Analysis the Drivers of Environmental Responsibility of Chinese Auto Manufacturing Industry Based on Triple Bottom Line

Abstract

1. Introduction

2. Literature Review

2.1. Corporate Environmental Responsibility and Triple Bottom Line

2.2. Drivers of CER in the Automotive Industry

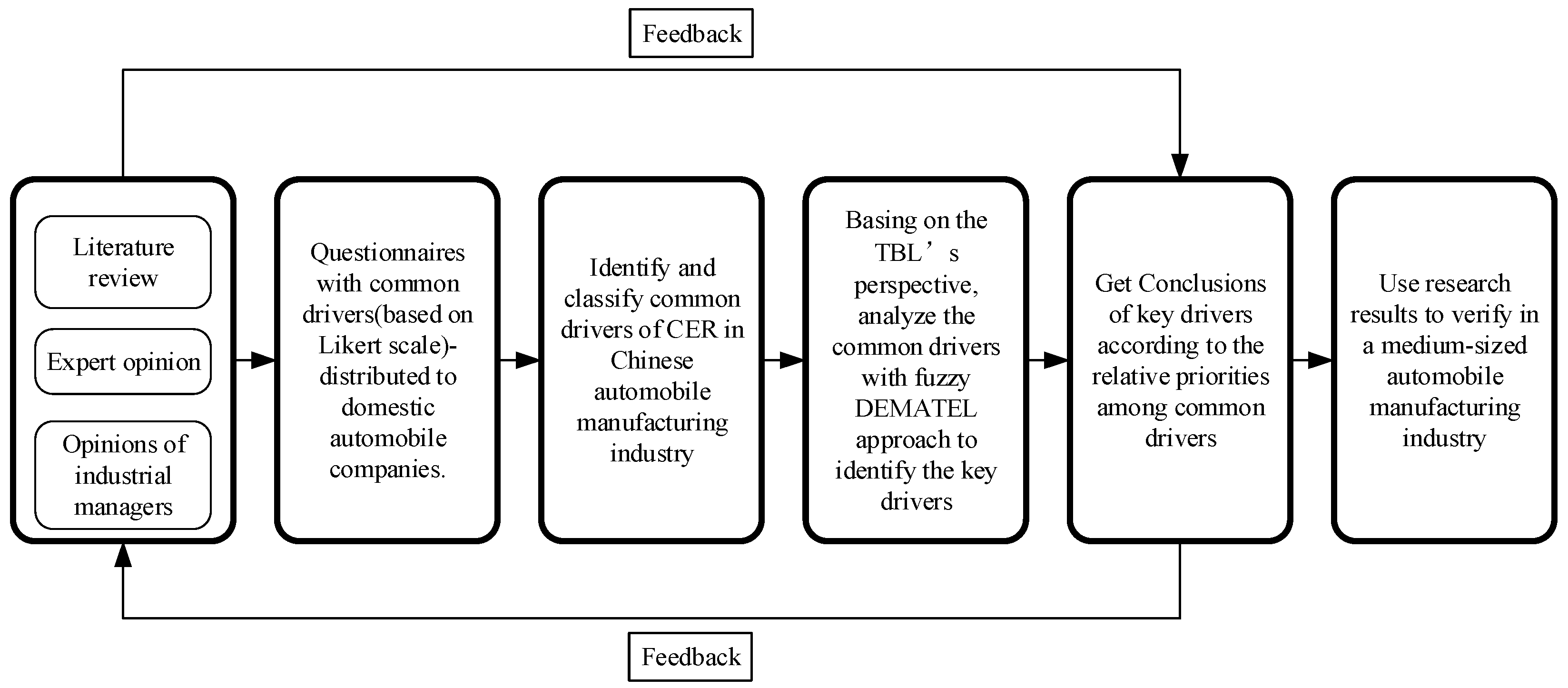

3. Identify Common Drivers of CER

4. The Fuzzy DEMATEL Method of Key Drivers

5. Case Study: An Explanation

5.1. Case Background

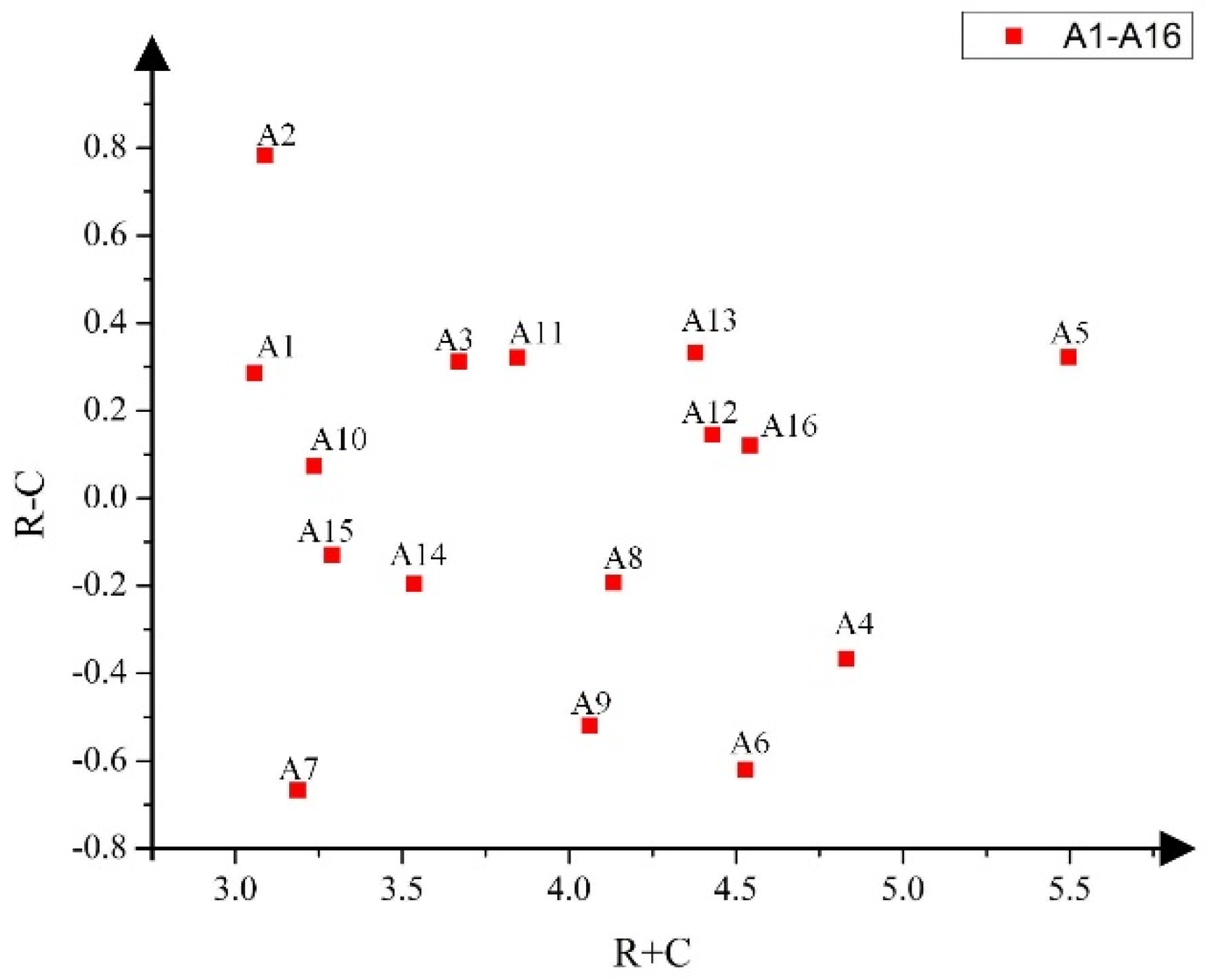

5.2. Results and Analysis

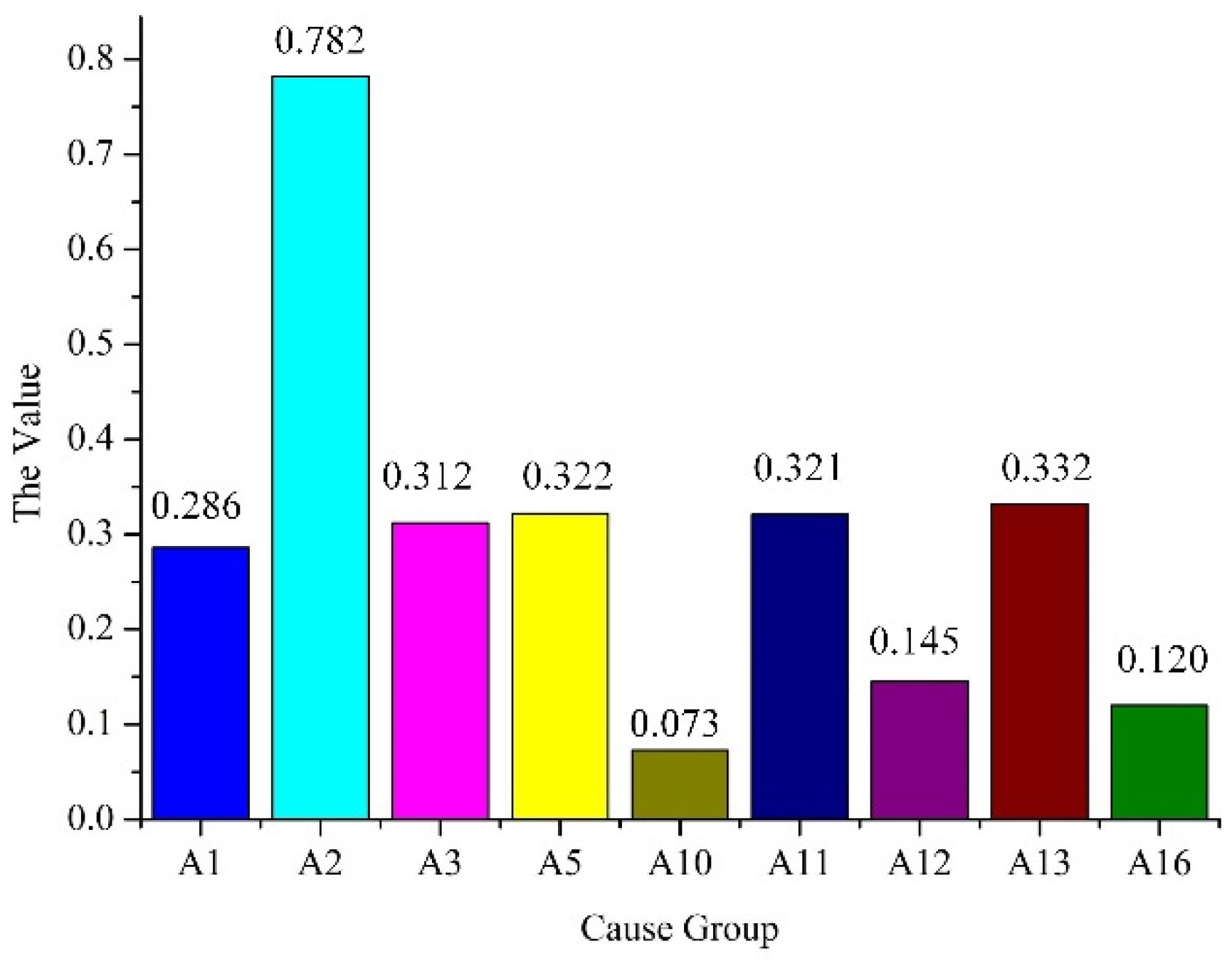

6. Discussion

7. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, F.W.; Zhao, B.J. Research on the Development Strategies of New Energy Automotive Industry Based on Car Charging Stations. Appl. Mech. Mater. 2015, 740, 985–988. [Google Scholar] [CrossRef]

- He, M.; Chen, J. Sustainable Development and Corporate Environmental Responsibility: Evidence from Chinese Corporations. J. Agric. Environ. Ethic 2009, 22, 323–339. [Google Scholar] [CrossRef]

- Li, P.C.; Zhang, H.M. Application Situation and Development Strategies of Green Manufacturing in China’s Automobile Industry. Adv. Mater. Res. 2014, 1049–1050, 945–948. [Google Scholar] [CrossRef]

- Severo, E.A.; de Guimarães, J.C.F.; Dorion, E.C.H. Cleaner production, social responsibility and eco-innovation: Generations’ perception for a sustainable future. J. Clean. Prod. 2018, 186, 91–103. [Google Scholar] [CrossRef]

