Experimental Study on the Effect of Basalt Fiber and Sodium Alginate in Polymer Concrete Exposed to Elevated Temperature

Abstract

1. Introduction

| Reference. | Alginate Type | Weight Fraction (% of Cement) | Remarks |

|---|---|---|---|

| Mohammadyan-Yasouj et al. [24] | NaAlg | 0.1 |

|

| Ouwerx et al. [19] | Alginate gel bead | - |

|

| Pathak et al. [16] | Alginic acid and metal alginates | - |

|

| Heidari et al. [21] | Alginic acid | 0.5 and 1 |

|

| Mignon et al. [22] | NaAlg, CaAlg | 0.5 and 1 |

|

| Reference. | Fiber Type | Length (mm) | Weight Fraction (%) | Remarks |

|---|---|---|---|---|

| Jiang et al. [54] | Basalt Polypropylene | 12 and 22 4–19 | 0.05, 0.1, 0.3, & 0.5 |

|

| Kabay [59] | Basalt | 12 and 24 | 0.07 and 0.14 |

|

| Ayoub et al. [62] | Basalt | 25 | 1, 2, and 3 |

|

| Kizilkanat et al. [57] | Basalt Glass | 12 12 | 0.25, 0.5, 0.75, and 1 |

|

| Fenu et al. [56] | Basalt Glass | 12 12 | 3 and 5 |

|

| Shafiqh et al. [55] | Basalt Polyvinyl Alcohol | 25 30 | 1, 2, and 3 |

|

| Girgin [63] | Basalt Glass | 24 24 | 2 |

|

| Afroz et al. [9] | Basalt (Chinese) Basalt (Russian) | 3 25 | 0.5 |

