Abstract

The dry roll-type electrostatic coal beneficiation technology under high voltage is used to study the beneficiation of low-grade and high-ash coal in Inner Mongolia, northern China. The optimal coal beneficiation conditions are determined by adjusting three parameters: the electrode voltage, the distance between the electrode and the drum, and the angle θ of the electrode. The best quality clean coal is obtained under the condition of voltage of 30 kV, angle θ of 75°, and electrode distance of 7 cm. Moreover, after separation, the quality of clean coal accounted for 48.41% of the raw coal mass, while the ash ratio decreased from 38.6% of the raw coal to 18.71% of the clean coal, which significantly improves the coal usability. Finally, through the methods of combustion characteristics analysis, infrared spectrum analysis, and combustion exhaust gas analysis of raw and clean coal, it is proven that the roll-type electrostatic separation technology has a high coal beneficiation effect on the high-ash, low-grade coal in Inner Mongolia.

1. Introduction

Renewable energy sources (solar power, hydropower, wind power, etc.) can provide clean energy and reduce environmental pollution. Energy sources such as nuclear energy, oil, and natural gas can be used more efficiently than coal, while leading to relatively less air pollution. Despite this, fossil fuels are unfortunately still largely used in China [1]. Among these, coal is among the most used because coal is a stable, cheap, and safe energy resource, therefore, coal will be China’s main energy sources for electricity for a long time [2]. However, the use of coal will inevitably cause environmental pollution, especially when low-grade coal with high ash content is used in thermal power stations, as it will cause serious air pollution, fly ash discharge, boiler slagging, and combustion efficiency reduction. In order to deal with this problem, low quality coal with a high ash content should be beneficiated before burning to improve coal quality. Therefore, this paper studies the beneficiation of high-ash coal and the combustion characteristics of the clean coal.

Coal beneficiation is a process commonly used to purify low-grade, high-ash coal to meet the usage requirements. Common coal beneficiation methods include jigging, dense medium cyclone, dense medium shallow groove, movable-sieve jigging, and flotation, and all these processes require a large amount of water for the treatment of low-grade raw coal, although the clean coal produced with these methods is of good quality, but the treatment process of tailings and sludge water may cause solid and water contamination caused from the wastewater. For this reason, dry beneficiation of coal has obvious advantages over wet processes [3].

Dry coal beneficiation methods, including hand picking, frictional separation, magnetic separation, electric separation, microwave separation, pneumatic oscillating table, air jig and air-dense medium fluidized bed beneficiation, etc., are carried out according to differences in physical properties between coal and refuse such as density, size, and shape [4].

The power used for coal burning in thermal power plants accounts for 50.6% of coal consumption. The selection of pre-beneficiation of coal must be combined with the characteristics of the pulverizing system of the thermal power plant. Because the coal in a thermal power plant will be pulverized to 75% less than 74 μm and be dried simultaneously, a fine coal dry preparation method will be reasonable from both a technical and economic view.

The roll-type electrostatic separation method is just one type of method adapted to dry and fine coal beneficiation. Therefore, this study will use roll-type electrostatic separator in this paper.

The roll-type electrostatic separator is widely used in the separation of metallic and nonmetallic minerals [5,6,7,8,9], waste electrical, and electronic products [10,11,12,13], different plastic products [14,15], and seed dehulling [16], and fine coal beneficiation [17]. Zhang Xinxi applied the roll-type electrostatic separator to study desulfurization and ash reduction from fine coal [18], and Chu Jianping applied the roll-type electrostatic separator to study the separation of coal rock components [19,20,21].

In addition, the coal particle size treated by this study and the coal particle size produced by the thermal power plant pulverizing system can be well matched, without any further crushing in the power plant.

2. Materials and Methods

The roll-type electrostatic separator used in this paper is negative corona electrostatic separator. Strong corona discharge will occur by applying negative high voltage to the electrode, then both coal and mineral particles will be negatively charged. Due to the different conductivities of coal and mineral particles, the charge of coal is opposite to the charge of mineral particles, so they are subjected to different electric field forces, have different trajectories, and then fall into different trays under the joint action of gravity and centrifugal forces, thus achieving the purpose of mutual separation [22,23,24].

As there are many factors affecting the roll-type electrostatic separation effect, such as electrode voltage, distance between the electrode and drum surface, angle between the electrode and drum, electrode shape, temperature, humidity, drum rotation speed, grade of coal, and size of coal particles, feed speed etc., it is difficult to determine their individual influence. Therefore, in this experiment, the electrode characteristics are the parameters under discussion. By studying the effects of the voltage of the electrode, the distance between the electrode and the surface of the drum, and the angle of the electrode and the drum, three results are analyzed to determine whether the coal separation has a relatively high efficiency. After separation, the clean coal with an ash content less than 20% is selected to compared with the raw coal using contrast tests. Therefore, the design of this experiment is divided into two steps: (1) to discuss the influence of the electrode parameters on the effect of coal electrostatic separation, and (2) to compare the combustion characteristics of the clean coal and raw coal by the spectral analysis, and the difference between the exhaust gas of these two types of coal after combustion to determine the feasibility of coal separation.

