Combustion Efficiency in a Fluidized-Bed Combustor with a Modified Perforated Plate for Air Distribution

Abstract

:1. Introduction

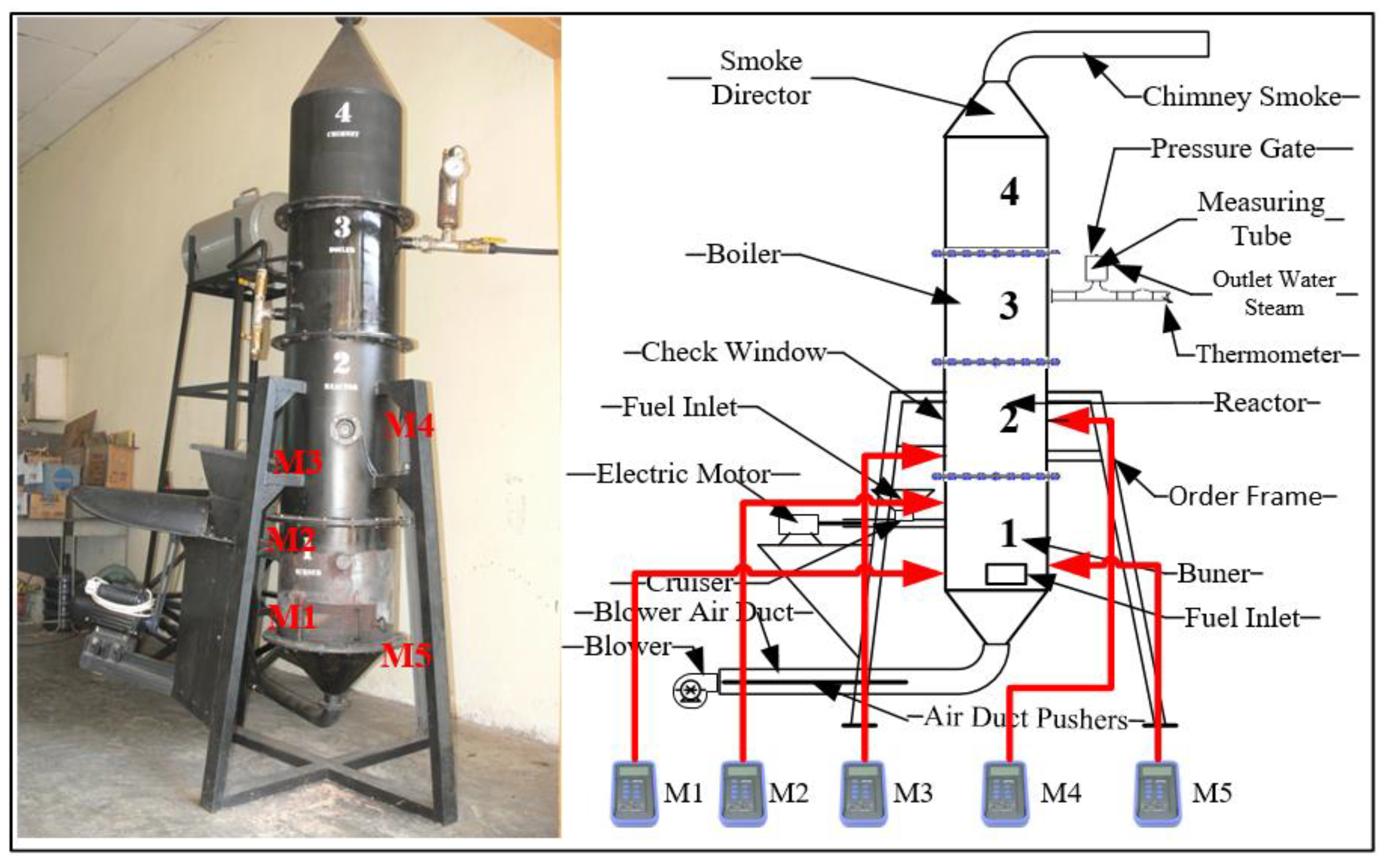