- Jiang, Z.; Jiang, Y.; Wang, Y.; Zhang, H.; Cao, H.; Tian, G. A hybrid approach of rough set and case-based reasoning to remanufacturing process planning. J. Intell. Manuf. 2019, 30, 19–32. [Google Scholar] [CrossRef]

- Ding, Z.; Jiang, Z.; Zhang, H.; Cai, W.; Liu, Y. An integrated decision-making method for selecting machine tool guideways considering remanufacturability. Int. J. Comput. Integr. Manuf. 2018, 33, 686–700. [Google Scholar] [CrossRef]

- Elkington, J. Accounting for The Triple Bottom Line. Meas. Bus. Excel. 1998, 2, 18–22. [Google Scholar] [CrossRef]

- Mazurkiewicz, P. Corporate Environmental Responsibility: Is a Common CSR Framework Possible; World Bank: Washington, DC, USA, 2004; pp. 1–18. [Google Scholar]

- González-Rodríguez, M.R.; Díaz-Fernández, M.C.; Biagio, S. The perception of socially and environmentally responsible practices based on values and cultural environment from a customer perspective. J. Clean. Prod. 2019, 216, 88–98. [Google Scholar] [CrossRef]

- Nawaz, W.; Linke, P.; Koҫ, M. Safety and sustainability nexus: A review and appraisal. J. Clean. Prod. 2019, 216, 74–87. [Google Scholar] [CrossRef]

- Gunningham, N. Shaping corporate environmental performance: A review. Environ. Policy Gov. 2009, 19, 215–231. [Google Scholar] [CrossRef]

- Wang, H. Systematic analysis of corporate environmental responsibility: Elements, structure, function, and principles. Chin. J. Popul. Resour. Environ. 2016, 14, 96–104. [Google Scholar] [CrossRef]

