Effect of Packing Material Composition on the Aerodynamic Processes in a Wavy Lamellar Plate-Type Biofilter

Abstract

1. Introduction

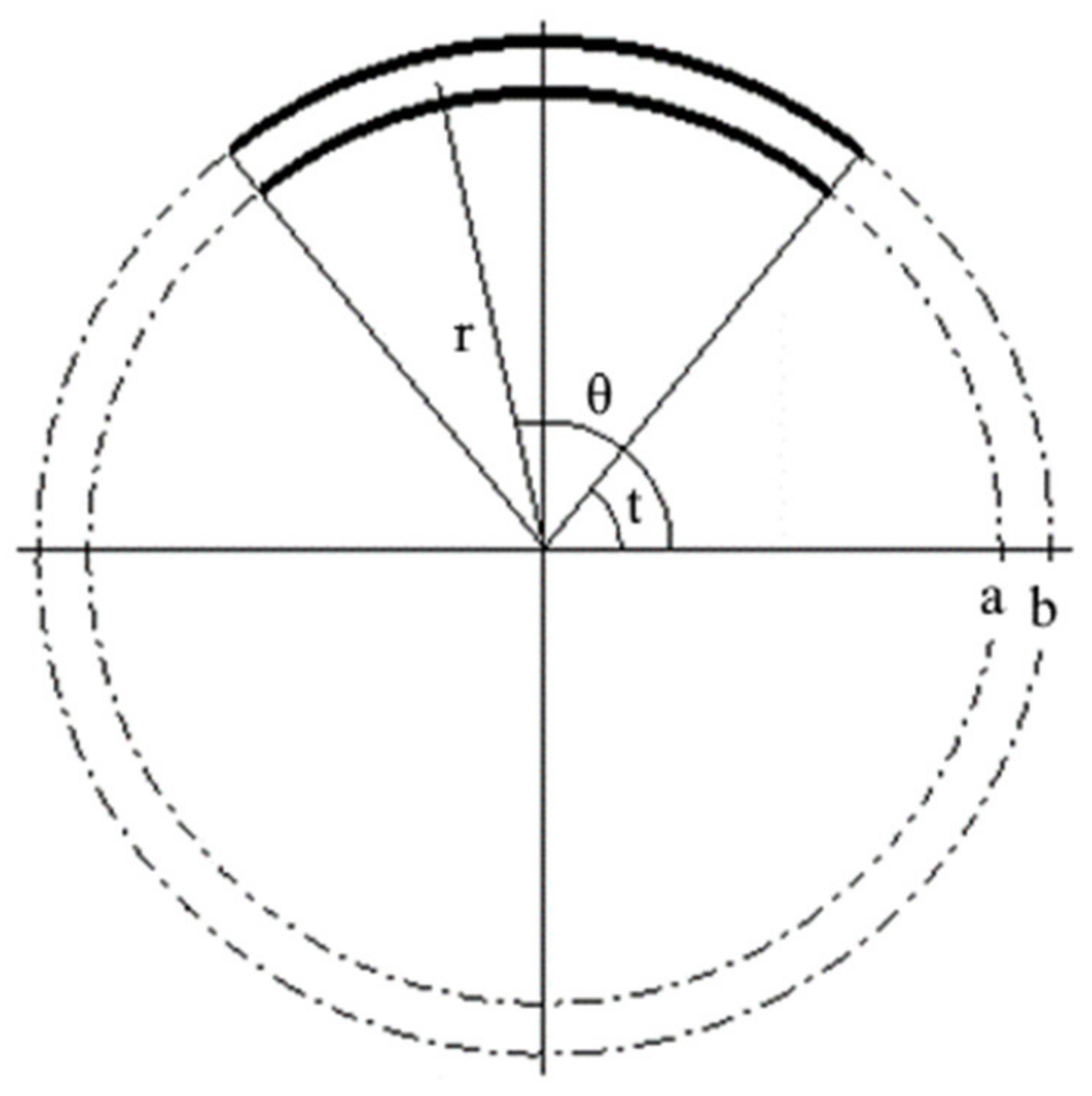

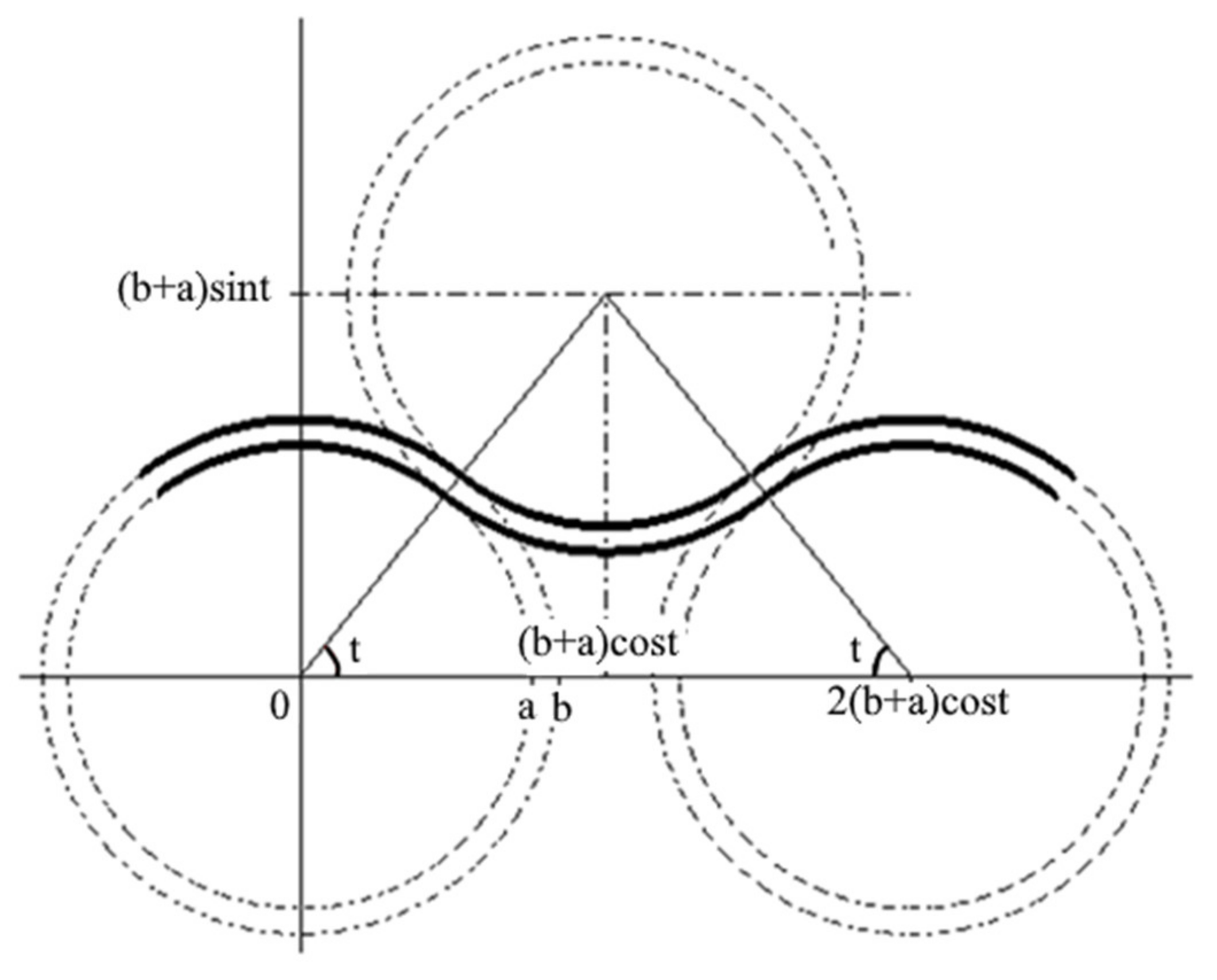

2. Materials and Methods

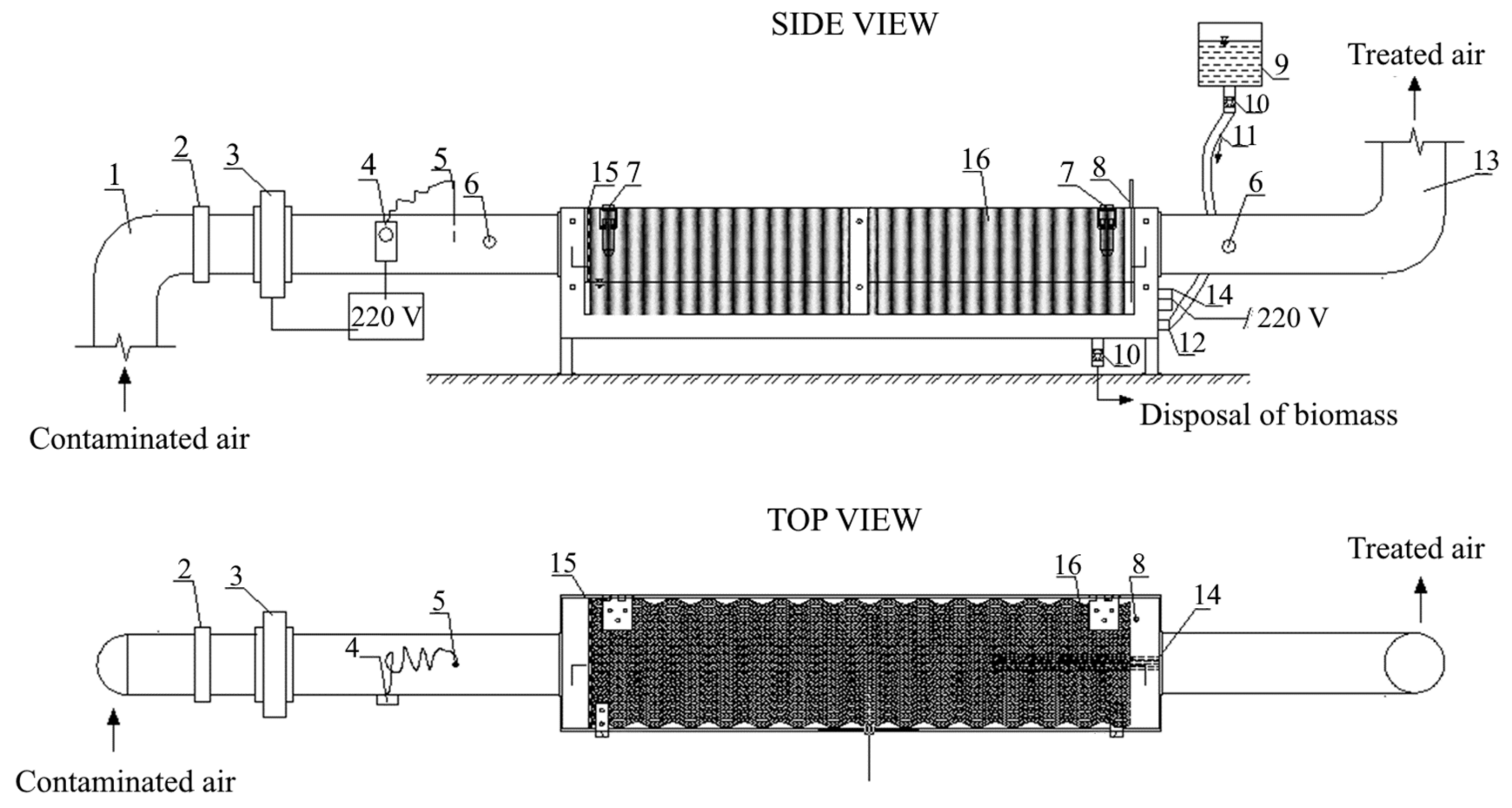

