Emerging Floating Photovoltaic System—Case Studies High Dam and Aswan Reservoir in Egypt

Abstract

1. Introduction

- -

- The numerical analysis of the FPV system and its benefits if added to Aswan Reservoir and High Dam.

- -

- The comparison between the three types of PV modules, mono-crystalline, polycrystalline, and thin film, to be used in an FPV installed above Aswan Reservoir and High Dam.

- -

- A water-saving effect study when the FPV is added to Aswan Reservoir and High Dam, considering what the hydropower can generate from the saved water in the presence of FPV.

- -

- The environmental impacts of adding an FPV to both Dams.

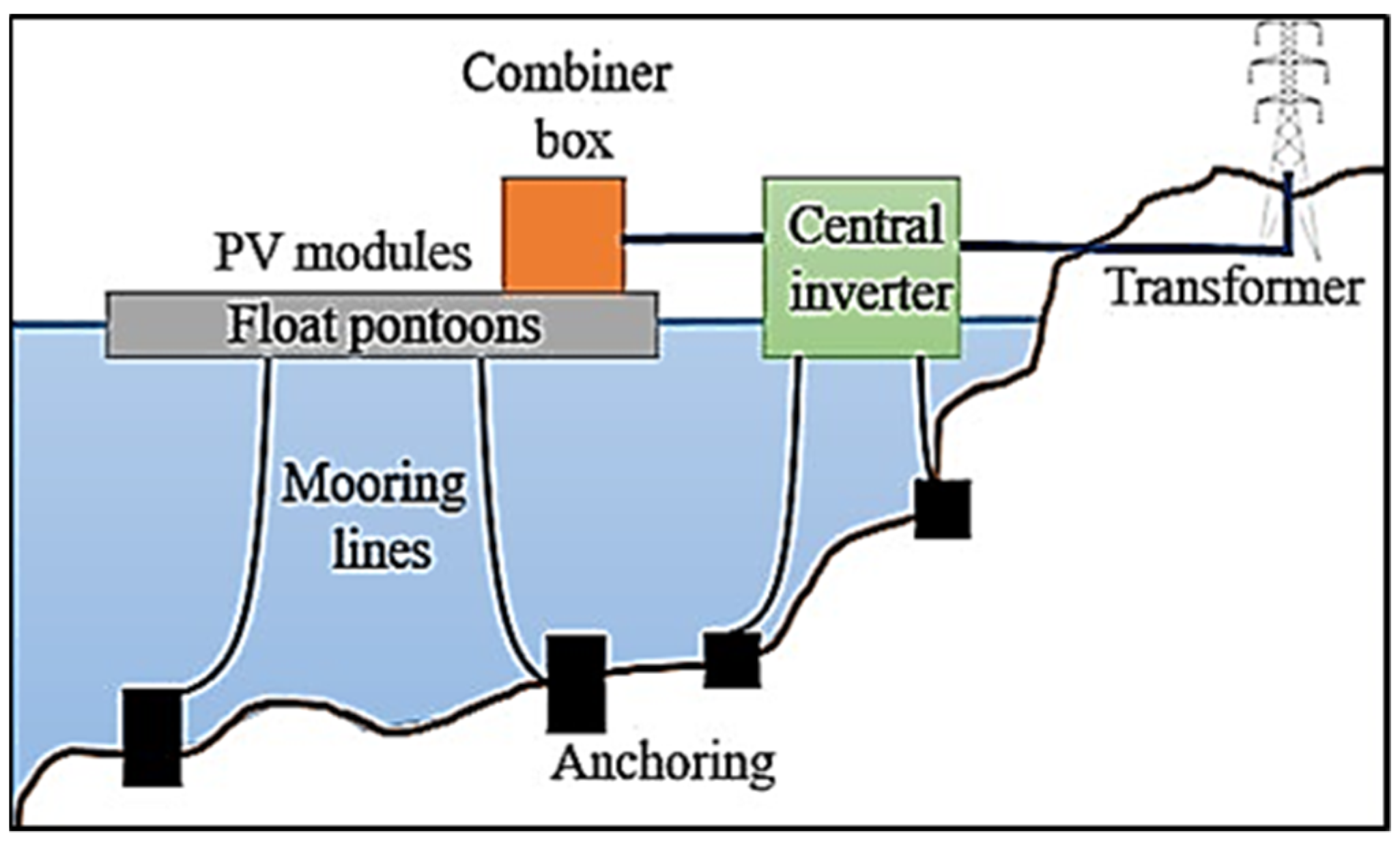

2. Overview of FPV System

- Roof-top photovoltaic;

- Canal photovoltaic;

- Off-shore photovoltaic;

- On-shore photovoltaic;

- Agri-photovoltaics;

- Floating photovoltaic (FPV).

- Coal mining subsidence area of Huainan City, China with of 60 MW capacity;

- Yamakura solar power plant in Japan has an installed capacity of 13.70 MW;

- Pei County in China has an installed capacity of 9.98 MW;

- Umenoki in Japan has an installed capacity of 7.55 MW;

- Jining GCL in China has an installed capacity of 6.78 MW;

- Hirotani Ike Floating Solar Plant in Japan has an installed capacity of 6.80 MW;

- Queen Elizabeth II Reservoir in the UK has an installed capacity of 6.34 MW;

- Cheongpung Lake in South Korea has an installed capacity of 3 MW;

- Otae Province in South Korea has an installed capacity of 3 MW.

