Effects of Different Amylose Contents of Foxtail Millet Flour Varieties on Textural Properties of Chinese Steamed Bread

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of WFMF

2.3. Amylose Content of WFMF

2.4. CSB Preparation

2.5. CSB Evaluation

2.6. Statistical Analysis

3. Results and Discussion

3.1. Height–diameter Ratio and Specific Volume of the CSB

3.2. CSB Texture Analysis

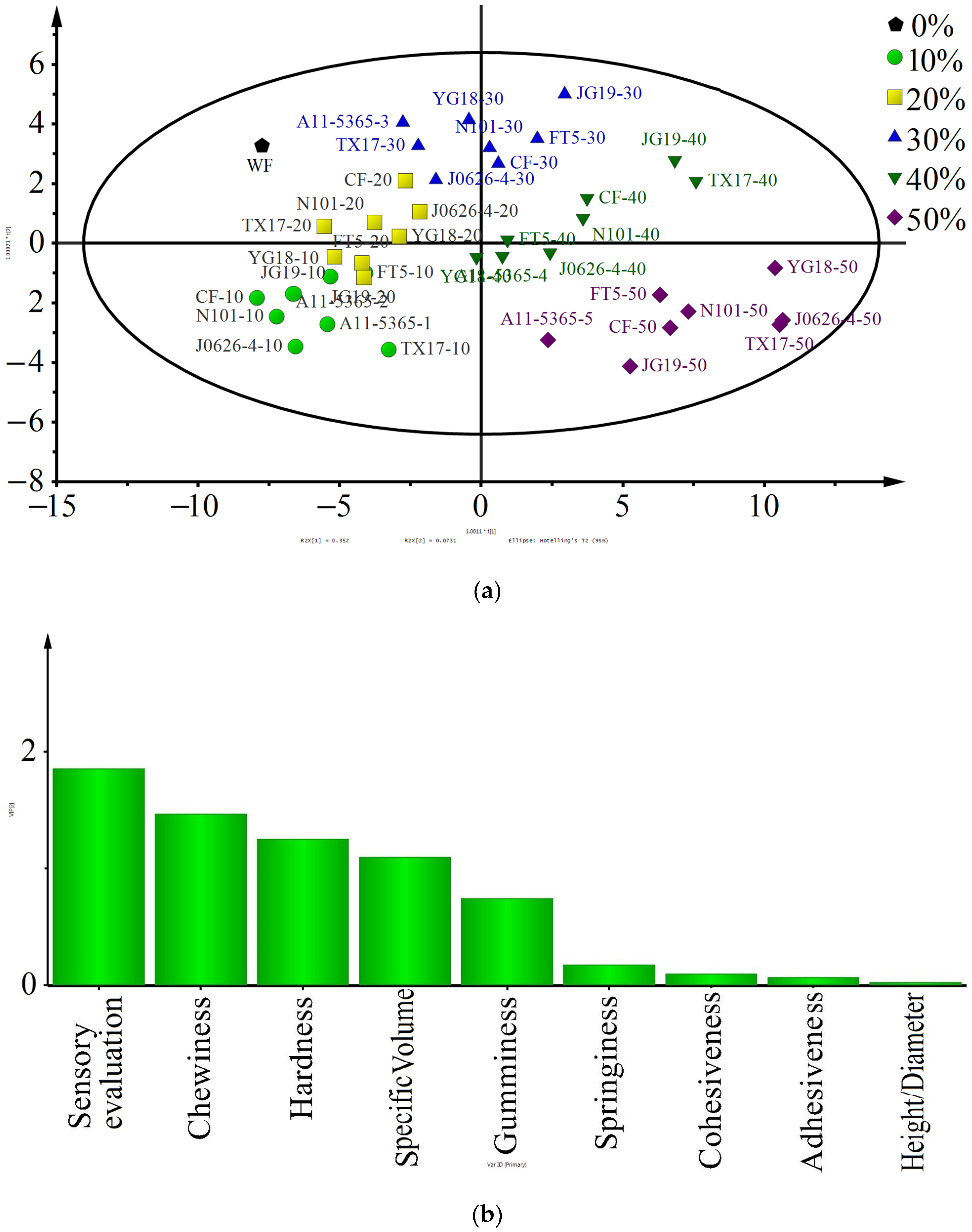

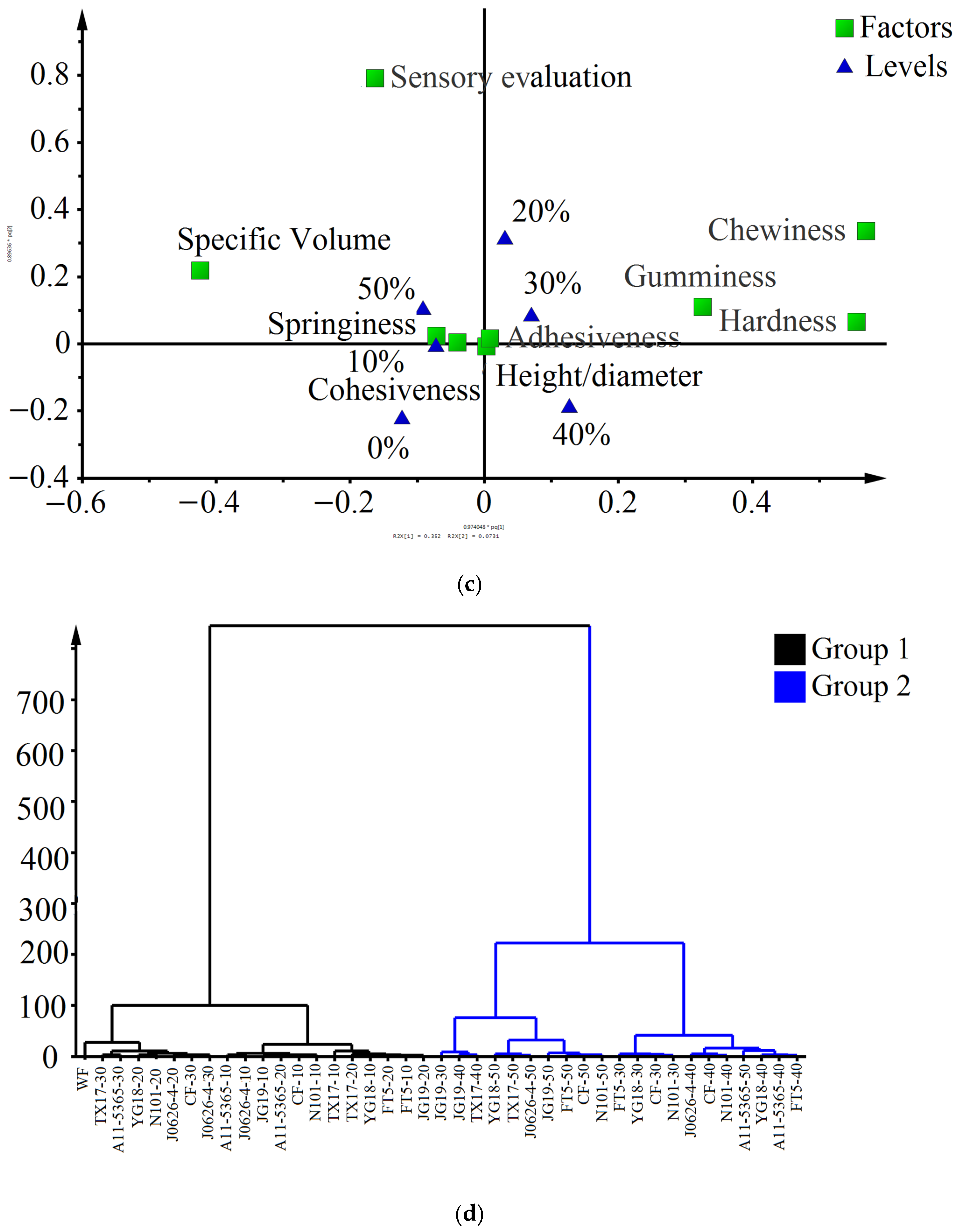

3.3. OPLS-DA of CSB

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fujita, S.; Sugimoto, Y.; Yamashita, Y.; Fuwa, H. Physicochemical studies of starch from foxtail millet (Setaria italica Beauv.). Food Chem. 1996, 55, 209–213. [Google Scholar] [CrossRef]

- Zhang, L.Z.; Liu, R.H. Phenolic and carotenoid profiles and antiproliferative activity of foxtail millet. Food Chem. 2015, 174, 495–501. [Google Scholar] [CrossRef] [PubMed]

- Mozaffarian, R.S.; Lee, R.M.; Kennedy, M.A.; Ludwig, D.S.; Mozaffarian, D.; Gortmaker, S.L. Identifying whole grain foods: A comparison of different approaches for selecting more healthful whole grain products. Public Health Nutr. 2013, 16, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Rezaei, S.; Najafi, M.A.; Haddadi, T. Effect of fermentation process, wheat bran size and replacement level on some characteristics of wheat bran, dough, and high-fiber Tafton bread. J. Cereal Sci. 2019, 85, 56–61. [Google Scholar] [CrossRef]

