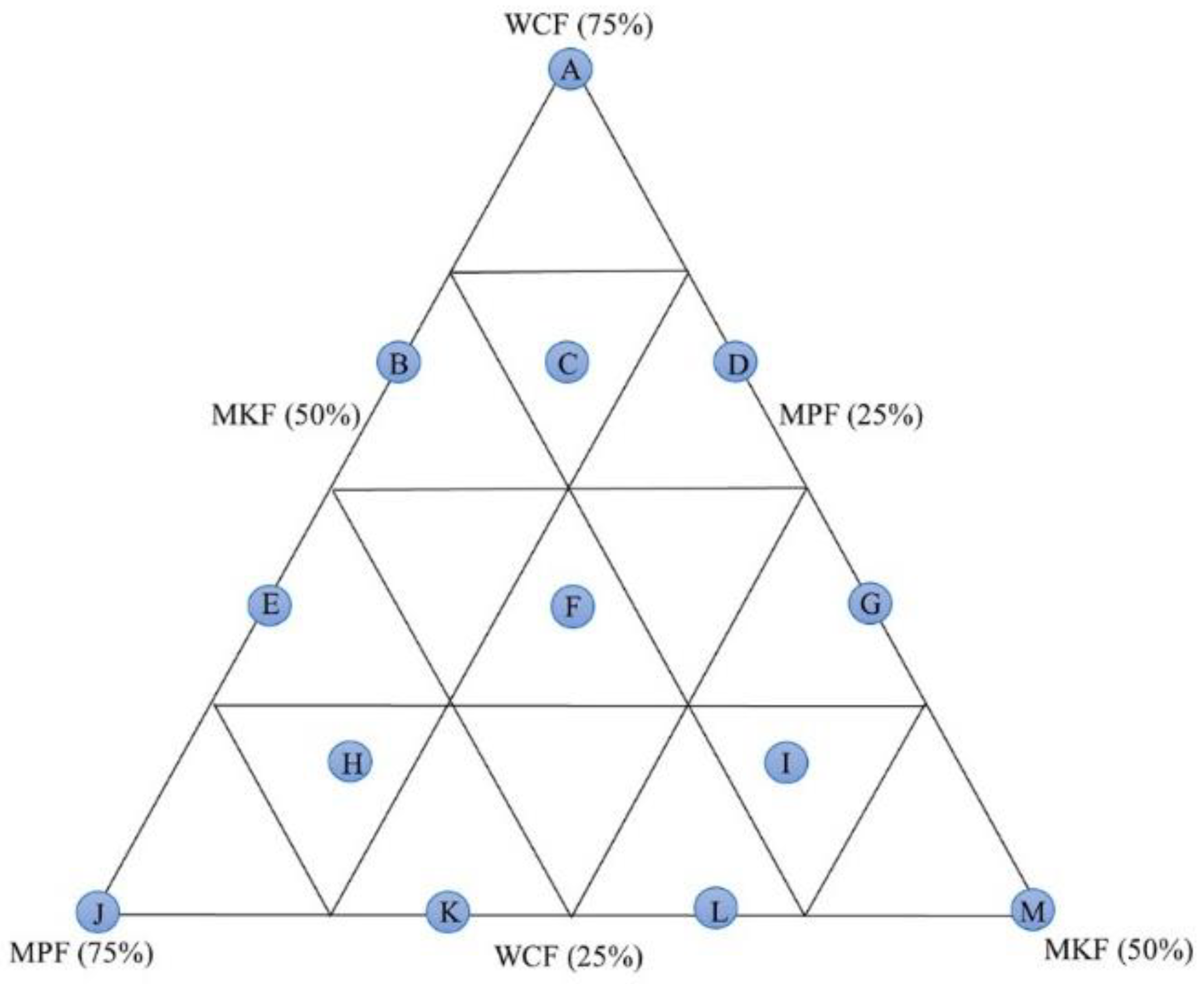

3.4. Mixture Design

3.5. Optimization Mixture Design

3.6. Sensory Evaluation of Extrudates

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). Production Quantities of Mangoes, Mangosteens and Guavas 2019. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 14 February 2021).

- Servicio de Información Agroalimentaria y Pesquera (SIAP). Panorama Agroalimentario 2020. Available online: https://nube.siap.gob.mx/gobmx_publicaciones_siap/pag/2020/Atlas-Agroalimentario-2020 (accessed on 14 February 2021).