|

| Zhao et al. [64] | Basalt | 18 | 1, 1.5, 2 & 2.5 |

|

| Katkhuda and Shatarat [65] | Basalt | 18 | 0.1, 0.3, 0.5, 1, and 1.5 |

|

| Sun et al. [66] | Basalt | 6 and 12 | 1, 2, 3, 4, & 5 |

|

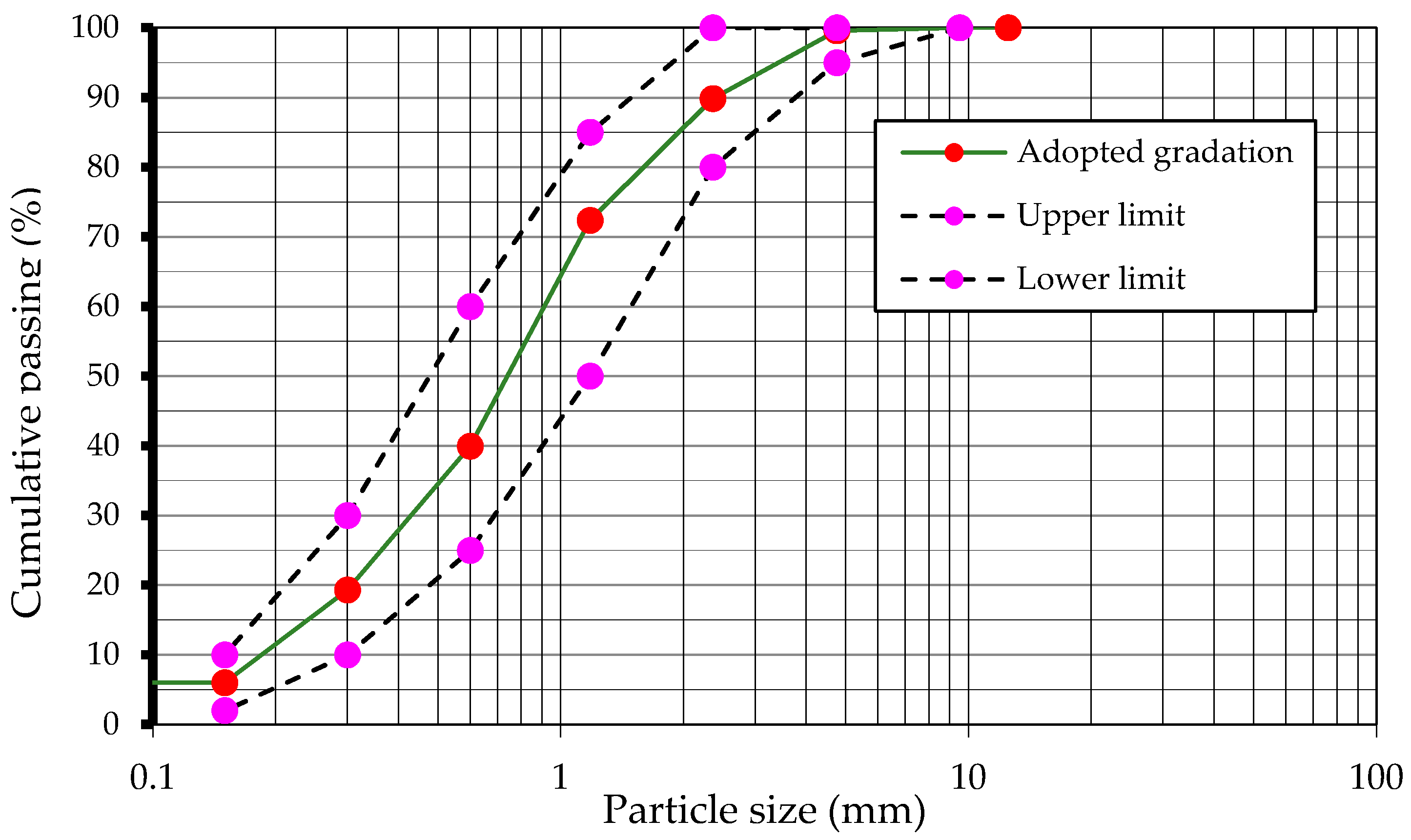

2. Materials and Methods

2.1. Materials

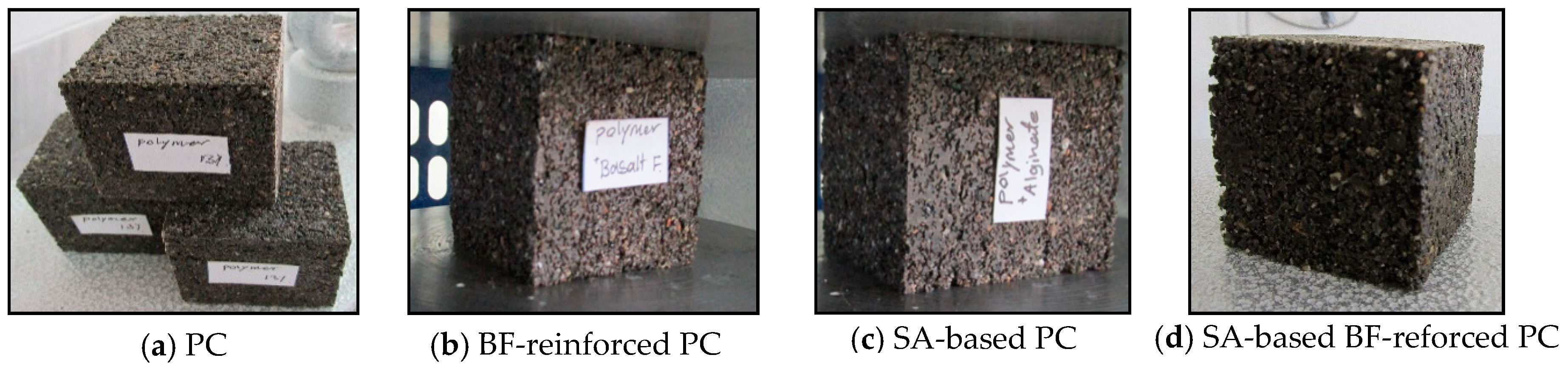

2.2. Mix Designs and Preparation of Specimens

2.3. Compressive Strength Testing

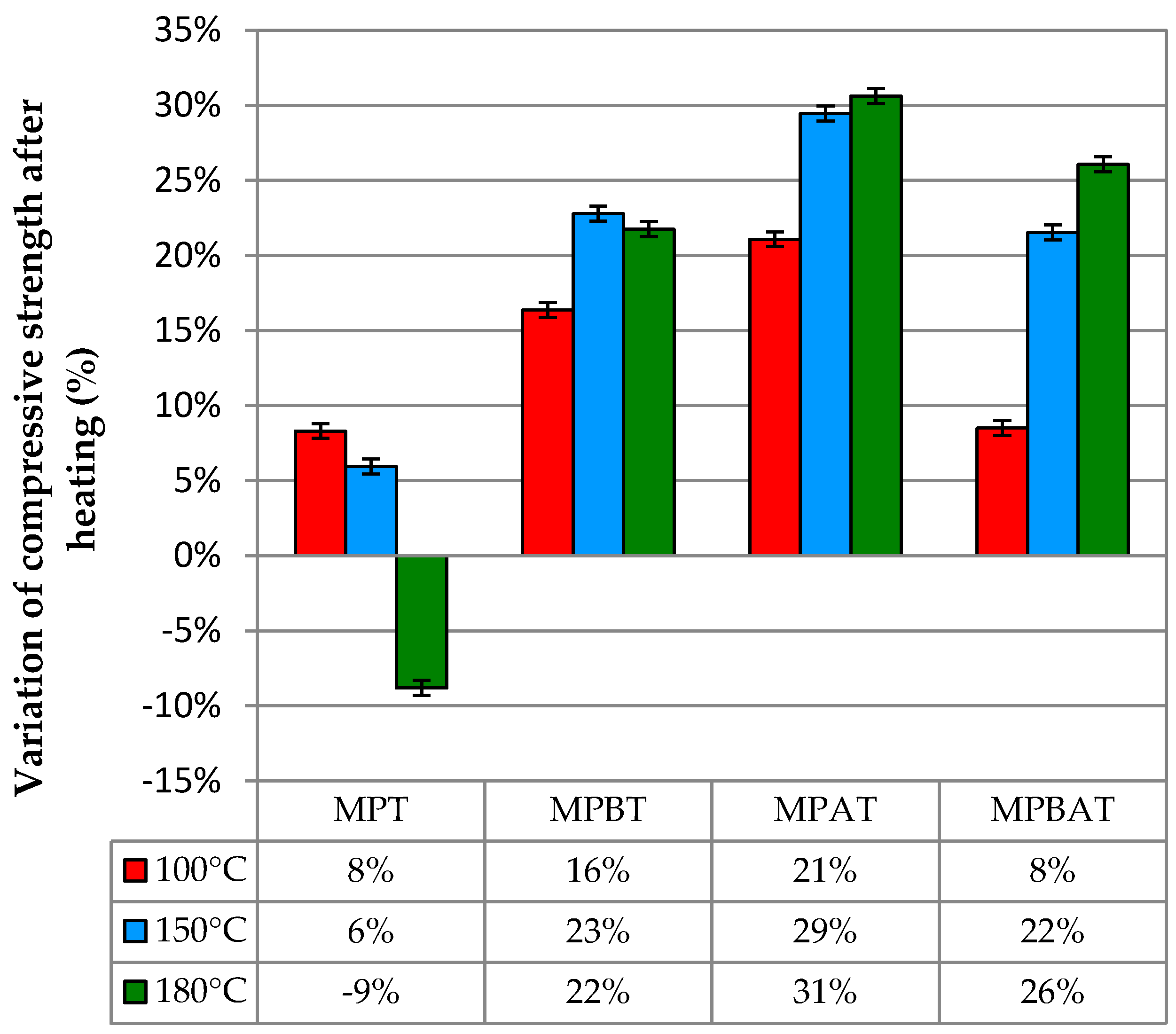

3. Result and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mohammadyan-Yasouj, S.E.; Marsono, A.K.; Abdullah, R.; Moghadasi, M. Wide beam shear behavior with diverse types of reinforcement. ACI Struct. J. 2015, 112, 199–208. [Google Scholar] [CrossRef][Green Version]

- Moghadasi, M.; Marsono, A.K.; Mohammadyan-Yasouj, S.E. A study on rotational behaviour of a new industrialised building system connection. Steel Compos. Struct. 2017, 25, 245–255. [Google Scholar]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Koloor, S.S.R.; Petrů, M. A Comparative Study of the Data-driven Stochastic Subspace Methods for Health Monitoring of Structures: A Bridge Case Study. Appl. Sci. 2020, 10, 3132. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Heidarrezaei, M.; Koloor, S.S.R.; Petru, M. Vehicle-assisted techniques for health monitoring of bridges. Sensors 2020, 20, 3460. [Google Scholar] [CrossRef] [PubMed]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Heidarrezaei, M.; Rahimian Koloor, S.S.; Petrů, M. Application of the Subspace-Based Methods in Health Monitoring of Civil Structures: A Systematic Review and Meta-Analysis. Appl. Sci. 2020, 10, 3607. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Koloor, S.S.R.; Petrů, M. Health Monitoring of Civil Infrastructures by Subspace System Identification Method: An Overview. Appl. Sci. 2020, 10, 2786. [Google Scholar] [CrossRef]

- Aslani, F.; Samali, B. Predicting the bond between concrete and reinforcing steel at elevated temperatures. Struct. Eng. Mech. 2013, 48, 643–660. [Google Scholar] [CrossRef]

- Shokravi, H.; Mohammadyan-Yasouj, S.E.; Rahimian Koloor, S.S.; Petrů, M.; Heidarrezaei, M. Effect of alumina additives on mechanical and fresh properties of self-compacting concrete: A review. Processes 2021. (under review). [Google Scholar]