- Chen, J.; Duan, W.; Ren, X.; Wang, C.; Pan, Z.; Diao, X.; Shen, Q. Effect of foxtail millet protein hydrolysates on lowering blood pressure in spontaneously hypertensive rats. Eur. J. Nutr. 2017, 56, 2129–2138. [Google Scholar] [CrossRef]

- Okarter, N.; Liu, R.H. Health benefits of whole grain phytochemicals. Crit. Rev. Food Sci. Nutr. 2010, 50, 193–208. [Google Scholar] [CrossRef]

- Schmiele, M.; Jaekel, L.Z.; Patricio, S.M.C.; Steel, C.J.; Chang, Y.K. Rheological properties of wheat flour and quality characteristics of pan bread as modified by partial additions of wheat bran or whole grain wheat flour. Inter. J. Food Sci. Technol. 2012, 47, 2141–2150. [Google Scholar] [CrossRef]

- Shan, S.; Li, Z.; Newton, I.P.; Zhao, C.; Li, Z.; Guo, M. A novel protein extracted from foxtail millet bran displays anti-carcinogenic effects in human colon cancer cells. Toxicol. Lett. 2014, 227, 129–138. [Google Scholar] [CrossRef]

- Iglesias-Puig, E.; Monedero, V.; Haros, M. Bread with whole quinoa flour and bifidobacterial phytases increases dietary mineral intake and bioavailability. LWT Food Sci. Technol. 2015, 60, 71–77. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Opassathavorn, A.; Zhu, F. Influence of Quinoa Flour on Quality Characteristics of Cookie, Bread and Chinese Steamed Bread. J. Texture Stud. 2015, 46, 281–292. [Google Scholar] [CrossRef]

- Fang, Y.; Qing, H.; Yu, J.; Gu, X.; Wang, M. Comparison of Tartary Buckwheat Flour and Sprouts Steamed Bread in Quality and Antioxidant Property. J. Food Qual. 2014, 37, 318–328. [Google Scholar] [CrossRef]

- Guo, X.N.; Yang, S.; Zhu, K.X. Influences of alkali on the quality and protein polymerization of buckwheat Chinese steamed bread. Food Chem. 2019, 283, 52–58. [Google Scholar] [CrossRef]

- Bhol, S.; Bosco, S.J.D. Influence of malted finger millet and red kidney bean flour on quality characteristics of developed bread. LWT Food Sci. Technol. 2014, 55, 294–300. [Google Scholar] [CrossRef]

- Topping, D. Cereal complex carbohydrates and their contribution to human health. J. Cereal Sci. 2007, 46, 220–229. [Google Scholar] [CrossRef]

- Burešová, I.; Tokár, M.; Mareček, J.; Hřivna, L.; Faměra, O.; Šottníková, V. The comparison of the effect of added amaranth, buckwheat, chickpea, corn, millet and quinoa flour on rice dough rheological characteristics, textural and sensory quality of bread. J. Cereal Sci. 2017, 75, 158–164. [Google Scholar] [CrossRef]

- Cordelino, I.G.; Tyl, C.; Inamdar, L.; Vickers, Z.; Marti, A.; Ismail, B.P. Cooking quality, digestibility, and sensory properties of proso millet pasta as impacted by amylose content and prolamin profile. LWT Food Sci. Technol. 2019, 99, 1–7. [Google Scholar] [CrossRef]

- Li, S.H.; Zhao, W.; Li, P.L.; Min, G.; Zhang, A.X.; Zhang, J.L.; Liu, Y.Y.; Liu, J.K. Effects of different cultivars and particle sizes of non-degermed millet flour fractions on the physical and texture properties of Chinese steamed bread. Cereal Chem. 2020, 97, 661–669. [Google Scholar] [CrossRef]

- Wu, C.; Liu, R.; Huang, W.; Rayas-Duarte, P.; Wang, F.; Yao, Y. Effect of sourdough fermentation on the quality of Chinese Northern-style steamed breads. J. Cereal Sci. 2012, 56, 127–133. [Google Scholar] [CrossRef]

- Sun, R.; Zhang, Z.; Hu, X.; Xing, Q.; Zhuo, W. Effect of wheat germ flour addition on wheat flour, dough and Chinese steamed bread properties. J. Cereal Sci. 2015, 64, 153–158. [Google Scholar] [CrossRef]

- Zhu, F.; Sakulnak, R.; Wang, S. Effect of black tea on antioxidant, textural, and sensory properties of Chinese steamed bread. Food Chem. 2016, 194, 1217–1223. [Google Scholar] [CrossRef]

- Almeida, E.L.; Chang, Y.K. Effect of the addition of enzymes on the quality of frozen pre-baked French bread substituted with whole wheat flour. LWT Food Sci. Technol. 2012, 49, 64–72. [Google Scholar] [CrossRef]