- Inverting underutilized bodies of water into money-making ponds.

- Zero costs when it comes to land acquisition.

- Lower grid connection costs and enhanced accessibility to the existing infrastructure.

- Increased output and operational efficiency as a result of the water’s inherent cooling nature when evaporated.

- Reduction in algae growth.

- Improved plant load factor (PLF).

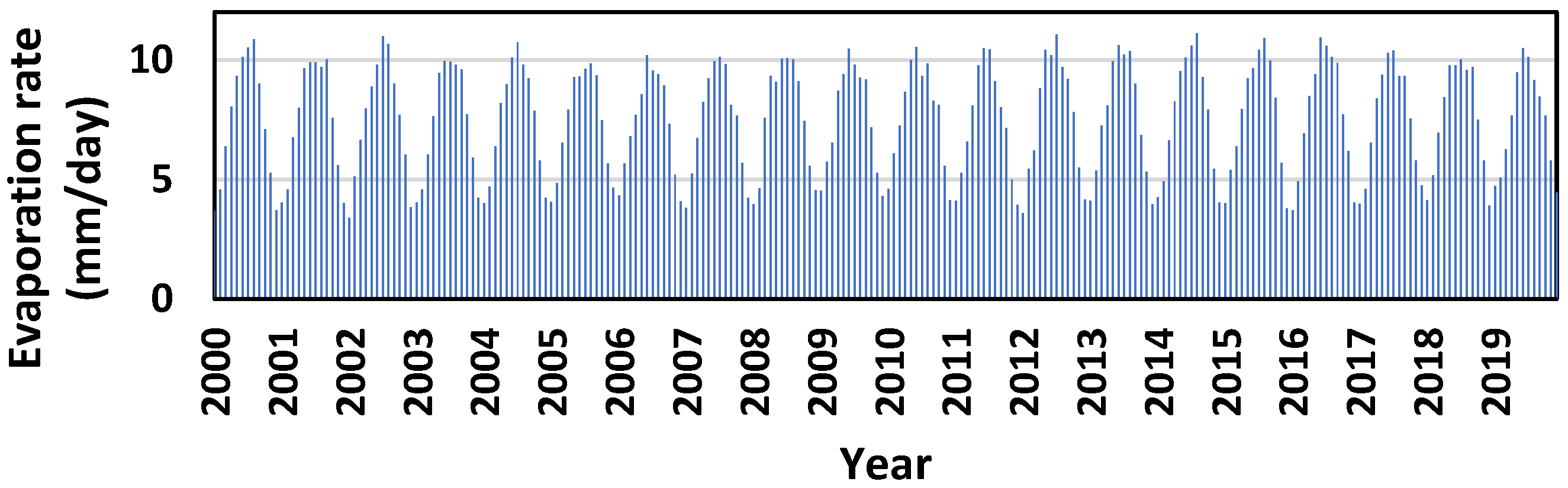

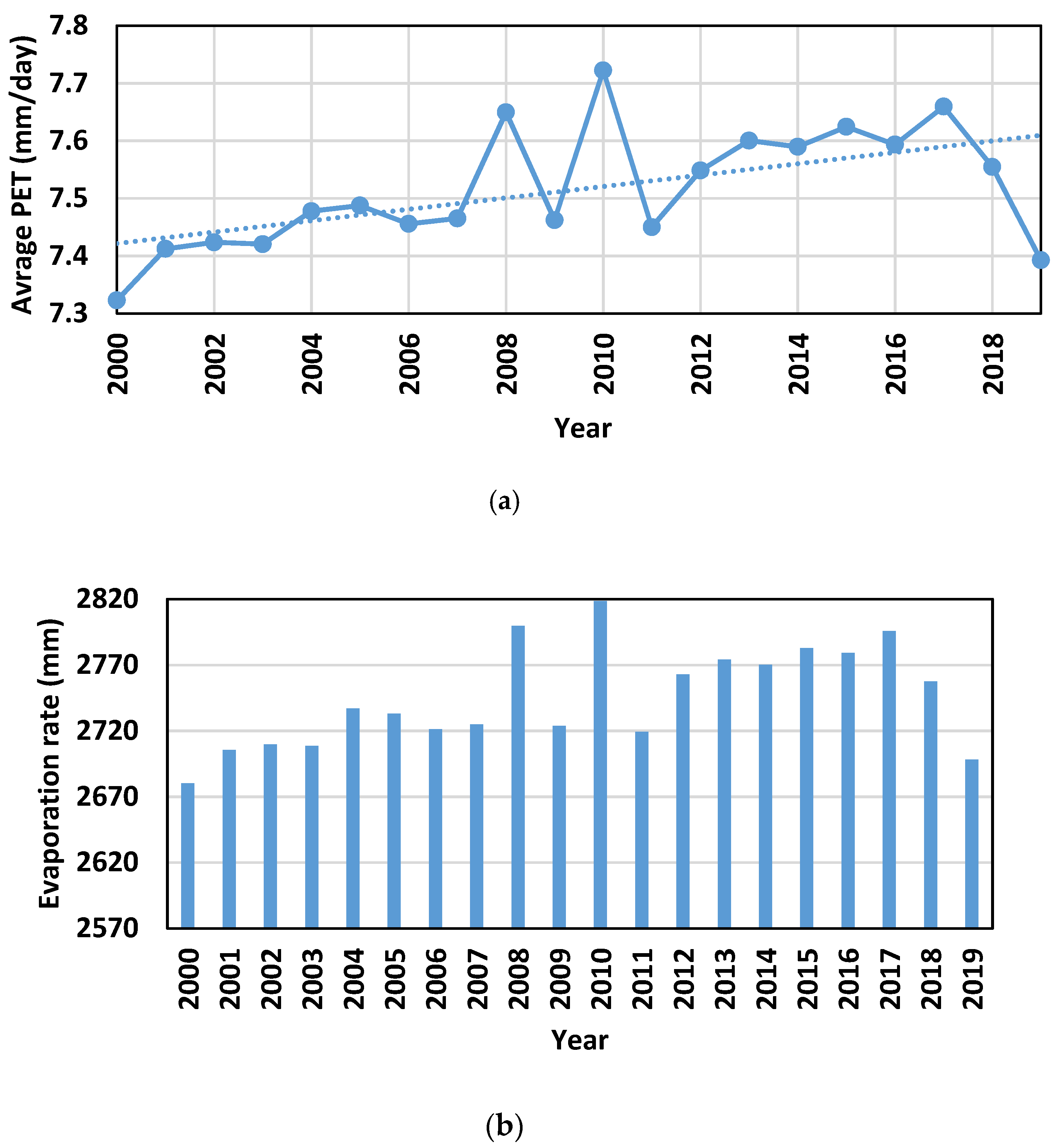

3. Need for Reducing Evaporation Rate

Potential Evapotranspiration Estimation

4. Electrical Performance of FPV System in Egyptian Reservoirs

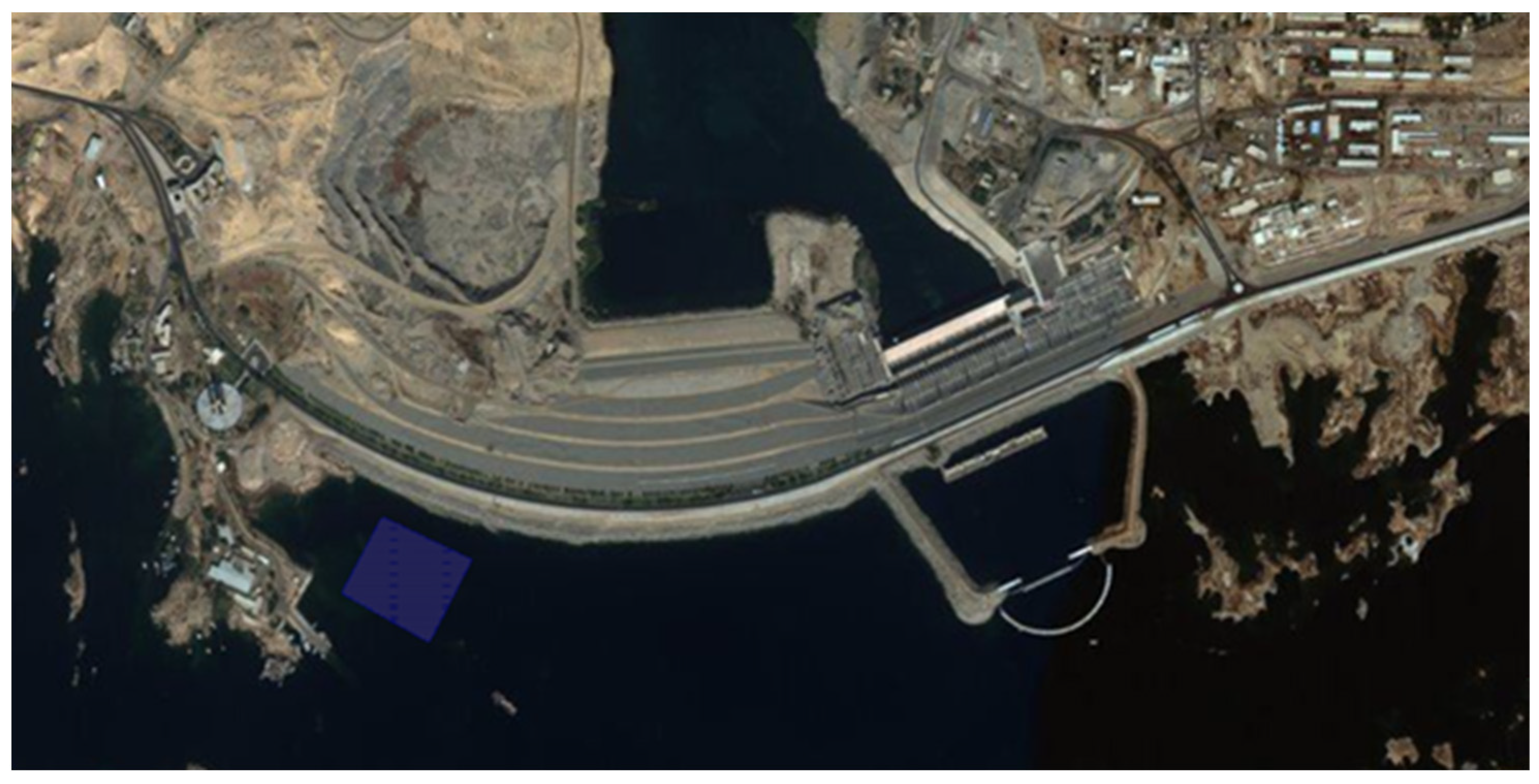

5. High Dam

5.1. FPV with Fixed Tracking System

5.1.1. Crystalline PV Panels

5.1.2. Thin Film PV Panel

5.2. FPV with Single Axis Tracking System

5.3. Losses and Irradiation Utilization Factor

6. Aswan Reservoir

7. Proposed System Analysis

7.1. Cost Analysis

7.2. Carbon Dioxide Analysis

7.3. Water–Energy Nexus Analysis

8. Discussion on the Limitations of the Study

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AC | Alternating current |

| AR | Aswan Reservoir |

| CF | Capacity factor |

| DC | Direct current |

| FPV | Floating photovoltaic |

| HD | High Dam |

| HEPP | Hydroelectric power plant |

| GERD | Grand Ethiopian Renaissance Dam |

| GHI | Global Horizontal Irradiance |

| LCOE | Levelized Cost of Energy |

| MCM | Million Cubic Meter |

| Mt | Metric Ton |

| NOCT | Nominal operating cell temperature |

| PET | Potential Evapotranspiration |

| POA | Plane of Array |

| PR | Performance ratio |

| PV | photovoltaic |