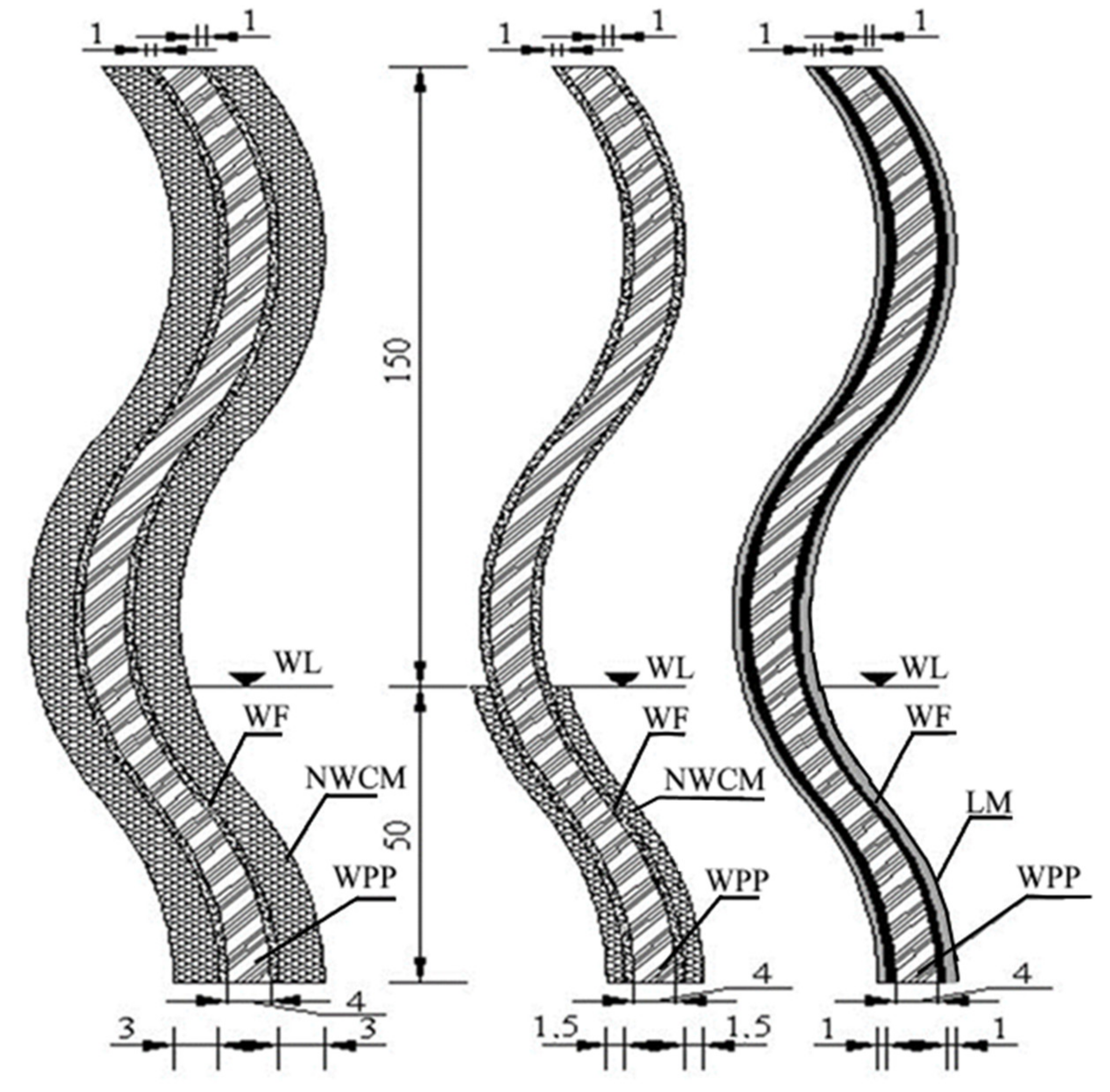

2.1. Biofilter Design

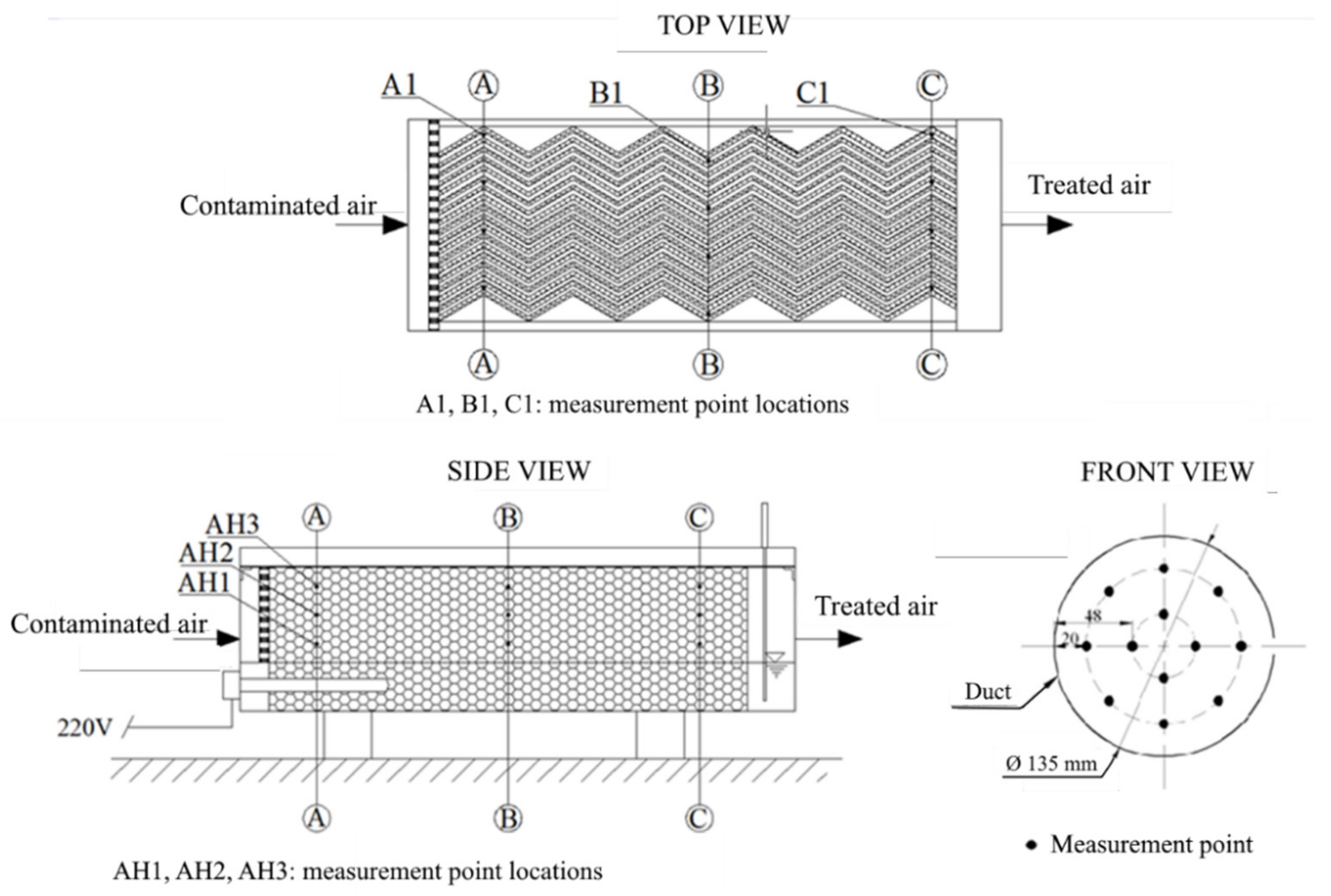

2.2. Pressure Drop Measurements

2.3. Statistical Data Evaluation

3. Results and Discussion

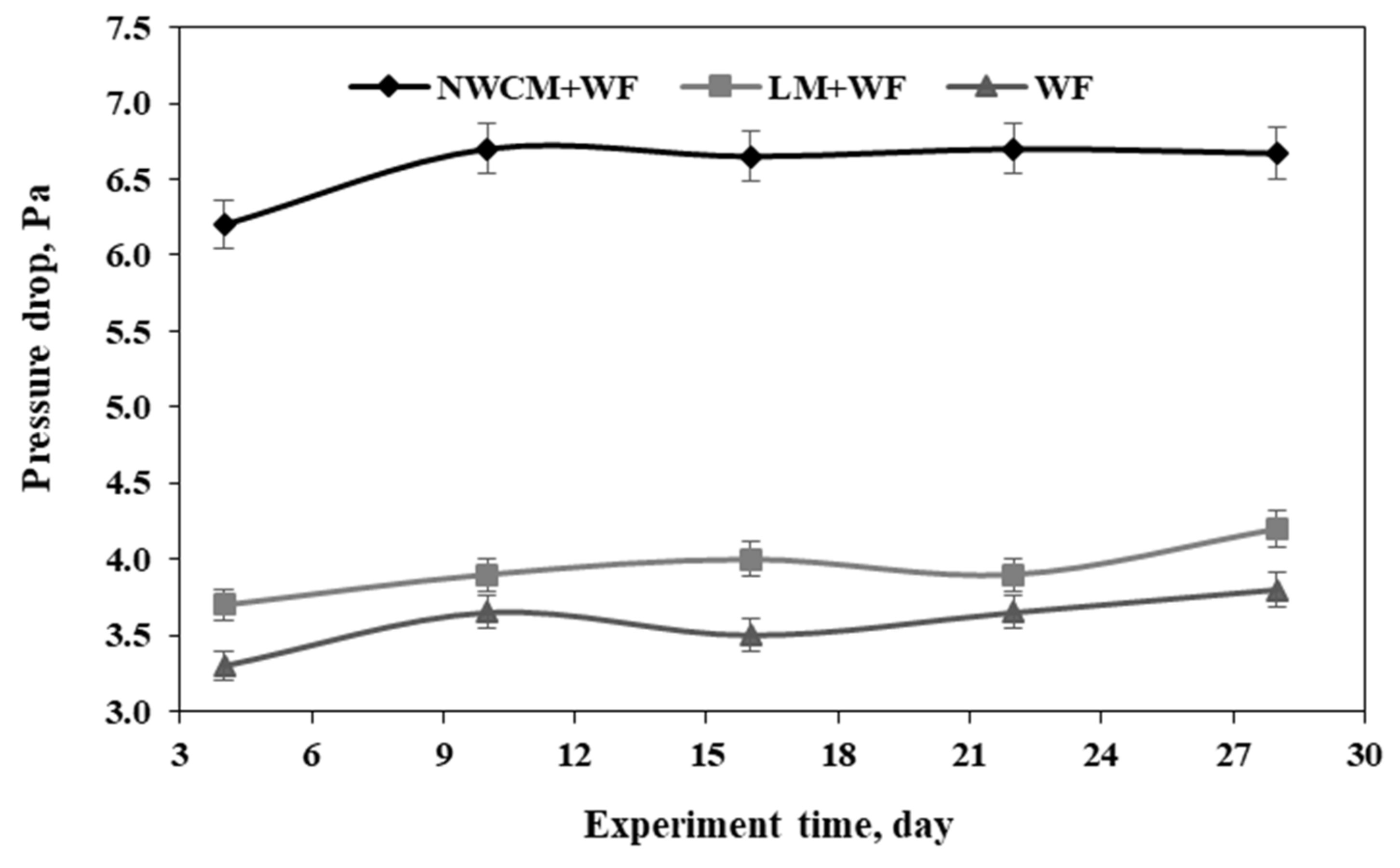

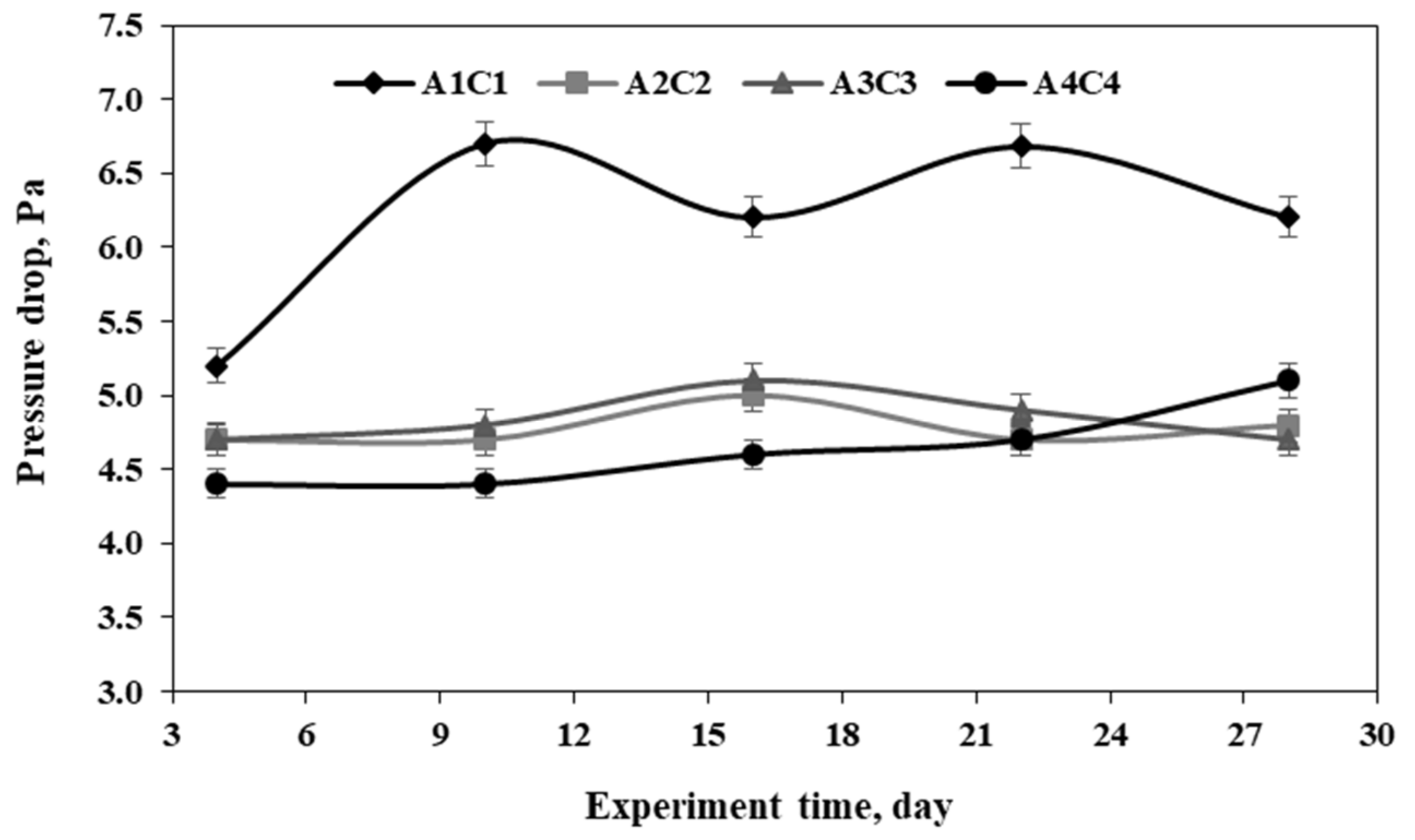

