A Theoretical Study on the Thermodynamic Cycle of Concept Engine with Miller Cycle

Abstract

1. Introduction

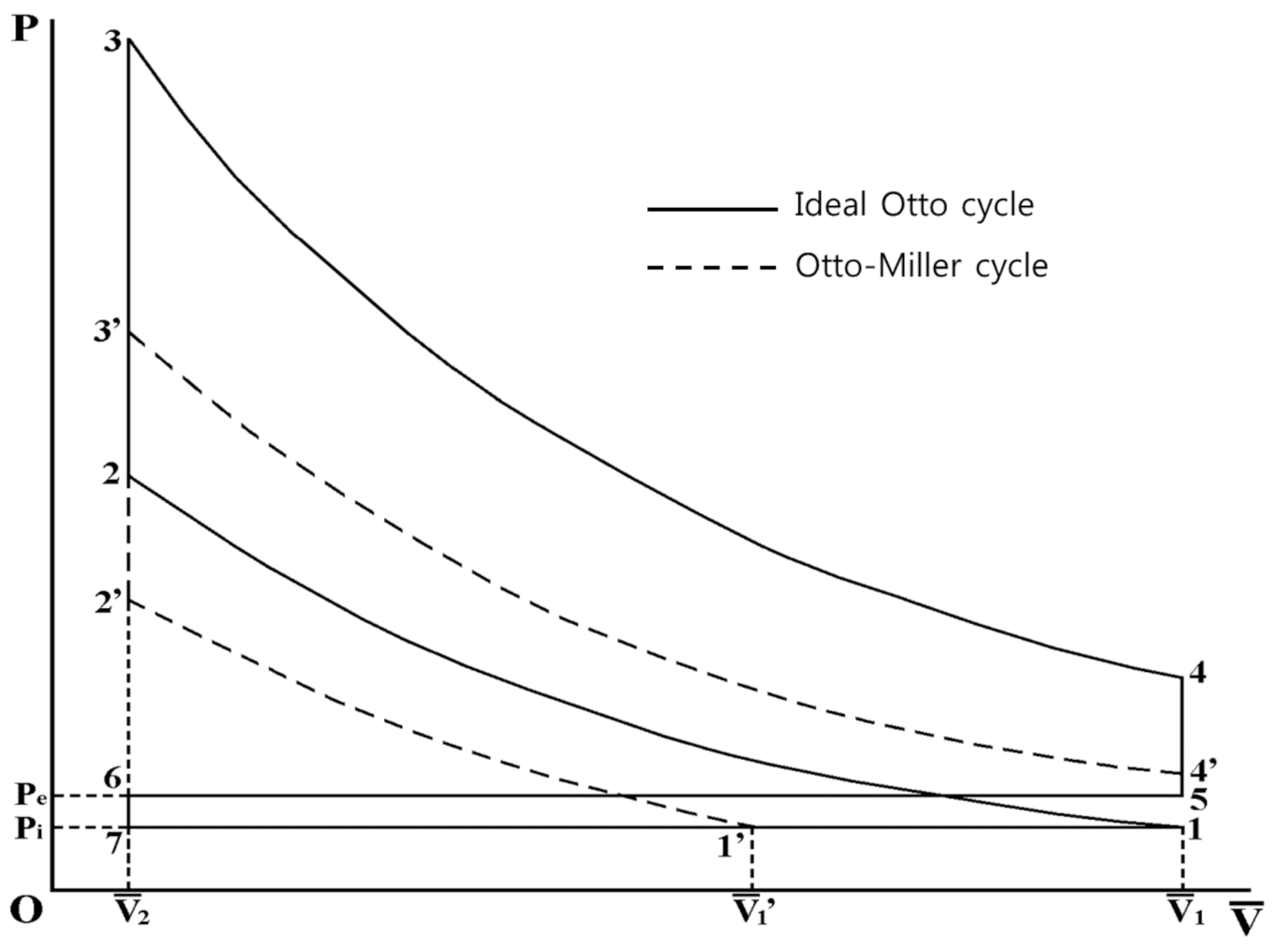

2. Otto–Miller Cycle

2.1. Cycle Curve and the Quantity of State in Each Process