2. Materials and Experimental Setup

Material of Fuel

3. Results and Discussion

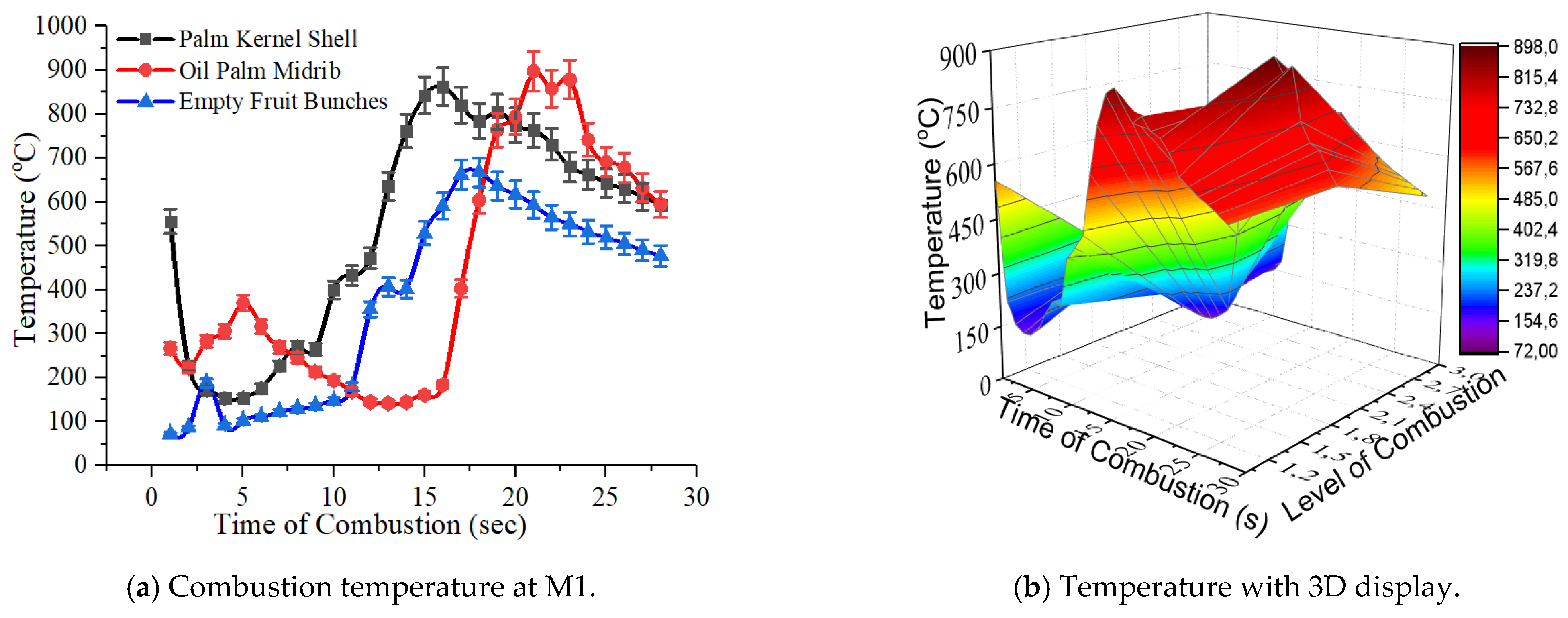

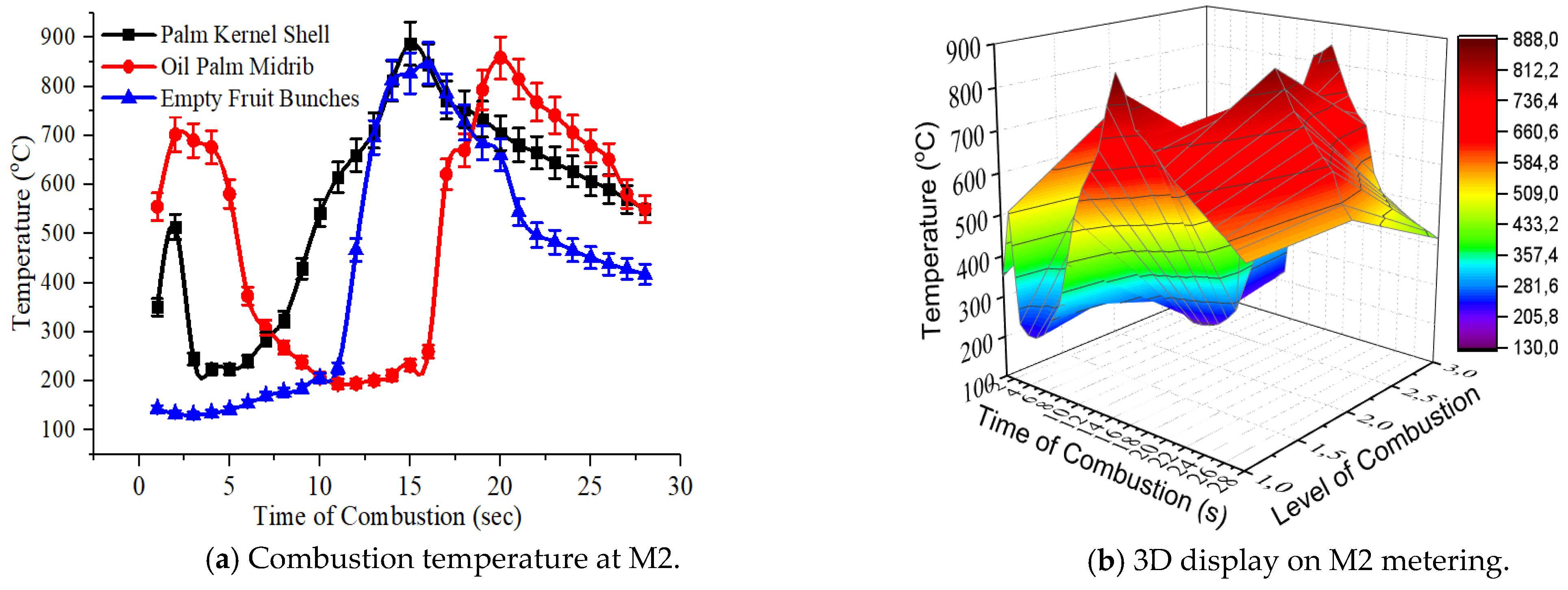

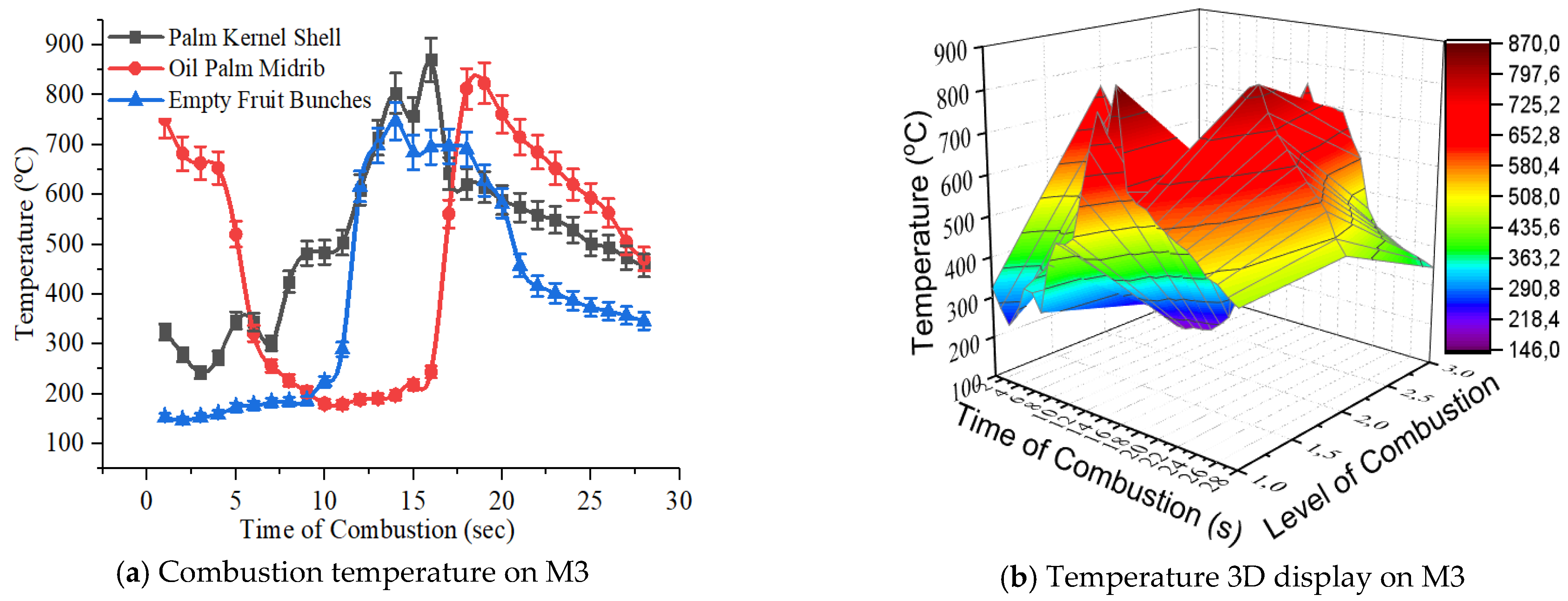

