3.1. Log-Gabor Filter

In image processing, the log-Gabor filter is very good at edge extraction. Its maximum bandwidth is limited within the range of approximately one frequency multiplier due to the existence of the dc component of the traditional Gabor filter, so the processing effect is not so good. The log-Gabor filter, as an improved version of the Gabor filter, has no DC component and no bandwidth limit. Therefore, the arbitrary bandwidth that the log-Gabor filter can pass through is established. Meanwhile, the bandwidth can be optimized to generate a filter with a minimum spatial domain, creating a visual field closer to the human eye.

The transfer function of the two-dimensional log-Gabor filter can be expressed as:

G(

f) represents the radial component, and its expression is as follows:

G(

θ) represents the angle component, and its expression is as follows:

Each parameter in the equation is as follows:

f0 is the center frequency of the filter; that is, the reciprocal of the bandwidth;

θ0 is the direction of the filter; and

σr and σθ are used to determine the radial and directional bandwidth, respectively.

The mathematical expression of

Bf and

Bθ is as follows:

Convolved with the image and the filter, the corresponding feature image can be obtained:

where

I(

x,

y) represents the gray value of the original image and

Gf0,θ represents the filter with a center frequency of

f0 and a direction of

θ0. The result of the convolution operation is

E0

f0,θ(

x,

y); that is, the filtering result.

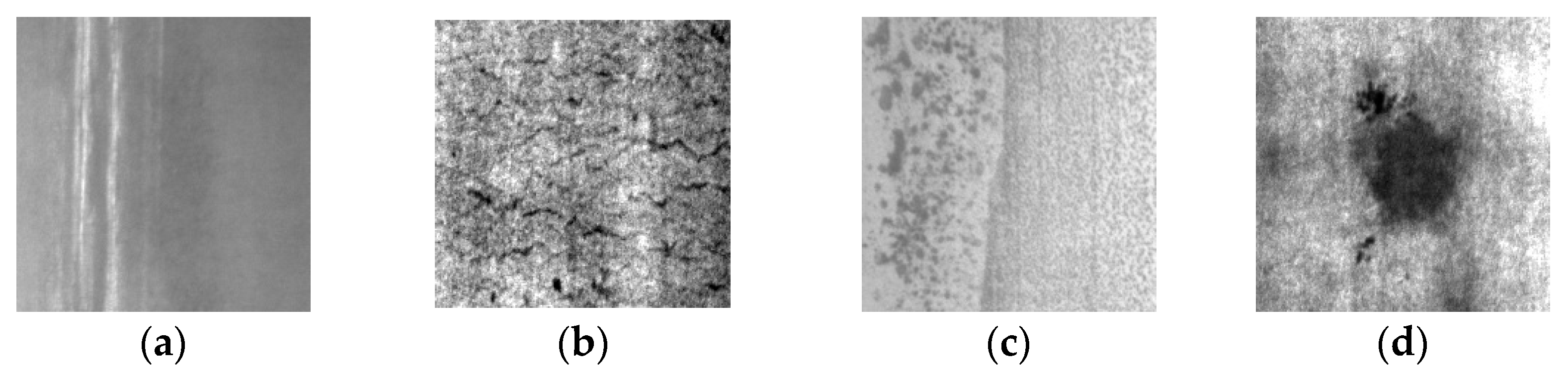

In the log-Gabor function, the direction

θ0 and center frequency

f0 are the decisive parameters for the generated filter template. In the same manner as in the previous section, under the condition that other parameters remain unchanged, these two main parameters are changed, and four different filter templates are generated by taking the central frequency of wavelength

f0 = 1/3 and

f0 = 1/12, and the direction

θ0 = 45 and

θ0 = 90, respectively. The resulting filter templates are shown in

Table 2.

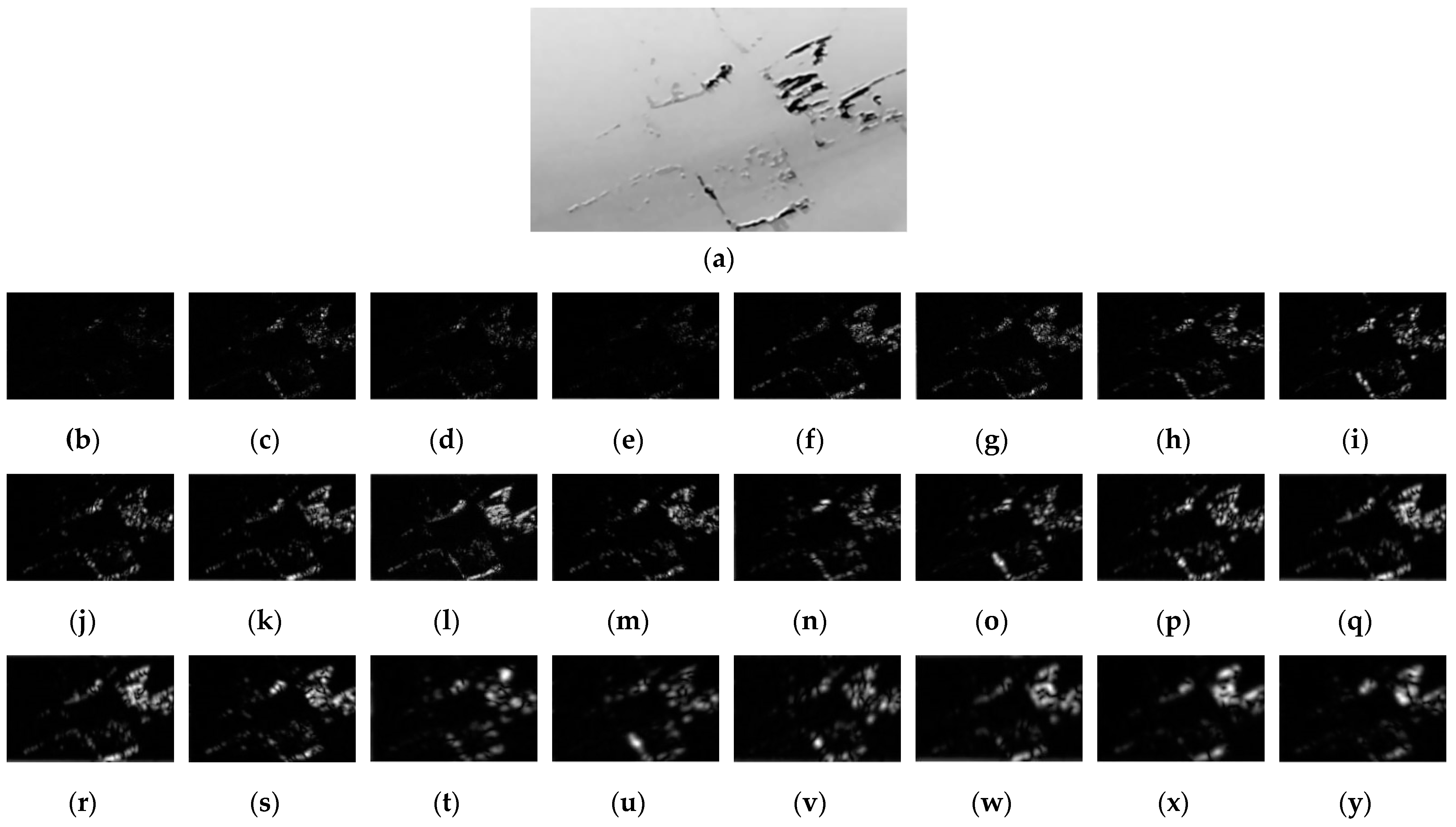

To achieve a better treatment effect, in which we put aside the workload and processing speed, we still choose four different wavelengths in the center frequency six different directions to generate the 24 different templates for processing, a scale of 4 (i.e., four different center frequencies), a direction to choose 6 different values, and a center frequency less than 2.5. The center frequencies

f0 (from left to right in

Figure 9) were selected as 1/2, 1/5, 1/12.5, and 1/31.25, and the direction

θ0 (from top to bottom in

Figure 9) was selected as 0, 30, 60, 90, 120, and 150. The 24 templates were used to convolve with the image respectively, and the results are shown in

Figure 9.

