Microwave Drying Characteristics and Drying Quality Analysis of Corn in China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Materials

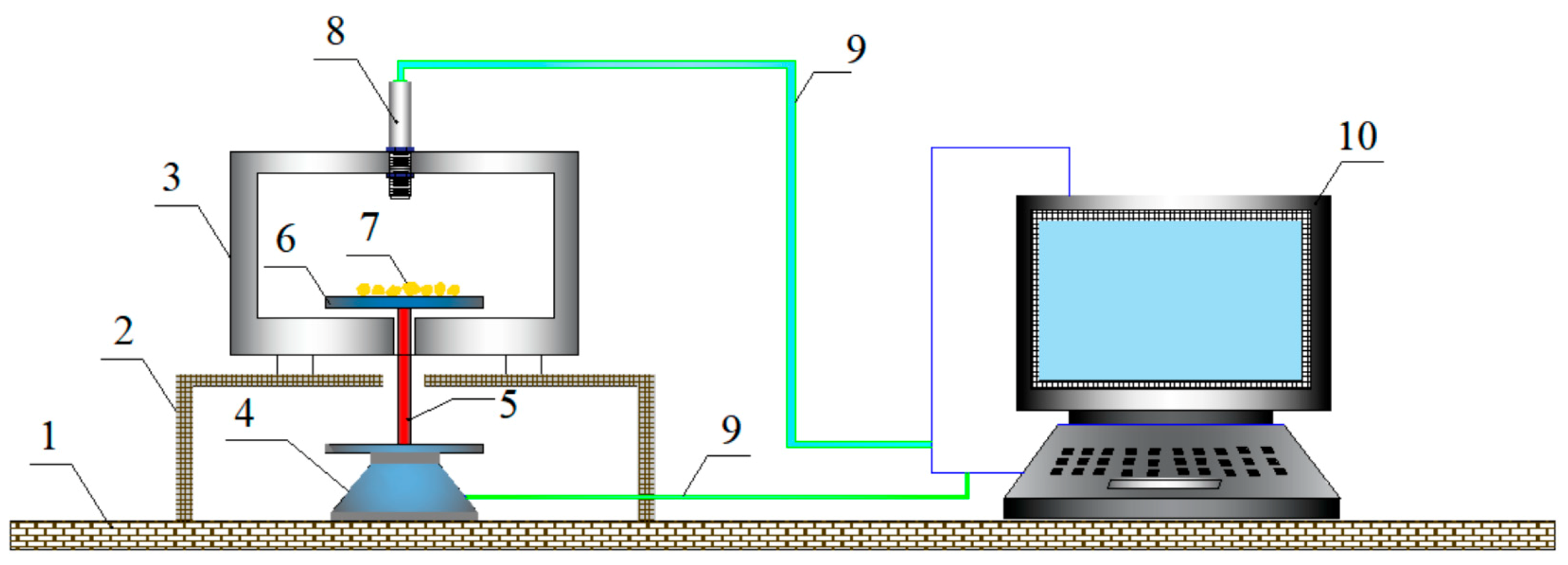

2.2. Test Equipment

2.2.1. Microwave Drying Equipment

2.2.2. Electrothermal Drying Equipment

2.3. Test Methods and Indices

2.3.1. Test Methods

2.3.2. Test Indices

3. Results and Discussion

3.1. Effects of Microwave Power on Drying Characteristics of Corn

3.2. The Effects of Load on the Microwave Drying Characteristics of Corn

3.3. Comparison between Microwave Drying and Electrothermal Drying of Corn

4. Comparison of Qualities of Corn after Microwave Drying and Electrothermal Drying

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature | Subscripts and Superscripts | ||

| M | dry-basis moisture content (g·g−1 (d.b.)) | t | time (min) |

| DR | drying rate (g/g·min−1 (d.b.)) | d | dried materials |

| T | temperature of the materials (°C) | ||

| E | energy consumption during drying (MJ) | ||

| average power (kW) | |||

References

- Minmin, J.; Guixiang, C.; Chaosai, L.; Wenlei, L.; Zhijing, Z. Effects of moisture content on elastic-plastic properties of bulk wheat. Trans. Chin. Soc. Agric. Eng. 2020, 36, 245–251. [Google Scholar]

