Multi-Objective Optimization of Microstructure of Gravure Cell Based on Response Surface Method

Abstract

1. Introduction

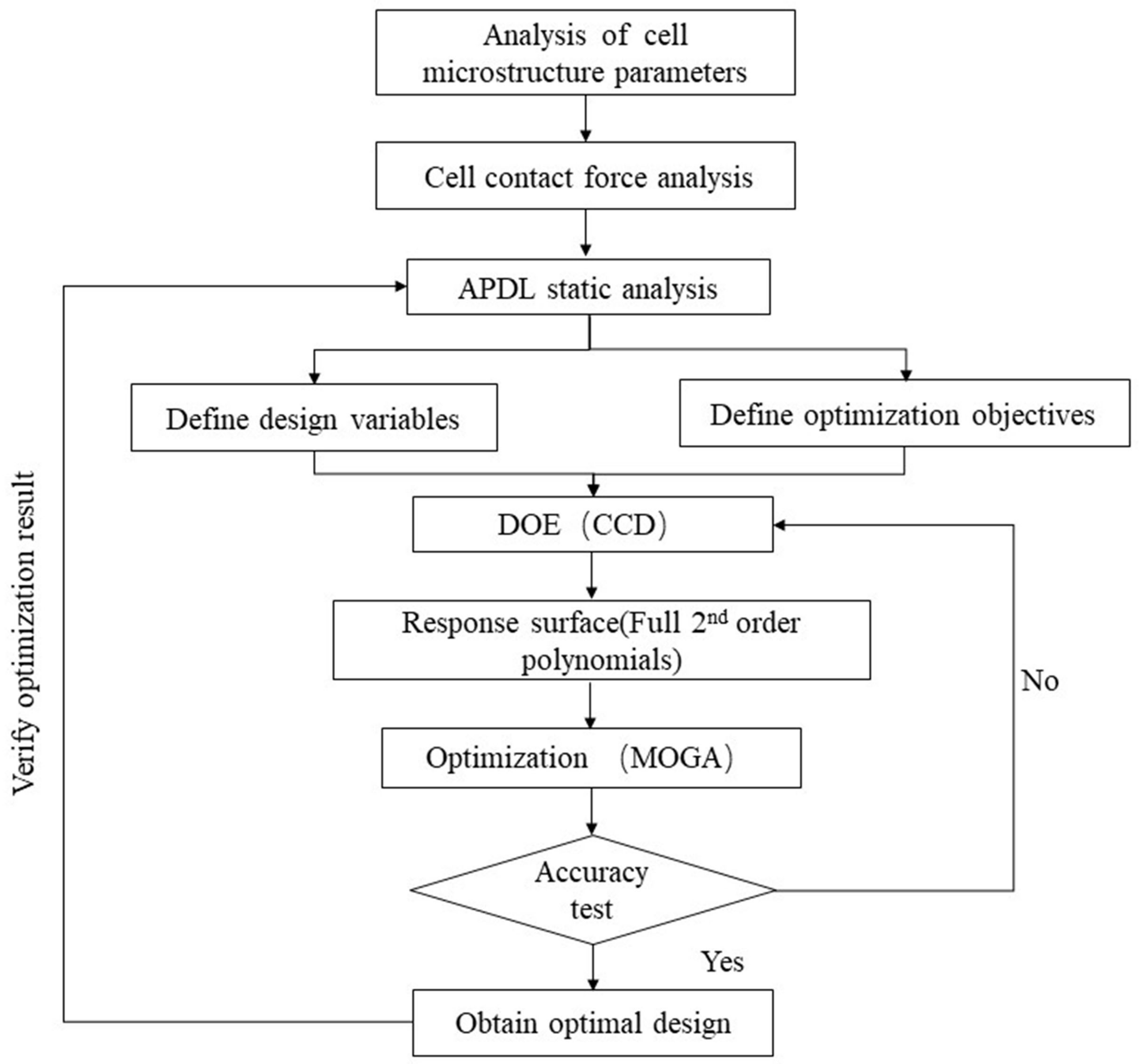

2. Materials and Methods

2.1. Response Surface Method (RSM)

2.2. Multi-Objective Genetic Algorithm (MOGA)

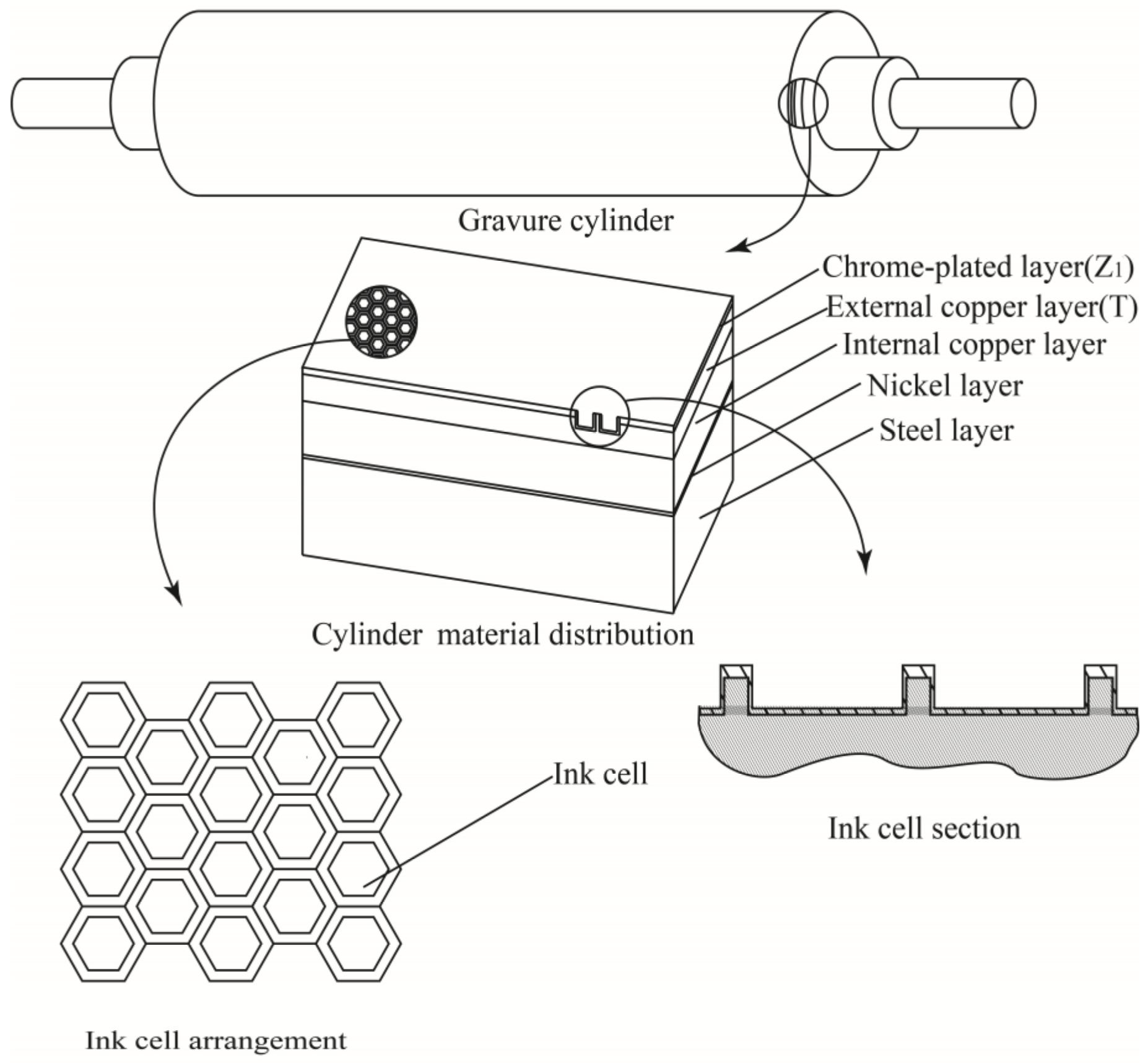

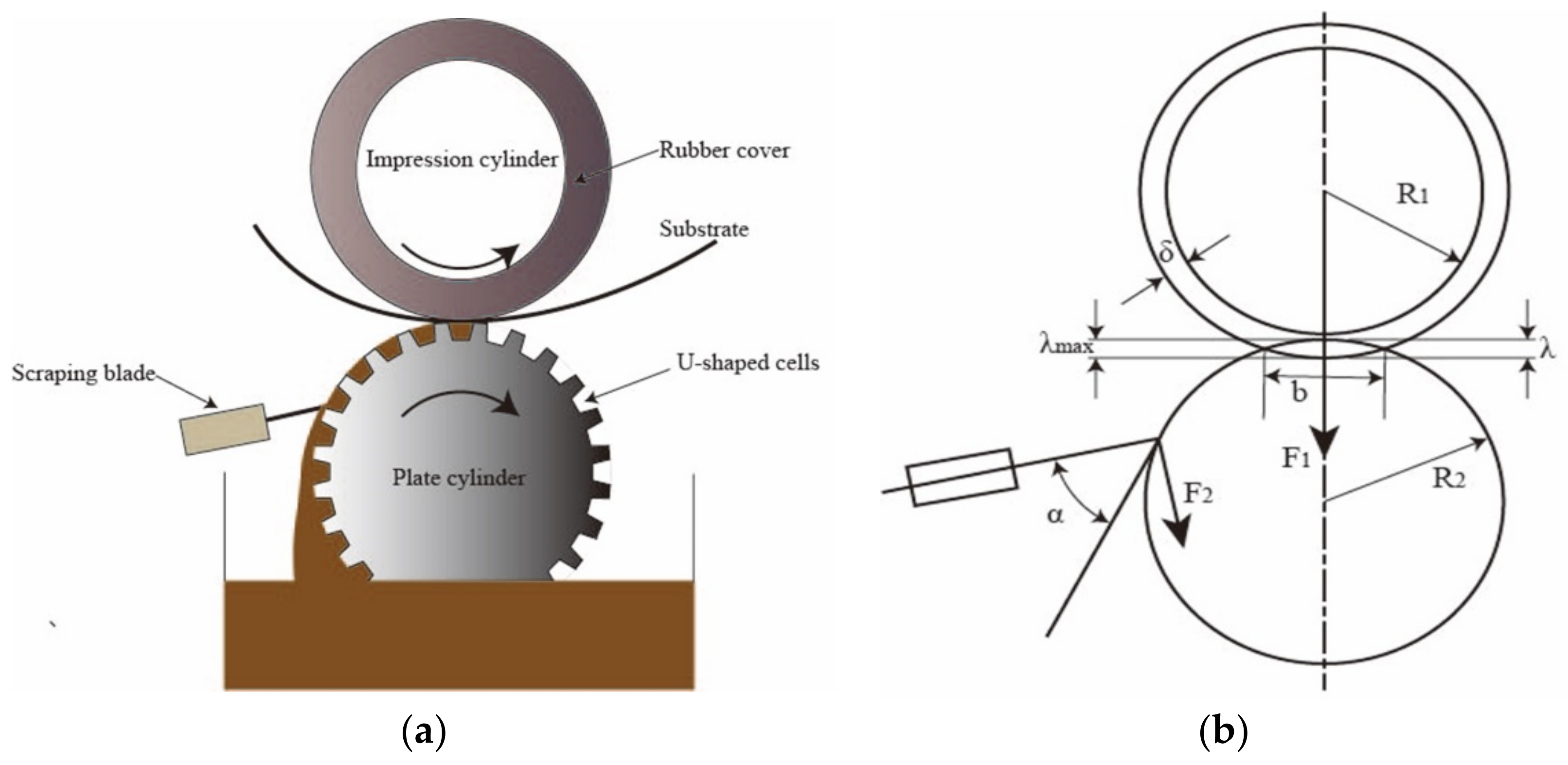

3. Finite Element Analysis (FEA)

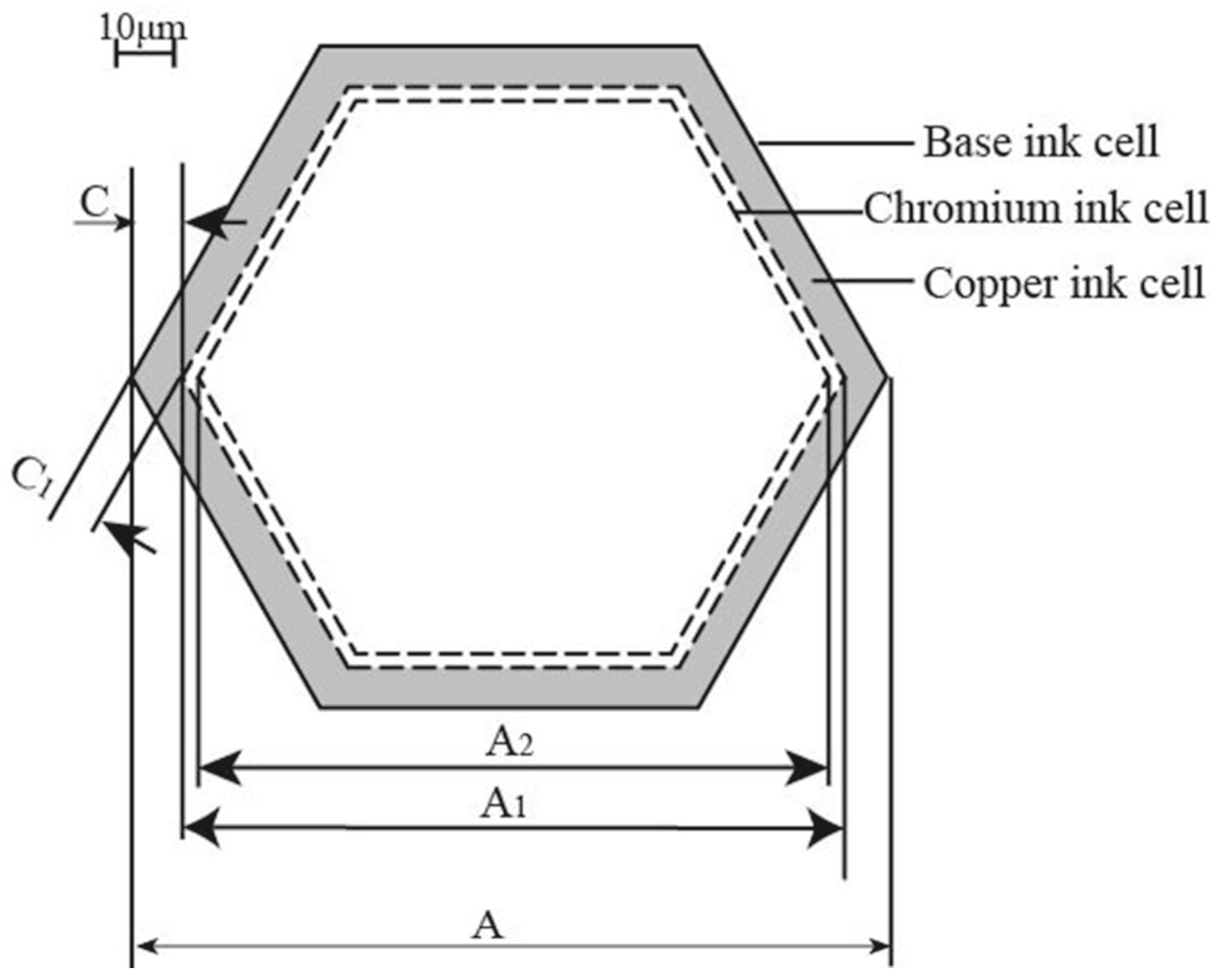

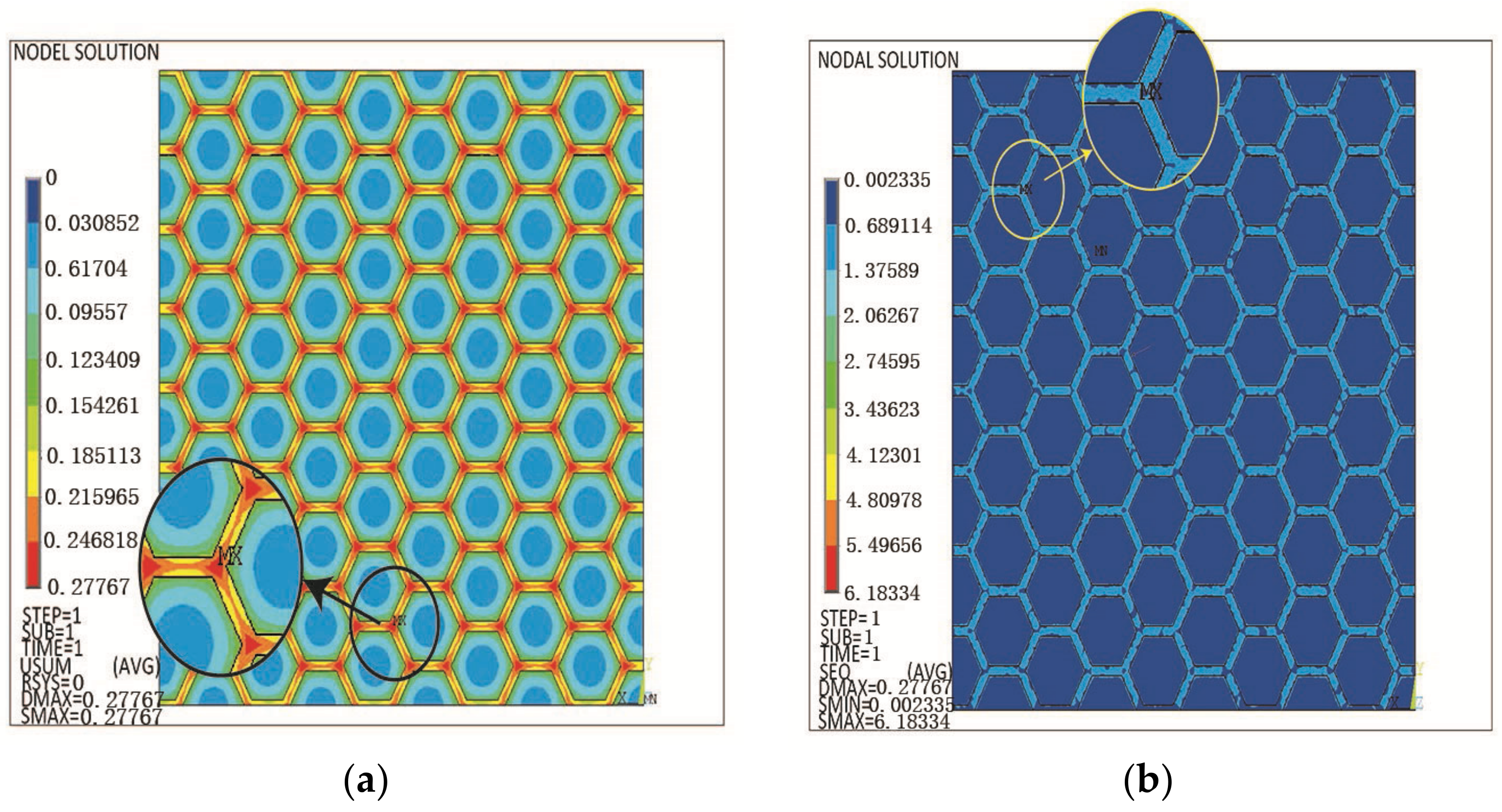

3.1. Regular Hexagonal Cell Microstructure

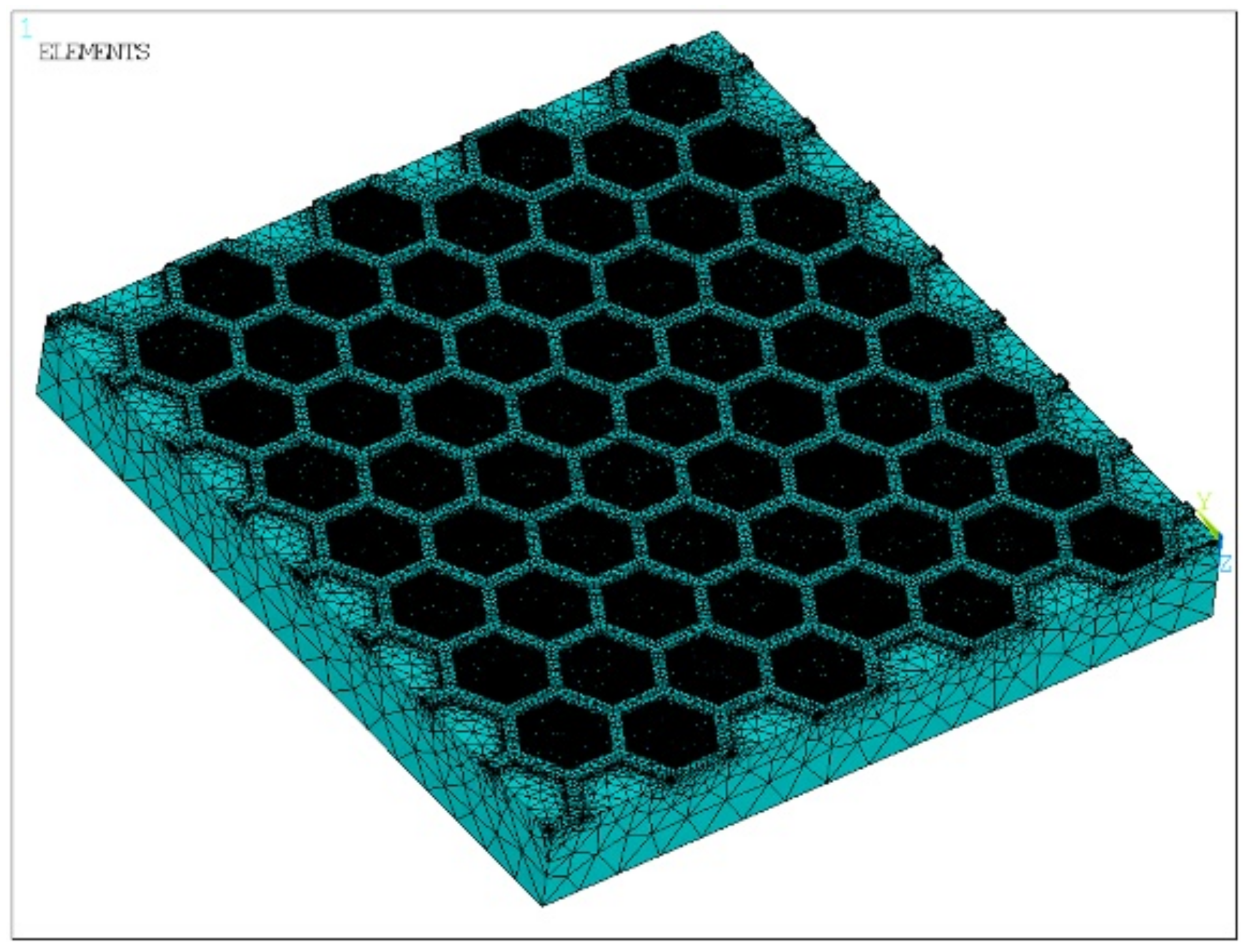

3.2. Modeling

3.3. Static Analysis

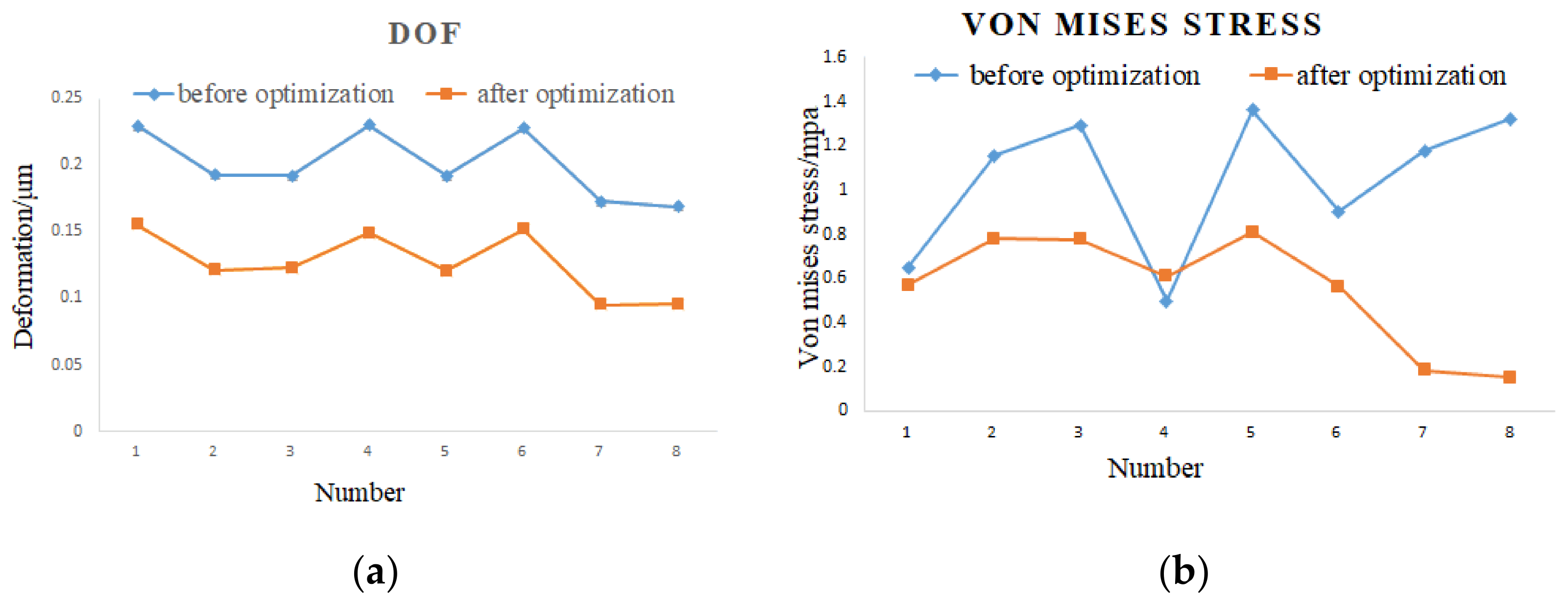

4. Results and Discussions

4.1. Design of Experiment (DOE)