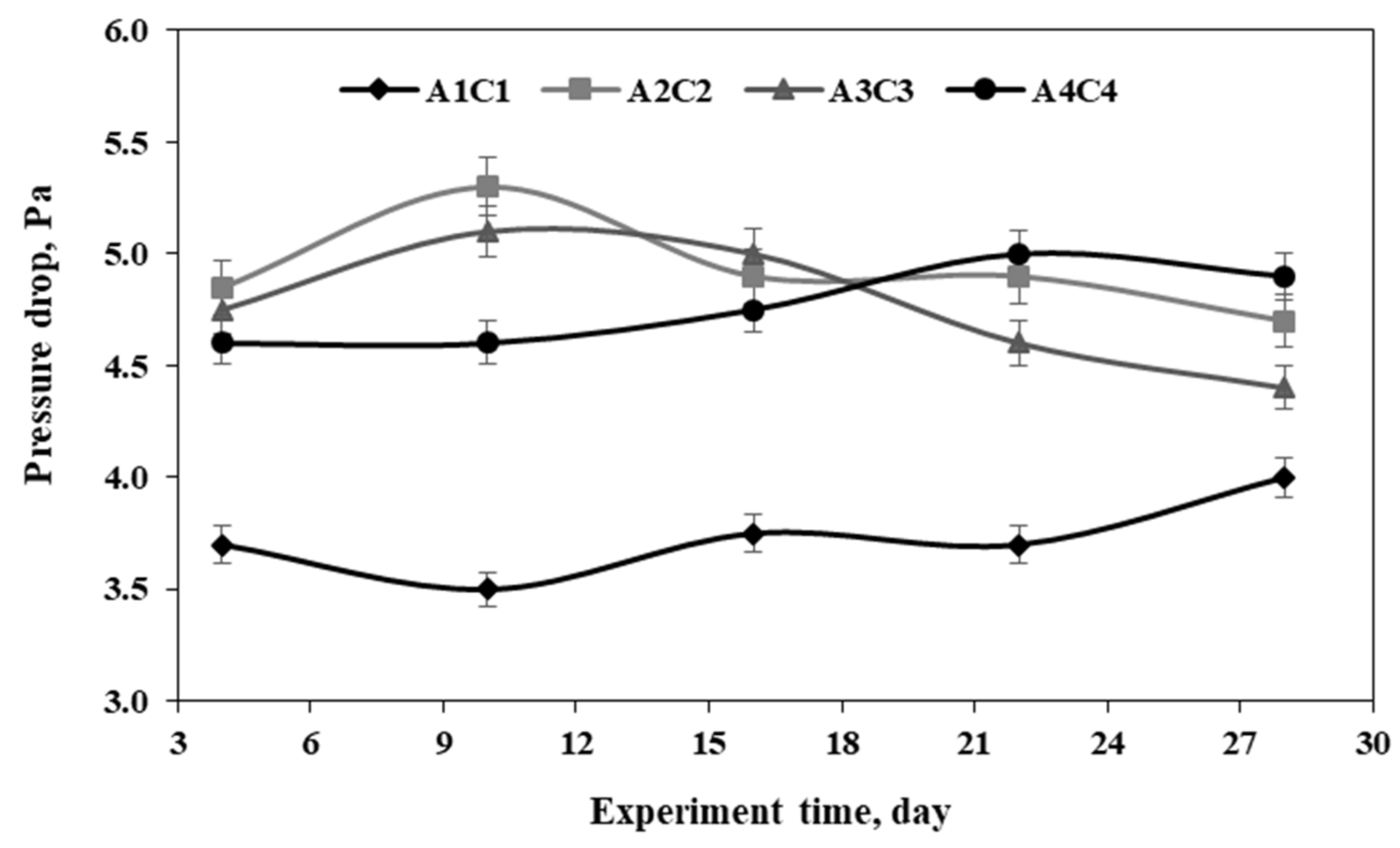

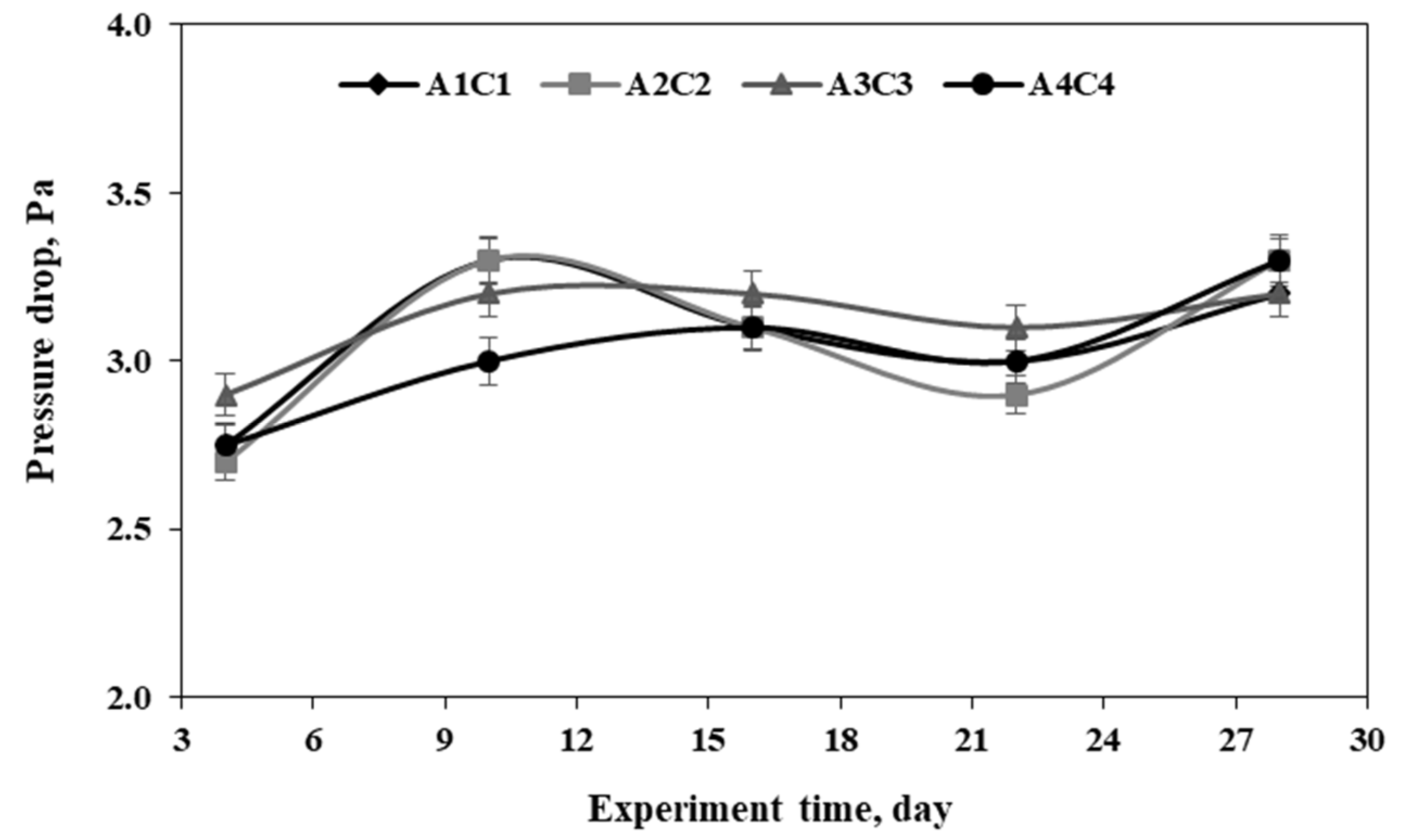

3.1. Pressure Drops of Different Packing Materials

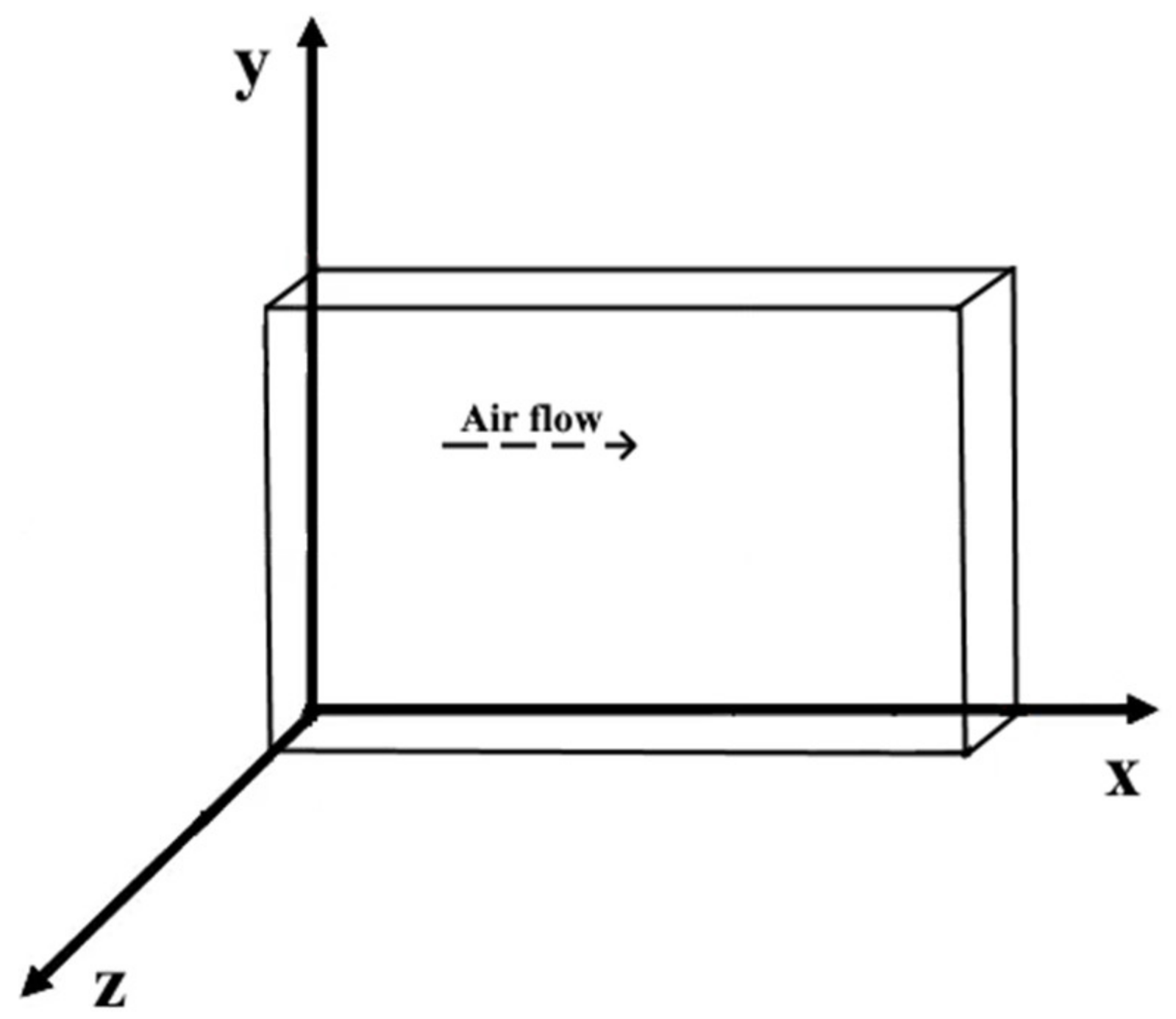

3.2. Modeling of Airflow Movement

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