- Zhang, L.; Liu, P. Review of research status of crop mildew. Grain Sci. Technol. Econ. 2020, 45, 89–90. [Google Scholar]

- Monteiro, R.L.; Link, J.V.; Tribuzi, G.; Carciofi, B.A.M.; Laurindo, J.B. Microwave vacuum drying and multi-flash drying of pumpkin slices. J. Food Eng. 2018, 232, 1–10. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, S.; Pan, Y.; Tang, Y.; Chen, G. Wave-absorbing material aided microwave freeze-drying of vitamin C solution frozen with preformed pores. Dry. Technol. 2020, 1–14. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, M.; Fang, Z.; Mujumdar, A.S.; Jiang, H.; Qian, H.; Ai, H. Drying kinetics and product quality of green soybean under different microwave drying methods. Dry. Technol. 2017, 35, 240–248. [Google Scholar] [CrossRef]

- Chua, L.Y.W.; Chua, B.L.; Figiel, A.; Chong, C.H.; Wojdyło, A.; Szumny, A.; Łycko, J. Drying of Phyla nodiflora Leaves: Antioxidant Activity, Volatile and Phytosterol Content, Energy Consumption, and Quality Studies. Processes 2019, 7, 210. [Google Scholar] [CrossRef] [Green Version]

- Zhao, P.; Liu, C.; Qu, W.; He, Z.; Gao, J.; Jia, L.; Ji, S.; Ruan, R. Effect of Temperature and Microwave Power Levels on Microwave Drying Kinetics of Zhaotong Lignite. Processes 2019, 7, 74. [Google Scholar] [CrossRef] [Green Version]

- Choo, C.O.; Chua, B.L.; Figiel, A.; Jałoszyński, K.; Wojdyło, A.; Szumny, A.; Łyczko, J.; Chong, C.H. Hybrid Drying of Murraya koenigii Leaves: Energy Consumption, Antioxidant Capacity, Profiling of Volatile Compounds and Quality Studies. Processes 2020, 8, 240. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Liu, D.; Yu, H.; Wang, D.; Li, J. Optimization of Microwave Coupled Hot Air Drying for Chinese Yam Using Response Surface Methodology. Processes 2019, 7, 745. [Google Scholar] [CrossRef] [Green Version]

- Thuto, W.; Banjong, K. Investigation of Heat and Moisture Transport in Bananas during Microwave Heating Process. Processes 2019, 7, 545. [Google Scholar] [CrossRef] [Green Version]

- Hemis, M.; Gariépy, Y.; Choudhary, R.; Raghavan, V. New coupling model of microwave assisted hot-air drying of a capillary porous agricultural product: Application on soybeans and canola seeds. Appl. Therm. Eng. 2017, 114, 931–937. [Google Scholar] [CrossRef]

- Hemis, M.; Choudhary, R.; Watson, D.G. A coupled mathematical model for simultaneous microwave and convective drying of wheat seeds. Biosyst. Eng. 2012, 112, 202–209. [Google Scholar] [CrossRef] [Green Version]

- Gürsoy, S.; Choudhary, R.; Watson, D.G. Microwave drying kinetics and quality characteristics of corn. Int. J. Agric. Biol. Eng. 2013, 6, 90. [Google Scholar]

- Smith, D.L.; Atungulu, G.G.; Sadaka, S.; Rogers, S. Implications of microwave drying using 915 MHz frequency on rice physicochemical properties. Cereal Chem. 2018, 95, 211–225. [Google Scholar] [CrossRef]

- Olatunde, G.A.; Atungulu, G.G.; Smith, D.L. One-pass drying of rough rice with an industrial 915 MHz microwave dryer: Quality and energy use consideration. Biosyst. Eng. 2017, 155, 33–43. [Google Scholar] [CrossRef]

- Shen, L.; Gao, M.; Zhu, Y.; Liu, C.; Wang, L.; Kamruzzaman, M.; Liu, C.; Zheng, X. Microwave drying of germinated brown rice: Correlation of drying characteristics with the final quality. Innov. Food Sci. Emerg. 2021, 70, 102673. [Google Scholar] [CrossRef]