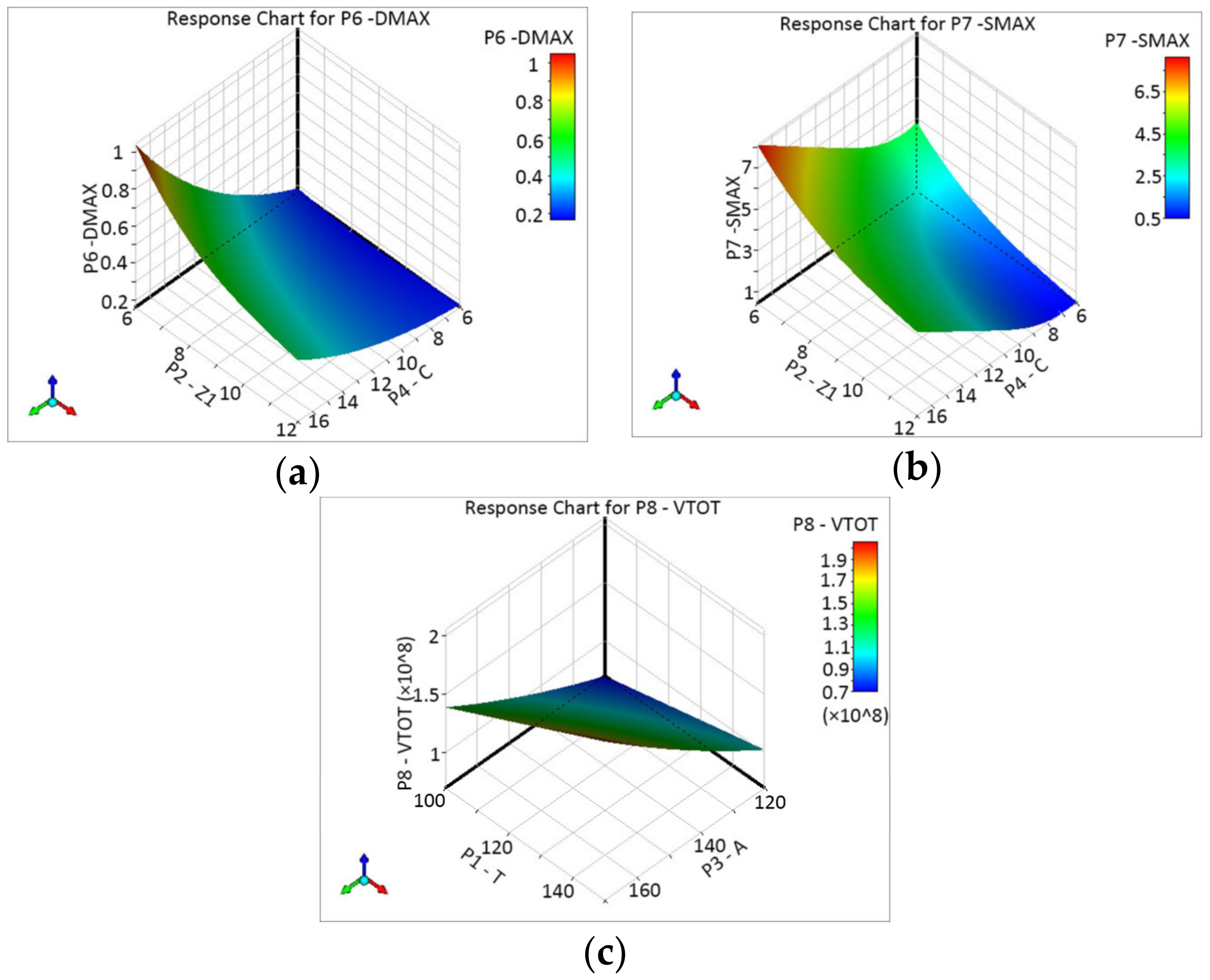

4.2. Response Surface Analysis

4.2.1. Full Second-Order Polynomials Response Surface Model

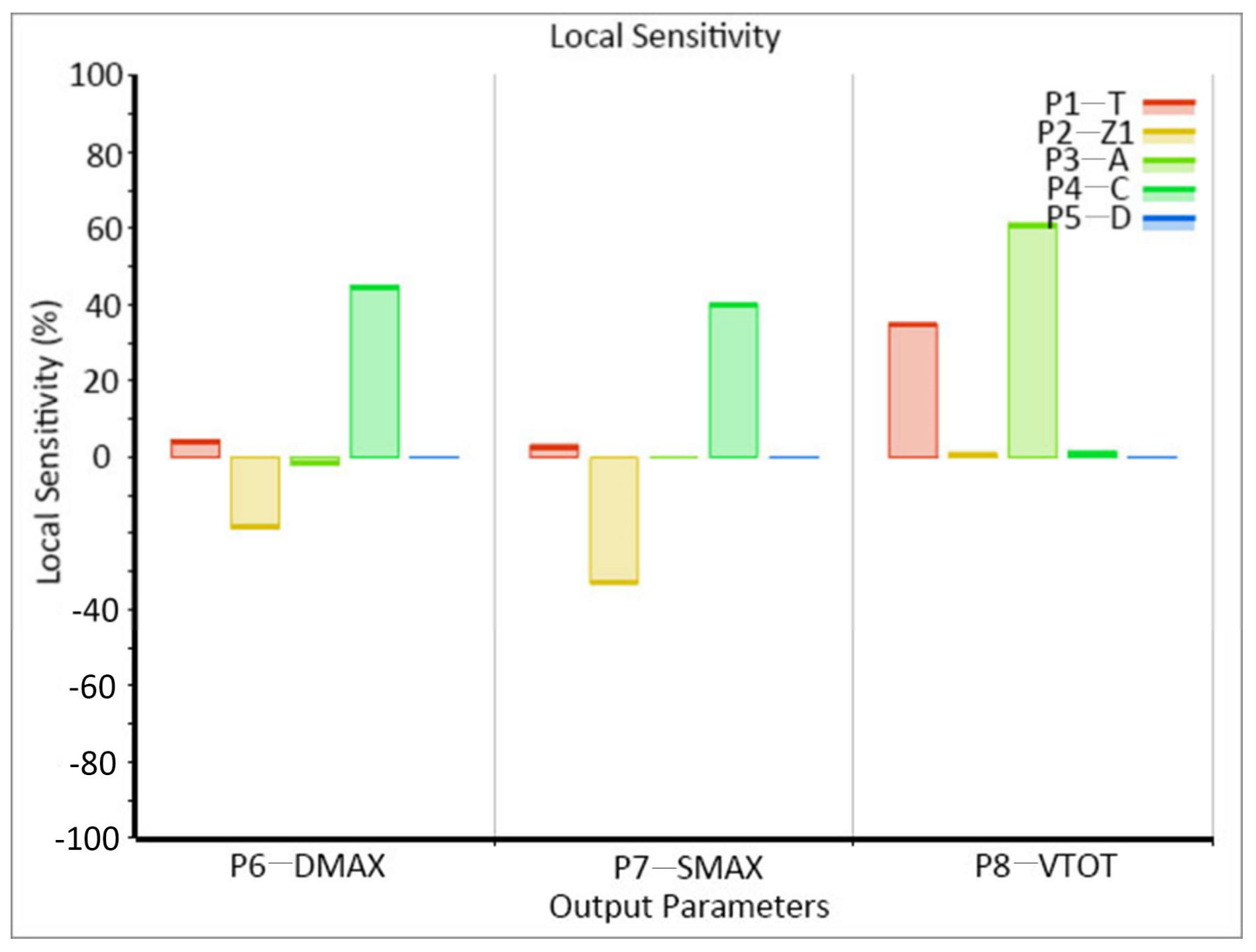

4.2.2. Sensitivity Analysis of Optimized Parameters

4.3. Pareto Optimal in Multi-objective Optimization

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grau, G.; Cen, J.; Kang, H.; Kitsomboonloha, R.; Scheideler, W.J.; Subramanian, V. Gravure-printed electronics: Recent progress in tooling development, understanding of printing physics, and realization of printed devices. Flex. Print. Electron. 2016, 1, 23. [Google Scholar] [CrossRef]

- Deng, P.J.; Fang, W.; Lu, J.D. Study about Influencing of printing process on gravure printing ink transfer. In Research on Food Packaging Technology; Yun, O., Min, X., Li, Y.T., Xunting, L., Eds.