2.2. Thermal Efficiency and Mean Effective Pressure (MEP) of Miller Cycle

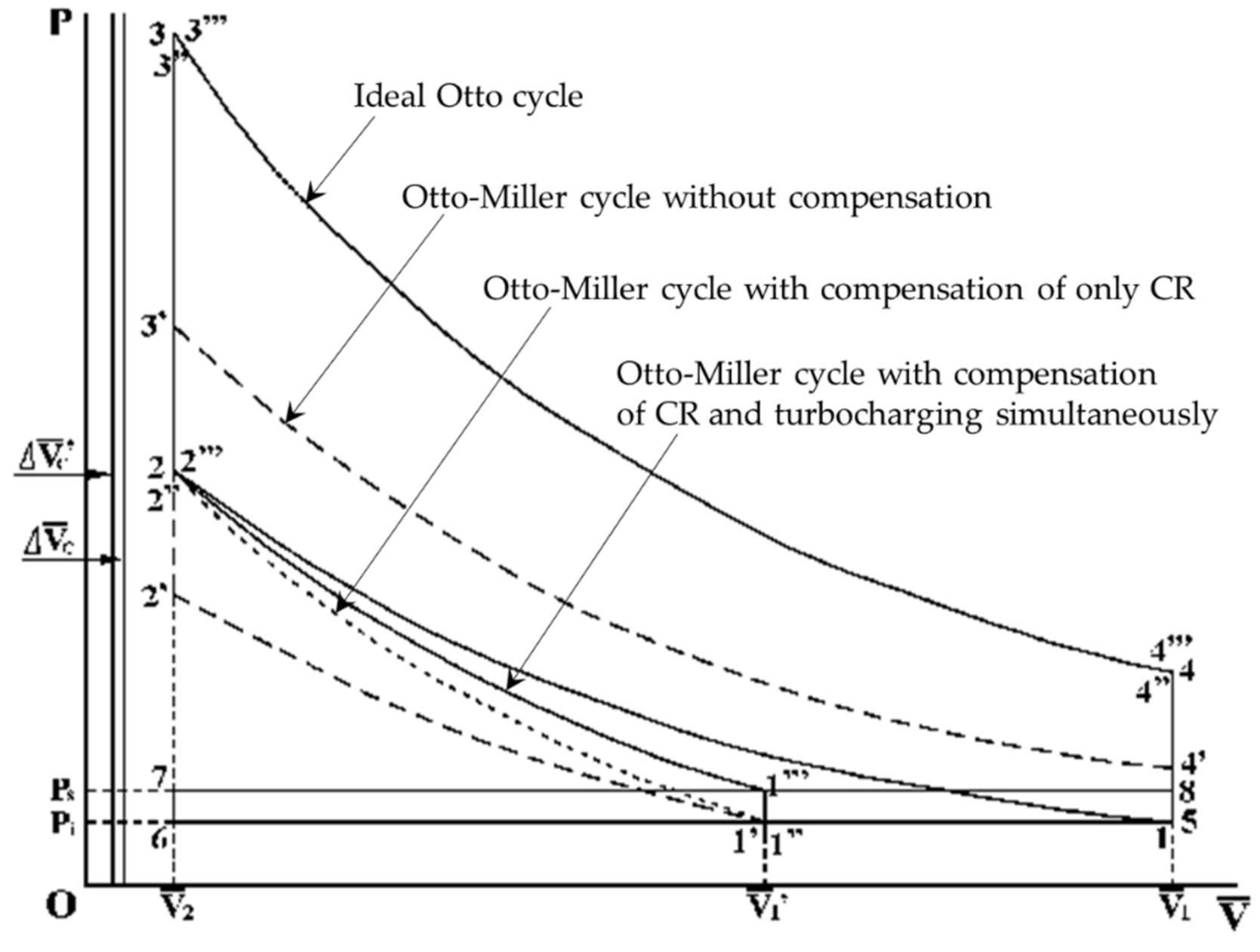

3. Compensation for Otto–Miller Cycle

3.1. Cycle Curve Showing Compensation for Otto–Miller Cycle

3.2. Compensation of Effective Compression Ratio (Maximum Pressure)