- Marchini, M.; Carini, E.; Cataldi, N.; Boukid, F.; Blandino, M.; Ganino, T.; Vittadini, E.; Pellegrini, N. The use of red lentil flour in bakery products: How do particle size and substitution level affect rheological properties of wheat bread dough? LWT Food Sci. Technol. 2021, 136. [Google Scholar] [CrossRef]

- Liu, C.; Liu, L.; Li, L.; Hao, C.; Zheng, X.; Bian, K.; Zhang, J.; Wang, X. Effects of different milling processes on whole wheat flour quality and performance in steamed bread making. LWT Food Sci. Technol. 2015, 62, 310–318. [Google Scholar] [CrossRef]

- Sharma, N.; Niranjan, K. Foxtail millet: Properties, processing, health benefits, and uses. Food Rev. Int. 2017, 34, 329–363. [Google Scholar] [CrossRef]

- Wang, X.Y.; Guo, X.N.; Zhu, K.X. Polymerization of wheat gluten and the changes of glutenin macropolymer (GMP) during the production of Chinese steamed bread. Food Chem. 2016, 201, 275–283. [Google Scholar] [CrossRef]

- Annor, G.A.; Tyl, C.; Marcone, M.; Ragaee, S.; Marti, A. Why do millets have slower starch and protein digestibility than other cereals? Trends Food Sci. Technol. 2017, 66, 73–83. [Google Scholar] [CrossRef]

- Fu, J.-T.; Chang, Y.-H.; Shiau, S.-Y. Rheological, antioxidative and sensory properties of dough and Mantou (steamed bread) enriched with lemon fiber. LWT Food Sci. Technol. 2015, 61, 56–62. [Google Scholar] [CrossRef]

- Chen, J.S.; Fei, M.J.; Shi, C.L.; Tian, J.C.; Sun, C.L.; Zhang, H.; Ma, Z.; Dong, H.X. Effect of particle size and addition level of wheat bran on quality of dry white Chinese noodles. J. Cereal Sci. 2011, 53, 217–224. [Google Scholar] [CrossRef]

- Kokawa, M.; Suzuki, Y.; Suzuki, Y.; Yoshimura, M.; Trivittayasil, V.; Tsuta, M.; Sugiyama, J. Viscoelastic properties and bubble structure of rice-gel made from high-amylose rice and its effects on bread. J. Cereal Sci. 2017, 73, 33–39. [Google Scholar] [CrossRef]

- Hsieh, P.-H.; Weng, Y.-M.; Yu, Z.-R.; Wang, B.-J. Substitution of wheat flour with wholegrain flours affects physical properties, sensory acceptance, and starch digestion of Chinese steam bread (Mantou). LWT Food Sci. Technol. 2017, 86, 571–576. [Google Scholar] [CrossRef]

- Lin, L.-Y.; Liu, H.-M.; Yu, Y.-W.; Lin, S.-D.; Mau, J.-L. Quality and antioxidant property of buckwheat enhanced wheat bread. Food Chem. 2009, 112, 987–991. [Google Scholar] [CrossRef]

- Machado Alencar, N.M.; Steel, C.J.; Alvim, I.D.; de Morais, E.C.; Andre Bolini, H.M. Addition of quinoa and amaranth flour in gluten-free breads: Temporal profile and instrumental analysis. LWT Food Sci. Technol. 2015, 62, 1011–1018. [Google Scholar] [CrossRef]

- Ning, J.; Hou, G.G.; Sun, J.; Wan, X.; Dubat, A. Effect of green tea powder on the quality attributes and antioxidant activity of whole-wheat flour pan bread. LWT Food Sci. Technol. 2017, 79, 342–348. [Google Scholar] [CrossRef]

- Liu, X.; Mu, T.; Sun, H.; Zhang, M.; Chen, J.; Fauconnier, M.L. Influence of different hydrocolloids on dough thermo-mechanical properties and in vitro starch digestibility of gluten-free steamed bread based on potato flour. Food Chem. 2018, 239, 1064–1074. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Mu, T.; Sun, H. Effects of starch from five different botanical sources on the rheological and structural properties of starch-gluten model doughs. Food Res. Int. 2018, 103, 156–162. [Google Scholar] [CrossRef] [PubMed]