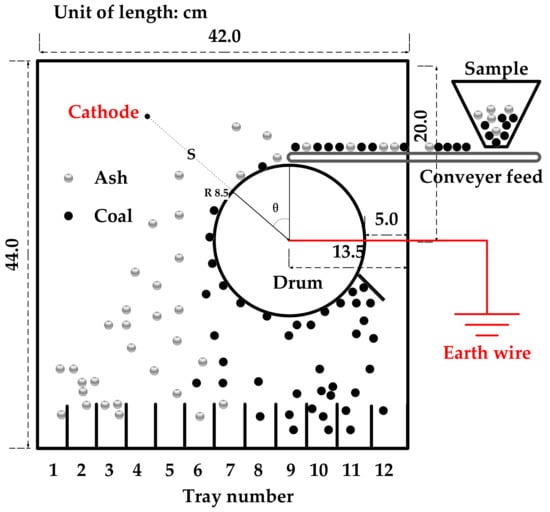

2.1. Experimental Device

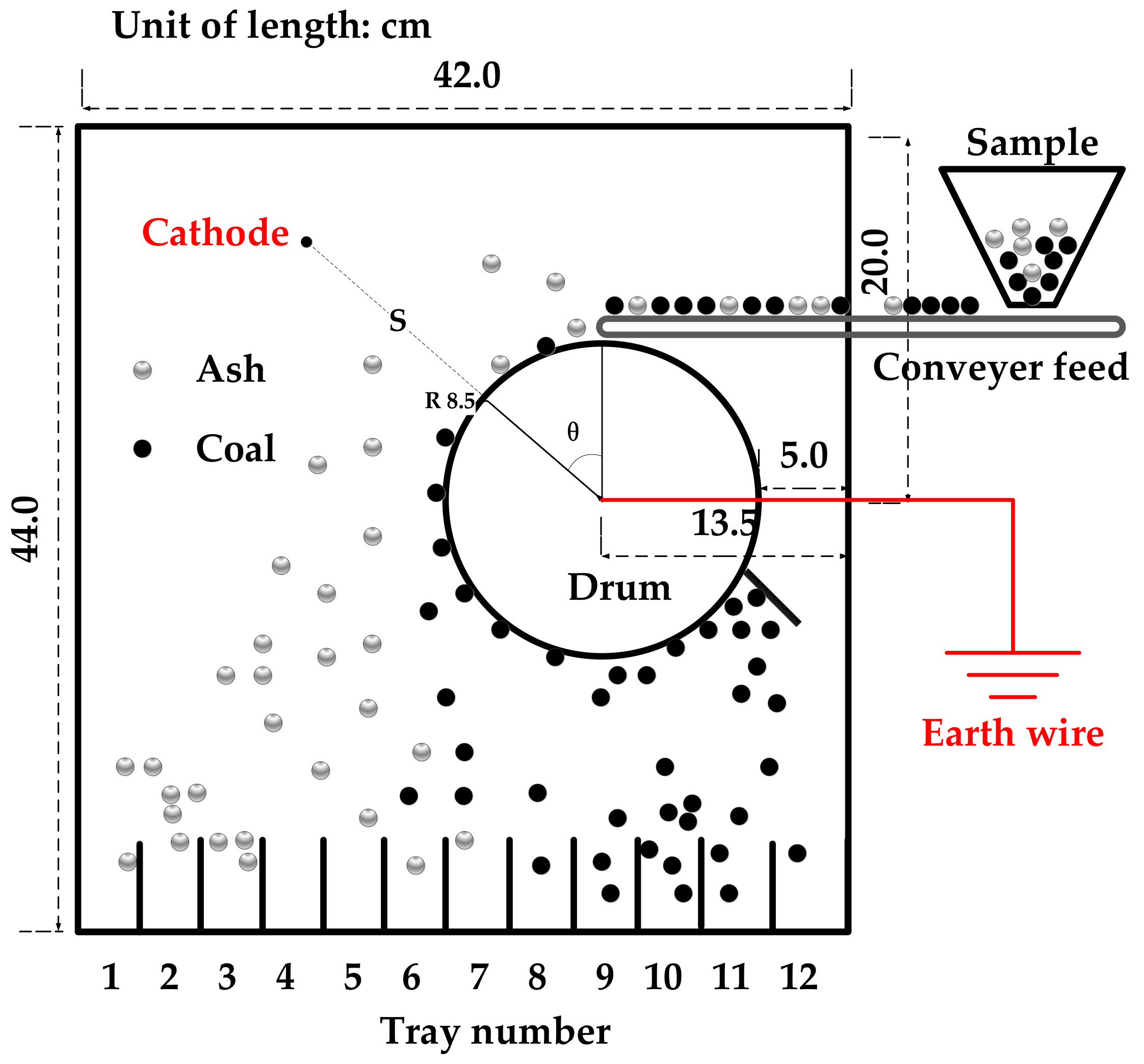

The experimental device developed in our laboratory mainly consists of a feeder, a conveyor belt, a drum, handmade electrodes, and trays. The device is constructed based on the principle of the roller type high-voltage electrostatic separator. Figure 1 shows the device diagram with 12 trays compared to traditional roll-type electrostatic separator with three trays, which ensures that we can more precisely analyze the yield and ash content of clean coal and tailings. The separation process of coal is divided into the following steps: (1) The sample is released from the funnel on the right and transported to the left side via the conveyor belt (non-conductor), falling on the surface of the rotating drum. (2) The coal and mineral particles pass through corona discharge and are negatively charged, and the mineral particles will lose electrons quickly through the drum and be induced by positive charge because of their good electrical conductivity. (3) The mineral particles, due to the action of the electric field force of the negative electrode, fly away from the surface of the drum and jump up. Meanwhile, coal particles do not easily lose the negative charge because of its poor conductivity, and the positive image charge will be induced on the drum surface by the negative charge. (4) The coal particles will attach to the drum surface by coulomb force caused by negative charge on the coal particles and positive image charge, so that the movement trajectory of coal and mineral particles are completely different, as clean coal particles are adsorbed on the drum and will be brushed down by the brush on the right side of the drum and fall into the trays on the right side. (5) Most mineral particles will fall into the trays on the left side under the influence of the forces of the electric field, gravity force, and centrifugal force. Experimental results show that the yield of clean coal particles is relatively small compared to that of mineral particles. The voltage V range of the electrodes in the high-voltage roll-type separator used in this experiment is 0–30 kV, the adjustable range of the angle θ (θ is defined as the angle between the line from the electrode to the center of the drum circle and the vertical line of the drum.) between the electrodes and the drum is 0–75°, and the adjustable range of distance S between the electrodes and the drum is 4–11 cm. As the above conditions change, the value of the current I will also change, and the current change is directly displayed on the electrostatic device.

Figure 1.

Main components of the originally developed experimental device.

2.2. Experimental Materials

In the experiment, the coal sample is obtained from Inner Mongolia. Inner Mongolia is the largest lignite producing region in China [25]. The lignite has a high ash content, volatile matter content, and water content; hence, its quality is usually low and quality improvement adopting coal beneficiation techniques is necessary. In this experiment, the sample size was 0.5–1 mm and was then dried and packed into bags for the experiment. Serious analyses have been conducted with apparatuses of proximate analyzer JIS M 8812: 2006 (Muffle Model: CM-150 SIBATA, Saitama, Japan) [26], ultimate analyzer (Model: MT-5 Yanaco, Kyoto, Japan), total sulfur analyzer (Model: HYDL-9), combustion characteristic analyzer (Model: DTA-60 Shimadzu, Kyoto, Japan), Fourier-transform infrared spectroscopy (FT-IR) (Model: FT/IR-6100 Jasco, Capalaba, Australia), combustion gas analyzer (Combustion Gas Analyzers, Model: PG-250 Horiba, Kyoto, Japan), and the dielectric constant of the coal samples was also determined. The results of the industrial and elemental analyses are shown in Table 1. The ash content and volatile matter percentage of the coal in Inner Mongolia are found be very high, whereas the content of fixed carbon is very low. Although the carbon in the coal is basically sulfur-free, its utilization value is still very low. The experiment is conducted with 100 ± 1 g of the sample each time. After the experiments, the coal sample in each tray is subjected to do proximate analysis, as specified in JIS M 8812: 2006. Then, the clean coal with an ash content of less than 20% satisfies with the standard of low-ash coal, as shown in Table 2. This standard is given in China’s GB/T 15224.1-2018 Classification for Quality of Coal—Part 1: Ash. The clean coal is then subjected to do subsequent experiments and analysis (Thermogravimeter-Differential Thermal Analyzer (TG-DTA), Fourier-transform infrared spectroscopy (FT-IR), combustion exhaust, and determination of the dielectric constant).

Table 1.

Proximate analysis (dry ash free basis) and ultimate analyses for raw coal in Inner Mongolia.

Table 2.

Classification of coal ash content in China.

2.3. Experiment to Assess the Influence of Electrode Characteristics

The most important factor affecting the experimental results is the magnitude of the electric field force. The experimental method used in this experiment is based on the process used in the metal beneficiation method, which is based on the voltage V of the electrode, the distance S between the electrode and the drum, and the angle θ. The experiment is carried out inside the laboratory at 25 °C, 40% humidity, and the drum rotational speed is 40 r.p.m. The experimental process is divided into two steps. The first step includes the selection of different values of the voltage, the distance S between the electrodes and the drum, and the angle between the electrode and the drum, to optimize the conditions for coal beneficiation. It is found that when the voltage V is lower than 20 kV, more of the sample falls into the trays on the left side because of the low magnitude of the electric field force. Therefore, the selected voltages are 20, 25, and 30 kV. When the distance S between the electrode and the drum is less than 5 cm, the visible spark discharge is generated in the test chamber owing to the excessive field strength. However, when the distance S exceeds 9 cm, the electric field force becomes too small to recover the sample. Therefore, three distances of 5, 7, and 9 cm are selected for the study. When the angle θ between the electrodes and the drum is less than 30°, the sample will be charged too early and start losing electrons too early to be recovered. Therefore, four angles θ of 30, 45, 60, and 75° are selected for the experiment. The optimum coal beneficiation condition (for the highest coal beneficiation efficiency) under the above-mentioned conditions is selected, and the coal beneficiation efficiency is computed, as shown in Equations (1)–(3).

where AR is ash removal rate, CMR is combustible matter recovery rate, SE is separation efficiency, Wtfeed is raw coal supply, ashfeed is ash rate of raw coal, Wtclean is recovery of clean coal, and ashclean is ash rate of clean coal. In the second step, proximate analysis, elemental analysis, total sulfur analysis, combustion characteristics analysis, infrared spectrum analysis, combustion exhaust analysis, and comparative experimental analysis of permittivity measurements are carried out for clean coal selected under the optimal separation conditions. This can help to confirm the difference in minerals content between raw coal and clean coal.