3.3. Simultaneous Compensation of Effective Compression Ratio and Intake Air Mass

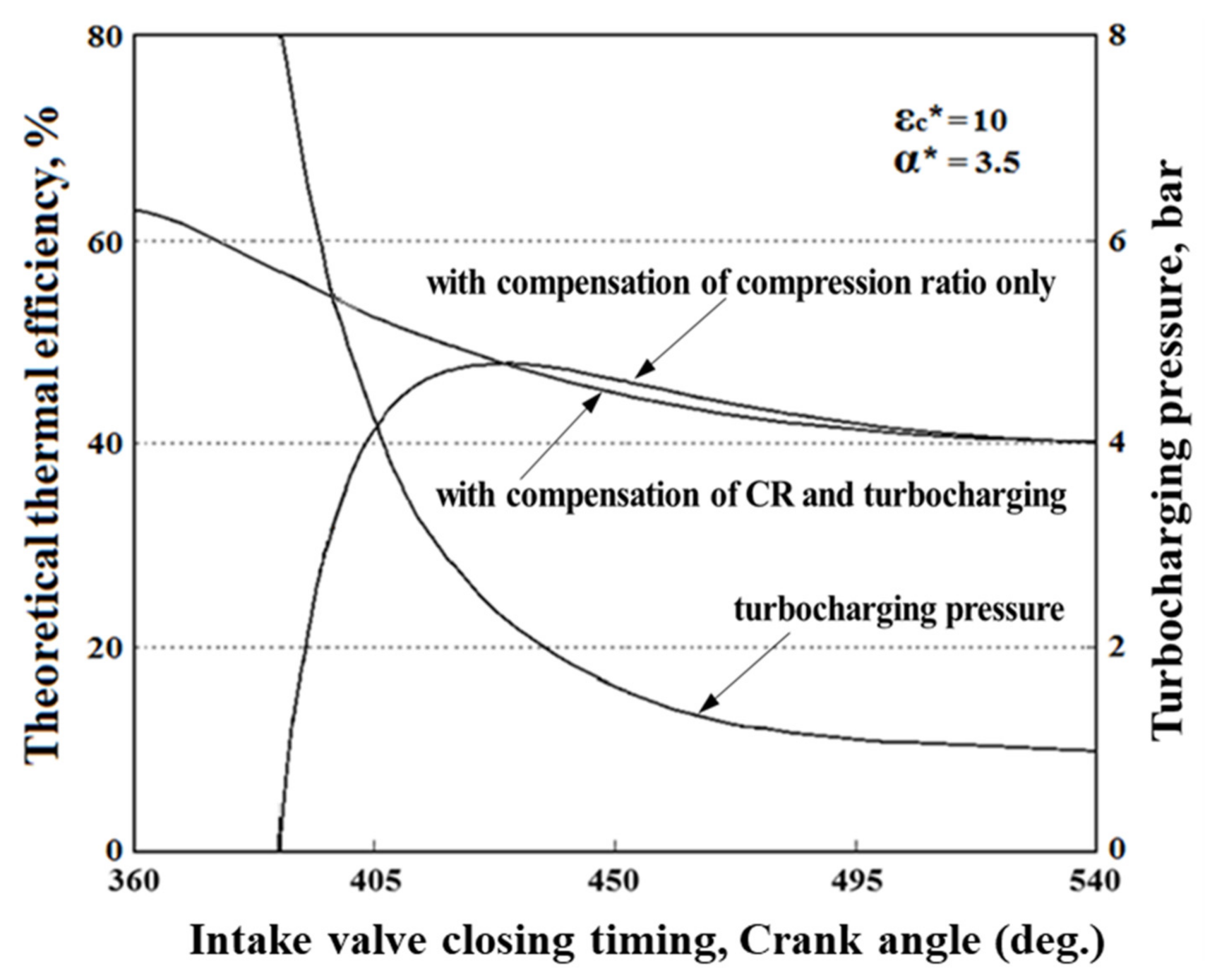

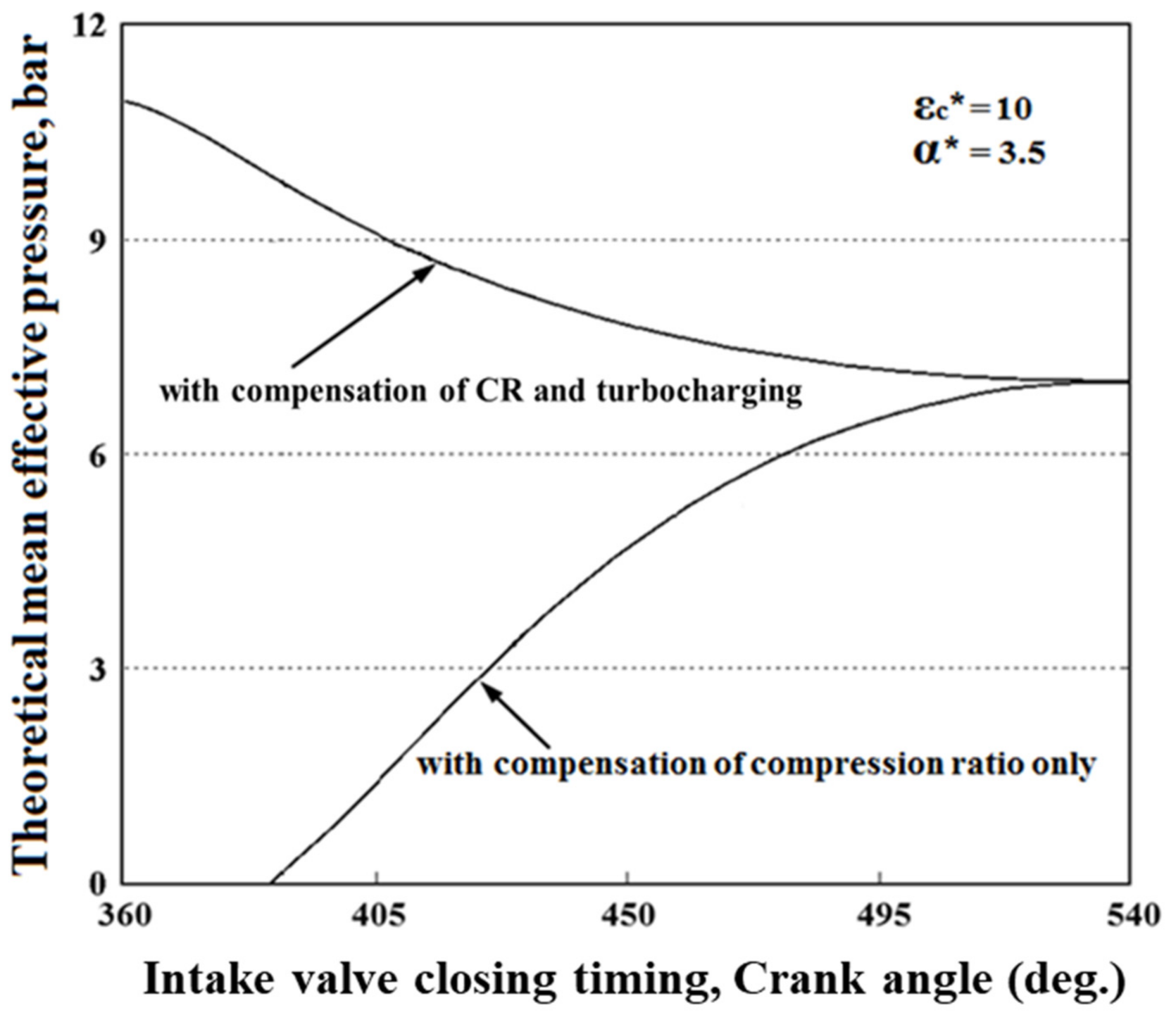

3.4. Thermal Efficiency and MEP of Otto–Miller Cycles with Compensation

4. Conclusions

- The Otto–Miller cycle can improve thermal efficiency and reduce NOx emissions by reducing compression work; however, it must compensate for the compression pressure and intake air mass by compensating the effective compression ratio or turbocharging.