| Sample | Name Code | Amylose (%) | Type of Cultivar |

|---|---|---|---|

| Jigu-19 | JG19 | 32.25 ± 0.68 | Japonica |

| Taixuan-17 | TX17 | 24.64 ± 0.37 | Japonica |

| Yugu-18 | YG18 | 15.19 ± 0.81 | Japonica |

| An11-5365 | A11-5365 | 25.50 ± 0.62 | Japonica |

| Ji0626-4 | J0626-4 | 12.36 ± 0.53 | Japonica |

| Chifeng-1 | CF1 | 7.40 ± 0.34 | Glutinous |

| Fente-5 | FT5 | 7.46 ± 0.65 | Glutinous |

| N101 | N101 | 5.25 ± 0.47 | Glutinous |

| Level (%) | Japonica | Glutinous | ||||||

|---|---|---|---|---|---|---|---|---|

| JG19 | TX17 | YG18 | A11-5365 | J0626-4 | CF1 | FT5 | N101 | |

| Height–Diameter Ratio | ||||||||

| 0 | 0.87 ± 0.05 Aa | 0.87 ± 0.05 Aa | 0.87 ± 0.05 Aab | 0.87 ± 0.05 Aa | 0.87 ± 0.05 Aab | 0.87 ± 0.05 Ab | 0.87 ± 0.05 Aab | 0.87 ± 0.05 Aa |

| 10 | 0.87 ± 0.01 Aa | 0.90 ± 0.07 Aa | 0.86 ± 0.02 Aab | 0.85 ± 0.01 Aa | 0.86 ± 0.03 Aab | 0.86 ± 0.01 Ab | 0.92 ± 0.03 Aa | 0.82 ± 0.02 Aab |

| 20 | 0.81 ± 0.03 ABab | 0.82 ± 0.03 ABa | 0.83 ± 0.01 ABab | 0.84 ± 0.03 Aa | 0.88 ± 0.05 Aa | 0.89 ± 0.04 Ab | 0.84 ± 0.03 Ab | 0.82 ± 0.10 ABab |

| 30 | 0.79 ± 0.03 Cab | 0.85 ± 0.02 BCa | 0.87 ± 0.02 ABa | 0.81 ± 0.03 BCa | 0.81 ± 0.01 BCb | 0.93 ± 0.07 Aab | 0.88 ± 0.01 ABab | 0.84 ± 0.03 BCab |

| 40 | 0.79 ± 0.02 Bab | 0.86 ± 0.01 Ba | 0.81 ± 0.03 Bb | 0.82 ± 0.01 Ba | 0.84 ± 0.03 Bab | 0.95 ± 0.08 Aab | 0.85 ± 0.03 Bb | 0.86 ± 0.00 Ba |

| 50 | 0.83 ± 0.02 Cb | 0.83 ± 0.01 Ca | 0.84 ± 0.02 BCab | 0.82 ± 0.03 Ca | 0.84 ± 0.02 BCab | 1.00 ± 0.04 Aa | 0.86 ± 0.01 BCab | 0.89 ± 0.00 Ba |

| Specific Volume (cm3/g) | ||||||||

| 0 | 2.25 ± 0.15 Aa | 2.25 ± 0.15 Aa | 2.25 ± 0.15 Aa | 2.25 ± 0.15 Aa | 2.25 ± 0.15 Aa | 2.25 ± 0.15 Aa | 2.25 ± 0.15 Aa | 2.25 ± 0.15 Aa |

| 10 | 2.10 ± 0.10 Aab | 2.09 ± 0.04 Aab | 1.52 ± 0.12 Bb | 1.96 ± 0.14 Ab | 1.91 ± 0.17 Ab | 2.02 ± 0.08 Aab | 1.92 ± 0.11 Ab | 2.03 ± 0.20 Aab |

| 20 | 2.00 ± 0.15 Aab | 1.93 ± 0.14 ABb | 1.54 ± 0.11 Cb | 1.97 ± 0.03 ABb | 1.84 ± 0.12 ABbc | 1.74 ± 0.08 BCbc | 1.87 ± 0.03 ABbc | 1.98 ± 0.04 ABb |

| 30 | 1.90 ± 0.08 Ab | 1.58 ± 0.08 Bc | 1.58 ± 0.10 Bb | 1.75 ± 0.06 ABc | 1.88 ± 0.05 Abc | 1.74 ± 0.18 ABbc | 1.78 ± 0.03 ABbcd | 1.87 ± 0.02 Abc |

| 40 | 1.56 ± 0.07 BCc | 1.50 ± 0.07 Cc | 1.67 ± 0.08 ABCb | 1.60 ± 0.06 ABCc | 1.64 ± 0.07 ABCcd | 1.75 ± 0.14 Abc | 1.69 ± 0.01 ABcd | 1.77 ± 0.04 Abc |

| 50 | 1.46 ± 0.09 BCc | 1.38 ± 0.08 Cc | 1.52 ± 0.07 ABCb | 1.60 ± 0.05 ABc | 1.56 ± 0.02 ABd | 1.65 ± 0.09 Ac | 1.66 ± 0.05 Ad | 1.68 ± 0.04 Ac |