3. Results and Discussion

The electrode characteristics are the main factors affecting coal beneficiation efficiency. The voltage V of the electrodes as well as the distance S and angle between the electrodes and the drum largely determine the effect of coal beneficiation because these parameters determine the magnitude of the electric field strength. A larger electric field strength will increase the charge of the particles and the magnitude of the force acting on the particles. Therefore, the optimal coal beneficiation conditions for different samples of coal need to be investigated, so as to gain high electrostatic coal beneficiation efficiency.

3.1. Effect of Electrode Characteristics on Coal Separation

3.1.1. Influence of Voltage on Coal Beneficiation Efficiency

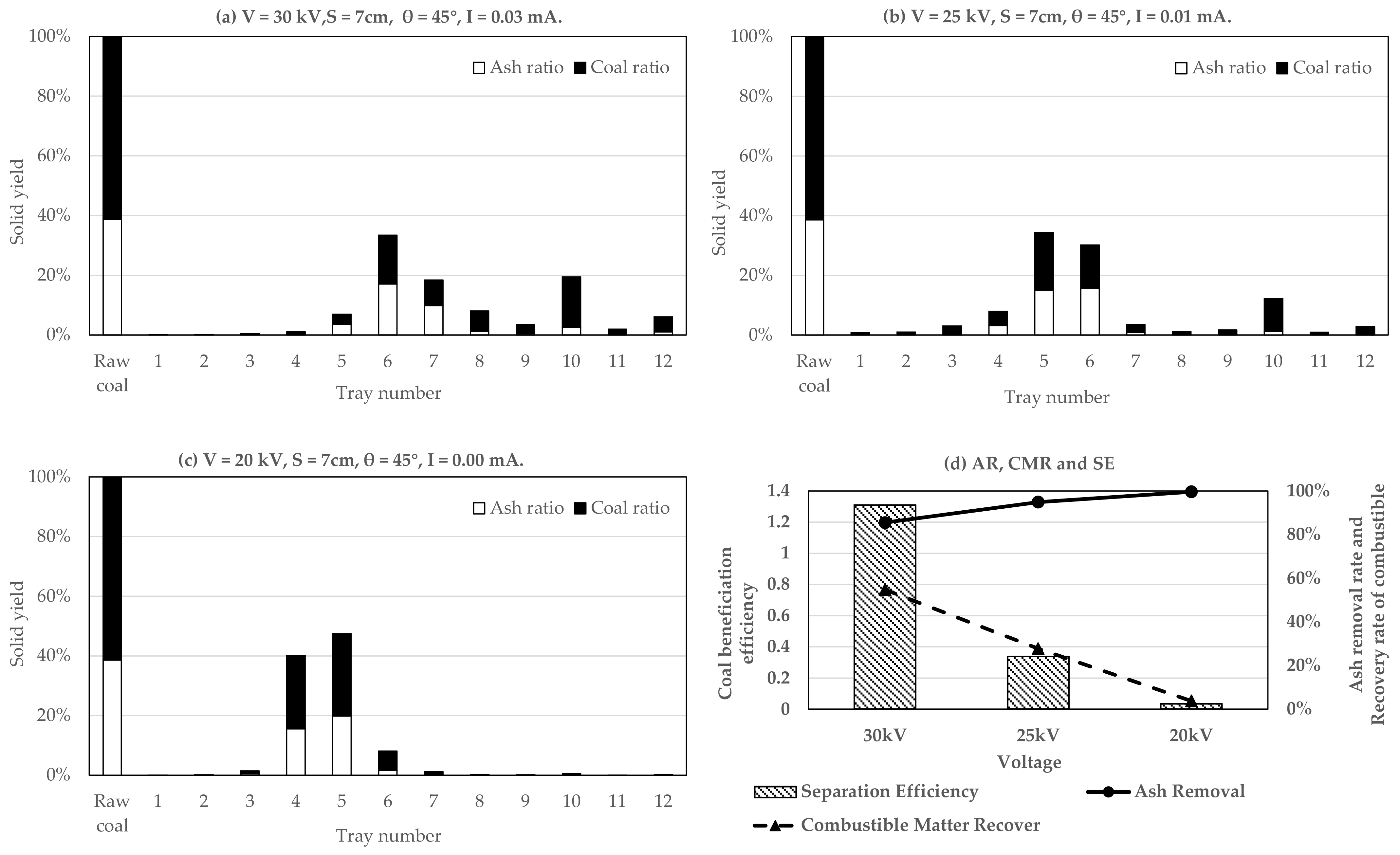

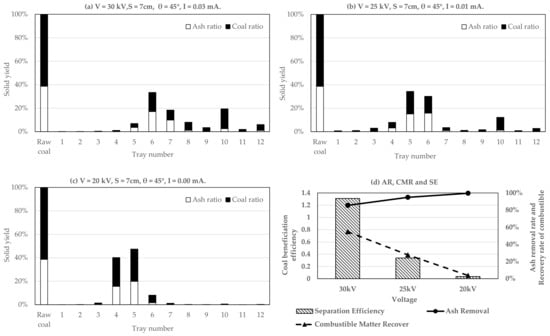

The magnitude of the electrode voltage V affects the magnitude of the charge of the particles. Generally, the higher the voltage, the stronger the charging effect of the particles. However, some types of coal have a similar conductivity and with some minerals; hence, excessively high voltage V may also cause both the clean coal and minerals to fall into the trays on the right side due to part of the charge on the mineral particles not releasing enough. On the contrary, if the voltage V is too low, it may be more difficult for clean coal particles to be adsorbed on the drum because they are not charged enough, thus falling into the trays on the left. Figure 2 shows the experimental results when the electrode voltage V is set to 20, 25, and 30 kV, while other conditions are kept constant (i.e., the distance S between the electrodes and the drum is 7 cm, and the angle θ is 45°).

Figure 2.

Influence of voltage V on coal beneficiation effect (three experimental conditions (a–c)): the distance S between the handmade electrodes and the drum is 7 cm, and the angle θ is 45°; (d): the results for AR, CMR and SE.

At 30 kV voltage V and 0.03 mA discharge current, it can be seen from Figure 2a that the yield from number 1, number 2, number 3, number 4, number 9, and number 11 trays are very low. The proportion of sample recovered from tray number 6 is the highest at 33.44%, followed by that from tray number 10, which is 19.45%. In the recovered coal, the ash contents in trays number 5–7 exceed 50% (51.70, 51.21, and 53.60%, respectively). However, low-ash coal samples with ash content less than 20% are recovered from trays number 8–12 (except for 20 kV. Under this condition, the sample cannot be separated effectively, and no sample is recovered from trays number 8–12). Tailings are recovered from trays number 5–7. This method of analysis is also used for the experiments at 25 kV (current is 0.01 mA) and 20 kV (current is 0 mA). The results are shown in Figure 2b,c, which indicate that the ash content of the tailings at the voltage V conditions of 25 and 20 kV are lower than those at 30 kV, thereby proving that the separation effect is relatively poor with these two conditions. Figure 2d shows the ash removal rate, combustible matter recovery rate, and the coal beneficiation efficiency. The results show that the ash removal rate will decrease slightly with the increase in voltage. By contrast, the combustible matter recovery rate will increase significantly. The coal beneficiation efficiency reaches a maximum value of 1.31 at a voltage V of 30 kV. As the voltage V of the high voltage V roll-type separator can be only adjusted to a maximum of 30 kV, this can be used as the optimal voltage.