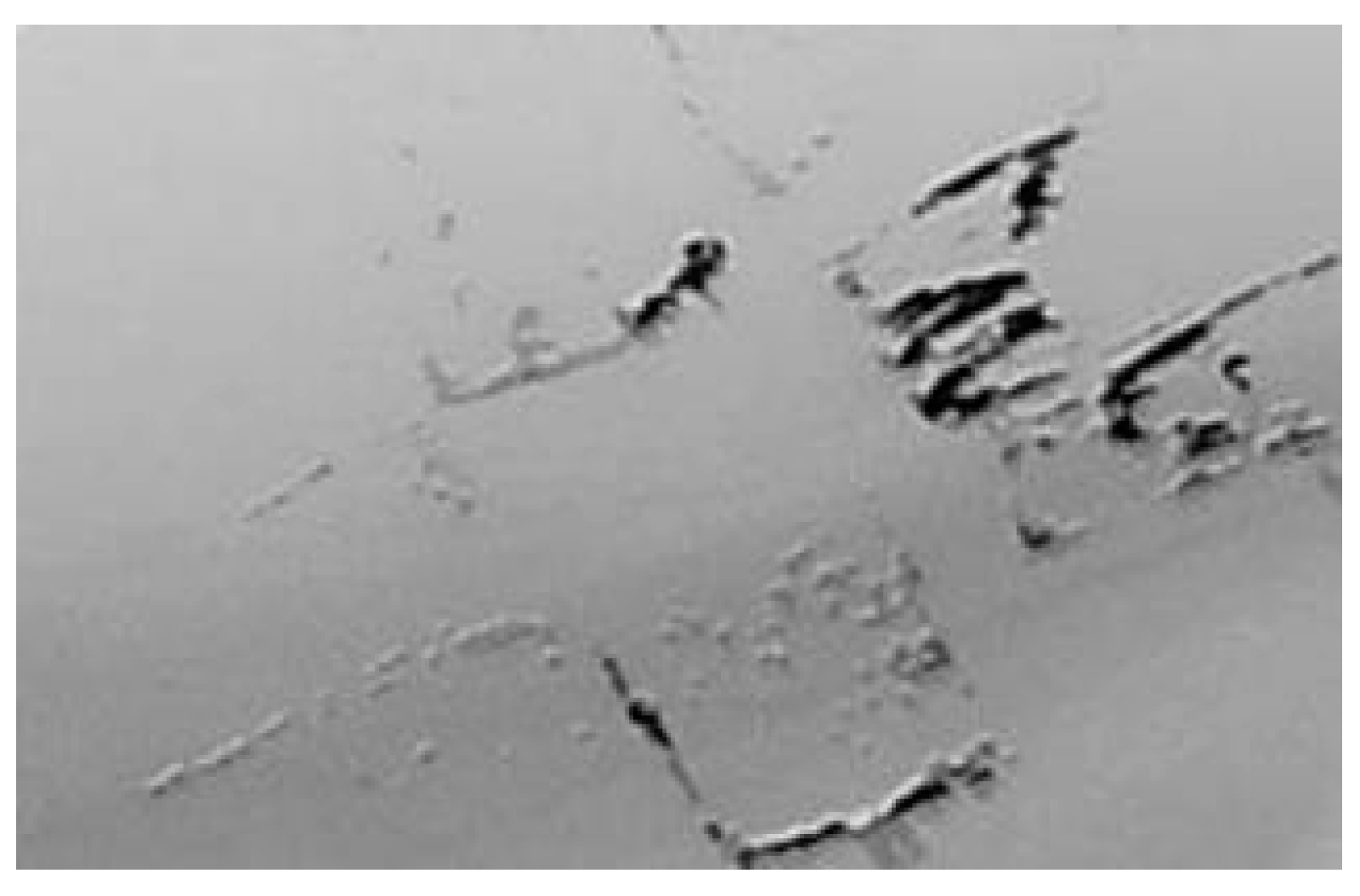

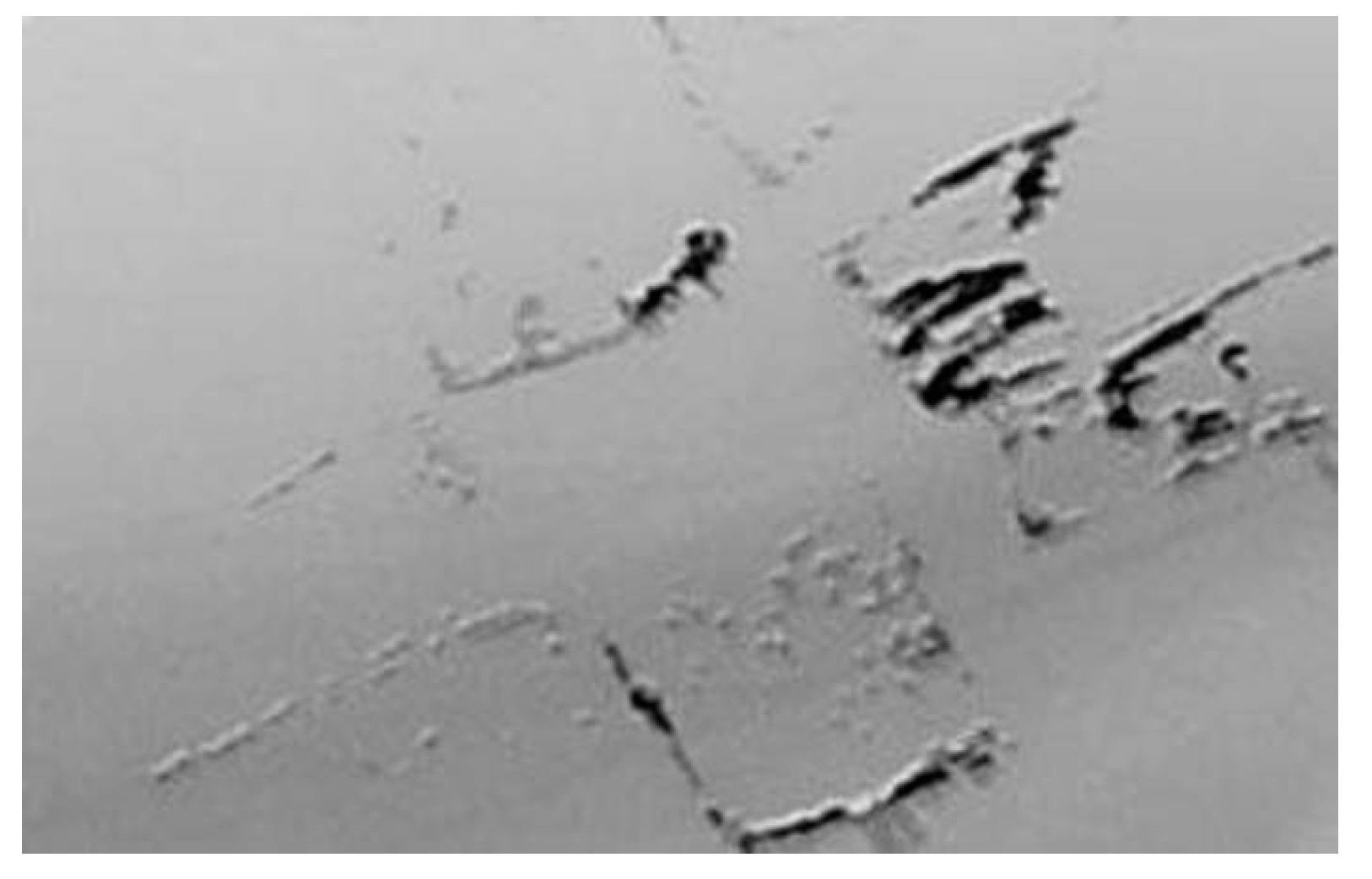

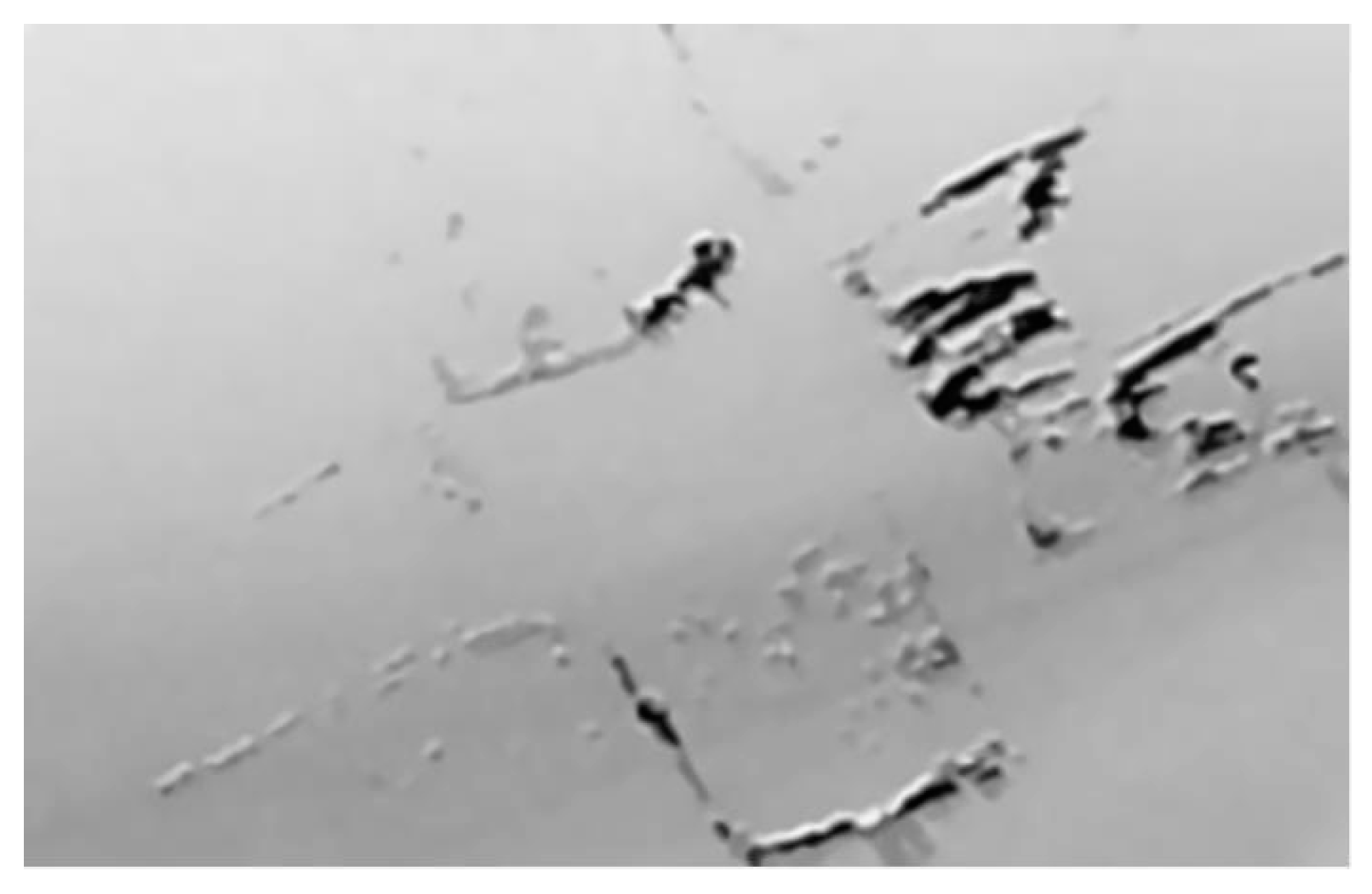

In

Figure 9b–y are the output images taken with the 24 templates.

To more intuitively observe the contrast results of the sharpness of each image after feature extraction using this method, we also calculated the average gradient value of the 24 images processed by the log-Gabor filter. The results are shown in

Table 3.

It can be seen from the data in the table that when f0 = 1/5 and θ0 = 120, the average gradient value reached the maximum value of 6.5184. Therefore, when the log-Gabor filter f0 = 1/5 and θ0 = 120 was used for feature extraction, the edge information was clearer, and the noise was less.

3.2. Log-Gabor Defect Feature Extraction Based on the LPSO Algorithm