| Sensory Evaluation | ||||||||

| 0 | 88.10 ± 2.46 Aa | 88.10 ± 2.46 Aa | 88.10 ± 2.46 Aa | 88.10 ± 2.46 Aa | 88.10 ± 2.46 Aa | 88.10 ± 2.46 Aa | 88.10 ± 2.46 Aa | 88.10 ± 2.46 Aa |

| 10 | 76.67 ± 3.46 Ac | 70.33 ± 4.63 Acd | 76.70 ± 3.14 Ab | 74.33 ± 5.61 Ab | 72.00 ± 3.84 Acd | 74.63 ± 2.80 Ab | 74.20 ± 4.27 Ab | 75.13 ± 5.46 Acd |

| 20 | 75.90 ± 3.03 ABc | 80.33 ± 3.88 ABab | 78.27 ± 3.67 ABb | 74.13 ± 2.25 Bb | 79.77 ± 4.98 ABabc | 80.77 ± 4.15 ABab | 78.30 ± 3.73 ABb | 81.40 ± 2.10 Aabc |

| 30 | 84.13 ± 3.69 Aab | 85.40 ± 0.95 Aab | 85.77 ± 4.39 Aa | 86.43 ± 4.61 Aa | 81.93 ± 2.18 Aab | 81.07 ± 3.88 Aab | 85.4 ± 3.73 Aa | 85.20 ± 5.66 Aab |

| 40 | 80.47 ± 5.00 Abc | 77.83 ± 5.51 Abc | 74.90 ± 2.19 Abc | 75.03 ± 3.56 Ab | 73.97 ± 4.93 Abcd | 75.23 ± 4.71 Ab | 78.83 ± 2.74 Ab | 78.67 ± 0.65 Abcd |

| 50 | 66.10 ± 1.82 Ad | 67.00 ± 6.08 Ad | 69.93 ± 1.48 Ac | 68.07 ± 6.20 Ab | 66.27 ± 6.98 Ad | 64.90 ± 6.07 Ac | 74.03 ± 2.12 Ab | 71.87 ± 3.37 Ad |

| Level (%) | Japonica | Glutinous | ||||||

|---|---|---|---|---|---|---|---|---|

| JG19 | TX17 | YG18 | A11-5365 | J0626-4 | CF1 | FT5 | N101 | |

| Hardness (N) | ||||||||

| 0 | 36.17 ± 3.26 Ad | 36.17 ± 3.26 Ac | 36.17 ± 3.26 Ae | 36.17 ± 3.26 Ad | 36.17 ± 3.26 Ae | 36.17 ± 3.26 Ad | 36.17 ± 3.26 Ac | 36.17 ± 3.26 Ab |

| 10 | 38.16 ± 0.49 Dd | 45.87 ± 3.47 BCb | 40.97 ± 1.45 CDde | 37.12 ± 2.41 Dd | 40.70 ± 2.87 CDde | 47.24 ± 3.00 Bcd | 57.76 ± 5.38 Aa | 36.69 ± 1.48 Db |

| 20 | 48.23 ± 6.56 Bc | 45.75 ± 3.76 BCb | 48.61 ± 2.78 Bcd | 47.29 ± 2.71 BCc | 51.12 ± 2.96 ABcd | 58.98 ± 7.87 Abc | 49.00 ± 0.21 Bab | 39.23 ± 2.78 Cb |

| 30 | 75.30 ± 4.27 Aa | 49.48 ± 3.27 Cb | 55.87 ± 6.48 BCbc | 52.39 ± 2.99 Bbc | 54.28 ± 4.93 Cc | 65.07 ± 2.42 Bb | 48.75 ± 9.41 Cab | 46.51 ± 6.38 Cab |

| 40 | 72.44 ± 7.55 ABab | 75.05 ± 5.97 Aa | 60.80 ± 5.30 BCDb | 59.23 ± 4.11 BCDab | 69.05 ± 5.88 ABCb | 84.01 ± 18.81 Aa | 43.58 ± 7.01 Dbc | 53.76 ± 8.58 CDa |

| 50 | 63.56 ± 3.22 BCb | 76.42 ± 5.49 Aa | 83.66 ± 9.09 Aa | 64.23 ± 9.87 BCa | 82.41 ± 10.10 Aa | 88.41 ± 8.26 Aa | 39.43 ± 1.05 Dbc | 52.86 ± 6.08 CDa |

| Cohesiveness | ||||||||

| 0 | 0.77 ± 0.01 Aa | 0.77 ± 0.01 Aa | 0.77 ± 0.01 Aa | 0.77 ± 0.01 Aa | 0.77 ± 0.01 Aa | 0.77 ± 0.01 Aa | 0.77 ± 0.01 Aa | 0.77 ± 0.01 Aa |