- Mohammadyan-Yasouj, S.E.; Heidari, N.; Shokravi, H. Influence of Waste Alumina Powder on Self-compacting Concrete Resistance under Elevated Temperature. J. Build. Eng. 2021, 14. (under review). [Google Scholar]

- Awal, A.S.M.A.; Shehu, I.A. Performance evaluation of concrete containing high volume palm oil fuel ash exposed to elevated temperature. Constr. Build. Mater. 2015, 76, 214–220. [Google Scholar] [CrossRef]

- Ahmad, S.; Sallam, Y.S.; Al-Hawas, M.A. Effects of key factors on compressive and tensile strengths of concrete exposed to elevated temperatures. Arab. J. Sci. Eng. 2014, 39, 4507–4513. [Google Scholar] [CrossRef]

- Thirumurugan, S.; Anandan, S. Residual strength characteristics of polymer fibre concrete exposed to elevated temperature. Eng. J. 2015, 19, 117–131. [Google Scholar] [CrossRef][Green Version]

- Fraternali, F.; Ciancia, V.; Chechile, R.; Rizzano, G.; Feo, L.; Incarnato, L. Experimental study of the thermo-mechanical properties of recycled PET fiber-reinforced concrete. Compos. Struct. 2011, 93, 2368–2374. [Google Scholar] [CrossRef]

- Rabehi, B.; Ghernouti, Y.; Boumchedda, K.; Li, A.; Drir, A. Durability and thermal stability of ultra high-performance fibre-reinforced concrete (UHPFRC) incorporating calcined clay. Eur. J. Environ. Civ. Eng. 2017, 21, 594–611. [Google Scholar] [CrossRef]

- Lee, S.-J.; Kim, S.-H.; Won, J.-P. Strength and fire resistance of a high-strength nano-polymer modified cementitious composite. Compos. Struct. 2017, 173, 96–105. [Google Scholar] [CrossRef]

- Pathak, T.S.; San Kim, J.; Lee, S.-J.; Baek, D.-J.; Paeng, K.-J. Preparation of alginic acid and metal alginate from algae and their comparative study. J. Polym. Environ. 2008, 16, 198–204. [Google Scholar] [CrossRef]

- Engbert, A.; Gruber, S.; Plank, J. The effect of alginates on the hydration of calcium aluminate cement. Carbohydr. Polym. 2020, 236, 116038. [Google Scholar] [CrossRef]

- Wang, J.; Mignon, A.; Snoeck, D.; Wiktor, V.; Van Vliergerghe, S.; Boon, N.; De Belie, N. Application of modified-alginate encapsulated carbonate producing bacteria in concrete: A promising strategy for crack self-healing. Front. Microbiol. 2015, 6, 1088. [Google Scholar] [CrossRef]

- Ouwerx, C.; Velings, N.; Mestdagh, M.M.; Axelos, M.A.V. Physico-chemical properties and rheology of alginate gel beads formed with various divalent cations. Polym. Gels Netw. 1998, 6, 393–408. [Google Scholar] [CrossRef]

- Abbas, W.A.; Mohsen, H.M. Effect of Biopolymer Alginate on some properties of concrete. J. Eng. 2020, 26, 121–131. [Google Scholar]

- Heidari, A.; Ghaffari, F.; Ahmadvand, H. Properties of Self Compacting Concrete Incorporating Alginate and Nano Silica. Asian J. Civil Eng. Build. Hous. 2015, 16, 1–16. [Google Scholar]

- Mignon, A.; Snoeck, D.; D’Halluin, K.; Balcaen, L.; Vanhaecke, F.; Dubruel, P.; Van Vlierberghe, S.; De Belie, N. Alginate biopolymers: Counteracting the impact of superabsorbent polymers on mortar strength. Constr. Build. Mater. 2016, 110, 169–174. [Google Scholar] [CrossRef]

- DeBrouse, D.R. Alginate-Based Building Materials; World Intellectual Property Organization: Geneva, Switzerland, 2012. [Google Scholar]

- Mohammadyan-Yasouj, S.E.; Ahangar, H.A.; Oskoei, N.A.; Shokravi, H.; Koloor, S.S.R.; Petrů, M. Thermal Performance of Alginate Concrete Reinforced with Basalt Fiber. Crystals 2020, 10, 779. [Google Scholar] [CrossRef]

- Barbuta, M.; Rujanu, M.; Nicuta, A. Characterization of polymer concrete with different wastes additions. Procedia Technol. 2016, 22, 407–412. [Google Scholar] [CrossRef]

- Lokuge, W.; Aravinthan, T. Effect of fly ash on the behaviour of polymer concrete with different types of resin. Mater. Des. 2013, 51, 175–181. [Google Scholar] [CrossRef]