- Sumaya-Martínez, M.; Medina-Carrillo, R.E.; González-Ocegueda, E.; Jiménez-Ruiz, E.I.; Balois-Morales, R.; Sánchez-Herrera, M.L.; López-Nahuatt, G. Mango (Mangifera indica L.) pulping byproducts: Antioxidant activity and bioactive compounds of three mango cultivars antioxidant activity by-products of mango. Rev. Bio Cienc. 2019, 6, 1–20. [Google Scholar]

- Tirado-Kulieva, V.; Atoche-Dioses, S.; Hernández-Martínez, E. Phenolic compounds of mango (Mangifera indica) by-products: Antioxidant and antimicrobial potential, use in disease prevention and food industry, methods of extraction and microencapsulation. Sci. Agropecu. 2021, 12, 283–293. [Google Scholar] [CrossRef]

- Marçal, S.; Pintado, M. Mango peels as food ingredient/additive: Nutritional value, processing, safety and applications. Trends Food Sci. Technol. 2021, 114, 472–489. [Google Scholar] [CrossRef]

- Choton, S.; Gupta, N.; Bandral, J.D.; Anjum, N.; Choudary, A. Extrusion technology and its application in food processing: A review. Pharma Innov. J. 2020, 9, 162–168. [Google Scholar] [CrossRef]

- Dey, D.; Richter, J.K.; Ek, P.; Gu, B.J.; Ganjyal, G.M. Utilization of Food Processing By-products in Extrusion Processing: A Review. Front. Sustain. Food Syst. 2021, 4, 3751. [Google Scholar] [CrossRef]

- Mazlan, M.M.; Talib, R.A.; Taip, F.S.; Chin, N.L.; Sulaiman, R.; Shukri, R.; Nor, M.Z.M. Changes in the physical properties and specific mechanical energy of corn-mango peel extrudates. CyTA-J. Food 2020, 18, 417–426. [Google Scholar] [CrossRef]

- Grasso, S. Extruded snacks from industrial by-products: A review. Trends Food Sci. Technol. 2020, 99, 284–294. [Google Scholar] [CrossRef]

- Siller-Cepeda, J.; Muy-Rangel, D.; Báez-Sañudo, M.; Araiza-Lizarde, E.; Ireta-Ojeda, A. Calidad poscosecha de cultivares de mango de maduración temprana, intermedia y tardía. Rev. Fitotec. Mex. 2009, 32, 45–52. [Google Scholar]

- Masud, F.; Rifai, A.; Sayuti, M. Mango seed kernel flour (Mangifera indica): Nutrient composition and potential as food. Malays. J. Nutr. 2020, 26, 101–106. [Google Scholar] [CrossRef]

- Ferrari, C.C.; Morgano, M.A.; Germer, S.P.M. Evaluation of water sorption isotherm, glass transistion temperature, vitamin C and color stability of mango peel powder during storage. SN Appl. Sci. 2021, 3, 210. [Google Scholar] [CrossRef]

- Secretaría de Economía. NMX-F-083-1986 Alimentos-Determinación de humedad en productos alimenticios. In Diario Oficial de la Federación; Dirección General de Normas: México City, México, 1986. [Google Scholar]

- Secretaría de Economía. NMX-F-608-NORMEX-2011 Alimentos–Determinación de proteínas en alimentos –Método de prueba. In Diario Oficial de la Federación; Dirección General de Normas: México City, México, 2011. [Google Scholar]

- Secretaría de Economía. NMX-F-607-NORMEX-2013 Alimentos–Determinación de cenizas en alimentos–Método de prueba. In Diario Oficial de la Federación; Direccion General de Normas: México City, México, 2013. [Google Scholar]

- Secretaría de Salud. NOM-086-SSA1-1994 Alimentos y bebidas no alcohólicas con modificaciones en su composición. Determinación de Extracto Etéreo en alimentos. Método de prueba. In Diario Oficial de la Federación; Dirección General de Normas: México City, México, 1994. [Google Scholar]

- Secretaría de Economía. NMX-F-613-NORMEX-2003 Determinación de fibra cruda en alimentos–Método de prueba. In Diario Oficial de la Federación; Dirección General de Normas: México City, México, 2003. [Google Scholar]

- AOAC (Association of Official Analytical Chemists). Method 986.25 Carbohydrates, Determination by difference, a Proximate Analysis. In Official Methods of Analysis, 15th ed.; Association of Official Analytical Chemist: Arlington, VA, USA, 1990; Volume I. [Google Scholar]

