Optimization of Friction Welding Parameters to Maximize the Tensile Strength of Magnesium Alloy with Aluminum Alloy Dissimilar Joints Using Genetic Algorithm

Abstract

:1. Introduction

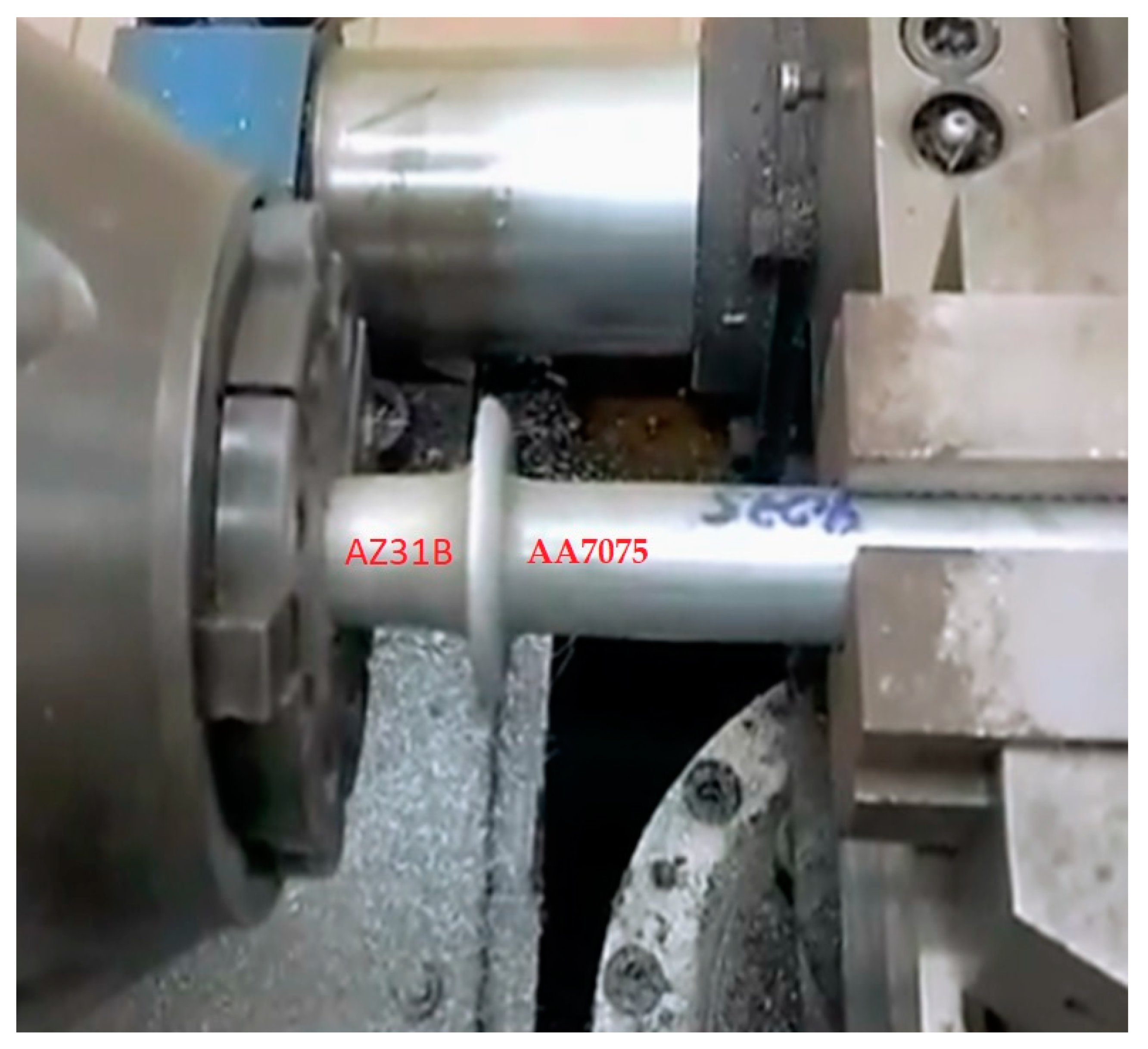

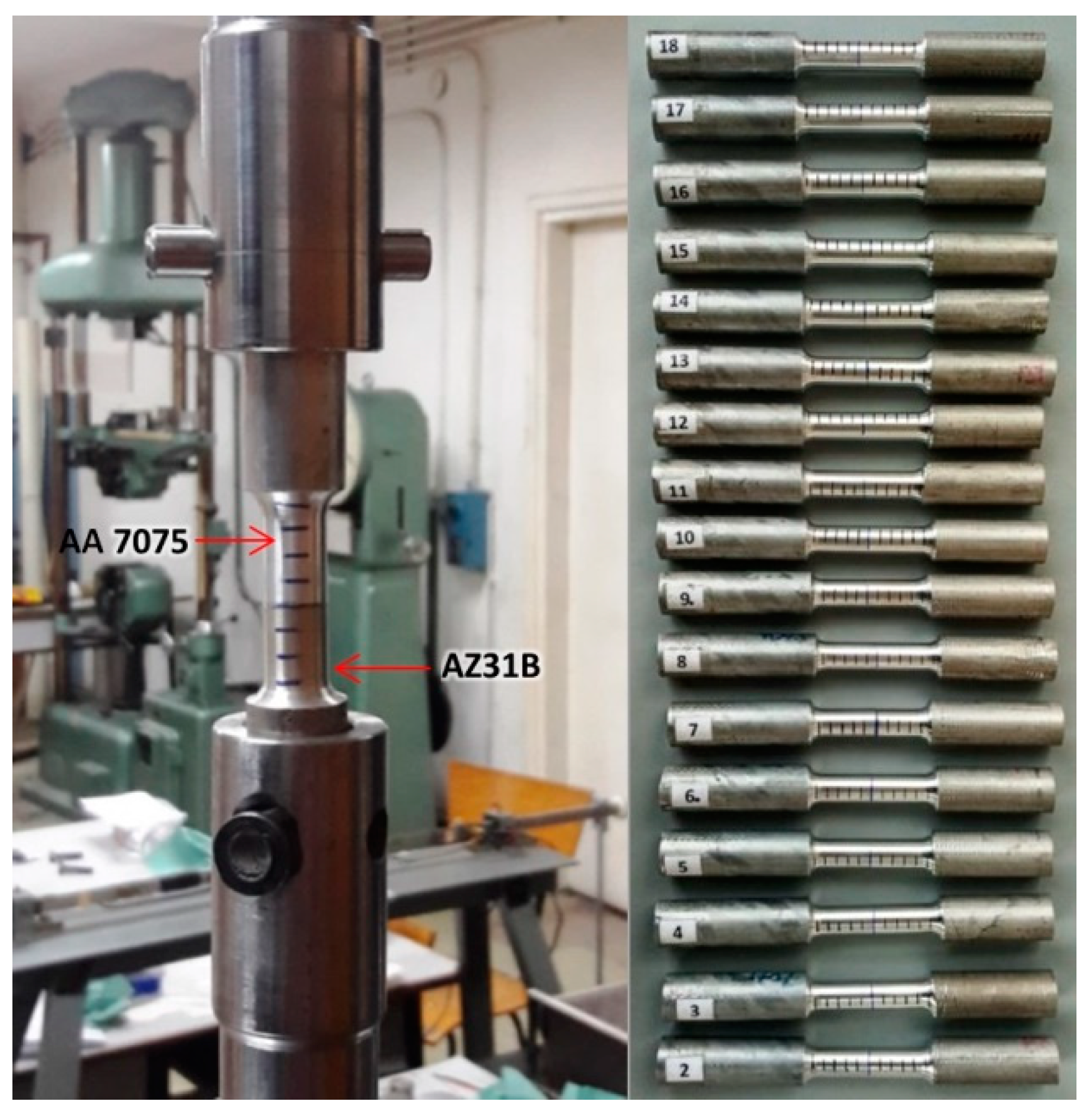

2. Materials and Methods

2.1. Materials

2.2. Welding Parameters

2.3. Tensile Test

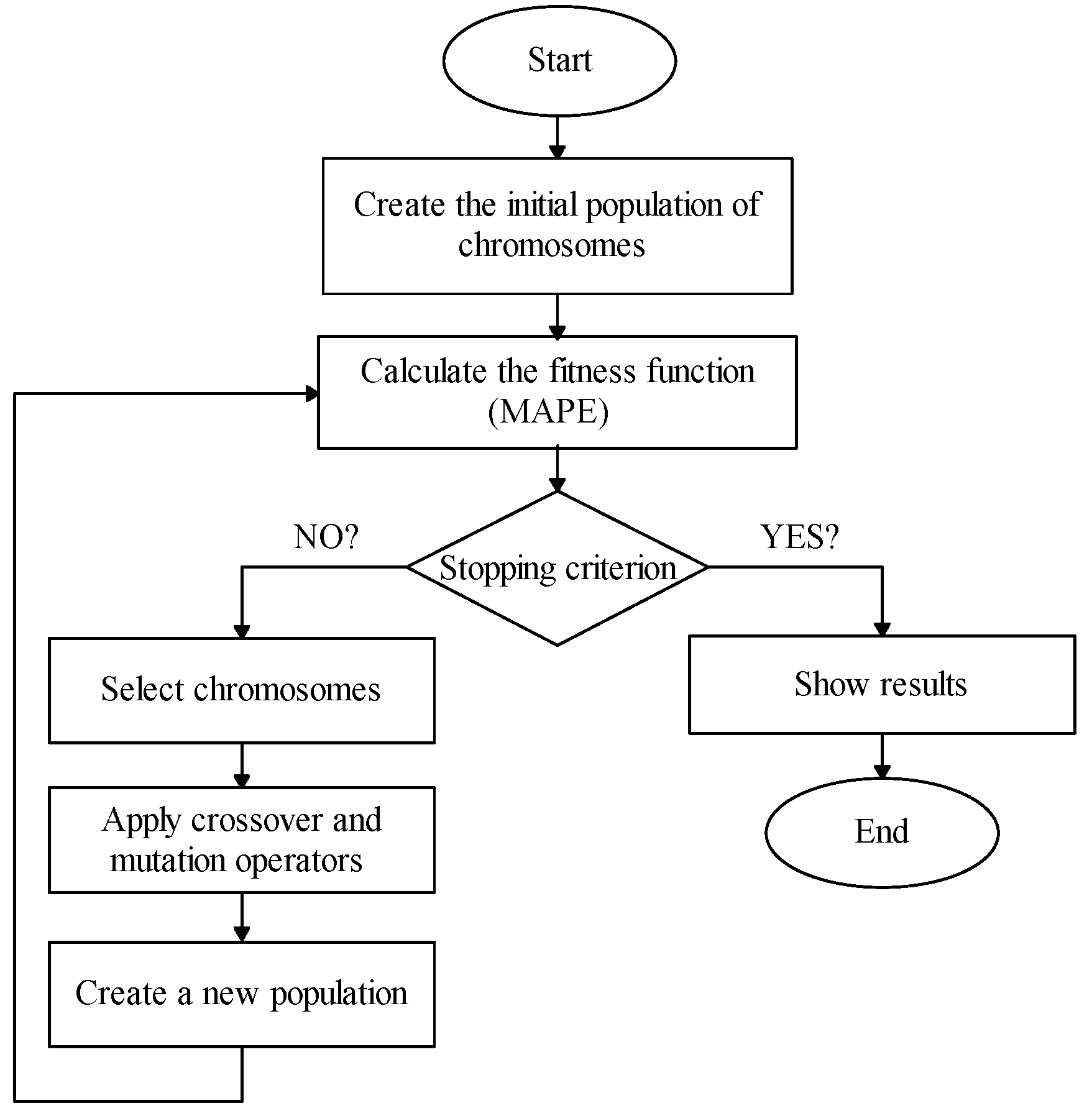