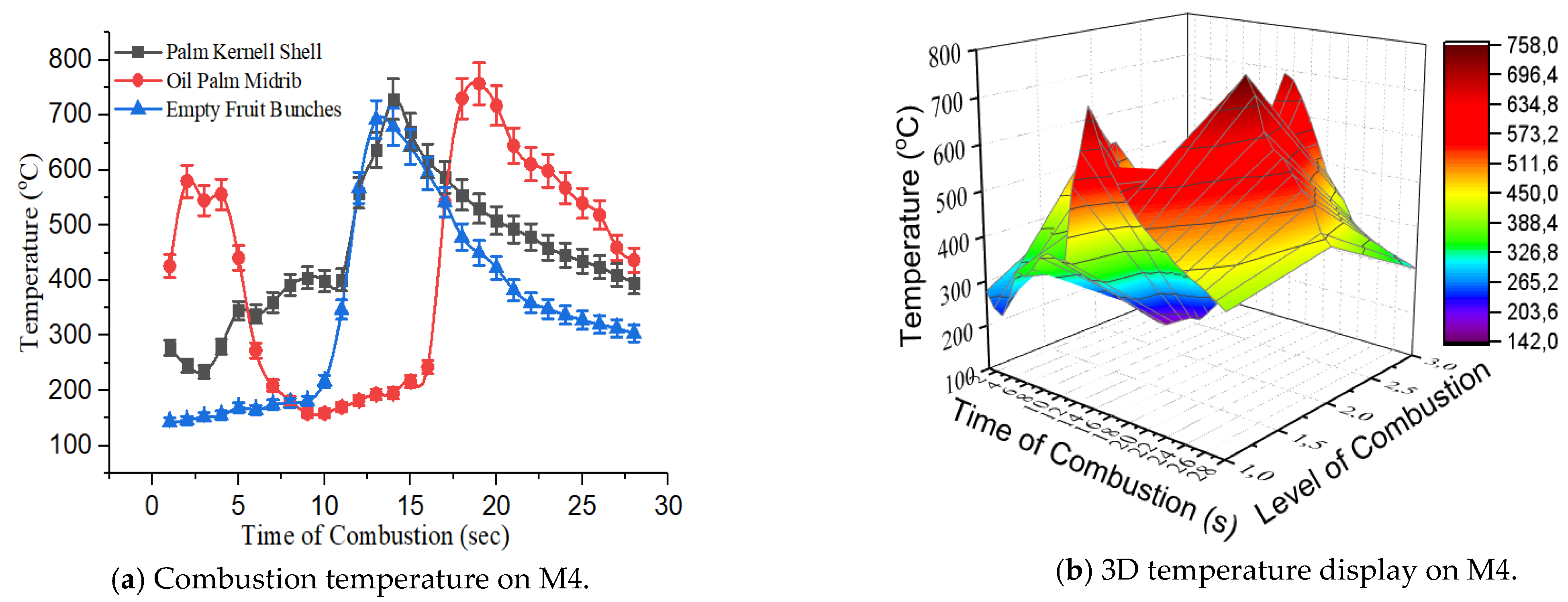

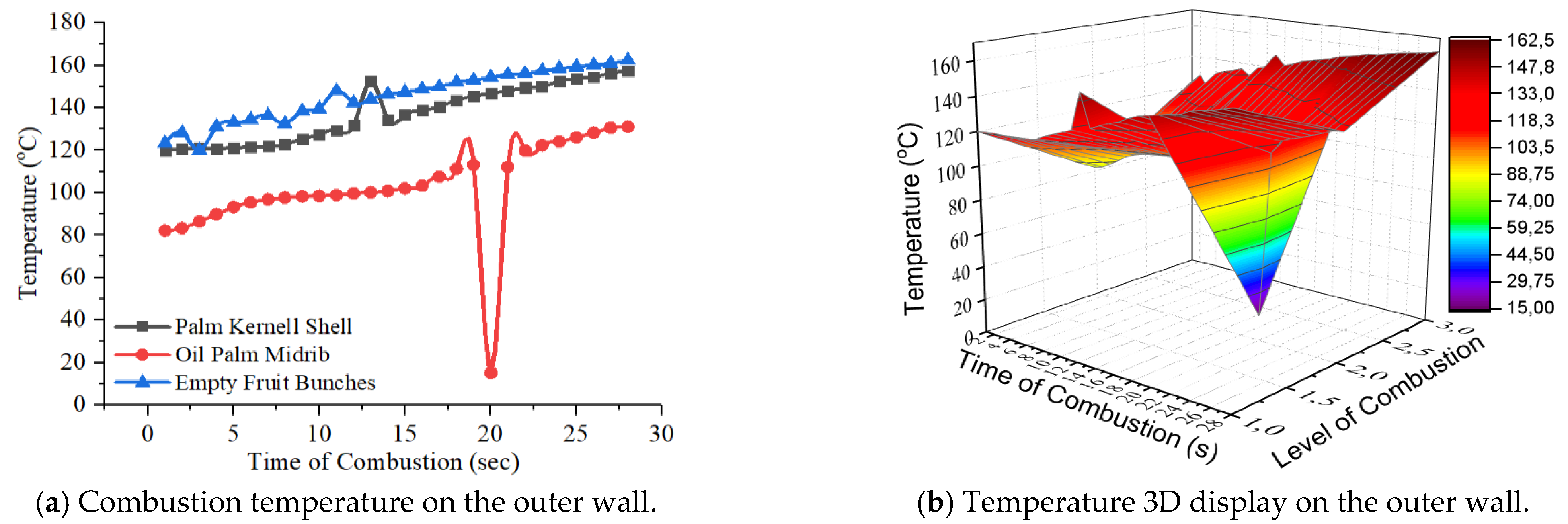

3.1. Temperature Influence of Walled Plate Modification

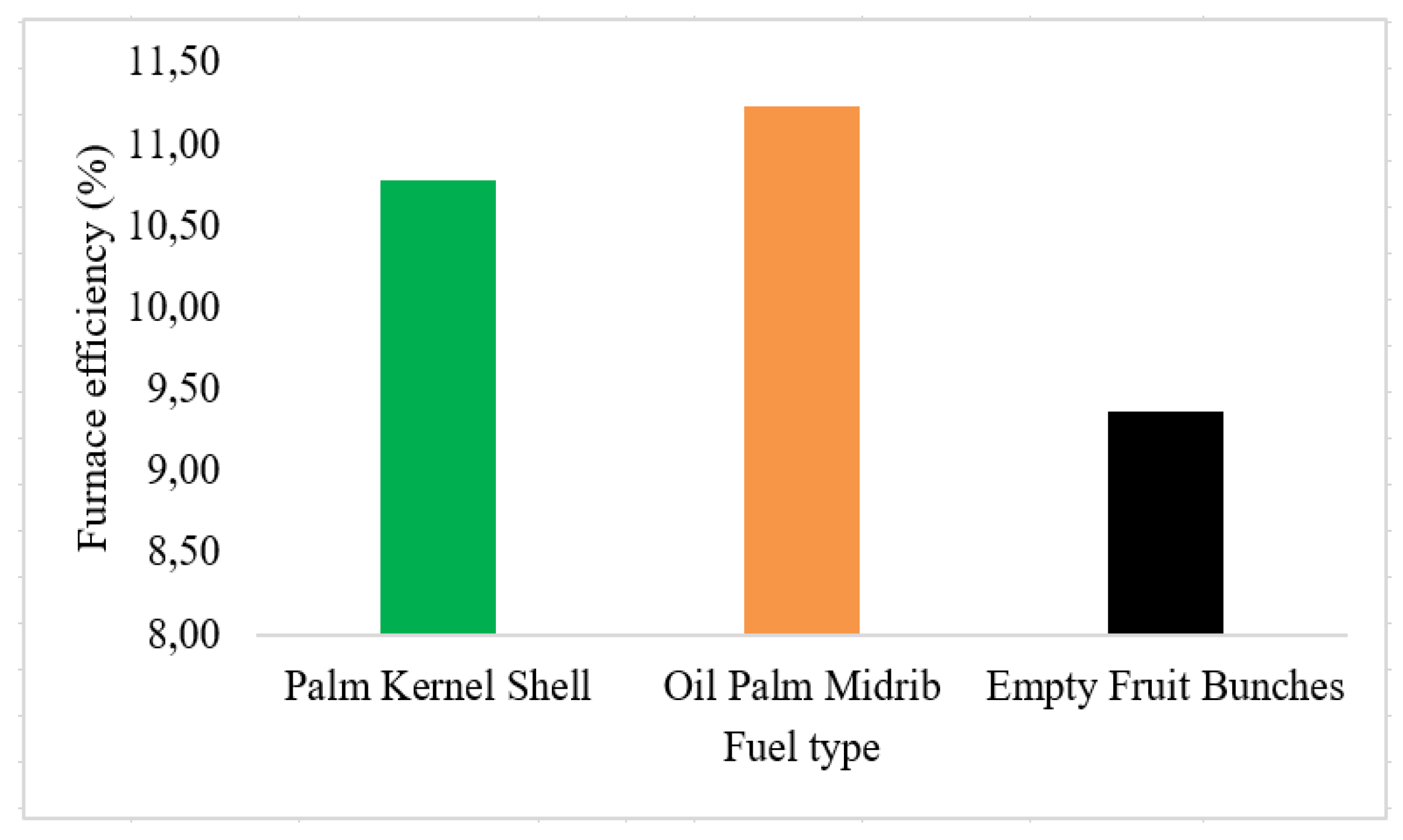