- Delgado-Nieblas, C.I.; Zazueta-Morales, J.J.; Gallegos-Infante, J.A.; Aguilar-Palazuelos, E.; Camacho-Hernández, I.L.; Ordorica-Falomir, C.A.; Pires De Melo, M.; Carrillo-López, A. Elaboration of functional snack foods using raw materials rich in carotenoids and dietary fiber: Effects of extrusion processing. CyTA-J. Food 2015, 13, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Korkerd, S.; Wanlapa, S.; Puttanlek, C.; Uttapap, D.; Rungsardthong, V. Expansion and functional properties of extruded snacks enriched with nutrition sources from food processing by-products. J. Food Sci. Technol. 2016, 53, 561–570. [Google Scholar] [CrossRef] [Green Version]

- Navarro-Cortez, R.O.; Hernández-Santos, B.; Gómez-Aldapa, C.A.; Castro-Rosas, J.; Herman-Lara, E.; Martínez-Sánchez, C.E.; Juárez-Barrientos, J.M.; Antonio-Cisneros, C.M.; Rodríguez-Miranda, J. Development of extruded ready-to-eat snacks using pumpkin seed (Cucurbita pepo) and nixtamalized maize (Zea mays) flour blends. Rev. Mex. Ing. Química 2016, 15, 409–422. [Google Scholar] [CrossRef]

- Anderson, R.A.; Conway, H.F.; Peplinski, A.J. Gelatinization of Corn Grits by Roll Cooking, Extrusion Cooking and Steaming. Starch-Stärke 1970, 22, 130–135. [Google Scholar] [CrossRef]

- Siddiq, M.; Sogi, D.S.; Dolan, K.D. Antioxidant properties, total phenolics, and quality of fresh-cut ‘Tommy Atkins’ mangoes as affected by different pre-treatments. LWT-Food Sci. Technol. 2013, 53, 156–162. [Google Scholar] [CrossRef]

- Benvenuti, S.; Pellati, F.; Melegari, M.; Bertelli, D. Polyphenols, Anthocyanins, Ascorbic Acid, and Radical Scavenging Activity of Rubus, Ribes, and Aronia. J. Food Sci. 2004, 69, FCT164–FCT169. [Google Scholar] [CrossRef]

- Gunenc, A.; Yeung, M.H.; Lavergne, C.; Bertinato, J.; Hosseinian, F. Enhancements of antioxidant activity and mineral solubility of germinated wrinkled lentils during fermentation in kefir. J Funct Foods. 2017, 32, 72–79. [Google Scholar] [CrossRef]

- Çam, M.; Hişil, Y.; Durmaz, G. Classification of eight pomegranate juices based on antioxidant capacity measured by four methods. Food Chem. 2009, 112, 721–726. [Google Scholar] [CrossRef]

- Rodríguez-Miranda, J.; Ramírez-Wong, B.; Vivar-Vera, M.A.; Solís-Soto, A.; Gómez-Aldapa, C.A.; Castro-Rosas, J.; Medrano-Roldan, H.; Delgado-Licon, E. Efecto de la concentración de harina de frijol (Phaseolus vulgaris L.), contenido de humedad y temperatura de extrusión sobre las propiedades funcionales de alimentos acuícolas. Rev. Mex. Ing. Química 2014, 13, 649–663. [Google Scholar]

- Gutiérrez Pulido, H.; de la Vara Salazar, R. Diseño de experimentos con mezclas. In Análisis y Diseño de Experimentos; McGraw Hill: México City, México, 2012; pp. 439–455. ISBN 978-607-15-0725-9. [Google Scholar]

- Pensamiento-Niño, C.A.; Gómez-Aldapa, C.A.; Hernández-Santos, B.; Juárez-Barrientos, J.M.; Herman-Lara, E.; Martínez-Sánchez, C.E.; Torruco-Uco, J.G.; Rodríguez-Miranda, J. Optimization and characterization of an extruded snack based on taro flour (Colocasia esculenta L.) enriched with mango pulp (Mangifera indica L.). J. Food Sci. Technol. 2018, 55, 4244–4255. [Google Scholar] [CrossRef]

- Chaparro Acuña, S.P.; Lara Sandoval, A.E.; Sandoval Amador, A.; Sosa Suarique, S.J.; Martínez Zambrano, J.J.; Gil González, J.H. Caracterización funcional de la almendra de las semillas de mango (Mangifera indica L.). Cienc. Desarro. 2015, 6, 67–75. [Google Scholar] [CrossRef] [Green Version]