- Cai, W.; Liu, C.; Lai, K.-H.; Li, L.; Cunha, J.; Hu, L. Energy performance certification in mechanical manufacturing industry: A review and analysis. Energy Convers. Manag. 2019, 186, 415–432. [Google Scholar] [CrossRef]

- Fujii, H.; Managi, S. Trends in corporate environmental management studies and databases. Environ. Econ. Policy Stud. 2016, 18, 265–272. [Google Scholar] [CrossRef][Green Version]

- Liu, Y.; Xi, B.; Wang, G. The impact of corporate environmental responsibility on financial performance—Based on Chinese listed companies. Environ. Sci. Pollut. Res. 2021, 28, 7840–7853. [Google Scholar] [CrossRef] [PubMed]

- Shabbir, M.S.; Wisdom, O. The relationship between corporate social responsibility, environmental investments and financial performance: Evidence from manufacturing companies. Environ. Sci. Pollut. Res. 2020, 27, 39946–39957. [Google Scholar] [CrossRef] [PubMed]

- Kennard, A. The Enemy of My Enemy: When Firms Support Climate Change Regulation. Int. Organ. 2020, 74, 187–221. [Google Scholar] [CrossRef]

- Gong, J.Z.Y.; Wang, G. An Investigation into Triple Bottom Line Assessment of Eco-Friendly Office Supplies: File Folders; University of British Columbia: Vancouver, BC, Canada, 2014. [Google Scholar]

- Casey, E.; Beaini, S.; Pabi, S.; Zammit, K.; Amarnath, A. The Triple Bottom Line for Efficiency: Integrating Systems Within Water and Energy Networks. IEEE Power Energy Mag. 2017, 15, 34–42. [Google Scholar] [CrossRef]