- Venkatesh, B.; Student, U.G. Review on performance of polymer concrete with resins and its applications. Int. J. Pure Appl. Math. 2018, 119, 175–184. [Google Scholar]

- Abd_Elmoaty, A.M. Self-healing of polymer modified concrete. Alexandria Eng. J. 2011, 50, 171–178. [Google Scholar] [CrossRef]

- Rebeiz, K.S. Precast use of polymer concrete using unsaturated polyester resin based on recycled PET waste. Constr. Build. Mater. 1996, 10, 215–220. [Google Scholar] [CrossRef]

- Reis, J.M.L. Effect of temperature on the mechanical properties of polymer mortars. Mater. Res. 2012, 15, 645–649. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Aravinthan, T.; Van Erp, G. Properties of epoxy polymer concrete matrix: Effect of resin-to-filler ratio and determination of optimal mix for composite railway sleepers. Constr. Build. Mater. 2016, 124, 287–300. [Google Scholar] [CrossRef]

- Golestaneh, M.; Amini, G.; Najafpour, G.D.; Beygi, M.A. Evaluation of mechanical strength of epoxy polymer concrete with silica powder as filler. World Appl. Sci. J. 2010, 9, 216–220. [Google Scholar]

- Elalaoui, O.; Ghorbel, E.; Mignot, V.; Ouezdou, M. Ben Mechanical and physical properties of epoxy polymer concrete after exposure to temperatures up to 250 C. Constr. Build. Mater. 2012, 27, 415–424. [Google Scholar] [CrossRef]

- Dias, D.P.; Thaumaturgo, C. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Reis, J.M.L. Mechanical characterization of fiber reinforced polymer concrete. Mater. Res. 2005, 8, 357–360. [Google Scholar] [CrossRef]

- Hassani Niaki, M.; Fereidoon, A.; Ghorbanzadeh Ahangari, M. Mechanical properties of epoxy/basalt polymer concrete: Experimental and analytical study. Struct. Concr. 2018, 19, 366–373. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, C.; Chu, P.K.; Lv, F.; Zhang, C.; Ji, J.; Zhang, R.; Wang, H. Mechanical and thermal properties of basalt fiber reinforced poly (butylene succinate) composites. Mater. Chem. Phys. 2012, 133, 845–849. [Google Scholar] [CrossRef]

- Mohamad, S.A.; Al-Hamd, R.K.S.; Khaled, T.T. Investigating the effect of elevated temperatures on the properties of mortar produced with volcanic ash. Innov. Infrastruct. Solut. 2020, 5, 1–11. [Google Scholar] [CrossRef]

- Abdel-Fattah, H.; El Hawary, M.M.; Falah, A. Effect of elevated temperatures on the residual fracture toughness of epoxy modified concrete. Kuwait J. Sci. Eng. 2000, 27, 27–39. [Google Scholar]

- Al-Salloum, Y.A.; Elsanadedy, H.M.; Abadel, A.A. Behavior of FRP-confined concrete after high temperature exposure. Constr. Build. Mater. 2011, 25, 838–850. [Google Scholar] [CrossRef]

- Behnood, A.; Ziari, H. Effects of silica fume addition and water to cement ratio on the properties of high-strength concrete after exposure to high temperatures. Cem. Concr. Compos. 2008, 30, 106–112. [Google Scholar] [CrossRef]

- Amin, M.; Tayeh, B.A. Investigating the mechanical and microstructure properties of fibre-reinforced lightweight concrete under elevated temperatures. Case Stud. Constr. Mater. 2020, 13, e00459. [Google Scholar] [CrossRef]

- Tang, Y.; Feng, W.; Feng, W.; Chen, J.; Bao, D.; Li, L. Compressive properties of rubber-modified recycled aggregate concrete subjected to elevated temperatures. Constr. Build. Mater. 2021, 268, 121181. [Google Scholar] [CrossRef]

- De Larissa, C.A.; dos Anjos, M.A.S.; de Sa, M.V.V.A.; de Souza, N.S.L.; de Farias, E.C. Effect of high temperatures on self-compacting concrete with high levels of sugarcane bagasse ash and metakaolin. Constr. Build. Mater. 2020, 248, 118715. [Google Scholar]

- Wang, W.-C.; Wang, H.-Y.; Chang, K.-H.; Wang, S.-Y. Effect of high temperature on the strength and thermal conductivity of glass fiber concrete. Constr. Build. Mater. 2020, 245, 118387. [Google Scholar] [CrossRef]