- Razo Avila, A.K. Determinación de la Calidad Fisicoquímica y Bromatológica de la Cáscara de Mango Manila (Mangifera indica L.) Como Alternativa de Aprovechamiento. Bachelor’s Thesis, Universidad Veracruzana, Córdoba, Veracruz, México, 29 January 2013. [Google Scholar]

- Ramírez García, A.; Torres Bustillos, L.; Cervantes Torre, G.; Corzo Rios, L.J. Caracterización química de la semilla de mango (Mangifera indica L.) y la valorización de algunos de sus componentes. In Proceedings of the XII Encuentro Participación de la Mujer en la Ciencia, Querétaro, Mexico, 13–15 May 2015. [Google Scholar]

- Moraru, C.I.; Kokini, J.L. Nucleation and Expansion During Extrusion and Microwave Heating of Cereal Foods. Compr. Rev. Food Sci. Food Saf. 2003, 2, 147–165. [Google Scholar] [CrossRef] [PubMed]

- Ainsworth, P.; İbanoğlu, Ş.; Plunkett, A.; Ibanoglu, E.; Stojceska, V. Effect of brewers spent grain addition and screw speed on the selected physical and nutritional properties of an extruded snack. J. Food Eng. 2007, 81, 702–709. [Google Scholar] [CrossRef]

- Paredes López, O.; Guevara Lara, F.; Bello Pérez, L.A. Los Alimentos Magicos de las Culturas Indígenas Mesoamericanas; Fondo de Cultura Económica: Mexico City, México, 2006; p. 167. ISBN 9786071614087. [Google Scholar]

- Torres Diaz, L.B.; Anticona Cabellos, G.J. Efecto de la Concentración de Almidón de Almendra de Mango Criollo (Mangifera indica L.) en la Obtención de Películas. Bachelor’s Thesis, Universidad Nacional Pedro Ruiz Gallo, Lambayeque, Perú, 8 October 2020. [Google Scholar]

- Ozer, E.A.; Herken, E.N.; Guzel, S.; Ainsworth, P.; Ibanoglu, S. Effect of extrusion process on the antioxidant activity and total phenolics in a nutritious snack food. Int. J. Food Sci. Technol. 2006, 41, 289–293. [Google Scholar] [CrossRef]

- Abdul Aziz, N.A.; Wong, L.M.; Rajeev, B. Nutritional and sensory quality evaluation of sponge cake prepared by incorporation of high dietary fiber containing mango (Mangifera indica var. Chokanan) pulp and peel flours. Int. J. Food Sci. Nutr. 2011, 62, 559–567. [Google Scholar] [CrossRef]

- Paula, A.M.; Conti-Silva, A.C. Texture profile and correlation between sensory and instrumental analyses on extruded snacks. J. Food Eng. 2014, 121, 9–14. [Google Scholar] [CrossRef] [Green Version]

- Quintana-Obregón, E.; San Martín-Hernández, C.; Muy-Rangel, M.; Vargas-Ortiz, M. Valoración de polvos de cáscara de mango (Mangifera indica L.) como una alternativa para la generación de alimentos funcionales. TIP Rev. Espec. Cienc. Químico-Biol. 2019, 22, 1–5. [Google Scholar] [CrossRef]

- De Lourdes García-Magaña, M.; García, H.S.; Bello-Pérez, L.A.; Sáyago-Ayerdi, S.G.; de Oca, M.M.M. Functional Properties and Dietary Fiber Characterization of Mango Processing By-products (Mangifera indica L., cv Ataulfo and Tommy Atkins). Plant Foods Hum. Nutr. 2013, 68, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Hincapié, G.A.; Vásquez, D.C.; Galicia, V.S.; Hincapié, C.A. Propiedades técnico-funcionales de la fibra dietaria de cáscaras de mango variedad hilacha (Mangifera indica L.): Efecto del secado por convección. Biotecnol. Sect. Agropecu. Agroind. 2014, 12, 153–160. [Google Scholar]

- Contreras-Jiménez, B.; Morales-Sánchez, E.; Reyes-Vega, M.L.; Gaytán-Martínez, M. Propiedades funcionales de harinas de maíz nixtamalizado obtenidas por extrusión a baja temperatura. CyTA-J. Food 2014, 12, 263–270. [Google Scholar] [CrossRef] [Green Version]