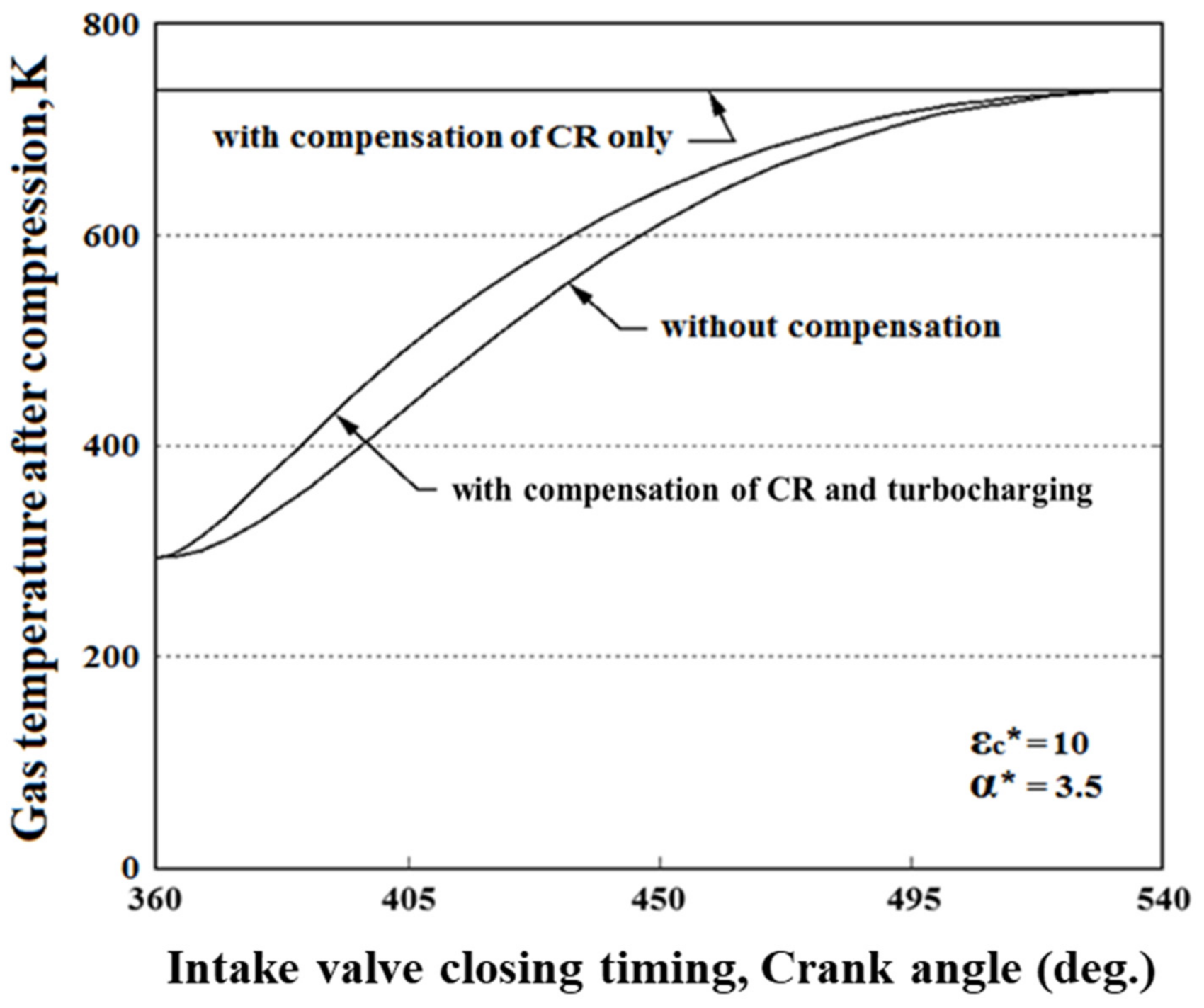

- The Miller effect yielded the maximum theoretical thermal efficiency at approximately 430 °CA. However, considering the actual engine characteristics and operating conditions, an appropriate effective compression ratio and boost pressure must be selected.

- When only the compression ratio was compensated, the theoretical thermal efficiency of the Otto–Miller cycle improved by approximately 18.8% compared to that of the Otto cycle.