3.1.2. Influence of the Electrode Distance on Coal Beneficiation Efficiency

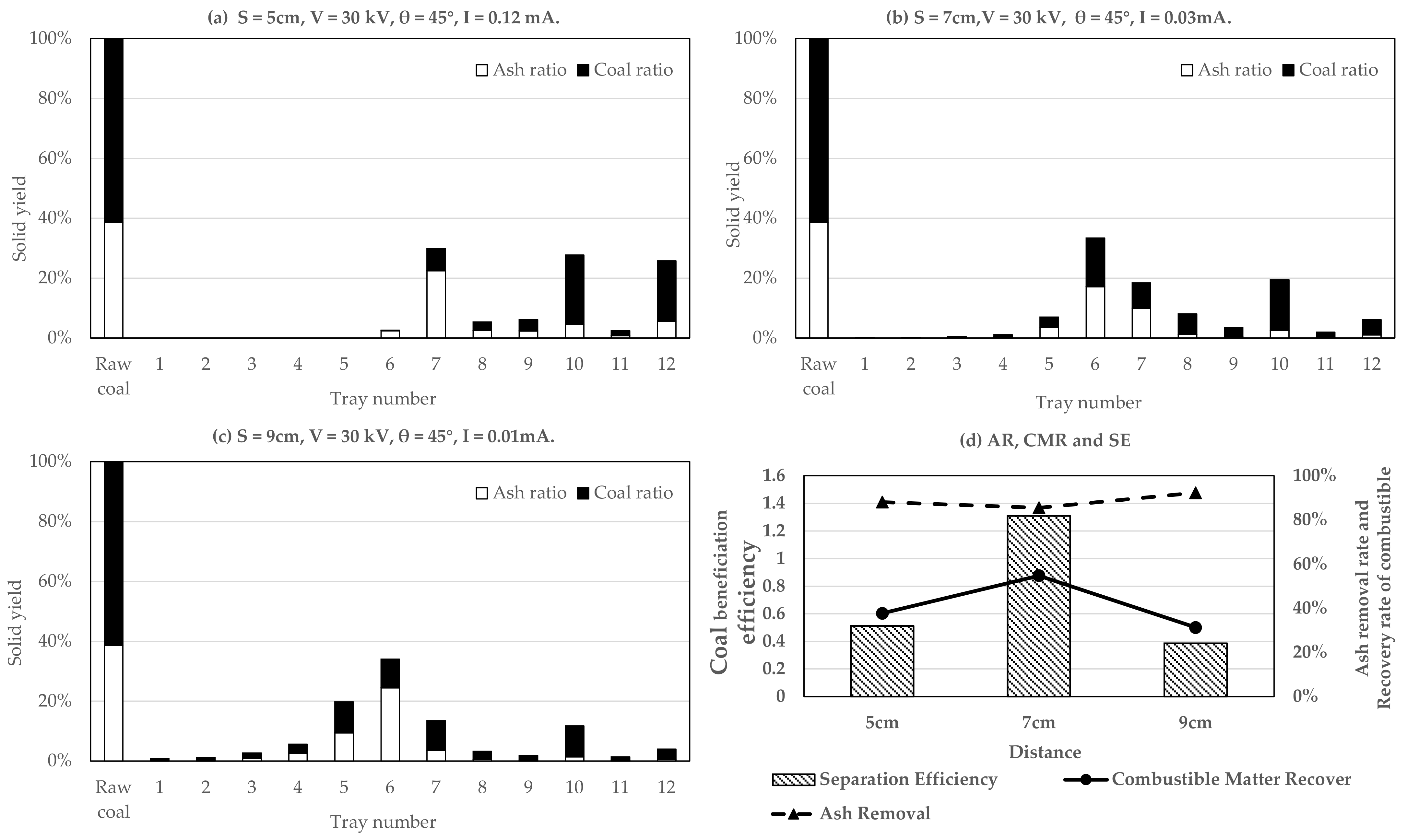

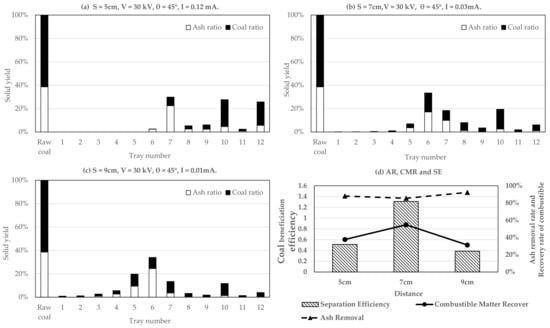

The distance S between the electrodes and the drum also determines the magnitude of the electric field strength, then affects the beneficiation efficiency. Generally, a shorter distance will generate a greater electric field strength and great corona discharge, and more electrons are gained by each particle, while the loss of electrons is delayed, so most of the particles will fall into the trays on the right. When the electrode voltage V is 30 kV and the angle θ between the electrodes and the drum is 45°, the distance S between the electrodes and the drum is adjusted to 5, 7, and 9 cm. Under these conditions, the results of coal beneficiation are shown in Figure 3.

Figure 3.

Influence of distance S on coal beneficiation effect (three experimental conditions (a–c)): the voltage V is 30 kV, and the angle θ is 45°; (d): the results for AR, CMR and SE.

When the distance S is 5 cm (discharge current is 0.12 mA), tailings with a very high ash content (more than 75%) are recovered from trays number 6 and number 7, while the ash content of the recovered coal from the trays in the right side are higher than 20%, except that of tray number 10. Therefore, relatively less clean coal can be recovered (only 27.61%). When the distance S is 9 cm (discharge current is 0.01 mA), the recovered materials from trays number 1–7 are all with ash contents higher than 20%. However, although the ash content of the recovered coals in trays number 8–12 is low, the distance S of 9 cm is not presumed as the optimum coal beneficiation condition, owing to a very low yield of clean coal (Figure 3c). Figure 3d shows that the ash removal rate is the lowest at a distance S of 7 cm, but the clean coal yield is the highest, and the coal beneficiation efficiency is the highest. So, a distance S of 7 cm can be considered as the ideal condition.