3. Modeling and Optimization

3.1. Mathematical Models

3.2. Fitness Function

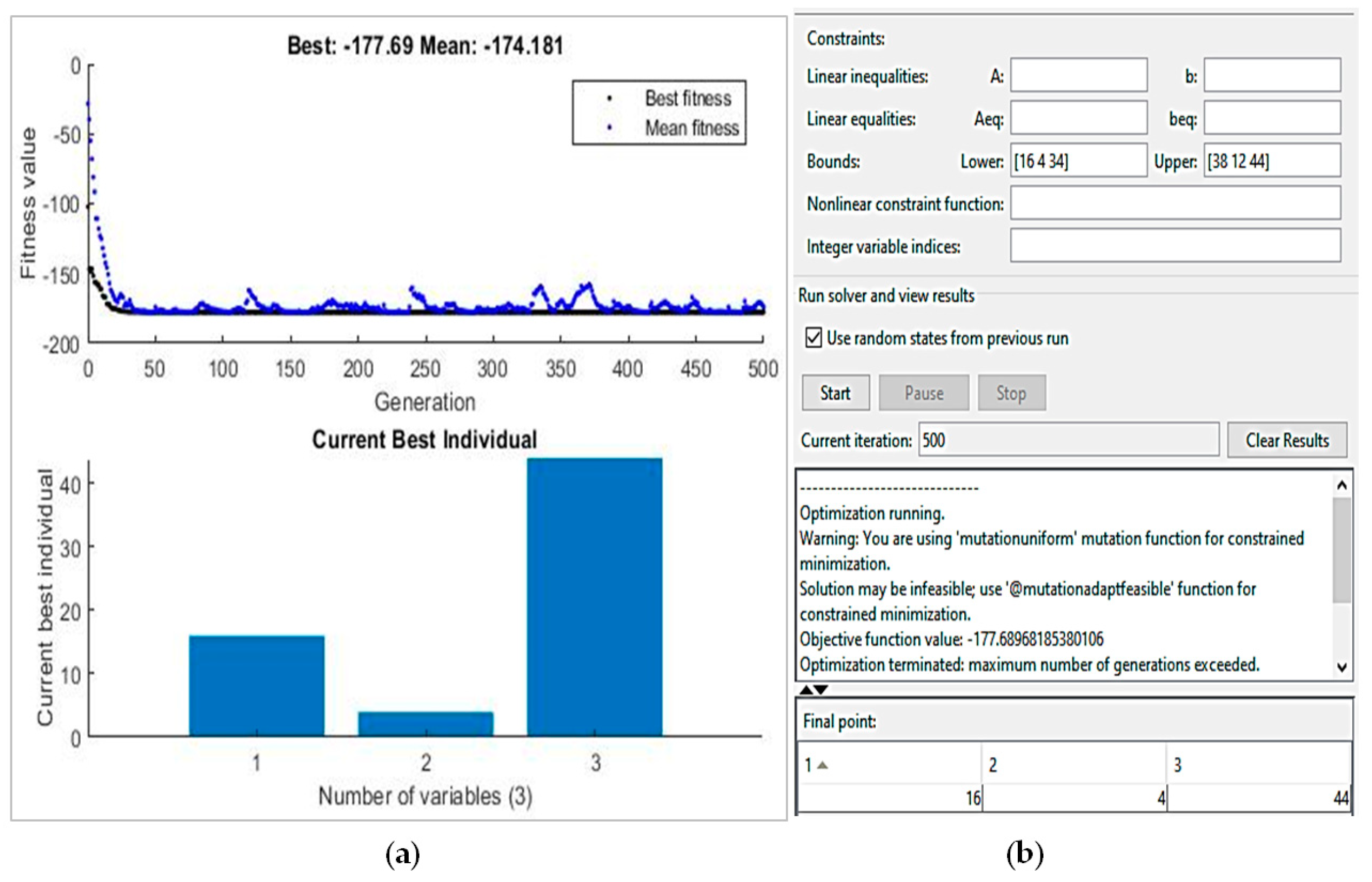

3.3. Optimization

4. Results and Discussion

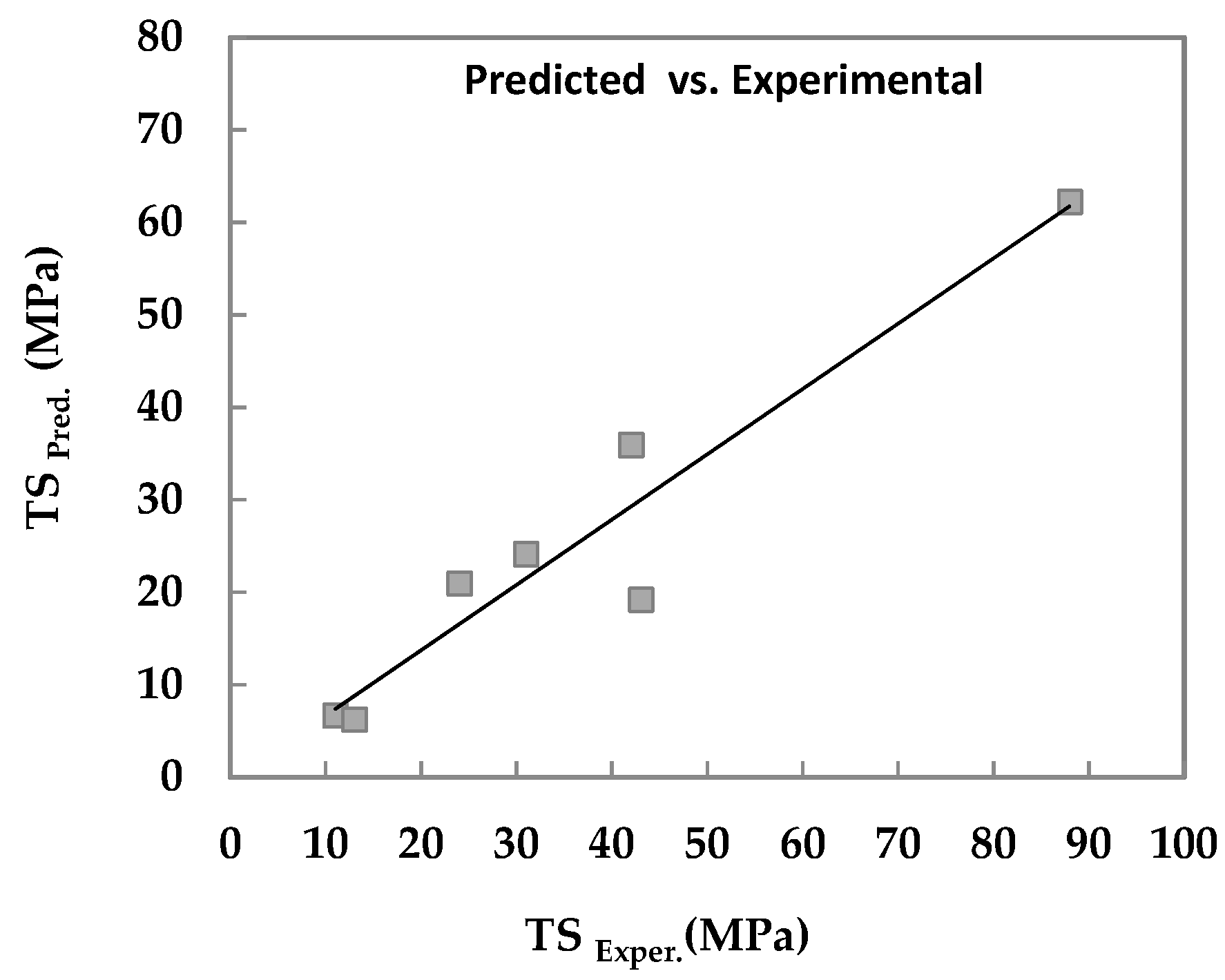