- In terms of enhancing only the thermal efficiency, it is more advantageous to compensate only the compression ratio, but when considering the engine output, it is effective to compensate the boost pressure also to maintain the intake air mass.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature | ||

| Constant specific heat | ||

| Huf | Lower heating value | |

| Rec | Ratio of the compression ratio to the expansion ratio | |

| VS | Displacement volume | |

| Wth | Theoretical cycle work | |

| Pressure ratio before and after combustion at Otto cycle | ||

| Compression ratio | ||

| Expansion ratio | ||

| Specific heat ratio | ||

| λaf | Air/fuel equivalence ratio | |

| Abbreviation | ||

| BDC | Bottom dead center | |

| CA | Crank angle | |

| EGR | Exhaust gas recirculation | |

| EIVC | Early intake valve closing | |

| LIVC | Late intake valve closing | |

| MEP | Mean effective pressure | |

| (c) | with compensation of only compression ratio | |

| (t) | with compensation of compression ratio and turbocharging simultaneously | |

| Subscripts | ||

| OM | Otto-Miller cycle | |

| OM_C | Otto-Miller cycle with compensation of only compression ratio | |

| OM_T | Otto-Miller cycle with compensation of compression ratio and turbocharging simultaneously | |

| th | Theoretical value | |

| Superscripts | ||

| * | apparent value (design value) | |

References

- Andresen, B.; Salamon, P.; Berry, R.S. Thermodynamics infinite time. Phys. Today 1984, 37, 62–70. [Google Scholar] [CrossRef]

- Chen, L.; Wang, J.; Sun, F. Power density analysis and optimization of an irreversible closed intercooled regenerated Brayton cycle. Math. Comput. Model. 2008, 48, 527–540. [Google Scholar] [CrossRef]

- Ebrahimi, R. Effects of mean piston speed, equivalence ratio and cylinder wall temperature on performance of an Atkinson engine. Math. Comput. Model. 2011, 53, 1289–1297. [Google Scholar] [CrossRef]

- Parlak, A. The effect of heat transfer on performance of the diesel cycle and exergy of the exhaust gas stream in a LHR diesel engine at the optimum injection timing. Energy Convers. Manag. 2005, 46, 167–179. [Google Scholar] [CrossRef]

- Jesudason, C.G. Focus on the Clausius inequalities as a consequence of modeling thermodynamic systems as a series of open Carnot cycles. Math. Comput. Model. 2009, 49, 835–842. [Google Scholar] [CrossRef]

- Miller, R.H. Supercharging and internally cooling for high output. Asme Trans. 1947, 69, 453–464. [Google Scholar]

- Kesgin, U. Efficiency improvement and NOx emission reduction potential soft wo-stage turbocharged Miller cycle for stationary natural gas engines. Int. J. Energy Res. 2005, 29, 189–216. [Google Scholar] [CrossRef]

- Hatamura, K.; Hayakawa, M.; Goto, T.; Hitomi, M. A study of the improvement effect of Miller-cycle on mean effective pressure limit for high-pressure supercharged gasoline engines. JSAE Rev. 1997, 18, 101–106. [Google Scholar] [CrossRef]

- Fukuzawa, Y.; Shimoda, H.; Kakuhama, Y.; Endo, H.; Tanaka, K. Development of high efficiency Miller cycle gas engine. Tech. Rev. 2001, 38, 146–150. [Google Scholar]

- Al-Sarkhi, A.; Akash, B.A.; Jaber, J.O.; Mohsen, M.S.; Abu-Nada, E. Efficiency of Miller engine at maximum power density. Int. Commun. Heat Mass Transf. 2002, 29, 1159–1167. [Google Scholar] [CrossRef]

- Sasaki, M.; Araki, S.; Miyata, T.; Kawaji, T. Development of capacity or hybrid system or urban buses. JSAE Rev. 2002, 23, 451–457. [Google Scholar] [CrossRef]

- Wu, C.; Puzinauskas, P.V.; Tsai, J.S. Performance analysis and optimization of a supercharged Miller cycle Otto engine. Appl. Therm. Eng. 2003, 23, 511–521. [Google Scholar] [CrossRef]

- Ge, Y.; Chen, L.; Sun, F.; Wu, C. Effects of heat transfer and friction on the performance of an irreversible air-standard Miller cycle. Int. Commun. Heat Mass Transf. 2005, 32, 1045–1056. [Google Scholar] [CrossRef]

- Ge, Y.; Chen, L.; Sun, F.; Wu, C. Reciprocating heat-engine cycles. Appl. Energy 2005, 81, 397–408. [Google Scholar] [CrossRef]

- Ge, Y.; Chen, L.; Sun, F.; Wu, C. Effects of heat transfer and variable specific heats of working fluid on performance of a Miller cycle. Int. J. Ambient Energy 2005, 26, 203–214. [Google Scholar] [CrossRef]