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 469, pp. 301–304. [Google Scholar]

- Dong, W. Research of Gravure Plate-Making Engraving Directly By Laser; South China University of Technology: Guangzhou, China, 2013. [Google Scholar]

- Chen, W.; Lai, W.; Wang, Y.; Wang, K.; Lin, S.; Yen, Y.; Hong, H.; Chou, T. Ultrafast laser engraving method to fabricate gravure plate for printed metal-mesh touch panel. Micromachines 2015, 6, 1483–1489. [Google Scholar] [CrossRef]

- Hennig, G.; Selbmann, K.H.; Brockelt, A. Laser Engraving in Gravure Industry. In Workshop on Laser Applications in Europe; Gries, W., Pearsall, T.P., Eds.; SPIE: Bellingham, WA, USA, 2006; Volume 6157. [Google Scholar]

- Yin, X.; Kumar, S. Flow visualization of the liquid-emptying process in scaled-up gravure grooves and cells. Chem. Eng. Sci. 2006, 61, 1146–1156. [Google Scholar] [CrossRef]

- Henniga, G.; Selbmann, K.H.; Pfinninger, S.; Brendel, J.; Bruning, S. Large scale laser microstructuring of gravure print rollers. In Photon Processing in Microelectronics and Photonics Vii; Holmes, A.S., Meunier, M., Arnold, C.B., Niino, H., Geohegan, D.B., Trager, F., Dubowski, J.J., Eds.; Spie-Int Soc Optical Engineering: Bellingham, WA, USA, 2008; Volume 6879. [Google Scholar]