- Zhou, J.; Lu, D.; Yang, Y.; Gong, Y.; Ma, X.; Yu, B.; Yan, B. Physical and Mechanical Properties of HighStrength Concrete Modified with Supplementary Cementitious Materials after Exposure to Elevated Temperature up to 1000 °C. Materials 2020, 13, 532. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Li, L.; Yuan, C.; Wang, Q.; Sarker, P.K.; Shi, X. Deterioration of ambient-cured and heat-cured fly ash geopolymer concrete by high temperature exposure and prediction of its residual compressive strength. Constr. Build. Mater. 2020, 262, 120924. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, T.; Liu, Z.; Li, G.; Jiang, J. Seismic behavior of steel reinforced concrete cross-shaped columns after exposure to high temperatures. Eng. Struct. 2021, 230, 111723. [Google Scholar] [CrossRef]

- Alharbi, Y.R.; Abadel, A.A.; Elsayed, N.; Mayhoub, O.; Kohail, M. Mechanical properties of EAFS concrete after subjected to elevated temperature. Ain Shams Eng. J. 2020. [Google Scholar] [CrossRef]

- Sarayu, K.; Gopinath, S.; Ramachandra, M.A.; Iyer, N.R. Structural stability of basalt fibers with varying biochemical conditions-A invitro and invivo study. J. Build. Eng. 2016, 7, 38–45. [Google Scholar] [CrossRef]

- Niaki, M.H.; Fereidoon, A.; Ahangari, M.G. Experimental study on the mechanical and thermal properties of basalt fiber and nanoclay reinforced polymer concrete. Compos. Struct. 2018, 191, 231–238. [Google Scholar] [CrossRef]

- Elalaoui, O.; Ghorbel, E.; Ouezdou, M. Ben Influence of flame retardant addition on the durability of epoxy based polymer concrete after exposition to elevated temperature. Constr. Build. Mater. 2018, 192, 233–239. [Google Scholar] [CrossRef]

- Gorninski, J.P.; Tonet, K.G.; Sokołowska, J.J. Use of polishing alumina as flame retardant in orthophthalic polyester resin matrix composites. In Proceedings of the Advanced Materials Research; Trans Tech Publications: Zürich, Switzerland, 2015; Volume 1129, pp. 209–216. [Google Scholar]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Shafiq, N.; Ayub, T.; Khan, S.U. Investigating the performance of PVA and basalt fibre reinforced beams subjected to flexural action. Compos. Struct. 2016, 153, 30–41. [Google Scholar] [CrossRef]

- Fenu, L.; Forni, D.; Cadoni, E. Dynamic behaviour of cement mortars reinforced with glass and basalt fibres. Compos. Part B Eng. 2016, 92, 142–150. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Sarkar, A.; Hajihosseini, M. Feasibility of Improving the Mechanical Properties of Concrete Pavement Using Basalt Fibers. J. Test. Eval. 2020, 48, 2908–2917. [Google Scholar] [CrossRef]

- Kabay, N. Abrasion resistance and fracture energy of concretes with basalt fiber. Constr. Build. Mater. 2014, 50, 95–101. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M. Effect of hybrid basalt fibre length and content on properties of cementitious composites. Mag. Concr. Res. 2020, 1–12. [Google Scholar] [CrossRef]

- Amuthakkannan, P.; Manikandan, V.; Jappes, J.T.W.; Uthayakumar, M. Effect of fibre length and fibre content on mechanical properties of short basalt fibre reinforced polymer matrix composites. Mater. Phys. Mech. 2013, 16, 107–117. [Google Scholar]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Mechanical properties of high-performance concrete reinforced with basalt fibers. Procedia Eng. 2014, 77, 131–139. [Google Scholar] [CrossRef]

- Girgin, Z.C.; Yıldırım, M.T. Usability of basalt fibres in fibre reinforced cement composites. Mater. Struct. 2016, 49, 3309–3319. [Google Scholar] [CrossRef]

- Zhao, Y.-R.; Wang, L.; Lei, Z.-K.; Han, X.-F.; Xing, Y.-M. Experimental study on dynamic mechanical properties of the basalt fiber reinforced concrete after the freeze-thaw based on the digital image correlation method. Constr. Build. Mater. 2017, 147, 194–202. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Sun, X.; Gao, Z.; Cao, P.; Zhou, C. Mechanical properties tests and multiscale numerical simulations for basalt fiber reinforced concrete. Constr. Build. Mater. 2019, 202, 58–72. [Google Scholar] [CrossRef]

- Afroz, M.; Patnaikuni, I.; Venkatesan, S. Chemical durability and performance of modified basalt fiber in concrete medium. Constr. Build. Mater. 2017, 154, 191–203. [Google Scholar] [CrossRef]

- Bi, J.; Huo, L.; Zhao, Y.; Qiao, H. Modified the smeared crack constitutive model of fiber reinforced concrete under uniaxial loading. Constr. Build. Mater. 2020, 250, 118916. [Google Scholar] [CrossRef]