3.1.3. Influence of the Electrode Angle on Coal Beneficiation Efficiency

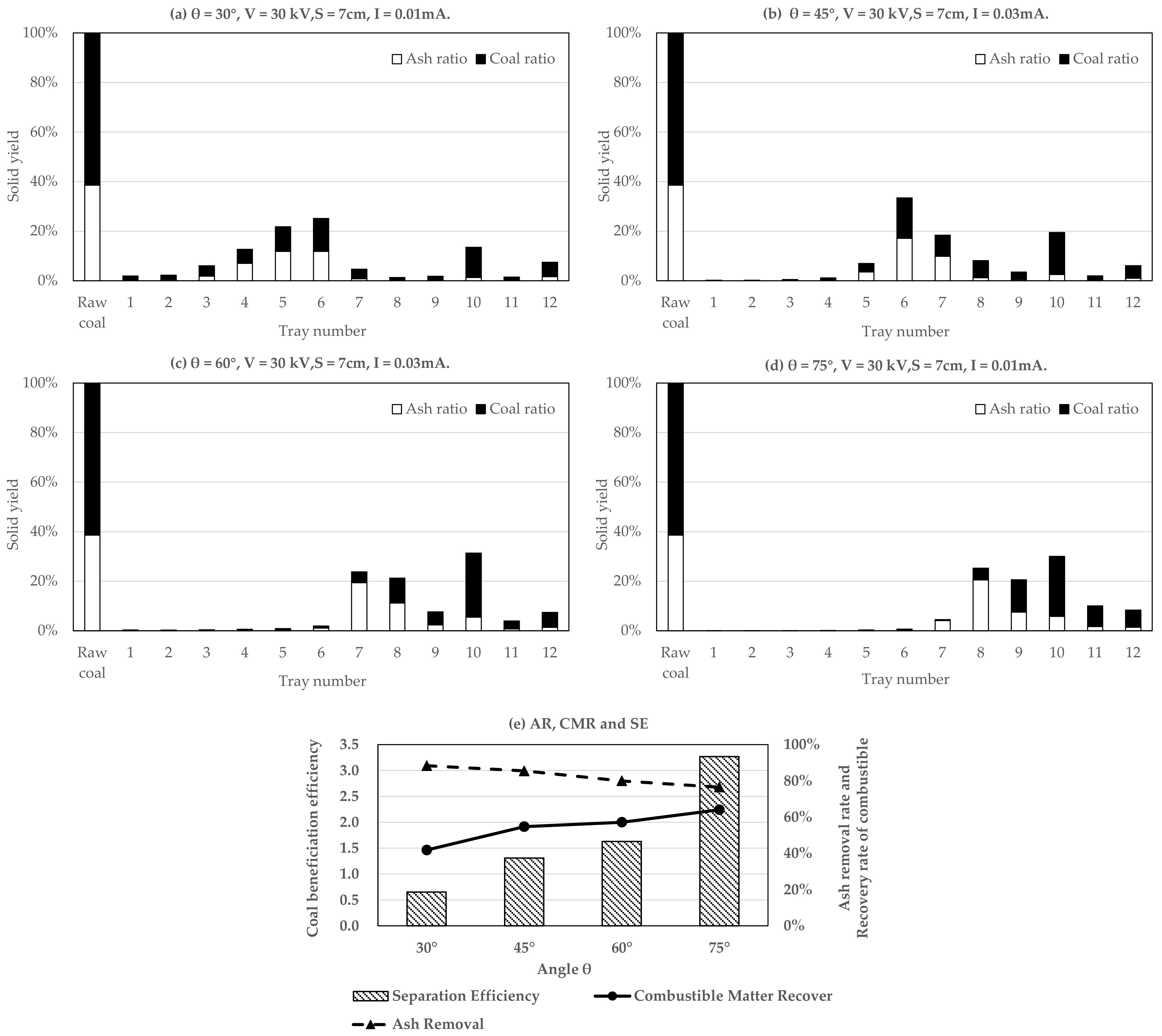

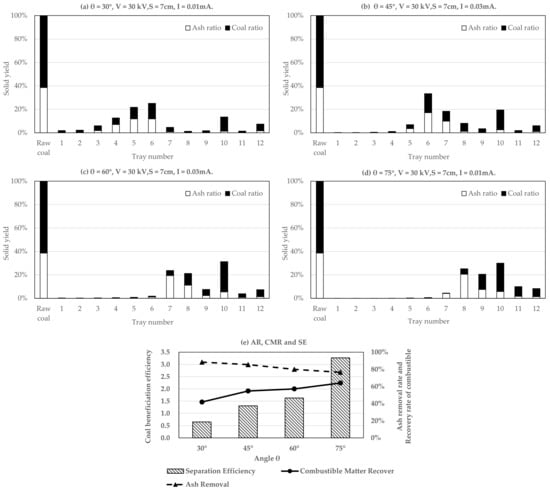

Similar to the electrode voltage V and distance S, the angle θ also has a great influence on the coal beneficiation efficiency. The angle θ between the electrodes and the drum determines the location and time of charging of the coal particles and the affect range of electric force. If the angle θ is small, the coal particles are charged early and shortly and release the charged electrons enough, and the electric force affect range is small, so this will cause most particles to fall into the trays on the left because of the small electric force act on the particles. On the contrary, an appropriate large electrode angle θ will cause more coal particles to fall into the trays on the right. Figure 4 shows that the test results with the electrode angles θ are 30, 45, 60, and 75° under the same conditions (30 kV, 7 cm).

Figure 4.

Influence of the angle θ on coal beneficiation effect (three experimental conditions (a–d)): the voltage V is 30 kV, and the distance S between the electrode and drum is 7 cm; (e): the results for AR, CMR and SE.

Figure 4a shows that when the angle θ is 30° (discharge current is 0.01 mA), the electrons are lost too early because the coal particles existing in the electric field obtain electrons too early. Hence, more coal particles fall into trays number 4, 5, and 6 on the left. In addition, the coal beneficiation efficiency at 30° is not ideal because there is only a small amount of coal recovered in trays number 7 to 11 (ash content is lower than 20%). Figure 4c shows that at 60° (discharge current is 0.03 mA), no coal is recovered from trays number 1–6, and the yield of tailings with high ash contents recovered from trays number 7–9 is very high, and clean coal with an ash content below 20% is recovered from trays number 10–12. The separation result of 75° (discharge current is 0.02 mA) electrode angle θ is similar to that of 60° electrode angle θ; however, the clean coal yield is higher at this condition (Figure 4d), which indicate that the effect of coal beneficiation with 75° electrode angle θ is better than of 60° electrode angle θ. Figure 4e also shows that although the ash removal rate decreases with the increase of the electrode angle θ, but the yield of clean coal and coal beneficiation efficiency increases along with the increase of the electrode angle θ. These results show that a maximum adjustable angle θ of 75° is ideal for the coal beneficiation.

Through analyzing the test data, the following conclusions can be drawn:

- The lower the voltage, the smaller the amount of charge on particles, and the particles cannot adhere well to the surface of the drum, thus reducing the coal beneficiation effect. As the highest voltage V of the electrostatic separator in this experiment is 30 kV, it is not possible to discuss whether a higher voltage V will have a better effect on the beneficiation. In fact, the voltage V is too high, which will produce breakdown discharge and affect the separation effect.

- The distance S between the electrode and the drum also affects the coal beneficiation effect greatly. Through an analysis of the three sets of data obtained with different distances, under the conditions of a voltage V of 30 kV and an angle θ of 45°, as the results of the distance S of 7 cm between the electrodes and the drum, the clean coal yield and coal beneficiation efficiency are highest. If the electrode distance S is too small, sometimes a strong electric arc phenomenon will occur, and result in the unstable charging of the particles and therefore affect the separation effect.

- Three angles θ of 30, 45, and 60° were designed for this test. It was found that the larger the angle θ, the better was the coal beneficiation effect; hence, the maximum angle θ of the electrode designed was increased to 75°. The test results confirm that the optimum condition with an angle θ of 75° results in the best coal beneficiation effect.

3.2. Analysis and Comparison of Raw Coal and Clean Coal

3.2.1. Composition Analysis of Clean Coal

The optimum conditions for voltage V, distance S, and angle θ have been discussed above (Section 3.1); these are 30 kV, 7 cm, and 75°, respectively. After separation, the quality of clean coal accounted for 48.41% of the raw coal mass, the proximate analysis results of clean coal show that the ash content decreases from 38.60 to 18.71%, the volatile matter content increases from 33.20% to 44.60%, and the water content increases from 2.90 to 10.11%. It is seen that the ash content in clean coal decreases significantly, which indicates that the raw coal, obtained from Inner Mongolia, is converted from high-ash coal to low-ash coal.