- Hennig, G.; Resing, M.; Mattheus, S.; Neuenschwander, B.; Bruening, S. Laser Microstructuring and Processing in Printing Industry. In 2011 Conference on Lasers and Electro-Optics; IEEE: New York, NY, USA, 2011. [Google Scholar]

- Li, Z.L.; Xia, Q.X.; Qin, X.F.; Wang, S.Z. Research on Laser Gravure Image Loss Less Compression; IEEE Computer Soc.: Los Alamitos, CA, USA, 2009; p. 72. [Google Scholar]

- Deng, P.; Zhang, G.; Fang, W.; Guo, J. Research on Computing Model of the Cell Volume for Electronic Engraved Gravure. In Advances in Printing and Packaging Technologies; Yun, O.Y., Min, X., Li, Y., Liu, X.T., Eds.; Scientific.Net: Bäch SZ, Sitzerland, 2013; Volume 262, p. 355. [Google Scholar]

- Deng, P.; Zhang, G.; Wang, Y.; Fang, W. Influence of Screen Ruling and Engraving Needle Tip Angle on Ink Transfer for Gravure. In Printing and Packaging Study; Yun, O.Y., Min, X., Li, Y., Eds.; Scientific.Net: Bäch SZ, Sitzerland, 2011; Volume 174, pp. 215–218. [Google Scholar]

- Tian, J.; Zhang, C.; Wang, Q. Analysis of craniocerebral injury in facial collision accidents. PLoS ONE 2020, 15, e0240359. [Google Scholar] [CrossRef]

- Tian, J.; Chen, Y.; Ma, Z. Numerical Simulation of Performance of an Air-Water Separator with Corrugated Plates for Marine Diesel Engines. Processes 2020, 8, 1617. [Google Scholar] [CrossRef]

- Sundararaghavan, V.; Zabaras, N. Classification and reconstruction of three-dimensional microstructures using support vector machines. Comput. Mater. Sci. 2005, 32, 223–239. [Google Scholar] [CrossRef]