- Yuan, J.; Zhao, T.; Ding, C. Effects of microwave treatments on rice quality and lipase activity. Sci. Agric. Sin. 2018, 21, 4131–4142. [Google Scholar]

- Pratap Singh, A.; Mandal, R.; Shojaei, M.; Singh, A.; Kowalczewski, P.Ł.; Ligaj, M.; Pawlicz, J.; Jarzębski, M. Novel Drying Methods for Sustainable Upcycling of Brewers’ Spent Grains as a Plant Protein Source. Sustainability 2020, 12, 3660. [Google Scholar] [CrossRef]

- Jin, X.; Wang, C.; Bi, Q.; Liu, Z.; Zhang, Z. Study on drying characteristics of corn based on 3D model. Int. J. Food Eng. 2020, 16. [Google Scholar] [CrossRef]

- Gwirtz, J.A.; Garcia Casal, M.N. Processing maize flour and corn meal food products. Ann. N. Y. Acad. Sci. 2014, 1312, 66–75. [Google Scholar] [CrossRef] [Green Version]

- Rahmanian-Koushkaki, H.; Nourmohamadi-Moghadami, A.; Zare, D.; Karimi, G. Experimental and theoretical investigation of hot air-infrared thin layer drying of corn in a fixed and vibratory bed dryer. Eng. Agric. Environ. Food 2017, 10, 191–197. [Google Scholar] [CrossRef]

- Abasi, S.; Minaei, S. Effect of Drying Temperature on Mechanical Properties of Dried Corn. Dry. Technol. 2014, 32, 774–780. [Google Scholar] [CrossRef]

- Bualuang, O.; Onwude, D.I.; Pracha, K. Microwave drying of germinated corn and its effect on phytochemical properties. J. Sci. Food Agric. 2017, 97, 2999–3004. [Google Scholar] [CrossRef] [PubMed]

- Crostack, H.A.; Nellesen, J.; Fischer, G.; Hofmann, M.; Rademacher, H.G.; Tillmann, W. Analysis of Crack Patterns in Drying Corn Starch by in-situ Radiography and X-ray Computer Tomography. Exp. Mech. 2012, 52, 917–932. [Google Scholar] [CrossRef]

- Wang, J.; Xi, Y.S. Drying characteristics and drying quality of carrot using a two-stage microwave process. J. Food Eng. 2005, 68, 505–511. [Google Scholar] [CrossRef]

- Soysal, Y. Microwave Drying Characteristics of Parsley. Biosyst. Eng. 2004, 89, 167–173. [Google Scholar] [CrossRef]

- Hemis, M.; Singh, C.B.; Jayas, D.S. Microwave-Assisted Thin Layer Drying of Wheat. Dry. Technol. 2011, 29, 1240–1247. [Google Scholar] [CrossRef]

- Hou, L.; Li, R.; Wang, S.; Datta, A.K. Numerical analysis of heat and mass transfers during intermittent microwave drying of Chinese jujube (Zizyphus jujuba Miller). Food Bioprod. Process. 2021, 129, 10–23. [Google Scholar] [CrossRef]

- Qi, S.; Han, J.; Lagnika, C.; Jiang, N.; Qian, C.; Liu, C.; Li, D.; Tao, Y.; Yu, Z.; Wang, L.; et al. Dielectric properties of edible fungi powder related to radio-frequency and microwave drying. Food Prod. Process. Nutr. 2021, 3, 1–13. [Google Scholar] [CrossRef]

- Mardaras, J.; Lombraña, J.I.; Villarán, M.C. Effect of the thermal level on the viability of microencapsulated living cells dehydrated by near fluidizing microwave drying. Dry. Technol. 2021, 39, 219–233. [Google Scholar] [CrossRef]

- Guo, J.; Zheng, L.; Li, Z. Microwave drying behavior, energy consumption, and mathematical modeling of sewage sludge in a novel pilot-scale microwave drying system. Sci. Total Environ. 2021, 777, 146109. [Google Scholar] [CrossRef] [PubMed]