rene, E.R.; Murthy, D.V.S.; Swaminathan, T. Effect of Flow Rate, Concentration and Transient—State Operations on the Performance of a Biofilter Treating Xylene Vapors. Water Air Soil Pollut. 2009, 211, 79–93. [Google Scholar] [CrossRef]

- Baltrėnas, P.; Januševičius, T.; Zagorskis, A.; Baltrėnaitė-Gedienė, E. Removal of ammonia by biofilters with straight and wavy lamellar plates. Int. J. Environ. Sci. Technol. 2020, 2020, 1–10. [Google Scholar] [CrossRef]

- Jeong, D.; Oh, J.; Yum, I.; Lee, Y. Removal of VOCs from their aqueous solution by pervaporation with PDMS-zeolite composite membrane. Desalin. Water Treat. 2010, 17, 242–247. [Google Scholar] [CrossRef]

- Omri, I.; Aouidi, F.; Bouallagui, H.; Godon, J.-J.; Hamdi, M. Performance study of biofilter developed to treat H2S from wastewater odour. Saudi J. Biol. Sci. 2013, 20, 169–176. [Google Scholar] [CrossRef] [PubMed]

- Santos, S.; Jones, K.; Abdul, R.; Boswell, J.; Paca, J. Treatment of wet process hardboard plant VOC emissions by a pilot scale biological system. Biochem. Eng. J. 2007, 37, 261–270. [Google Scholar] [CrossRef]