3.2.2. Analysis of the Combustion Characteristics

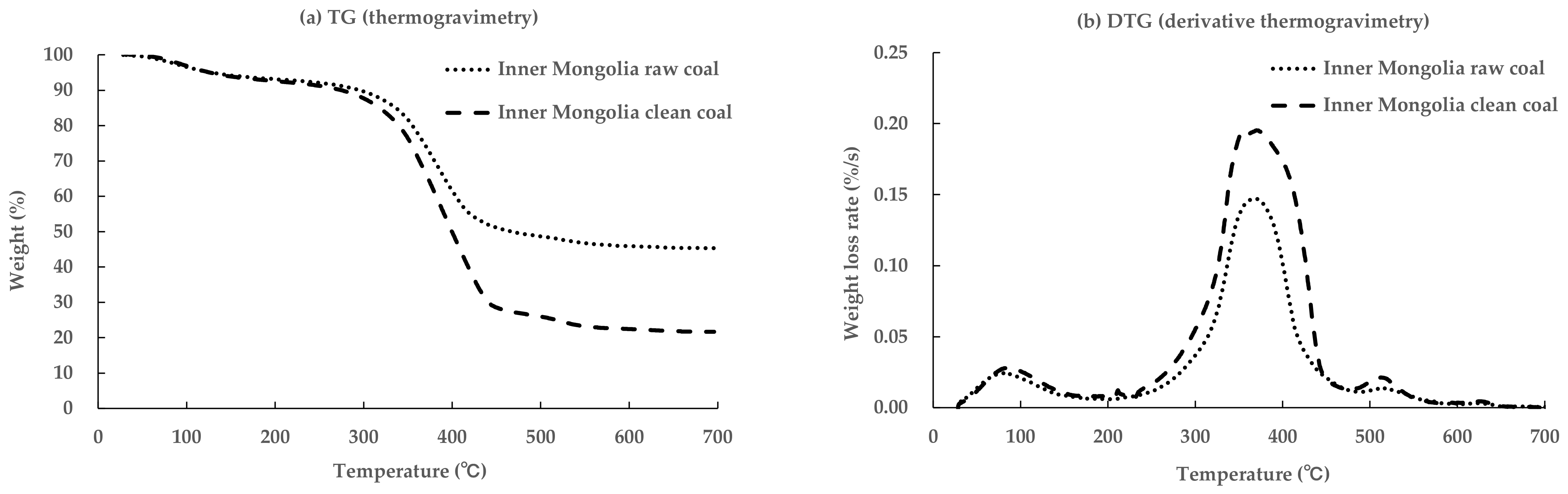

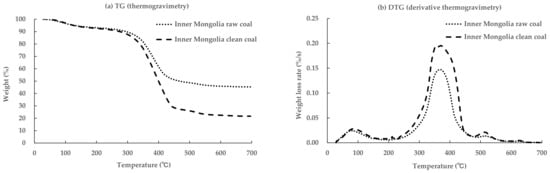

The combustion characteristics of raw coal and clean coal are analyzed to determine whether the latter is more suitable for combustion. The combustion characteristics of raw coal and clean coal are analyzed using a thermogravimeter-differential thermal analyzer (TG-DTA) [27]. The experimental procedure is as follows: 10 mg of sample is heated at a heating rate of 20 °C/min in an environment of air. Sample sizes are in the range 0.5–1 mm. The comparative results between raw coal and clean coal are shown in Figure 5.

Figure 5.

TG-DTA comparison of raw coal and filtered clean coal. (a): TG (thermogravimetry); (b): DTG (derivative thermogravimetry).

The combustion of coal occurs in three stages: dehydration, volatile combustion, and coke combustion. From the curve shown in Figure 5a, it is evident that when the temperature rises to approximately 150 °C, the weight loss rate decreases; this is because the water has completely evaporated, and the coke has not yet started to burn. Figure 5b shows similar results.

After the experiment, the residual weight of clean coal is found to be less than half of the weight of raw coal. Figure 5b shows the weight loss rates of clean coal and raw coal. Similarly, the loss rate of clean coal is faster than that of raw coal; the highest loss rate is observed at 370 °C. The ignition temperature of raw coal is slightly higher than that of clean coal, and its maximum weight loss rate is slightly lower than that of clean coal, which indicates that clean coal is easier to burn and burns faster. However, a higher burnout temperature of clean coal also indicates that the clean coal has a higher fixed carbon content. All these observations prove that clean coal is more suitable for combustion than raw coal. Table 3 shows the combustion characteristics of raw coal and clean coal in Inner Mongolia.

Table 3.

Combustion characteristics of raw coal and clean coal.

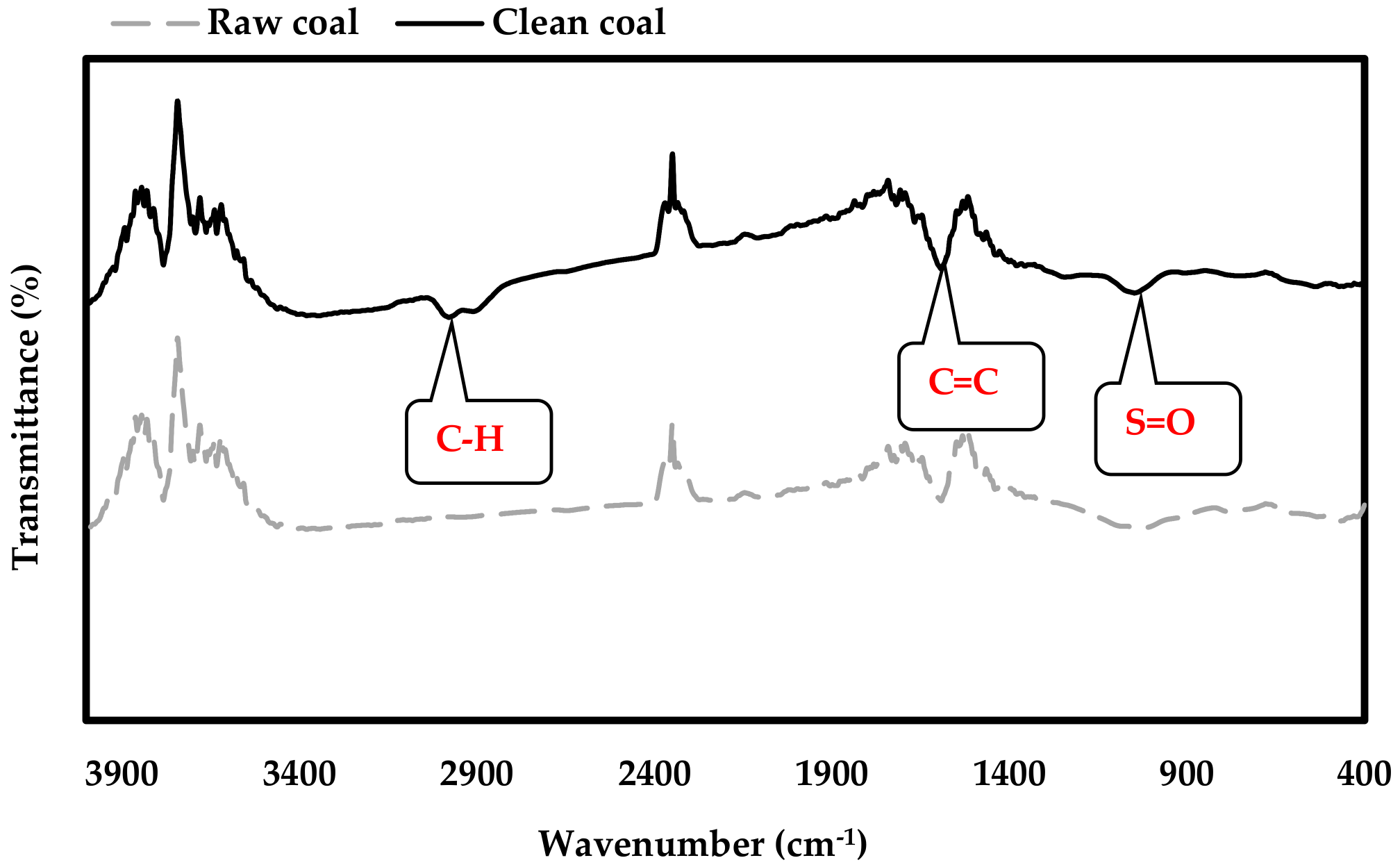

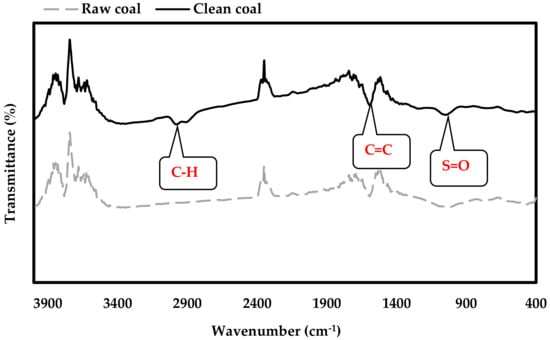

3.2.3. FT-IR Analysis

After confirming that the clean coal is more suitable for combustion, it is necessary to further verify whether the compositional structure of the clean coal ensures it to be more suitable for use than the raw coal. The results of the infrared spectrum analysis are shown in Figure 6.