- Kipcak, A.S.; İsmail, O. Microwave drying of fish, chicken and beef samples. J. Food Sci. Technol. 2021, 58, 281–291. [Google Scholar] [CrossRef] [PubMed]

- Silva, E.G.; Gomez, R.S.; Gomes, J.P.; Silva, W.P.; Porto, K.Y.N.; Rolim, F.D.; Carmo, J.E.F.; Andrade, R.O.; Santos, I.B.; Sousa, R.A.A.; et al. Heat and Mass Transfer on the Microwave Drying of Rough Rice Grains: An Experimental Analysis. Agriculture 2021, 11, 8. [Google Scholar] [CrossRef]

- Boshkova, I.L.; Volgusheva, N.V.; Boshkov, L.Z. Analytical study of temperature field during microwave drying of the material. J. Phys. Conf. Ser. 2020, 1683, 22044. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, R.; Wang, J.; Dong, Y. Microwave-assisted synthesis and characterization of acetylated corn starch. Starch-Stärke 2014, 66, 515–523. [Google Scholar] [CrossRef]

| Number | Microwave Power (W) | Sample Weight (g) |

|---|---|---|

| 1 | 70 | 60 |

| 2 | 70 | 100 |

| 3 | 70 | 200 |

| 4 | 280 | 100 |

| Number | Drying Temperature (°C) | Sample Weight (g) |

|---|---|---|

| 1 | 60 | 100 |

| 2 | 80 | 100 |

| 3 | 100 | 100 |

| 4 | 120 | 100 |

| 5 | 140 | 100 |

| Load (g) | Drying Time (min) | Energy Consumption (MJ) | Energy Consumption Per Unit Mass (MJ/kg) |

|---|---|---|---|

| 60 | 44 ± 1 | 0.317 ± 0.007 | 5.28 ± 0.108 |

| 100 | 69 ± 2 | 0.468 ± 0.013 | 4.68 ± 0.147 |

| 200 | 95 ± 2 | 0.662 ± 0.015 | 3.31 ± 0. 073 |

| Number | Drying Conditions | Energy Consumption E (MJ) | Time t (min) | |

|---|---|---|---|---|

| 1 | Electrothermal, 60 °C | 4.320 ± 0.147 | 478 ± 16 | 0.151 ± 0.005 |

| 2 | Electrothermal, 80 °C | 2.520 ± 0.112 | 267 ± 12 | 0.157 ± 0.007 |

| 3 | Electrothermal, 100 °C | 4.140 ± 0.137 | 168 ± 6 | 0.411 ± 0.014 |

| 4 | Electrothermal, 120 °C | 5.220 ± 0.155 | 110 ± 3 | 0.791 ± 0.023 |

| 5 | Electrothermal, 140 °C | 5.040 ± 0.148 | 78 ± 2 | 1.077 ± 0.032 |

| 6 | Microwave, 70 W | 0.468 ± 0.014 | 69 ± 2 | 0.115 ± 0.004 |

| 7 | Microwave, 280 W | 0.608 ± 0.018 | 22 ± 1 | 0.460 ± 0.014 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Liu, H.; Liu, H.; Zhang, X.; Hong, Q.; Chen, W.; Zeng, X. Microwave Drying Characteristics and Drying Quality Analysis of Corn in China. Processes 2021, 9, 1511. https://doi.org/10.3390/pr9091511

Liu H, Liu H, Liu H, Zhang X, Hong Q, Chen W, Zeng X. Microwave Drying Characteristics and Drying Quality Analysis of Corn in China. Processes. 2021; 9(9):1511. https://doi.org/10.3390/pr9091511

Chicago/Turabian StyleLiu, Haili, Haoyu Liu, Heyun Liu, Xu Zhang, Qingchao Hong, Wang Chen, and Xi Zeng. 2021. "Microwave Drying Characteristics and Drying Quality Analysis of Corn in China" Processes 9, no. 9: 1511. https://doi.org/10.3390/pr9091511

APA StyleLiu, H., Liu, H., Liu, H., Zhang, X., Hong, Q., Chen, W., & Zeng, X. (2021). Microwave Drying Characteristics and Drying Quality Analysis of Corn in China. Processes, 9(9), 1511. https://doi.org/10.3390/pr9091511