| RES | Renewable Energy Sources |

| SAF | solar access factor |

| SEC | Specific electricity consumption |

| STC | Standard test conditions |

| TOF | tilt orientation factor |

| β | Tilt angle |

Appendix A. Electrical Specifications of PV Panels

| S.No | Parameters | Poly Crystalline | Mono Crystalline | Thin Film |

|---|---|---|---|---|

| 1. | Manufacturer | Canadian Solar | Solar World | First Solar |

| 2. | Model Name | CS6P-240P | SW 235 | FS-6420 December 2017 |

| 3. | Power output capacity (W) | 240 | 235 | 420 |

| 4. | Dimensions (mm) | 1638 × 982 × 40 | 1001 × 1675 × 31 | 2009 × 1232 × 49 |

| 5. | Weight (kg) | 20 | 21.2 | 36 |

| 6. | Temperature coefficient at maximum power (/°C) | −0.43 | −0.45 | −0.35 |

| 7. | Temperature coefficient open circuit voltage (/°C) | −0.34 | −0.33 | −0.28 |

| 8. | Temperature coefficient short circuit voltage (/°C) | +0.065 | +0.042 | +0.04 |

| 9. | Operating temperature (°C) | −40 to +85 | −40 to +90 | −40 to +85 |

| 10. | Module efficiency (%) | 14.61 | 13.12 | 17 |

| 11. | Power tolerance (W) | ±5 | ±3 | ±5 |

| 12. | Standard Test Conditions (STC)—Irradiance of 1000 W/m2, Temperature 25 °C & air mass AM1.5 | |||

| 13. | peak power of PV module (W) | 240 | 235 | 420 |

| 14. | maximum power voltage (V) | 29.9 | 30.3 | 180.4 |

| 15. | maximum power current (A) | 8.03 | 7.77 | 2.33 |

| 16. | open circuit voltage (V) | 37 | 37.5 | 218.5 |

| 17. | short circuit current (A) | 8.53 | 8.19 | 2.54 |

| 18. | Nominal operating cell temperature (NOCT)—Irradiance of 800 W/m2 and ambient temperature of 20 °C | |||