- Fairley, S.; Tyler, B.D.; Kellett, P.; D’Elia, K. The Formula One Australian Grand Prix: Exploring the triple bottom line. Sport Manag. Rev. 2011, 14, 141–152. [Google Scholar] [CrossRef]

- Wise, N. Outlining triple bottom line contexts in urban tourism regeneration. Cities 2016, 53, 30–34. [Google Scholar] [CrossRef]

- Depken, D.; Zeman, C. Small business challenges and the triple bottom line, TBL: Needs assessment in a Midwest State, U.S.A. Technol. Forecast. Soc. Chang. 2018, 135, 44–50. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Wu, K.-J.; Ma, L.; Kuo, T.C.; Sai, F. A hierarchical framework for assessing corporate sustainability performance using a hybrid fuzzy synthetic method-DEMATEL. Technol. Forecast. Soc. Chang. 2019, 144, 524–533. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A stochastic approach for sustainability analysis under the green economics paradigm. Stoch. Environ. Res. Risk Assess. 2013, 28, 1743–1753. [Google Scholar] [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.; Chiu, K.K.-S. Multi-Attribute Approach to Sustainable Supply Chain Management Under Un-Certainty. Ind. Manag. Data Syst. 2016, 116, 777–800. [Google Scholar] [CrossRef]

- Esquer-Peralta, J.; Velazquez, L.; Munguia, N. Perceptions of core elements for sustainability management systems (SMS). Manag. Decis. 2008, 46, 1027–1038. [Google Scholar] [CrossRef]

- Palvia, P.; Baqir, N.; Nemati, H. ICT for socio-economic development: A citizens’ perspective. Inf. Manag. 2018, 55, 160–176. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Chiu, A.S.; Liang, D. Sustainable consumption and production in business decision-making models. Resour. Conserv. Recycl. 2018, 128, 118–121. [Google Scholar] [CrossRef]

- Bergenwall, A.L.; Chen, C.; White, R.E. TPS’s process design in American automotive plants and its effects on the triple bottom line and sustainability. Int. J. Prod. Econ. 2012, 140, 374–384. [Google Scholar] [CrossRef]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Neri, A.; Cagno, E.; Lepri, M.; Trianni, A. A triple bottom line balanced set of key performance indicators to measure the sustainability performance of industrial supply chains. Sustain. Prod. Consum. 2021, 26, 648–691. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K. Analyzing disposition decisions for sustainable reverse logistics: Triple Bottom Line approach. Resour. Conserv. Recycl. 2019, 150, 104448. [Google Scholar] [CrossRef]

- Hussain, N.; Rigoni, U.; Orij, R.P. Corporate Governance and Sustainability Performance: Analysis of Triple Bottom Line Performance. J. Bus. Ethics 2018, 149, 411–432. [Google Scholar] [CrossRef]

- Chen, Y.; Lawell, C.-Y.C.L.; Muehlegger, E.J.; Wilen, J.E. Modeling Supply and Demand in the Chinese Automobile Industry. In Proceedings of the 2017 Annual Meeting, Chicago, IL, USA, 30 July–1 August 2017. [Google Scholar]

- Azevedo, S.; Barros, M. The application of the triple bottom line approach to sustainability assessment: The case study of the UK automotive supply chain. J. Ind. Eng. Manag. 2017, 10, 286–322. [Google Scholar] [CrossRef]

- Kumar, D.; Rahman, Z.; Chan, F.T.S. A fuzzy AHP and fuzzy multi-objective linear programming model for order allocation in a sustainable supply chain: A case study. Int. J. Comput. Integr. Manuf. 2017, 30, 535–551. [Google Scholar] [CrossRef]

- Mathivathanan, D.; Kannan, D.; Haq, A.N. Sustainable supply chain management practices in Indian automotive industry: A multi-stakeholder view. Resour. Conserv. Recycl. 2018, 128, 284–305. [Google Scholar] [CrossRef]

- Wang, H. Factor analysis of corporate environmental responsibility. Environ. Dev. Sustain. 2009, 12, 481–490. [Google Scholar] [CrossRef]

- Dummett, K. Drivers for Corporate Environmental Responsibility (CER). Environ. Dev. Sustain. 2006, 8, 375–389. [Google Scholar] [CrossRef]

- Kehbila, A.G.; Ertel, J.; Brent, A.C. Strategic corporate environmental management within the South African automotive industry: Motivations, benefits, hurdles. Corp. Soc. Responsib. Environ. Manag. 2009, 16, 310–323. [Google Scholar] [CrossRef]

- Cai, W.; Lai, K.-H.; Liu, C.; Wei, F.; Ma, M.; Jia, S.; Jiang, Z.; Lv, L. Promoting sustainability of manufacturing industry through the lean energy-saving and emission-reduction strategy. Sci. Total Environ. 2019, 665, 23–32. [Google Scholar] [CrossRef]

- Nunes, B.; Bennett, D. Green operations initiatives in the automotive industry: An environmental reports analysis and benchmarking study. Benchmarking: Int. J. 2010, 17, 396–420. [Google Scholar] [CrossRef]

- Yucheng, C.; You, J.; Wang, R.; Shi, Y. Designing a mixed evaluating system for green manufacturing of automotive industry. Probl. Ekorozwoju 2016, 11, 73–86. [Google Scholar]

- Babiak, K.; Trendafilova, S. CSR and environmental responsibility: Motives and pressures to adopt green management practices. Corp. Soc. Responsib. Environ. Manag. 2011, 18, 11–24. [Google Scholar] [CrossRef]