- Committee, A.C.I. Guide for the use of polymers in concrete. ACI Comm. Rep. 2009, 548, 1–100. [Google Scholar]

- He, D.; Lu, Z. Experimental Study on Mechanical Properties of Chopped Basalt Fiber Reinforced Concrete. J. Henan Univ. Nat. Sci. 2009, 3, 320–322. [Google Scholar]

- Donkor, P.; Obonyo, E. Earthen construction materials: Assessing the feasibility of improving strength and deformability of compressed earth blocks using polypropylene fibers. Mater. Des. 2015, 83, 813–819. [Google Scholar] [CrossRef]

- Lahouar, M.A.; Caron, J.-F.; Pinoteau, N.; Forêt, G.; Benzarti, K. Mechanical behavior of adhesive anchors under high temperature exposure: Experimental investigation. Int. J. Adhes. Adhes. 2017, 78, 200–211. [Google Scholar] [CrossRef]

- Joshani, M.; Koloor, S.S.R.; Abdullah, R. Damage Mechanics Model for Fracture Process of Steel-concrete Composite Slabs. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2012; pp. 339–345. [Google Scholar]

| Remarks | Filler and Polymer | Codes & Sample Size (mm) | Test Age (Day) | Conducted Tests and Sample Monitoring | Ref. | ||

|---|---|---|---|---|---|---|---|

| Amount (% of the Total Volume (Vol%) or the Total Weight (wt %)) | Details | Name | |||||

| 100, 150, & 200 Vol% | 50–60, 600, & 1100 μm Size | Silica Fume |

| - |

| Golestaneh et al. 2010 [32] |

| 10, 15, & 20 wt % | Epoxy, Bisphenol A | Epoxy Resin | |||||

| 88 Vol% | 245 μm | Only Coarse Aggregate |

| 7 |

| Reis 2012 [30] |

| 12 wt % | Diglycidyl ether bisphenol A & an aliphatic amineHardener, RR515 | Epoxy Resin | |||||

| - | (0–4) × 103 μm | Sand |

| 7 & 28 |

| Elalaoui et al. 2012 [33] |

| - | (4–10) × 103 μm | Gravel | |||||

| 6, 9, 13, & 16 wt % | Bisphenol A diglycidyl ether resin, Eponal 371 | Epoxy resin | |||||

| 0, 3, 10, 13, 20, 21, & 23 Vol% | 15 μm (Type F) | Fly Ash |

| 3, 7, 14, 21, & 28 |

| Lokuge & Aravinthan 2013 [26] |

| 20, 22, 30, 40, & 43 Vol% | Orthophthalic | Polyester Resin | |||||

| Bisphenol | Vinylester Resin | ||||||

| Thixotropic | Epoxy Resin | ||||||

| 0, 10, 20, 30, 40, 50, & 60 Vol% | Fire Retardant, Hollow Microsphere, Fly Ash | light-weight Filler |

|

| Ferdous et al. 2016 [31] | |

| Remarks | Basalt and Polymer | Codes & Sample Size (mm) | Test Age (Day) | Conducted Tests and Sample Monitoring | Ref. | ||||

|---|---|---|---|---|---|---|---|---|---|

| Amount (% of the Total Volume (Vol%) or the Total Weight (wt %)) | Etra details | Diameter (μm) | Length (mm) | Name | |||||

| (0, 0.5, 1) Vol% | - | 9 | 45 | Basalt Fibre (BF) |

| 28 |

| Dias & Thaumaturgo 2005 [34] |

| A/B = 1 (13.85 wt %) & 47.7 wt % | A: SiO2/Al2O3 ratio = 5.35, (Na2O + K2O)/SiO2 = 0.209, B:SiO2/Na2O = 2.24, KOH = 14M | - | - | Geopolymer (Poly(Siloxo-Sialate)) | |||||

| 1 & 2 Vol% | - | Chopped | 6 | Carbon Fiber (CF) |

| 7 |

| Reis 2005 [35] |

| 6 | Glass Fiber (GF) | ||||||||

| 20% wt % | Eposil 551 (Silicem®), Based on a diglycidyl-ether of bisphenol A, Aliphatic amine hardener | - | - | Epoxy Polymer | |||||

| (0.0–15) Vol% | - | 10 | continuous twistless roving | BF (coated by silane coupling agent) |

| - |

| Zhang et al. 2012 [37] |

| 20–30 wt % | Diglycidyl ether of bisphenol A resin (DGEBA), Low viscosity (CY 184), Polyaminehardener (Aradur ®2965) | - | - | Resin | |||||