Particle swarm optimization (PSO) is an intelligent algorithm developed through swarm intelligence. It was mainly inspired by the predator–prey behavior of bird groups and was researched to simulate such behavior. It has been widely used in solving optimization problems.

The update of speed is mainly completed according to the following formula:

The mathematical expression of the position update is as follows:

where

represents the inertia weight;

,

;

and

represent the velocity and position of the

particle, respectively;

and

are learning factors for the particle update speed;

is a random number; and

and

represent the current locally and globally optimal solutions for the particle, respectively.

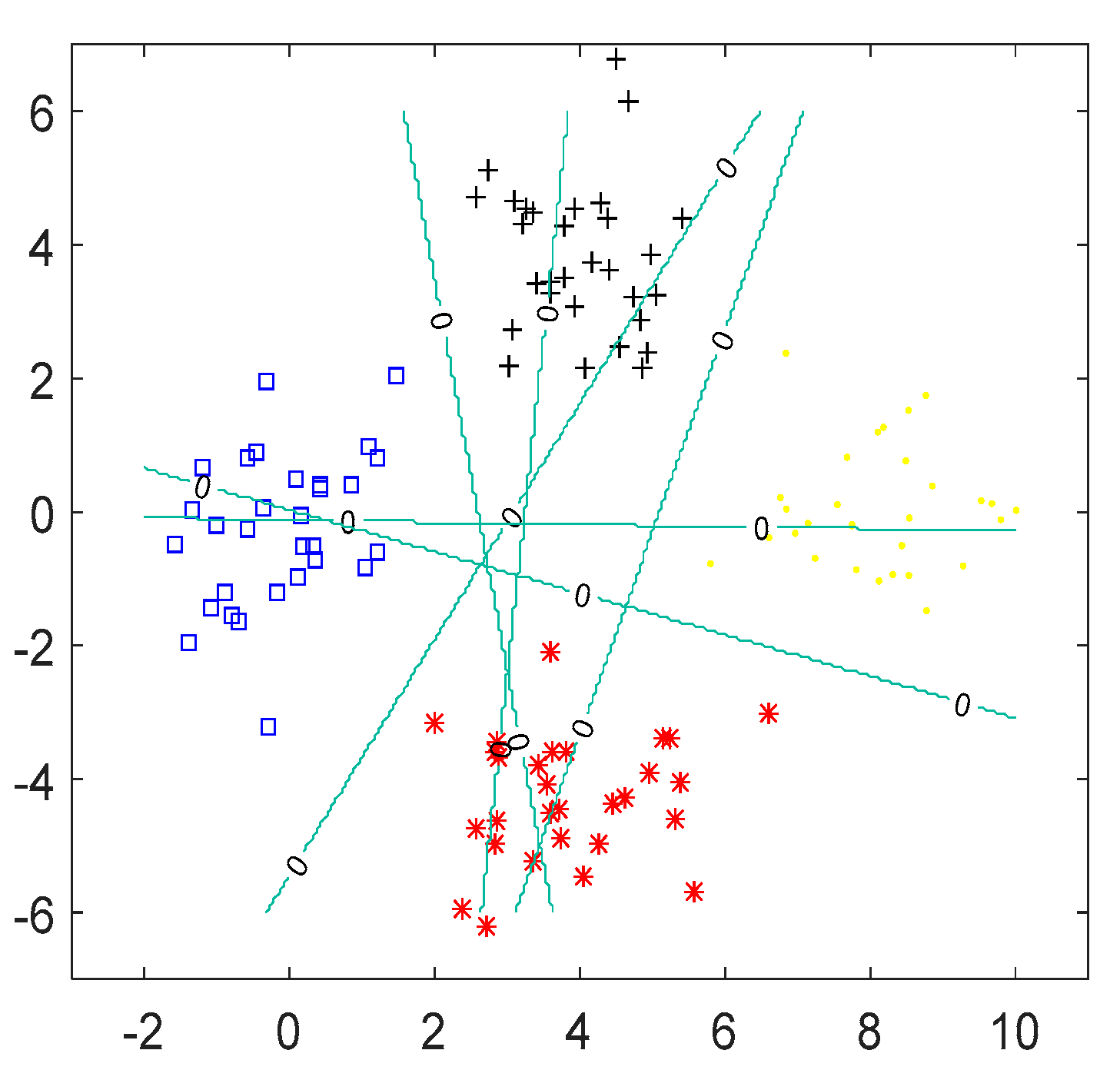

Because of the advantages of a distributed search, only a few parameters, and simple implementation, the PSO algorithm is often used to find an optimal solution. However, it also has some disadvantages, as shown in