3.2. Combustion Efficiency

- Eff is the efficiency,

- Pin is the power input, and

- Pout is the power output.

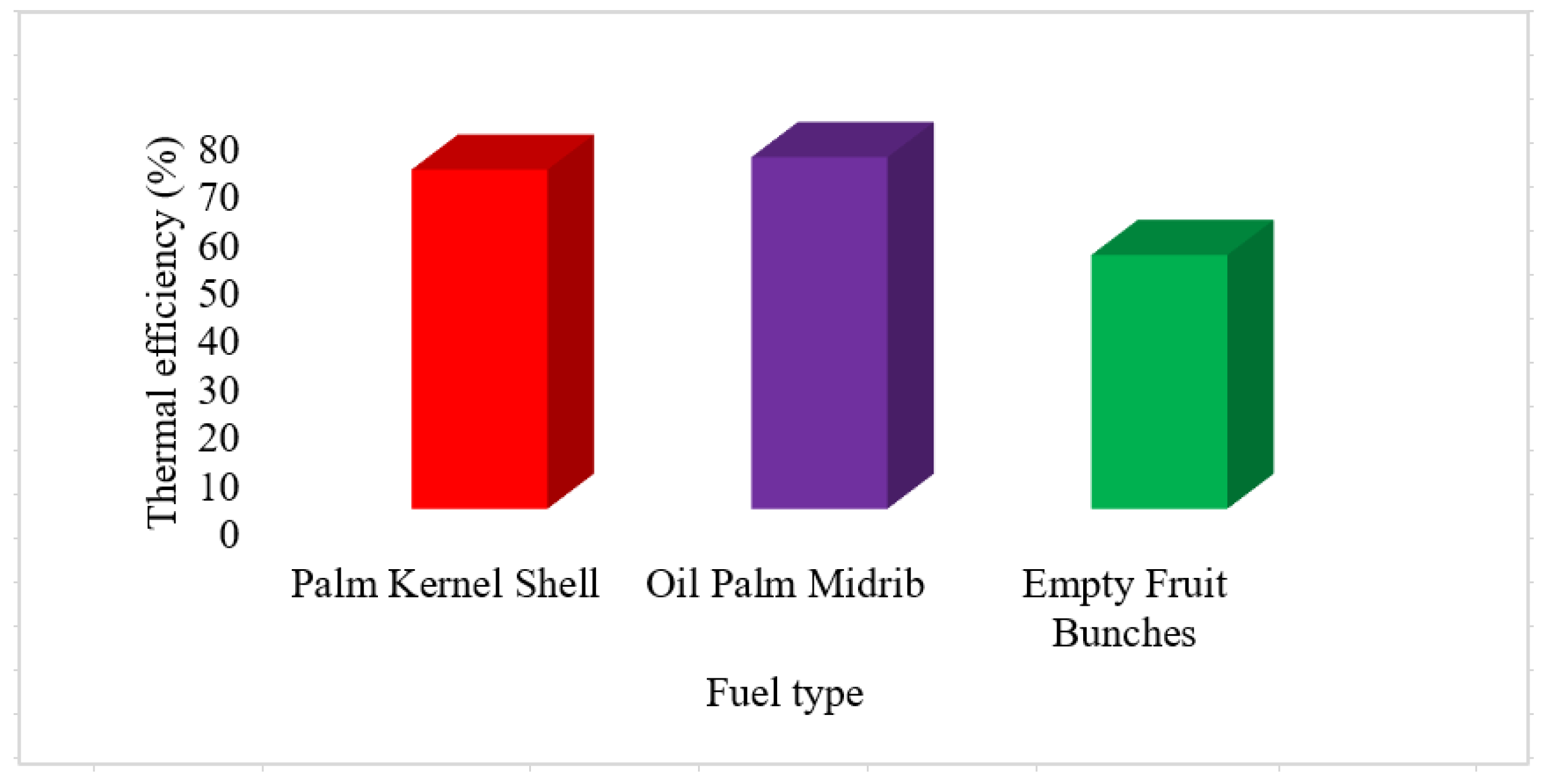

3.3. Thermal Efficiency

- is the efficiency thermal,

- ma is the liters of water,

- Cp is the calorific value,

- ΔT is the last value − first value,

- mb is the fuel weight, and

- LHVfuel is the lower heating value.