- Lee, J.W.; Kim, Y.M. Antecedents of Adopting Corporate Environmental Responsibility and Green Practices. J. Bus. Ethics 2016, 148, 397–409. [Google Scholar] [CrossRef]

- Goli, Y.S.; Ye, J.; Ye, Y.; Kalgora, B. Impact of Ecological Related Innovations Enhancing the Efficiency of Corporate Environmental Responsibility. Am. J. Ind. Bus. Manag. 2020, 10, 191–217. [Google Scholar] [CrossRef]

- Chen, Y.-S. The Drivers of Green Brand Equity: Green Brand Image, Green Satisfaction, and Green Trust. J. Bus. Ethics 2009, 93, 307–319. [Google Scholar] [CrossRef]

- Ho, C.-W. Does Practicing CSR Makes Consumers Like Your Shop More? Consumer-Retailer Love Mediates CSR and Behavioral Intentions. Int. J. Environ. Res. Public Heal. 2017, 14, 1558. [Google Scholar] [CrossRef] [PubMed]

- Jahanshahi, A.A.; Brem, A. Antecedents of Corporate Environmental Commitments: The Role of Customers. Int. J. Environ. Res. Public Heal. 2018, 15, 1191. [Google Scholar] [CrossRef]

- Sevinç, A.; Eren, T. Determination of KOSGEB Support Models for Small- and Medium-Scale Enterprises by Means of Data Envelopment Analysis and Multi-Criteria Decision Making Methods. Process 2019, 7, 130. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, Z.; Zhang, H.; Wang, Y.; Yang, Y.; Li, Y. An integrated MCDM approach considering demands-matching for reverse logistics. J. Clean. Prod. 2019, 208, 199–210. [Google Scholar] [CrossRef]

- Hamdia, K.M.; Arafa, M.; Alqedra, M. Structural damage assessment criteria for reinforced concrete buildings by using a Fuzzy Analytic Hierarchy process. Undergr. Space 2018, 3, 243–249. [Google Scholar] [CrossRef]

- Wu, W.; Lan, L.W.; Lee, Y. Factors hindering acceptance of using cloud services in university: A case study. Electron. Libr. 2013, 31, 84–98. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy Sets, Fuzzy Logic, and Fuzzy Systems: Selected Papers by Lotfi A Zadeh; State University of New York at Binghamton: New York, NY, USA, 1996; pp. 394–432. [Google Scholar] [CrossRef]

- Lin, R.-J. Using fuzzy DEMATEL to evaluate the green supply chain management practices. J. Clean. Prod. 2013, 40, 32–39. [Google Scholar] [CrossRef]

- He, Z.-X.; Shen, W.-X.; Li, Q.-B.; Xu, S.-C.; Zhao, B.; Long, R.-Y.; Chen, H. Investigating external and internal pressures on corporate environmental behavior in papermaking enterprises of China. J. Clean. Prod. 2018, 172, 1193–1211. [Google Scholar] [CrossRef]

- Li, X.; Du, J.; Long, H. Green Development Behavior and Performance of Industrial Enterprises Based on Grounded Theory Study: Evidence from China. Sustainability 2019, 11, 4133. [Google Scholar] [CrossRef]

- Dicuonzo, G.; Galeone, G.; Ranaldo, S.; Turco, M. The Key Drivers of Born-Sustainable Businesses: Evidence from the Italian Fashion Industry. Sustainability 2020, 12, 10237. [Google Scholar] [CrossRef]

| No. | Main Driers | Explanation | Common Drivers |

|---|---|---|---|

| 1 | Policy drivers | Policy drivers can be categorized into two areas, namely compulsory aspect (regulations, standards, etc.) and incentive aspect. | Incentives (A1) Government regulations (A2) Standards (A3) |

| 2 | Technological drivers | Technological drivers can help corporate achieve the sustainable development. | Green technology import (A4) Green technology innovation (A5) |

| 3 | Corporate internal motivations | These motivations mainly focus on company level, such as its own development and the demand of company’s internal staff, etc. | Top management commitment (A6) Employee demand (A7) Financial benefits (A8) Shareholders motivation (A9) Company image (A10) Competitive advantage (A11) |

| 4 | Corporate external pressure | Companies need to do things that they are unwilling to do but must do to meet the needs of the public. | Consumers demand (A12) Green supply chain pressure (A13) Societal expectation (A14) Media pressure (A15) Market trend (A16) |

| Linguistic Terms | Triangular Fuzzy Numbers |

|---|---|

| No influence (N) | (0,0,0.25) |

| Very low influence (VL) | (0,0.25,0.5) |

| Low influence (L) | (0.25,0.5,0.75) |

| High influence (H) | (0.5,0.75,1) |

| Very high influence (VH) | (0.75,1,1) |

| Criteria | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | A11 | A12 | A13 | A14 | A15 | A16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | N | VL | VL | H | H | H | N | H | H | N | N | N | VL | N | VL | H |