| 10 | 0.74 ± 0.01 BCb | 0.74 ± 0.02 BCb | 0.76 ± 0.01 Aba | 0.77 ± 0.01 Aba | 0.77 ± 0.02 Aa | 0.75 ± 0.01 ABCb | 0.74 ± 0.02 Cb | 0.77 ± 0.01 Aa |

| 20 | 0.71 ± 0.01 Dc | 0.73 ± 0.01 ABb | 0.74 ± 0.01 Ab | 0.73 ± 0.00 ABCb | 0.73 ± 0.01 ABCDb | 0.72 ± 0.01 CDc | 0.74 ± 0.01 Ab | 0.72 ± 0.00 BCDb |

| 30 | 0.67 ± 0.02 Cd | 0.70 ± 0.01 ABc | 0.72 ± 0.01 Ac | 0.71 ± 0.00 Ab | 0.68 ± 0.02 BCc | 0.68 ± 0.01 BCd | 0.69 ± 0.01 Bc | 0.69 ± 0.00 Bc |

| 40 | 0.61 ± 0.03 Df | 0.65 ± 0.00 ABCd | 0.67 ± 0.01 ABd | 0.68 ± 0.01 Ac | 0.64 ± 0.02 CDd | 0.66 ± 0.03 ABCd | 0.64 ± 0.02 BCd | 0.65 ± 0.02 ABCd |

| 50 | 0.64 ± 0.01 ABe | 0.59 ± 0.02 Ce | 0.61 ± 0.03 BCe | 0.67 ± 0.04 Ac | 0.59 ± 0.03 Ce | 0.62 ± 0.02 BCe | 0.61 ± 0.02 BCe | 0.58 ± 0.01 Ce |

| Springiness (mm) | ||||||||

| 0 | 5.65 ± 0.08 Aa | 5.65 ± 0.08 Aa | 5.65 ± 0.08 Aa | 5.65 ± 0.08 Aa | 5.65 ± 0.08 Aa | 5.65 ± 0.08 Aa | 5.65 ± 0.08 Aa | 5.65 ± 0.08 Aa |

| 10 | 5.51 ± 0.14 Aab | 5.52 ± 0.68 Aa | 5.73 ± 0.07 Aa | 5.30 ± 0.29 Aa | 5.47 ± 0.28 Aa | 5.75 ± 0.31 Aa | 5.51 ± 0.12 Aab | 5.51 ± 0.31 Aab |

| 20 | 5.70 ± 0.21 Aa | 5.50 ± 0.26 Aa | 5.51 ± 0.66 Aab | 5.78 ± 0.23 Aa | 5.50 ± 0.24 Aa | 5.62 ± 0.11 Aa | 5.44 ± 0.19 Aab | 5.44 ± 0.27 Aab |

| 30 | 5.27 ± 0.16 Abc | 5.48 ± 0.08 Aa | 5.48 ± 0.30 Aab | 5.63 ± 0.93 Aa | 5.55 ± 0.27 Aa | 5.47 ± 0.09 Aa | 5.20 ± 0.17 Ac | 5.35 ± 0.28 Aab |

| 40 | 5.15 ± 0.11 Ac | 5.04 ± 0.45 Aa | 5.49 ± 0.27 Aab | 5.43 ± 0.05 Aa | 5.42 ± 0.30 Aa | 5.37 ± 0.45 Aa | 5.41 ± 0.03 Abc | 5.18 ± 0.40 Aab |

| 50 | 5.12 ± 0.16 ABc | 5.03 ± 0.37 ABa | 5.08 ± 0.17 ABb | 5.23 ± 0.18 Aa | 5.15 ± 0.16 ABa | 5.31 ± 0.11 Aa | 4.78 ± 0.12 Bd | 4.96 ± 0.11 ABb |

| Gumminess (N) | ||||||||

| 0 | 27.91 ± 2.37 Ad | 27.91 ± 2.37 Ac | 27.91 ± 2.37 Ad | 27.91 ± 2.37 Ad | 27.91 ± 2.37 Ac | 27.91 ± 2.37 Ac | 27.91 ± 2.37 Ab | 27.91 ± 2.37 Ab |

| 10 | 28.43 ± 0.35 Dd | 34.05 ± 1.94 BCb | 31.29 ± 0.64 CDcd | 28.32 ± 1.62 Dd | 31.36 ± 1.61 CDbc | 35.30 ± 2.32 Bbc | 42.66 ± 3.03 Aa | 28.21 ± 1.48 Db |

| 20 | 34.28 ± 4.08 BCc | 33.49 ± 2.87 BCDb | 36.02 ± 1.88 Bbc | 34.52 ± 1.87 BCc | 37.12 ± 1.75 ABb | 42.19 ± 5.14 Ab | 28.95 ± 0.62 CDb | 28.22 ± 2.01 Db |