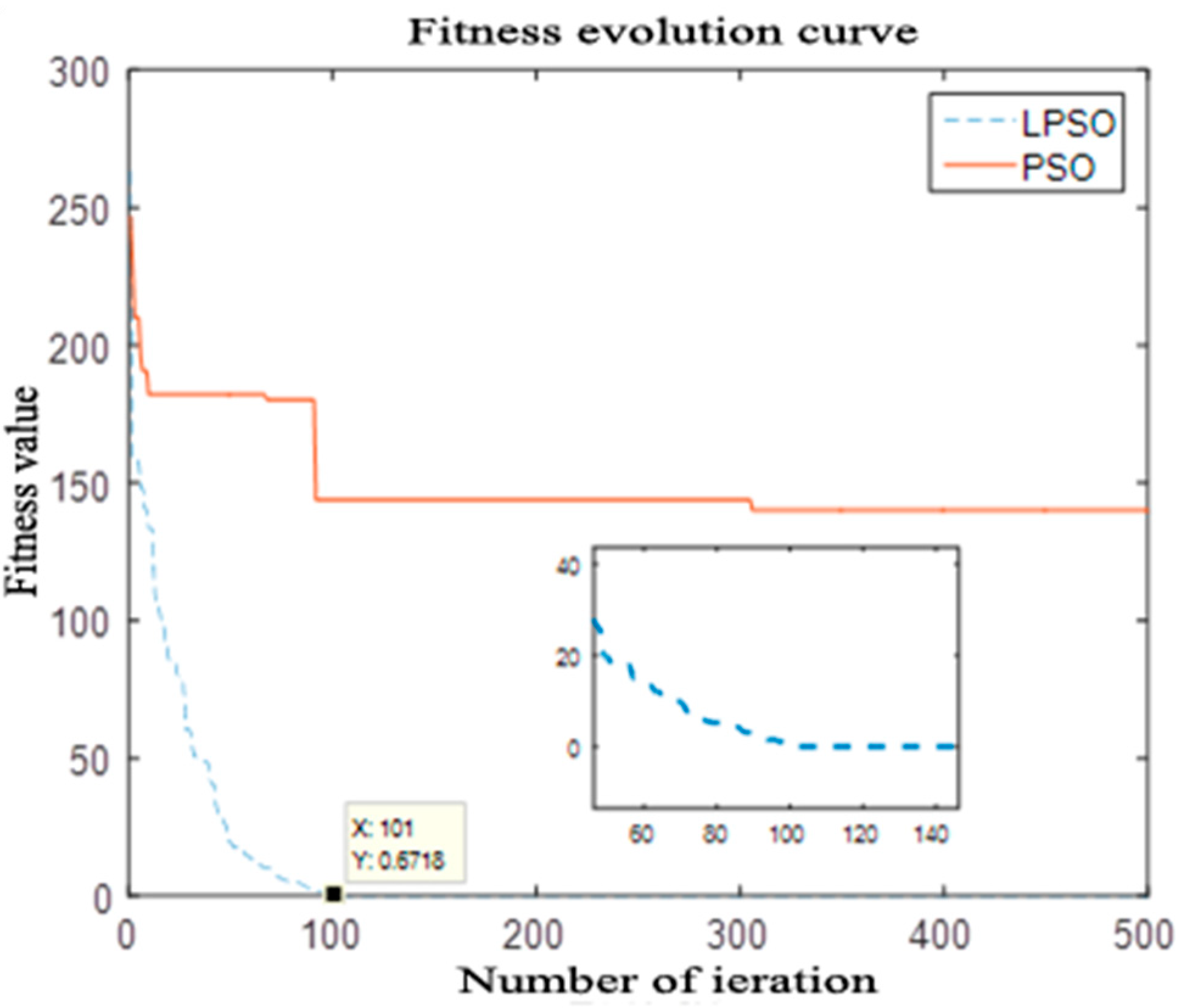

Figure 10. When it finds the optimal solution in the region, it concludes that it has found the global optimal solution. It soon stops iteration, falls into the local optimal solution, and cannot find the global optimal solution, resulting in poor solution quality.

So, we modified the PSO algorithm with the Lévy flight strategy. Lévy flight strategy is a particle flight strategy with strong randomness [

28]. It initializes the spatial position of the bird flock through such random walk characteristics as frequent search at a short distance and small search at a long distance to expand the search range and enrich the population diversity, and it can jump out of the local optimal solution [

29].

The variance of Lévy flight shows an exponential relationship over time. Many scholars have studied how to generate a random number that obeys the Lévy distribution. This method achieved good results and was gradually recognized by people and widely used. Thus, the method for generating random step sizes that obey Lévy’s distribution has been named after it ever since, and is known as the Mantegna algorithm. The formula can be expressed as:

where

represents the step length of Lévy flight;

is a power;

is the learning factor of Lévy flight, usually 1.5; and

and

represent two random variables that conform to the distribution of Equation (14):

The parameter

in the above equation, and the other parameter,

, can be obtained using Equation (15):

where Γ represents the standard Gamma function.