| 19. | Peak power of PV module (W) | 170 | 170.9 | 317.2 |

| 20. | Voltage at maximum power (V) | 27.0 | 27.5 | 168.7 |

| 21. | Current at maximum power (A) | 6.18 | 6.22 | 1.88 |

| 22. | open circuit voltage (V) | 33.8 | 34.0 | 206.3 |

| 23. | Short circuit current (A) | 6.76 | 6.6 | 2.04 |

References

- Global Energy Review in 2020. Available online: https://www.iea.org/reports/global-energy-review-2020/renewables (accessed on 14 April 2021).

- United Nations. The Impact of Renewable Energy Technologies on Global Energy Efficiency. Available online: https://www.un.org/en/chronicle/article/impact-renewable-energy-technologies-global-energy-efficiency (accessed on 14 April 2021).

- Hydropower Status Report. Available online: https://www.hydropower.org/resources/status-report (accessed on 14 April 2021).

- Fayek, H.H.; Abdalla, O.H. Maximization of Renewable Power Generation for Optimal Operation of the Egyptian Grid. In Proceedings of the 2020 IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020; pp. 1033–1038. Available online: https://ieeexplore.ieee.org/document/9152450 (accessed on 14 April 2021). [CrossRef]

- Abdalla, O.H.; Fayek, H.H.; Ghany, A.A. Steady-State and Transient Performances of the Egyptian Grid with Benban Photovoltaic Park. In Proceedings of the Cigre Egypt 2019 Conference, The Future of Electricity Grids—Challenges and Opportunities, Cairo, Egypt, 6–8 March 2019; p. 205. Available online: https://www.researchgate.net/publication/342420850_Steady-State_and_Transient_Performances_of_the_Egyptian_Grid_with_Benban_Photovoltaic_Park (accessed on 14 April 2021).