- Flores-Farías, R.; Martínez-Bustos, F.; Salinas-Moreno, Y.; Ríos, E. Caracterización de harinas comerciales de maíz nixtamalizado. Agrociencia 2002, 36, 557–567. [Google Scholar]

- Altan, A.; McCarthy, K.L.; Maskan, M. Evaluation of snack foods from barley-tomato pomace blends by extrusion processing. J. Food Eng. 2008, 84, 231–242. [Google Scholar] [CrossRef]

- Jin, Z.; Hsieh, F.; Huff, H. Effects of soy fiber, salt, sugar and screw speed on physical properties and microstructure of corn meal extrudate. J. Cereal Sci. 1995, 22, 185–194. [Google Scholar] [CrossRef]

- Yaǧci, S.; Göǧüş, F. Response surface methodology for evaluation of physical and functional properties of extruded snack foods developed from food-by-products. J. Food Eng. 2008, 86, 122–132. [Google Scholar] [CrossRef]

- Rosso Ceron, A.M.; Toro Uribe, S. Optimización de las Condiciones de Extracción Sólido-Líquido de Polifenoles a Partir de la Almendra de Mango Hilacha (Mangifera indica. Var. Magdalena River) y Ajuste de sus Parámetros Cinéticos. Bachelor’s Thesis, Universidad Industrial de Santader, Bucaramanga, Colombia, 22 August 2011. [Google Scholar]

- Ramírez Hernández, J.H.; García Flores, C.F.; Vizcaíno Reséndiz, J.A.; Cárdenas Mariel, J.; Gutiérrez Cantú, F.J.; Murga Mariel, H.; Villagrán Rueda, S. ¿Qué son y para qué sirven los antioxidantes? Cienc. Hombre 2012, 25, 6–7. [Google Scholar]

- Sogi, D.S.; Siddiq, M.; Greiby, I.; Dolan, K.D. Total phenolics, antioxidant activity, and functional properties of “Tommy Atkins” mango peel and kernel as affected by drying methods. Food Chem. 2013, 141, 2649–2655. [Google Scholar] [CrossRef] [PubMed]

- Ajila, C.M.; Leelavathi, K.; Prasada Rao, U.J.S. Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J. Cereal Sci. 2008, 48, 319–326. [Google Scholar] [CrossRef]

- Conde, E. Revalorización de Residuos Agroindustriales y Forestales para la Obtención de Antioxidantes Naturales con Aplicaciones en la Industria Alimentaria, Cosmética y/o Farmacéutica. Master’s Thesis, Universidad de Vigo, Ourence, España, 2009. [Google Scholar]

- Dorta, E.; Lobo, M.G.; González, M. Using drying treatments to stabilise mango peel and seed: Effect on antioxidant activity. LWT-Food Sci. Technol. 2012, 45, 261–268. [Google Scholar] [CrossRef]

- Kumar, S.B.; Ravi, R.; Saraswathi, G. Optimization of fruit punch using mixture design. J. Food Sci. 2010, 75, S1–S7. [Google Scholar] [CrossRef]

- Lazic, Z.R. Selection of the responses. In Design of Experiments in Chemical Engineering: A Practical Guide; Wiley-VCH: Weinheim, Germany, 2004; pp. 170–184. ISBN 978-3-527-60459-3. [Google Scholar]

- Osorio-Oviedo, Á.A. Pruebas de análisis sensorial para el desarrollo de productos de cereales infantiles en Venezuela. Publ. Cienc. Tecnol. 2019, 13, 27–37. [Google Scholar] [CrossRef]

- Ačkar, Đ.; Jozinović, A.; Babić, J.; Miličević, B.; Panak Balentić, J.; Šubarić, D. Resolving the problem of poor expansion in corn extrudates enriched with food industry by-products. Innov. Food Sci. Emerg. Technol. 2018, 47, 517–524. [Google Scholar] [CrossRef]

- Van Trijp, H.C.M.; Van Kleef, E. Newness, value and new product performance. Trends Food Sci. Technol. 2008, 19, 562–573. [Google Scholar] [CrossRef]

- Steenkamp, J.B.E.M.; Gielens, K. Consumer and Market Drivers of the Trial Probability of New Consumer Packaged Goods. J. Consum. Res. 2003, 30, 368–384. [Google Scholar] [CrossRef]

- Basu, S.; Shivhare, U.S. Rheological, textural, micro-structural and sensory properties of mango jam. J. Food Eng. 2010, 100, 357–365. [Google Scholar] [CrossRef]