| A2 | L | N | VH | L | L | H | N | L | L | N | N | VL | H | N | H | L |

| A3 | VL | H | N | VL | VL | VL | H | L | L | N | L | L | H | L | H | L |

| A4 | L | L | VL | N | H | H | H | L | VL | H | H | L | H | VL | VL | H |

| A5 | H | L | L | VH | N | H | VH | VH | H | H | VH | L | L | H | L | H |

| A6 | L | VL | VL | H | H | N | H | VL | H | H | VL | VL | L | L | VL | VL |

| A7 | N | N | VL | L | N | H | N | VL | L | VL | N | N | VL | N | VL | N |

| A8 | VL | VL | L | H | VH | H | H | N | VH | H | L | VL | H | N | N | L |

| A9 | VL | VL | N | H | H | H | L | VL | N | N | L | VL | VL | H | N | VL |

| A10 | N | N | VL | VL | VL | H | L | H | N | N | H | L | N | H | H | N |

| A11 | N | N | VL | L | H | H | N | VH | H | H | N | H | VL | N | N | H |

| A12 | N | VL | H | H | VH | H | N | H | H | VL | L | N | VH | L | VL | VH |

| A13 | VL | VL | H | H | H | VL | L | L | L | N | L | H | N | H | H | H |

| A14 | N | N | VL | VL | H | L | N | N | VL | VL | N | H | L | N | H | H |

| A15 | VL | N | L | L | L | L | L | N | N | VL | N | H | VL | H | N | VL |

| A16 | L | VL | VL | H | H | L | N | H | H | N | VL | H | H | H | L | N |

| Criteria | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | A11 | A12 | A13 | A14 | A15 | A16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.082 | 0.25 | 0.25 | 0.75 | 0.75 | 0.5 | 0.082 | 0.75 | 0.75 | 0.082 | 0.082 | 0.082 | 0.25 | 0.082 | 0.25 | 0.75 |

| A2 | 0.5 | 0.082 | 0.928 | 0.5 | 0.5 | 0.75 | 0.082 | 0.5 | 0.5 | 0.082 | 0.082 | 0.25 | 0.75 | 0.082 | 0.75 | 0.5 |

| A3 | 0.25 | 0.75 | 0.082 | 0.25 | 0.25 | 0.25 | 0.75 | 0.5 | 0.5 | 0.082 | 0.5 | 0.5 | 0.75 | 0.5 | 0.75 | 0.5 |

| A4 | 0.5 | 0.5 | 0.25 | 0.082 | 0.75 | 0.75 | 0.25 | 0.5 | 0.25 | 0.75 | 0.75 | 0.5 | 0.75 | 0.25 | 0.25 | 0.75 |

| A5 | 0.75 | 0.5 | 0.5 | 0.918 | 0.082 | 0.75 | 0.928 | 0.928 | 0.75 | 0.75 | 0.928 | 0.5 | 0.5 | 0.75 | 0.5 | 0.75 |

| A6 | 0.5 | 0.25 | 0.25 | 0.75 | 0.75 | 0.082 | 0.75 | 0.25 | 0.75 | 0.75 | 0.25 | 0.25 | 0.5 | 0.5 | 0.25 | 0.25 |

| A7 | 0.082 | 0.082 | 0.25 | 0.5 | 0.082 | 0.75 | 0.082 | 0.25 | 0.5 | 0.25 | 0.082 | 0.082 | 0.25 | 0.082 | 0.25 | 0.082 |

| A8 | 0.25 | 0.25 | 0.5 | 0.75 | 0.928 | 0.75 | 0.75 | 0.082 | 0.928 | 0.75 | 0.5 | 0.25 | 0.75 | 0.082 | 0.082 | 0.5 |

| A9 | 0.25 | 0.25 | 0.082 | 0.75 | 0.75 | 0.75 | 0.5 | 0.25 | 0.082 | 0.082 | 0.5 | 0.25 | 0.25 | 0.75 | 0.082 | 0.25 |

| A10 | 0.082 | 0.082 | 0.25 | 0.25 | 0.25 | 0.75 | 0.5 | 0.75 | 0.082 | 0.082 | 0.75 | 0.5 | 0.082 | 0.75 | 0.75 | 0.082 |

| A11 | 0.082 | 0.082 | 0.25 | 0.5 | 0.75 | 0.75 | 0.082 | 0.928 | 0.75 | 0.75 | 0.082 | 0.75 | 0.25 | 0.082 | 0.082 | 0.75 |

| A12 | 0.082 | 0.25 | 0.75 | 0.75 | 0.928 | 0.75 | 0.082 | 0.75 | 0.75 | 0.25 | 0.5 | 0.082 | 0.928 | 0.5 | 0.25 | 0.928 |

| A13 | 0.25 | 0.25 | 0.75 | 0.75 | 0.75 | 0.25 | 0.5 | 0.5 | 0.5 | 0.082 | 0.5 | 0.75 | 0.082 | 0.75 | 0.75 | 0.75 |

| A14 | 0.082 | 0.082 | 0.25 | 0.25 | 0.75 | 0.5 | 0.082 | 0.082 | 0.25 | 0.25 | 0.082 | 0.75 | 0.5 | 0.082 | 0.75 | 0.75 |

| A15 | 0.25 | 0.082 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.082 | 0.082 | 0.25 | 0.082 | 0.75 | 0.25 | 0.75 | 0.082 | 0.25 |

| A16 | 0.5 | 0.25 | 0.25 | 0.75 | 0.75 | 0.5 | 0.082 | 0.75 | 0.75 | 0.082 | 0.25 | 0.75 | 0.75 | 0.75 | 0.5 | 0.082 |

| Criteria | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | A11 | A12 | A13 | A14 | A15 | A16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.8 | 2.3 | 2.3 | 0.7 | 0.7 | 4.7 | 0.8 | 7 | 7 | 0.8 | 0.8 | 0.8 | 2.3 | 0.8 | 2.3 | 7 |