- Abdelhaleem, F.S.; Helal, E.Y. Impacts of Grand Ethiopian Renaissance Dam on Different Water Usages in Upper Egypt. Br. J. Appl. Sci. Technol. 2015, 8, 461–483. [Google Scholar] [CrossRef]

- Hamed, K.H. Stochastic Investigation of the GERD-AHD Interaction through First Impoundment and Beyond. In Grand Ethiopian Renaissance Dam Versus Aswan High Dam; Negm, A.M., Abdel-Fattah, S., Eds.; The Handbook of Environmental Chemistry; Springer International Publishing AG: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Assouline, S.; Narkis, K.; Or, D. Evaporation suppression from water reservoirs: Efficiency considerations of partial covers. Water Resour. Res. 2011, 47. [Google Scholar] [CrossRef]

- Wurbs, R.A.; Ayala, R.A. Reservoir evaporation in Texas, USA. J. Hydrol. 2014, 510, 1–9. [Google Scholar] [CrossRef]

- Acharya, M.; Devraj, S. Floating Solar Photovoltaic (FSPV): A Third Pillar to Solar PV Sector? TERI Discussion Paper: Output of the ETC India Project; The Energy and Resources Institute: New Delhi, India, 2019. [Google Scholar]

- Sahu, A.; Yadav, N.; Sudhakar, K. Floating photovoltaic power plant: A review. Renew. Sustain. Energy Rev. 2016, 66, 815–824. [Google Scholar] [CrossRef]

- Ranjbaran, P.; Yousefi, H.; Gharehpetian, G.; Astaraei, F.R. A review on floating photovoltaic (FPV) power generation units. Renew. Sustain. Energy Rev. 2019, 110, 332–347. [Google Scholar] [CrossRef]

- Sukarso, A.P.; Kim, K.N. Cooling Effect on the Floating Solar PV: Performance and Economic Analysis on the Case of West Java Province in Indonesia. Energies 2020, 13, 2126. [Google Scholar] [CrossRef]

- Farfan, J.; Breyer, C. Combining floating solar photovoltaic power plants and hydropower reservoirs: A virtual battery of great global potential. Energy Procedia 2018, 155, 403–411. [Google Scholar] [CrossRef]

- Liu, L.; Sun, Q.; Li, H.; Yin, H.; Ren, X.; Wennersten, R. Evaluating the benefits of integrating floating photovoltaic and pumped storage power system. Energy Convers. Manag. 2019, 194, 173–185. [Google Scholar] [CrossRef]

- Nazififard, M.; Taheri, S.M.; Nazififardarani, K. Novel Floating Photovoltaic Cover Systems Generating Electricity and Prevent Evaporative Losses for Agriculture Industry in Iran. In Proceedings of the 3rd International Conference of IEA, Tehran, Iran, 28 February 2017; pp. 1–5. [Google Scholar]

- Lee, N.; Grunwald, U.; Rosenlieb, E.; Mirletz, H.; Aznar, A.; Spencer, R.; Cox, S. Hybrid floating solar photo-voltaics-hydropower systems: Benefits and global assessment of technical potential. Renew. Energy 2020, 162, 1415–1427. [Google Scholar] [CrossRef]

- Nagananthini, R.; Nagavinothini, R. Investigation on floating photovoltaic covering system in rural Indian reservoir to minimize evaporation loss. Int. J. Sustain. Energy 2021, 1–25. [Google Scholar] [CrossRef]

- Rosa-Clot, M.; Tina, G.M. Integration of PV Floating with Hydroelectric Power Plants (HPPs). In Floating PV Plants; Academic Press: Cambridge, MA, USA, 2020; pp. 89–100. [Google Scholar]

- Cazzaniga, R.; Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M. Integration of PV floating with hydroelectric power plants. Heliyon 2019, 5, e01918. [Google Scholar] [CrossRef] [PubMed]

- Mckay, A. Floatovoltaics: Quantifying the Benefits of a Hydro fits of a Hydro of a Hydro ydro f PV floating with hydroel. Bachelor’s Theses, Pomona College, Claremont, CA, USA, 2013; p. 74. Available online: https://scholarship.claremont.edu/pomona_theses/74 (accessed on 14 April 2021).

- Lopes, M.P.C.; Neto, S.D.A.; Branco, D.A.C.; de Freitas, M.A.V.; Fidelis, N.D.S. Water-energy nexus: Floating photovoltaic systems promoting water security and energy generation in the semiarid region of Brazil. J. Clean. Prod. 2020, 273, 122010. [Google Scholar] [CrossRef]

- Gorjian, S.; Sharon, H.; Ebadi, H.; Kant, K.; Scavo, F.B.; Tina, G.M. Recent technical advancements, economics and environmental impacts of floating photovoltaic solar energy conversion systems. J. Clean. Prod. 2021, 278, 124285. [Google Scholar] [CrossRef]

- Trapani, K.; Santafé, M.R. A review of floating photovoltaic installations: 2007–2013. Prog. Photovolt. Res. Appl. 2014, 23, 524–532. [Google Scholar] [CrossRef]

- World Bank. Floating PV Power Plants. Available online: http://documents1.worldbank.org/curated/en/579941540407455831/pdf/Floating-Solar-Market-Report-Executive-Summary.pdf (accessed on 14 April 2021).