| 30 | 50.13 ± 1.88 Aa | 34.68 ± 1.84 DEb | 39.95 ± 4.15 BCb | 37.28 ± 2.09 CDbc | 37.13 ± 2.46 CDb | 44.29 ± 2.14 Bb | 33.82 ± 0.45 DEb | 32.00 ± 4.45 Eab |

| 40 | 43.80 ± 3.12 BCb | 48.86 ± 3.63 ABa | 40.97 ± 3.45 BCb | 40.11 ± 2.49 BCab | 43.82 ± 2.84 BCa | 54.98 ± 10.37 Aa | 27.89 ± 3.85 Db | 34.73 ± 4.92 CDa |

| 50 | 40.31 ± 2.17 Cb | 45.35 ± 1.79 BCa | 51.19 ± 7.28 ABa | 42.72 ± 4.40 BCa | 48.62 ± 4.66 ABCa | 55.18 ± 4.03 Aa | 29.54 ± 4.93 Db | 30.76 ± 2.90 Dab |

| Chewiness (mJ) | ||||||||

| 0 | 157.70 ± 12.26 Ad | 157.70 ± 12.26 Ac | 157.70 ± 12.26 Ad | 157.70 ± 12.26 Abc | 157.70 ± 12.26 Ac | 157.70 ± 12.26 Ac | 157.70 ± 12.26 Ab | 157.70 ± 12.26 Aa |

| 10 | 156.75 ± 5.79 Dd | 188.24 ± 29.09 BCbc | 179.47 ± 4.49 BCDbcd | 150.4 ± 16.86 Dc | 171.34 ± 2.91 CDc | 203.27 ± 23.87 Bbc | 235.14 ± 19.58 Aa | 155.54 ± 15.98 Da |

| 20 | 188.58 ± 25.97 BCDcd | 184.66 ± 24.01 BCDc | 199.34 ± 34.01 ABCcd | 199.88 ± 17.40 ABCab | 203.85 ± 3.38 ABb | 236.91 ± 26.68 Aab | 157.52 ± 4.84 CDb | 154.07 ± 18.12 Da |

| 30 | 264.39 ± 17.74 Aa | 189.87 ± 7.45 CDEbc | 217.93 ± 12.07 BCbc | 210.84 ± 45.76 BCDa | 206.34 ± 17.82 CDb | 242.35 ± 15.52 ABab | 175.77 ± 7.56 DEb | 170.63 ± 18.68 Ea |

| 40 | 225.49 ± 18.13 ABb | 246.84 ± 34.85 ABa | 225.55 ± 28.9 ABab | 217.96 ± 14.97 ABa | 237.73 ± 23.95 ABa | 298.12 ± 76.19 Aa | 150.69 ± 20.29 Cb | 179.92 ± 27.75 BCa |

| 50 | 206.68 ± 17.35 Cbc | 227.64 ± 7.49 BCab | 260.61 ± 45.96 ABa | 223.74 ± 28.44 BCa | 250.22 ± 16.61 ABCa | 293.33 ± 23.95 Aa | 141.41 ± 26.97 Db | 152.41 ± 14.98 Da |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Zhao, W.; Min, G.; Li, P.; Zhang, A.; Zhang, J.; Wang, Y.; Liu, Y.; Liu, J. Effects of Different Amylose Contents of Foxtail Millet Flour Varieties on Textural Properties of Chinese Steamed Bread. Processes 2021, 9, 1131. https://doi.org/10.3390/pr9071131

Li S, Zhao W, Min G, Li P, Zhang A, Zhang J, Wang Y, Liu Y, Liu J. Effects of Different Amylose Contents of Foxtail Millet Flour Varieties on Textural Properties of Chinese Steamed Bread. Processes. 2021; 9(7):1131. https://doi.org/10.3390/pr9071131

Chicago/Turabian StyleLi, Shaohui, Wei Zhao, Guang Min, Pengliang Li, Aixia Zhang, Jiali Zhang, Yunting Wang, Yingying Liu, and Jingke Liu. 2021. "Effects of Different Amylose Contents of Foxtail Millet Flour Varieties on Textural Properties of Chinese Steamed Bread" Processes 9, no. 7: 1131. https://doi.org/10.3390/pr9071131

APA StyleLi, S., Zhao, W., Min, G., Li, P., Zhang, A., Zhang, J., Wang, Y., Liu, Y., & Liu, J. (2021). Effects of Different Amylose Contents of Foxtail Millet Flour Varieties on Textural Properties of Chinese Steamed Bread. Processes, 9(7), 1131. https://doi.org/10.3390/pr9071131