4.1. Results of Modeling

4.2. Results of Optimization

4.3. Validation of Experiment

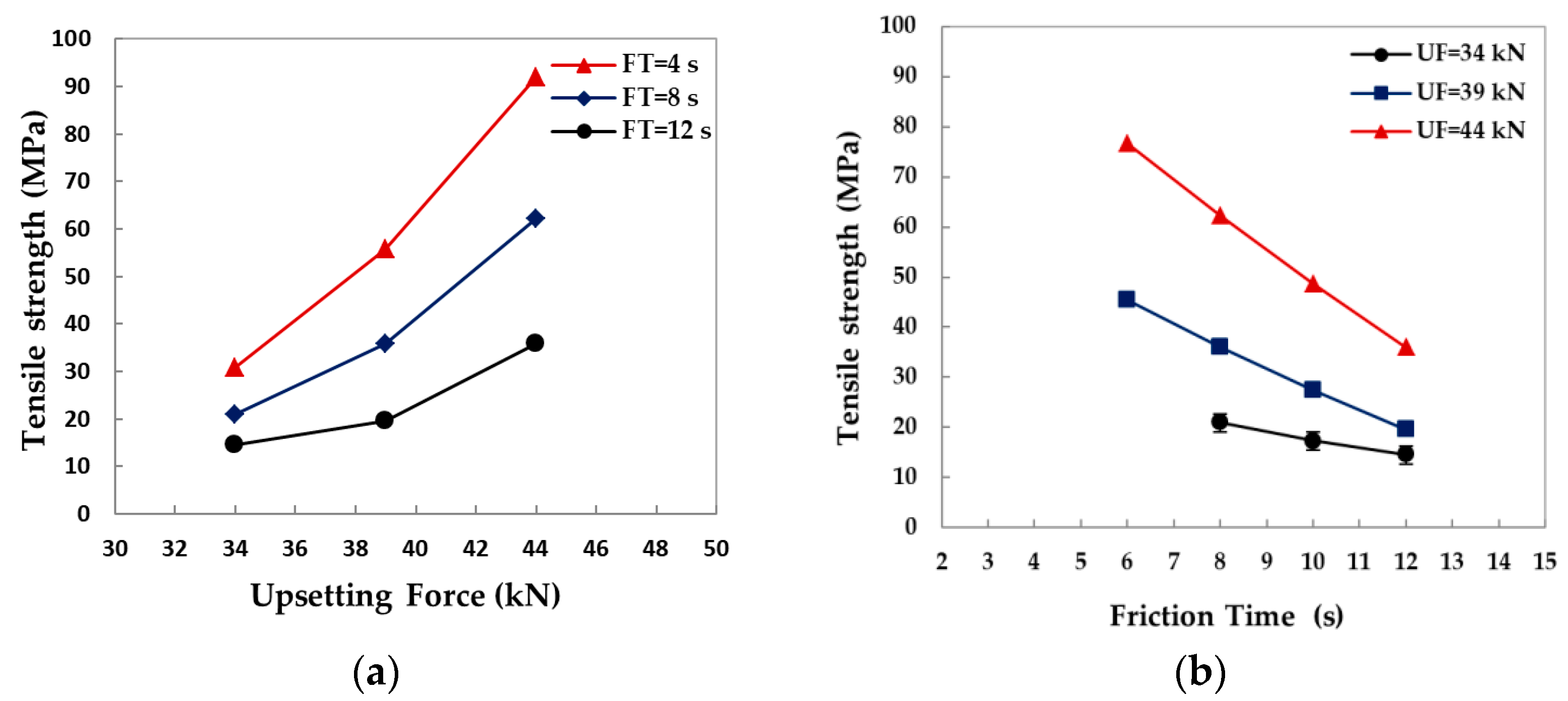

4.4. Effect of the Welding Parameters on the TS

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, L. Welding and Joining of Magnesium Alloys; Woodhead Publishing Limited, Abington Hall, Granta Park: Cambridge, UK, 2010. [Google Scholar]