3.4. Measurement Heat Transfer Coefficient

- q is the convection heat rate;

- M1 is the temperature fluid;

- M5 is the temperature wall;

- ro1 is the outer radius of the cylinder;

- ri1 is the radius in cylinder;

- ro2 is the outer radius of insulation;

- ri2 is the outer radius in isolation;

- ro3 is the cylinder outer radius;

- ri3 is the radius in the cylinder;

- k1 is the thermal conductivity of the plate;

- k2 is the insulating conductivity;

- ho is the convection heat transfer coefficient;

- Ao is the outer cross-sectional area;

- hi is the coefficient in the wall; and

- Ai is the inner cross-sectional area.

4. Conclusions

- Combustion temperatures at M1 and M2 reached 863 °C and 887 °C, respectively, for PKS fuel. The highest combustion temperature recorded at M1 was obtained from OPM fuel at 898 °C. Meanwhile, the highest combustion temperature at M2 was recorded from the combustion of PKS at 863 °C.

- Modification of the perforated plate with four air suppliers from the blower to the combustion chamber shows maximum results. EFB fuels exhibited a slower combustion temperature trend compared to PKS and OPM fuels.

- Furnace efficiency levels using PKS, OPM, and EFB fuels were 10.78%, 11.23%, and 9.36%, respectively. Based on these results, it can be reported that OPM fuel shows the maximum combustion furnace efficiency.

- The highest thermal efficiency in the FBC fuel chamber reached 72.62% for the OPM fuel. Meanwhile, thermal efficiency for the PKS and EFB fuels was 70.03% and 52.43% respectively.