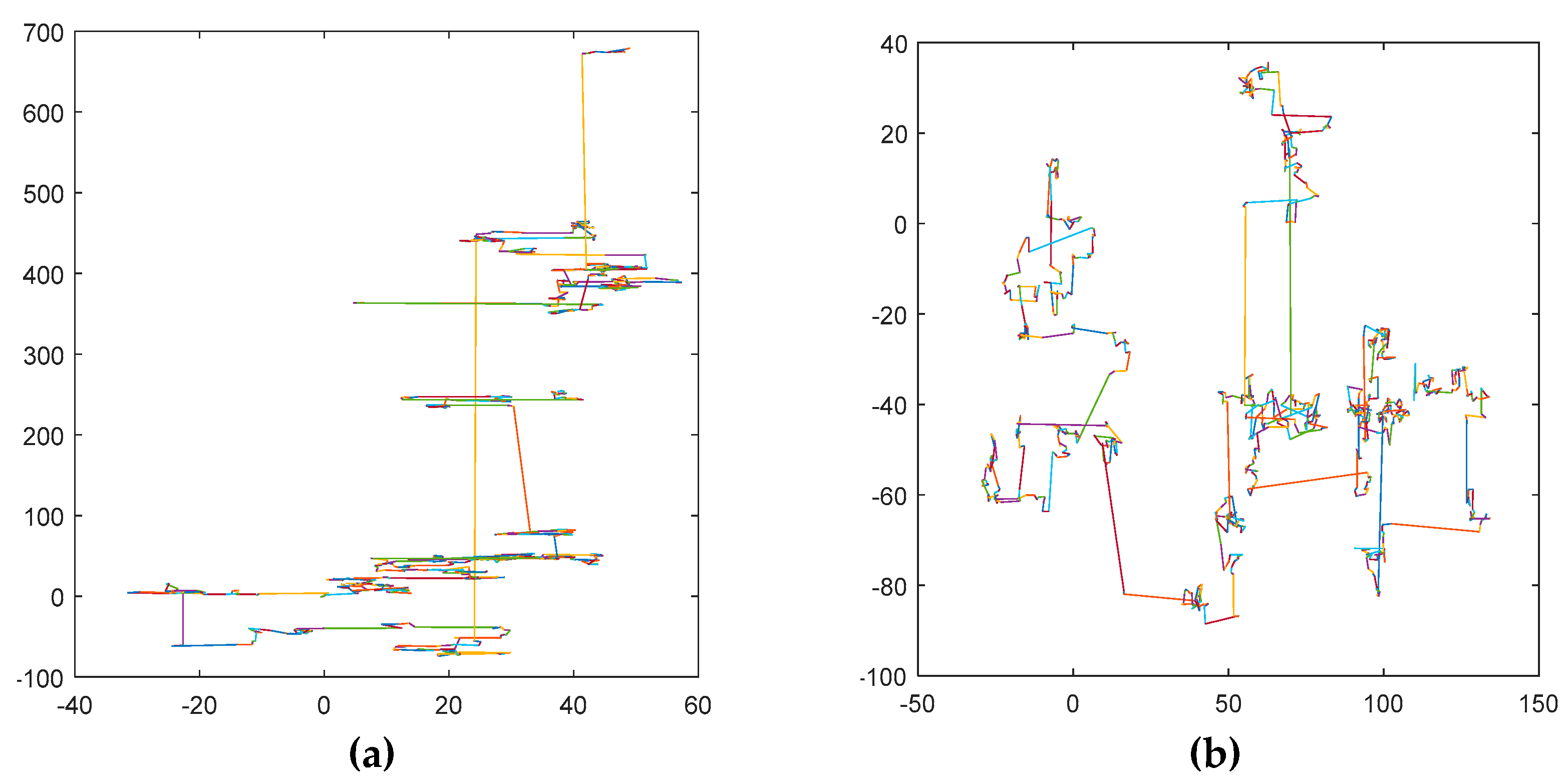

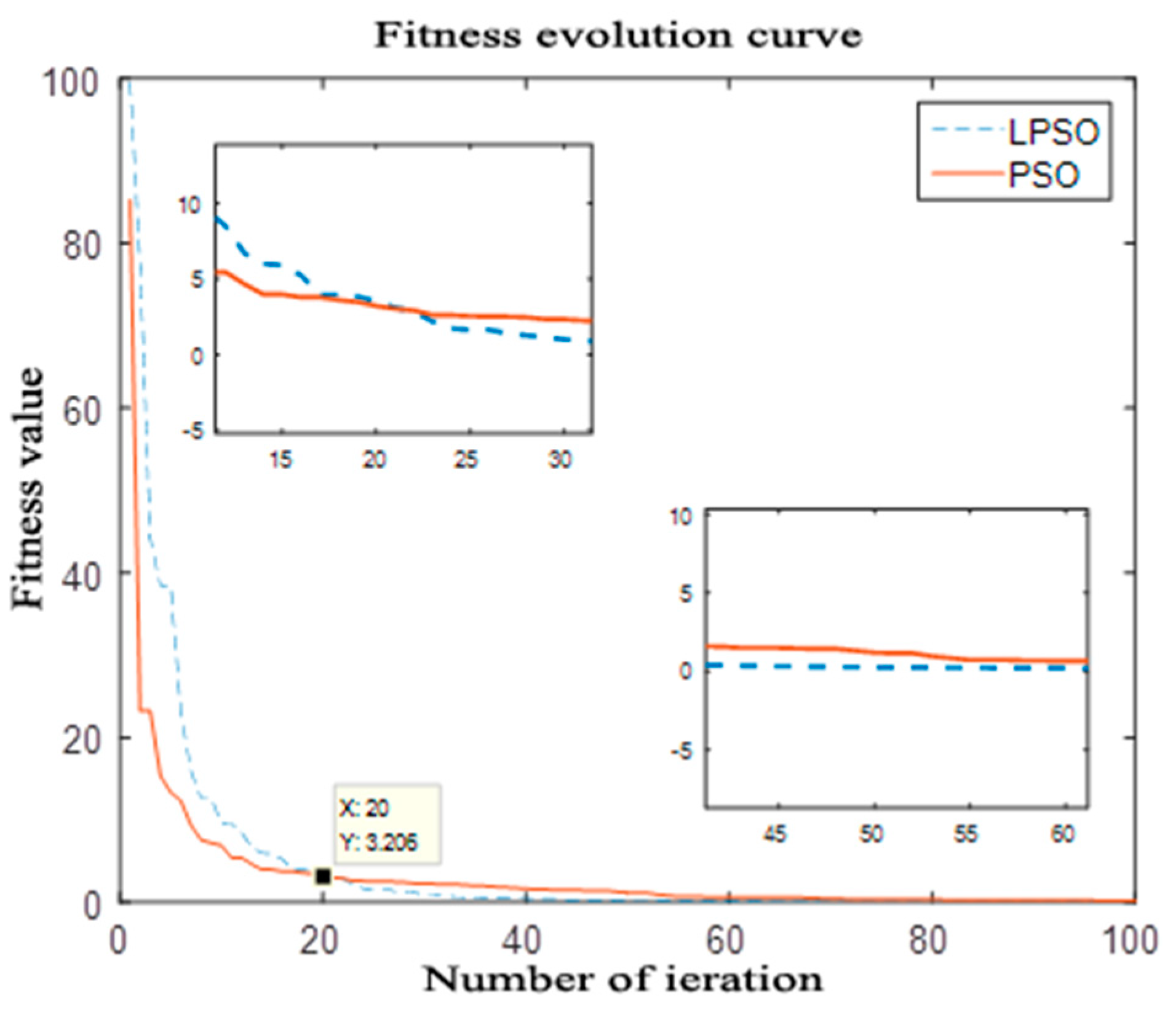

Figure 11 shows the trajectory simulation of the Lévy random flight algorithm. The left figure shows the flight trajectory of 500 iterations, and the right figure shows the flight trajectory of 1000 iterations. When observing its trajectory, it can be seen that the Lévy flight maintained its good flight characteristics after both 500 and 1000 iterations, and did not fall into the local optimal solution. However, the PSO algorithm can easily fall into the local optimal solution after a certain number of iterations.

Since Lévy flight has a good flight characteristic, in this article, the Lévy flight strategy was applied to the PSO algorithm in order to avoid using the PSO algorithm. Seeking an optimal solution from a locally optimal solution can affect the accuracy of solving the shortcomings, so it can expand the search scope in the solving process, jump out of the local optimum, and determine the global optimal solution.

The PSO algorithm improved by Lévy flight was called the LPSO algorithm. The mathematical expression of the particle velocity update is shown in Equation (16):

where

is the step size factor.

Therefore, according to the velocity update expression, the mathematical expression of the particle position update can be obtained as shown in Equation (17):

Although the log-Gabor filter can be used to extract feature details in a very comprehensive way, the optimal parameters of different images are also different. This requires that many filters be used for each image, and the clarity of output images with different parameters is calculated and compared one by one, which leads to the low efficiency of the actual work. Therefore, an adaptive log-Gabor filter was proposed in this paper; that is, a filter could be obtained through the optimization algorithm so that the output result of this filter was the clearest, and no artificial screening was needed.

In this paper, an improved LPSO algorithm was used to improve the log-Gabor filter adaptively. According to the above, the main constituent parameters of the log-Gabor function are the center frequency and the direction . So, the parameters to be adapted were and . The two parameters were adjusted adaptively so that the filter could select the optimal parameters on its own for different defect images.

Firstly, the initial parameters of the adaptive algorithm were set. To achieve a better effect, the number of particles was selected as 50, and each particle contained a set of filter parameters, which was equivalent to generating 50 sets of filters. The initial velocity of each particle was randomly selected between −2 and 2; the initial values of the center frequency and radial bandwidth were randomly selected between 0 and 1. The x direction was chosen randomly between 0 and . The initial values of pim and pgm randomly determined were set to the initial values of the individual optimal solution and the global optimal solution.

Next, we set the fitness function, which was used to express the good or bad qualities of an individual image. In this paper, the definition of the image was determined by the average gradient value. The higher the average gradient was, the better the result of feature extraction, and the clearer the image was. Our goal was to find an image with the highest resolution and the most detailed information. At this point, the adaptive optimization filter we designed could be understood as a function aimed at solving the maximum value of the function. The average gradient value could be used as the criterion of the output result. Therefore, we could generate a fitness function employing the average gradient value function of the image. The mathematical expression for the mean gradient was briefly mentioned above, and is explained in detail here.