- Hong, K.M.; Shin, Y.C. Prospects of laser welding technology in the automotive industry: A review. J. Mater. Process. Technol. 2017, 245, 46–69. [Google Scholar] [CrossRef]

- Liu, L.; Ren, D.; Liu, F. A review of dissimilar welding techniques for magnesium alloys to aluminum alloys. Materials 2014, 7, 3735–3737. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vill, V.I. Friction Welding of Metals; American Welding Society: New York, NY, USA, 1962. [Google Scholar]

- American Welding Society. Recommended Practice for Friction Welding; AWS: Miami, FL, USA, 1989. [Google Scholar]

- Crossland, B. Friction welding. Contemp. Phys. 1971, 12, 559–574. [Google Scholar] [CrossRef]

- Kato, K.; Tokisue, H. Dissimilar friction welding of aluminium alloys to other materials. Weld. Int. 2004, 18, 861–867. [Google Scholar] [CrossRef]

- Kimura, M.; Fuji, A.; Shibata, S. Joint properties of friction welded joint between pure magnesium and pure aluminium with post-weld heat treatment. Mater. Des. 2015, 85, 169–179. [Google Scholar] [CrossRef]

- Liang, Z.; Qin, G.; Wang, L.; Meng, X.; Li, F. Microstructural characterization and mechanical properties of dissimilar friction welding of 1060 aluminum to AZ31B magnesium alloy. Mater. Sci. Eng. A 2015, 645, 170–180. [Google Scholar] [CrossRef]

- Liang, Z.; Qin, G.; Geng, P.; Yang, F.; Meng, X. Continuous drive friction welding of 5A33 Al alloy to AZ31B Mg alloy. J. Manuf. Process. 2017, 25, 153–162. [Google Scholar] [CrossRef]

- Guo, W.; You, G.; Yuan, G.; Zhang, X. Microstructure and mechanical properties of dissimilar inertia friction welding of 7A04 aluminum alloy to AZ31 magnesium alloy. J. Alloys Compd. 2017, 695, 3267–3277. [Google Scholar] [CrossRef]

- Murti, K.G.K.; Sundaresan, S. Parameter optimization in friction welding dissimilar materials. Metal Constr. 1983, 15, 331–335. [Google Scholar]

- Paventhan, R.; Lakshminarayanan, P.R.; Balasubramanian, V. Prediction and optimization of friction welding parameters for joining aluminium alloy and stainless steel. Trans. Nonferrous Met. Soc. China 2011, 21, 1480–1485. [Google Scholar] [CrossRef]

- Sathiya, P. Optimization of friction welding parameters using evolutionary computational techniques. J. Mater. Process. Technol. 2009, 209, 2576–2584. [Google Scholar] [CrossRef]

- Kumaran, S.S.; Muthukumaran, S.; Vinodh, S. Optimization of friction welding of tube to tube plate using an external tool by hybrid approach. J. Alloys Compd. 2011, 509, 2758–2769. [Google Scholar] [CrossRef]

- Canyurt, O. Estimation of welded joint strength using genetic algorithm approach. Int. J. Mech. Sci. 2005, 47, 1249–1261. [Google Scholar] [CrossRef]

- Canyurt, O. Fatigue strength estimation of adhesively bonded tubular joint using genetic algorithm approach. Int. J. Mech. Sci. 2004, 46, 359–370. [Google Scholar] [CrossRef]

- Meran, C. Prediction of the optimized welding parameters for the joined brass plates using genetic algorithm. Mater. Des. 2006, 27, 356–363. [Google Scholar] [CrossRef]

- Padmanaban, G.; Balasubramanian, V. Prediction of tensile strength and optimization of process parameters for friction stir welded AZ31B magnesium. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2010, 224, 1519–1528. [Google Scholar] [CrossRef]

- Winiczenko, R.; Salat, R.; Awtoniuk, M. Estimation of tensile strength of ductile iron friction welded joints using hybrid intelligent methods. Trans. Nonferrous Met. Soc. China. 2013, 23, 385–391. [Google Scholar] [CrossRef]