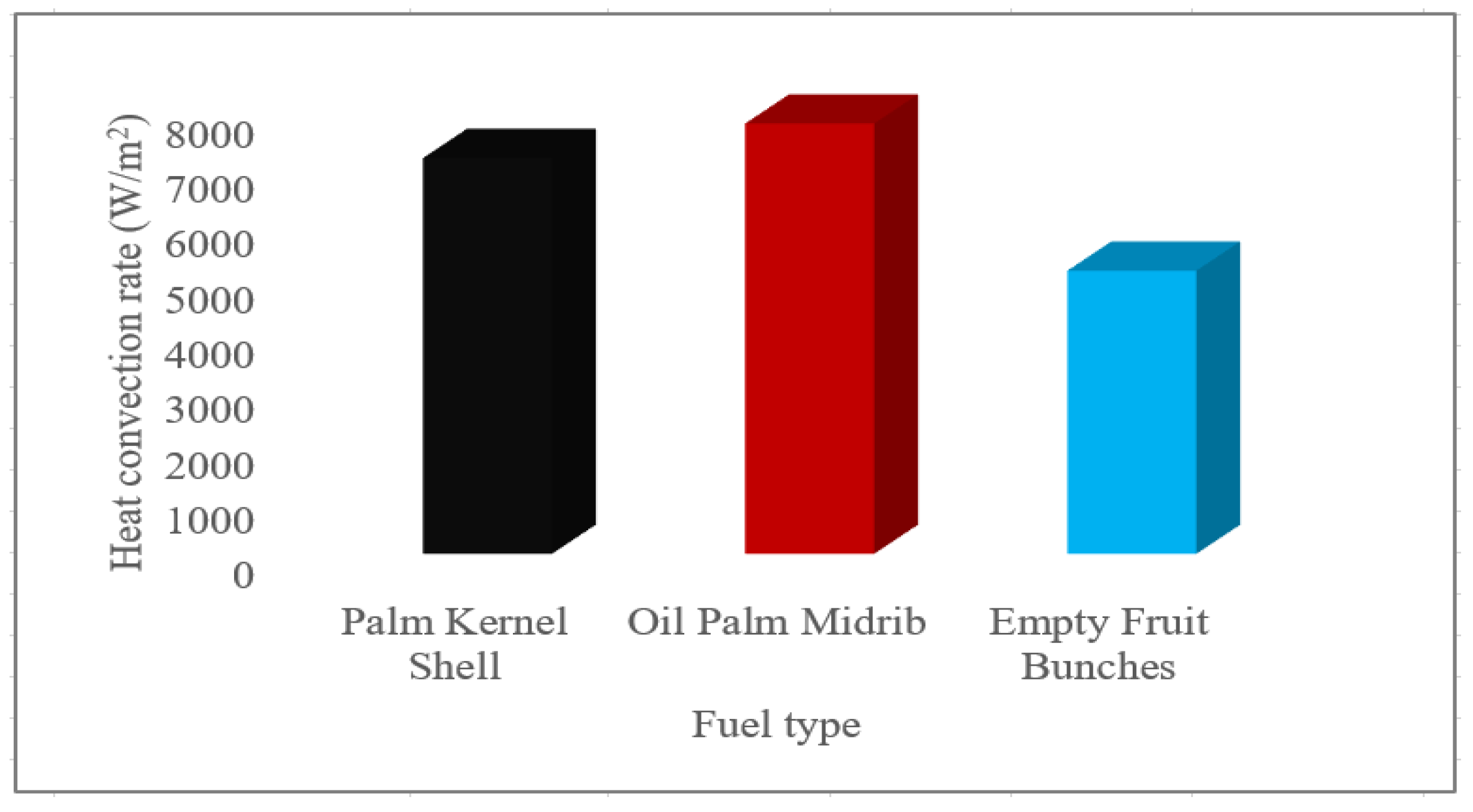

- The highest heat transfer rate was obtained from OPM fuels reaching 7792.36 W/m2, while the heat transfer rates for PKS and EFB fuels were 7167.38 W/m2 and 5127.83 w/m, respectively.

- Overall, the plate modification applied in this study showed perfect results, indicating that all the fuels used could be burned and nothing remained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Erdiwansyah; Mamat, R.; Sani, M.S.M.; Sudhakar, K. Renewable energy in Southeast Asia: Policies and recommendations. Sci. Total Environ. 2019, 670, 1095–1102. [Google Scholar] [CrossRef]

- Erdiwansyah; Mahidin; Mamat, R.; Sani, M.S.M.; Khoerunnisa, F.; Kadarohman, A. Target and demand for renewable energy across 10 ASEAN countries by 2040. Electr. J. 2019, 32, 106670. [Google Scholar] [CrossRef]

- Murphy, C.A.; Schleifer, A.; Eurek, K. A taxonomy of systems that combine utility-scale renewable energy and energy storage technologies. Renew. Sustain. Energy Rev. 2021, 139, 110711. [Google Scholar] [CrossRef]

- Shahidul, M.I.; Malcolm, M.L.; Begum, S.; Hashmi, M.S.J.; Islam, M.S.; Eugene, J.J. Renewable Energy Production From Environmental Hazardous Palm Oil Mill Waste Materials: A Review; Hashmi, S., Choudhury IABT-E of R and SM, Eds.; Elsevier: Oxford, UK, 2020; pp. 902–914. ISBN 978-0-12-813196-1. [Google Scholar]

- Ng, K.H.; Yuan, L.S.; Cheng, C.K.; Chen, K.; Fang, C. TiO2 and ZnO photocatalytic treatment of palm oil mill effluent (POME) and feasibility of renewable energy generation: A short review. J. Clean. Prod. 2019, 233, 209–225. [Google Scholar] [CrossRef]

- Ahmad, A.; Buang, A.; Bhat, A.H. Renewable and sustainable bioenergy production from microalgal co-cultivation with palm oil mill effluent (POME): A review. Renew. Sustain. Energy Rev. 2016, 65, 214–234. [Google Scholar] [CrossRef]

- Mahidin; Saifullah; Erdiwansyah; Hamdani; Hisbullah; Hayati, A.P.; Zhafran, M.; Sidiq, M.A.; Rinaldi, A.; Fitria, B.; et al. Analysis of power from palm oil solid waste for biomass power plants: A case study in Aceh Province. Chemosphere 2020, 253, 126714. [Google Scholar] [CrossRef]

- Tewarson, A. Generation of heat and chemical compounds in fires. SFPE Handb. Fire Prot. Eng. 2002, 82–161. Available online: https://www.semanticscholar.org/paper/Generation-of-Heat-and-Chemical-Compounds-in-Fires-Tewarson/845faf6dc5e9d9bc6da273f5b21078b62df83a1a (accessed on 11 August 2021).

- Ishikawa, T.; Kasumi, K.; Tanaka, F.; Moinuddin, K.A.M. Combustion efficiency during fires in tunnels with natural ventilation by vitiated air including descending smoke. Fire Saf. J. 2020, 120, 103093. [Google Scholar] [CrossRef]

- White, J.P.; Link, E.D.; Trouvé, A.; Sunderland, P.B.; Marshall, A.W. A general calorimetry framework for measurement of combustion efficiency in a suppressed turbulent line fire. Fire Saf. J. 2017, 92, 164–176. [Google Scholar] [CrossRef]

- Qin, L.; Han, J.; Chen, W.; Yao, X.; Tadaaki, S.; Kim, H. Enhanced combustion efficiency and reduced pollutant emission in a fluidized bed combustor by using porous alumina bed materials. Appl. Therm. Eng. 2016, 94, 813–818. [Google Scholar] [CrossRef]

- Peng, W.; Liu, Z.; Motahari-Nezhad, M.; Banisaeed, M.; Shahraki, S.; Beheshti, M. A detailed study of oxy-fuel combustion of biomass in a circulating fluidized bed (CFB) combustor: Evaluation of catalytic performance of metal nanoparticles (Al, Ni) for combustion efficiency improvement. Energy 2016, 109, 1139–1147. [Google Scholar] [CrossRef]

- Permchart, W.; Kouprianov, V.I. Emission performance and combustion efficiency of a conical fluidized-bed combustor firing various biomass fuels. Bioresour. Technol. 2004, 92, 83–91. [Google Scholar] [CrossRef]