Figure 6.

FT-IR analysis of raw coal and clean coal.

As this experiment uses the pure physical coal beneficiation method and no reagents are added, the results show that the compositions of raw coal and clean coal have not changed significantly. The data in the study of Singh and Nandi [28] are used to identify the different functional groups. The Fourier-transform infrared spectroscopy [FT-IR] analysis shows that the functional group strengths of raw coal and clean coal changed at different wavelengths. In the range 2850–3000 cm−1, the C-H bond of clean coal was stronger than that of raw coal, indicating an increase in the contents of carbon and hydrogen molecules in clean coal. A small increase in the C=C bond in the range 1600–1659 cm−1 also proves that the carbon molecules increased in clean coal. Moreover, strengthening of the S=O bond in the range 1029–1072 cm−1 proves the increase in sulfur content in clean coal; the increase in the proportion of sulfur in the clean coal can be attributed to the sulfur not being removed from the coal extracted from Inner Mongolia.

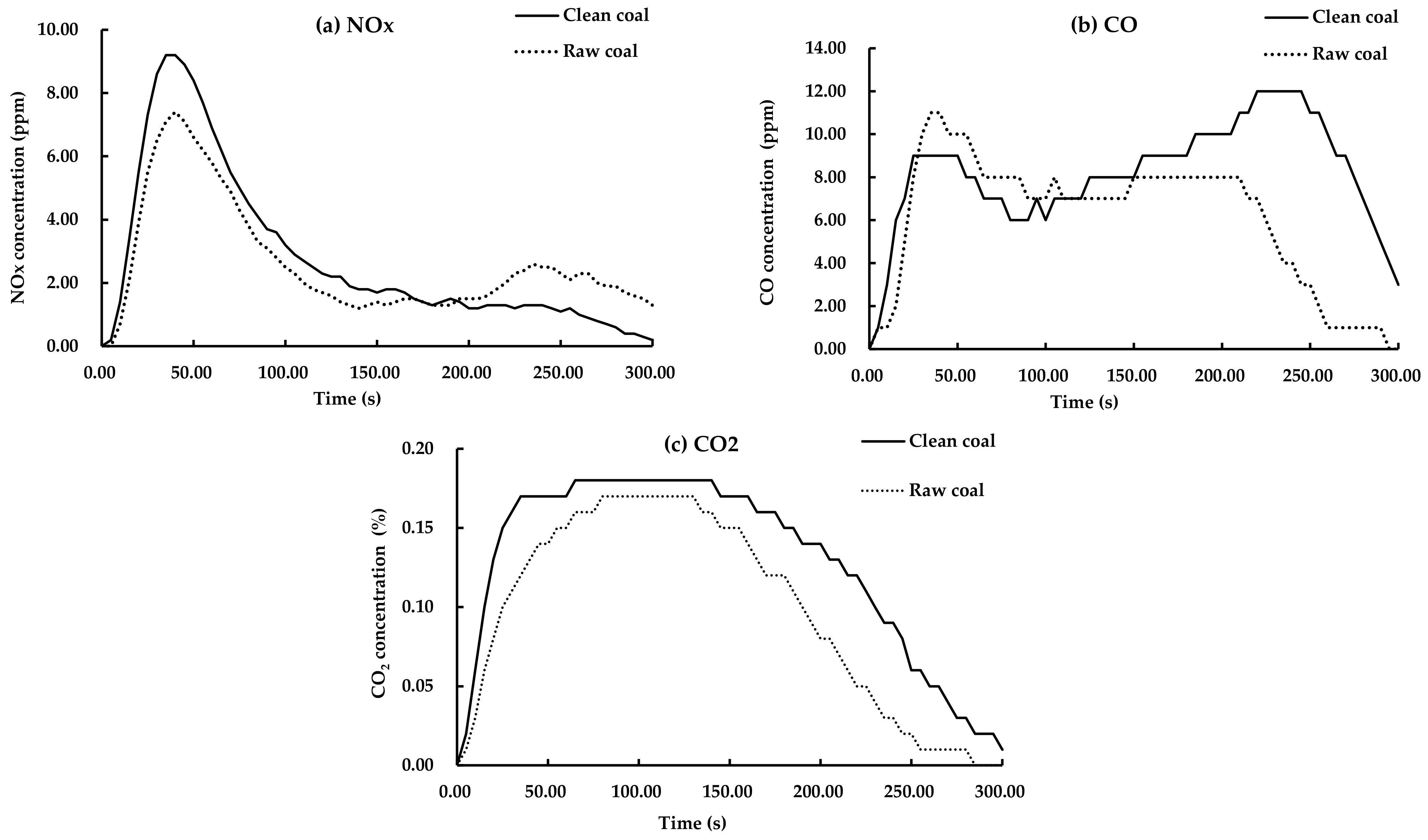

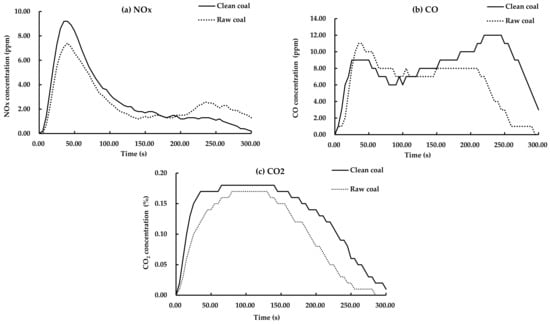

3.2.4. Analysis of the Combustion Exhaust

Finally, the direct analysis of the exhaust gas composition during coal combustion is used to verify whether the air pollution caused by clean coal is less than that caused by raw coal. The analysis results of coal combustion exhaust, using the combustion gas analyzer, are shown in Figure 7.

Figure 7.

Analysis of the combustion exhaust. (a): the concentration of NOx; (b): the concentration of CO; (c): the concentration of CO2.

The experimental conditions are set as follows: 200 mg of sample, 800 °C, and an air flow rate of 4 L/min. Figure 7a shows that the combustion of clean coal produces more CO2 than raw coal under the same conditions; This is because C content in the clean coal increases after removing the ash. Therefore, with the same quality, clean coal produces more CO2 than raw coal when combusted. The discharge curve of CO is shown in Figure 7b. Initially, the amount of CO produced by clean coal is less than that produced by raw coal because of the burn of more volatile matters; however, this behavior is reversed after 120 s because raw coal contains more materials, so the carbon content in the raw coal becomes very low and therefore the raw coal soon approaches the burnt-out state, and the CO emission decreases thereafter. However, after the initial combustion, the surface of clean coal is covered by ash, and the remaining clean coal components cannot be completely combusted, which leads to a higher amount of CO emission. It is shown that the clean coal was found to be easier and more efficient for combustion than the original raw coal.

4. Conclusions

In this study, the roll-type electrostatic separator was used to beneficiate low-grade coal with high ash content obtained from Inner Mongolia. After the optimum conditions were determined, a series of comparative analyses of raw coal and clean coal were conducted. According to the results, under the experimental conditions, the ash content of the clean coal can be reduced to approximately half of that of high-ash raw coal. Moreover, the clean coal was found to be more suitable and efficient for combustion than the original raw coal. At the same time, its composition structure was more suitable for industrial production. From these results, it was shown that this method can be used for the preparation of a specific coal type (such as high-ash coal) in a specific area (Inner Mongolia). This method can be utilized for power generation when directly burning, which ultimately decreases the subsequent air pollution.