The mathematical expression of the average gradient value is shown in Equation (18):

where

represents the average gradient of the gradient image

; and the table

shows the gradient of the image at the point

. This can be expressed as follows:

where

and

respectively represent the gradient of the image in the

and

directions obtained by the Sobel gradient operator.

According to the definition of the average gradient, the higher the output average gradient is, the higher the definition will be. The above formula was used to solve the problem of the maximum, so when using an adaptive algorithm, we could take the reciprocal value, select the average gradient as the fitness function, and solve the convergence problem of the minimum; therefore, for this problem, we set the fitness function as the type shown in (20):

where

represents the fitness value.

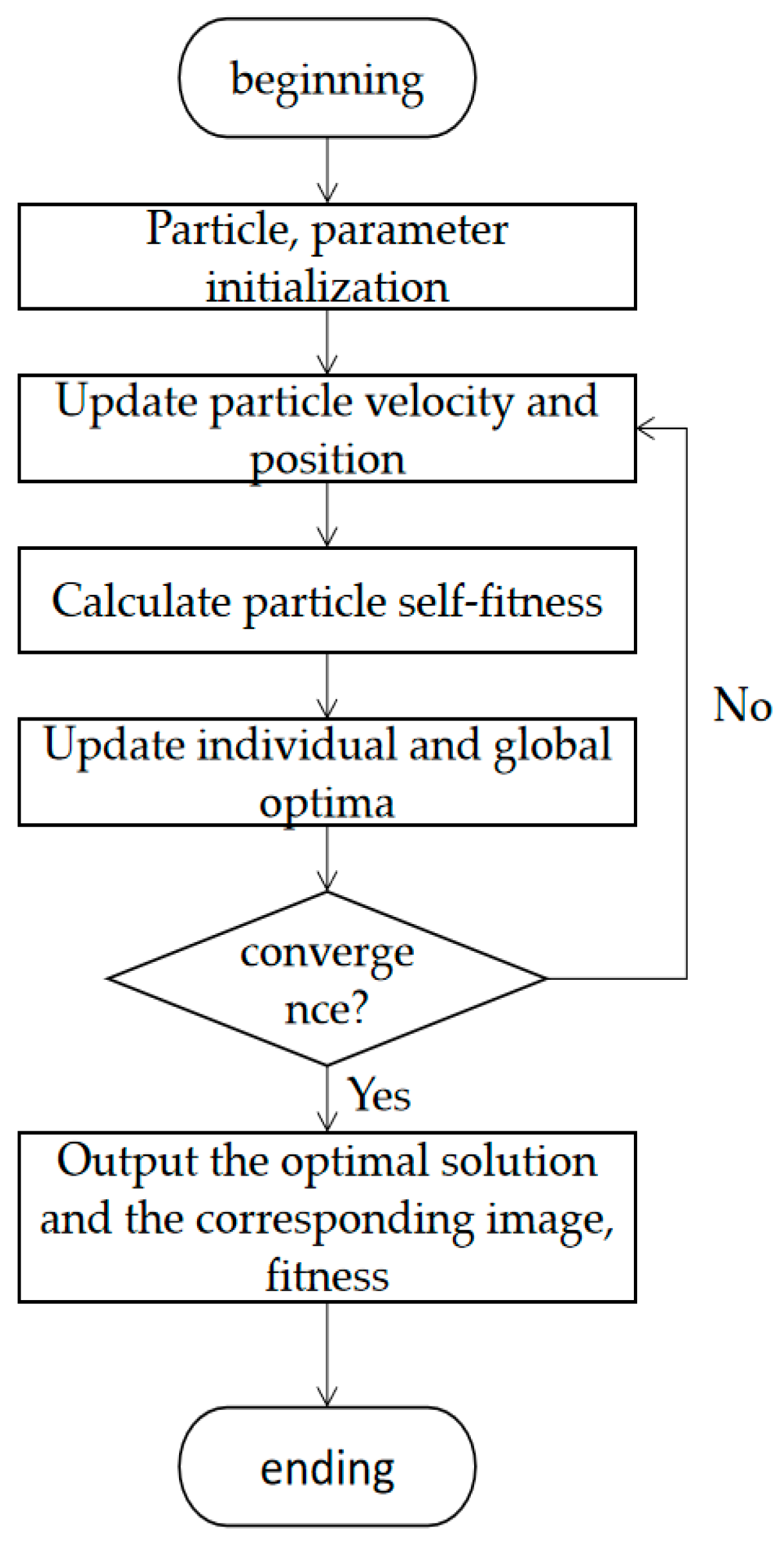

Finally, we set the convergence conditions. In this problem, since the average gradient value was positive, the fitness function was always set as positive, and what we needed was a higher clarity; that is, the lower the fitness value in this paper, the better it would meet the standards of this paper. Therefore, no specific restriction was made on fitness, so only the convergence condition was set as the number of iterations. When the number of iterations reached the set value, the current global optimal solution and fitness at this time could be outputted. The basic flow chart for designing an adaptive log-Gabor filter is shown in

Figure 12:

3.3. Defect-Type Detection

After feature extraction, binary images often still have some subtle miscellaneous points, and sometimes the edge information is not coherent enough, which will affect the accuracy of type judgment. To filter out the clutter and make the edge information smooth and coherent, the morphological processing method was used. Morphological processing can be divided into expansion, corrosion, open operation, and closed operation. The following four methods were introduced:

1. Expansion

The main function of expansion is to eliminate the clutter in feature areas extracted from binary images, fill in the gaps between useful information, make the lines of feature areas smooth and continuous, and highlight the area of interest more. The mathematical expression is as follows:

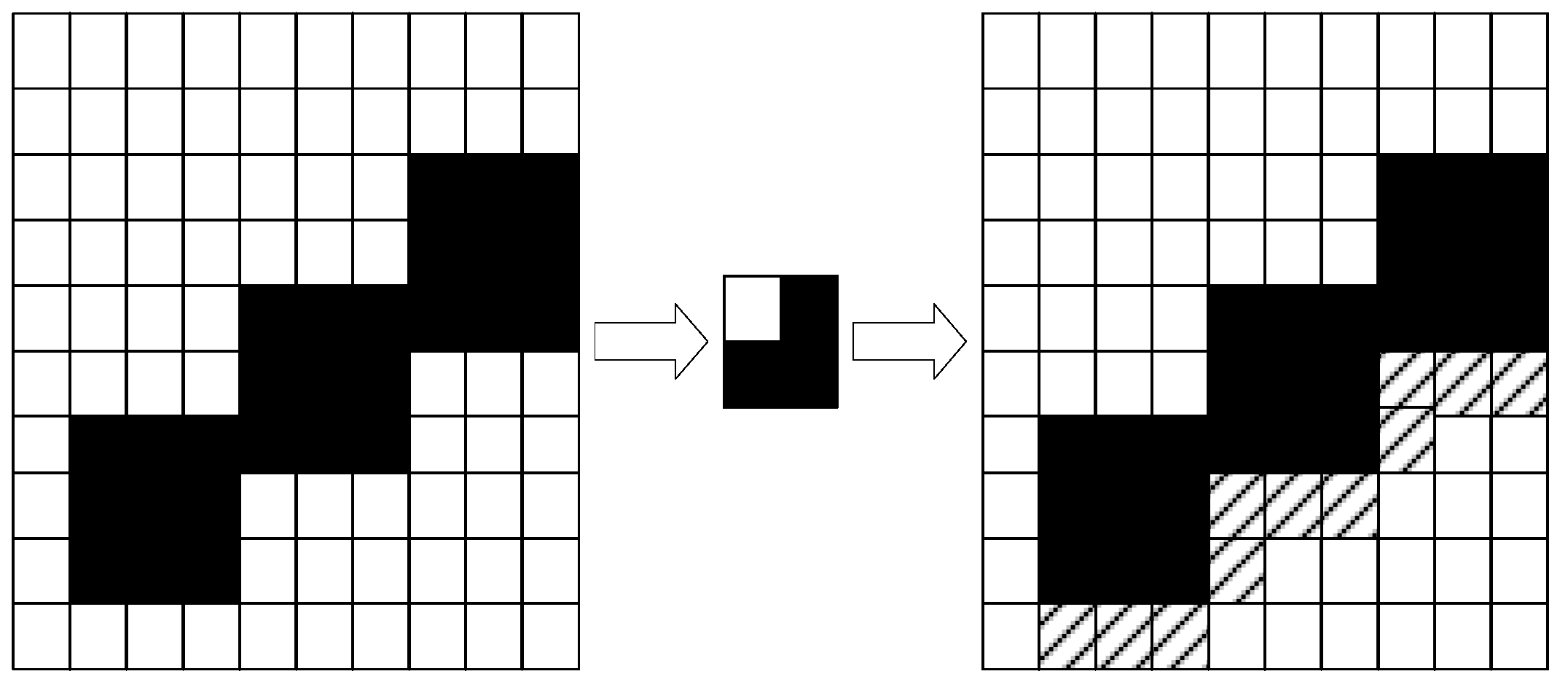

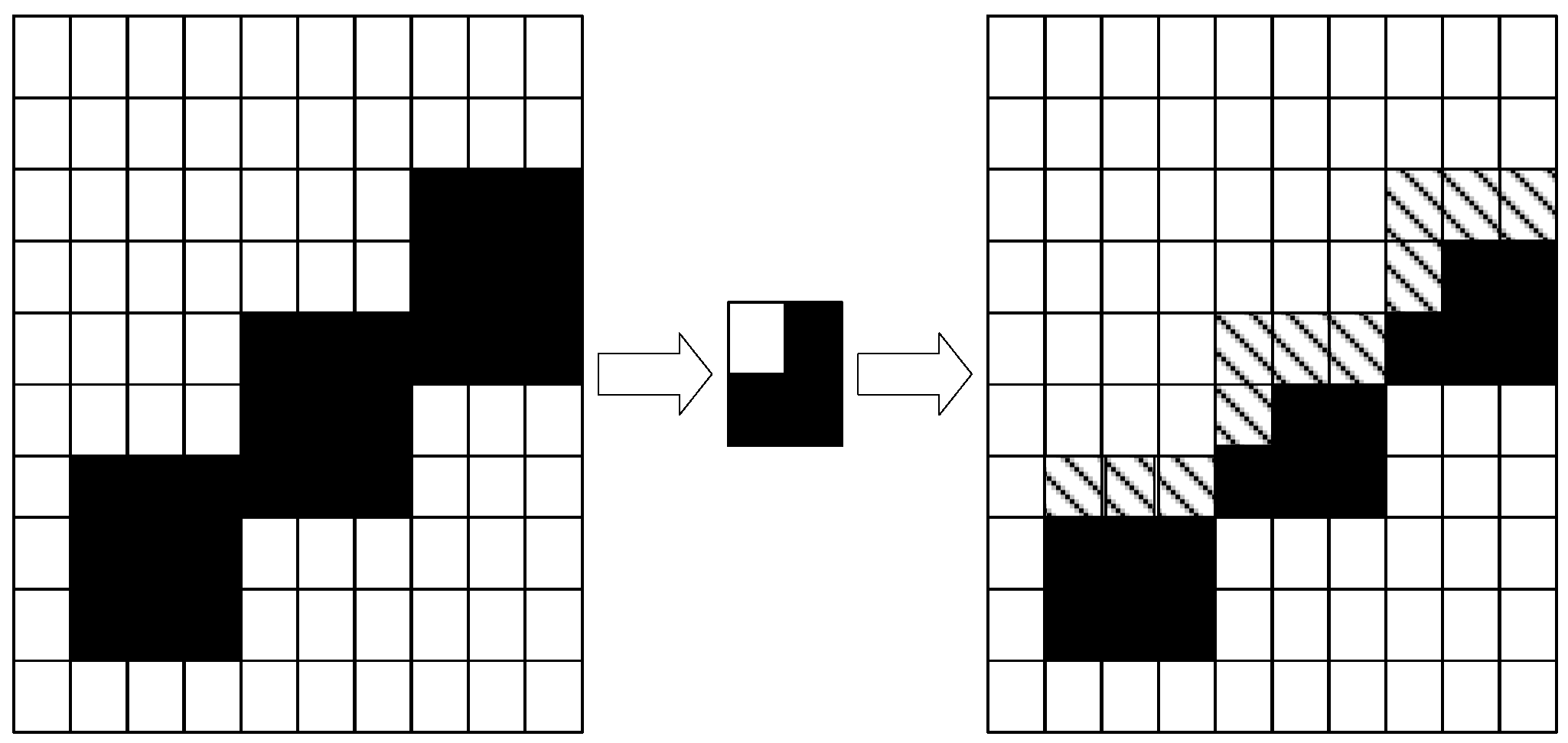

The principle of expansion is shown in

Figure 13.

In the figure, the black and white boxes represent black and white pixels, and the dotted boxes represent pixels that have been expanded and filled.

Therefore, Formula (21) can be understood as: A was the feature image to be expanded, and we used structural element B to expand image A by placing the origin of structural element B on the position of the point in image A, obtaining the maximum value of the pixel point in the area covered by B, and assigning this maximum value to the specified pixel.

2. Corrosion

Corrosion is the main function of the binary image, including the characteristics of the region outside of the background on some useless eliminate miscellaneous points, leaving only useful features. The mathematical expression for corrosion operations is as follows:

The corrosion principle is shown in

Figure 14:

The black and white boxes in the figure represent black and white pixels, and the dashed boxes represent pixels that have been corroded away.

Formula (22) can be understood as using structure B to corrode image A. We placed the origin of structural element B at the position of the points in image A. If the element position of 1 in B was all white at the corresponding midpoint of A, then the value of the output image at the corresponding point was white; otherwise, the value was black. This is the opposite of expansion.

3. Open operation

In the combination of expansion and corrosion operations, the image is first corroded, and then expanded. The expression is as follows:

4. Closed operation

Although understood in a similar way to an open operation, the principle is the opposite. A closed operation is an operation in which the image is first expanded and then corroded. The expression for the closed operation is shown below:

Since the purpose of this paper was to extract the defective part and make a type judgment, to determine the accuracy of the defect, we needed to eliminate the useless information and highlight the defective part. Firstly, we needed to use the corrosion operation to corrode the useless elements, which was similar to the filtering process. The expansion operation was then used to connect the breakpoints and unclear points on some characteristic line segments.

As the number of connected regions was needed in the following defect type detection, the number of connected regions was identified to determine whether there was a defect, and the calculation of defect edge circumference also was used. Therefore, after the operation, the edge information of the feature was extracted to lay a foundation for the subsequent work.