- Grubišić-Čabo, F.; Nižetić, S.; Giuseppe Marco, T. Photovoltaic panels: A review of the cooling techniques. Trans. FAMENA 2016, 40, 63–74. [Google Scholar]

- Trapani, K.; Millar, D.L. Proposing offshore photovoltaic (PV) technology to the energy mix of the Maltese islands. Energy Convers. Manag. 2013, 67, 18–26. [Google Scholar] [CrossRef]

- Trapani, K.; Millar, D.L. The thin film flexible floating PV (T3F-PV) array: The concept and development of the prototype. Renew. Energy 2014, 71, 43–50. [Google Scholar] [CrossRef]

- Kim, S.H.; Yoon, S.J.; Choi, W. Design and construction of 1 MW class floating PV generation structural system using FRP members. Energies 2017, 10, 1142. [Google Scholar] [CrossRef]

- Rao, B.B.; Sandeep, V.M.; Rao, V.U.M.; Venkateswarlu, B. Potential Evapotranspiration Estimation for Indian Conditions: Improving Accuracy through Calibration Coefficients. 2012. Available online: http://nicra-icar.in/nicrarevised/images/Books/Potential%20Evapotranspiration%20estimation.pdf (accessed on 21 February 2021).

- Perakis, C.; El Shenawy, E.; El Ghetany, H.; Kyriakarakos, G. Design of autonomous PV/RO desalination systems—Case studies for Egypt and Greece. Desalination Water Treat. 2017, 74, 12–20. [Google Scholar] [CrossRef]

- Ferrer-Gisbert, C.; Ferrán-Gozálvez, J.J.; Redón-Santafé, M.; Gisbert, P.F.; Sánchez-Romero, F.J.; Torregrosa-Soler, J.B. A new photovoltaic floating cover system for water reservoirs. Renew. Energy 2013, 60, 63–70. [Google Scholar] [CrossRef]

- Nagananthini, R.; Nagavinothini, R.; Balamurugan, P. Floating Photovoltaic Thin Film Technology—A Review. In Intelligent Manufacturing and Energy Sustainability; Springer: Singapore, 2020; pp. 329–338. [Google Scholar]

- NASA Prediction of Worldwide Energy Resource. Available online: https://power.larc.nasa.gov (accessed on 2 February 2021).

- Folsom Labs. Helioscope Solar Design Software. 2020. Available online: https://help.helioscope.com/ (accessed on 9 March 2021).

- Renewable Energy Capacity Statistics 2021; The International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2021; ISBN 978-92-9260-342-7. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2021/Apr/IRENA_RE_Capacity_Statistics_2021.pdf (accessed on 14 April 2021).

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration-Guidelines for Computing Crop Water Requirements—FAO Irrigation and Drainage Paper 56; FAO: Rome, Italy, 1998; Volume 300, p. D05109. [Google Scholar]

- Wang, H.; Yang, Y.; Keller, A.A.; Li, X.; Feng, S.; Dong, Y.N.; Li, F. Comparative analysis of energy intensity and carbon emis-sions in wastewater treatment in USA, Germany, China and South Africa. Appl. Energy 2016, 84, 873–881. [Google Scholar] [CrossRef]

- Taboada, M.; Caceres, L.; Graber, T.; Galleguillos, H.; Cabeza, L.; Rojas, R. Solar water heating system and photovoltaic floating cover to reduce evaporation: Experimental results and modeling. Renew. Energy 2017, 105, 601–615. [Google Scholar] [CrossRef]

- Haas, J.; Khalighi, J.; de la Fuente, A.; Gerbersdorf, S.; Nowak, W.; Chen, P.-J. Floating photovoltaic plants: Ecological impacts versus hydropower operation flexibility. Energy Convers. Manag. 2020, 206, 112414. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Cicu, M.; Rosa-Clot, M.; Tina, G.; Ventura, C. Floating photovoltaic plants: Performance analysis and design solutions. Renew. Sustain. Energy Rev. 2018, 81, 1730–1741. [Google Scholar] [CrossRef]

- Trapani, K.; Millar, D.L.; Smith, H.C. Novel offshore application of photovoltaics in comparison to conventional marine renewable energy technologies. Renew. Energy 2013, 50, 879–888. [Google Scholar] [CrossRef]

| S.No | Mounting | Type of PV Panel | Orientation | POA Irradiance (kWh/m2) | PV Power (MWp) | PV Energy (GWh/year) | PR (%) | Specific Yield (kWhp/kWp) |

|---|---|---|---|---|---|---|---|---|

| 1. | Fixed Mount (β = 25°) | Poly crystalline | Portrait | 2491.1 | 5.18 | 9.77 | 75.7 | 1884.8 |

| Landscape | 2491.1 | 4.75 | 9.34 | 78.8 | 1963.2 | |||

| Mono crystalline | Portrait | 2491.1 | 4.90 | 9.08 | 74.3 | 1850.5 | ||

| Landscape | 2491.1 | 4.50 | 8.72 | 77.8 | 1937.1 | |||

| Thin Film | Portrait | 2494.9 | 6.30 | 11.93 | 75.8 | 1892.0 | ||

| Landscape | 2494.9 | 5.87 | 11.71 | 80.0 | 1995.9 | |||

| 2. | Single-axis tracking | Poly crystalline | Portrait | 2616.6 | 4.94 | 10.28 | 79.6 | 2081.5 |

| Landscape | 2732.2 | 4.55 | 9.87 | 79.3 | 2166.4 | |||

| Mono crystalline | Portrait | 2612.1 | 4.67 | 9.58 | 78.5 | 2049.5 | ||

| Landscape | 2727.6 | 4.31 | 9.18 | 78.1 | 2130.5 | |||

| Thin Film | Portrait | 2582.8 | 6.00 | 12.70 | 82.0 | 2118.0 | ||

| Landscape | 2683.8 | 5.60 | 12.30 | 81.8 | 2196.1 |

| S.No | Mounting | Type of PV Panel | Orientation | Modules | TOF (%) | SAF (%) | Operating Temperature (°C) | Inverter AC Nameplate (MW) |