- Fullwood, D.T.; Niezgoda, S.R.; Adams, B.L.; Kalidindi, S.R. Microstructure sensitive design for performance optimization. Prog. Mater. Sci. 2010, 55, 477–562. [Google Scholar] [CrossRef]

- Guan, J.; Wang, G.C.; Guo, T.; Song, L.B.; Zhao, G.Q. The microstructure optimization of H-shape forgings based on preforming die design. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2009, 499, 304–308. [Google Scholar] [CrossRef]

- Shabani, M.O.; Mazahery, A. The GA optimization performance in the microstructure and mechanical properties of MMNCs. Trans. Indian Inst. Metals 2012, 65, 77–83. [Google Scholar] [CrossRef]

- Yin, Y.; Qi, R.; Zhang, H.; Xi, S.; Zhu, Y.; Liu, Z. Microstructure design to improve the efficiency of thermal barrier coatings. Theor. Appl. Mech. Lett. 2018, 8, 18–23. [Google Scholar] [CrossRef]

- Noruzi, R.; Ghadai, S.; Bingol, O.R.; Krishnamurthy, A.; Ganapathysubramanian, B. NURBS-based microstructure design for organic photovoltaics. Comput. Aided Des. 2020, 118, 13. [Google Scholar] [CrossRef]

- Hambli, R. Application of response surface method for FEM bending analysis. Int. J. Veh. Des. 2005, 39, 1–13. [Google Scholar] [CrossRef]

- Brooghani, S.Y.A.; Khalili, K.; Shahri, S.E.E.; Kang, B.S. Loading path optimization of a hydroformed part using multilevel response surface method. Int. J. Adv. Manuf. Technol. 2014, 70, 1523–1531. [Google Scholar] [CrossRef]

- Subasi, A.; Sahin, B.; Kaymaz, I. Multi-objective optimization of a honeycomb heat sink using Response Surface Method. Int. J. Heat Mass Transf. 2016, 101, 295–302. [Google Scholar] [CrossRef]

- Liu, S. Multi-objective optimization design method for the machine tool’s structural parts based on computer-aided engineering. Int. J. Adv. Manuf. Technol. 2015, 78, 1053–1065. [Google Scholar] [CrossRef]

- Zhou, G.; Ma, Z.D.; Cheng, A.G.; Li, G.Y.; Huang, J. Design optimization of a runflat structure based on multi-objective genetic algorithm. Struct. Multidiscip. Optim. 2015, 51, 1363–1371. [Google Scholar] [CrossRef]

- Wen, T.; Xu, F.; Lu, T.J. Structural optimization of two-dimensional cellular metals cooled by forced convection. Int. J. Heat Mass Transf. 2007, 50, 2590–2604. [Google Scholar] [CrossRef]

- Liu, G.; Hou, D.H.; Zhao, X.J.; Yuan, D.W.; Li, L.; Sun, Y.L. Power transformer’s electrostatic ring optimization based on ANSYS parametric design language and response surface methodology. Appl. Sci. 2019, 9, 4286. [Google Scholar] [CrossRef]

- Raeisian, L.; Niazmand, H.; Ebrahimnia-Bajestan, E.; Werle, P. Thermal management of a distribution transformer: An optimization study of the cooling system using CFD and response surface methodology. Int. J. Electr. Power Energy Syst. 2019, 104, 443–455. [Google Scholar] [CrossRef]

- Li, J.I.; Liu, Z.J.; Jabbar, M.A.; Gao, X.K. Design optimization for cogging torque minimizatior using response surface methodology. IEEE Trans. Magn. 2004, 40, 1176–1179. [Google Scholar] [CrossRef]

- Kazakov, P.V. The genetic algorithms for multi-objective optimization: Review. Inf. Tekhnologii 2011, 10, 2–8. [Google Scholar]

- Liu, G.; Luo, R.; Liu, S. A new interval multi-objective optimization method for uncertain problems with dependent interval variables. Int. J. Comput. Methods 2020, 17. [Google Scholar] [CrossRef]

- Fleming, C.F.P. Genetic algorithms for multiobjective optimization: Formulation discussion and generalization. Proceedings of The 5th International Conference on Genetic Algorithms; Morgan Kaufmann Publishers Inc.: San Francisco, CA, USA, 1993; pp. 416–423. [Google Scholar]

- Zhu, Z.; Cai, Y.-F.; Chen, L.; Xia, C.-G.; Destech Publicat, I.N.C. Research on the Parameters Optimization of Hydro-Mechanical Compound Transmission with Moga. In Proceedings of the 2018 International Conference on Electrical, Control, Automation and Robotics, Munich, Germany, 20–24 August 2018; Volume 307, pp. 47–54. [Google Scholar]

- Barbarosie, C.; Toader, A.-M. Shape and topology optimization for periodic problems. Struct. Multidiscip. Optim. 2010, 40, 381–391. [Google Scholar] [CrossRef]

- Barbarosie, C.; Toader, A.M. Optimization of bodies with locally periodic microstructure by varying the periodicity pattern. Netw. Heterog. Media 2014, 9, 433–451. [Google Scholar] [CrossRef][Green Version]

- Li, H.; Li, H.; Xiao, M.; Zhang, Y.; Fu, J.J.; Gao, L. Robust topology optimization of thermoelastic metamaterials considering hybrid uncertainties of material property. Compos. Struct. 2020, 248, 16. [Google Scholar] [CrossRef]

- Li, N. Researcher on the Printing Pressure of the Gravure Printer; Xi’an University of Technology: Xi’an, China, 2009. [Google Scholar]

- Kuninaka, H.; Hayakawa, H. Contact and quasi-static impact of Hamilton system. J. Phys. Soc. Jpn. 2006, 75. [Google Scholar] [CrossRef]

- Sohn, D.; Won, H.-S.; Jang, B.; Kim, J.-H.; Lee, H.-J.; Choi, S.T. Extended JKR theory on adhesive contact between elastic coatings on rigid cylinders under plane strain. Int. J. Solids Struct. 2015, 71, 244–254. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, G.; Li, L. Research on Friction between Gravure Roller and Scraping Blade. In Research on Food Packaging Technology; Yun, O., Min, X., Li, Y.T., Xunting, L., Eds.; Scientific.Net: Bäch SZ, Sitzerland, 2014; Volume 469, pp. 399–403. [Google Scholar]

- Draper, N.R.S. Applied Regression Analysis; Wiley-Interscience: New York, NY, USA, 1998. [Google Scholar]