- Winiczenko, R. Effect of friction welding parameters on the tensile strength and microstructural properties of dissimilar AISI 1020-ASTM A536 joints. Int. J. Adv. Manuf. Tech. 2016, 84, 941–955. [Google Scholar] [CrossRef] [Green Version]

- Srichok, T.; Pitakaso, R.; Sethanan, K.; Sirirak, W.; Kwangmuang, P. Combined Response Surface Method and Modified Differential Evolution for Parameter Optimization of Friction Stir Welding. Processes 2020, 8, 1080. [Google Scholar] [CrossRef]

- Rutkowski, L. Computational intelligence, Methods and Techniques; Springer: Berlin, Germany, 2008. [Google Scholar]

- Deb, K. Optimization for Engineering Design; Prentice-Hall: New Delhi, India, 1998. [Google Scholar]

- Gen, M.; Cheng, R. Genetic Algorithms and Engineering Design; Wiley: New York, NY, USA, 1997. [Google Scholar]

- MATLAB 7.6 R2008a. Documentation R.; MathWorks, Inc.: Natick, MA, USA, 2008. [Google Scholar]

- Srinivasan, M.; Loganathan, C.; Balasubramanian, V.; Nguyen, Q.B.; Gupta, M.; Narayanasamy, R. Feasibility of joining AZ31B magnesium metal matrix composite by friction welding. Mater. Des. 2011, 32, 1672–1676. [Google Scholar] [CrossRef]

| Material | Chemical Composition | Mechanical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mg | Al | Zn | Cu | Si | Mn | Fe | Tensile strength | Yield strength | Elongation | Hardness | |

| (MPa) | (MPa) | (%) | HB | ||||||||

| AZ 31B | Rest | 2.5–3.5 | 0.6–1.4 | 0.01 | 0.08 | 0.2–1.0 | 0.003 | 248 | 152 | 8 | 49 |

| AA 7075 | 2.25 | Rest | 5.67 | 1.62 | 0.17 | 0.14 | 0.29 | 540 | 480 | 7 | 150 |

| No | Friction Force (FF) | Friction Time (FT) | Upsetting Force (UF) | Ultimate Tensile Strength (UTS) |