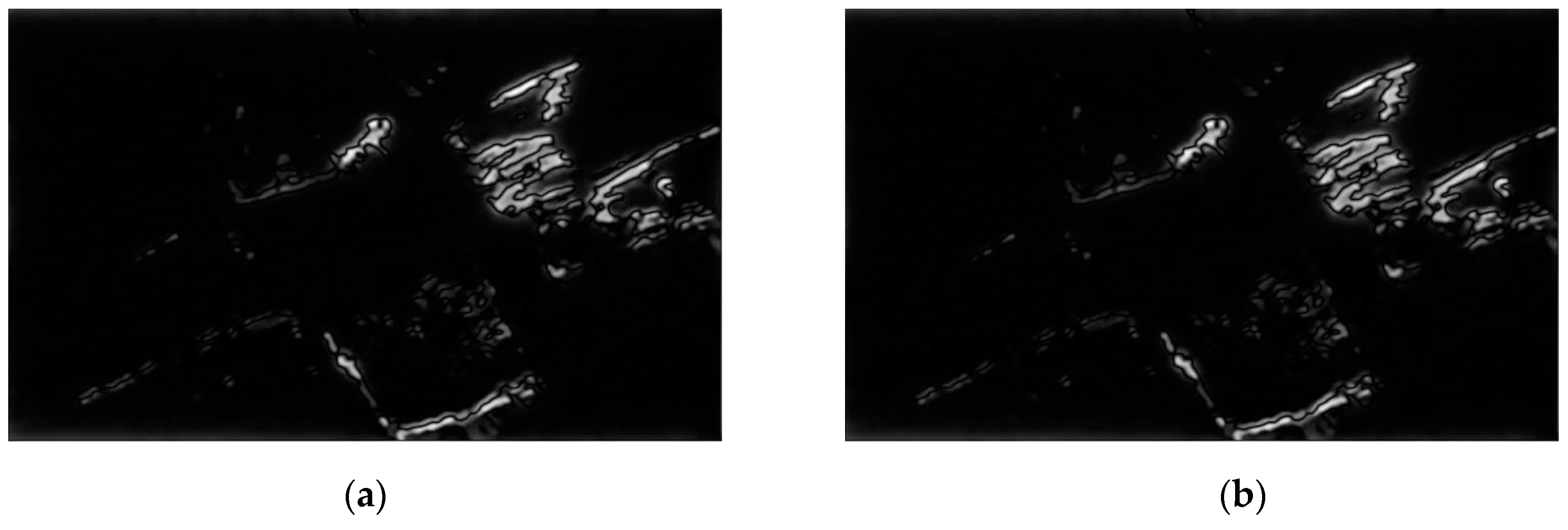

Taking the scratch image in

Figure 8 as an example, the morphological processing method selected in this paper was completed for these two feature images, and the results of the open operation and extracted feature edge detection are shown in

Figure 15.

As can be seen in the figure, after the operation was completed, the information in the feature area became more abundant, the defect location became more prominent, and some small useless points were filtered out. By observing the edge images obtained, it was found that this method could extract the edges of defects and form connected regions one by one. By calculating the number of connected regions, it could determine whether the image had defects. If the connected regions were not 0, it meant that the image had defects. This was used to screen whether the image had defects or not.

Defect-type detection is a process of classifying images by analyzing various attribute information of images and taking them as a classification basis. So far, the categories of classifiers are very complex. In this paper, the HOG+SVM classifier was used to classify leaf defects.

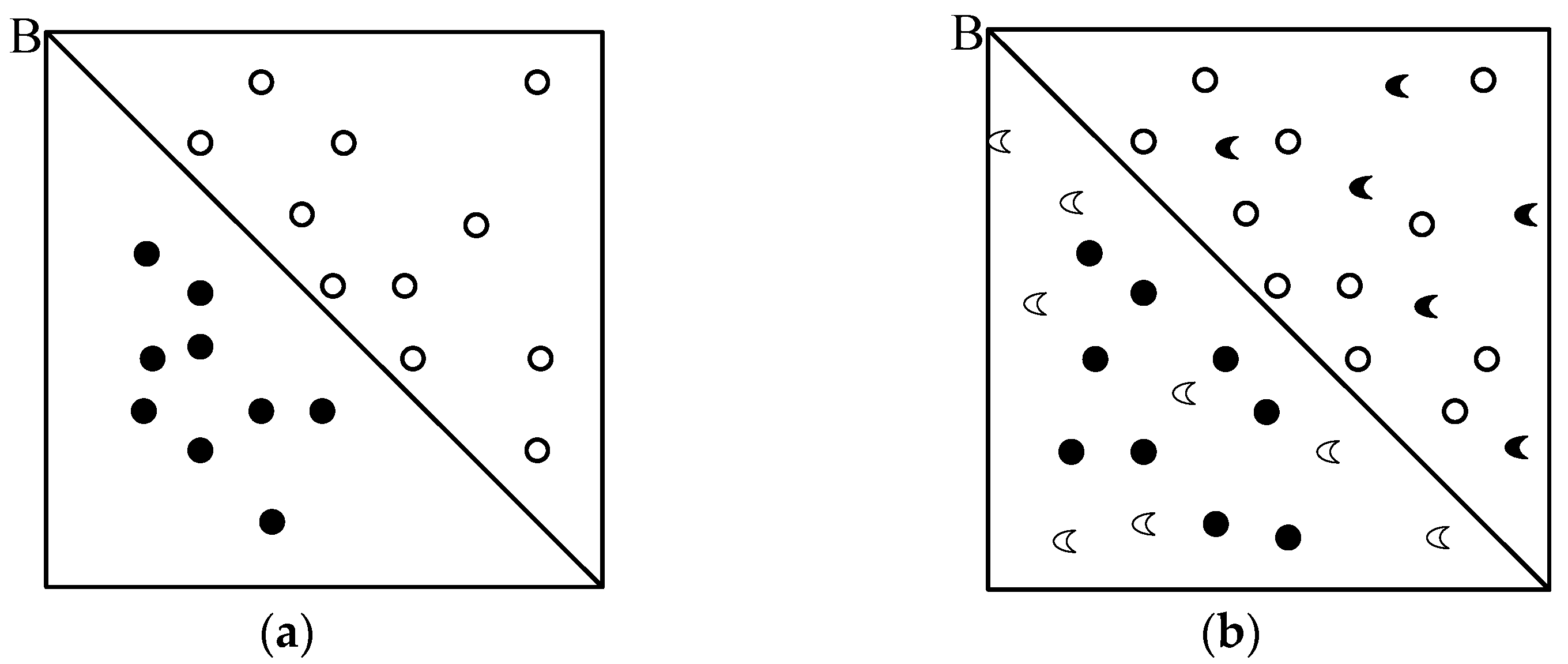

A support vector machine (SVM) classifier is a binary classifier and a supervised learning model in the field of machine learning. It is usually used to complete pattern recognition, classification, and regression analysis. It is divided into the training stage and testing stage. The main principle is to find a hyperplane between the two classes and separate the two classes by linear or nonlinear separation, as shown in

Figure 16.

Figure 16a shows a classical SVM dichotomy model, while

Figure 16b shows an SVM multi-classification model; B denotes the hyperplane used to divide. This hyperplane satisfies the formula:

It is considered that the online part is 1 and the offline part is −1. The two ends of the plane are enlarged and distinguished by the positive and negative poles.

As a feature descriptor, the histogram of oriented gradient (HOG) is mainly used for object detection in visual and image processing. The HOG feature calculates and collects the histogram of the gradient direction of the local area of the image and combines these features into feature vectors. Its main working principle is to divide the image into each cell unit, collect the orientation histogram of the gradient or edge density of each cell point, and combine the collected histogram information into feature vectors, which can be used as the basis to describe the image features.

The main step of combining the two to generate a HOG+SVM classifier for binary classification was to input the positive and negative sample sets to be trained. Then, the positive and negative sample sets were read to calculate the HOG feature; the feature vector was then synthesized by the HOG feature and put into the SVM classifier for training, and the detection factor was generated. Finally, the positive and negative sample sets were put into the SVM classifier for training, and the training results were saved.

Due to the binary nature of the SVM classifier, the defect types that needed to be distinguished in this paper could be divided into four categories: spot type, sand-hole type, crack type, and scratch type. Therefore, the concept of the SVM multi-classifier was introduced, and a four-classifier system that met the requirements of this paper was designed. The basic idea of the quadclassifier was to divide the four categories into two groups of complementary classification sets. As shown in

Figure 16b, the online part was considered as 1, while the offline part was −1.

According to this principle, every two different categories of the four categories are divided once to generate six training sets, namely six classical binary classifiers. When training type 1 was used, the sample set containing type 1 was positioned as a positive sample set, and the sample set not containing type 1 was defined as a negative sample set. These six binary classifiers were trained separately. During the test, when an image of type 1 was inputted, if the output results of the classifier containing type 1 were all positive, the image could be considered to belong to class 1.

The main steps of the HOG+SVM quadclassifier designed in this paper were as follows:

Step 1: Input four sample sets;

Step 2: Generate six different training sets and calculate the HOG feature of each training set;

Step 3: Put the HOG feature into the SVM quadclassifier for training and generate detection factors;

Step 4: Input the positive and negative sample sets of class I (I = 1, 2, 3, 4) into the SVM quadclassifier for training;

Step 5: Save the training results and output the accuracy rate.

After the above steps, we tested and outputted the judgment accuracy of each type, and saved the training results. When entering the program, the training results could be directly called to input an image to be tested, and then the category to which the image belonged was outputted. The simulation results are shown in

Figure 17.