- Legesse, M.B.; Emire, S.A. Functional and physicochemical properties of mango seed kernels and wheat flour and their blends for biscuit production. Afr. J. Food Sci. Technol. 2012, 3, 193–203. [Google Scholar]

- Pathak, D.; Majumdar, J.; Raychaudhuri, U.; Chakraborty, R. Characterization of physicochemical properties in whole wheat bread after incorporation of ripe mango peel. J. Food Meas. Charact. 2016, 10, 554–561. [Google Scholar] [CrossRef]

- Shabeer, M.; Sultan, M.T.; Abrar, M.; Suffyan Saddique, M.; Imran, M.; Saad Hashmi, M.; Sibt-e-Abbas, M. Utilization of Defatted Mango Kernel in Wheat-Based Cereals Products: Nutritional and Functional Properties. Int. J. Fruit Sci. 2016, 16, 444–460. [Google Scholar] [CrossRef]

- Atoche Chauca, L.S.; García Siu, M.W. Aprovechamiento de Residuos Agroindustriales (Cáscara de Mango) para la Formulación de Cupcakes. Bachelor’s Thesis, Universidad Nacional del Santa, Nuevo Chimbote, Perú, 2017. [Google Scholar]

- Alam, M.S.; Pathania, S.; Sharma, A. Optimization of the extrusion process for development of high fibre soybean-rice ready-to-eat snacks using carrot pomace and cauliflower trimmings. LWT 2016, 74, 135–144. [Google Scholar] [CrossRef]

- Gumul, D.; Ziobro, R.; Zieba, T.; Rój, E. Physicochemical characteristics of cereal extrudates with different levels of defatted blackcurrant seeds. J. Food Qual. 2013, 36, 385–393. [Google Scholar] [CrossRef]

| Point | Mixtures | WCF a (%) | MPF b (%) | MKF c (%) |

|---|---|---|---|---|

| A | 1 | 75.00 | 25.00 | 0.00 |

| B | 2 | 58.33 | 41.67 | 0.00 |

| D | 3 | 58.33 | 25.00 | 16.67 |

| E | 4 | 41.67 | 58.33 | 0.00 |

| F | 5 | 41.67 | 41.67 | 16.67 |

| G | 6 | 41.67 | 25.00 | 33.33 |

| J | 7 | 25.00 | 75.00 | 0.00 |

| K | 8 | 25.00 | 58.33 | 16.67 |

| L | 9 | 25.00 | 41.67 | 33.33 |

| M | 10 | 25.00 | 25.00 | 50.00 |

| F | 11 | 41.67 | 41.67 | 16.67 |

| C | 12 | 58.33 | 33.33 | 8.33 |

| H | 13 | 33.33 | 58.33 | 8.33 |

| I | 14 | 33.33 | 33.33 | 33.33 |

| Analysis | WCF a | MPF b | MKF c |

|---|---|---|---|

| Moisture (%) | 11.51 | 7.99 | 6.86 |

| Protein (%) | 7.57 | 2.88 | 6.31 |

| Ash (%) | 1.24 | 1.74 | 1.97 |

| Fat (%) | 2.22 | 1.51 | 9.94 |

| Total carbohydrates (%) | 75.89 | 74.65 | 72.37 |

| Fiber (%) | 1.57 | 11.23 | 2.55 |

| Mixture | EI 1,2 | Hardness 1 (N) | WAI 1,3 (g Wet/g Sample) | WSI 1,4 (%) | Total Polyphenol 1 (mg GAE/100 g Sample) | DPPH 1 (mg Etrolox/g Sample) | ABTS 1 (mg Etrolox/g Sample) |

|---|---|---|---|---|---|---|---|

| 1 | 1.18 ± 0.01 a,b | 63.55 ± 13.34 a | 4.67 ± 0.10 a,b | 14.20 ± 0.49 a | 4821 ± 32.87 a | 101.38 ± 3.21 a | 133.53 ± 8.81 a |

| 2 | 1.10 ± 0.01 d,e | 85.91 ± 14.81 c,d | 4.41 ± 0.04 a,c | 21.43 ± 0.54 b,c | 6055 ± 44.26 a | 123.63 ± 6.29 b,c | 151.80 ± 7.50a,b |

| 3 | 1.19 ± 0.01 b | 64.14 ± 12.55 a | 4.03 ± 0.05 d,e | 17.46 ± 0.11 d | 5294 ± 32.54 a | 158.54 ± 6.52 e | 100.71 ± 2.86 e |