|---|---|---|---|---|

| # | kN | s | kN | MPa |

| S1 | 24 | 8 | 34 | 24 |

| S2 | 24 | 12 | 44 | 42 |

| S3 | 24 | 10 | 39 | 10 |

| S4 | 24 | 8 | 44 | 88 |

| S5 | 31 | 8 | 39 | 11 |

| S6 | 31 | 12 | 39 | 13 |

| S7 | 38 | 12 | 34 | 31 |

| # | Parameter | Notation | Unit | Bounds | |

|---|---|---|---|---|---|

| Lower | Upper | ||||

| 1 | Friction Force | FF | kN | 12 | 38 |

| 2 | Friction Time | FT | s | 2 | 12 |

| 3 | Upsetting Force | UF | kN | 34 | 44 |

| Parameters | Value |

|---|---|

| Population size | 80 |

| Crossover friction | 0.8 |

| Mutation friction | 0.2 |

| Number generations | 500 |

| No. Simulations | Selection | Crossover | Mutation | MAPEQUAD | MAPECUB |

|---|---|---|---|---|---|

| A | B | C | D | E | |

| 1 | Un | Sc | Um | 0.1679 | 0.1664 |

| 2 | Ro | Sc | Um | 0.1673 | 0.1686 |

| 3 | Un | Sp | Um | 0.1680 | 0.1662 |

| 4 | Ro | Sp | Um | 0.1687 | 0.1656 |

| 5 | Un | Tp | Um | 0.1653 | 0.1669 |

| 6 | Ro | Tp | Um | 0.1662 | 0.1663 |

| 7 | Un | In | Um | 0.5992 | 0.9569 |

| 8 | Ro | In | Um | 0.1660 | 0.1674 |

| 9 | Un | He | Um | 0.00093 | 0.00212 |

| 10 | Ro | He | Um | 0.1783 | 0.1608 |

| 11 | Un | He | Ga | 0.0987 | 0.0914 |

| 12 | Ro | He | Ga | 0.1362 | 0.1173 |

| 13 | Un | Sc | Ga | 0.1558 | 0.1393 |

| 14 | Ro | Sc | Ga | 0.1618 | 0.1281 |

| 15 | Un | Sp | Ga | 0.1342 | 0.1297 |

| 16 | Ro | Sp | Ga | 0.1487 | 0.1404 |

| 17 | Un | Tp | Ga | 0.1359 | 0.1618 |

| 18 | Ro | Tp | Ga | 0.1463 | 0.1494 |

| 19 | Un | In | Ga | 0.1482 | 0.1356 |

| 20 | Ro | In | Ga | 0.1489 | 0.1245 |

| 21 | Un | He | Af | 0.0925 | 0.0928 |

| 22 | Ro | He | Af | 0.1451 | 0.1516 |

| 23 | Un | Sc | Af | 0.1675 | 0.8659 |

| 24 | Ro | Sc | Af | 0.1662 | 0.1488 |

| 25 | Un | Sp | Af | 0.1708 | 0.8821 |

| 26 | Ro | Sp | Af | 0.1544 | 0.1451 |

| 27 | Un | Tp | Af | 0.2362 | 0.2025 |

| 28 | Ro | Tp | Af | 0.1490 | 0.1583 |

| 29 | Un | In | Af | 1.8928 | 2.599 |

| 30 | Ro | In | Af | 0.1563 | 0.155 |

| 31 | Re | He | Um | 0.1475 | 0.1653 |

| 32 | Re | Sc | Um | 0.1674 | 0.1662 |

| 33 | Re | Sp | Um | 0.1656 | 0.1659 |

| 34 | Re | Tp | Um | 0.1682 | 0.1650 |

| 35 | Re | In | Um | 0.1667 | 0.1654 |

| 36 | Re | He | Ga | 0.1583 | 0.1279 |

| 37 | Re | Sc | Ga | 0.1481 | 0.1256 |

| 38 | Re | Sp | Ga | 0.1337 | 0.1320 |

| 39 | Re | Tp | Ga | 0.1414 | 0.1461 |

| 40 | Re | In | Ga | 0.1415 | 0.1390 |

| 41 | Re | He | Af | 0.1377 | 0.1591 |

| 42 | Re | Sc | Af | 0.1536 | 0.1583 |

| 43 | Re | Sp | Af | 0.1607 | 0.1534 |

| 44 | Re | Tp | Af | 0.1543 | 0.1412 |

| 45 | Re | In | Af | 0.1693 | 0.1717 |

| 46 | To | He | Um | 0.1722 | 0.1966 |

| 47 | To | Sc | Um | 0.1686 | 0.1680 |

| 48 | To | Sp | Um | 0.1688 | 0.1656 |

| 49 | To | Tp | Um | 0.1720 | 0.1687 |

| 50 | To | In | Um | 0.1641 | 0.1666 |

| 51 | To | He | Ga | 0.1420 | 0.1426 |

| 52 | To | Sc | Ga | 0.1494 | 0.1343 |

| 53 | To | Sp | Ga | 0.1677 | 0.1479 |

| 54 | To | Tp | Ga | 0.1411 | 0.1325 |

| 55 | To | In | Ga | 0.1539 | 0.1424 |

| 56 | To | He | Af | 0.1692 | 0.1660 |

| 57 | To | Sc | Af | 0.1509 | 0.1498 |

| 58 | To | Sp | Af | 0.1610 | 0.1772 |

| 59 | To | Tp | Af | 0.1519 | 0.1658 |

| 60 | To | In | Af | 0.1624 | 0.1620 |

| # | FF (kN) | FT (s) | UF (kN) | UTS | ||

|---|---|---|---|---|---|---|

| Predicted (MPa) | Observed (MPa) | Errors % | ||||

| 1 | 16 | 4 | 44 | 178 | 175 | 1.69 |

| 2 | 16 | 4 | 44 | 178 | 180 | −1.12 |

| 3 | 16 | 4 | 44 | 178 | 176 | 1.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winiczenko, R.; Skibicki, A.; Skoczylas, P. Optimization of Friction Welding Parameters to Maximize the Tensile Strength of Magnesium Alloy with Aluminum Alloy Dissimilar Joints Using Genetic Algorithm. Processes 2021, 9, 1550. https://doi.org/10.3390/pr9091550

Winiczenko R, Skibicki A, Skoczylas P. Optimization of Friction Welding Parameters to Maximize the Tensile Strength of Magnesium Alloy with Aluminum Alloy Dissimilar Joints Using Genetic Algorithm. Processes. 2021; 9(9):1550. https://doi.org/10.3390/pr9091550

Chicago/Turabian StyleWiniczenko, Radosław, Andrzej Skibicki, and Paweł Skoczylas. 2021. "Optimization of Friction Welding Parameters to Maximize the Tensile Strength of Magnesium Alloy with Aluminum Alloy Dissimilar Joints Using Genetic Algorithm" Processes 9, no. 9: 1550. https://doi.org/10.3390/pr9091550

APA StyleWiniczenko, R., Skibicki, A., & Skoczylas, P. (2021). Optimization of Friction Welding Parameters to Maximize the Tensile Strength of Magnesium Alloy with Aluminum Alloy Dissimilar Joints Using Genetic Algorithm. Processes, 9(9), 1550. https://doi.org/10.3390/pr9091550