| A2 | 4.7 | 0.8 | 8.5 | 4.7 | 4.7 | 7 | 0.8 | 4.7 | 4.7 | 0.8 | 0.8 | 2.3 | 7 | 8 | 7 | 4.7 |

| A3 | 2.3 | 7 | 0.8 | 2.3 | 2.3 | 2.3 | 7 | 4.7 | 4.7 | 0.8 | 4.7 | 4.7 | 7 | 4.7 | 7 | 4.7 |

| A4 | 4.7 | 4.7 | 2.3 | 8 | 7 | 7 | 4.7 | 4.7 | 2.3 | 7 | 7 | 4.7 | 7 | 0.2 | 2.3 | 7 |

| A5 | 7 | 4.7 | 4.7 | 8.5 | 0.8 | 7 | 8.5 | 8.5 | 7 | 7 | 8.5 | 4.7 | 4.7 | 7 | 4.7 | 7 |

| A6 | 4.7 | 2.3 | 2.3 | 7 | 7 | 0.8 | 7 | 2.3 | 7 | 7 | 2.3 | 2.3 | 4.7 | 4.7 | 2.3 | 2.3 |

| A7 | 0.8 | 0.8 | 2.3 | 4.7 | 4.7 | 7 | 0.8 | 2.3 | 7 | 2.3 | 0.8 | 0.8 | 2.3 | 0.8 | 2.3 | 0.8 |

| A8 | 2.3 | 2.3 | 2.3 | 7 | 2.3 | 7 | 7 | 0.8 | 4.7 | 7 | 4.7 | 2.3 | 7 | 0.8 | 0.8 | 4.7 |

| A9 | 2.3 | 2.3 | 4.7 | 7 | 7 | 7 | 4.7 | 2.3 | 8.5 | 0.8 | 4.7 | 2.3 | 2.3 | 7 | 0.8 | 2.3 |

| A10 | 0.8 | 0.8 | 0.8 | 4.7 | 2.3 | 7 | 4.7 | 7 | 0.8 | 0.8 | 7 | 4.7 | 0.8 | 7 | 7 | 0.8 |

| A11 | 0.8 | 0.8 | 2.3 | 4.7 | 7 | 7 | 0.8 | 8.5 | 7 | 7 | 0.8 | 7 | 4.7 | 0.8 | 0.8 | 7 |

| A12 | 0.8 | 2.3 | 7 | 7 | 8.5 | 7 | 0.8 | 7 | 7 | 2.3 | 4.7 | 0.8 | 8.5 | 4.7 | 2.3 | 8.5 |

| A13 | 2.3 | 2.3 | 7 | 7 | 7 | 2.3 | 4.7 | 4.7 | 4.7 | 0.8 | 4.7 | 8.5 | 0.8 | 7 | 7 | 7 |

| A14 | 0.8 | 0.8 | 2.3 | 2.3 | 7 | 4.7 | 0.8 | 0.8 | 2.3 | 2.3 | 0.8 | 8.5 | 4.7 | 0.8 | 7 | 7 |

| A15 | 2.3 | 0.8 | 4.7 | 4.7 | 4.7 | 4.7 | 47 | 0.8 | 0.8 | 2.3 | 0.8 | 8.5 | 2.3 | 7 | 0.8 | 2.3 |

| A16 | 7 | 2.3 | 2.3 | 7 | 7 | 4.7 | 0.8 | 7 | 7 | 0.3 | 2.3 | 8.5 | 7 | 7 | 4.7 | 0.8 |

| Criteria | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | A11 | A12 | A13 | A14 | A15 | A16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 6.2 | 6.7 | 8.2 | 16.3 | 15.9 | 13.8 | 7.7 | 14.5 | 15.1 | 6.7 | 7.3 | 8.3 | 10.3 | 7.5 | 8.1 | 14.6 |