- Al-Sarkhi, A.; Jaber, J.O.; Probert, S.D. Efficiency of a Miller engine. Appl. Energy 2006, 83, 343–351. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, J. Performance analysis of an irreversible Miller heat engine and its optimum criteria. Appl. Therm. Eng. 2007, 27, 2051–2058. [Google Scholar] [CrossRef]

- Al-Sarkhi, A.; Al-Hinti, I.; Abu-Nada, E.; Akash, B. Performance evaluation of irreversible Miller engine under various specific heat models. Int. Commun. Heat Mass Transf. 2007, 34, 897–906. [Google Scholar] [CrossRef]

- Lin, J.C.; Hou, S.S. Performance analysis of an air-standard Miller cycle with considerations of heat loss as a percentage of fuel’s energy, friction and variable specific heats of working fluid. Int. J. Therm. Sci. 2008, 47, 182–191. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, W.; Sun, F. Power efficiency, entropy-generation rate and ecological optimisation for a class of generalised irreversible universal heat-engine cycles. Appl. Energy 2007, 84, 512–525. [Google Scholar] [CrossRef]

- Liu, J.; Chen, J. Optimum performance analysis of a class of typical irreversible heat engines with temperature-dependent heat capacities of the working substance. Int. J. Ambient Energy 2010, 31, 59–70. [Google Scholar] [CrossRef]

- Gatowski, J.A.; Balles, E.N.; Chun, K.M.; Nelson, F.E.; Ekchian, J.A.; Heywood, J.B. Heat Release Analysis of Engine Pressure Data. SAE Trans. 1984, 961–977. [Google Scholar] [CrossRef]

- Klein, M. A specific heat ratio model and compression ratio estimation, Department of Electrical Engineering. Ph.D. Thesis, Linkoping University, Linköping, Sweden, 2004. [Google Scholar]

- Brunt, M.; Rai, H.; Emtage, A. The Calculation of Heat Release Energy from Engine Cylinder Pressure Data. SAE Trans. 1998, 1596–1609. [Google Scholar] [CrossRef]

- Ceviz, M.A.; Kaymaz, I. Temperature and air–fuel ratio dependent specific heat ratio functions for lean burned and unburned mixture. Energy Convers. Manag. 2005, 46, 2387–2404. [Google Scholar] [CrossRef]

- Maiboom, A.; Tauzia, X.; Hetet, J.F. Experimental study of various effects of exhaust gas recirculation (EGR) on combustion and emissions of an automotive direct injection diesel engine. Energy 2008, 33, 22–34. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, S.; Huang, J.; He, Y.; Huang, X.; Lin, L.; Li, S. Experimental investigation of applying miller cycle to reduce NOx emission from diesel engine. J. Power Energy 2005, 219, 631–638. [Google Scholar] [CrossRef]

- Hou, S.S. Comparison of performances of air standard Atkinson and Otto cycles with heat transfer considerations. Energy Convers. Manag. 2007, 48, 1683–1690. [Google Scholar] [CrossRef]

- Lin, J.-C.; Hou, S.S. Influence of heat loss on the performance of an air-standard Atkinson cycle. Appl. Energy 2007, 84, 904–920. [Google Scholar] [CrossRef]

- Endo, H.; Tanaka, K.; Kakuhama, Y.; Goda, Y.; Fujiwaka, T.; Nishigaki, M. Development of the lean burn Miller cycle gas engine. In Proceedings of the 5th International Symposium on Diagnostics and Modeling of Combustion in Internal Combustion Engines (COMODIA 2001), Nagoya, Janpan, 1–4 July 2001. [Google Scholar]

- Gheorghiu, V.; Ueberschar, D. Enhancement potential of the thermal conversion efficiency of ICE cycles especially for use in hybrid vehicles. In Proceedings of the 5th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics (HEFEAT2007), Sun City, South Africa, 1–4 July 2007. [Google Scholar]

- Wang, Y.; Ruxton, T. An experimental investigation of NOx emission reduction from automotive engine using the Miller cycle. In Proceedings of the ASME 2004 Fall Technical Conference, Long Beach, CA, USA, 24–27 October 2004. [Google Scholar]