- Wang, D.; Wang, H.; Xing, J.; Wang, Y. Investigation of the thermal-hydraulic characteristics in the shell side of heat exchanger with quatrefoil perforated plate. Int. J. Therm. Sci. 2021, 159, 106580. [Google Scholar] [CrossRef]

- Mentzoni, F.; Kristiansen, T. Two-dimensional experimental and numerical investigations of parallel perforated plates in oscillating and orbital flows. Appl. Ocean Res. 2020, 97, 102042. [Google Scholar] [CrossRef]

- Hani, M.R.; Mahidin, M.; Husin, H.; Khairil, K.; Hamdani, H.; Erdiwansyah, E.; Hisbullah, H.; Faisal, M.; Mahyudin, M.; Muhtadin, M. Experimental Studies on Combustion Characteristics of OilPalm Biomass in Fluidized-Bed: A Heat Energy Alternative. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 68, 9–28. [Google Scholar] [CrossRef]

- Ninduangdee, P.; Kuprianov, V.I. Combustion of Oil Palm Shells in a Fluidized-bed Combustor Using Dolomite as the Bed Material to Prevent Bed Agglomeration. Energy Procedia 2014, 52, 399–409. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Wang, J.; Min, C.; Xie, G.; Sundén, B. Performance of fuel-air combustion in a reheating furnace at different flowrate and inlet conditions. Energy 2020, 206, 118206. [Google Scholar] [CrossRef]

- Han, S.H.; Lee, Y.S.; Cho, J.R.; Lee, K.H. Efficiency analysis of air-fuel and oxy-fuel combustion in a reheating furnace. Int. J. Heat Mass Transf. 2018, 121, 1364–1370. [Google Scholar] [CrossRef]

- Holman, J.P. Perpindahan Kalor (terjemahan E. Jasfi). Jkt. Penerbit Erlangga (Buku Asli 1986). 1988. Available online: https://onesearch.id/Record/IOS2862.UNMAL000000000013905 (accessed on 11 August 2021).

- Xiao, G.; Zeng, J.; Nie, J. A practical method to evaluate the thermal efficiency of solar molten salt receivers. Appl. Therm. Eng. 2021, 190, 116787. [Google Scholar] [CrossRef]

- Wichangarm, M.; Matthujak, A.; Sriveerakul, T.; Sucharitpwatskul, S.; Phongthanapanich, S. Investigation on thermal efficiency of LPG cooking burner using computational fluid dynamics. Energy 2020, 203, 117849. [Google Scholar] [CrossRef]

- Agrawal, B.N.; Sinha, S.; Kuzmin, A.V.; Pinchuk, V.A. Effect of vegetable oil share on combustion characteristics and thermal efficiency of diesel engine fueled with different blends. Therm. Sci. Eng. Prog. 2019, 14, 100404. [Google Scholar] [CrossRef]

- Yu, Z.; Tao, L.; Huang, L.; Wang, D. Numerical investigation on cooling heat transfer and flow characteristic of supercritical CO2 in spirally fluted tubes. Int. J. Heat Mass Transf. 2020, 163, 120399. [Google Scholar] [CrossRef]

- Gogoi, B.; Baruah, D.C. Steady state heat transfer modeling of solid fuel biomass stove: Part 1. Energy 2016, 97, 283–295. [Google Scholar] [CrossRef]

- Faisal, M.; Usman, U. Analisa Perpindahan Panas Pada Tungku Rocket Tipe Silinder Berbahan Bakar Biomassa. In Proceedings of the Prosiding SEMDI-UNAYA (Seminar Nasional Multi Disiplin Ilmu UNAYA), Banda Aceh, Indonesia, 20–21 June 2019; Volume 3, pp. 393–401. [Google Scholar]

| Component | Measurement |

|---|---|

| Model HT-306 | Dual channel input |

| Input sensor | Thermocouple type “K” |

| Resolution | HT-306:1 °C/1 °F |

| Response time | 15 S |

| Wide measuring range | −50 °C~+1300 °C (−58 °F~+1999 °F) |

| Power supply | Baterai 6F22 9V |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erdiwansyah; Mahidin; Husin, H.; Nasaruddin; Muhtadin; Faisal, M.; Gani, A.; Usman; Mamat, R. Combustion Efficiency in a Fluidized-Bed Combustor with a Modified Perforated Plate for Air Distribution. Processes 2021, 9, 1489. https://doi.org/10.3390/pr9091489

Erdiwansyah, Mahidin, Husin H, Nasaruddin, Muhtadin, Faisal M, Gani A, Usman, Mamat R. Combustion Efficiency in a Fluidized-Bed Combustor with a Modified Perforated Plate for Air Distribution. Processes. 2021; 9(9):1489. https://doi.org/10.3390/pr9091489

Chicago/Turabian StyleErdiwansyah, Mahidin, Husni Husin, Nasaruddin, Muhtadin, Muhammad Faisal, Asri Gani, Usman, and Rizalman Mamat. 2021. "Combustion Efficiency in a Fluidized-Bed Combustor with a Modified Perforated Plate for Air Distribution" Processes 9, no. 9: 1489. https://doi.org/10.3390/pr9091489

APA StyleErdiwansyah, Mahidin, Husin, H., Nasaruddin, Muhtadin, Faisal, M., Gani, A., Usman, & Mamat, R. (2021). Combustion Efficiency in a Fluidized-Bed Combustor with a Modified Perforated Plate for Air Distribution. Processes, 9(9), 1489. https://doi.org/10.3390/pr9091489