- Hsiao, J.C.; Shivam, K.; Chou, C.L.; Kam, T.Y. Shape design optimization of a robot arm using a surrogate-based evolutionary approach. Appl. Sci. 2020, 10, 2223. [Google Scholar] [CrossRef]

| Name | Size | Name | Size |

|---|---|---|---|

| External copper layer thickness (T) | 120 μm | Base cell size (A) | 150 μm |

| Surface chrome layer thickness (Z1) | 8 μm | Screen wall width (C) | 10 μm |

| Number of cells | 8 × 8 | Cell depth (D) | 30 μm |

| Node | T | Z1 | C | D | DMAX | SMAX | ||

|---|---|---|---|---|---|---|---|---|

| 1 | 100 | 9 | 145 | 11.5 | 35.5 | 0.294 | 2.788 | 1.01 × 108 |

| 2 | 117.916 | 8.149 | 137.916 | 9.942 | 42.442 | 0.276 | 2.461 | 1.07 × 108 |

| 3 | 117.916 | 8.149 | 137.916 | 13.058 | 28.558 | 0.424 | 4.008 | 1.07 × 108 |

| 4 | 117.916 | 8.149 | 152.083 | 9.942 | 28.558 | 0.27 | 2.639 | 1.3 × 108 |

| 5 | 117.916 | 8.149 | 152.083 | 13.058 | 42.442 | 0.413 | 4.058 | 1.3 × 108 |

| 6 | 117.916 | 9.85 | 137.916 | 9.942 | 28.558 | 0.250 | 1.71 | 1.07 × 108 |

| 7 | 117.916 | 9.85 | 137.916 | 13.058 | 42.442 | 0.359 | 3.372 | 1.08 × 108 |

| 8 | 117.916 | 9.85 | 152.083 | 9.942 | 42.442 | 0.244 | 1.802 | 1.3 × 108 |

| 9 | 117.916 | 9.85 | 152.083 | 13.058 | 28.558 | 0.355 | 3.098 | 1.31 × 108 |

| 10 | 125 | 6 | 145 | 11.5 | 35.5 | 0.474 | 5.315 | 1.25 × 108 |

| 11 | 125 | 9 | 120 | 11.5 | 35.5 | 0.333 | 2.552 | 0.86 × 108 |

| 12 | 125 | 9 | 145 | 6 | 35.5 | 0.164 | 1.392 | 1.24 × 108 |

| 13 | 125 | 9 | 145 | 11.5 | 11 | 0.318 | 2.849 | 1.25 × 108 |

| 14 | 125 | 9 | 145 | 11.5 | 35.5 | 0.318 | 2.902 | 1.25 × 108 |

| 15 | 125 | 9 | 145 | 11.5 | 60 | 0.319 | 2.671 | 1.25 × 108 |

| 16 | 125 | 9 | 145 | 17 | 35.5 | 0.635 | 5.507 | 1.27 × 108 |

| 17 | 125 | 9 | 170 | 11.5 | 35.5 | 0.314 | 2.900 | 1.72 × 108 |

| 18 | 125 | 12 | 145 | 11.5 | 35.5 | 0.278 | 1.720 | 1.26 × 108 |

| 19 | 132.083 | 8.1499 | 137.916 | 9.942 | 28.558 | 0.29 | 2.391 | 1.19 × 108 |

| 20 | 132.083 | 8.1499 | 137.916 | 13.058 | 42.442 | 0.44 | 3.76 | 1.2 × 108 |

| 21 | 132.083 | 8.1499 | 152.083 | 9.942 | 42.442 | 0.283 | 2.688 | 1.45 × 108 |

| 22 | 132.083 | 8.1499 | 152.083 | 13.058 | 28.558 | 0.427 | 4.053 | 1.46 × 108 |

| 23 | 132.083 | 9.85 | 137.916 | 9.942 | 42.442 | 0.263 | 1.753 | 1.2 × 108 |

| 24 | 132.083 | 9.85 | 137.916 | 13.058 | 28.558 | 0.375 | 3.478 | 1.2 × 108 |

| 25 | 132.083 | 9.85 | 152.083 | 9.942 | 28.558 | 0.255 | 1.733 | 1.45 × 108 |

| 26 | 132.083 | 9.85 | 152.083 | 13.058 | 42.442 | 0.369 | 3.107 | 1.46 × 108 |

| 27 | 150 | 9 | 145 | 11.5 | 35.5 | 0.342 | 3.133 | 1.5 × 108 |

| Node | T | Z1 | C | D | DMAX | SMAX | ||

|---|---|---|---|---|---|---|---|---|

| 1 | 100.76 | 8.949 | 120.15 | 6.53 | 29.95 | 0.155 | 0.094 | 6.878 × 107 |

| 2 | 100.52 | 9.042 | 120.24 | 6.269 | 55.04 | 0.158 | 1.4886 | 6.882 × 107 |

| 3 | 100.3 | 8.5 | 120.96 | 6.349 | 38.68 | 0.157 | 0.220 | 6.943 × 107 |

| Node | T | Z1 | C | D | DMAX | SMAX | ||

|---|---|---|---|---|---|---|---|---|

| Before | 120 | 8 | 150 | 10 | 30 | 0.27 | 2.739 | 1.284 × 108 |

| After | 100.76 | 8.949 | 120.15 | 6.53 | 29.95 | 0.155 | 0.094 | 6.879 × 107 |

| Change | The maximum deformation was reduced by 44.4%, and the total model volume was reduced by 46.3%. | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Xing, J.; Dong, L.; Zhu, H. Multi-Objective Optimization of Microstructure of Gravure Cell Based on Response Surface Method. Processes 2021, 9, 403. https://doi.org/10.3390/pr9020403

Wu S, Xing J, Dong L, Zhu H. Multi-Objective Optimization of Microstructure of Gravure Cell Based on Response Surface Method. Processes. 2021; 9(2):403. https://doi.org/10.3390/pr9020403

Chicago/Turabian StyleWu, Shuang, Jiefang Xing, Ling Dong, and Honjuan Zhu. 2021. "Multi-Objective Optimization of Microstructure of Gravure Cell Based on Response Surface Method" Processes 9, no. 2: 403. https://doi.org/10.3390/pr9020403

APA StyleWu, S., Xing, J., Dong, L., & Zhu, H. (2021). Multi-Objective Optimization of Microstructure of Gravure Cell Based on Response Surface Method. Processes, 9(2), 403. https://doi.org/10.3390/pr9020403