| 4 | 1.07 ± 0.01 e,f | 109.83 ± 16.67 f,g | 4.46 ± 0.02 a | 29.12 ± 0.44 e | 6548 ± 38.91 a | 104.38 ± 3.59 a,b | 165.87 ± 7.46 b,c,d |

| 5 | 1.09 ± 0.01 d,e,f | 87.77 ± 13.14 c,d,e | 4.63 ± 0.16 a,b | 22.20 ± 0.16 c | 7157 ± 42.23 a | 173.77 ± 6.94 f,g | 265.74 ± 9.32 f |

| 6 | 1.17 ± 0.03 a,b | 67.86 ± 10.98 a,b | 4.42 ± 0.10 a | 17.02 ± 0.29 d | 6997 ± 48.82 a | 198.93 ± 6.07 h,i | 173.18 ± 6.83 d |

| 7 | 1.05 ± 0.02 f,g | 115.62 ± 15.40 g | 5.78 ± 0.11 f | 31.51 ± 0.69 f | 7242 ± 46.40 a | 134.71 ± 6.59 c,d | 212.67 ± 9.64 g |

| 8 | 1.03 ± 0.05 g | 96.40 ± 12.75 d,e | 4.46 ± 0.01 a | 30.20 ± 0.14 g | 5069 ± 16.60 a | 173.26 ± 6.53 e,f | 128.05 ± 5.16 a |

| 9 | 1.12 ± 0.02 c,d | 74.73 ± 11.47 a,b,c | 4.85 ± 0.08 b | 21.94 ± 0.14 c | 7455 ± 52.26 a | 192.60 ± 6.32 g,h | 284.77 ± 12.0 f |

| 10 | 1.15 ± 0.01 a,c | 63.45 ± 6.67 a | 3.37 ± 0.03 g | 20.66 ± 0.25 b | 7365 ± 42.22 a | 209.24 ± 7.55 i | 380.00 ± 10.4 h |

| 11 | 1.09 ± 0.01 d,e,f | 85.42 ± 11.67 c,d | 3.82 ± 0.04 e | 24.04 ± 0.23 h | 6942 ± 46.16 a | 157.56 ± 7.59 d,e | 170.08 ± 3.58 c,d |

| 12 | 1.15 ± 0.04 a,c | 83.45 ± 8.53 c,d | 4.14 ± 0.01 c,d | 19.41 ± 0.16 i | 6530 ± 42.02 a | 128.12 ± 4.29 c,d | 153.87 ± 6.95 a,b,c |

| 13 | 1.06 ± 0.02 e,f,g | 101.11 ± 13.24 e,f | 4.42 ± 0.18 a | 28.52 ± 0.05 e | 7028 ± 44.89 a | 150.03 ± 6.81 e | 175.56 ± 5.55 d |

| 14 | 1.12 ± 0.03 c,d | 79.73 ± 9.12 b,c | 3.86 ± 0.05 e | 24.47 ± 0.16 h | 7493 ± 50.15 a | 189.82 ± 7.34 g,h | 243.66 ± 3.09 i |

| Variable | λ1 (WCF) 1 | λ2 (MPF) 2 | λ3 (MKF) 3 | λ1 λ2 | λ1 λ3 | λ2 λ3 | λ1 λ2 λ3 | Pred-R2 |

|---|---|---|---|---|---|---|---|---|

| Physical properties | ||||||||

| EI 4 | 1.175 | 1.014 | 1.15 | N.S. 7 | N.S. 7 | N.S. 7 | N.S. 7 | 85.62 |

| Hardness | 62.26 | 115.76 | 63.68 | 44.91 | 24.07 | −13.28 | N.S. 7 | 97.20 |

| WAI 5 | 4.26 | 5.15 | 3.73 | N.S. 7 | N.S. 7 | N.S. 7 | N.S. 7 | 47.49 |

| WSI 6 | 15.34 | 33.37 | 20.32 | N.S. 7 | N.S. 7 | N.S. 7 | N.S. 7 | 91.86 |

| Chemical properties | ||||||||

| Total Polyphenol | No model | |||||||

| DPPH | 110.48 | 134.25 | 225.84 | N.A. | N.A. | N.A. | N.A. | 90.39 |

| ABTS | 138.15 | 192.62 | 392.62 | −37.44 | −575.06 | −401.87 | 2264.32 | 86.63 |

| Appearance | ||

| Mixture 1 * | Mixture 6 * | Mixture 12 * |

| 6.63 ± 1.45 a | 6.12 ± 1.55 a | 6.37 ± 1.61 a |

| Taste | ||

| Mixture 1 * | Mixture 6 * | Mixture 12 * |

| 6.80 ± 1.47 a | 5.50 ± 1.85 b | 6.49 ± 1.55 a |

| Texture | ||

| Mixture 1 * | Mixture 6 * | Mixture 12 * |

| 6.42 ± 1.77 a | 5.68 ± 1.84 b | 6.19 ± 1.77 a,b |

| Authors | Conditions of Extrusion | Formulation | EI 1 | H 2 | WAI 3 | WSI 4 | TP 5 | DPPH 6 | ABTS 7 |