| A2 | 10.5 | 5.9 | 15.3 | 15.3 | 15.1 | 16.9 | 8.8 | 13.2 | 14.0 | 7.2 | 8.0 | 11.2 | 15.9 | 8.8 | 13.9 | 13.6 |

| A3 | 8.0 | 11.4 | 8.1 | 13.1 | 13.2 | 13.0 | 14.1 | 13.2 | 14.0 | 7.1 | 14.4 | 13.6 | 16.0 | 12.3 | 13.9 | 13.7 |

| A4 | 11.3 | 9.9 | 10.2 | 13.4 | 19.0 | 19.0 | 13.3 | 15.3 | 13.5 | 14.5 | 15.2 | 14.6 | 17.1 | 9.3 | 10.4 | 17.2 |

| A5 | 15.2 | 11.5 | 14.5 | 24.2 | 16.8 | 22.8 | 19.4 | 21.5 | 20.9 | 16.8 | 18.8 | 17.6 | 18.0 | 17.9 | 14.8 | 20.2 |

| A6 | 10.3 | 7.1 | 9.1 | 17.5 | 17.4 | 11.6 | 14.6 | 11.3 | 16.0 | 13.4 | 9.8 | 11.0 | 13.3 | 12.3 | 9.4 | 11.3 |

| A7 | 4.4 | 3.7 | 6.3 | 11.0 | 10.9 | 13.1 | 15.8 | 7.5 | 10.1 | 6.6 | 5.3 | 5.9 | 7.6 | 5.5 | 6.3 | 6.0 |

| A8 | 8.1 | 7.1 | 9.1 | 17.7 | 13.2 | 17.6 | 14.6 | 9.8 | 17.7 | 13.5 | 12.1 | 11.0 | 15.7 | 8.7 | 7.7 | 13.4 |

| A9 | 7.7 | 6.8 | 10.7 | 16.4 | 16.6 | 16.4 | 11.6 | 10.4 | 9.5 | 7.2 | 11.2 | 10.3 | 10.7 | 13.6 | 7.2 | 10.8 |

| A10 | 5.4 | 4.5 | 6.4 | 13.5 | 11.4 | 15.9 | 11.0 | 14.0 | 8.8 | 7.0 | 12.7 | 12.2 | 8.6 | 13.0 | 12.4 | 8.6 |

| A11 | 7.1 | 6.0 | 9.6 | 16.5 | 18.2 | 18.3 | 9.4 | 18.1 | 17.2 | 14.2 | 9.1 | 16.1 | 14.4 | 9.5 | 8.1 | 16.5 |

| A12 | 8.5 | 8.7 | 15.6 | 20.5 | 21.8 | 20.0 | 10.9 | 18.2 | 19.0 | 10.9 | 14.1 | 12.4 | 2.1 | 14.7 | 11.3 | 20.0 |

| A13 | 9.3 | 8.3 | 15.3 | 19.7 | 19.8 | 15.2 | 13.6 | 15.3 | 16.0 | 8.7 | 13.3 | 19.3 | 12.2 | 16.2 | 15.2 | 18.1 |

| A14 | 6.0 | 4.9 | 8.5 | 11.8 | 16.1 | 13.5 | 7.4 | 8.6 | 10.5 | 7.9 | 7.1 | 16.3 | 12.6 | 8.1 | 12.9 | 14.8 |

| A15 | 6.9 | 4.8 | 10.2 | 13.1 | 13.4 | 13.1 | 10.6 | 8.0 | 8.5 | 7.6 | 6.7 | 15.5 | 9.9 | 13.1 | 6.6 | 10.0 |

| A16 | 13.7 | 8.1 | 10.8 | 19.9 | 19.9 | 17.2 | 9.9 | 17.4 | 18.3 | 8.8 | 11.1 | 18.9 | 17.9 | 16.1 | 12.8 | 12.3 |

| Criteria | R | C | R + C | R − C |

|---|---|---|---|---|

| A1 | 1.672 | 1.386 | 3.058 | 0.286 |

| A2 | 1.936 | 1.154 | 3.090 | 0.782 |

| A3 | 1.991 | 1.679 | 3.670 | 0.312 |

| A4 | 2.232 | 2.599 | 4.831 | −0.367 |

| A5 | 2.909 | 2.587 | 5.496 | 0.322 |

| A6 | 1.954 | 2.574 | 4.528 | −0.620 |

| A7 | 1.260 | 1.927 | 3.187 | −0.667 |

| A8 | 1.970 | 2.163 | 4.133 | −0.193 |

| A9 | 1.771 | 2.291 | 4.062 | −0.520 |

| A10 | 1.654 | 1.581 | 3.235 | 0.073 |

| A11 | 2.083 | 1.762 | 3.845 | 0.321 |

| A12 | 2.287 | 2.142 | 4.429 | 0.145 |

| A13 | 2.355 | 2.023 | 4.378 | 0.332 |

| A14 | 1.670 | 1.866 | 3.536 | −0.196 |

| A15 | 1.580 | 1.710 | 3.290 | −0.130 |

| A16 | 2.331 | 2.211 | 4.542 | 0.120 |

| Key Drivers | R − C | Rg | Ranking |

|---|---|---|---|

| Incentives (A1) | 0.286 | 36.57 | 6 |

| Government regulations (A2) | 0.782 | 100.00 | 1 |

| Standards (A3) | 0.312 | 39.89 | 5 |

| Green technology innovation (A5) | 0.322 | 41.18 | 3 |

| Company image (A10) | 0.073 | 9.34 | 9 |

| Competitive advantage (A11) | 0.321 | 41.04 | 4 |

| Consumers demand (A12) | 0.145 | 18.54 | 7 |

| Green supply chain pressure (A13) | 0.332 | 42.46 | 2 |

| Market trend (A16) | 0.120 | 15.35 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Zhang, M.; Yan, W.; Liu, Y.; Jiang, Z.; Li, S. Analysis the Drivers of Environmental Responsibility of Chinese Auto Manufacturing Industry Based on Triple Bottom Line. Processes 2021, 9, 751. https://doi.org/10.3390/pr9050751

Zhang H, Zhang M, Yan W, Liu Y, Jiang Z, Li S. Analysis the Drivers of Environmental Responsibility of Chinese Auto Manufacturing Industry Based on Triple Bottom Line. Processes. 2021; 9(5):751. https://doi.org/10.3390/pr9050751

Chicago/Turabian StyleZhang, Hua, Meihang Zhang, Wei Yan, Ying Liu, Zhigang Jiang, and Shengqiang Li. 2021. "Analysis the Drivers of Environmental Responsibility of Chinese Auto Manufacturing Industry Based on Triple Bottom Line" Processes 9, no. 5: 751. https://doi.org/10.3390/pr9050751

APA StyleZhang, H., Zhang, M., Yan, W., Liu, Y., Jiang, Z., & Li, S. (2021). Analysis the Drivers of Environmental Responsibility of Chinese Auto Manufacturing Industry Based on Triple Bottom Line. Processes, 9(5), 751. https://doi.org/10.3390/pr9050751