Author Contributions

Conceptualization, C.L. and Q.W.; data curation, C.L.; formal analysis, C.L.; funding acquisition, Q.W.; investigation, C.L. and Q.W.; methodology, C.L. and Q.W.; project administration, Q.W.; resources, Q.W.; software, C.L.; supervision, Q.W.; validation, Q.W.; visualization, C.L.; writing—original draft, C.L.; writing—review and editing, Q.W. All authors have read and agreed to the published version of the manuscript.

Funding

This study was partially supported by the special funds for Basic Researches (B) (No. 15H05119, FY2015~FY2017) of Grant-in-Aid Scientific Research of the Japanese Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan.

Acknowledgments

We would like to thank Japan Student Services Organizations for a grant that made it possible to complete this study.

Conflicts of Interest

The authors declare no conflict of interest. The funder had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Xiao, K.; Qin, A.; Wang, W.; Lu, S.; Wang, Q. Study on the Characteristics of Size-Segregated Particulate Water-Soluble Inorganic Ions and Potentially Toxic Metals during Wintertime in a High Population Residential Area in Beijing, China. Processes 2021, 9, 552. [Google Scholar] [CrossRef]

- Höök, M.; Zittel, W.; Schindler, J.; Aleklett, K. Global coal production outlooks based on a logistic model. Fuel 2010, 89, 3546–3558. [Google Scholar] [CrossRef] [Green Version]

- Dwari, R.K.; Rao, K.H. Dry beneficiation of coal—A review. Miner. Process. Extr. Metall. Rev. 2007, 28, 177–234. [Google Scholar] [CrossRef]

- Chen, Q.; Yang, Y. Development of dry beneficiation of coal in China. Coal Prep. 2003, 23, 3–12. [Google Scholar] [CrossRef]

- Iuga, A.; Dǎscǎlescu, L.; Morar, R.; Csorvassy, I.; Neamiu, V. Corona-electrostatic separators for recovery of waste non-ferrous metals. J. Electrost. 1989, 23, 235–243. [Google Scholar] [CrossRef]

- Iuga, A.; Neamtu, V.; Suarasan, I.; Morar, R.; Dascalescu, L. Optimal high-voltage energization of corona-electrostatic separators. IEEE Trans. Ind. Appl. 1998, 34, 286–293. [Google Scholar] [CrossRef]

- Venter, J.A.; Vermaak, M.K.G.; Bruwer, J.G. Influence of surface effects on the electrostatic separation of zircon and rutile. J. South. Afr. Inst. Min. Metall. 2008, 108, 55–60. [Google Scholar]

- Morar, R.; Iuga, A.; Cuglesan, I.; Muntean, O.; Dascalescu, L. Iron ore beneficiation using roll-type high-intensity electric field separators. IEEE Trans. Ind. Appl. 1999, 35, 218–224. [Google Scholar] [CrossRef]

- Tripathy, S.K.; Ramamurthy, Y.; Kumar, C.R. Modeling of high-tension roll separator for separation of titanium bearing minerals. Powder Technol. 2010, 201, 181–186. [Google Scholar] [CrossRef]

- Veit, H.M.; Diehl, T.R.; Salami, A.P.; Rodrigues, J.D.S.; Bernardes, A.M.; Tenório, J.A.S. Utilization of magnetic and electrostatic separation in the recycling of printed circuit boards scrap. Waste Manag. 2005, 25, 67–74. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Xu, Z.; Zhou, Y. Application of corona discharge and electrostatic force to separate metals and nonmetals from crushed particles of waste printed circuit boards. J. Electrost. 2007, 65, 233–238. [Google Scholar] [CrossRef]

- Li, J.; Lu, H.; Xu, Z.; Zhou, Y. A model for computing the trajectories of the conducting particles from waste printed circuit boards in corona electrostatic separators. J. Hazard. Mater. 2008, 151, 52–57. [Google Scholar] [CrossRef] [PubMed]

- Iuga, A.; Samuila, A.; Neamtu, V.; Morar, R.; Beleca, R.; Das, S.; Dascalescu, L. Removal of metallic particles from acrylonitrile butadiene styrene wastes using electrostatic separation methods. IEEE Trans. Ind. Appl. 2010, 47, 322–330. [Google Scholar] [CrossRef]

- Tilmatine, A.; Medles, K.; Younes, M.; Bendaoud, A.; Dascalescu, L. Roll-type versus free-fall electrostatic separation of tribocharged plastic particles. IEEE Trans. Ind. Appl. 2010, 46, 1564–1569. [Google Scholar] [CrossRef]

- Tilmatine, A.; Medles, K.; Bendimerad, S.E.; Boukholda, F.; Dascalescu, L. Electrostatic separators of particles: Application to plastic/metal, metal/metal and plastic/plastic mixtures. Waste Manag. 2009, 29, 228–232. [Google Scholar] [CrossRef]

- Butunoi, T.; Buda, G.; Dragos, C.; Samuila, A.; Neamtu, V.; Morar, R.; Dascalescu, L.; Iuga, A. Wheat seeds separation in high-intensity electric field. In Proceedings of the 2011 7th International Symposium on Advanced Topics in Electrical Engineering (Atee), Bucharest, Romania, 12–14 May 2011; pp. 1–6. [Google Scholar]

- Higashiyama, Y.; Asano, K. Recent progress in electrostatic separation technology. Part. Sci. Technol. 1998, 16, 77–90. [Google Scholar] [CrossRef]

- Zhang, X. Study on Desulfurization and Ash Reduction of Fine Coal. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 1994. [Google Scholar]

- Chu, J. Effect of particle size on mineral dissociation and electrostatic separation of coal. Coal Prep. Technol. 2011, 6, 1–4. [Google Scholar] [CrossRef]

- Chu, J. Study on the Relationship between Coal Chemical Degree and High Voltage Separation. Coal Eng. 2011, 7, 100–101. [Google Scholar] [CrossRef]

- Chu, J. Study on the Relationship between Coal and Rock Composition and High Voltage Separation. Goal Prep. Technol. 2003, 5, 14–17. [Google Scholar] [CrossRef]

- Abel, W.T.; Zulkoski, M.; Gauntlett, G.J. Dry separation of pyrite from coal. Ind. Eng. Chem. Prod. Res. Dev. 1972, 11, 342–347. [Google Scholar] [CrossRef]

- Butcher, D.A.; Rowson, N.A. Electrostatic separation of pyrite from coal. Magn. Electr. Sep. 1995, 6, 19–30. [Google Scholar] [CrossRef]

- Knoll, F.S.; Taylor, J.B. Advances in electrostatic separation. Min. Metall. Explor. 1985, 2, 106–114. [Google Scholar] [CrossRef]

- Chen, X.Y.; Zhang, Y.F.; Zhou, Q. Analysis of Lignite Character in Inner Mongolia China. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 2019 the 3rd International Conference on Sustainable Energy Engineering, Shanghai, China, 24–26 May 2019; IOP Publishing: Philadelphia, PA, USA, 2019; Volume 342, p. 012020. [Google Scholar] [CrossRef]

- Sarkar, J.K.; Wang, Q. Different pyrolysis process conditions of south Asian waste coconut Shell and characterization of gas, bio-char, and bio-oil. Energies 2020, 13, 1970. [Google Scholar] [CrossRef]

- Sarkar, J.K.; Wang, Q. Characterization of pyrolysis products and kinetic analysis of waste jute stick biomass. Processes 2020, 8, 837. [Google Scholar] [CrossRef]

- Ken, B.S.; Nandi, B.K. Desulfurization of high sulfur Indian coal by oil agglomeration using Linseed oil. Powder Technol. 2019, 342, 690–697. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).