|---|---|---|---|---|---|---|---|---|---|

| This work | Single-Screw 3:1 compression ratio 19.05 mm screw diameter Die 3 mm 17% FM 8, 120 °C, 100 rpm | 58.33% White Corn Flour 33.33% Mango Peel Flour 8.33% Mango Kernel Flour | 1.15 ± 0.04 | 83.45 ± 8.53 | 4.14 ± 0.01 | 19.41 ± 0.16 | 6530 ± 42.02 | 128.12 ± 4.29 | 153.87 ± 6.95 |

| Mazlan et al. [8] | Single-screw extruder 4:1 compression ratio Die 4 mm 17% FM 8, 100 rpm, 144 °C | 17.09% Mango Peel Flour 82.91% Corn Grits | 2.06 ± 0.02 | 64.88 ± 3.16 | N.E. 9 | N.E. 9 | N.E. 9 | N.E. 9 | N.E. 9 |

| Korked et al. [20] | Single-Screw extruder 4:1 compression ratio 14% FM 8, 180 rpm, 180 °C | 72.6% Corn Grits 8% Wheat Flour 8%Rice Flour 0.5% Margarine 5.45% Defatted soybean melt 5.45% Mango peel fiber | 3.18 ± 0.11 | 297 ± 11.51 | N.E. 9 | N.E. 9 | 929 ± 0.70 | N.E. 9 | N.E. 9 |

| Alam et al. [65] | Co-rotating Twin-screw 85% FM 8, 313 rpm, 164 °C | 85% Rice flour 7.5% Defatted soy flour 3.75% Carrot pomace powder 3.75% cauliflower trimmings powder | 1.06 | 55.2 | 5.8 | 20.1 | N.E. 9 | N.E. 9 | N.E. 9 |

| Gumul et al. [66] | Single-Screw Die 3 mm 1:2 compression ratio 14% FM 8, 190 rpm, 180 °C | 10% Defatted Blackcurrant seed 90% Cornmeal | 2.80 ± 0.01 | 26.4 ± 3.58 | 9.92 ± 0.57 | 14.94 ± 0.72 | N.E. 9 | N.E. 9 | N.E. 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina-Rendon, E.A.; Guatemala-Morales, G.M.; Padilla-Camberos, E.; Corona-González, R.I.; Arriola-Guevara, E.; García-Fajardo, J.A. Production of Extrudate Food with Mango By-Products (Mangifera indica): Analysis of Physical, Chemical, and Sensorial Properties. Processes 2021, 9, 1660. https://doi.org/10.3390/pr9091660

Medina-Rendon EA, Guatemala-Morales GM, Padilla-Camberos E, Corona-González RI, Arriola-Guevara E, García-Fajardo JA. Production of Extrudate Food with Mango By-Products (Mangifera indica): Analysis of Physical, Chemical, and Sensorial Properties. Processes. 2021; 9(9):1660. https://doi.org/10.3390/pr9091660

Chicago/Turabian StyleMedina-Rendon, Esther Alicia, Guadalupe María Guatemala-Morales, Eduardo Padilla-Camberos, Rosa Isela Corona-González, Enrique Arriola-Guevara, and Jorge Alberto García-Fajardo. 2021. "Production of Extrudate Food with Mango By-Products (Mangifera indica): Analysis of Physical, Chemical, and Sensorial Properties" Processes 9, no. 9: 1660. https://doi.org/10.3390/pr9091660

APA StyleMedina-Rendon, E. A., Guatemala-Morales, G. M., Padilla-Camberos, E., Corona-González, R. I., Arriola-Guevara, E., & García-Fajardo, J. A. (2021). Production of Extrudate Food with Mango By-Products (Mangifera indica): Analysis of Physical, Chemical, and Sensorial Properties. Processes, 9(9), 1660. https://doi.org/10.3390/pr9091660