|---|---|---|---|---|---|---|---|---|

| 1. | Fixed Mount (β = 25°) | Poly crystalline | Portrait | 21,602 | 99.7 | 93.7 | 41.2 | 4.16 |

| Landscape | 19,812 | 99.7 | 97.8 | 41.7 | 3.83 | |||

| Mono crystalline | Portrait | 20,872 | 99.7 | 93.4 | 41.2 | 3.95 | ||

| Landscape | 19,148 | 99.7 | 97.8 | 41.7 | 3.61 | |||

| Thin Film | Portrait | 15,010 | 99.9 | 91.4 | 41.0 | 5.05 | ||

| Landscape | 13,973 | 99.9 | 96.5 | 41.6 | 4.72 | |||

| 2. | Single-axis tracking | Poly crystalline | Portrait | 18,339 | 104.7 | 98.6 | 42.5 | 3.97 |

| Landscape | 18,975 | 107.4 | 98.4 | 43.0 | 3.66 | |||

| Mono crystalline | Portrait | 19,890 | 104.6 | 98.7 | 42.5 | 3.75 | ||

| Landscape | 18,339 | 109.2 | 98.3 | 43.0 | 3.46 | |||

| Thin Film | Portrait | 14,279 | 103.4 | 98.8 | 42.3 | 4.81 | ||

| Landscape | 13,339 | 107.4 | 98.4 | 42.8 | 4.50 |

| S.No | Mounting | Type of PV Panel | Orientation | Inverter Loss (%) | Shading Loss (%) | Irradiance Loss (%) | Temperature Loss (%) |

|---|---|---|---|---|---|---|---|

| 1. | Fixed Mount (β = 25°) | Poly crystalline | Portrait | 1.9 | 6.3 | 0.2 | 10.2 |

| Landscape | 2.0 | 2.2 | 0.2 | 10.2 | |||

| Mono crystalline | Portrait | 2.5 | 6.6 | 0.2 | 11.2 | ||

| Landscape | 2.3 | 2.2 | 0.1 | 11.3 | |||

| Thin Film | Portrait | 2.0 | 8.6 | 0.7 | 8.4 | ||

| Landscape | 2.1 | 3.5 | 0.6 | 8.5 | |||

| 2. | Single-axis tracking | Poly crystalline | Portrait | 2.0 | 1.4 | 0.1 | 10.7 |

| Landscape | 1.9 | 1.7 | 0.0 | 10.8 | |||

| Mono crystalline | Portrait | 2.4 | 1.3 | 0.1 | 11.7 | ||

| Landscape | 2.5 | 1.7 | 0.0 | 11.8 | |||

| Thin Film | Portrait | 2.1 | 1.2 | 0.5 | 8.8 | ||

| Landscape | 2.1 | 1.6 | 0.4 | 8.9 |

| S.No | Mounting | Type of PV Panel | Orientation | Area (m2) | POA Irradiance (kWh/m2) | PV Energy (GWh/year) | PR (%) | Specific Yield (kWhp/kWp) |

|---|---|---|---|---|---|---|---|---|

| 1. | Fixed Mount (β = 25°) | Poly crystalline | Portrait | 45,103.62 | 2491.1 | 9.569 | 76.8 | 1913.8 |

| Landscape | 52,142.54 | 2491.1 | 9.934 | 79.8 | 1968.8 | |||

| Mono crystalline | Portrait | 54,677.37 | 2491.1 | 9.527 | 76.5 | 1905.4 | ||

| Landscape | 61,594.18 | 2491.1 | 9.729 | 78.1 | 1945.9 | |||

| Thin Film | Portrait | 42,288.17 | 2494.9 | 9.777 | 78.4 | 1955.5 | ||

| Landscape | 46,725.92 | 2494.9 | 10.13 | 81.2 | 2026.7 | |||

| 2. | Single-axis tracking | Poly crystalline | Portrait | 54,171.21 | 2678.4 | 10.65 | 79.5 | 2129.5 |

| Landscape | 60,782.67 | 2800.7 | 11.09 | 79.2 | 2217.5 | |||

| Mono crystalline | Portrait | 57,322.46 | 2632.6 | 10.5 | 78.3 | 2093.8 | ||

| Landscape | 64,078.02 | 2796.3 | 10.91 | 78.0 | 2182.0 | |||

| Thin Film | Portrait | 44,342.92 | 2639.5 | 10.81 | 81.9 | 2161.9 | ||

| Landscape | 49,455.60 | 2753.1 | 1.26 | 81.8 | 2251.2 |

| S.No | Mounting | Type of PV Panel | Orientation | No.of Modules | TOF (%) | SAF (%) | Operating Temperature (°C) | Inverter Capacity (MW) | Water Saving (m3) |

|---|---|---|---|---|---|---|---|---|---|

| 1. | Fixed Mount (β = 25°) | Poly crystalline | Portrait | 15,625 | 99.7 | 94.6 | 41.3 | 4.02 | 123,812.00 |

| Landscape | 15,625 | 99.7 | 98.6 | 41.8 | 4.02 | 143,134.25 | |||

| Mono crystalline | Portrait | 21,276 | 99.7 | 94.5 | 41.6 | 4.02 | 150,092.50 | ||