- Zigmontienė, A.; Žarnauskas, L. Investigation and analysis of air-cleaning biofilter hybrid biocharge quantitative and qualitative parameters. J. Environ. Eng. Landsc. Manag. 2011, 19, 81–88. [Google Scholar] [CrossRef]

- Sakuma, T.; Jinsiriwanit, S.; Hattori, T.; Deshusses, M.A. Removal of ammonia from contaminated air in a biotrickling filter—Denitrifying bioreactor combination system. Water Res. 2008, 42, 4507–4513. [Google Scholar] [CrossRef]

- Baltrėnas, P.; Zagorskis, A. Investigation into the Air Treatment Efficiency of Biofilters of Different Structures. J. Environ. Eng. Landsc. Manag. 2010, 18, 23–31. [Google Scholar] [CrossRef]

- Gaudin, F.; Andrès, Y.; Le Cloirec, P. Packing material formulation for odorous emission biofiltration. Chemosphere 2008, 70, 958–966. [Google Scholar] [CrossRef]

- Gallastegui, G.; Ramirez, A.Á.; Elías, A.; Jones, J.; Heitz, M. Performance and macrokinetic analysis of biofiltration of toluene and p-xylene mixtures in a conventional biofilter packed with inert material. Bioresour. Technol. 2011, 102, 7657–7665. [Google Scholar] [CrossRef]

- Lee, S.-H.; Li, C.; Heber, A.J.; Ni, J.; Huang, H. Biofiltration of a mixture of ethylene, ammonia, n-butanol, and acetone gases. Bioresour. Technol. 2013, 127, 366–377. [Google Scholar] [CrossRef]

- Rahul; Mathur, A.K.; Balomajumder, C. Biological treatment and modeling aspect of BTEX abatement process in a biofilter. Bioresour. Technol. 2013, 142, 9–17. [Google Scholar] [CrossRef]

- Woudberg, S.; Van Jaarsveld, J.; Dumont, E. Predicting the pressure drop of a biofilter and the specific surface area of the packing material. Powder Technol. 2019, 342, 233–245. [Google Scholar] [CrossRef]

- Shareefdeen, Z.; Herner, B.; Webb, D.; Polenek, S.; Wilson, S. Removing volatile organic compound (VOC) emissions from a printed circuit board manufacturing facility using pilot- and commercial-scale biofilters. Environ. Prog. 2002, 21, 196–201. [Google Scholar] [CrossRef]

- Ryu, H.W.; Cho, K.-S.; Chung, D.J. Relationships between biomass, pressure drop, and performance in a polyurethane biofilter. Bioresour. Technol. 2010, 101, 1745–1751. [Google Scholar] [CrossRef]

- Dorado, A.D.; Lafuente, J.; Gabriel, D.; Gamisans, X. The role of water in the performance of biofilters: Parameterization of pressure drop and sorption capacities for common packing materials. J. Hazard. Mater. 2010, 180, 693–702. [Google Scholar] [CrossRef]

- Morgan-Sagastume, F.; Sleep, B.E.; Allen, D.G. Effects of Biomass Growth on Gas Pressure Drop in Biofilters. J. Environ. Eng. 2001, 127, 388–396. [Google Scholar] [CrossRef]

- Andreasen, R.R.; Nicolai, R.E.; Poulsen, T.G. Pressure drop in biofilters as related to dust and biomass accumulation. J. Chem. Technol. Biotechnol. 2012, 87, 806–816. [Google Scholar] [CrossRef]

- Baltrėnas, P.; Kleiza, J.; Idzelis, R.L. Investigation into The Aerodynamic Processes Of Air Treatment Using A Plate-Type Biofilter. Environ. Technol. 2015, 37, 1–13. [Google Scholar] [CrossRef]

- Baskaran, D.; Rajamanickam, R.; Vaidyalingam, B. Effect of concentration and gas flow rate on the removal of gas-phase trichloroethylene in a novel packed biofilter. Bioresour. Technol. Rep. 2020, 9, 100387. [Google Scholar] [CrossRef]

- Kennes, C.; Thalasso, F. Review: Waste gas biotreatment technology. J. Chem. Technol. Biotechnol. 1998, 72, 303–319. [Google Scholar] [CrossRef]

- Kumar, M.; Giri, B.S.; Kim, K.-H.; Singh, R.P.; Rene, E.R.; López, M.E.; Rai, B.N.; Singh, H.; Prasad, D.; Singh, R.S. Performance of a biofilter with compost and activated carbon based packing material for gas-phase toluene removal under extremely high loading rates. Bioresour. Technol. 2019, 285, 121317. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baltrėnas, P.; Januševičius, T.; Kleiza, J. Effect of Packing Material Composition on the Aerodynamic Processes in a Wavy Lamellar Plate-Type Biofilter. Processes 2021, 9, 625. https://doi.org/10.3390/pr9040625

Baltrėnas P, Januševičius T, Kleiza J. Effect of Packing Material Composition on the Aerodynamic Processes in a Wavy Lamellar Plate-Type Biofilter. Processes. 2021; 9(4):625. https://doi.org/10.3390/pr9040625

Chicago/Turabian StyleBaltrėnas, Pranas, Tomas Januševičius, and Jonas Kleiza. 2021. "Effect of Packing Material Composition on the Aerodynamic Processes in a Wavy Lamellar Plate-Type Biofilter" Processes 9, no. 4: 625. https://doi.org/10.3390/pr9040625

APA StyleBaltrėnas, P., Januševičius, T., & Kleiza, J. (2021). Effect of Packing Material Composition on the Aerodynamic Processes in a Wavy Lamellar Plate-Type Biofilter. Processes, 9(4), 625. https://doi.org/10.3390/pr9040625