| (0.5, 1, 1.5, & 2) Vol% | - | 13 | 24 | BF |

| 14 & 28 |

| Sarayu et al. 2016 [50] |

| 97–85 vol% | Mp 114 °C, Vicat softening temperature 96 °C | - | - | Polymer/Styrene Butadiene Rubber (SBR) | |||||

| (0, 70, 72.5, 75, 77.5, & 80) Vol% | - | 1–5 | - | Crushed Basalt (aggregate) |

| 7 & 28 |

| Niaki et al. 2017 [36] |

| Cutting Length (mm) | 10 |

|---|---|

| Diameter (μm) | 17 |

| Density (gr/cm3) | 2.65 |

| Elastic modulus (GPa) | 93–110 |

| Tensile strength (MPa) | 4100–4800 |

| Elongation (%) | 1.3–3.2 |

| Softening point (˚C) | 1050 |

| Water absorption (%) | <0.5 |

| Name ** | BF (%) * | SA (%) * | Evaluation Temperature (°C) |

|---|---|---|---|

| MPT0 | - | - | 0 |

| MPT100 | - | - | 100 |

| MPT150 | - | - | 150 |

| MPT180 | - | - | 180 |

| MPBT0 | 0.2 | - | 0 |

| MPBT100 | 0.2 | - | 100 |

| MPBT150 | 0.2 | - | 150 |

| MPBT180 | 0.2 | - | 180 |

| MPAT0 | - | 0.1 | 0 |

| MPAT100 | - | 0.1 | 100 |

| MPAT150 | - | 0.1 | 150 |

| MPAT180 | - | 0.1 | 180 |

| MPBAT0 | 0.2 | 0.1 | 0 |

| MPBAT100 | 0.2 | 0.1 | 100 |

| MPBAT150 | 0.2 | 0.1 | 150 |

| MPBAT180 | 0.2 | 0.1 | 180 |

| Name | Variation to MPT0 (%) | Variation after Heating (%) | ||

|---|---|---|---|---|

| 7-Day | ||||

| MPT0 | 43.7 | - | - |  |

| MPT100 | 47.33 | +8.31 | +8.31 | |

| MPT150 | 46.3 | +5.95 | +5.95 | |

| MPT180 | 39.85 | −8.81 | −8.81 | |

| MPBT0 | 33.8 | −21.10 | - |  |

| MPBT100 | 39.33 | −10.00 | +16.36 | |

| MPBT150 | 41.5 | −5.03 | +22.78 | |

| MPBT180 | 41.15 | −5.83 | +21.75 | |

| MPAT0 | 34.3 | −21.51 | - |  |

| MPAT100 | 41.53 | −4.97 | +21.08 | |

| MPAT150 | 44.4 | +1.60 | +29.45 | |

| MPAT180 | 44.8 | +2.52 | +30.61 | |

| MPBAT0 | 35.3 | −19.22 | - |  |

| MPBAT100 | 38.3 | −12.36 | +8.50 | |

| MPBAT150 | 42.9 | −1.83 | +21.53 | |

| MPBAT180 | 44.5 | +1.83 | +26.06 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadyan-Yasouj, S.E.; Ahangar, H.A.; Oskoei, N.A.; Shokravi, H.; Koloor, S.S.R.; Petrů, M. Experimental Study on the Effect of Basalt Fiber and Sodium Alginate in Polymer Concrete Exposed to Elevated Temperature. Processes 2021, 9, 510. https://doi.org/10.3390/pr9030510

Mohammadyan-Yasouj SE, Ahangar HA, Oskoei NA, Shokravi H, Koloor SSR, Petrů M. Experimental Study on the Effect of Basalt Fiber and Sodium Alginate in Polymer Concrete Exposed to Elevated Temperature. Processes. 2021; 9(3):510. https://doi.org/10.3390/pr9030510

Chicago/Turabian StyleMohammadyan-Yasouj, Seyed Esmaeil, Hossein Abbastabar Ahangar, Narges Ahevani Oskoei, Hoofar Shokravi, Seyed Saeid Rahimian Koloor, and Michal Petrů. 2021. "Experimental Study on the Effect of Basalt Fiber and Sodium Alginate in Polymer Concrete Exposed to Elevated Temperature" Processes 9, no. 3: 510. https://doi.org/10.3390/pr9030510

APA StyleMohammadyan-Yasouj, S. E., Ahangar, H. A., Oskoei, N. A., Shokravi, H., Koloor, S. S. R., & Petrů, M. (2021). Experimental Study on the Effect of Basalt Fiber and Sodium Alginate in Polymer Concrete Exposed to Elevated Temperature. Processes, 9(3), 510. https://doi.org/10.3390/pr9030510