| Landscape | 21,276 | 99.7 | 98.6 | 41.8 | 4.02 | 169,079.53 | |||

| Thin Film | Portrait | 11,904 | 99.8 | 94.5 | 41.3 | 4.02 | 116,083.45 | ||

| Landscape | 11,904 | 99.8 | 98.0 | 41.8 | 4.02 | 128,265.31 | |||

| 2. | Single-axis tracking | Poly crystalline | Portrait | 20,833 | 107.2 | 98.5 | 42.8 | 4.02 | 148,703.07 |

| Landscape | 20,833 | 112.1 | 98.0 | 43.4 | 4.02 | 166,851.90 | |||

| Mono crystalline | Portrait | 21,276 | 106.9 | 98.6 | 42.8 | 4.02 | 157,353.57 | ||

| Landscape | 21,276 | 111.9 | 98.1 | 43.3 | 4.02 | 175,897.84 | |||

| Thin Film | Portrait | 11,904 | 105.6 | 98.6 | 42.6 | 4.02 | 121,723.84 | ||

| Landscape | 11,904 | 110.2 | 98.2 | 43.1 | 4.02 | 135,758.44 |

| Sl.No | Mounting | Type of PV Panel | Orientation | Inverter Loss (%) | Shading Loss (%) | Irradiance Loss (%) | Temperature Loss (%) |

|---|---|---|---|---|---|---|---|

| 1. | Fixed Mount | Poly crystalline | Portrait | 2.0 | 5.4 | 0.2 | 9.7 |

| Landscape | 2.0 | 1.4 | 0.1 | 9.8 | |||

| Mono crystalline | Portrait | 2.4 | 3.7 | 0.1 | 11.2 | ||

| Landscape | 2.4 | 1.4 | 0.1 | 11.3 | |||

| Thin Film | Portrait | 2.1 | 5.5 | 0.6 | 8.4 | ||

| Landscape | 2.1 | 2.0 | 0.6 | 8.5 | |||

| 2. | Single-axis tracking | Poly crystalline | Portrait | 2.0 | 1.5 | 0.1 | 10.7 |

| Landscape | 2.0 | 2.0 | 0.0 | 10.8 | |||

| Mono crystalline | Portrait | 2.5 | 1.5 | 0.0 | 11.8 | ||

| Landscape | 2.5 | 1.9 | 0.0 | 11.9 | |||

| Thin Film | Portrait | 2.1 | 1.4 | 0.4 | 8.9 | ||

| Landscape | 2.1 | 1.8 | 0.3 | 9.0 |

| S.No | Category | Cost Component | Crystalline (2019 USD/kW) | Thin Film (2019 USD/kW) |

|---|---|---|---|---|

| 1. | Module and inverter | Modules | 557.01 | 360.57 |

| Inverters | 89.8 | 89.8 | ||

| 2. | BoS | Racking and mounting | 108.5 | 108.5 |

| Grid connection | 53.4 | 53.4 | ||

| Cabling/wiring | 47.8 | 47.8 | ||

| Safety and security | 22.7 | 22.7 | ||

| Monitoring and control | 25.3 | 25.3 | ||

| 3. | Installation | Mechanical installation | 46.1 | 46.1 |

| Electrical installation | 31.4 | 31.4 | ||

| Inspection | 3.3 | 3.3 | ||

| 4. | Soft costs | Margin | 104.0 | 104.0 |

| Financing costs | 60.6 | 60.6 | ||

| System design | 79.5 | 79.5 | ||

| Permitting | 58.1 | 58.1 | ||

| Incentive application | 18.8 | 18.8 | ||

| Costumer acquisition | 14.8 | 14.8 | ||

| 5. | Floating structure | Pontoons | 1583.35 | - |

| Moorings | 178.76 | 178.76 | ||

| Installations | 608.61 | 608.61 | ||

| Project Management | 93.56 | 93.56 | ||

| Annual O & M | 2.26 | 1.58 |

| FPV System | FPV Energy (MWh/Year) | CO2 Saving from Solar Energy Production (Tons) | CO2 Saving from Reduction in Evaporation (Tons) | Total CO2 Saving (Tons) |

|---|---|---|---|---|

| Fixed mount | 1934 | 38,680.00 | 410.61 | 39,090.61 |

| Single-axis tracking | 2193 | 43,860.00 | 410.61 | 44,270.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ravichandran, N.; Fayek, H.H.; Rusu, E. Emerging Floating Photovoltaic System—Case Studies High Dam and Aswan Reservoir in Egypt. Processes 2021, 9, 1005. https://doi.org/10.3390/pr9061005

Ravichandran N, Fayek HH, Rusu E. Emerging Floating Photovoltaic System—Case Studies High Dam and Aswan Reservoir in Egypt. Processes. 2021; 9(6):1005. https://doi.org/10.3390/pr9061005

Chicago/Turabian StyleRavichandran, Nagananthini, Hady H. Fayek, and Eugen Rusu. 2021. "Emerging Floating Photovoltaic System—Case Studies High Dam and Aswan Reservoir in Egypt" Processes 9, no. 6: 1005. https://doi.org/10.3390/pr9061005

APA StyleRavichandran, N., Fayek, H. H., & Rusu, E. (2021). Emerging Floating Photovoltaic System—Case Studies High Dam and Aswan Reservoir in Egypt. Processes, 9(6), 1005. https://doi.org/10.3390/pr9061005