- Wang, Y.; Lin, L.; Roskilly, A.P.; Zeng, S.; Huang, J.; He, Y.; Huang, X.; Huang, H.; Wei, H.; Li, S.; et al. An analytic study of applying Miller cycle to reduce NOx emission from petrol engine. Appl. Therm. Eng. 2007, 27, 1779–1789. [Google Scholar] [CrossRef]

- Branyon, D.; Simpson, D. Miller Cycle Application to the Scuderi Split Cycle Engine (by Downsizing the Compressor Cylinder). SAE Tech. Paper 2012. [Google Scholar] [CrossRef]

- Wei, S.; Zhao, X.; Liu, X.; Qu, X.; He, C.; Leng, X. Research on effects of early intake valve closure (EIVC) miller cycle on combustion and emissions of marine diesel engines at medium and low loads. J. Energy 2019, 173, 45–58. [Google Scholar] [CrossRef]

- Liu, H.; Ma, J.; Tong, L.; Ma, G.; Zheng, Z.; Yao, M. Investigation on the Potential of High Efficiency for Internal Combustion Engines. Energies 2018, 11, 513. [Google Scholar] [CrossRef]

- Liu, H.; Cui, Y.; Chen, B.; Kyritsis, D.C.; Tang, Q.; Feng, L.; Wang, Y.; Li, Z.; Geng, C.; Yao, M. Effects of Flame Temperature on PAHs and Soot Evolution in Partially Premixed and Diffusion Flames of a Diesel Surrogate. Energy Fuels 2019, 33, 11821–11829. [Google Scholar] [CrossRef]

- Brooks, J.; Lane, A. Features of an Atkinson Two-Stroke Engine. SAE Tech. Paper. 1994. [Google Scholar] [CrossRef]

- Chen, L.; Ge, Y.; Sun, F.; Wu, C. Effects of heat transfer, friction and variable specific heats on performance of an irreversible dual cycle. Energy Convers. Manag. 2006, 47, 3224–3234. [Google Scholar] [CrossRef]

- Baek, H.M.; Lee, J.W.; Jeong, K.S.; Choi, J.S. Theoretical investigation of Miller cycle characteristics. J. Korea Soc. Mar. Eng. 2017, 41, 507–513. [Google Scholar]

- Boggs, D.; Hilbert, H.; Schechter, M. The Otto-Atkinson Cycle Engine-Fuel Economy and Emissions Results and Hardware Design. SAE Trans. 1995, 220–232. [Google Scholar] [CrossRef]

- Tuttle, J. Controlling Engine Load by Means of Early Intake-Valve Closing. SAE Trans. 1982, 1648–1662. [Google Scholar] [CrossRef]

- Blakey, S.; Saunders, R.; Ma, T.; Chopra, A. A Design and Experimental Study of an Otto Atkinson Cycle Engine Using Late Intake Valve Closing. SAE Tech. Paper 1991, 632–640. [Google Scholar] [CrossRef]

- Atkinson, C.M.; Petreanu, S.; Clark, N.N.; Atkinson, R.J.; McDaniel, T.I.; Nandkumar, S.; Famouri, P. Numerical Simulation of a Two-Stroke Linear Engine-Alternator Combination. SAE Tech. Paper 1999, 1416–1430. [Google Scholar] [CrossRef]

- Schenk, C.; Dekraker, P. Potential Fuel Economy Improvements from the Implementation of cEGR and CDA on an Atkinson Cycle Engine. SAE Tech. Paper 2017. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, J.; Noh, K.; Lee, C. A Theoretical Study on the Thermodynamic Cycle of Concept Engine with Miller Cycle. Processes 2021, 9, 1051. https://doi.org/10.3390/pr9061051

Oh J, Noh K, Lee C. A Theoretical Study on the Thermodynamic Cycle of Concept Engine with Miller Cycle. Processes. 2021; 9(6):1051. https://doi.org/10.3390/pr9061051

Chicago/Turabian StyleOh, Jungmo, Kichol Noh, and Changhee Lee. 2021. "A Theoretical Study on the Thermodynamic Cycle of Concept Engine with Miller Cycle" Processes 9, no. 6: 1051. https://doi.org/10.3390/pr9061051

APA StyleOh, J., Noh, K., & Lee, C. (2021). A Theoretical Study on the Thermodynamic Cycle of Concept Engine with Miller Cycle. Processes, 9(6), 1051. https://doi.org/10.3390/pr9061051